PNEUMATIC FLOORING NAILER

Q550

OPERATING INSTRUCTIONS

WARNING

Read these instructions thoroughly before using this tool and keep it

handy for reference.

Revision 03/10 Printed in Canada

PRIMATECH PNEUMATIC NAILER Q550

The pneumatic nailer Q550 is a professional precision tool

specially developed for the installation of 3/8" to 3/4" solid and

engineered hardwood flooring. It has been designed for easy

maintenance where major components can be accessed within

seconds without the need of any tool. Weighting only 8.7 pounds

(4 kg), this ergonomically designed tool makes the installation of

hardwood floor very easy, allowing the operator to set and nail

the boards in the standing position. It uses standard L- type 18GA

cleats available in lengths of 1¾" (45 mm), 1½" (38 mm) and 1¼"

(32 mm). For best result, only PRIMATECH cleats should be used.

Read carefully these instructions before operating this tool. It is

important to understand warnings/cautions and the safety

measures to ensure safe use of this tool.

9. Never service or repair the tool, clear obstructions or make

adjustments while the air supply hose is connected.

10. Only compressed air should be used to power this tool ; do

not exceed 110 psi (7.6 bar).

11. Never use oxygen or any other compressed gas as a power

source for this tool.

12. Always wear OSHA-required Z-87 safety glasses with side

shields.

13. Always wear proper ear and feet protection while the air

supply hose is connected.

14. Always remove cleats from the feeder channel before

servicing tool.

DO NOT REMOVE OR ALTER SAFETY. NEVER DEPRESS

THE SAFETY CONTACT WITH YOUR HANDS WHEN TOOL IS

CONNECTED TO AIR SUPPLY. EXTREME CAUTION IS

ADVISED WHEN USING THIS TOOL.

CONNECTION & AIR SUPPLY SYSTEM

The Q550 is built around the

Primpact valve engine, a

breakthrough technology for

pneumatic tools. Primpact main

features are:

• short nose and compact valve design with an allaround striking surface

• high-speed action and few moving parts, for a

powerful yet soft stroke and increased precision.

• reciprocal striking system that regulates the depth

of penetration independently from the mallet impact

• finely threaded screw-in cartridge assembly

Additional information is available directly from the manufacturer:

1135 Jeremie-Fortin, Quebec, QC

Canada, G1J 1R8

Phone: 1 (800) 363-1962 or 1 (418) 522-7744

Fax: 1 (418) 522-7466

email: support@primatech.ca

web: www.primatech.ca/support

SAFETY MEASURES

These important guidelines should always be followed to work

safely with the PRIMATECH pneumatic nailer model Q550:

To ensure maximum performance and efficiency, and also a

minimum of care, the P RIMATECH pneumatic nailer requires clean,

dry air. It is necessary to use a filter and a pressure regulator.

This tool needs a detachable male coupler with 3/8" NPT male

treads. The use of a 3/8" (1 cm) diameter air supply hose is

recommended. A smaller hose or a hose longer than 50' (15 m)

could cause a pressure drop when the tool is activated

repeatedly.

ALWAYS USE A FREE-FLOW CONNECTION FOR THE

COMPRESSED AIR SUPPLY TO PREVENT THAT THE TOOL

STAYS CHARGED AFTER DISCONNECTING THE AIR SUPPLY

HOSE.

UNLOAD TOOL BEFORE CONNECTING AIR TO PREVENT

ACCIDENTAL DISCHARGE.

AFTER MOVING TOOL TO A DIFFERENT WORK AREA, OR

AFTER ANY MAINTENANCE TO THE TOOL, ALWAYS

ENSURE PROPER OPERATION BY ACTUATING TOOL

SEVERAL TIMES WITHOUT CLEATS OVER THE

SUBFLOORING .

Dirt, dust, and other particles in the air supply can cause sluggish

operation or premature wear of many components of the tool.

Drain water from the compressor tank regularly. The compressor

start-stop limits should be set to deliver an air pressure of at least

100 psi (7 bar) at all time. Consult the compressor manual or

dealer for instructions on how to make this adjustment.

1. Read these instructions thoroughly before using this tool

and keep it handy for reference if necessary.

2. Always keep hands, feet or other body parts away from the

nail ejection area.

3. Never aim the tool in any direction other than the working

area.

4. Always carry or manipulate the tool by its handle while the

air supply hose is connected.

5. Never hit the head cap of the actuator if the plastic base is

not sitting perfectly on the working surface.

6. Never leave the tool laying down on its side while the air

supply hose is connected; the tool should always be left on

the floor, standing on its plastic base.

7. Do not alter or remove safety.

8. Always disconnect the air supply hose when the tool is not

in use or when move to another work area.

At 80 psi (5.5 bar) and 100 hits per minute, the tool consumes

approximately 3.8 cu.ft (110 ) of air per minute at 70°F (21°C).

Higher air pressure will increase the consumption of compressed

air.

The tool is designed to be operated with a compressed air

pressure of 80 psi (5.5 bar). Occasionally, a higher pressure

could be necessary, for example to use the tool with different

species of harder wood. In these more difficult cases, the

compressed air pressure can be increased up to 100 psi

(7.0 bar). It is very important not to exceed this maximum

pressure to prevent leaks, premature wear or damages to the

tool.

Check the compressed air supply hose before connecting to

ensure that they are free from dirt or particles that can alter the

performance of the tool. Pay special attention to any air leaks. Do

not use a compressed air pressure higher than 110 psi (7.6 bar).

Higher pressure can cause premature wear or damage to certain

components. After assembly, check all the connections to

prevent the leaks and to have maximum efficiency.

In some environments, ear protection might be

required, as working condition may include

exposure to high noise levels which lead to

hearing damage.

TO PREVENT ACCIDENTAL DAMAGE TO THE FINISHED

SURFACE OF THE INSTALLED FLOOR, REST THE TOOL

ONTO THE SUBFLOORING WHEN CONNECTING AIR,

LOADING TOOL WITH NAILS OR PERFORMING ANY

MAINTENANCE TO THE TOOL.

LOADING THE TOOL

Insert a row of PRIMATECH's cleats inside the feeder channel and

pull back on the plastic tab gently until it engages behind the

cleats. To release, simply squeeze the tab with your thumb and

index and allow the spring to recoil slowly. The clip must be

released slowly to prevent damage. The Q550 uses standard Ltype 18GA cleats available in lengths of 1¾" (45 mm), 1½"

(38 mm) and 1¼" (32 mm). Make sure that the proper type of

cleats is used. Primatech's 18GA cleats are packaged into green

color-coded boxes. For MAXIMUM PERFORMANCE, always use

PRIMATECH cleats.

USE ONLY THE TYPE OF CLEATS IDENTIFIED ON THE

FEEDER CHANNEL. THE USE OF ANY OTHER TYPE OF

CLEATS WILL DAMAGE THE TOOL.

OPERATION

Unload tool and rest it onto the subflooring, Connect the hose

and cycle tool once or twice without nails. After loading the tool

with PRIMATECH cleats, the PNEUMATIC NAILER model Q550 is

ready for use.

Wearing safety boots and safety hat is also

highly recommended.

NOTE: All the personal protection equipments

must meet national standards.

Be it raw, factory finished or engineered, hardwood is a

natural material subject to various factors, such as humidity,

subflooring, installation procedure, type of tools, fasteners,

etc. Installer should always ensure optimal surface

preparation, comply with all manufacturer's

recommendations and conduct a pre-installation test prior

beginning any installation.

BEFORE STARTING AN INSTALLATION, FASTEN DOWN

FEW BOARDS TO ASCERTAIN THAT YOU ARE USING

THE RIGHT FASTENER AND THAT THE TOOL IS

PROPERLY ADJUSTED.

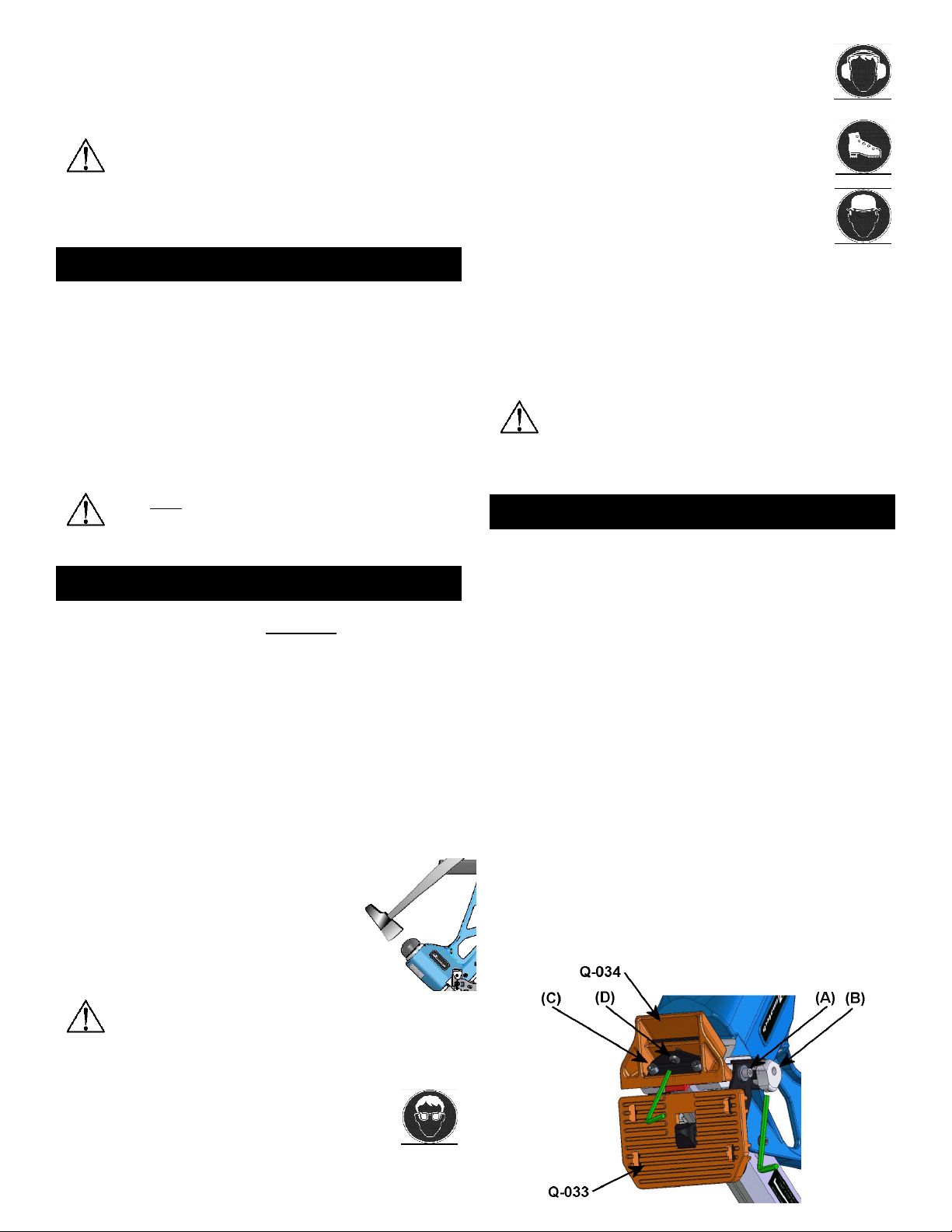

ADJUSTING FOR HARDWOOD THICKNESS

The Q550 pneumatic nailer is fitted with a fully adjustable plastic

base Q-033, designed to prevent contact with the top edge of the

flooring. Since there is no standard among manufacturers about

the dimensions of the tongue, it is important to adjust the nailer

to fit the flooring prior any installation. The Q550 also features a

resting block Q-034 which prevent damage to the top edge of the

flooring by positioning the tool against the tongue, preventing the

gate/foot assembly from contacting the board.

Only use the 2.5 lbs (1.1 kg) hammer supplied with the tool. The

use of other type of hammers may affect performance. The

rubber face of the hammer can be used with care to help position

the boards.

With the flooring firmly in place, position the tool onto the flooring,

with the resting block Q-034 against the tongue. Apply downward

pressure to ensure proper seating of the cleat. Strike the head

cap Q-001 with the hammer to activate the tool,

Use only the RUBBER FACE of the hammer to

activate the tool. Using the steel end will

damage the tool and void the warranty. If

wood is slightly twisted, hitting the tool with more

force will assist in pulling the board up snugly.

NEVER strike the head cap when the tool is not

sitting on the working surface.

OPERATING THE TOOL WHEN THE SAFETY CONTACT IS

NOT FULLY DEPRESSED WILL CAUSE PREMATURE WEAR

OR DAMAGE TO THE DRIVING BLADE, PISTON AND

CYLINDER.

Eye protection is recommended and should be

worn by the operator and other in working area.

Accidental ejection of nails or wood debris could

cause severe eye injury.

Step 1: adjusting the base for flooring thickness:

Using the supplied Allen wrench, loosen but do not remove

screws (A); one on each side of the tool.

With the tool in an upside down position, place a short piece

of flooring against the gate/foot assembly (Q-029/Q-032).

Engage the Allen wrench in knob (B) as shown; rotate to

move the base up or down. Note that knob (B) has a rotation

range of only about 1/2 turn. Do not apply force when a limit

is reached.

Adjust the height of the plastic base to obtain a small gap

between the gate/foot assembly and the top side of the

tongue of the sample board. A gap of 1/32", about half the

thickness of the nail, should be adequate for most situations.

Tighten both screws (A).

Step 2: adjusting the resting block for the width of the tongue:

Using the Allen wrench, loosen by about 1/2 turn n do not

remove the two screws (C).

With the short piece of flooring still against the gate/foot

assembly, adjust the gap between the resting block and the

tongue with screw (D). A small gap of 1/32", about half the

thickness of the nail, should be adequate for most situations.

Tighten both screws (C).

Ensure that screw (D) is slightly tighten. Do not apply force

on screw (D) once screws (C) are tighten.

After completing the adjustment procedure, proceed with the

installation of few boards. Carefully check for the proper

positioning of the nail onto the board. Check again after few more

rows to insure that all parts are secured in place. Tool may lose

adjustment over time if this procedure is not strictly followed.

BEFORE STARTING AN INSTALLATION, NAIL DOWN FEW

BOARDS TO ASCERTAIN THAT YOU ARE USING THE RIGHT

TOOL AND FASTENER.

PREVENTIVE MAINTENANCE

This tool requires minimal lubrication. Use only

detergent-free oil such as Primatech P-090. Few drops

of oil weekly in the air inlet is sufficient. Other types of

lubricant may degrade the seals.

Check periodically to make sure that all screws are tight. Pay

particular attention to the two screws holding the feeder channel

as well as the screws and nuts on the feeder channel assembly

who might loosen up over time. Be careful not to strip the threads

when tightening. The use of an medium strength adhesive

sealant such as the Loctite 242 is recommended for those screws

and nuts.

MAINTENANCE & REPAIR

Most adjustments to the tool can be made with the 3/16" and

5/32" Allen wrench supplied with the tool. These can be

conveniently stored above the feeder channel Q-048.

Disassembly of the tool must be done in a clean environment.

Some parts can be easily damaged if disassembled with

improper tools or by inadequate methods. Maintenance should

only be performed by trained personnel. Use only genuine

PRIMATECH replacement parts.

TO PREVENT INJURY, ALWAYS DISCONNECT THE AIR

SUPPLY HOSE WHEN SERVICING OR DISASSEMBLING THE

TOOL.

When servicing the tool, do not twist or force any parts. Damage

may result from such abuse. If parts do not come loose easily,

contact your PRIMATECH distributor for more information.

NEVER apply threadlocker

or adhesive onto cylinder

or head threads.

When opening the tool for maintenance, always clean all

components of dirt, grit, or particles. Inspect the tool carefully for

broken parts or excessive wear, and replace if necessary. When

ordering parts, be sure to specify the right part number, and also

the tool serial number.

AFTER ANY MAINTENANCE TO THE TOOL, REMOVE ALL

CLEATS BEFORE CONNECTING AIR AND ACTUATE THE

TOOL REPEATEDLY OVER A PIECE OF WOOD OR

SUBFLOORING TO INSURE PROPER OPERATION.

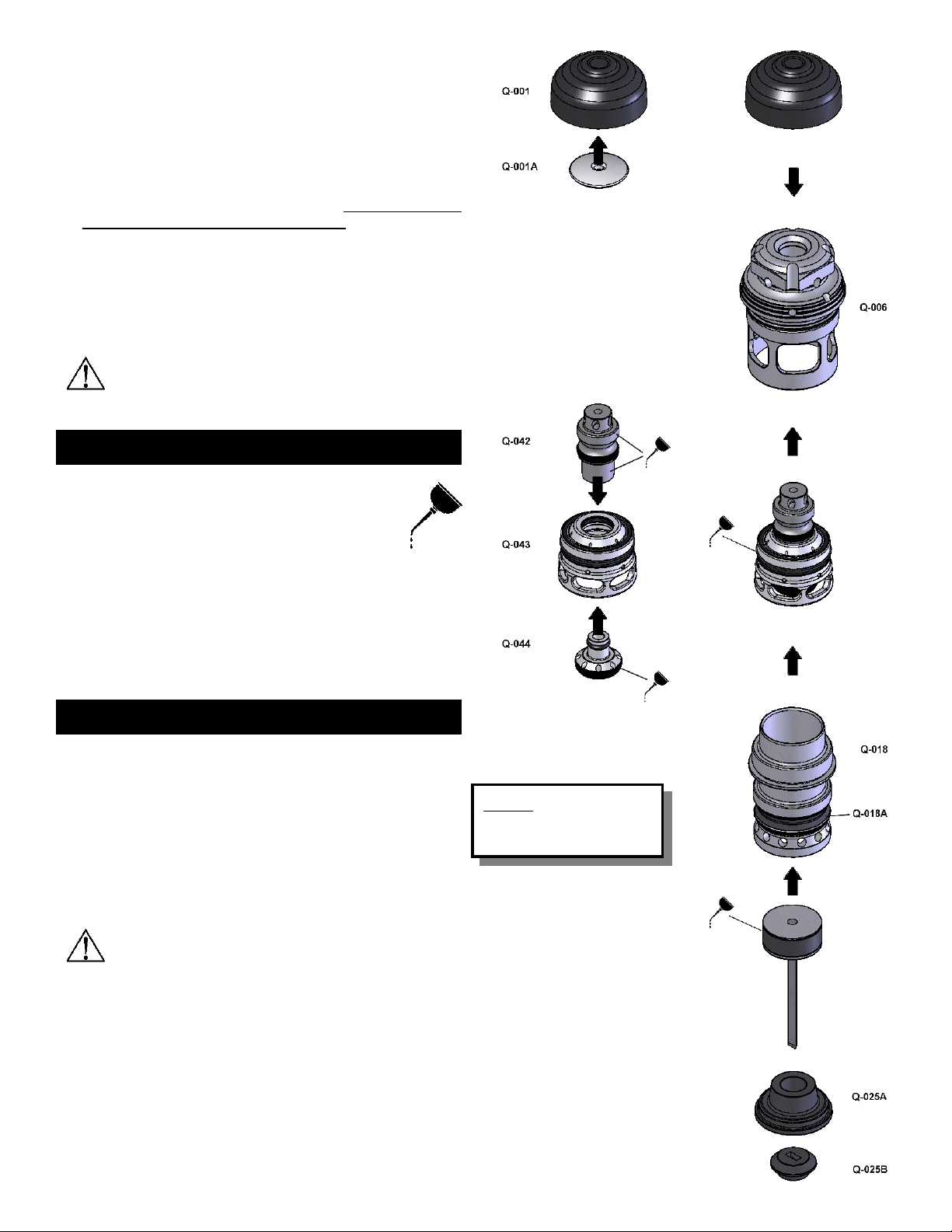

ASSEMBLING THE VALVE

All the components required to drive nails in and reset the tool

are packed in a cartridge assembly which is simply inserted into

the tool. This section describes how to assemble all the

components together. However, it is usually not necessary to

completely disassemble the valve. Refer to next section,

"CLEANING THE VALVE" for more information on how to open the

tool for regular maintenance. The following procedure assumes

that the gate/foot assembly (Q-029/Q-032) along with the resting

block Q-034 are already installed. Refer to the "Replacement

Parts" document for a complete list and schematic of the tool.

1. It is usually not required to separate the head disk Q-001A

from the head cap Q-001. If necessary, insert the head disk

Q-001A firmly in place into the head cap Q-001.

2. Align the inner shape of the head cap Q-001 with the shape

of the head Q-006 and snap the cap in place. It is usually

not required to remove the head cap from the head.

3. Check the condition of all rings and seals on the actuator

Q-042, actuator cap Q-044 and main valve Q-043.

4. Lightly lubricate actuator Q-042 as shown and insert it into

valve Q-043.

5. Lightly lubricate the permanent seal of actuator cap Q-044

as shown. Do not lubricate the small o-ring (see part

Q-044C on schematic). Insert the actuator cap as shown

and forcibly snap it into the actuator Q-042

6. Insert the valve sub-assembly completely into the head

Q-006.

7. Check that the band-valve Q-018A is properly installed onto

the main cylinder Q-018. Screw the cylinder Q-018

completely onto the head body Q-006 and tighten firmly by

hand. Take care not do damage the threads. Pull down the

valve Q-043 to sit it onto the cylinder.

ALWAYS CHECK THAT THE CYLINDER IS COMPLETELY

SCREW-ON THE HEAD BEFORE INSERTING THE ASSEMBLY

INTO THE TOOL. THE CYLINDER WILL LOOSEN-UP WHEN

THE CARTRIDGE IS TAKEN-OFF THE TOOL.

ALWAYS PULL DOWN THE VALVE AGAINST THE CYLINDER

BEFORE INSERTING THE HEAD ASSEMBLY.

8. Check that the piston sub-assembly, including rings and

driving blade, is sliding easily into the cylinder Q-018. It

should offer some resistance, but if it moves too easily, it

may be required to replace the piston wear-ring Q-022A.

9. Insert the seal bushing Q-025B in the lower section of main

body Q-006 and engage it onto the upper portion of the

gate/foot assembly (Q-029/Q-032). A flat screwdriver can

help location the seal bushing correctly. Use the wooden

handle of the hammer to tap the seal bushing completely in

place. It is usually not necessary to pull-out the seal bushing

Q-025B for maintenance.

10. With the tool in the upright position, push the bumper

Q-025A in place, indexed onto the seal bushing Q-025B and

use the wooden handle to seat the bumper in position.

11. Insert the piston sub-assembly into the main body Q-016

and engage the driving blade Q-023 in the seal bushing

opening. Depress the safety contact Q-062 to ensure that

the driving blade has engaged the gate/foot assembly

guiding channel.

Complete 'cartridge' assembly

12. Loosen the lock P-616D and insert the whole head

assembly into the main body Q-016; the main cylinder

Q-018 engaging onto the piston assembly. Screw the head

assembly completely. Take care not do damage the

threads. Rotate the lock clockwise and tighten with the Allen

key using moderate force.

NEVER APPLY THREADLOCKER OR ADHESIVE ONTO

CYLINDER OR HEAD THREADS.

IT IS MOST IMPORTANT THAT THE MAIN CYLINDER BE

FULLY SCREWED & TIGHTENED ONTO THE HEAD

ASSEMBLY BEFORE BEING INSERTED INTO THE MAIN

BODY.

AFTER REASSEMBLY, ALWAYS ACTUATE THE TOOL

REPEATEDLY WITHOUT CLEATS AGAINST A PIECE OF

WOOD TO INSURE PROPER OPERATION.

This tool features a head lock to

maintain firmly in place the head

assembly during operation. Before

inserting the head assembly,

ensure that the P-616D lock is free

to swivel and rotate it away from

the head opening. After inserting

the head assembly in place, rotate

the P-616D lock and tighten with

the Allen key using moderate force.

To remove the head assembly, simply unscrew the P-616D

screw ¼ turn and rotate it counter-clockwise.

CLEANING THE VALVE

If the tool becomes sluggish or does not set the cleat, it may

indicate excessive dirt, dust, other particles, or even water, in the

head assembly, thereby impeding the cycling of the valve. The

first step in troubleshooting is to clean up the head assembly.

1. Unscrew the head assembly Q-006 and take it out of the

tool. The long arm of a Allen wrench may be inserted into

one of hole at the base of head Q-006 to help unlock the

assembly.

2. Pull-out the piston assembly and unscrew the cylinder

Q-018. Perform a visual inspection of the driving blade

Q-023, the wear-ring Q-022A and the inner surface of the

cylinder Q-018. Do not remove the driving blade from the

piston.

3. Pull-out the valve assembly Q-043 and perform a visual

inspection of all rings. Check that the actuator assembly

Q-042/Q-044 is sliding easily on valve Q-043. Clean and

lubricate lightly. It is usually not necessary to take apart the

actuator assembly.

4. If necessary, actuator cap Q-044 may be unsnapped from

actuator Q-042 by inserting the long arm of an Allen wrench

through the hole on top of the actuator and using a hammer

with moderate force to get the parts apart.

5. Clean the inside wall of the head body Q-006 and lubricate

lightly with a non-detergent oil. Check the o-ring Q-006A. It

is generally not necessary to remove the head cap Q-001.

REPLACING THE DRIVING BLADE

The driving blade is not sold separately, but supplied as a

complete subassembly with the piston Q-022. Never remove the

driving blade from the piston.

INSTALLING THE SAFETY

You shouldn't need to remove the safety stop mechanism unless

the element Q-061 do not swivel or has a broken tip.

a) Assemble together parts Q-061, Q-061A , Q-061C and

Q-061D.

b) Insert the short end of Q-061B as shown.

c) Put two drops of adhesive sealant onto the thread area of

Q-061C, near its cylindrical end. Make sure no sealant is

retained on the end or exterior wall.

d) Insert the assembly into the hole in the tool body as shown.

e) Tight together with screw P-153A, holding Q-061C.

1. Unscrew the head assembly Q-006 and take it out of the

tool.

2. Pull-out the piston assembly from the cylinder. Remove any

debris and assess condition of cylinder Q-018. If marked or

grouged, use a fine sand paper to smooth out walls. The

piston Q-022 must be allowed to move without restriction.

3. Insert the piston sub-assembly into the main body Q-016

and engage the driving blade Q-023 in the seal bushing

opening. Depress the safety contact Q-062 to ensure that

the driving blade has engaged the gate/foot assembly

guiding channel.

4. Tighten the cylinder Q-018 onto the head Q-006 and follow

the procedure to complete the assembly of the head.

INSTALLING THE BASE ASSEMBLY

The plastic base can be installed or

removed without the need of a tool.

a) First, insert connecting stem

Q-061B to the safety contact

Q-062.

b) Lift the safety contact and fully

slide-in the plastic base Q-033

onto the brackets Q-035A & B.

c) The safety contact should

simply drop into place. Insert

the locking rod Q-062A until it

snaps. It should engage the safety contact.

TROUBLESHOOTING

This section will help to diagnose common problems and will

give suggestions on how to solve them. Consult our on-line

Technical Support site at www.primatech.ca/support for

updated documents and more tips.

TO PREVENT INJURY, ALWAYS DISCONNECT THE

AIR SUPPLY HOSE WHEN ADJUSTING, SERVICING

OR DISASSEMBLING THE TOOL.

(1) FIRST: CHECK THE COMPRESSED AIR SUPPLY

Many of problems come from a faulty or inadequate

compressed air supply system. Before attempting to repair

the tool, the following points should be checked:

a)check the pressure at the output of the compressor;

adjust to 80-100 psi (5.5-7.0 bar) as required

b)check the tank pressure of the compressor & adjust the

start/stop limits

c)check the air delivery system

d)use fewer tools simultaneously; do not exceed the

capacity of the compressor or of the delivery system

e)drain water from the compressor

(2) SECOND: CHECK FOR AIR LEAKS

At rest, this tool should not have any air leak. Before

attempting to repair the tool and replace parts, check the

following:

a)Check rings Q-006A, Q-016A, Q-042A, Q-043B and

Q-043C; replace if necessary

b)The top edge of main cylinder Q-018 should be free of

dents.

c)Clean & lubricate the head assembly; re-assemble the

head assembly carefully

d)Check interior of head Q-006 for scratches

(3) TOOL DOES NOT DRIVE CLEATS

a)Check that there are cleats in the feeder channel

b)Make sure the feeder clip is engaged behind the cleats

c)Check the front end of the feeder channel for burrs or

damages

d)Check the safety mechanism

e)Check if the driver is stuck in down position (see 6

below)

f)Check for obstruction in the cleat ejection area

(4) CLEATS ARE NOT SET COMPLETELY

a)First, verify air supply (see 1 above)

b)Clean tool and lubricate tool; particularly the head

assembly

c)Increase air pressure when working with harder woods;

do not exceed 110 psi (7.6 bar)

d)Check the driving blade for broken end

e)Check piston wear-ring Q-022A; replace if piston is

sliding to easily

f)Check seal bushing Q-025B

g)Check the adjustment of the base and ensure the tool

is well seated on the floor while ejecting

(5) TOOL DOES NOT ACTIVATE

a)Check the air supply

b)Inspect the head assembly and check all seals;

reassemble carefully

(6) DRIVING BLADE DOES NOT RETURN

a)Check for jammed cleat or obstruction

b)Check gate/foot and end of feeder channel for

damages or burrs.

c)Check the driving blade Q-023

d)Inspect the head assembly and check all seals; clean

& lubricate.

e)Check band-valve Q-018A.

f)Check that the bumper Q-025A and seal bushing

Q-025B are in place.

(7) BROKEN OR WORN DRIVING BLADE

Replace the driving blade Q-023. Failure to follow the

instructions carefully will result in repeated breakage of the

driving blade.

(8) POOR FEED OR TOOL JAMMING

a)Make sure the feeder clip engages behind the cleats

b)Check the gate/foot assembly for damages or wear

c)Check the front end of the feeder channel for burrs or

damages

(9) OTHER PROBLEMS

Contact Primatech:

by phone 1 (800) 363-1962

1 (418) 522-7744

by email support@primatech.ca

consult our on-line Technical Support site at

http://www.primatech.ca/support

ACCESSORIES

OTHER PRIMATECH NAILERS

Q-033F Self-adhesive felt pad

P-080 Hammer

H-082 Double-head hammer

P-084 White rubber cap

P-090 Non detergent oil

A-800 Extension Handle

The A-800 extension handle allows to operate the tool at a

higher or lower position. Il provides a better tool control, improve

ease and stability when sliding the tool sideways.

A-400

Prim-Jack

PRIMATECH offers a full line of professional tools for the

installation of hardwood flooring. Standard models for 5/8" to

33/32" solid flooring (16-26 mm):

H300 'Single Hit' manual nailer

H330 'Multiple-Hits' manual nailer

P240 pneumatic nailer

P250A Primpact pneumatic nailer with adjustable base

P250F Primpact pneumatic nailer with standard fixed

base

Models for solid flooring 3/8" to 5/8" (10-16 mm):

Q500 manual nailer

Q510 manual nailer with adjustable base

Q550 Primpact pneumatic nailer with adjustable base

R610 manual nailer for engineered flooring

PRIMATECH CLEATS

The

Prim-Jack

hold flooring strips tight for nailing. It can straighten

crooked or bowed flooring strips and hold in the nailing

position. The Prim-Jack is designed as one tool that will

both push or pull the flooring strips tight. With its

removable shoe you can efficiently position the jack on the

floor or in the field of flooring without damage to the

flooring, enabling hands-free operation for nailing.

floor tightening jack is designed to

For best results with your Q550 pneumatic nailer, always use

PRIMATECH cleats:

1¾" (45 mm), 18GA L-type

1½" (38 mm), 18GA L-type

1¼" (32 mm), 18GA L-type

Q550

REPLACEMENT PARTS

PIÈCES DE RECHANGE

Grip H-083A Gaine

Hammer P-080 Marteau

White rubber cap P-084 Caoutchouc du marteau

Handle grip P-154 Gaine

Head lock P-616D Barrure de tête

Head cap Q-001 Chapeau

Head body Q-006 Tête

Head o-rings Q-006A Joints torique de la tête

Main body Q-016 Bâti

o-ring Q-016A Joint torique

Main cylinder Q-018 Cylindre

Band-valve Q-018A Élastique

Wear ring Q-022A Bague d'usure

Piston / blade assembly Q-023 Piston & tige de poussée

Bumper & seal bushing Q-025 Pare-chocs & bague d'étanchéité

Foot Q-029 Plaque

Gate Q-032 Plaque guide

Adjustable plastic base Q-033 Semelle ajustable

Resting block Q-034 Bloc d'appui

Bracket Q-034A Équerre

Brackets Q-035 A&B Équerres

Cam axle Q-036 Axe des cames

Left cam Q-036A Came gauche

Right cam Q-036B Came droit

Actuator Q-042 Déclencheur

u-cup seal Q-042A Joint rectangulaire

Valve Q-043 Valve

Actuator cap assembly Q-044 Couvercle du déclencheur

Clip assembly Q-046 Coulisseau

Feeder channel assembly Q-048 Magasin assemblé

Safety anchor Q-061 Butoir

Connecting stem Q-061B Tige de connexion

Spring Q-061D Ressort

Safety contact Q-062 Palpeur de sécurité

Locking rod Q-062A Tige de blocage

04/09

IMPORTANT

IMPORTANT

ALWAYS TIGHTEN BY HAND

BEFORE INSERTING OR

TIGHTENING THE VALVE ASSEMBLY

INTO THE TOOL.

NEVER APPLY THREAD SEALANT

OR ADHESIVE ONTO CYLINDER OR

HEAD THREADS.

CAUTION

TO PREVENT INJURY, ALWAYS DISCONNECT

AIR SUPPLY WHEN ADJUSTING, SERVICING OR

DISASSEMBLING THE TOOLS.

IMPORTANT

T OUJOURS RESSERRER

FERMEMENT LE CYLINDRE SUR LA

TÊTE AVANT D'INTRODUIRE

L'ASSEMBLAGE DANS L'OUTIL.

NE JAMAIS UTILISER DE

SCELLANT OU ADHÉSIF SUR LES

FILETS DU CYLINDRE OU DE LA

TÊTE.

ATTENTION

POUR ÉVITER TOUT RISQUE DE BLESSURE,

TOUJOURS DÉCONNECTER L’ALIMENTATION EN

AIR COMPRIMÉ LORS DE L’ENTRETIENT OU DU

DÉMONTAGE DE L’OUTIL.

IMPORTANT

REFER TO THE INSTRUCTIONS MANUAL AND

READ THE "SAFETY MEASURES" SECTION

BEFORE USING OR SERVICING TOOLS.

www.primatech.ca/support

Consult our on-line Technical Support site

for updated documents.

Printed in Canada

RÉFÉRER À LA NOTICE D’UTILISATION ET LIRE LA

SECTION "CONSIGNES DE SÉCURITÉ" AVANT

D’UTILISER OU RÉPARER L’OUTIL.

www.primatech.ca/support

Consultez notre site de soutien technique

pour une mise à jour des documents.

Loading...

Loading...