Primes CompactPowerMonitor Series, CPM C-9, CPM F-10, CPM F-20, CPM F-30 Operating Manual

...

Operating Manual

35,0(6

Translation of the original instructions

CompactPowerMonitor CPM

CPM C-9, CPM F-1, CPM F-10, CPM F-20, CPM F-30

LaserDiagnosticsSoftware LDS

PowerMonitorSoftware PMS

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

IMPORTANT!

READ CAREFULLY BEFORE USE.

KEEP FOR FUTURE USE.

Revision 02/2019 EN

3

CompactPowerMonitor CPM

35,0(6

Table of contents

1 Basic safety instructions 7

2 Symbol explanations 9

3 About this operating manual 10

4 Conditions at the installation site 10

5 Introduction 10

5.1 System description .................................................................................................................10

5.2 Measuring principle .................................................................................................................10

5.3 Overview of the CompactPowerMonitor CPM types ................................................................ 11

5.4 Connection overview ............................................................................................................... 12

5.5 Short overview installation .......................................................................................................13

6 Transport 14

7 Installation 15

7.1 Preparation .............................................................................................................................15

7.2 Installation position .................................................................................................................. 15

7.3 Align the CompactPowerMonitor CPM .................................................................................... 15

7.4 Install the CompactPowerMonitor CPM ................................................................................... 16

7.5 Remove the CompactPowerMonitor CPM ............................................................................... 19

8 Connect cooling circuit 20

8.1 Water quality ...........................................................................................................................20

8.2 Water pressure ........................................................................................................................ 20

8.3 Humidity .................................................................................................................................. 21

8.4 Temperature fluctuations of the inflowing cooling water ...........................................................22

8.5 Flow rate ................................................................................................................................. 22

8.6 Connect hoses ........................................................................................................................ 23

9 Electrical connection 24

9.1 Power supply ..........................................................................................................................24

9.2 PRIMES bus ............................................................................................................................ 24

9.3 Connect the safety interlock .................................................................................................... 25

9.4 Connecting the PC via the USB interface ................................................................................26

9.4.1 Scope of delivery ........................................................................................................26

9.4.2 Connect PC ................................................................................................................ 26

9.4.3 Install the USB driver manually ....................................................................................27

9.5 Connecting the PC via RS232 interface and optional PRIMES converter .................................28

9.5.1 Scope of delivery ........................................................................................................28

9.5.2 Connect PC ................................................................................................................ 28

9.6 Parallel operation of the CompactPowerMonitor PMC and, for example, the

FocusMonitor FM+ .................................................................................................................. 30

9.7 Analog output .........................................................................................................................31

10 Display, control elements and audible signals 32

10.1 Measured value display ...........................................................................................................32

10.2 Status display .........................................................................................................................32

10.3 External display (Option) .......................................................................................................... 33

10.4 Control Elements .....................................................................................................................33

10.5 Audible signals ........................................................................................................................33

4

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

11 Measuring with the optional LaserDiagnosticsSoftware LDS 34

11.1 Safety instructions ................................................................................................................... 34

11.2 Getting ready for operation ......................................................................................................35

11.3 Perform power measurement ..................................................................................................35

11.3.1 Connect the CompactPowerMonitor CPM with the LaserDiagnosticsSoftwareLDS .... 35

11.3.2 Choose power measurement mode ............................................................................ 36

11.3.3 Configure settings (Device control) ............................................................................36

11.3.4 Starting a power measurement ................................................................................... 37

11.3.5 Measurement results display ....................................................................................... 37

12 Install the PowerMonitorSoftware PMS 38

12.1 Start software and select operating mode ...............................................................................38

12.1.1 For connection via the RS232 and PRIMES converter ................................................. 38

12.1.2 For connection via the USB interface .......................................................................... 38

12.2 Testing the Interface ................................................................................................................39

12.3 Testing the communication of multiple devices ........................................................................40

13 Measuring with the PowerMonitor Software PMS 41

13.1 Safety instructions ................................................................................................................... 41

13.2 Getting ready for operation ......................................................................................................42

13.3 Starting the software ...............................................................................................................42

13.4 Perform power measurement ..................................................................................................42

13.5 The graphical user interface of the PowerMonitor Software PMS .............................................43

13.6 Measuring value display ..........................................................................................................44

13.6.1 Window A (Numerical display) ..................................................................................... 44

13.6.2 Window B (Graphical display) ...................................................................................... 45

13.6.3 Status window ............................................................................................................ 45

14 Storage 46

15 Maintenance and service 46

16 Measures for the product disposal 46

17 Declaration of conformity 47

18 Technical data 48

18.1 CPM C-9 ................................................................................................................................48

18.2 CPM F-1, CPM F-10, CPM F-20, CPM F-30 ........................................................................... 49

19 Dimensions 50

19.1 Dimensions CPM C-9..............................................................................................................50

19.2 Dimensions CPM F-1 ..............................................................................................................51

19.3 Dimensions CPM F-10 ............................................................................................................52

19.4 Dimensions CPM F-20 ............................................................................................................53

19.5 Dimensions CPM F-30 ............................................................................................................54

20 Appendix 55

20.1 Operation of the CompactPowerMonitor with PanelDisplay (without PC) .................................55

20.1.1 Pin assignment 9-pole D-Sub socket .......................................................................... 56

20.1.2 Measurement display .................................................................................................. 56

20.2 Mounting position of a CompactPowerMonitor CPM with oval wheel meter ............................57

20.3 Accessories fiber adapter ........................................................................................................ 58

Revision 02/2019 EN

5

CompactPowerMonitor CPM

35,0(6

PRIMES - The Company

PRIMES manufactures measuring devices used to analyze laser beams. These devices are employed for

the diagnostics of high-power lasers ranging from CO

length range from infrared through to near UV is covered, offering a wide variety of measuring devices to

determine the following beam parameters:

• Laser power

• Beam dimensions and position of an unfocused beam

• Beam dimensions and position of a focused beam

• Beam quality factor M²

PRIMES is responsible for both the development, production, and calibration of the measuring devices. This

guarantees optimum quality, excellent service, and a short reaction time, providing the basis for us to meet all

of our customers’ requirements quickly and reliably.

lasers and solid-state lasers to diode lasers. A wave-

2

PRIMES GmbH

Max-Planck-Str. 2

64319 Pfungstadt

Germany

Tel +49 6157 9878-0

info@primes.de

www.primes.de

6

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

1 Basic safety instructions

Intended use

The CompactPowerMonitor CPM is exclusively intended for measurements which are carried out in or nearby the optical path of high power lasers. Please mind and adhere to the specifications and limit values given

in chapter 18 „Technical data“ on page 48. Other forms of usage are improper. The information contained

in this operating manual must be strictly observed to ensure proper use of the device.

Using the device for unspecified use is strictly prohibited by the manufacturer. By usage other than intended

the device can be damaged or destroyed. This poses an increased health hazard up to fatal injuries. When

operating the device, it must be ensured that there are no potential hazards to human health.

The device itself does not emit any laser radiation. During the measurement, however, the laser beam is

guided onto the device which causes reflected radiation (laser class 4). That is why the applying safety regulations are to be observed and necessary protective measures need to be taken.

In measuring mode, the laser control’s safety interlock must be connected with the device.

Observing applicable safety regulations

Please observe valid national and international safety regulations as stipulated in ISO/CEN/TR standards as

well as in the IEC-60825-1 regulation, in ANSI Z 136 “Laser Safety Standards” and ANSI Z 136.1 “Safe Use

of Lasers”, published by the American National Standards Institute, and additional publications, such as the

“Laser Safety Basics”, the “LIA Laser Safety Guide”, the “Guide for the Selection of Laser Eye Protection”

and the “Laser Safety Bulletin”, published by the Laser Institute of America, as well as the “Guide of Control

of Laser Hazards” by ACGIH.

Necessary safety measures

If people are present within the danger zone of visible or invisible laser radiation, for example near laser

systems that are only partly covered, open beam guidance systems, or laser processing areas, the following

safety measures must be implemented:

• Connect the laser control’s safety interlock to the device. Check that the safety interlock will switch off the

laser properly in case of error.

• Please wear safety goggles adapted to the power, power density, laser wave length and operating mode

of the laser beam source in use.

• Depending on the laser source, it may be necessary to wear suitable protective clothing or protective

gloves.

• Protect yourself from direct laser radiation, scattered radiation, and beams generated from laser radiation

(by using appropriate shielding walls, for example, or by weakening the radiation to a harmless level).

• Use beam guidance or beam absorber elements that do not emit any hazardous substances when they

come in to contact with laser radiation and that can withstand the beam sufficiently.

• Install safety switches and/or emergency safety mechanisms that enable immediate closure of the laser

shutter.

• Ensure that the device is mounted securely to prevent any movement of the device relative to the beam

axis and thus reduce the risk of scattered radiation. This in the only way to ensure optimum performance

during the measurement.

Employing qualified personnel

The device may only be operated by qualified personnel. The qualified personnel must have been instructed

in the installation and operation of the device and must have a basic understanding of working with highpower lasers, beam guiding systems and focusing units.

Conversions and modifications

The device must not be modified, neither constructionally nor safety-related, without our explicit permission.

The device must not be opened e.g. to carry out unauthorized repairs. Modifications of any kind will result in

the exclusion of our liability for resulting damages.

Revision 02/2019 EN

7

CompactPowerMonitor CPM

35,0(6

Liability disclaimer

The manufacturer and the distributor of the measuring devices do not claim liability for damages or injuries

of any kind resulting from an improper use or handling of the devices or the associated software. Neither the

manufacturer nor the distributor can be held liable by the buyer or the user for damages to people, material

or financial losses due to a direct or indirect use of the measuring devices.

8

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

2 Symbol explanations

The following symbols and signal words indicate possible residual risks:

DANGER

Means that death or serious physical injuries will occur if necessary safety precautions are not

taken.

WARNING

Means that death or serious physical injuries may occur if necessary safety precautions are not

taken.

CAUTION

Means that minor physical injury may occur if necessary safety precautions are not taken.

NOTICE

Means that property damage may occur if necessary safety precautions are not taken.

The following symbols indicating requirements and possible dangers are used on the device:

Warning against a danger zone.

Do not touch.

Read and observe the operating instructions and safety guidelines before startup!

Further symbols that are not safety-related:

Here you can find useful information and helpful tips.

Revision 02/2019 EN

With the CE designation, the manufacturer guarantees that its product meets the requirements of

the relevant EC guidelines.

Call for action

X

9

CompactPowerMonitor CPM

35,0(6

3 About this operating manual

This documentation describes the installation and operation of the CompactPowerMonitor CPM and performing measurements using the CompactPowerMonitor CPM, the optional LaserDiagnosticsSoftware LDS

or the PowerMonitorSoftware PMS.

For measurement operation with a PC, the LaserDiagnosticsSoftware LDS (option) or the PowerMonitorSoftware PMS must be installed on the PC. The PowerMonitorSoftware PMS is included in the scope of delivery.

For a detailed description of the software installation, file management and evaluation of the measured data,

please refer to the separate operating manual LaserDiagnosticsSoftware LDS.

4 Conditions at the installation site

• The device must not be operated in a condensing atmosphere.

• The ambient air must be free of organic gases.

• Protect the device from splashes of water and dust.

• Operate the device in closed rooms only.

5 Introduction

5.1 System description

The CompactPowerMonitor CPM is a measuring device for the determination of the laser power of laser

beams in the multikilowatt range. The main field of application is the control of laser powers of CO2 or solidstate lasers as well as high power diode lasers available at the work piece. The device is able to measure

both collimated and divergent beams.

5.2 Measuring principle

The CompactPowerMonitor CPM measures the laser power according to a calorimetric principle. The irradiated laser power is absorbed by a water-cooled absorber inside the device. By measuring the cooling water

flow rate and the respective temperature difference between the inflowing and the outflowing water, the

absorbed power is determined.

10

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

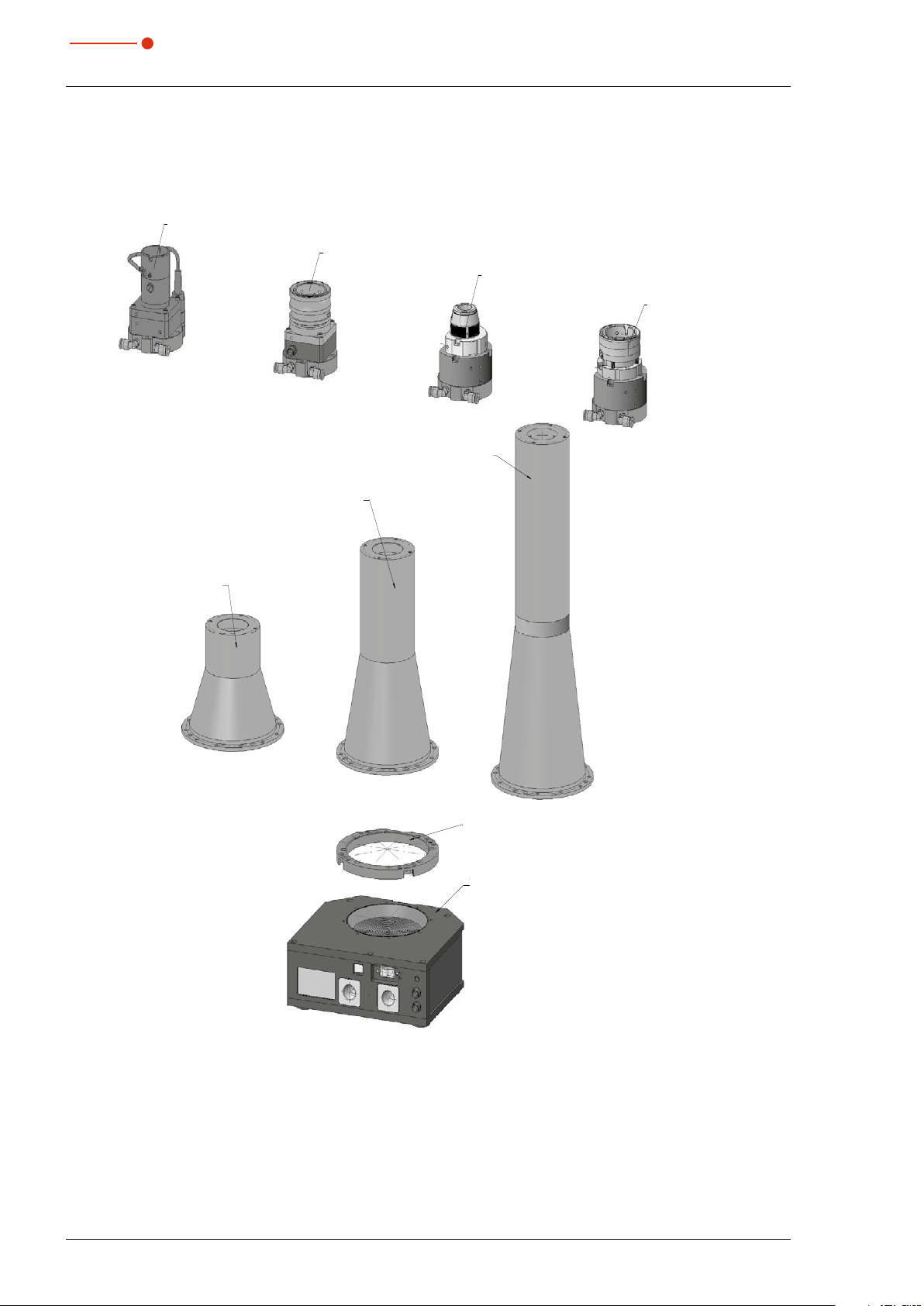

5.3 Overview of the CompactPowerMonitor CPM types

The various CompactPowerMonitor CPM types differ mainly in regards to the inlet aperture, the absorber

size, the measurable laser power, and the cooling water flow rate required by this. The port and operating

unit is the same on each device.

Device type Entrance aperture

CPM C-9

CPM F-1

CPM F-10

in mm

55

45 0.5

90 0.5

Average power density

in kW/cm²

5(Ø <10 mm)

5(Ø 10 – 30mm)

0,5(Ø 30 – 55 mm)

CPM F-20

CPM F-30

Tab. 5.1: Overview of the CompactPowerMonitor CPM types

135 0.5

180 0,5

Revision 02/2019 EN

11

35,0(6

5.4 Connection overview

CompactPowerMonitor CPM

Analog outputPRIMES bus (RS485)USB connection

Water inlet flow

(Water In)

Fig. 5.1: Connections of the CompactPower Monitor CPM

Water return flow

(Water out)

Safety interlock

12

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

5.5 Short overview installation

1. Installing the LaserDiagnosticsSoftware LDS on the PC (option)

• Please contact PRIMES or your PRIMES distribution partner to order the

software

2. Taking safety precautions Chapter 1 on page7

3. Installing the device

• Follow the safety instructions

• Set the installation position

• Mount the device stably

4. Connect the water-cooling

• Determine flow rate according Tab. 8.5 on page22

• Connect hoses (hose outer diameter of 12 mm)

5. Power supply

• Connect power supply

See separate Operating Manual

of the LaserDiagnosticsSoftware

LDS

Chapter 7 on page15

Chapter 8 on page20

Chapter 9.1 on page24

• Connect safety interlock

6. Connection with the PC

• Via USB (scope of delivery)

• Via RS232/RS485 converter (optional)

7. Parallel operation of CompactPowerMonitor PMC and,

• For example, the FocusMonitor

8. Perform the measurement

• Follow the safety instructions

• Perform the measurement with the optional LaserDiagnosticsSoftware LDS

9. Installing the PowerMonitorSoftware PMS on the PC

• Software is part of the scope of delivery

10. Perform the measurement

Chapter 9.3 on page25

Chapter 9.4 on page26

Chapter 9.5 on page28

Chapter 9.6 on page30

Chapter 11 on page34

Chapter 12 on page38

Chapter 13 on page41

• Follow the safety instructions

• Perform the measurement with the PowerMonitorSoftware PMS

Revision 02/2019 EN

13

35,0(6

6 Transport

NOTICE

Damaging/destroying the device

Hard hits or falls may damage the device.

Touching the absorber can lead to burn-in by the laser radiation at the points of contact.

Burn-in lead to damage to the absorber and increase the scattered radiation.

Do not touch the absorber.

X

Handle the device carefully when transporting it.

X

Only transport the device in the original PRIMES transport box.

X

NOTICE

Damage/destruction of the device caused by leaking or freezing cooling water

Leaking cooling water can damage the device. Transporting the device at temperatures near

or below freezing and without emptying the cooling circuit completely can damage the

device.

CompactPowerMonitor CPM

Empty the lines of the cooling circuit completely.

X

Even when the lines of the cooling circuit have been emptied, a small amount of residual

X

water will remain in the device at all times. This may leak out and end up inside the device.

Close the connector plug of the cooling circuit with the included sealing plug.

NOTICE

Damaging/Destruction of the flow rate meter

The flow rate meter is not designated for high rotational speed.

Do not use compressed air for emptying the cooling circuit.

X

14

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

7 Installation

7.1 Preparation

Check the space available before mounting the device, especially the required space for the connection

cables and hoses (please see chapter 19 „Dimensions“ on page 50). The device must be firmly assembled

and must be mounted with screws (see chapter 7.4 on page16).

7.2 Installation position

The CPM F-1 is to be operated in a horizontal position. With regard to the other device types, the installation

position can be chosen freely. Concerning the versions with a oval wheel meter, please mind the mounting

position according to chapter 20.2 on page57.

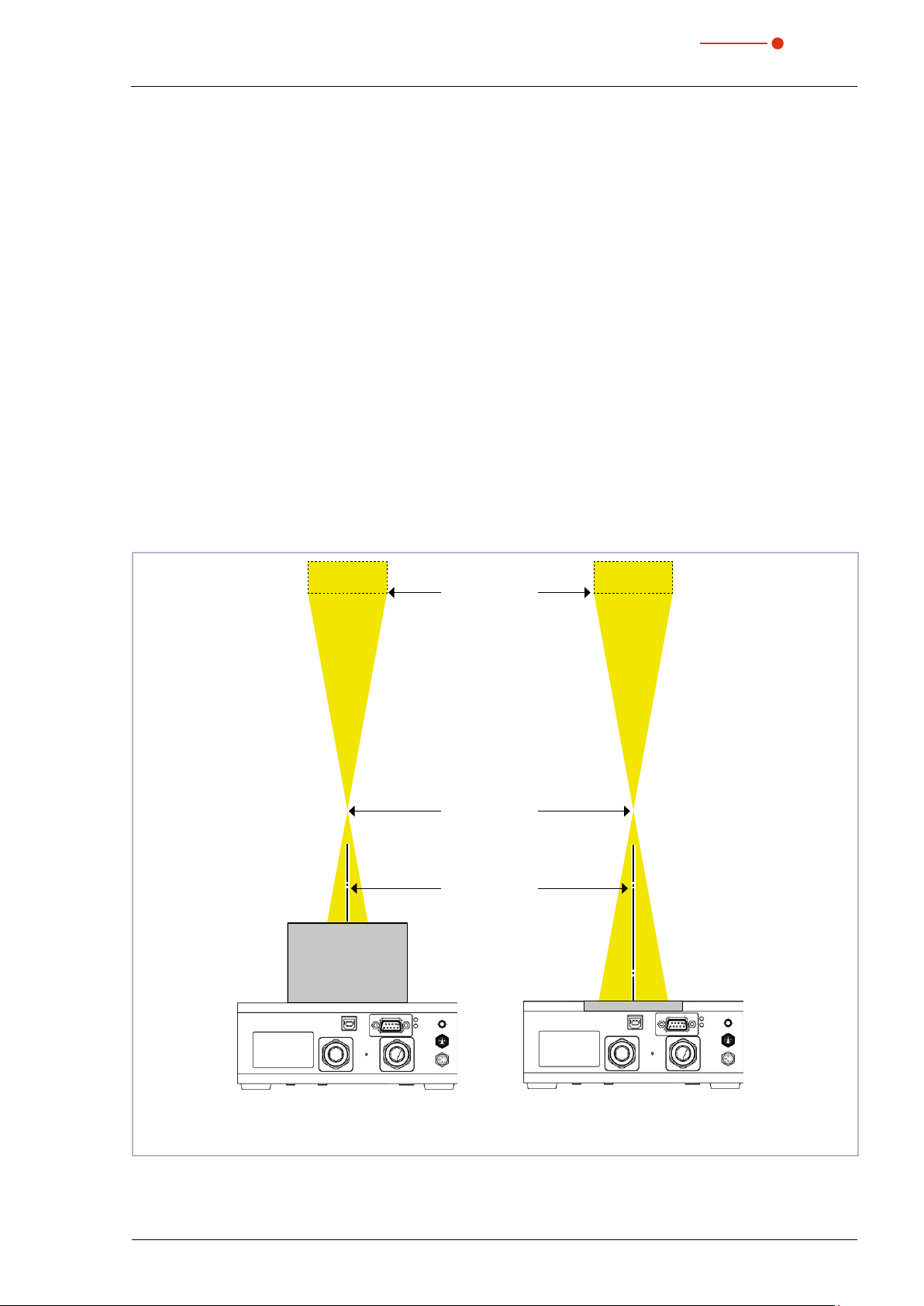

7.3 Align the CompactPowerMonitor CPM

The laser beam must hit the center of the entrance aperture not only with a collimated but also with a divergent beam. Please make sure that the beam diameter, the power, and the power density do not exceed the

limit values stated in the technical data.

For the correct alignment - especially with regard to divergent radiations behind the focusing optics - the

specifications in Fig. 7.1 on page15 are to be considered.

Aperture diameter on

CPM C-9 with conical

reflector 55mm

Focusing optics

Focusing plane

Beam axis

centerd in

inlet aperture

Aperture diameter for

devices with plane absorber

depending on device type:

45, 90, 135 oder 180mm

Fig. 7.1: Alignment of the CompactPowerMonitor CPM to the laser beam

Revision 02/2019 EN

CompactPowerMonitor CPM C-9

with conical reflector and

cylindrical absorber

CompactPowerMonitor

CPM F-1; F-10; F-20 and F-30

with plane absorber

15

CompactPowerMonitor CPM

35,0(6

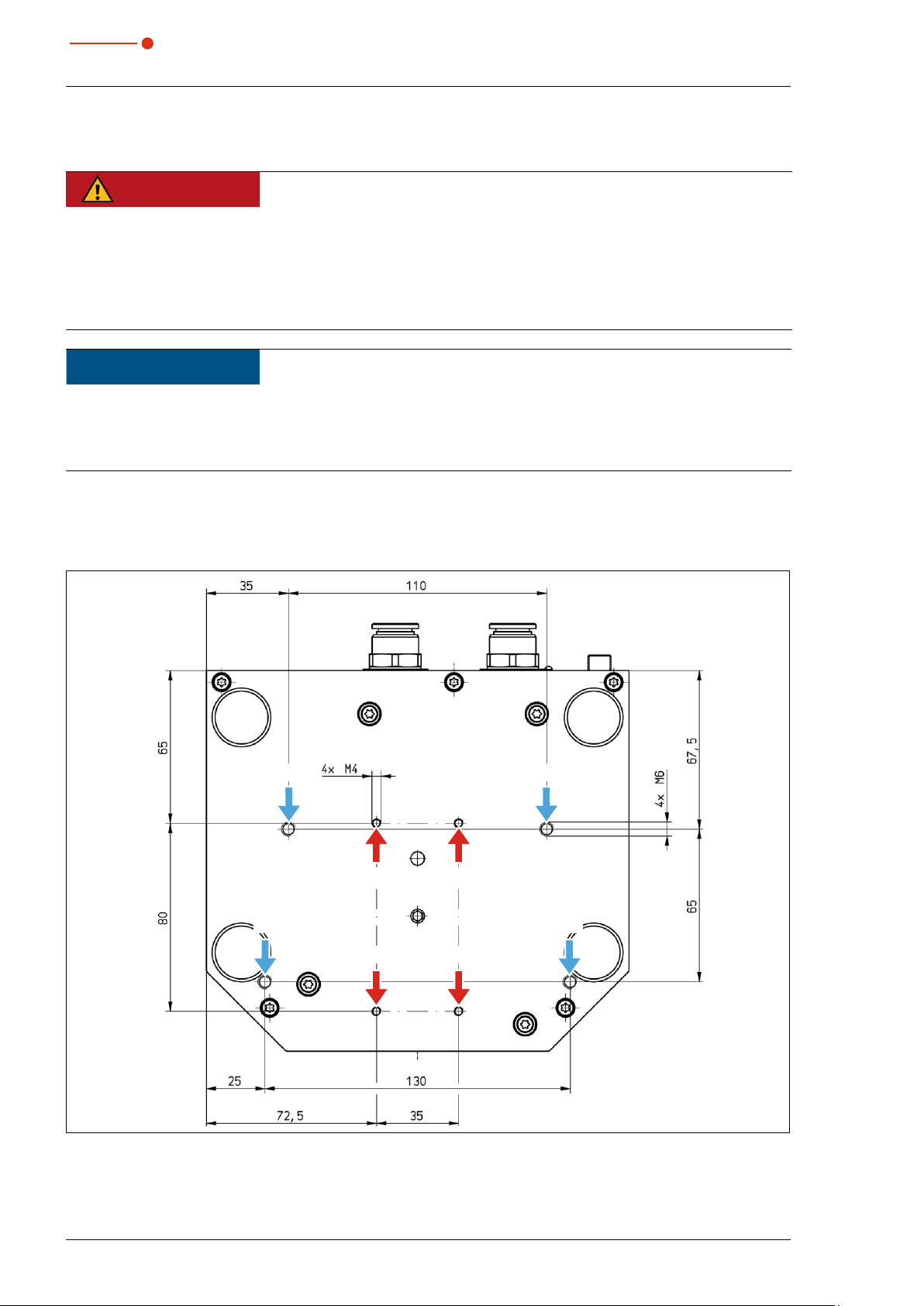

7.4 Install the CompactPowerMonitor CPM

DANGER

Serious eye or skin injury due to laser radiation

If the device is moved from its calibrated position, increased scattered or directed reflection

of the laser beam occurs during measuring operation (laser class 4).

Mount the device so that it cannot be moved by an unintended push or a pull on the cables

X

or hoses.

NOTICE

Damage/Destruction of the device

Too long fixing screws can damage internal components in the device.

The fastening screws must not be screwed in more than 8 mm into the housing.

X

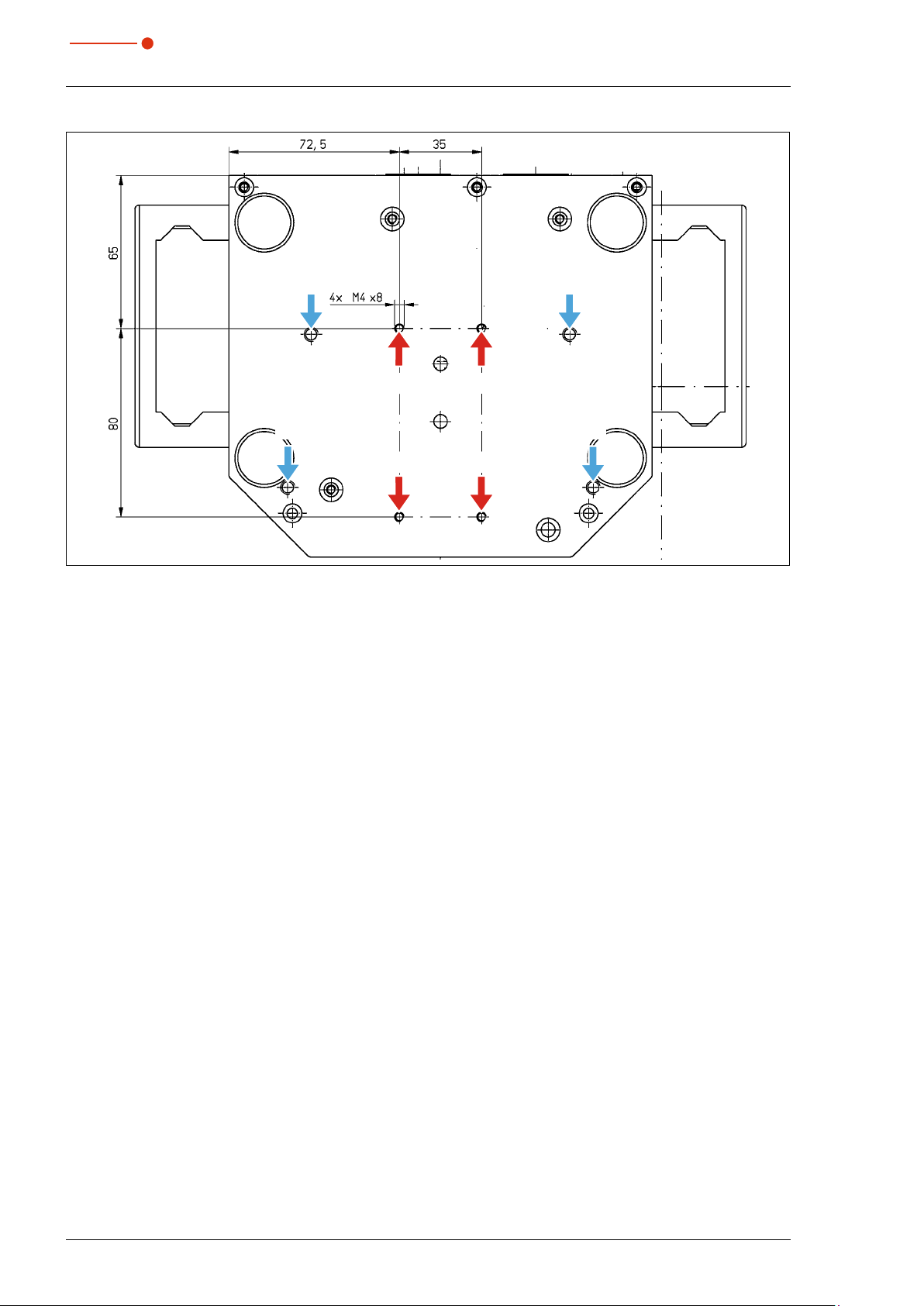

There are fastening screw threads M4 and M6 in the bottom of the housing which are intended for the

mounting on a customer‘s mount. We recommend screws of the strength class 8.8 and a tightening torque

of 5N∙m.

M6M6

M4

M6 M6

M4

Fig. 7.2: Fastening screw threads in the bottom of the housing of the CPM C-9

M4

M4

16

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

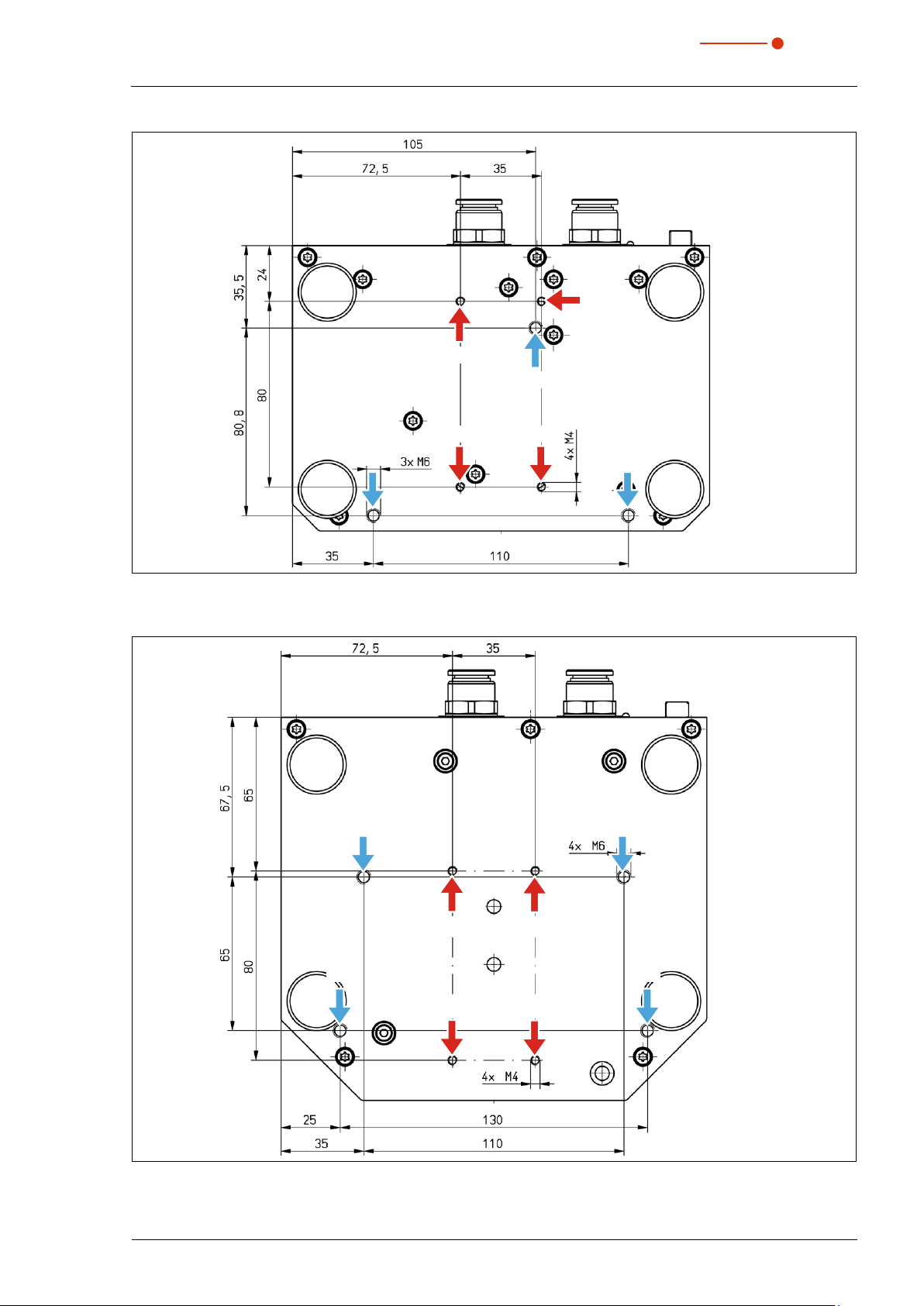

M4

M4

M6

M4M4

M6 M6

Fig. 7.3: Fastening screw threads in the bottom of the housing of the CPM F-1

M6

M6

M6

M4

M4

M4

M4

M6

Fig. 7.4: Fastening screw threads in the bottom of the housing of the F-10

Revision 02/2019 EN

17

CompactPowerMonitor CPM

35,0(6

M6

M4

M6

M4

Fig. 7.5: Fastening screw threads in the bottom of the housing of the CPM F-20

M4

M4

M6

M6

18

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

M6

M6

Fig. 7.6: Fastening screw threads in the bottom of the housing of the CPM F-30

M4 M4

M4 M4

M6

M6

7.5 Remove the CompactPowerMonitor CPM

1. First of all turn the the laser source off.

2. Turn off the voltage supply.

3. Ensure that moving parts, e.g. robot arms, etc. are at a standstill and that they cannot be set in motion

unintentionally.

4. Switch the cooling curcuit off.

5. Remove all connection cables and hoses of the cooling circuit.

6. Remove the device.

NOTICE

Damaging/Destruction of the flow rate meter

The flow rate meter is not designated for high rotational speed.

Do not use compressed air for emptying the cooling circuit.

X

7. Empty the cooling circuit completely and seal the connector plugs by means of the enclosed sealing

plugs.

Revision 02/2019 EN

19

35,0(6

8 Connect cooling circuit

DANGER

Fire hazard; Damage/Destruction of the device due to overheating

If there is no water cooling or a water flow rate which is insufficient, there is a danger of

overheating, which can damage the device or set it on fire.

Operate the device with a connected water cooling only and a sufficient water flow rate (see

X

chapter 8.5 on page22).

Connect the laser control’s safety interlock with the device. The safety interlock is only re-

X

leased if there is a minimum of cooling.

8.1 Water quality

NOTICE

Damage/Destruction of the device due to different chemical potentials

CompactPowerMonitor CPM

The parts of the device which get in contact with cooling water consist of copper, brass or

stainless steel. Connecting the unit to a colling curcuit containing aluminum components

may cause corrosion of the aluminum due to the different chemical potentials.

Do not connect the device on a cooling circuit in which aluminum components are installed.

X

• The device can be operated with tap water as well as demineralized water.

• Do not operate the device on a cooling circuit containing additives such as anti-freeze.

• Do not operate the device on a cooling circuit in which aluminum components are installed. Especially when

it comes to the operation with high powers and power densities, it may otherwise lead to corrosion in the

cooling circuit. In the long term, this reduces the efficiency of the cooling circuit.

• Should the cooling fail, the device can withstand the laser radiation for a few seconds. In this case, please

check the device as well as the water connections for damages.

• Large dirt particles or teflon tape may block internal cooling circuits. Therefore, please thoroughly rinse the

system before connecting it.

An operation with strongly deionized water (DI-water, conductivity < 30µS/cm) is only possible with

the respective connection parts – we would be glad to advise you as necessary.

8.2 Water pressure

Normally, 2 bar primary pressure according to Tab. 8.1 on page20 at the entrance of the absorber are

sufficient (in case of an unpressurized outflow).

Device type Primary pressure

CPM C-9, CPM F-1 2 bar

CPM F-10, CPM F-20, CPM F-30 3 bar

Tab. 8.1: Primary pressure

20

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

NOTICE

Damage/Destruction of the device due to overpressure

The maximum permissible water inlet pressure must not exceed 4bar.

X

8.3 Humidity

• The device must not be operated in a condensing atmosphere. The humidity has to be considered in order

to prevent condensates within and outside the device.

• The temperature of the cooling water must not be lower than the dew point (see Tab. 8.2 on page21).

NOTICE

Damage/Destruction of the device due to condensing water

Condensation water inside of the device can lead to damage.

Mind the dew-point in Tab. 8.2 on page21.

X

Do only cool the device during the measuring operation. We recommend starting the cooling approx. 2minutes before the measurement and terminating it approx. 1 minute after the measurement.

40

35

30

25

20

15

10

Cooling water temperature in °C

5

0

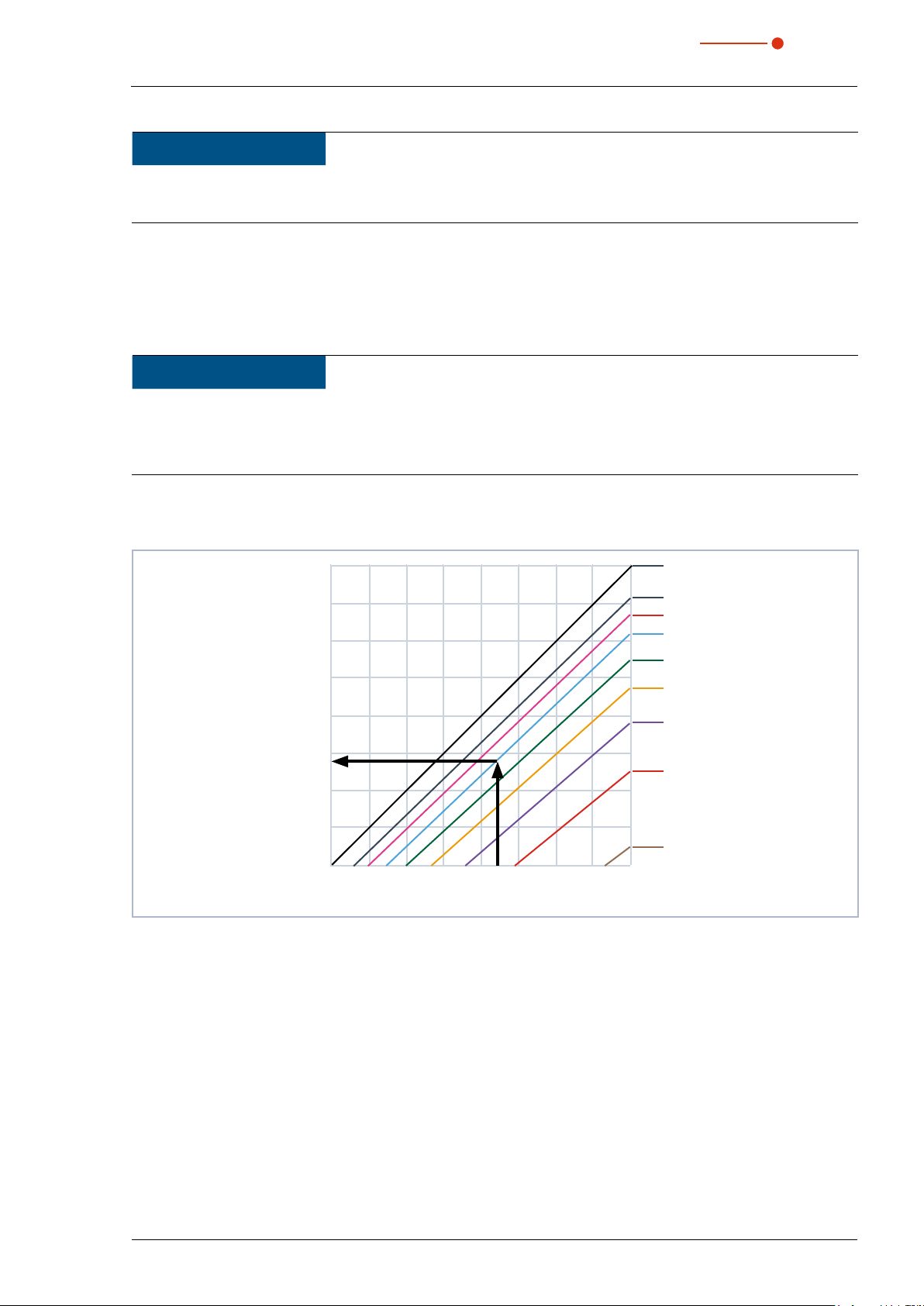

Tab. 8.2: Dew point Diagram

Example

Air temperature: 22°C

Relative humidity: 60%

0 5 10 15 20 25 30 35 40

Air temperature in °C

100

80

70

60

50

40

30

20

Relative humidity in %

10

The cooling water temperature cannot fall below 14°C.

Revision 02/2019 EN

21

CompactPowerMonitor CPM

35,0(6

8.4 Temperature fluctuations of the inflowing cooling water

It is important that the temperature of the inflowing water remains constant. The fluctuation of temperature

should not exceed 0.5 ° C per minute or 0.05 ° C per 5 seconds.

8.5 Flow rate

The safety interlock is unblocked at:

Device type Flow rate in l/min

CPM F-1 0.5

CPM F-10, CPM C-9 4

CPM F-20 8

CPM F-30 15

Tab. 8.3: Minimum flow rate

The highest measurement accuracy is reached at a typical flow rate of:

Device type Flow rate in l/min

CPM F-1 1.5 – 2

CPM F-10, CPM C-9 8 – 11

CPM F-20 15 – 22

CPM F-30 25 – 35

Tab. 8.4: Recommended flow rate

For the maximum laser power in case of a fixed flow rate the following rule is applicable:

Flow rate multiplied by 1.4 = maximum laser power. For 5 l/min this equals about 7 kW.

This calculation serves to prevent a possible overload.

Typical flow rates and temperature rises for the highest measurement accuracy can be found in Tab. 8.5 on

page22.

Beam power in kW

8 7 6 5 4 3 2 1,5 1 0,5

12 9.55 8.36 7.17 5.97 4.78 3.58 2.39 1.79 1.19 0.60

11 10.42 9.12 7.82 6.51 5.21 3.91 2.61 1.95 1.30 0.65

10 11.46 10.03 8.60 7.17 5.73 4.30 2.87 2.15 1.43 0.72

9 12.74 11.15 9.55 7.96 6.37 4.78 3.18 2.39 1.59 0.80

8 14.33 12.54 10.75 8.96 7.17 5.37 3.58 2.69 1.79 0.90

7 16.38 14.33 12.28 10.24 8.19 6.14 4.09 3.07 2.05 1.02

Flow rate in l/min

6 19.11 16.72 14.33 11.94 9.55 7.17 4.78 3.58 2.39 1.19

5 22.93 20.06 17.20 14.33 11.46 8.60 5.73 4.30 2.87 1.43

Temperature rise in °C

Tab. 8.5: Flow rates/temperature rise/beam power - a linear extrapolation up to 20 kW is possible

22

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

8.6 Connect hoses

The flow direction (Water In/Water Out) indicated on the device has to be strictly observed. The plug connectors are intended for hoses with an outer diameter of 12 mm.

The plug connectors are sealed with sealing plugs in order to ensure that no residual water can escape.

Please remove the the sealing plugs and keep for future transportations or shipping.

Remove the sealing plugs of the water connections

Release ring

1. Push

2. Pull

Fig. 8.1: Remove the sealing plugs of the water connections

1. Please push down the release ring of the connection and pull

out the plug with your free hand.

2. Remove the sealing plugs of the water connections and keep

it in a save place.

3. Close the flow line (Water In) and the return flow (Water Out)

of the device, by inserting the hose as far as possible (approx.

20mm deep).

Revision 02/2019 EN

23

CompactPowerMonitor CPM

35,0(6

9 Electrical connection

9.1 Power supply

The CompactPowerMonitor CPM requires a supply voltage of 24V±5% (DC) for the operation. A suitable

power supply with an adapter is included in the scope of delivery.

Please use only the provided PRIMES power supply and connection lines.

When the CompactPowerMonitor CPM is connected via the USB interface, the power is supplied by the PC

through the USB interface. If other devices are connected to the PC that also consume power, it may be

necessary to use a separate power supply.

CPM

Adapter

Fig. 9.1: Connect power supply using the example of the CPM F-10

PRIMES power supply

Connect the power supply unit via the adapter to the 9pin D-Sub socket (RS485) of the CompactPowerMonitor CPM.

9.2 PRIMES bus

The device is supplied with power by means of the 9 pin D-Sub socket. Using an optional PRIMES converter

or a PRIMES power supply with integrated converter, the socket can also be used to connect a PC to enable

communication (see chapter 9.5 on page28).

D-Sub socket, 9 pin

(top view, plug-in side)

15

Pin Function

1 Ground

2 RS485 (+)

3 +24V

4 Not assigned

69

Tab. 9.1: Pin assignment PRIMES bus

24

5 Not assigned

6 Ground

7 RS485 (–)

8 +24V

9 Not assigned

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

9.3 Connect the safety interlock

The device can be damaged when the water flow rate is too low, the inlet temperature Tin too high, or the

temperature difference TD too great. The safety interlock protects the device from damages by turning off the

laser in this case.

If the water flow rate is too low, the inlet temperature Tin is too high, or the temperature difference TD is too

great, then Pin 1 and Pin 4 are connected. Pin 1 and Pin 3 are connected when required by the operating

condition values.

NOTICE

Damaging/Destruction of the device

If the safety interlock is not connected, this may lead to damages to the device due to overheating.

Make sure to connect the safety interlock of the laser control in a way that ensures that the

X

laser is turned off whenever this connection is interrupted.

A suitable connection cable with a device plug and free ends is included in the scope of delivery

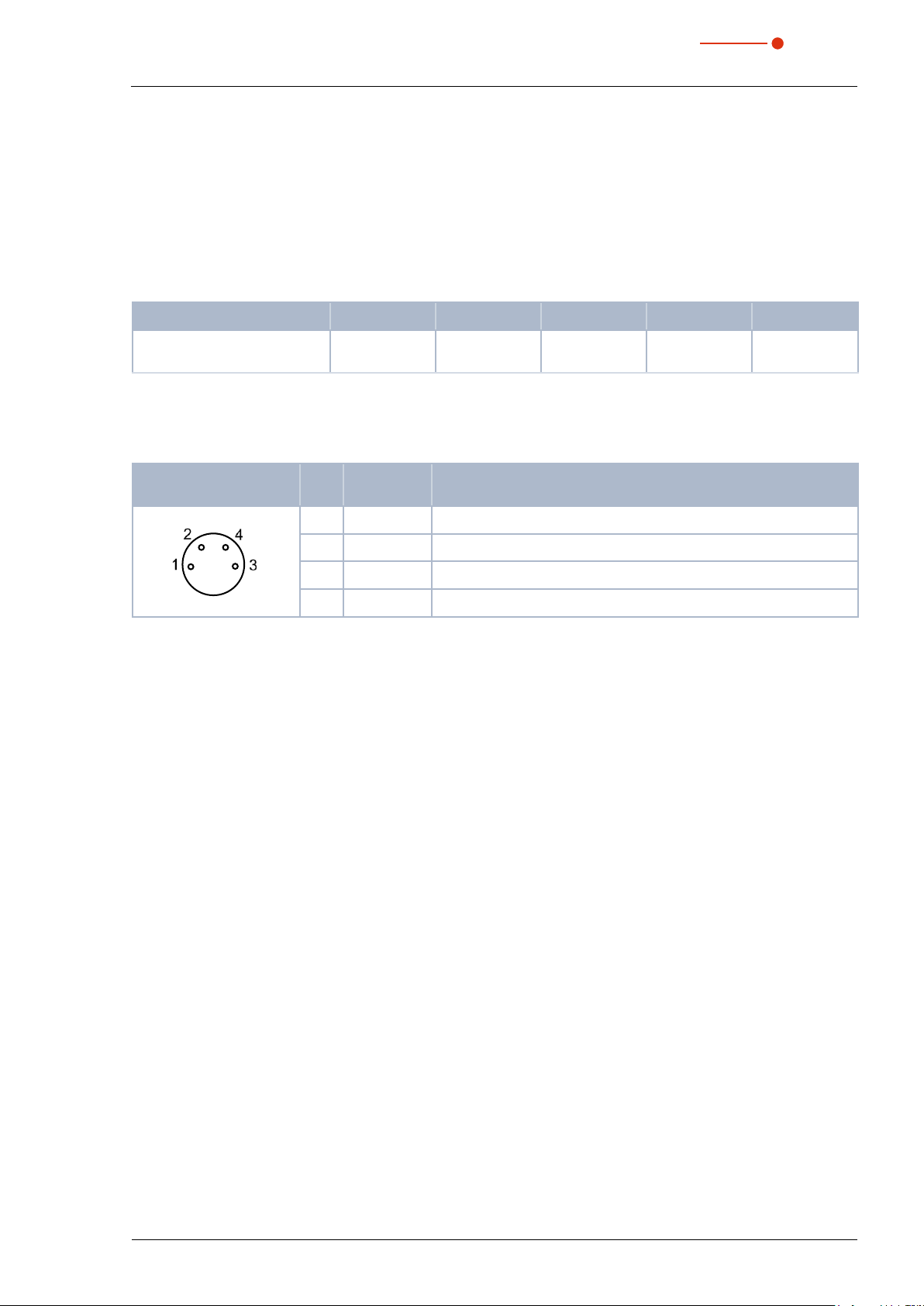

Pin assignment socket

(top view, plug-in side)

4 1 Brown Mutual pin

13

Tab. 9.2: Pin assignment safety interlock

Pin Wire color Function

3 Blue Connected with Pin1 when ready for operation

4 Black Connected with Pin1 when in safety interlock mode

(water flow rate too low)

Revision 02/2019 EN

25

35,0(6

9.4 Connecting the PC via the USB interface

9.4.1 Scope of delivery

For the communication with the PC via USB the following is required:

CompactPowerMonitor CPM

PRIMES standard power supply

with adapter

(included in scope of delivery)

+

Fig. 9.2: Scope of delivery

USB connecting cable

(included in scope of delivery)

In case of short lines (with a maximum

length of 3 m) and a high quality USB cable

(scope of delivery), the voltage supply from

the PC via USB can be sufficient.

9.4.2 Connect PC

If the PRIMES USB connecting cable and PRIMES power supply are connected simultaneously

during initial installation, the USB driver may not be recognized in exceptional cases. During initial

installation, only connect the device via the USB connecting cable. Once the USB connection has

been established, the power supply can be connected as necessary.

1. Connect the device to the PC via the PRIMES USB connection cable (plug/plug):

• For a PC with an Internet connection, the USB driver is automatically installed.

• For a PC without an Internet connection, the USB driver must be installed manually (see chapter 9.4.3 on

page27). The USB driver has to be installed before the device is connected.

2. If necessary, connect the power supply unit via the adapter to the 9pin D-Sub socket (RS485) of the

device.

CPM

Adapter

PRIMES connection cable,

plug/plug

L=3 m

USB

PC

Fig. 9.3: Connection of the PC via USB using the example of the CPM F-10

In general, a USB interface without additional interference suppression measures is not in conformity with the EMC directive. In industrial environments with strong sources of interference, there could

therefore be disruptions in the connection and disruptions in data transmission.

RIMES power supply

26

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

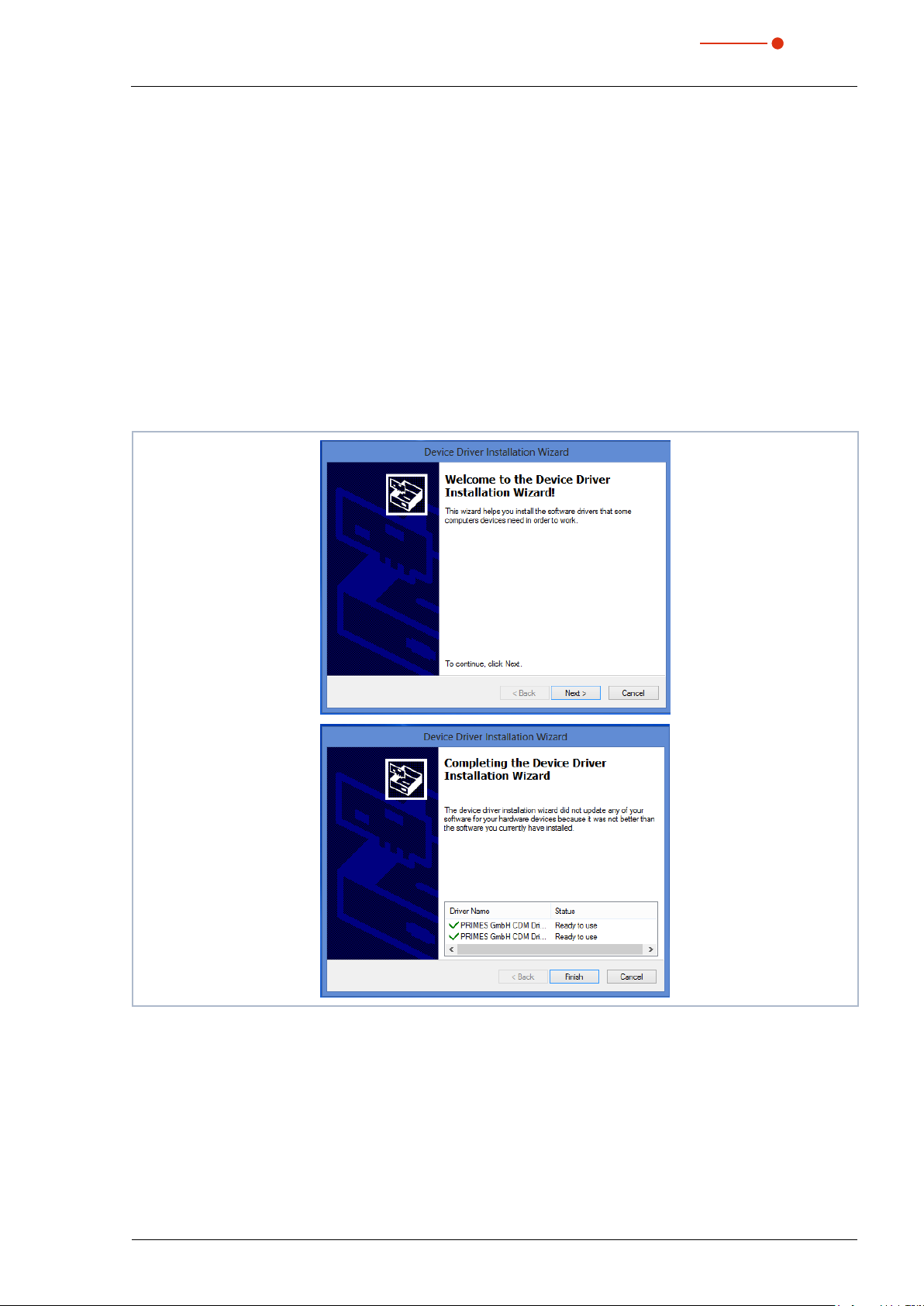

9.4.3 Install the USB driver manually

The PRIMES USB driver for all USB-capable devices can be found on the enclosed PRIMES data medium or

on the PRIMES website at: https://www.primes.de/en/support/downloads/software.html

®

The USB driver can be installed for 32bit and 64bit Windows

data medium included in the scope of delivery. Administrator rights are necessary in order to install the USB

driver.

• Driver installation software dpinst_x64.exe for Windows® 7/8/10 (64bit)

• Driver installation software dpinst_x86.exe for Windows® 7 (32bit)

1. Connect the supplied PRIMES data medium to your PC.

2. Open the USBdriver folder.

3. Start the desired USB driver installation software (32- or 64bit) by double-clicking.

4. Follow the instructions on the screen.

operating systems by means of the PRIMES

Fig. 9.4: Windows® menu for USB driver installation

5. Click Finish in order to complete the installation.

6. Connect the CompactPowerMonitor CPM according to chapter 9.4.2 on page26.

Revision 02/2019 EN

27

CompactPowerMonitor CPM

35,0(6

9.5 Connecting the PC via RS232 interface and optional PRIMES converter

When there is no free D-sub socket on the PC, the device can be connected to the PC with the optional

PRIMES USB converter and the PRIMES connecting cable (socket/socket).

9.5.1 Scope of delivery

For the communication with the PC via RS232 interface, you require:

PRIMES standard power

supply with adapter (in-

cluded in scope of delivery)

Fig. 9.5: Scope of delivery

9.5.2 Connect PC

NOTICE

Damaging/Destruction of the device

Connecting or disconnecting the bus cable when it is connected with the supply voltage

leads to voltage peaks, which may damage communication modules of the measuring device.

Only establish connections when the power supply unit is turned off. Do not disconnect any

X

plugs as soon as the supply voltage is switched on.

PRIMES RS485/RS232 converter

(option, Order-No. 180-005-003)

+

D-Sub connecting cable

(option, Order-No. 180-004-009)

+

USB-Serial converter

(option, Order-No. 180-006-001)

+

28

NOTICE

Damaging/Destruction of the PC

The supply voltage of 24V is ensured by means of the RS485-based PRIMES bus. If the

measuring device is directly connected with the PC, the PC may be damaged.

Only connect your PC with the measuring system via a PRIMES RS485/RS232 interface

X

converter.

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

1. Connect the device with the PRIMES converter via the PRIMES connector cable (plug/plug).

2. Connect the PC with the PRIMES converter via the PRIMES connector cable (socket/socket).

3. Connect the power supply unit via the adapter to the 9pin D-Sub socket (RS485) of the PRIMES converter.

CPM

PRIMES converter

PRIMES connection cable,

socket/socket

L=2 m

PRIMES connection cable

plug/plug

L=2 m

Adapter

or

RS232 USB

PC

PRIMES power supply

PRIMES-

USB-Serial converter

L=0.1m

Fig. 9.6: Connection to the PC via RS232 and PRIMES converter using the example of the CPM F-10

Revision 02/2019 EN

29

CompactPowerMonitor CPM

35,0(6

9.6 Parallel operation of the CompactPowerMonitor PMC and, for example, the FocusMonitor FM+

A measuring device, such as the FocusMonitor FM+, can be connected with the CompactPowerMonitor

CPM via the RS485 interfaces (PRIMES bus). The signal of the CompactPowerMonitor CPM is transmitted to

the PC through the ethernet interface of the FocusMonitor FM+.

PRIMES Power supply

Ethernet

PRIMES bus RS485

socket/socket

L

=10m

max

Fig. 9.7: Connection of the FocusMonitor FM + with the CompactPowerMonitor using the example of the CPM F-10

NOTICE

Damage/Destruction of the device due to overvoltage

When disconnecting the electric cables during operation (when the supply voltage is connected), voltage peaks can be generated that could destroy the communication modules of

the measuring devices.

Turn off the power supply before disconnecting the bus cables.

X

30

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

9.7 Analog output

The CompactPowerMonitor CPM has an analog voltage output (analog output) that emits a voltage value

analogous to the measured laser power. The analog signal is effected via the 4-pin device socket M8 (see

Fig. 5.1 on page12). The output voltage amounts to a maximum of 10 V. The output voltage of 10 V is

scaled to the maximum output value of the connected device (see Tab. 9.3 on page31). A suitable connection cable is included in the scope of delivery.

The load resistance at the analog output should not be smaller than 100 kOhm.

CPM C-9 CPM F-1 CPM F-10 CPM F-20 CPM F-30

An output voltage of 1V

equals approx.

Tab. 9.3: Output voltage and laser power

1 000W 250 W 1 000W 2 500W 4000W

When power is supplied through the USB port, it is not necessary to hook up 24 V through Pin 1 and Pin 2.

Pin assignment socket

(top view, plug-in side)

Tab. 9.4: Socket assignment of the analog output

Pin Wire color Function

1 Brown 24V (input power supply)

2 White Ground for the power supply

3 Blue Ground for the analog signal

4 Black Analog signal 0 – 10V (output)

Revision 02/2019 EN

31

CompactPowerMonitor CPM

35,0(6

10 Display, control elements and audible signals

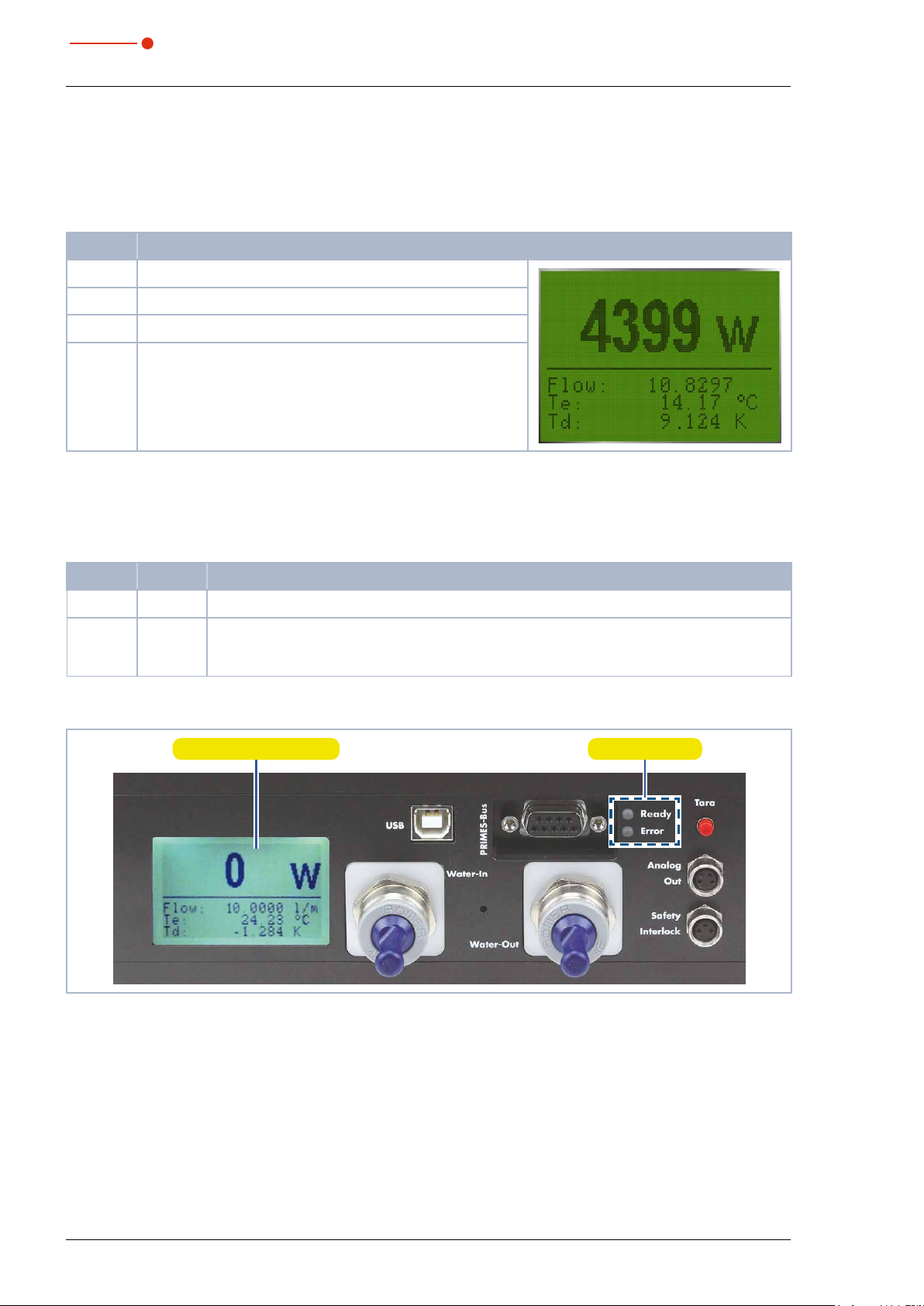

10.1 Measured value display

The display on the connector side of the device shows the following measurement values:

Display Meaning

W Laser power in W

Flow Water flow rate in l/min

Te Water temperature at the entrance in °C

Td Temperature difference between water input and output in

Tab. 10.1: Meaning of the measured display

Kelvin (a temperature difference of 1K corresponds to a temperature difference of 1°C).

10.2 Status display

The status displays indicate different states of the CompactPower Monitor CPM.

LED Color Meaning

Ready Green Voltage supply is turned on.

Error

Tab. 10.2: Meaning of the status display

Red

Possible errors: Safety interlock has triggered:

The water flow rate is too low, the inlet temperature T

ence T

is too great.

D

Measured value display Status display

is too high, or the temperature differ-

in

Fig. 10.1: Display

After the connection of all cables you can turn on the power supply. The green status display (Ready) on the

front of the CompactPowerMonitor CPM lights up. In case of an error, the red status display (Error) lights up.

32

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

10.3 External display (Option)

The external display (PanelDisplay, Order-No. 130-005-003) allows the measured power to be displayed

without PC at a maximum distance of approx. 20m from the measuring position (see chapter 20.1 on

page55).

10.4 Control Elements

By means of the Tara button, the measurement values can be reset to zero.

We recommend the following procedure before every measurement:

1. Turn on the cooling and wait for approx. 2 minutes.

2. Push the Tara button.

3. Start the measurement according to chapter 11 on page34 or chapter 13 on page41.

Tara button

Fig. 10.2: Tara button

10.5 Audible signals

When the temperature of the absorber exceeds 60°C, the warning signal will sound:

1. Turn off the laser immediately.

If water leaks out of the device after the warning signal has sounded, the device may be damaged by overheating and cease to be operable. The overpressure caused in the standing cooling water can also cause

leaks in the hoses and connectors.

2. Check the device for leaks.

• In the case a leak is identified, please send the device to PRIMES for inspection.

If no leaks are identified:

3. Check the absorber for possible damage.

4. Check the flow rate and proper flow rate in accordance with Chapter 8.5 on page22.

5. Perform a function test:

• Check that the safety interlock will turn off the laser properly in case of error.

• If the device stops working properly, please send the device to PRIMES for inspection.

Revision 02/2019 EN

33

CompactPowerMonitor CPM

35,0(6

11 Measuring with the optional LaserDiagnosticsSoftware LDS

11.1 Safety instructions

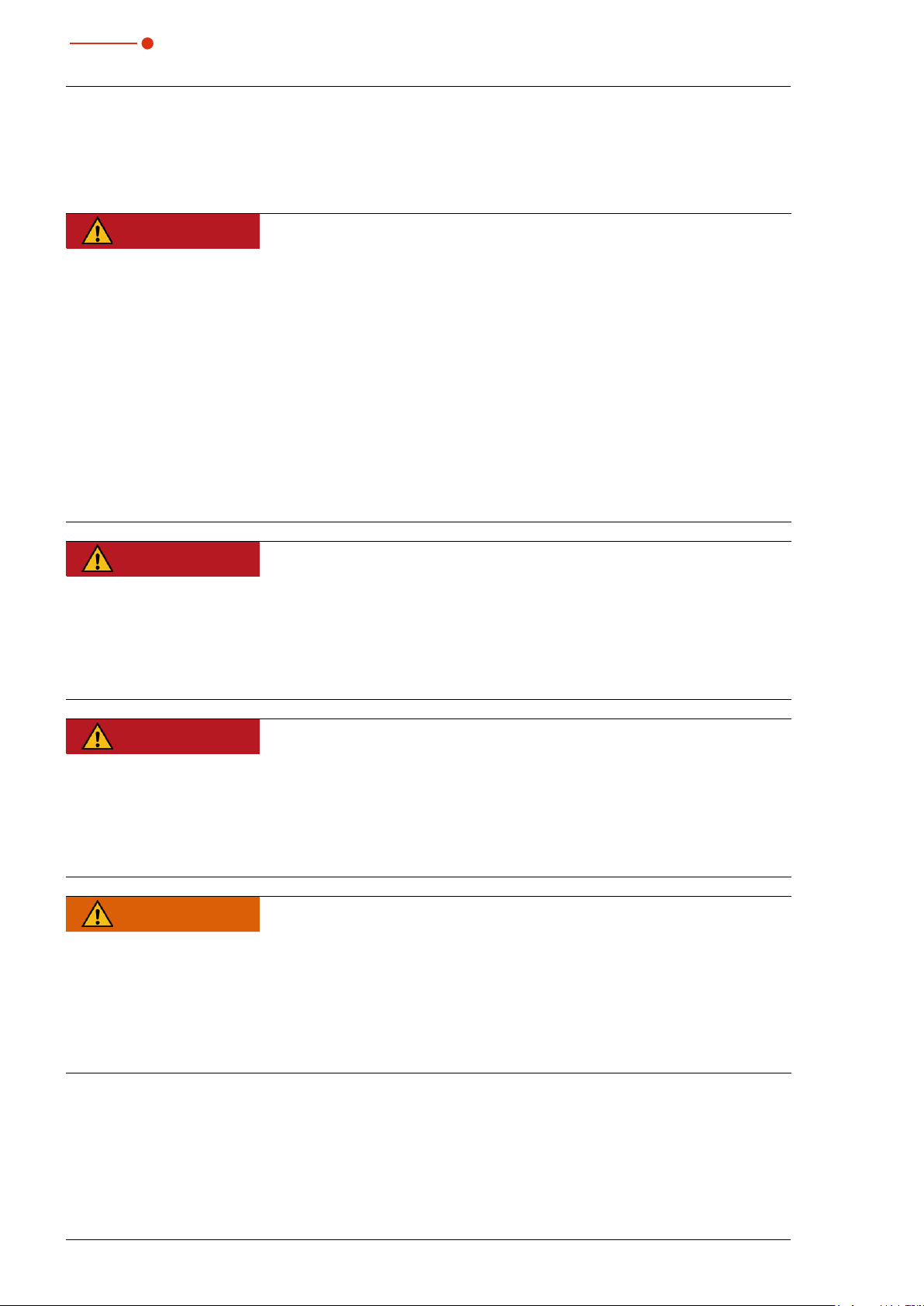

DANGER

Serious eye or skin injury due to laser radiation

During the measurement the laser beam is guided on the device, which causes scattered or

directed reflection of the laser beam (laser class 4).

For example, with 10kW of laser power, some 100 W of scattered radiation can occur.

The CompactPowerMonitor CPM must not be operated in any of the available configurations without taking the following precautions.

Please wear safety goggles adapted to the power, power density, laser wave length and

X

operating mode of the laser beam source in use.

Wear suitable protective clothing and protective gloves.

X

Protect yourself from laser radiation by separating protective devices (e.g. by using appro-

X

priate shielding).

DANGER

Serious eye or skin injury due to laser radiation

If the device is moved from its calibrated position, increased scattered or directed reflection

of the laser beam occurs during measuring operation (laser class 4).

When mounting the device, please ensure that it cannot be moved, neither due to an unin-

X

tended push or a pull on the cables or hoses.

DANGER

Fire hazard; Damage/Destruction of the device due to overheating

If the safety interlock is not connected, the unit may overheat and be damaged or catch fire

if there is no water or too low flow.

Connect the laser control’s safety interlock to the device. Check that the safety interlock will

X

switch off the laser properly in case of error.

WARNUNG

Burn hazard; Damage of the absorber – Do not touch

Touching the hot absorber can cause severe burns.

Touching the absorber can lead to burn-in by the laser radiation at the points of contact.

Burn-in lead to damage to the absorber and increase the scattered radiation.

Do not touch the absorber.

X

34

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

11.2 Getting ready for operation

1. Connect the laser control’s safety interlock to the device.

• Check that the safety interlock will switch off the laser properly in case of error.

2. Turn on the voltage supply.

• The green status display (Ready) must light up.

3. Please wait, until the measured value display is illuminated.

4. Turn on the water cooling.

• After a few seconds the red status display (Error) must extinguish.

5. After approx. 2 minutes, the device temperature equals the temperature of the cooling water.

• The CompactPowerMonitor CPM is now ready for operation.

11.3 Perform power measurement

For the purpose of getting to know the CompactPowerMonitor CPM, this chapter describes a power measurement with the LaserDiagnosticsSoftware LDS as an example.

For a detailed description of the software installation, file management and evaluation of the measured data,

please refer to the separate operating manual LaserDiagnosticsSoftware LDS.

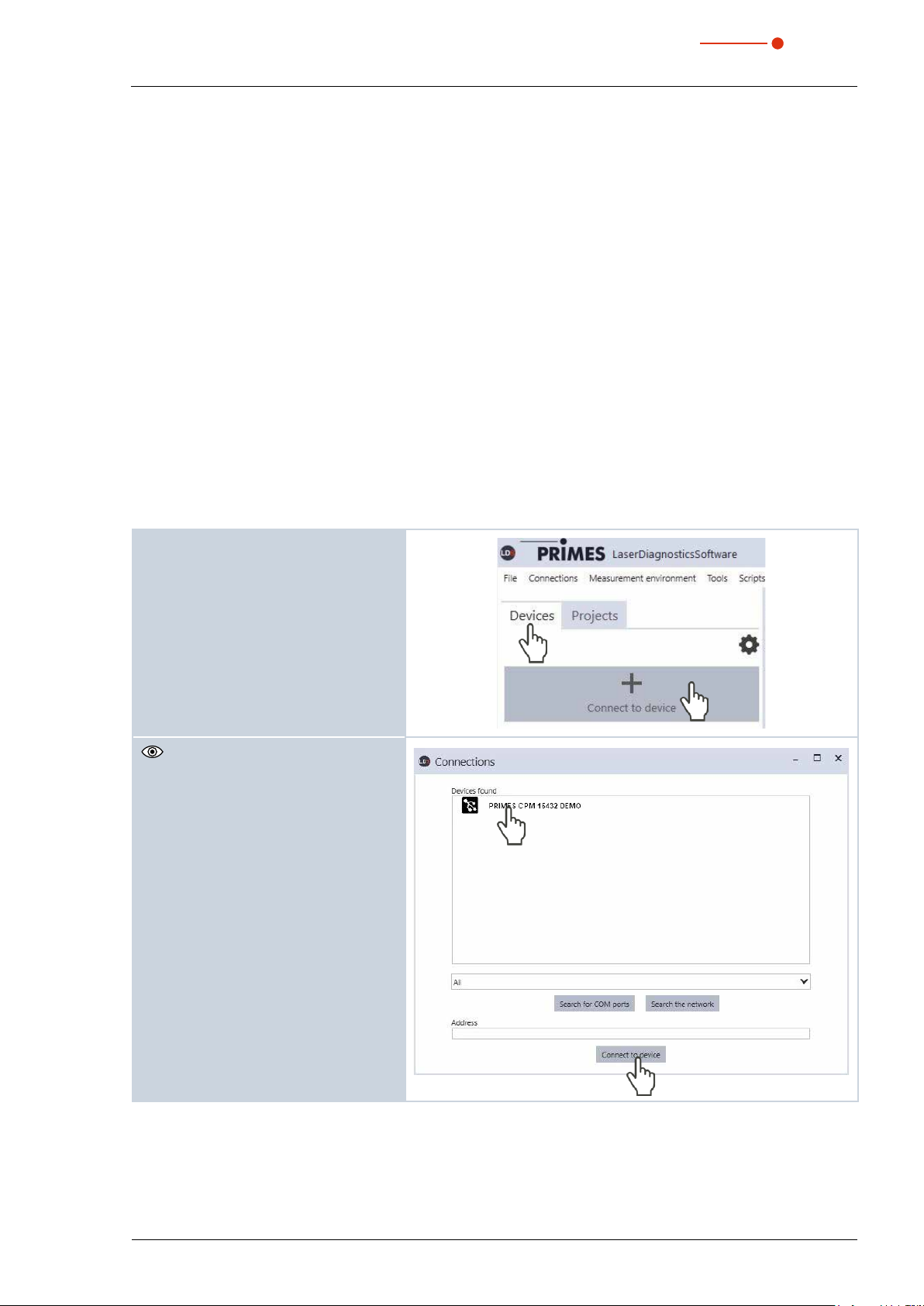

11.3.1 Connect the CompactPowerMonitor CPM with the LaserDiagnosticsSoftwareLDS

1. Start the LaserDiagnosticsSoftwareLDS.

2. Click on the Devices tab.

3. Click on the + Connect to device

button under the tab.

The Connections window appears.

4. Click on the desired device.

5. Click on the Connect to device button.

Revision 02/2019 EN

35

35,0(6

11.3.2 Choose power measurement mode

The CompactPowerMonitorCPM is

displayed as a connected device.

1. Click on the connected device.

The corresponding Device control

opens.

The Power Measurement toolbench

opens.

CompactPowerMonitor CPM

11.3.3 Configure settings (Device control)

1. Start and end a measurement as

described in chapter 11.3.4 on

page37.

Before the device offset can be determined, the device must go through a

thermalization period.

2. After a measurement has ended and

without the laser turned on, press the

Start button.

3. After the display in the Power Mea-

surement tool stabilizes, click on the

Stop button.

4. Click on the Set current value as

offset button.

• The value will show up in the Additional Offset in W entry window.

• The device offset can also be entered

manually with the tara key on the device (see chapter 10.4 on page33).

5. Enter the measurement duration in

min.

• If a measurement duration is not

entered, the power will be measured

indefinitely.

6. Enter the Measurement frequency

in Hz.

36

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

11.3.4 Starting a power measurement

1. Follow the safety instructions in chapter 11.1 on page34.

2. Turn on the laser.

3. Click on the Start button.

The progress of the measurement is

displayed.

When a measuring period is entered in the

Device control > Measurement duration in min. entry window, the measure-

ment is terminated automatically.

4. Click on the Stop button.

• The measurement is completed.

5. Turn off the laser.

11.3.5 Measurement results display

The measurement results are shown in the opened tool Power Measurement after the measurement is com-

pleted (see below).

A detailed description of the tools and the assessment of the measuring results can be found in the separate

operating manual for the LaserDiagnosticsSoftware LDS.

Revision 02/2019 EN

37

CompactPowerMonitor CPM

35,0(6

12 Install the PowerMonitorSoftware PMS

For the operation of the CompactPowerMonitor CPM with a PC, the PowerMonitorSoftware PMS has to be

installed. The installation is started by double-clicking the file “PMS v.2.xx Setup” and following the instructions on the screen.

12.1 Start software and select operating mode

Start the PowerMonitorSoftware PMS by double-clicking the PowerMonitorSoftware PMS-Icon .

12.1.1 For connection via the RS232 and PRIMES converter

See „Fig. 9.6: Connection to the PC via RS232 and PRIMES converter using the example of the CPM F-10“

on page29.

After the start-up the software tries to establish a connection with the serial interface “COM2”. If the serial interface “COM1” is the only one available, as it is the case with most notebooks, you have to select it explicitly

in Com port in the menu Communication > Free Communication.

When using the USB serial converter, please choose the operating mode USB2Serial.

12.1.2 For connection via the USB interface

See „Fig. 9.3: Connection of the PC via USB using the example of the CPM F-10“ on page26.

If the device was connected via USB, the operating mode USB has to be selected in the menu Communi-

cation > Free Communication. Then press the Scan button.

Operating mode

Fig. 12.1: Menü Free Communication

Serial interface

38

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

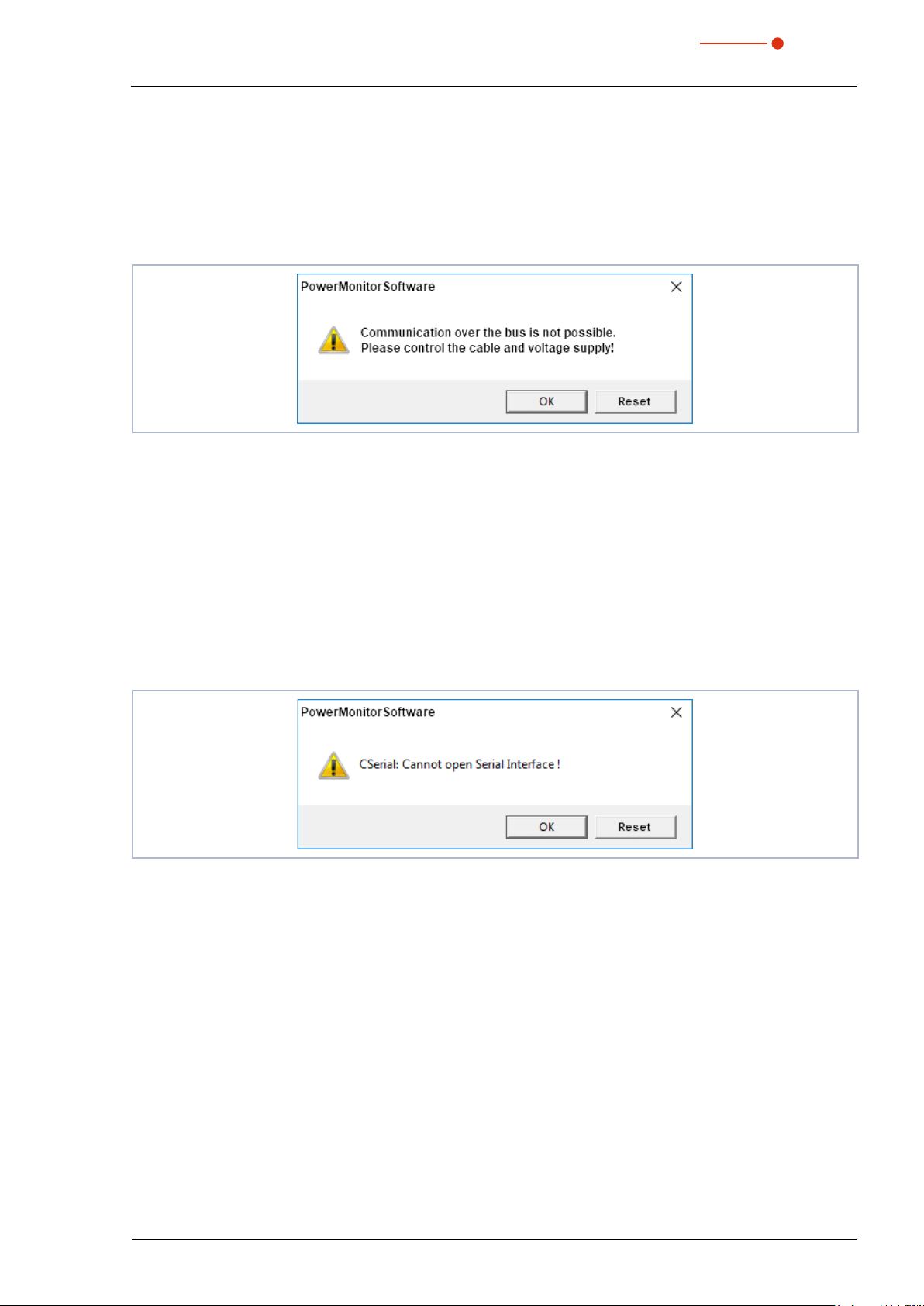

12.2 Testing the Interface

After connecting the devices, the communication between the PC and the measuring system can be

checked. This is what the menu Communication > Free Communication is there for. First of all, the interface is checked by starting the software on the PC.

Possible error message

Fig. 12.2: Possible error message

Reason

• The communication via the bus system is not possible.

Remedy

1. Check the cabling of the devices.

2. Ensure that the voltage supply is connected and turned on (the communication is only possible if the bus

is supplied with 24V direct current voltage).

3. Turn off the voltage supply and turn it on again.

Possible error message (only when operated with the PRIMES converter)

Fig. 12.3: Possible error message

Reason

• The software can not open the preset interface.

Remedy

1. Check whether another software, e.g. a fax software or a parallel running LaserDiagnosticsSoftware LDS,

is just using the interface. A serial port can only be used by one software at a time.

2. Check whether the software opens the right port. After starting the software, the interface used can be

changed in the menu Free Communication. Here, all interfaces available for the software are displayed

(drop-down list Com port).

Revision 02/2019 EN

39

CompactPowerMonitor CPM

35,0(6

12.3 Testing the communication of multiple devices

The communication is checked via the PC by means of the PowerMonitorSoftware PMS. For this purpose, a

certain command is sent to each device. If a device replies as stated in Tab. 12.1 on page40 the communication works without any problems.

Start the PowerMonitorSoftware PMS. Select Communication > Free communication. In the appearing

window the address of the sender (PC) has to be entered in the field FROM, the address of the recipient has

to be entered in the field TO (PRIMES device) and the command is entered in the text field on the right. The

command is confirmed by clicking the button Send. The reply of the device appears below in the bus monitor.

Command line for USB

Address of the sender

Address of the receiver

Fig. 12.4: Menu Free Communication

Device FROM (PC) TO (Device) Command Reply

FocusMonitor 64 161 qr aID FocusMonitor

BeamMonitor 64 144 qr aID BeamMonitor

CompactPowerMonitor CPM 64 113 (112) qr ready Power Monitor

Tab. 12.1: Table for the function control

Text field for the

command input

The command for a query request is qr (query request).

If no reply is received from a device:

1. Turn off the voltage supply and turn it on again. Send the command again.

2. Check the cabling of the device. Are all the plugs connected?

3. A device blocks the PRIMES bus. Turn off the voltage supply and take the faulty device off the bus. Put

the the system back into operation.

4. The PC blocks the PRIMES bus. This is indicated by the red LED “Send“ at the interface converter which

glows permanently. Start the PC again.

40

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

13 Measuring with the PowerMonitor Software PMS

13.1 Safety instructions

DANGER

Serious eye or skin injury due to laser radiation

During the measurement the laser beam is guided on the device, which causes scattered or

directed reflection of the laser beam (laser class 4).

For example, with 10kW of laser power, some 100 W of scattered radiation can occur.

The CompactPowerMonitor CPM must not be operated in any of the available configurations without taking the following precautions.

Please wear safety goggles adapted to the power, power density, laser wave length and

X

operating mode of the laser beam source in use.

Wear suitable protective clothing and protective gloves.

X

Protect yourself from laser radiation by separating protective devices (e.g. by using appro-

X

priate shielding).

DANGER

Serious eye or skin injury due to laser radiation

If the device is moved from its calibrated position, increased scattered or directed reflection

of the laser beam occurs during measuring operation (laser class 4).

When mounting the device, please ensure that it cannot be moved, neither due to an unin-

X

tended push or a pull on the cables or hoses.

DANGER

Fire hazard; Damage/Destruction of the device due to overheating

If the safety interlock is not connected, the unit may overheat and be damaged or catch fire

if there is no water or too low flow.

Connect the laser control’s safety interlock to the device. Check that the safety interlock will

X

switch off the laser properly in case of error.

WARNUNG

Burn hazard; Damage of the absorber – Do not touch

Touching the hot absorber can cause severe burns.

Revision 02/2019 EN

Touching the absorber can lead to burn-in by the laser radiation at the points of contact.

Burn-in lead to damage to the absorber and increase the scattered radiation.

Do not touch the absorber.

X

41

CompactPowerMonitor CPM

35,0(6

13.2 Getting ready for operation

1. Connect the laser control’s safety interlock to the device.

• Check that the safety interlock will switch off the laser properly in case of error.

2. Turn on the voltage supply.

• The green status display (Ready) must light up.

3. Please wait, until the measured value display is illuminated.

4. Turn on the water cooling.

• After a few seconds the red status display (Error) must extinguish.

5. After approx. 2 minutes, the device temperature equals the temperature of the cooling water.

Press the tara button to adjust the offset to zero.

• The CompactPowerMonitor CPM is now ready for operation.

13.3 Starting the software

Start the PowerMonitorSoftware PMS by double-clicking the shortcut on the desktop or by double-clicking the application „PMS.exe“ in the PMS directory. The graphical user interface appears, as displayed in Fig.

13.1 on page43.

When the communication is established, different measuring values are displayed. If no communication is

established, press the Start/Stop button in the upper right corner. If a communication is still not possible

afterwards, proceed as described in chapter 12.2 on page39.

13.4 Perform power measurement

1. Click the button Start.

2. Turn on the laser.

3. The measured power is updated every second on the measured value display of the device (see chapter

Fig. 10.1 on page32) or on the screen of the PC (see chapter 13.6 on page44).

• After about 15 seconds the display reaches about 99 % of the final value.

42

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

13.5 The graphical user interface of the PowerMonitor Software PMS

You can open different dialogue windows via the menu bar.

Fig. 13.1: Menu Selection in the menu bar

File > Settings

Here, a different device address can be entered.

File > Protocol

The determined measuring results can be written in a tab-separated text file. Activate the check box Write

and type in a file name or choose a file. Click OK.

File > Quit

Terminates the software.

Communication > Free communication

Opens the dialogue window for the communication.

Info

Provides information regarding the software.

This operating manual describes the software version v2.57 valid at the point of printing. Due to

the fact that the operating software is continuously developed further, it is possible that a different

version number is printed on the attached PRIMES data medium. The correct function of the device

with the software is still ensured.

Revision 02/2019 EN

43

CompactPowerMonitor CPM

35,0(6

13.6 Measuring value display

The graphical user interface is divided into three display parts (see Fig. 13.2 on page44):

• The numerical display of the current measuring values (window A)

• The temporal development of the laser power or the flow rate or of the cooling water temperature (window B)

• Status window

13.6.1 Window A (Numerical display)

In window A below the large display in Fig. 13.2 on page44: 969 W the following measured values are

displayed:

• The current measuring value

• The minimum value and the maximum value

• The average value (button Average) of the chosen time interval (drop-down list Time)

With the averaging of the power measuring values (Time 10s, 20s, 30s, 50s, max = 90s) a noise

can be reduced, which enables very accurate measurements.

Display area Adjustment area

A

Adjustment area

Control

for window A

B

Time series temperature/water flow

Fig. 13.2: The graphical user interface during a measurement

With option switches Current, Min, Max, Average in the configuration range Control set which measured

value is shown in large digits (see Tab. 13.1 on page44).

Selection Display

Time series power

Adjustment area

Scale

for window B

Status window

Current Display of the current power

Min Display of the minimum power measured

Max Display of the maximum power measured

Average Display of the average value within the chosen measurement duration

Tab. 13.1: Selection for large display of the measured value

44

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

Settings

The maximum duration (Max) for the averaging is 90 seconds.

A possible zero offset can be compensated with the button Use current value as offset or numerically via

the input field Zero level.

13.6.2 Window B (Graphical display)

In window B two time series are displayed.

Time series power

You can scale the y-axis (power) of the window automatically or with fixed values (200W or 500W). In the

setting Automatic the y-axis is scaled with the difference of the measured minimum and maximum value.

Time series temperature/Flow rate

Here, the cooling water flow rate or the input temperature (T

) or the difference temperature (T

in

) between

diff

the input and the output can be controlled. The choice can be made by means of the option switches

in the adjustment area Scale.

• Flow rate

• T

in

• T

diff

Push button clear

Deletes all numerical and graphical displays in the windows.

Select list Time: Frequency

In this select list you choose the duration of the measurement as well as the measurement rate (number of

measurements per time unit). Possible settings:

Measurement

duration

90 s 1 s

10 min 2 s

30 min 2 s

2 h 5 s

10 h 5 s

50 h 10 s

Fig. 13.3: Setting Time: Frequency

Measurement

rate

≙ 1Hz

≙ 0,5Hz

≙ 0,5Hz

≙ 0,2Hz

≙ 0,2Hz

≙ 0,1Hz

13.6.3 Status window

In the bottom right window (Status) of the user interface (see Fig. 13.2 on page44) error messages can

appear in red font. These errors have to be remedied before a measurement.

Revision 02/2019 EN

45

35,0(6

14 Storage

Please note before storing:

NOTICE

Damage/destruction of the device caused by leaking or freezing cooling water

Leaking cooling water can damage the device. Storing the device at temperatures near or

below freezing and without emptying the cooling circuit completely can damage the device.

Empty the lines of the cooling circuit completely.

X

Even when the lines of the cooling circuit have been emptied, a small amount of residual

X

water will remain in the device at all times. This may leak out and end up inside the device.

Close the connector plug of the cooling circuit with the included sealing plugs.

Store the device in the original PRIMES transport box.

X

NOTICE

Damaging/Destruction of the flow rate meter

CompactPowerMonitor CPM

The flow rate meter is not designated for high rotational speed.

Do not use compressed air for emptying the cooling circuit.

X

15 Maintenance and service

The operator is responsible for determining the maintenance intervals for the measuring device.

PRIMES recommends a maintenance interval of 12 months for inspection and validation or calibration.

If the device is used only sporadically, the maintenance interval can also be extended up to 24 months.

16 Measures for the product disposal

Due to the Electrical and Electronic Equipment Act (“Elektro-G“) PRIMES is obliged to dispose PRIMES measuring devices manufactured after August, 2005, free of charge. PRIMES is a registered manufacturer in the

German “Used Appliances Register“ (Elektro-Altgeräte-Register “EAR“) with the number

WEEE-Reg.-Nr. DE65549202.

Provided that you are located in the EU, you are welcome to send your PRIMES devices to the following address where they will be disposed free of charge (this service does not include shipping costs):

PRIMES GmbH

Max-Planck-Str. 2

64319 Pfungstadt

Germany

46

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

17 Declaration of conformity

Revision 02/2019 EN

47

CompactPowerMonitor CPM

35,0(6

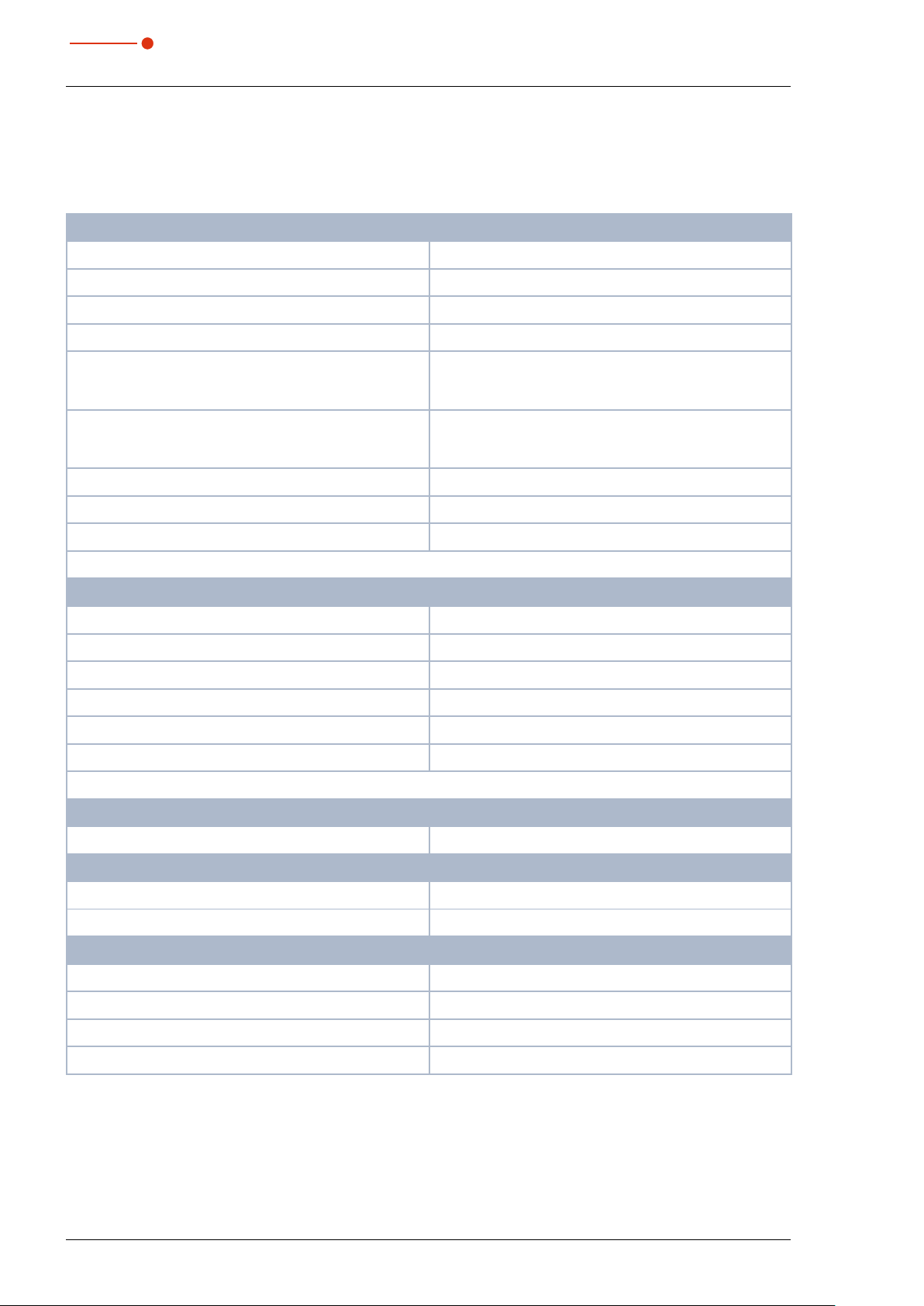

18 Technical data

18.1 CPM C-9

Measurement parameters

Max. power range 0.5–9kW

Irradiation time continuous

Wavelength range 800 – 1100nm and 10600nm

Inlet aperture 55mm

1)

Max. power density at beam diameter

Average power density at beam diameter

1)

Accuracy ±3%

Reproducibility ±1.5%

10kW/cm² (Ø<10mm)

5kW/cm² (Ø 10–30 mm)

0,5kW/cm² (Ø 30–55 mm)

5kW/cm² (Ø <10 mm)

5kW/cm² (Ø 10–30mm)

0.5kW/cm² (Ø 30–55 mm)

Time constant <10s

1)

A central beam incidence is assumed.

Supply data

Power supply, DC 24V ±5%, max.0.5A

Min. cooling water pressure 2bar

Max. cooling water pressure 4bar

Recommended cooling water flow rate 8 – 11l/min

Cooling water flow rate (warning level) 4l/min

Cooling water temperature T

2)

Please contact PRIMES in advance in case you intend not to work within this specification.

2)

in

Dew point temperatur <Tin<30°C

Communication

Interfaces RS485/USB

Dimensions and Weights

Dimensions (L x W x H) 180 × 162 × 136mm

Weight (approx.) 5.1kg

Environmental conditions

Operating temperature range 15 – 40°C

Storage temperature range 5 – 50°C

Reference temperature 22°C

Permissible relative humidity (non condensing) 10 – 80%

48

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

18.2 CPM F-1, CPM F-10, CPM F-20, CPM F-30

Measurement parameters CPM F-1 CPM F-10 CPM F-20 CPM F-30

Max. power range 0.1–1,4kW 0.5–10kW 1–20kW 2–30kW

Irradiation time continuous

Wavelength range 800 – 1100nm 800 – 1100nm 800 – 1100nm 800 – 1100nm

Inlet aperture 45mm 90mm 135mm 180mm

Max. power density 1kW/cm² 1kW/cm² 1kW/cm² 1kW/cm²

Average power density 0.5kW/cm² 0.5kW/cm² 0.5kW/cm² 0.5kW/cm²

Accuracy ±3%

Reproducibility ±1.5%

Time constant <10s <10s <10s <15s

Supply data CPM F-1 CPM F-10 CPM F-20 CPM F-30

Power supply, DC 24V ±5%, max.0.5A

Min. cooling water pressure 2bar 3bar 3bar 3bar

Max. cooling water pressure 4bar 4bar 4bar 4bar

Recommended cooling water

flow rate

Cooling water flow rate

(warning level)

Cooling water temperature T

1)

Please contact PRIMES in advance in case you intend not to work within this specification.

Communication CPM F-1 CPM F-10 CPM F-20 CPM F-30

Interfaces RS485/USB

Dimensions and Weights CPM F-1 CPM F-10 CPM F-20 CPM F-30

Dimensions (L x W x H) 180 x 123 x

Weight (approx.) 2.2kg 3.1kg 4.7kg 5.8kg

Environmental conditions CPM F-1 CPM F-10 CPM F-20 CPM F-30

Operating temperature range 15 – 40°C

Storage temperature range 5 – 50°C

Reference temperature 22°C

Permissible relative humidity

(non condensing)

in

1 – 2l/min 8 – 11l/min 15 – 23l/min 25 – 35l/min

0,5l/min 4l/min 8l/min 15l/min

1)

71mm

Dew point temperatur <Tin<30°C

180 x 162 x

71mm

260 × 162 x

113mm

10 – 80%

260 × 220 x

113mm

Revision 02/2019 EN

49

35,0(6

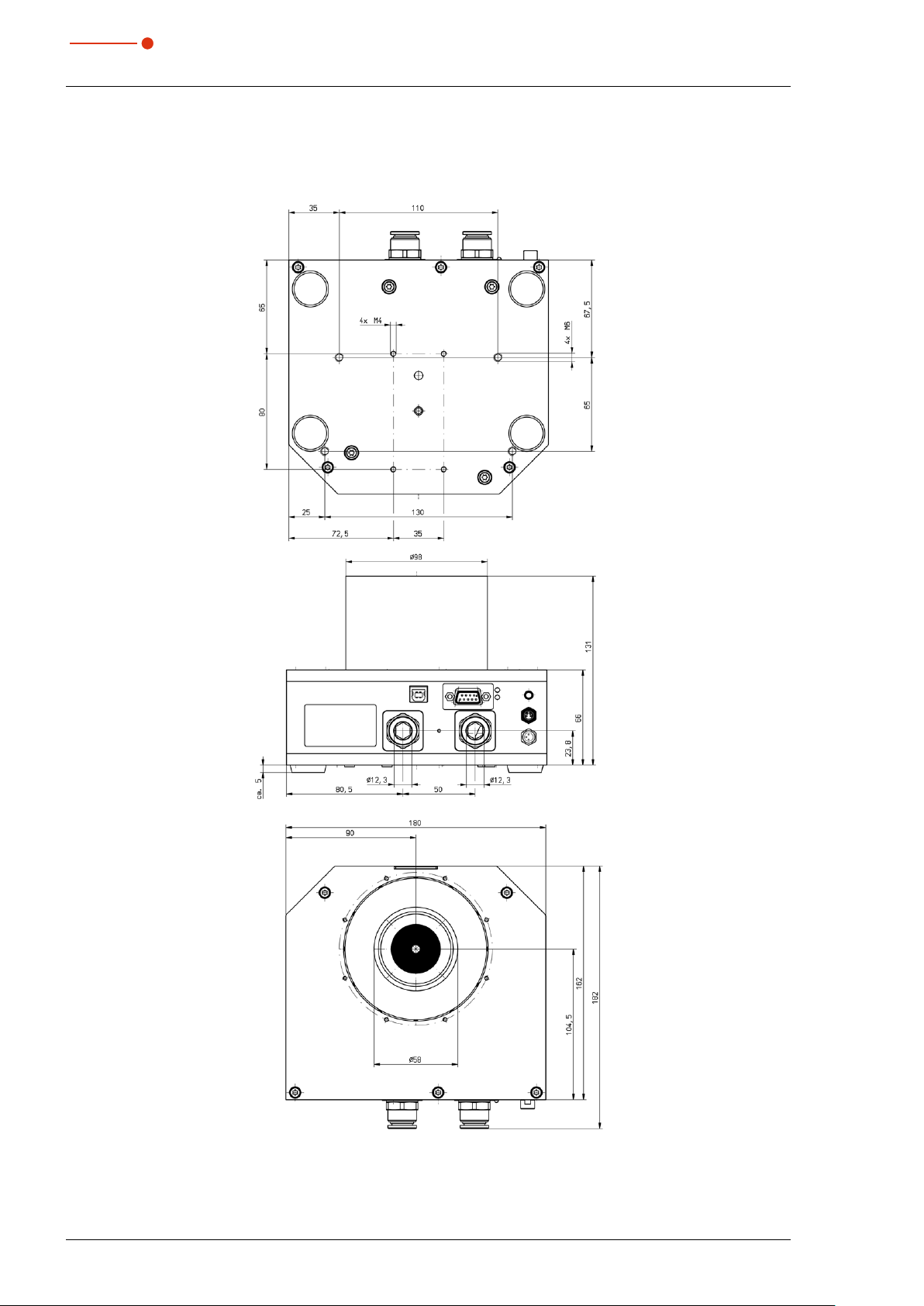

19 Dimensions

19.1 Dimensions CPM C-9

CompactPowerMonitor CPM

All dimensions in mm (general tolerance ISO 2768-v)

50

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

19.2 Dimensions CPM F-1

All dimensions in mm (general tolerance ISO 2768-v)

Revision 02/2019 EN

51

35,0(6

19.3 Dimensions CPM F-10

CompactPowerMonitor CPM

All dimensions in mm (general tolerance ISO 2768-v)

52

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

19.4 Dimensions CPM F-20

All dimensions in mm (general tolerance ISO 2768-v)

Revision 02/2019 EN

53

35,0(6

19.5 Dimensions CPM F-30

CompactPowerMonitor CPM

All dimensions in mm (general tolerance ISO 2768-v)

54

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

20 Appendix

20.1 Operation of the CompactPowerMonitor with PanelDisplay (without PC)

By option there is a external control display (PanelDisplay, Order-No. 130-005-003) available for the operation of the system. The display is operated via the standard PRIMES bus and therefore enables the reading

from a greater distance from the measuring position without a PC.

1. Please connect the display and the CPM by the 9-pole D-Sub cable for the PRIMES RS485 bus (on the

front or on the rear side).

2. Connect the power supply unit via the adapter to the 9pin D-Sub socket (RS485) of the PanelDisplay.

CPM

PRIMES connection cable

PanelDisplay

Fig. 20.1: Connecting the CompactPower Monitor CPM to the Panel Display

plug/plug

L

=20m

max

Adapter

PRIMES power supply

Revision 02/2019 EN

55

35,0(6

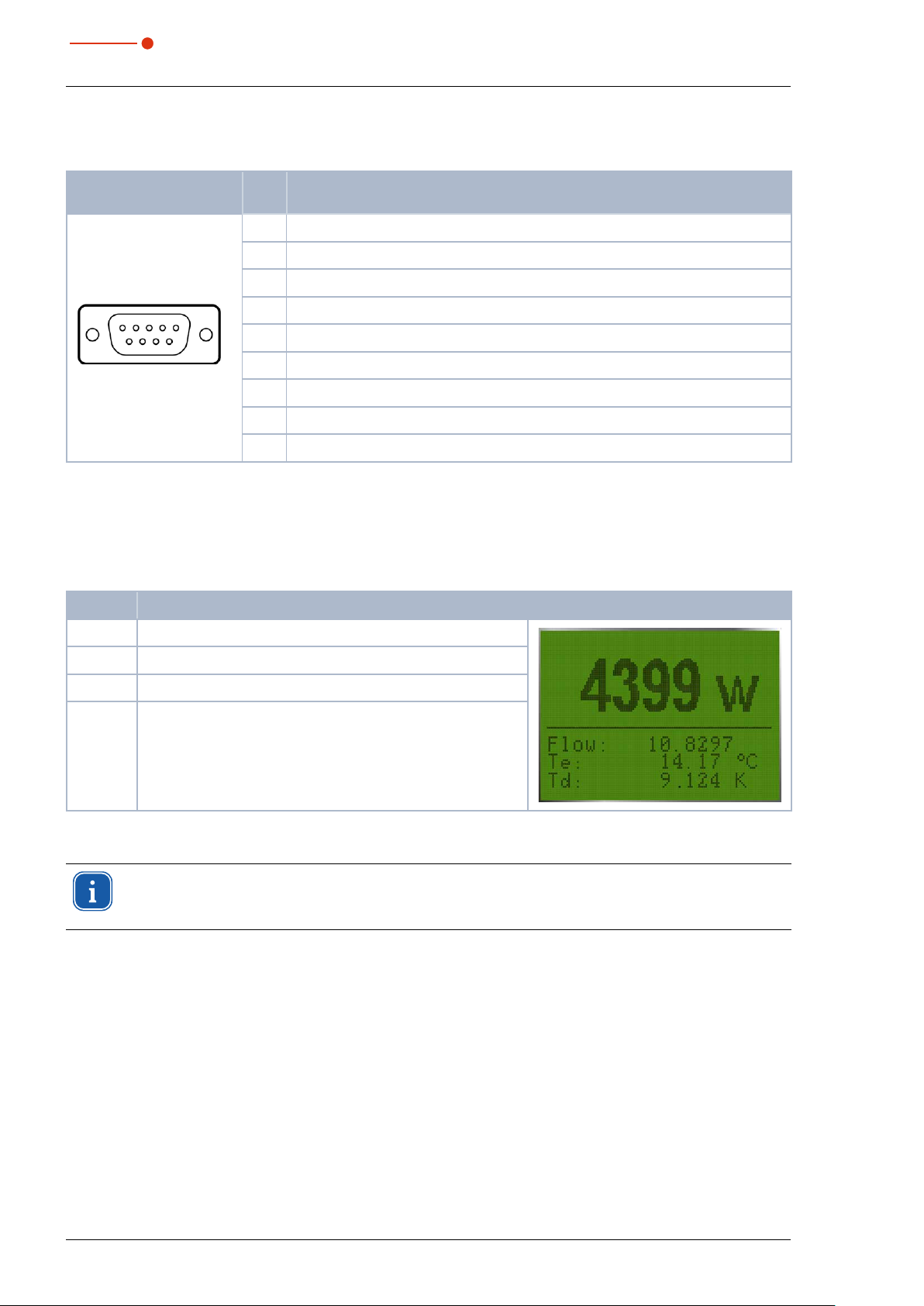

20.1.1 Pin assignment 9-pole D-Sub socket

CompactPowerMonitor CPM

D-Sub socket, 9 pin

(top view, plug-in side)

15

69

Tab. 20.1: Pin assignment D-Sub socket on the PanelDisplay

Pin Function

1 Ground

2 RS485 (+)

3 +24V

4 Not assigned

5 Not assigned

6 Ground

7 RS485 (–)

8 +24V

9 Not assigned

20.1.2 Measurement display

The PanelDisplay reflects the display of the CompactPowerMonitor CPM. The PanelDisplay shows the following measurement values:

Display Meaning

W Laser power in W

Flow Water flow rate in l/min

Te Water temperature at the entrance in °C

Td Temperature difference between water input and output in

Tab. 20.2: Meaning of the measured display

Kelvin (a temperature difference of 1K corresponds to a temperature difference of 1°C).

For the operation with the PowerMonitorSoftware via PC, you have to change the operating mode

of the display from “Active” to “Passive”. Further information can be found in the operating manual

„Panel Display“, chapter „Operating Mode“.

56

Revision 02/2019 EN

CompactPowerMonitor CPM

35,0(6

20.2 Mounting position of a CompactPowerMonitor CPM with oval wheel meter

Please note during installation, that the axis of the oval wheel meter must always be horizontal.

Oval wheel meter axis

Fig. 20.2: Position of the oval wheel meter axis

Correct mounting position

The device can either stand on its

feet (A) or the connections and display are in an upright position (B)

Incorrect mounting position

The flat side of the oval wheel

meter must not point downwards

(to the table).

A B

Tab. 20.3: Mounting position of the CompactPowerMonitor CPM with oval wheel meter

Revision 02/2019 EN

For a continuous operation, the oval wheel meter axis has to be positioned horizontally. For a short

period of time (a few hours per year) the CPM with oval wheel meter can be operated in the “incorrect“ installation position without immediately causing damages to the device. Longer operation

periods, however, may wear off the flow rate sensor.

57

35,0(6

20.3 Accessories fiber adapter

134-001-001

CPM F -10

136-002-031

CPM Fiber Connector LLK-D

136-002-019

Adapter Ring to Fiber Adapter CPM F-10

136-002-044

CPM F-10 DOME 216,5 mm

136-002-046

CPM F-10 DOME 346,5 mm

136-002-032

CPM Fiber Connector LLK-B

136-002-045

CPM F-10 DOME 111,5 mm

136-002-033

CPM Fiber Connector QD

136-002-030

CPM Fiber Connector QBH

Example: Fiber adapter and dome for CPM F-10

CPM Fiber connector LLK-B

136-002-032

CPM Fiber connector LLK-D

136-002-031

CPM F-10 Dome 346,5mm

136-002-046

CompactPowerMonitor CPM

CPM Fiber connector QBH

136-002-030

CPM Fiber connector QD

136-002-033

CPM F-10 Dome 111,5mm

136-002-045

CPM F-10 Dome 216,5mm

136-002-044

Adapter ring to fiber adapter CPM F-10

136-002-019

CPM F-10

134-001-001

For information about other fiber adapters for the CompactPowerMonitor CPM, see the PRIMES documentation “Installation fiber adapter”.

58

Revision 02/2019 EN

Loading...

Loading...