Revision 01/2018 EN

PRIMES

BeamMonitor BM+

BM+ 60, BM+ 100

LaserDiagnosticsSoftware LDS 2.98

Translation of the original instructions

Operating Manual

IMPORTANT!

READ CAREFULLY BEFORE USE.

KEEP FOR FUTURE USE.

PRIMES

BeamMonitor BM+ with LDS 2.98

4

Revision 01/2018 EN

Table of contents

1 BASIC SAFETY INSTRUCTIONS 8

2 SYMBOL EXPLANATIONS 10

3 ABOUT THIS OPERATING MANUAL 11

4 INTRODUCTION 12

4.1 Laser beam measurement .....................................................................................................12

5 SYSTEM DESCRIPTION 13

6 CONDITIONS AT THE INSTALLATION SITE 13

7 INSTALLATION 14

7.1 Preparation .............................................................................................................................14

7.2 Installation position .................................................................................................................14

7.3 Alignment ...............................................................................................................................14

7.4 Mounting ................................................................................................................................15

8 ELECTRICAL CONNECTIONS 16

8.1 Connection BeamMonitor BM+ with the standard power supply and the PC (example) ........18

8.2 Operation of two measuring devices .....................................................................................19

9 STATUS DISPLAY 20

10 SOFTWARE 21

10.1 System requirements .............................................................................................................21

10.2 Installing the software ............................................................................................................21

10.3 Starting the software .............................................................................................................. 22

10.3.1 Graphical user interface ..........................................................................................22

10.3.1 The menu bar .........................................................................................................24

10.3.2 The tool bar ............................................................................................................. 25

10.3.3 Menu overview ........................................................................................................26

10.4 Establishing an Ethernet Connection ..................................................................................... 28

10.4.1 Establishing a connection to PC .............................................................................28

10.4.2 Changing the IP address ........................................................................................29

11 SOFTWARE FUNCTIONS IN DETAIL 31

11.1 Settings ..................................................................................................................................31

11.1.1 Sensor parameter ...................................................................................................31

11.1.2 Measuring Environment (menu Measuring>>Environment) ............................. 33

11.1.3 Beam find (Menu Measurement>>BeamFind settings) ..................................34

11.1.4 Single measurement (menu Measurement>>Single measurement) ...............35

11.1.5 Adjustment mode .................................................................................................. 39

11.2 Presentation and documentation of the measuring results .................................................... 42

11.2.1 Tool bar of the LDS .................................................................................................42

11.2.2 False colors .............................................................................................................43

11.2.3 False colors (filtered) ..............................................................................................44

11.2.4 Isometry .................................................................................................................. 44

11.2.5 Caustic display (2D-display) ...................................................................................45

11.2.6 Isometry 3D ............................................................................................................ 49

11.2.7 Review 86 % or 2

nd

Moment....................................................................................50

11.2.8 Symmetry Check ....................................................................................................51

11.2.9 Fixed Contour Lines ................................................................................................52

PRIMES

BeamMonitor BM+ with LDS 2.98

5

Revision 01/2018 EN

11.2.10 Variable Contour Lines............................................................................................53

11.2.11 Graphical Review ....................................................................................................54

11.2.12 Color Tables ............................................................................................................54

11.2.13 Evaluation (option) ..................................................................................................55

11.3 File .........................................................................................................................................56

11.3.1 New .........................................................................................................................56

11.3.2 Open .......................................................................................................................56

11.3.3 Save ........................................................................................................................56

11.3.4 Save As... ................................................................................................................ 56

11.3.5 Export .....................................................................................................................56

11.3.6 Load measurement preferences .............................................................................56

11.3.7 Save measurement preferences .............................................................................56

11.3.8 Protocol ...................................................................................................................56

11.3.9 Print ........................................................................................................................57

11.3.10 Print preview... .........................................................................................................57

11.3.11 Recently opened files .............................................................................................57

11.3.12 Exit ..........................................................................................................................57

11.4 Edit .........................................................................................................................................57

11.4.1 Copy ........................................................................................................................57

11.4.2 Clear plane .............................................................................................................57

11.4.3 Clear all planes ....................................................................................................... 57

11.5 Communication ......................................................................................................................58

11.5.1 Free Communication ...............................................................................................58

11.5.2 Scan device list .......................................................................................................58

11.6 Script ...................................................................................................................................... 59

11.6.1 Editor ......................................................................................................................59

11.6.2 List ..........................................................................................................................59

11.6.3 Python .....................................................................................................................59

12 MEASURING 60

12.1 Special safety instructions ......................................................................................................60

12.2 Requirements .........................................................................................................................60

12.3 Possible Types of Measurement .............................................................................................61

12.3.1 Single Measurement ............................................................................................... 61

12.3.2 Caustic measurement ............................................................................................. 61

12.4 Brief Instruction for a first Single Measurement .....................................................................61

12.5 Measurement with a DBY-PS+ Detector ................................................................................65

13 DISCUSSION OF THE MEASURING RESULTS AND ERROR ANALYSIS 67

14 TROUBLESHOOTING 68

15 DETECTORS 69

15.1 Changing the Detector ...........................................................................................................70

16 MAINTENANCE AND SERVICE 72

17 TRANSPORT 72

18 MEASURES FOR THE PRODUCT DISPOSAL 72

19 DECLARATION OF CONFORMITY 73

20 TECHNICAL DATA 74

PRIMES

BeamMonitor BM+ with LDS 2.98

6

Revision 01/2018 EN

21 DIMENSIONS 75

21.1 BeamMonitor BM+ 60 ............................................................................................................75

21.2 BeamMonitor BM+ 100 ..........................................................................................................76

22 APPENDIX 77

22.1 System control (option) ..........................................................................................................77

22.2 Description of the MDF file format..........................................................................................77

23 BASIS OF BEAM DIAGNOSIS 79

23.1 Laser beam parameter ..........................................................................................................79

23.1.1 Rotationally symmetric beams ................................................................................ 79

23.1.2 Non rotationally symmetric beams: .........................................................................80

23.2 Calculation of beam data .......................................................................................................81

23.2.1 Determination of the zero level ...............................................................................81

23.2.2 Determination of the beam position ........................................................................ 82

23.2.3 Radius determination with the 2

nd

moment method of the

power density distribution .......................................................................................82

23.2.4 Radius determination with the method of the 86 % power inclusion .....................83

23.2.5 Further radius definitions (option) ........................................................................... 84

PRIMES

BeamMonitor BM+ with LDS 2.98

7

Revision 01/2018 EN

PRIMES - the company

PRIMES is a manufacturer of measuring devices used for the characterization of laser beams. These devices

are used for the diagnostics of high power lasers that range from high power CO2-lasers and solid-state

to fiber lasers and diode lasers. A great variety of measuring devices for the determination of the following

parameters is available:

• The laser power

• The beam dimensions and the beam position of an unfocussed beam

• The beam dimensions and the beam position of a focussed beam

• The diffraction index M²

Both the development and the production of the measuring devices are effected by PRIMES. This is how we

ensure an optimal quality, excellent service and a short reaction time which is the basis to meet our customers‘ requirements fast and reliably.

Max-Planck-Str. 2 - 64319 Pfungstadt -Germany- info@primes.de - www.primes.de

35,0(6

PRIMES

BeamMonitor BM+ with LDS 2.98

8

Revision 01/2018 EN

1 Basic safety instructions

Intended use

The BeamMonitor BM+ has been designed exclusively for measurements carried out in or near the optical

path of high-power lasers. Please observe and adhere to the specifications and limit values given in Chapter

„20 Technical Data“ on page 74. Other uses are considered to be improper. The information contained in

this operating manual must be strictly observed to ensure proper use of the device.

Using the device for unspecified use is strictly prohibited by the manufacturer. By usage other than intended

the device can be damaged or destroyed. This poses an increased health hazard up to fatal injuries. When

operating the device, it must be ensured that there are no potential hazards to human health.

The device itself does not emit any laser radiation. During the measurement, however, the laser beam is

guided onto the device which causes reflected radiation (laser class 4). That is why the applying safety

regulations are to be observed and necessary protective measures need to be taken.

Observing applicable safety regulations

Personal protection is required when humans are present in a dangerous zone with uncovered visible or

invisible laser radiation or particularly uncovered laser beam systems, beam guiding systems or process

regions. This holds true for any application of this equipment. During measurement procedures there is

always an unavoidable risk of laser radiation through direct or reflected emissions. The applicable safety

regulations are stipulated in ISO/CEN/TR standards as well as in the IEC-60825-1 regulation, in ANSI Z

136 “Laser Safety Standards” and ANSI Z 136.1 “Safe Use of Lasers”, published by the American National

Standards Institute, and additional publications, such as the “Laser Safety Basics”, the “LIA Laser Safety

Guide”, the “Guide for the Selection of Laser Eye Protection” and the “Laser Safety Bulletin”, published by

the Laser Institute of America, as well as the “Guide of Control of Laser Hazards” by ACGIH.

Taking necessary safety measures

If there are people present within the danger zone of visible or invisible laser radiation, for example near

laser systems that are only partly covered, open beam guidance systems or laser processing areas, the

following safety measures need to be taken:

• Please wear safety goggles (OD 6) adapted to the power, power density, laser wave length and

operating mode of the laser beam source in use.

• Please protect yourself from direct laser radiation, scattered radiation as well as from beams

generated from laser radiation (for example by using appropriate shielding walls or by weakening the

radiation to a harmless level).

• Please use beam guidance – or beam absorber elements which do not emit any hazardous particles

as soon as they get in contact with laser radiation and which resist the beam sufficiently.

• Please install safety switches and / or emergency safety mechanisms which enable an immediate

closure of the laser shutter.

• Ensure that the device is mounted securely to prevent any movement of the device relative to the

beam axis and thus reduce the risk of scattered radiation. This in the only way to ensure optimum

performance during the measurement.

Employing qualified personnel

Das Gerät darf ausschließlich durch Fachpersonal bedient werden. Das Fachpersonal muss in die Montage

und Bedienung des Gerätes eingewiesen sein und grundlegende Kenntnisse über die Arbeit mit Hochleistungslasern, Strahlführungssystemen und Fokussiereinheiten haben.

Modifications

The manufacturer and the distributor of the measuring devices do not claim liability for damages or injuries

of any kind resulting from an improper use or handling of the devices or the associated software. Neither the

PRIMES

BeamMonitor BM+ with LDS 2.98

9

Revision 01/2018 EN

manufacturer nor the distributor can be held liable by the buyer or the user for damages to people, material

or financial losses due to a direct or indirect use of the measuring devices.

Liability disclaimer

The manufacturer and the distributor of the measuring devices do not claim liability for damages or injuries

of any kind resulting from an improper use or handling of the devices or the associated software. Neither

the manufacturer nor the distributor can be held liable by the buyer or the user for damages to people or

material or financial losses due to a direct or indirect use of the measuring devices.

PRIMES

BeamMonitor BM+ with LDS 2.98

10

Revision 01/2018 EN

2 Symbol explanations

The following symbols and signal words indicate possible residual risks:

DANGER

means that death or serious physical injuries will occur if necessary safety precautions are not taken.

WARNING

means that death or serious physical injuries can occur if necessary safety precautions are not taken.

CAUTION

means that a slight physical injury can occur if necessary safety precautions are not taken.

NOTICE

means that property damages can occur if necessary safety precautions are not taken.

The device itself or the packing bears the following symbols to indicate requirements and possible

dangers:

Warning of hand injuries

Read and observe the operating instructions and safety guidelines before the

start-up!

Further symbols that are not security relevant:

i

Here you can find useful information and helpful tips.

With the CE designation, the manufacturer guarantees that its product meets the requirements of

the relevant EC guidelines.

Call for action

PRIMES

BeamMonitor BM+ with LDS 2.98

11

Revision 01/2018 EN

3 About this operating manual

This documentation describes the work with the BeamMonitor BM+ and the operation with the “LaserDiagnosticsSoftware” (in the following called “LDS”).

As far as the description of the software is concerned, the focus lies upon the configuration- and communication settings as well as the measuring operation.

i

This operating manual describes the software version v2.98.8, which is applicable at the time of

printing. Due to the fact that the user software is continuously advanced, it may be possible that

the attached installation CD bears a different version number. The correct functioning of the device,

however, is ensured with the software.

Should you have any questions, please be so kind as to provide us with the software version installed on

your computer. The software version, the creation date as well as the Windows® version our LaserDiagnosticsSoftware was programmed for can be found in the following menu item: Help>>About LaserDiag-

nosticsSoftware.

Fig. 3.1: Information regarding the latest software version

PRIMES

BeamMonitor BM+ with LDS 2.98

12

Revision 01/2018 EN

4 Introduction

4.1 Laser beam measurement

Laser beams in industrial applications, whether they be CO2, Nd:YAG- diode or fibre lasers, work with invisible beams in the infra-red or near infra-red spectral range (NIR). Hence changes in beam quality or power

cannot be detected visually, and only become evident from the outcome of their application. Under some

circumstances, this results in very expensive rejects being produced.

If the deterioration in quality is not recognised in the manufacturing process, this usually results in the subsequent failure of the product in use, with consequences for the manufacturer of rectification, replacement

and loss of image.

This is where PRIMES beam diagnostics devices for measuring beam quality, focusability and laser power

come in. Process monitoring in production with laser beam diagnostics devices by PRIMES enables consistent quality assurance and allows the timely detection and elimination of malfunctions of laser beams.

PRIMES measuring devices allow the reliable recording of current beam parameters, and enable ongoing

documentation of beam properties for quality assurance purposes. This is a requirement that should not be

underestimated in many industrial areas, such as automotive or medical technology.

With PRIMES devices for beam diagnostics, troubleshooting of laser applications is simplified considerably.

The beam intensity profile, beam diameter, beam caustic before and after focusing, and laser power to be

applied are directly measured and analysed. Based on the readings and their evaluation, maintenance and

servicing personnel can work in a targeted way on repair. Loss of time and system downtimes due to “trying

out” possible causes of the problem are effectively avoided.

The same applies to process optimisation and approval of process windows in laser material processing.

Only if the focal position and focal dimension and also the intensity profile of the laser beam are known, can

processes such as laser beam cutting, welding or drilling be adjusted to the particular component geometry,

materials be selected and the breadth of process windows be determined reliably.

PRIMES

BeamMonitor BM+ with LDS 2.98

13

Revision 01/2018 EN

5 System description

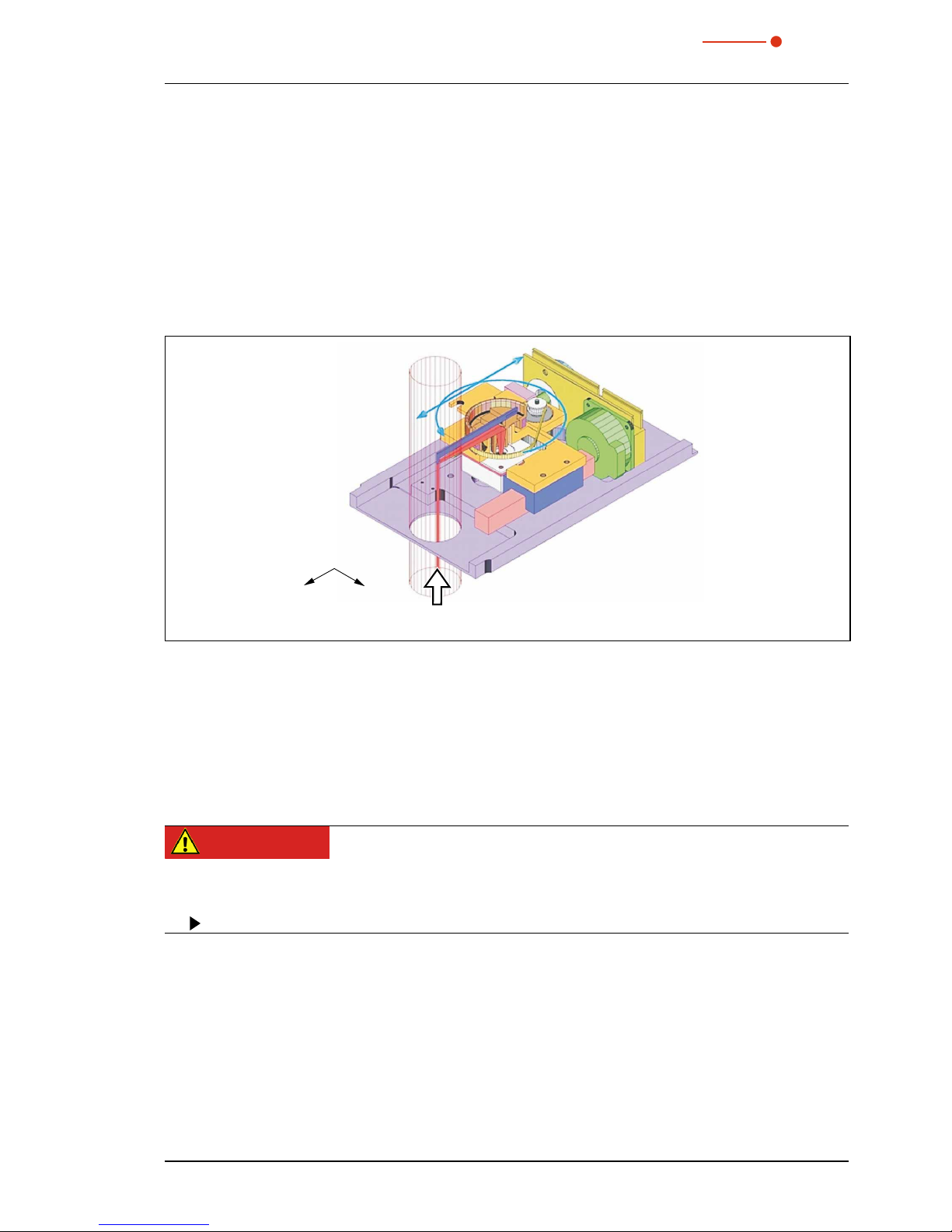

The BeamMonitor BM+ (see Fig. 5.1) is a device to analyze the spatial power density distribution of the

raw beam of CO2 or NIR lasers. Results of the measurements are beam radius, beam position and power

density profile.

The BeamMonitor BM+ is using the scanning measuring principle. Its dimensions are adapted to the rawbeam diameter which needs a larger aperture. The BeamMonitor BM+ has no z-axis. Due to the availability

of different detectors, it is possible to use the BeamMonitor BM+ with a wide range of wavelengths and

power densities.

Laser beam

x

y

Fig. 5.1: Optomechanical assembly of the BeamMonitor BM+

6 Conditions at the installation site

• The measuring devices must not be operated in a condensing atmosphere.

• The ambient air must be free of organic trace gases.

• Please protect the devices from water and dust.

• Operate the measuring devices in closed rooms only.

DANGER

Fire an explosion hazards due to laser radiation

Scattered radiation is developed during the measurement.

Do not store ammable materials or highly ammable substances in the area of measurement.

PRIMES

BeamMonitor BM+ with LDS 2.98

14

Revision 01/2018 EN

7 Installation

7.1 Preparation

The measuring device must be assembled stably and must be affixed by means of screws (see chapterl

7.4 on page 15).

DANGER

Fire hazard; Damaging/Destruction of the device

After passing the device, the laser beam has to be absorbed completely. Fire bricks or other

partly-absorbing surfaces are not suitable!

Please use an adequate absorber, e.g. the PRIMES PowerMonitor.

7.2 Installation position

The BeamMonitor BM+ can also be mounted horizontally or vertically.

Mounting surface

BeamMonitor BM+

Mounting surface

BeamMonitor BM+

Mounting surface

BeamMonitor BM+

Mounting surface

BeamMonitor BM+

Horizontal mounting Vertikal mounting

Beam incidence

Fig. 7.1: Mounting options for the BeamMonitor BM+

7.3 Alignment

The BeamMonitor BM+ has to be positioned correctly and a solid assembly needs to be ensured. The beam

has to hit the measuring aperture perpendicular and centrally.

DANGER

Serious eye or skin injury due to laser radiation

If the proportion of the laser beam diameter with regard to the diameter of the aperture is

too large, scattered radiation could occur during the measurement operation.

The laser beam diameter must not exceed 0.7 times the aperture diameter.

Especially in case of a high beam quality, we would recommend to remain below 0.6. Otherwise, a falsification

of the measuring results due to the cutting off of border fields is to be expected. Especially when it comes

to the determination of radii according to the 2nd-moments-method, problems are possible. Moreover, there

is a danger of a heating up of the housing.

PRIMES

BeamMonitor BM+ with LDS 2.98

15

Revision 01/2018 EN

7.4 Mounting

DANGER

Serious eye or skin injury due to laser radiation

If the appropriate position of the measuring device is changed, this could cause increased

scattered radiation during the measurement.

When mounting the device, please ensure that it cannot be moved, neither due to an unintended push or a pull on the cables and hoses.

NOTICE

Damage/Destruction of the device

Due to screws which are too long, internal components could be destroyed.

Please consider, that the fastening screws must only extend up to 10 mm into the housing.

There are four tapped holes M6 in the mounting surface of the housing intended for the customer’s mounting. Please use at least four screws to fasten the device. The total length of the screws depends on the

dimensions of the customer’s mounting. The dimensioned order of the fixing holes can be found in chapter

19 on page 73.

PRIMES

BeamMonitor BM+ with LDS 2.98

16

Revision 01/2018 EN

8 Electrical connections

The BeamMonitor BM+ require a supply voltage of 24 V ±10 % (DC) for the operation. A fitting power supply

is part of the scope of delivery. Only use cables with an equipment grounding conductor in order to connect

the power supply unit with the local electricity network.

A further device, such as a PowerMonitor PM, can be connected to the BeamMonitor BM+ via the RS485

interface (PRIMES bus). The signal from the PM is forwarded through the BeamMonitor BM+ to the PC via

the Ethernet interface. The additional measuring device is electrically supplied via the power supply of the

BeamMonitor BM+.

i

Before connecting the PC via the Ethernet interface, you must install the LDS software on the

computer (see chapter 9.2 on page 20).

Power On/Off

Power In

BM

+

BeamMonitor

Ethernet

PRIMES-Bus

RS 485

RS485

On/Off-Switch

Status display Ethernet connection

Power supply connection

Fig. 8.1: Connections of the BeamMonitor BM+

i

Please ensure that all electrical connections are established before starting the software!

PRIMES

BeamMonitor BM+ with LDS 2.98

17

Revision 01/2018 EN

Power supply connection

Harting M12-P-PCB-THR-2PC-5P-LCOD-M-STR

Pin Function

1 +24 V

2 Not assigned

3 GND

4 Not assigned

5 FE

Tab. 8.1: Connection socket for the power supply

PRIMES Bus

Pole arrangement D-Sub-socket, 9 pole (view of plug-in side)

15

6

9

Pin Function

1 GND

2 RS 485 (+)

3 +24 V

4 Trigger RS 485 (+)

5 Not assigned

6 GND

7 RS 485 (–)

8 +24 V

9 Trigger RS 485 (–)

Tab. 8.2: D-Submin-socket, PRIMES-Bus

In case you would like to use self-configured cables, please keep the following aspects in mind:

• The length of the cable reaching from the power supply to the measuring device must not exceed 1.8 m.

Otherwise the voltage drop of the cable would be too high.

• Please use shielded cable only and observe, that the shielding is efficient continuously.

• The cable length between the BeamMonitor BM+ and the second device (via RS485) must neither

exceed 2 m.

PRIMES

BeamMonitor BM+ with LDS 2.98

18

Revision 01/2018 EN

8.1 Connection BeamMonitor BM+ with the standard power supply and the PC (example)

Power On/Off

Power In

BM

+

BeamMonitor

Ethernet

PRIMES-Bus

RS 485

Ethernet Crossover Cable

Ethernet

PC

BeamMonitor BM+

PRIMES Power Supply

Fig. 8.2: Connection of the BeamMonitor BM+

Connect the BeamMonitor BM+ via a cross over cable with the PC or via a patch cable with the network.

PRIMES

BeamMonitor BM+ with LDS 2.98

19

Revision 01/2018 EN

8.2 Operation of two measuring devices

Power On/Off

Power In

BM

+

BeamMonitor

Ethernet

PRIMES-Bus

RS 485

Ethernet

PC

BeamMonitor BM+

PRIMES Power Supply

Error

Power

Interlock

PRIMES-Bus

RS 485

RS 485

RS 485

Analog

Out

USB

Clean

Compressed Air

Water Out

Water In

PM100

PowerMonitor

PowerMonitor 100

PRIMES Bus

RS485

Fig. 8.3: Connection of the BeamMonitor BM+ and the PowerMonito

i

For connection of several devices please use only one power supply (typically PRIMES power

supply).

NOTICE

There is a danger of damage

When disconnecting the bus connections during the operation (when the system is connected with the supply voltage), voltage peaks can develop which could destroy communication modules of the measuring devices.

Please turn off the power supply before disconnecting the bus cables.

PRIMES

BeamMonitor BM+ with LDS 2.98

20

Revision 01/2018 EN

9 Status display

The status display consists of a light ring, which indicates different states of the BeamMonitor BM+ by different colors and static or rotating light.

Color Lighting state Meaning

White The entire ring illumi-

nates

The supply voltage is applied

Yellow Rotating light The measuring tip rotates

Red Rotating light The measuring tip rotates and the y-axis is moved

-->measurement is running

Fig. 9.1: States of the status display

PRIMES

BeamMonitor BM+ with LDS 2.98

21

Revision 01/2018 EN

10 Software

In order to operate the measuring devices, the “PRIMES LaserDiagnosticsSoftware” (LDS) has to be installed

on the computer. The program can be found on the enclosed medium.

10.1 System requirements

Operating system: Windows® XP,/Vista/7/10

Processor: Intel® Pentium® 1 GHz (or comparable processor)

Free disc space: 15 MB

Monitor: 19“ screen diagonal is recommended, resolution at least 1024x768

i

When operating on a notebook, please deactivate all power saving functions. Otherwise problems

could occur due to the fast serial data transmission.

10.2 Installing the software

The installation of the software is menu driven and is effected by means of the enclosed medium. Please

start the installation by double-clicking the file “Setup LDS v.2.98.8.exe” and follow the instructions.

þ

Fig. 10.1: Setup of the PRIMES Software

If not stipulated differently, the installation software stores the main program “LaserDiagnosticSoftware.exe” in

the directory “Programs/PRIMES/LDS”. Moreover, the settings file “laserds.ini” is also copied into this directory.

In the file “laserds.ini” the setting parameters for the PRIMES-measuring devices are stored.

PRIMES

BeamMonitor BM+ with LDS 2.98

22

Revision 01/2018 EN

10.3 Starting the software

i

Please do not start the software before all devices are connected and turned on.

Please start the program by double-clicking the PRIMES symbol

in the new start menu group or the

desktop link.

10.3.1 Graphical user interface

Firstly, a start window is opened in which you can choose, whether you would like to measure or whether

you would just like to depict an existing measurement (factory setting “measurement”).

Fig. 10.2: Start window of the LaserDiagnosticsSoftware

After the detection of the connected device, the graphical user interface and several important dialogue

windows are opened.

In order to ensure that corresponding information can be assigned quickly, special markups for menu items,

menu paths and texts of the user interface will be used in the following chapters.

Markup Description

Text

Marks menu items.

Example: Dialogue window Sensor parameters

Text1>>Text2

Marks the navigation to certain menu items. The Order of the menus is depicted

by means of the Sign “>>”

Example: Presentation>>Caustic...

Text

Marks buttons, options and fields.

Example: With the button Start ....

PRIMES

BeamMonitor BM+ with LDS 2.98

23

Revision 01/2018 EN

The graphical user interface mainly consists of the menu as well as the tool bar by means of which different

dialogue or display windows can be called up.

Menu bar

Tool bar

Dialogue window

Fig. 10.3: The main elements of the user interface

It is possible to open different measuring and dialogue windows simultaneously. In this case, windows that

are basically important (for the measurement or the communication) remain in the foreground. All other

dialogue windows are overwritten as soon as a new window is opened.

Fig. 10.4: The main dialogue windows

PRIMES

BeamMonitor BM+ with LDS 2.98

24

Revision 01/2018 EN

10.3.1 The menu bar

In the menu bar, all main and sub menus offered by the program can be opened.

PRIMES

BeamMonitor BM+ with LDS 2.98

25

Revision 01/2018 EN

10.3.2 The tool bar

By clicking the symbols in the tool bar, the following program menus can be reached immediately.

File administration Presentation File selection Plane selection

1 2 3 4 5 6 7 8 9 10 11

1 - Create a new data record

2 - Open an existing data record

3 - Save the current data record

4 - Open the isometric view of the selected data record

5 - Open the variable contours line view

6 - Open review (86%)

7 - Open false color presentation

8 - Caustic presentation 2D

9 - List with all data records opened

10 - Display of the selected measuring plane

11 - Display of the measuring devices available for the bus by means of graphical symbols

All measuring results are always written into the document selected in the tool bar (item 9).

It is only possible to display documents chosen here. After opening, the data set has to be explicitly selected

(please see also chapter „11.2 Presentation and documentation of the measuring results“ on page 42).

i

Only the device selected in the tool bar is ready for the measurement.

Example:

A BeamMonitor BM+ as well as a PowerMonitor are connected with each other via a PRIMES bus. Both

devices are turned on and the LaserDiagnosticsSoftware is started. Then, the symbol of the device detected

first is activated, e.g. of the BeamMonitor BM+. For a power measurement with the PowerMonitor it is sufficient, to click on the device symbol (PM) in the tool bar. Then you can activate the power measurement via

Measurement>>Power measurement.

Fig. 10.5: Activating the PowerMonitor for a power measurement

PRIMES

BeamMonitor BM+ with LDS 2.98

26

Revision 01/2018 EN

10.3.3 Menu overview

File

New Opens a new file for the measuring data.

Open Opens a measuring file with the extensions “.foc” or “.mdf”.

Close Closes the file selected in the tool bar.

Close all Closes all files opened.

Save Saves the current file in foc- or mdf format.

Save as Opens the menu for the storage of the files selected in the tool bar. Only files with the

extensions “.foc” or “.mdf” can be imported safely

Export Exports all current data in protocol format “.xls” and “.pkl”.

Load measurement

preferences

Opens a file with measurement settings with the extension “.ptx”.

Save measurement

preferences

Opens the menu to save the settings of the last program run. Only files with the

extension “.ptx” can be opened.

Protocol Starts a protocol of the numeric results. They can either be written into a file or a

data base.

Print Opens the standard print menu.

Print preview Shows the content of the printing order.

Recently opened files Shows the file opened before.

Exit Terminates the program.

Edit

Copy Copies the current window to the clipboard.

Clear plane Deletes the data of the plane selected in the tool bar.

Clear all planes Deletes all data of the file selected in the tool bar

Change user level... By entering a password a different user level is activated.

Measurement

Environment Here, different system parameters can be entered, e.g.

- Reference value for the laser power

- Focal length

- Wave length

- Remarks

Sensor parameters The following device parameters can be e.g. set here:

- The spatial resolution

- The mechanical movement limits in z-direction

- Selection of one of the measuring devices connected with the bus

- The manual settings of the z-axis

LQM-Adjustment Not relevant for BeamMonitor BM+

Beamfind settings Setting parameter for a beamfind procedure. Relevant for BeamMonitor BM+ only.

CCD info Not relevant for BeamMonitor BM+

CCD

settings

Not relevant for BeamMonitor BM+

Power measurement Opens the measuring window power measurement.

Single... This menu item enables the start of single measurements, of the monitor mode and

the video mode.

Caustic... Enables the start of a caustic measurement. Not only automatic measurements but

also serial measurements of manually set parameters are possible. The automatic

measurement starts with a beam search and then caries out the entire measuring

procedure independently. Only the z-range that is to be examined as well as the

desired measuring plane have to entered.

Start adjustment mode Starts a special monitor mode optimized for the application of the BeamMonitor BM+

for the alignment of laser resonators.

PRIMES

BeamMonitor BM+ with LDS 2.98

27

Revision 01/2018 EN

Options Enables the setting of device parameters (advanced users only)

Presentation

False colors... False color display of the spatial power density distribution.

False colors (filtered)... Usage of a spatial filtration (spline-function) on the false color display of the power

density distribution.

Isometry... 3-dimensional presentation of the spatial power density distribution.

Isometry 3D... Allows a 3D presentation of caustic and power density distribution with spatial rota-

tion as well as an optional isophote display.

Review (86%)... Numerical overview of measuring results in the different layers basing on the 86%

beam radius definition.

Review (2. Moments)... Numerical overview of the measuring results in the different layers basing on the 2nd

moment beam radius definition.

Caustic... Results of the caustic measurement and the results of the caustic fit – such as beam

propagation ratio K, focus position and focus radius.

Raw beam... Not relevant for BeamMonitor BM+

Symmetry check... Analysis tool to check the beam symmetry especially for the alignment of laser reso-

nators. No standard feature of the devices.

Fixed contour lines… Display of the spatial laser density distribution with fixed intersection lines for 6 differ-

ent power levels.

Variable contour lines… Display of the spatial power density distribution with freely selectable intersection

lines.

Graphical review Enables a selection of graphical displays – among them the radius, the x- and y-

position above the z-position and the time.

System state Not relevant for BeamMonitor BM+.

Evaluation parameter Loading stored evaluation parameters.

Color tables... Different color charts are available in order to analyse e.g. diffraction phenomena in

detail.

Tool bar In order to display or to hide the tool bar.

Position Not relevant for BeamMonitor BM+

Evaluation Comparison of the measured values with defined limit values and evaluation (option-

ally).

Communication

Rescan bus The system searches the bus for the different device addresses. This is necessary

whenever the device configuration at the PRIMES bus was changed after starting the

software.

Free Communication Darstellung der Kommunikation auf dem PRIMES-Bus. Display of the communication

on the PRIMES bus

Scan device list Lists the device addresses of the single PRIMES devices.

Script

Editor Opens the script generator, a tool, by means of which complex measuring proce-

dures are controlled automatically (with a script language developed by PRIMES).

List Shows a list of the opened windows.

Python Opens the script generator in order to control complex measuring procedures auto-

matically (script language Python).

Help

Activation Enables the activation of special functions

About LaserDiagnosticSoftware Provides information regarding the software version

PRIMES

BeamMonitor BM+ with LDS 2.98

28

Revision 01/2018 EN

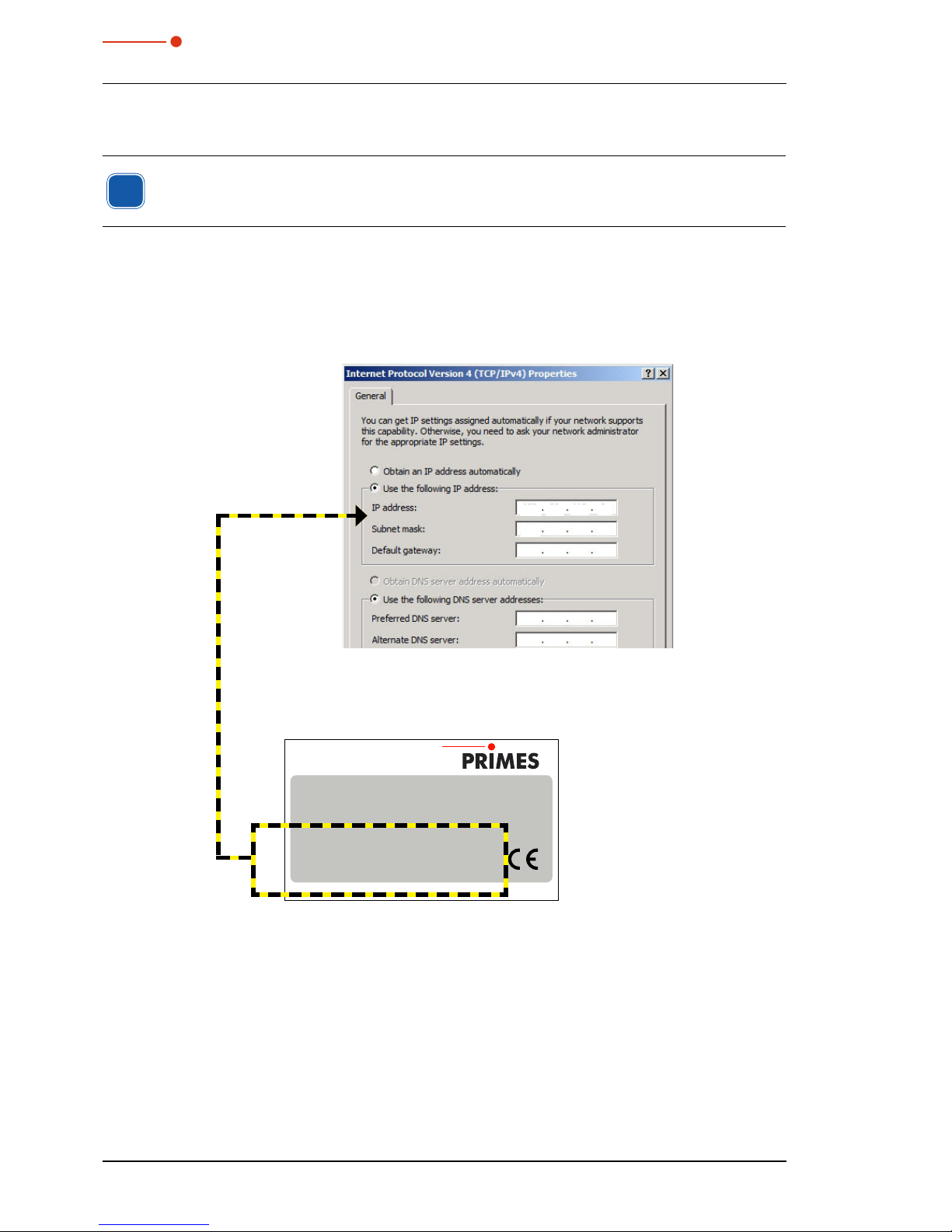

10.4 Establishing an Ethernet Connection

i

The BeamMonitor BM+ has a stipulated IP address which is given on the identification

plate. If the BeamMonitor BM+ is switched on before the network is connected, the static

IP address is used.

The PC must also have an IP address in the same subnet, for example:

IP Address: 192.168.116.80

Subnet mask: 255.255.255.0

The first three blocks of the IP address must match the IP of the BeamMonitor BM+!

192

255

168

255

116

255800

Identification Plate BeamMonitor BM+

www.primes.de

Type

S/N

2017

8285

BeamMonitor

BM+

DHCP enabled

MAC-Address

IP-Address

Static IP-Address

192.168.116.84

00 03 F4 07 6C E3

Built

10.4.1 Establishing a connection to PC

1. Please start the PRIMES LaserDiagnosticsSoftware.

2. Choose the mode TCP in the menu Communication>>Free communication (the option “second IP”

must not be activated!).

3. Enter the IP in the field “TCP”.

4. Click on the “connect” button (“connected” appears in the bus monitor).

5. Click on the “save” button (the configuration is saved and does not have to be repeated after a

restart).

PRIMES

BeamMonitor BM+ with LDS 2.98

29

Revision 01/2018 EN

192 168 116 84

Fig. 10.6: Establishing a connection in the menu Free Communication

10.4.2 Changing the IP address

You can change the preset IP address in the menu Communication>>Free communication by means of

the following commands:

IP-address

(Sample address)

192. 168. 116. 84

Commands

se0328

xyz se0329xyz se0330xyz se0331xyz

In this case xyz are place holders of the four IP-address bytes (values 1 - 255) which always have to be

entered with three digits!

For example, the number 84 has to be entered like this: 084.

For reasons of clarity the symbol marks a space.

Example: You will change the IP address from 192.168.116.85 to 192.168.116.86.

1. Please start the PRIMES LaserDiagnosticsSoftware.

2. Open the menu Communication>>Free Communication.

3. Choose the mode “TCP” (the option “second IP” must not be activated!).

4. Enter the IP in the field “TCP”.

5. Click on the “connect” button (“connected” appears in the bus monitor).

6. Activate the check box Write bus protocol (the protocol can be helpful in case of problems).

7. Enter the following in the field Command (please make sure that the blank character is entered cor-

rectly):

se0331086

8. Click to Send and wait for the confirmation in the bus monitor (in Fig. 10.7 „-> Adr:0331 Wert: 086“)

9. Please turn off the device and turn it on again. After this restart the IP-address is updated.

PRIMES

BeamMonitor BM+ with LDS 2.98

30

Revision 01/2018 EN

Confirmation

se0331 086

Adr: 0331 Wert:086

Fig. 10.7: Changing the IP address in the menu Free Communication

PRIMES

BeamMonitor BM+ with LDS 2.98

31

Revision 01/2018 EN

11 Software functions in detail

The LaserDiagnosticsSoftware is the control centre for all PRIMES measuring devices which measures the

beam distribution as well as focus geometries by means of which the beam propagation characteristics can

be determined. The LDS includes all functions necessary for the control of measurements and displays the

measuring results graphically.

Moreover, the systems uses the measured data to carry out an evaluation in order to give the operator of

the beam diagnosis an information regarding the reliability of the measuring results.

11.1 Settings

Due to the fact that the LDS is designed multifunctionally for all PRIMES devices, a few device-specific settings have to be made before a measurement. Moreover, the system and beam geometry provided by the

customer are to be considered.

11.1.1 Sensor parameter

Mechanical limits

This function is not relevant for the BeamMonitor BM+.

Fig. 11.1: Dialogue window Sensor parameters

Device

By means of this option, you can select the device which is supposed to be operated. Depending on the

number of devices connected, additional device numbers are assigned.

RPM (rotations per minute)

The rotational speed of the BeamMonitor BM+ can not be changed.

PRIMES

BeamMonitor BM+ with LDS 2.98

32

Revision 01/2018 EN

Resolution

Possible settings:

• 32 x 32 up to 1024 x 1024

Generally, 128 pixels per line and a total of 128 lines is sufficient. The resolution in y-direction stipulates the

number of lines and the resolution in x-direction the number of scanning points per line. The measuring time

gets longer if the number of measuring tracks increase. In case of 128 x 128 pixels the minimum distance

between two measurements with regard to the time is 8 to 9 seconds.

The time for the data transfer depends on the amount of data and on the interface. The amount of data

increases with a higher resolution. The performance of the computer also has an influence on the data

transfer time.

Detector

When the device is connected with the PC, the software will set the correct detector automatically. A manual

selection is not possible.

Manual z-axis

Please activate this option if the z-position of the measuring plane is not run by the internal z-axis.

In this case, please enter the z-values for each plane manually in the menu Measurement settings >>

single measurement. The software then carries out a caustic analysis on the basis of the determined

beam radii and the z-values.

The beam propagation ratio can also be determined this way, using the measured data of the unfocused

beam in different distances from the beam source.

Input field z-position

Fig. 11.2: Manual entry of the z-position

Twisted tip

Not relevant for the BeamMonitor BM+, this function must not be activated.

Radius correction

Activate the radius correction when measuring rectangular or linear laser beams. This option compensates

the curvature of the scanning tracks.

PRIMES

BeamMonitor BM+ with LDS 2.98

33

Revision 01/2018 EN

11.1.2 Measuring Environment (menu Measuring>>Environment)

Fig. 11.3: Dialogue window Measuring environment

In the dialogue window Measuring Environment data such as the laser type, information on the focusing

optic etc. can be stored (the input field Device-laser distance is not relevant for BeamMonitor BM+. These

data can be read via Presentation>>Review.

i

Please note that the symbol # must not be entered in the comment field. This symbol is used as a

separator in the software. If it is entered in the comment field, problems could occur when it comes

to storing or activating measuring data..

A line break can be enforced by means of the following key combination:

<Ctrl> + <Enter>

Entering the laser power is a reference value for the relative power position in the menu point Single

measurement or Caustic measurement. Stating the focal length is relevant for the evaluation of the

caustic measurements. From the caustic process and the entered focal length the raw beam diameter on

the focussing optic can be calculated.

Furthermore, a z-axes offset as well as a coordinate rotation angle can be entered. The wave-length is the

basis for a correct determination of the beam propagation ratio.

There are the following options:

• 10.6 µm for die CO

2

- laser radiation

• 1.06 µm for Nd:YAG - laser radiation

• 0.632 µm for HeNe - laser radiation.

A µm-value can also be typed in numerically.

By means of the button Apply the entries can also be changed after a measurement. With the button Ap-

ply all planes the entered values are inserted and settled, while the button Apply only refers to the value

in the current plane.

PRIMES

BeamMonitor BM+ with LDS 2.98

34

Revision 01/2018 EN

11.1.3 Beam find (Menu Measurement>>BeamFind settings)

Here, the parameters for the automated beam find are set. The general presetting is helpful for many standard applications.

Fig. 11.4: Dialogue window BeamFind settings

The Beam find parameters can be set as follows:

Pixel X, Pixel Y

The selection of the spatial resolution. Search problems can occur with regard to very small beams with 64

x 64 pixels in a 8 mm x 8 mm window, as the pixel distance is about 120 µm. In this case we recommend

the enlargement of resolution.

Trigger

The signal threshold (Trigger) is dependant on the zero level of the measuring system.

Percent

The percentage value indicates by how much the signal has to exceed the zero level in order to be recognized

as a beam. This value is determined by means of the signal-to-noise ratio of the detector.

Window Size Factor

The window size factor determines the size of the measuring window when it comes to the beam search.

The factor indicates how big the measuring window has to be in relation to the beam diameter.

PRIMES

BeamMonitor BM+ with LDS 2.98

35

Revision 01/2018 EN

11.1.4 Single measurement (menu Measurement>>Single measurement)

1

2

3

4

5

6

7

8

9

10

11

12

13

141516171819

21

22

20

23

1 Single

Monitor

LineScan (option)

Starts a measurement in the chosen plane

Starts repeated measurements in the chosen plane automatically

Starts a measurement of a single trace with fixed y-axis

2 Start

Starts a measurement in the currently chosen plane

3 Stop

Finishes the measurement in the currently chosen plane

4 Reset

The measuring device is reset

5 Stop Motor

Stops the rotating measuring tip after the measurement is finished

6 Plane

Selection of the measuring plane (0-49) either explicit or by means of the buttons (+/-)

7 Entry field

Numerical entry of the z-position

8 Copy

Copies all settings (window size and – position; x, y, z; etc.) from the former plane to the current plane

(e.g. 1>>2)

9 Find beam

Starts an automatic beam search in the current measuring plane

10 Scan

Not relevant for BeamMonitor BM+

11 Ampl.

Slide control in order to adjust the electrical amplification

12 Power

Slide control in order to adjust the laser power to save it in the software

13 Entry field Power Numerical input of the laser power to save it in the software

14 Entry field Ampl. Numerical input of the electrical amplification

15 Averaging

Analysis of the serial measurements. Averaging algorithms: average value, values of the maximum

pixels and the value of the maximum trace

16 Averaging

Selectable number (1 – 50) of single measurements for the averaging

17 LED symbol and

bar graph display

Display for the degree of the signal saturation (LED green≙ok, red≙not ok)

18

False color Activates the option of the false color presentation

19 Zoom

Magnification settings for the measuring window

20 Symmetric

This option enforces the usage of square measurement windows, whose size is only adjustable via x.

21 X/Y

Setting of the size of the measuring window

22 Display

Measuring window shows the current measuring result.

23 Z

Slide control in order to set the z-position

PRIMES

BeamMonitor BM+ with LDS 2.98

36

Revision 01/2018 EN

With this dialogue window either single measurements or repeated measurements can be carried out.

The measuring mode Monitor starts a continuously repeating measurement with current settings. The repetition rate is dependant on the spatial resolution as well as the rpm. With 64 x 64 pixels the measuring time

is about 10 seconds.

The monitor operation can be terminated by clicking the button Cancel in the status window (in the bottom

right corner of the screen).

Fig. 11.5: Status window

The measuring window position can be set either manually or automatically.

With the button FindBeam the measuring window of the BeamMonitor BM+ is set automatically. In this case,

the system only searches in the range given in the currently set window in the set z-position. Afterwards the

window FindBeam appears.

In case the beam search is completed successfully, a measurement window with the found beam in the

measuring field of the single measurement window appears. However, at that point the window size is not

yet optimized. With the button Start the beam can then be recorded.

As far as the manual beam search is concerned the position as well as the size of the measuring window

within the mechanical limits can be stipulated by the operator. The choices can be made in a pop-up menu,

where [x] for square measuring windows or respectively [x] and [y] for rectangular are to be stipulated. The

maximum size of the measuring windows is - in case of the BeamMonitor BM+ – in the standard configuration 8 mm x 8 mm (optional up to 24 mm x 12 mm).

The position of the measuring window is changed by clicking on the frame and moving it by means of the

mouse. The position of the window in z-direction (height) can be stipulated by means of the z-slide control or

by means of a numerical entry. The zoom function enables a detail enlargement in the measuring window.

Size of the measuring window

In order to minimize the measurement errors, we recommend a measuring window size which ensures that

the beam diameter equals 30 % to 70 % of the base side length of the measuring window. The distribution

has to be preserved at full extent without a restriction by the border of the measuring window.

Electrical amplification

The power density distribution is measured by a detector. Its analogue output signal is amplified and then

digitalized. There are different detectors available (see Tab. 15.1 on page 69)

In case the detector oversaturated (red LED symbol in the display for the signal saturation or – respectively

– a ADC value of 4095 in the presentation Variable Contour Lines), please reduce the amplification

by means of the slide control “ampl.” and repeat the measurement.

Not only an oversaturation but also a low amplification lead to unsecured or false results. We recommend

the readjustment of the amplification in order to receive correct results.

Laser power

The laser power can not only be set by means of the slide control but by entering it numerically. The reference

value for the laser power is entered in the dialogue window Measurement>>Environment. The calculation

of power densities refers to the power values set here.

Please click on the button Start to start the measurement.

Up to 50 single measurement planes can be part of one measuring file. This is relevant for measurements

of the beam caustic as well as for time or power series. It is possible to switch for presentation between the

individual measuring planes.

PRIMES

BeamMonitor BM+ with LDS 2.98

37

Revision 01/2018 EN

With the button Copy the measurement settings (window size and position, power and amplification) can

be copied from the previous measuring plane.

By means of the option Averaging the average of the results of up to 50 single measurements per each

plane is determined. There are different analysis algorithms available:

Selection Function

Average determines the average value of the distributions measured

Max. pixel

determines the pointwise maxima of the distributions measured

Max. trace

determines the maximum traces of the distributions measured

The selection Max. pixel, Max. trace are especially helpful when it comes to pulsed laser radiation. The radii

determined in case of Max. pixel are not always reliable due to zero point uncertainties.

During a measurement, the status of the measurement system is constantly displayed. These are:

• the current measuring plane

• the run of the reference cycle

• positioning the measuring head

• the measurement

• the data transmission – the progress is shown by means of the bar display

By means of the button Stop you can cancel a running measurement which also ends the monitor operation.

Please click on the Reset button afterwards.

With the button Stop Motor the rotation of the measuring tip is stopped after the completion of the current

measurement. Please click the Reset button afterwards.

CAUTION

Danger of injury due to rotating parts

The measuring tips of the BeamMonitor BM+ keep rotating for a short period of time after

the supply voltage was turned off.

Do not reach into the entrance of the measuring device and do not hold any items into it, as

long as the measuring tip is rotating.

PRIMES

BeamMonitor BM+ with LDS 2.98

38

Revision 01/2018 EN

Options

This menu should be used only by advanced users. Please keep in mind that most of the items are not

relevant for BeamMonitor BM+.

The only exception is the presentation of the beam dimensions, which allows to switch from radius to diameter (see Fig. 11.6).

Fig. 11.6: Setting for the display of the diameter

PRIMES

BeamMonitor BM+ with LDS 2.98

39

Revision 01/2018 EN

11.1.5 Adjustment mode

This measurement and display menu is intended for the specific requirements as far as the adjustment of

laser resonators with the BeamMonitor BM+ is concerned. The beam symmetry of the power density distribution measured last is presented.

Typical measuring procedure:

Automatic beam search with the button FindBeam, afterwards a monitor operation is started by means of

the Continuous button. With regard to this, the succeeding measurements are cyclically typed in into the

planes 0 to 19 (whereas 19 is then again followed by 0).

By means of the keys >>AdjustingPanel and >>MeasuringPanel you can choose between two different

kinds of notation. In the measurement menu of the adjustment mode a false color presentation of the last

two measurements together with the values of the beam position as well as the beam radius are displayed.

Fig. 11.7: The measuring menu of the adjustment mode

The second notation is the symmetry menu.

The symmetry menu compares the results of the last three measurements with regard to their beam symmetry in different power ranges.

Moreover, the following is displayed: the radius ratio between Rx to Ry (calculated by means of the 2nd moment

method) as well as the volume of the power density distribution (as a relative measure for the laser power).

The results are displayed numerically and emphasized visually by means of colored squares.

Green stands for a minimum deviation from the cyclical symmetry and red for the maximum deviation. Yellow

(white) indicates a medium value.

PRIMES

BeamMonitor BM+ with LDS 2.98

40

Revision 01/2018 EN

Fig. 11.8: Symmetry menu of the adjustment mode

The measuring results can be documented automatically. Either via the record of the measured beam radii

and the beam position in a log file with the button Log (please see Fig. 11.10 on page 41) or by storing

the entire measuring data with the button Document. In the menu item Document the temporal distance of

two measurements (Delay) can be set upon request.

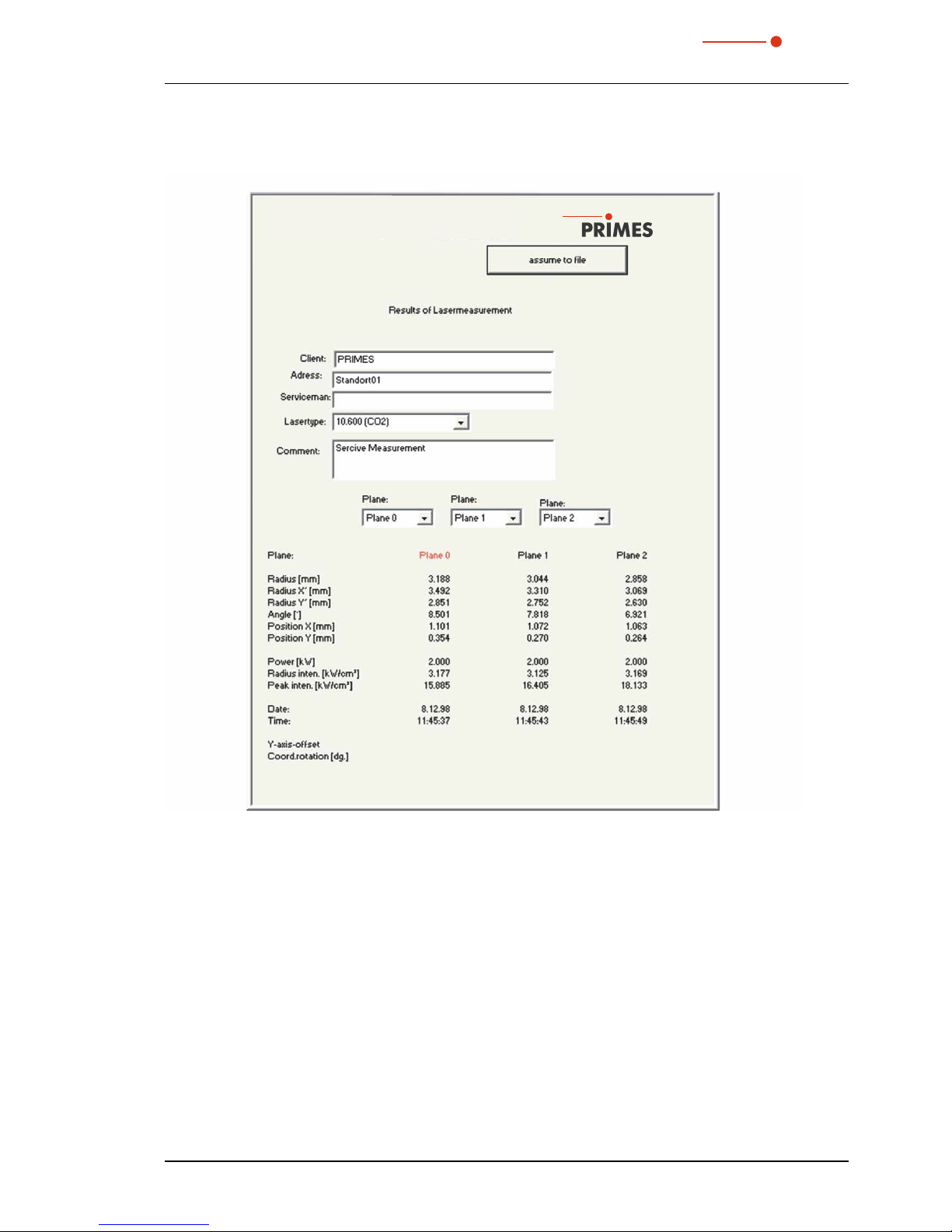

With the menu item Report exemplary results can be stored, e. g. as a service report (please see

Fig. 11.10 on page 41) and can later be printed.

Fig. 11.9: Document window

PRIMES

BeamMonitor BM+ with LDS 2.98

41

Revision 01/2018 EN

With the button Assume to file the report page in the data set is stored as well. Upon request, the name

of the service technician or the company name can be stored permanently in the settings file “laserds.ini”.

John Miller

Fig. 11.10: Example of a report page

PRIMES

BeamMonitor BM+ with LDS 2.98

42

Revision 01/2018 EN

11.2 Presentation and documentation of the measuring results

This chapter describes the presentation, analysis and storage of measuring results.

In order to carry out comparisons between different measurements, the program can manage several

measuring data sets simultaneously. The opened data sets are shown in the tool bar. In order to open one

presentation, the data which is to be examined is selected in the list of the data selection and afterwards

the desired kind of presentation is chosen.

By clicking on the symbols of the tool bar the following program menus can be reached.

11.2.1 Tool bar of the LDS

Data administration Notation Data selection Plane selection

1 2 3 4 5 6 7 8 9 10 11

1. Create a new data set

2. Open existing data set

3. Save data set

4. Open isometry presentation of selected data set

5. Open variable contour lines display

6. Open review (86 %)

7. Open false color presentation

8. Caustic presentation

9. List containing all data sets opened

10. Display of the chosen measuring plane

11. Display of the devices available at the bus by means of graphical symbols

In the menus for the notation of single measurements (Variable contour lines, Isometry and

False color presentation) the option Autoscale effects the usage of the entire display range for the

measuring values.

Moreover, you have the possibility of switching between different image memories of series of measurements

by means of the plane selection. Switching is also possible by means of the cursor keys up/down if the

plane selection is selected. If the plane selection in the display menus is set on Global, switching simultaneously between the planes is possible via the selection in the tool bar.

The title of the dialogue window indicates the name of the data sets shown.

For the parallel evaluation of several measurements the program has 50 image memories which can record

one measurement each. These image memories (measuring plane) can also be used in order to record

changed measurement values in case of a parameter variation.

Due to the variation of the z-position in the different planes a caustic measurement is realized. Due to a

change of the laser power it is possible to simulate, e.g. the thermal inflow-behavior of the system. Similarly,

time series are possible. Respective displays are, for instance, possible by means of the menu item Graphi-

cal review.

PRIMES

BeamMonitor BM+ with LDS 2.98

43

Revision 01/2018 EN

11.2.2 False colors

Here, a false color presentation of the measured power density distribution is generated.

Fig. 11.11: Dialogue window False colors

The used color scale is shown on the left. For a higher sensitivity, e.g. for the analysis of diffraction figures,

it is possible to switch the used color scale in the menu Presentation>>Color Tables.

By means of the slide control on the right hand side of the color scale you can display the sections of different ADC values with the corresponding radii.

Apart from the automatic scaling, there are three more types of scaling.

Scale on density

All planes of a caustic measurement are scaled on the maximum measured power density. This is supposed

to help comparing the different planes more easily.

Pixel scale

This scaling is only interesting when it comes to the usage of asymmetric measuring windows. In this case

the axis of the windows are no longer a function of the measuring window size but of the number of pixels

measured.

Window scale

With regard to this function, all measuring windows of a caustic measurement are enlarged to the size of

the maximum measuring window. This function, too, is supposed to help comparing the different measuring

planes of a caustic measurement more easily.

Beam axis

The beam axes can be displayed.

PRIMES

BeamMonitor BM+ with LDS 2.98

44

Revision 01/2018 EN

11.2.3 False colors (filtered)

The special function of the filter is called spline – function. It is characterized by the fact that the position of

the maximum is maintained. The single pixels in the matrix are weighed by means of a 1-2-1 filter in order

to reduce the noise.

This filter can also be used multiple times without the position of the maxima being moved.

Fig. 11.12: Dialogue window False colors (ltered)

11.2.4 Isometry

This menu item generates a spatial display of the measured power density distribution of a plane. The false

color display can be deactivated.

A turn of the distribution by 90°, 180° and 270° each is possible.

Fig. 11.13: Dialogue window Presentation>>Isometry (on the left with a deactivated color display)

PRIMES

BeamMonitor BM+ with LDS 2.98

45

Revision 01/2018 EN

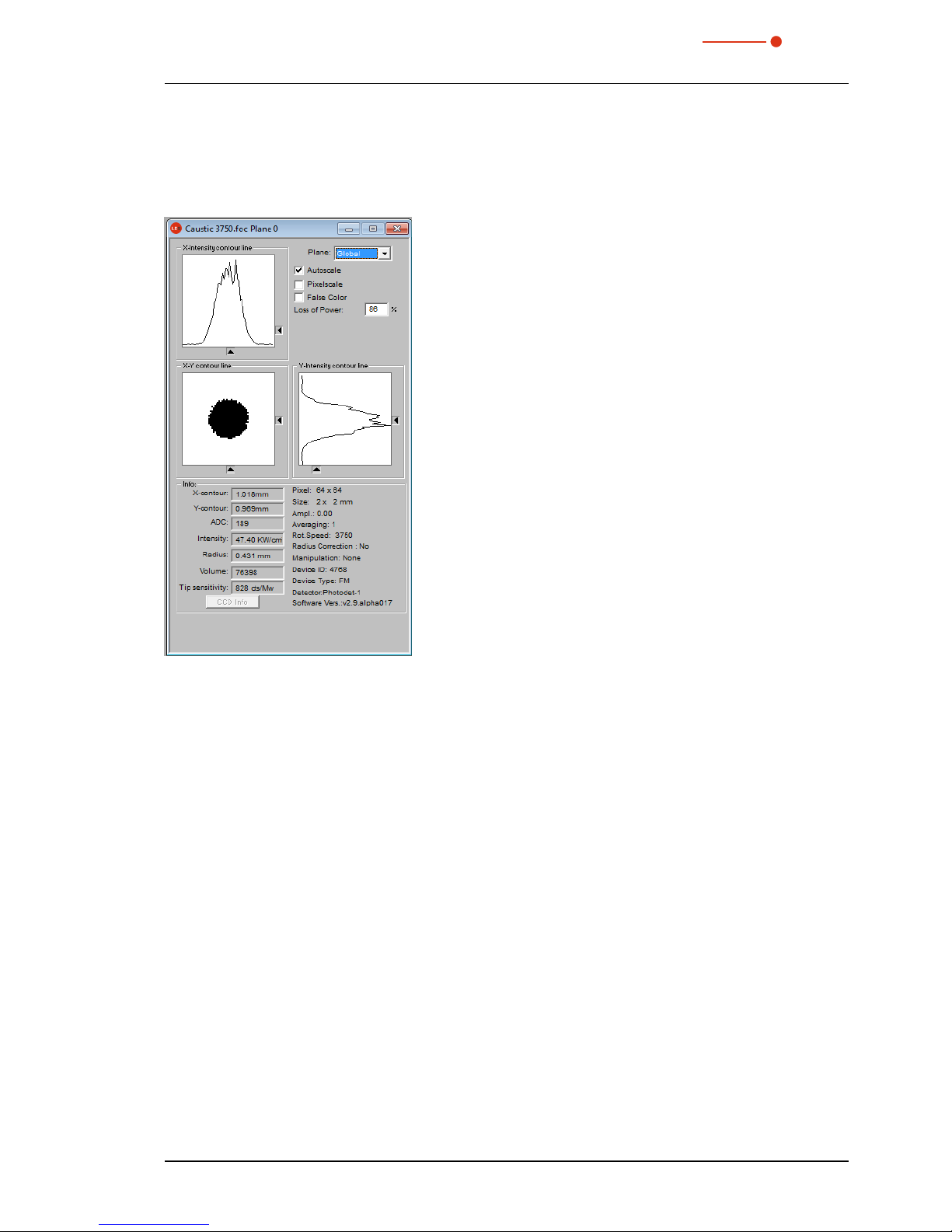

11.2.5 Caustic display (2D-display)

The results of the caustic measurement can be displayed by means of the menu item Presentation>>Caustic.

On the left Fig. 11.14 shows the measured beam parameter either on the basis of the 86%-radii or the moment evaluation according to ISO 11146. In the middle of the picture the graphic shows the caustic profile.

The beam radii are depicted on the beam spread direction. On the right the false color presentation of one

measurement plane each – among other things selectable with the mouse - is shown together with numerical results of this single plane.

Fig. 11.14: Dialogue window Presentation>>Caustic

The red line depicts a compensating curve according to the calculated fits which can be displayed via the

check box Fit in the 2D presentation

Compensating curve

In order to evaluate the caustic, a hyperbolic compensating curve (ISO 11146) is adapted to the measuring values. This compensating curve describes the propagation of an ideal laser beam mathematically. The

development of the compensating curve is theoretically determined by means of the following parameters:

• standardized beam propagation factor M² or respectively beam propagation ratio

• z-position

• focus radius

• rayleigh length

Standardized beam propagation factor M² (or respectively the beam propagation ratio K=

)

The standardized beam propagation ratio describes how well the respective laser beam can be focused in

relation to the single mode. The single mode is the best beam which is theoretically possible and has a beam

propagation factor of 1. All other beams have higher values. For welding lasers (CO

²

) the values range from

2 to 5. With regard to cutting lasers (CO²) values from 1.1 to 2.5 are common. In case of beam sources with

a higher laser power the beam propagation factors are generally smaller than those of sources with lower

laser powers.

Z-Position

This value provides the position of the focus points in the z-position. As the compensation curve takes the

measurement points into consideration, the calculated z-position is not necessarily located at the beam

radius, which has measured the smallest position.

The device coordinates are given. Information with regard to the absolute position in space can be found in

chapter 23.2.4 on page 83. Possibly also on basis of a TCP calibration (option).

PRIMES

BeamMonitor BM+ with LDS 2.98

46

Revision 01/2018 EN

Focus radius

The focus radius is the smallest beam radius in the caustic. Generally, this value is similar to the smallest

value measured.

Due to different reasons it may occur that the adaption to the measurement values was not carried out.

This is the case if the compensation curve does not lie close to the measurement values. In this case the

parameters of the adapted compensation curve are to be discarded.

The review function (please see chapter page 36) provides more information on this topic.

Rayleigh length

The Rayleigh length is a derived parameter and describes the distance in z-direction with regard to which

the beam radius has increased by the factor

2

(=1.41) and concerning which the beam area has increased

by the factor 2. The Rayleigh-length increases with the beam propagation ratio and the focal width of the

focusing optic (please see chapter 21 on page 76). The doubled Rayleigh length is an approximate point

of reference, up to which material thickness (metal) a procession is possible with the optic employed.

In order to make sure that the adapted values have a high significance, the measurement is to be carried

out in a z-range of at least two Rayleigh-lengths. A range of four Rayleigh lengths – as demanded in the

ISO 11146 would be even better. 5 to 6 Rayleigh lengths would be ideal. However, this demand is often

confronted with the problem of quickly sinking power densities of the laser beam which is to be measured.

In case of a distance of two Rayleigh-lengths from the focus the power density has sunk to just a quarter.

In this case the caustic measurement consists of a compromise between the desired measurement range

in z-direction and the power density (signal-to-noise ratio) necessary for a perfect measurement.

Fig. 11.15: Result window Caustic>>Advanced

For the examination of asymmetric beams the dimensions of the main axes of the beam can be determined.

On the basis of these values the program also calculates direction dependent beam propagation factors as

well as beam position values. The related curves are shown via the two check boxes radius x, y while the

numerical values are provided by the detail menu.

PRIMES

BeamMonitor BM+ with LDS 2.98

47

Revision 01/2018 EN

Review

This function checks whether the results and settings of the caustic measurement are within the reliable range.

OK

Not OK

(in the measuring planes

5 and 15)

Fig. 11.16: Result window of the evaluation function

Under “spread” the average standard deviation of the caustic fit according to the 2nd moment method radii

is stated. A “tick” () is set if the standard deviation is smaller than 3.5 % and if all of the measuring values

lie within a range of ± 3 * standard deviation.

Valued functions Test criterion

Positive evaluation

Spread Average relative standard devia-

tion of the caustic fit according

to the 2nd moment method

Standard deviation < 3.5 %, all measurement values

within a range of ± 3 * standard deviation

Fill factor The proportion beam diameter

to the measuring window size

In the range 0.3 – 0.6

Z-range Measuring range in z-direction At least 4 Rayleigh-lengths

Measurement planes Number of measurement planes

per Rayleigh length

At least 3 measurement planes per Rayleigh length

(Z

Min+Zr

) < Z0 < (Z

Max−Zr

) Minimum measurement range

above and below the focusing

plane

The focus lies within the minimum measurement

range and this range accounts for at least one Rayleigh length in every z-direction

Signal/noise ratio Examines the signal-to-noise

ratio

FocusMonitor: S/N > 40

Signal override Examines the maximum power

density value

Below 4000 Counts

Tab. 11.1: Criteria for the evaluation

If all criteria are fulfilled, the measuring results have a high reliability. The absolute accuracy can not be stated

from the standard deviation from the fits as all the systematic measuring errors as well as the accuracy of

the calibration are additionally taken into account when it comes to the absolute error.

PRIMES

BeamMonitor BM+ with LDS 2.98

48

Revision 01/2018 EN

As far as the BeamMonitor BM+ is concerned different detectors can be used. Therefore, not the amplitude

but the signal-to-noise ratio (S/N ratio) is evaluated as different detectors can have a different noise.

For the evaluation the detector set in the menu Measurement>>Sensor parameter is used. In case

the S/N ratio lies above 40:1 a green tick (

) is displayed. A red cross () indicates a S/N ratio lower than

25:1; in this case noise components can increase the measurement inaccuracy for the beam diameter as

well as derived sizes.

In case only the last, outermost plane of a caustic shows a bad signal-to-noise ratio, it is often still possible

to receive strong results. If several planes are affected, a measuring tip – detector combination which is accurately adapted to the application can lead to a higher signal-to-noise ratio.

PRIMES

BeamMonitor BM+ with LDS 2.98

49

Revision 01/2018 EN

11.2.6 Isometry 3D

This function generates three-dimensional displays of the power density distribution of a plane and all planes

in false colors.

The presentation window is divided. On the left the caustic, on the right the power density distribution in a

plane is displayed. The horizontal size of the single windows can be changed by drawing the separating bar

by means of your mouse.

The graphics can be rotated along all three axes with the left mouse button, with the right mouse button they

can be positioned in the window.

Change window size

1 2 3 4 5 6 7

Fig. 11.17: Presentation in 3D

1

3D presentation of the

plane

Inserts the 3D presentation of the power density distribution in the plane in

the display window.

2

3D presentation of the

caustic

Additionally inserts the 3D presentation of the caustic in the presentation

window.

3

Magnification in the plane

In the left part of the presentation window a magnification of the plane displayed on the right is inserted (the desired area can be clicked by means of

the left mouse button in the right window).

4 Rotation

Causes a rotation of both graphics along the z-axis.

5

Plane selection

Here the plane, which is to be displayed, can be chosen (you can also choose

the desired plane in the 3D caustic by means of the left mouse button).

6 Zoom

Slide control for a continuous magnification of the presentation

7 Contour

Slide control for a contour trimming along the power density.

PRIMES

BeamMonitor BM+ with LDS 2.98

50

Revision 01/2018 EN

11.2.7 Review 86 % or 2nd Moment

For the radius definition there are two basic determination possibilities: