Page 1

OPERATING INSTRUCTIONS

MODEL DS60A DOUBLE SHEET CONTROLLER

CALIBRATE

PUSHBUTTON

MULTI-FUNCTION

INDICATOR (RED,

GREEN, AMBER)

POWER

INDICATOR

(GREEN)

SENSOR

RECEPTACLE

The Prime Controls Model DS60A Double Sheet Controller comprises a microcontrollerbased control module in an 18 mm threaded aluminum housing that can be connected

to a family of permanent magnet sensors through a 12 mm receptacle at the face end.

A four-pin connector at the rear end provides connections for power, ground, sourcing

output, and sinking output. Status and setup controls on the face include a green power

indicator, a multi-color multi-function indicator and a pushbutton switch.

The DS60A requires a dc power source in the voltage range of 12 to 24 volts at 100

mA.

The pin-out is as follows:

Pin 1 - Power Brown wire on standard cable

Pin 2 - Sourcing Output White wire on standard cable

Pin 3 - Common Blue wire on standard cable

Pin 4 - Sinking Output Black wire on standard cable

When power is applied, the green power indicator is solidly ON.

During normal sensing operation, the multi-color indicator tracks the state of the sinking

and sourcing outputs. When the outputs are off, the indicator is green. When the

outputs are on, i.e. the sinking output is low (sinking current) and the sourcing output is

high (sourcing current), the indicator is red. In meter mode, the multi-function indicator

flashes at a rate proportional to the strength of the signal from the attached sensor. It

flashes green if the signal is in the nominal range and red when double thick material is

sensed. During calibration, the multi-function indicator flashes different colors at various

rates to indicate the status of the process as described later in this document.

The small calibrate pushbutton mounts flush with the face of the unit to insure no

inadvertent activations that can cause loss of calibration.

December 18,2007

Page 2

PROBES

The DS60A operates with several different Prime magnetic probes including Models

PM4, PM10, and PM15. All probes are potted and completely sealed. The probes do

not respond to small amounts of fine metal filings, oil or dirt.

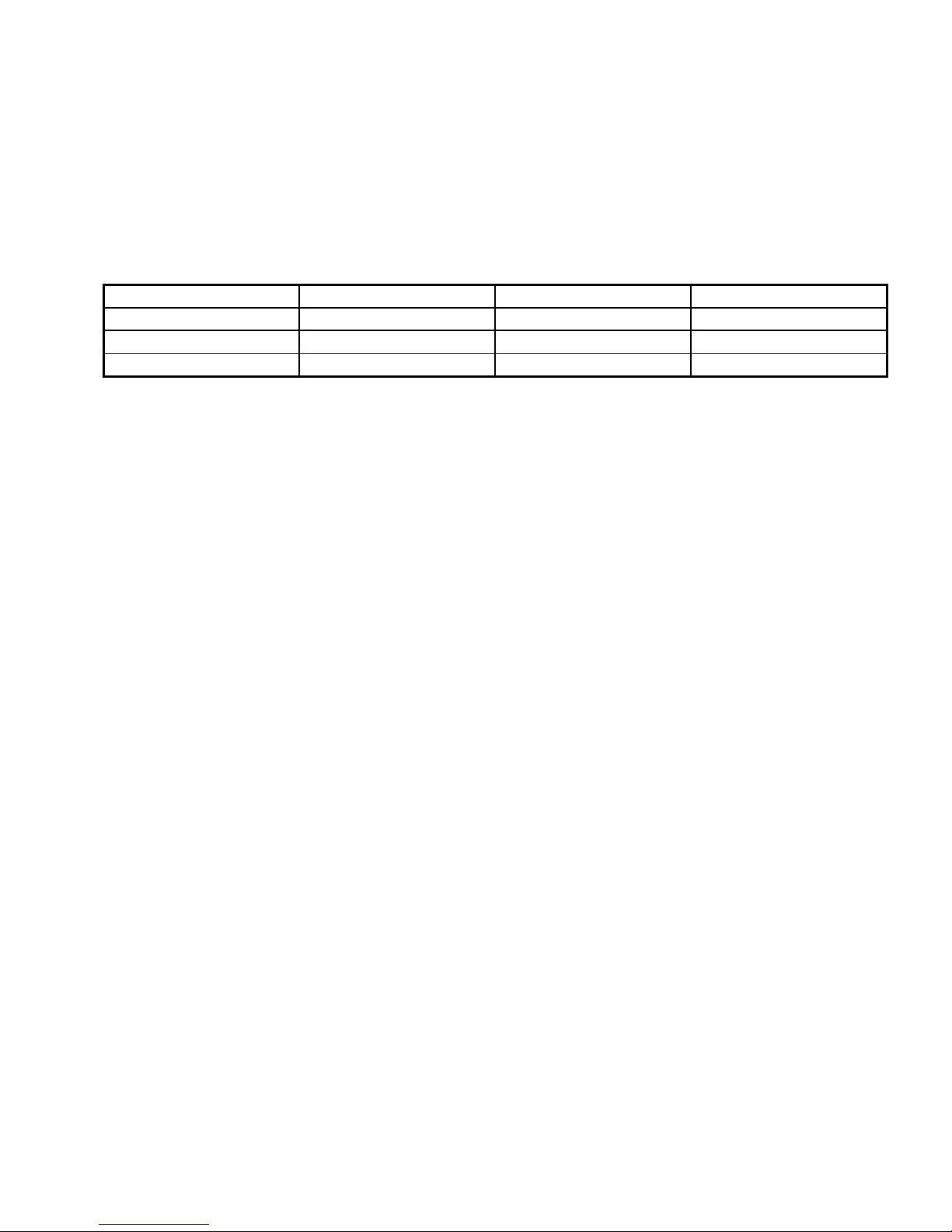

Probe Model Min thickness Max thickness Probe Diameter

PM4 .04 mm (.0015”) .40 mm (.015”) 18 mm (0.70”)

PM10 .10 mm (.004”) 1.0 mm (.040”) 30 mm (1.18”)

PM15 .15 mm (.006”) 1.5 mm (.060”) 36 mm (1.42”)

INSTALLATION

Installation of the individual components of the DS 60A system is covered in the

following paragraphs:

DS60A Control Module

The control module is designed to mount with a simple bracket where convenient

between the probe and a higher level controller such as a PLC. Avoid mounting

locations with excessive heat and vibration.

Probes

The probe must be mounted so that the sheet is in contact with the probe face as it

passes. The face of the probe is made of magnetic material and will last for many years

of operation.

The Model DS60A Double Sheet Detector can operate with no contact between the

sheet material and the probe if the gap is kept very small and is held constant. A

constant gap is very important since a small change in gap causes significant change in

the sensor signal. If the system is to be operated with a gap between the probe and the

sheet material, the unit must be calibrated after the gap is established. If the gap is too

large, the unit will not calibrate.

Electrical Wiring

The connection between the probe and the DS60A Controller requires a Prime Controls

adapter cable model CBL110-X where X indicates length.

Power to the controller and the outputs from the controller connect through an industry

standard male, four-pin “Micro” style connector. For this connection use Prime Controls

cable CBL104-3.

2

Page 3

METER MODE

The DS60A Controller provides a feature for monitoring the sensitivity to the target

materials. To invoke “meter” mode, press and hold the pushbutton switch for three or

more seconds. When the switch is released, the multi-function indicator begins flashing

at a rate proportional to the strength of the sensor signal. For minimum or no signal, the

flash rate is approximately 1 Hz. For maximum signal, the flash rate is approximately

25 Hz. The color of the indicator is green if the signal is below the current calibration

threshold and red if above the threshold.

Press and release the pushbutton to exit meter mode. The indicator reverts to following

the outputs.

The gauging function of the controller remains active during meter mode. As the sensor

signal moves above and below the calibration threshold, the outputs switch accordingly

as indicated by the color of the indicator.

MULTI-FUNCTION INDICATOR INTERPRETATION

The multi-function indicator provides information about the state of the controller.

During normal gauging, the state of the indicator follows the outputs directly. When the

outputs are ON (sourcing output high, sinking output low), the indicator is red, and when

the outputs are OFF, the indicator is green.

In meter mode, the indicator flashes at a rate proportional to the strength of the signal

from the attached sensor. For minimum or no signal, the flash rate is approximately 1

Hz. For maximum signal, the flash rate is approximately 25 Hz. The color of the

indicator is green if the signal is below the current calibration threshold and red if above

the threshold.

During one-sample calibration, the indicator turns off momentarily, and then if calibration

is successful, the indicator flashes amber 4 times in succession at a 5 Hz rate then

reverts to following the state of the outputs. If calibration is not successful (the sensor

signal is too weak), the indicator flashes red at a 10 Hz rate for 15 seconds or until the

pushbutton is pressed again. If 15 seconds elapse with no repress, the indicator reverts

to tracking the outputs.

When two-sample calibration is invoked, the indicator begins flashing amber indefinitely

at a 2.5 Hz rate until the pushbutton is pressed for recording of the second calibration

point. After the pushbutton is pressed for recording the second point, the indicator

flashes amber 4 times in succession at a 5 Hz rate then reverts to following the state of

the outputs.

3

Page 4

PUSHBUTTON OPERATION

The calibration pushbutton allows control of the operational mode of the DS60A

controller as follows:

1. From gauge mode, tap and release within 0.7 seconds to calibrate on current

conditions. If bad calibration (e.g. no metal against the probe face), unit enters

error reporting mode.

2. From error mode, tap the pushbutton once to retry calibration.

3. From gauge mode, tap the pushbutton twice within 0.7 seconds to enter twosample calibration mode and record the first point. LED flashes amber until a

third tap records the second calibration point. If good calibration, LED flashes

amber 4 times and returns to gauge mode. If bad calibration (e.g. no difference

in thickness between first and second samples), unit enters error reporting mode.

4. From error mode, tap the pushbutton once to restart calibration.

5. From gauge mode, hold the pushbutton in for at least three seconds, the

controller enters meter mode.

6. From meter mode, tap the pushbutton once to exit meter mode.

CALIBRATION

The DS60A Controller offers two modes of calibration or “teach”, a one-sample mode

and a two-sample mode. Both are invoked through the pushbutton on the face of the

unit.

The one-sample mode simply sets the gauge threshold at 125% of the signal present at

the time the pushbutton switch is pressed.

The latest calibration information is always stored in non-volatile memory and is

restored at power-up.

One-sample Calibration

1. Mount the sensor and place the material to be sensed against the face of the

probe.

2. Tap the calibration pushbutton.

If the calibration is successful, the indicator flashes amber 4 times at a 5 Hz rate and

then reverts to following the output. If calibration is successful, the new calibration

value is stored in non-volatile memory. The outputs turn ON for double and OFF for

single.

4

Page 5

If the sensor signal is too weak or too strong, the calibration will fail. The controller

indicates the failure by flashing the indicator red at a 10 Hz rate for 15 seconds or until

the pushbutton is pressed again. If the pushbutton is not pressed within 15 seconds,

the controller aborts calibration and re-installs the previous calibration parameters.

Two-sample calibration

Two-sample calibration may be used for two purposes: for looser or tighter control of the

positioning of the gauge threshold and and/or to reverse the operational logic of the

outputs. Two-sample calibration places the gauge threshold at the midpoint between

the two recorded samples. Whereas the single-sample calibration always discriminates

on a 25% change in signal relative to the sample point, the separation of sample points

in the two-sample mode may vary according to the user’s needs.

Inverting the gauge logic works as follows:

Outputs ON with Thinner Material (Single)

1. Place the thicker material or double sample against the probe face.

2. Tap the pushbutton twice in succession within 0.7 seconds. The first sample is

taken and the indicator flashes amber indefinitely at a 2.5 Hz rate.

3. Place the thinner material or single sample against the probe face.

4. Tap the pushbutton once. The second sample is taken, the new threshold

installed, and the indicator flashes amber four times at a 5 Hz rate and then

reverts to following the outputs.

After this calibration, the outputs turn ON for a single and OFF for a double. Note that

for double detection this mode reports a double when power is lost to the sensor.

Outputs ON with Thicker Material (Double)

1. Place the thinner material or single sample against the probe face.

2. Tap the pushbutton twice in succession within 0.7 seconds. The first sample is

taken and the indicator flashes amber indefinitely at a 2.5 Hz rate.

3. Place the thicker material or double sample against the probe face.

4. Tap the pushbutton once. The second sample is taken, the new threshold

installed, and the indicator flashes amber four times at a 5 Hz rate and then

reverts to following the outputs.

The outputs turn ON for a double and OFF for a single.

5

Page 6

DS60A DRIVE CIRCUITRY

V+

1

3

COM

30V

50 mA

50 mA

CONTROLLER

CONTROLLER DIMENSIONS

30V

30V

CONTROLLER RECEPTACLE

(Micro Style)

SOURCE

2

SINK

4

23.80

(0.938)

SET

PWR OUT

SENSOR RECEPTACLE

(Pico Style)

18 mm x 1 mm THREAD

15.85

(0.625)

DS60 CONTROLLER HOUSING

51.0

(2.00)

8.90

(.350)

12mm x 1mm THREAD

6

Page 7

SPECIFICATIONS

Power

Type: DC

V+ Connection: 12 mm Connector, Pin 1

Common 12 mm Connector, Pin 3

Voltage: 12 to 24 volts

Max Current: 25 milliamps + sourcing output load

Protection: Reverse polarity protected.

Logic Output Electrical Specifications

Sinking Output

Open Drain

Connection: 12 mm Connector, Pin 4

Max. applied voltage: 30 Volts, TVS limited

Max. current, momentary: 40 Amps

Max. current, sustained: 50 mA, fuse limited

Max. off state leakage @ 30 V: 25 uA

Over-current protection: Self resetting 50 mA fuse.

ESD protection: Transient Voltage Suppressor @ 30 Volts

Sourcing Output

Connection: 12 mm Connector, Pin 2

Max. source current: 50 mA, fuse limited

Output Voltage High: Supply Volt age less 1 volt

Over-current protection: Self resetting fuse

ESD protection: Transient Voltage Suppressor @ 30 Volts

7

Page 8

LIMITATION AND EXCLUSION OF WARRANTIES

All goods purchased form PRIME CONTROLS, INC. shall be free from defects in

materials, design and workmanship under normal conditions of use for one year from

the date of shipment. THIS WARRANTY IS THE SOLE WARRANTY AND IS

EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED, WARRANTY OF

MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE. THE LIABILITY

OF PRIME CONTROLS TO ANY PURCHASER SHALL BE LIMITED EXCLUSIVELY

TO THE COST OF REPLACEMENT OR REPAIR OF DEFECTIVE PARTS, AND

SHALL NOT INCLUDE LIABILITY FOR ANY DIRECT, CONSEQUENTIAL OR

INCIDENTAL DAMAGES WHATSOEVER, WHETHER FORESEEN OR

UNFORESEEN, INCLUDING BUT NOT LIMITED TO LOST PROFITS, LOST SALES,

OR INJURY TO PERSONS OR PROPERTY

8

Loading...

Loading...