ECO Valve

Uses:

• Back Pressure valve

• Anti-Siphon valve

• Pressure Sustaining valve

• Pressure Relief valve

Instruction Manual

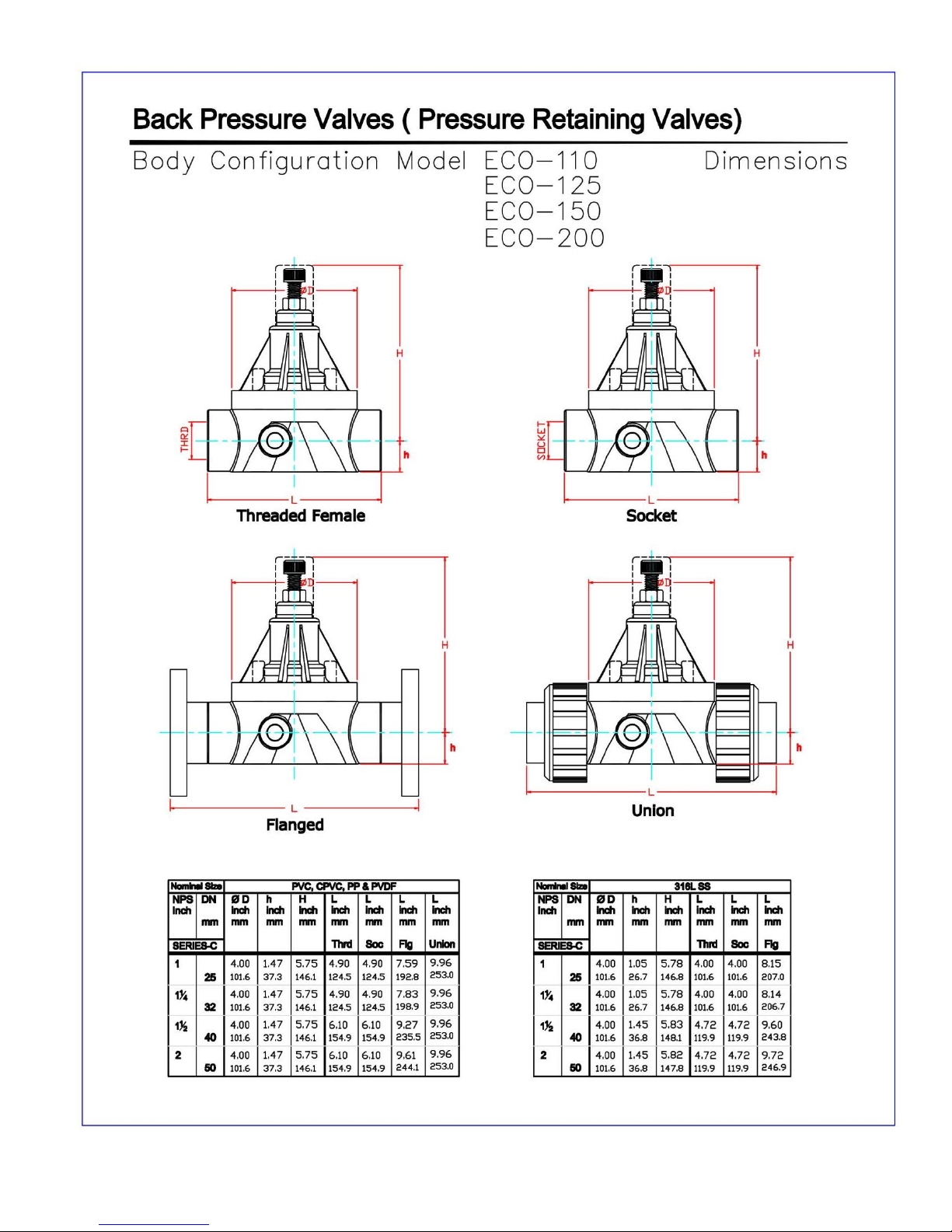

1” (High Flow), 1 ¼”, 1 ½” and 2” (“C” Series)

ECO-110, ECO-125, ECO-150 and

ECO-200

06/2017

Rev. 4

Please note:

This instruction manual provides detailed information and instructions that must be read, understood and

followed to ensure that the equipment is installed, operated and serviced in an appropriate manner.

Failure to do so before using may result in hazardous consequences and/or improper operation.

Manufactured by:

PRIMARY FLUID 1050 Cooke Blvd., Burlington, Ontario, L7T 4A8

SYSTEMS INC. Tel: (905) 333-8743 Fax: (905) 333-8746

Call Toll Free: 1-866-324-6422

E-Mail: sales@ecovalve.ca

http:www.ecovalve.ca

2

Introduction

The following instructions are to provide information on the Installation, operation and

maintenance of ECO Valve, diaphragm style valves, manufactured by Primary Fluid Systems

Inc. The valves are designed to help improve the performance and safe operation of most

positive displacement pumps.

Various materials of construction are available dependent on the requirements of the

application and the type of fluids being transferred.

The valve(s) are factory set at 50 PSIG with a field adjustment range of 7-150 PSIG. Other

factory set pressure ranges (within the range of the valve) is available upon request.

Features of ECO Valve:

• PVC, PP, CPVC (Corzan), PVDF and 316L S/S wetted construction

• PVC diaphragm with PVC valve bodies

• PTFE laminated to EPDM backer diaphragm standard on all other material

• Optional Viton or EPDM wetted diaphragm materials

• only one elastomer is present in the wetted end

• Turn down handle limits pressure to 150 PSIG

• Locking adjustable pressure screw

• Color-coded caps indicate size at a glance

• Built-in gauge port on both sides of valve body (pre-drilled & threaded optional)

• Specially designed spring provides consistent pressure adjustments through the range

(7-150 PSIG)

• Eco valve is available in several configurations to meet your needs, such as threaded,

socket, flanged, union in DIN, BSPT and American Standard

• Built-in downstream manual air release, for ease of pump priming

• Built-in anti-siphon

Back Pressure Valve/Anti-siphon:

Diaphragm Back Pressure Valves serve two primary functions. The first is to provide a

constant discharge pressure on the pump, which improves the performance, efficiency and

consistency of the delivered volume. Secondly, the valve performs as an anti-siphon

mechanism against positive or negative pressures in the downstream line. The valve is

designed to allow for the venting of air into the downstream pipeline. This provides for easier

priming of metering pumps that function under a suction lift. This is accomplished by a simple

adjustment of the handle.

The valve comes complete with a gauge port located on both sides of the valve body; the ports

are normally not drilled or tapped for a gauge connection. (See gauge installation

instructions on page 5)

Caution:

The gauge port is solely for the installation of the gauge and must not be used for the

bleeding or venting of the system. Improper operation of the valve and/or hazardous

consequences could result. (See gauge installation instructions)

3

Back Pressure /Pressure Sustaining Valve: Reason for Selection and Use

Metering pumps having an atmospheric discharge system pressure or less than 20 psi will

benefit from the installation of a back pressure control valve. Metering pumps in general

require downstream back pressure to ensure smoother function of the discharge check

assemblies, which enhances the accuracy of the discharge flow.

Pressure Relief Valves:

Diaphragm Pressure Relief Valves are designed to relieve excess line pressure that exceeds

the set pressure of the valve. This protects the system piping from overpressure that could

result in hazardous leakage and/or damage to the pump and other system components.

The Pressure Relief Valves are normally recommended to be set between 5 and 10 PSIG

above the system operating pressure.

When ECO valves are used as a pressure relief valve it is a two port valve, thus designed for

off line installations. This requires the valve to be installed on a tee branch of the discharge line

of the pump for piping back to supply tank or feed side of pump.

The valve comes complete with a gauge port located on both sides of the valve body; the ports

are normally not drilled or tapped for a gauge connection. (See gauge installation

instructions on page 5)

Caution:

The gauge port is solely for the installation of the gauge and cannot be used for the

bleeding or venting of the system. Improper operation and/or hazardous consequences

could result. (See gauge installation instructions)

Pressure Relief Valves: Reason for Selection and Use

Most positive displacement pumps require the use of a pressure relief valve; it should always

be installed on the downstream side of the pump to protect the system from over pressure

which can cause pipe leakage and/or rupture. There should not be any type of valve located

between the pump discharge or the pressure relief valve, for the pressure relief valve to

function properly.

Installation and Maintenance of Back Pressure Valves:

Back pressure control valves are installed on the discharge line of the pump. The valve should

be located as reasonable close as possible of the pump discharge to ensure check valve

seating. When pumping to a process line without an injection valve, the back pressure valve

should be installed as close as possible to the injection point to prevent siphoning.

When used in conjunction with a pressure relief valve, always locate the back pressure valve

on the downstream side of the relief valve.

4

The valve is supplied from the factory pre-set at 50 psig. To increase the pressure setting,

back off the lock nut located beneath the colour coded bonnet cap. Turn the Allan bolt using a

5/16” or #8 hex key clockwise to increase pressure setting or counter clockwise to reduce

pressure setting. Approximately one (1) full turn of the handle is equal to 10 psig.

If maintenance is required on the valve:

1. Ensure that the valve is properly isolated from the line, not under pressure and

properly flushed of chemical before proceeding to disassembly.

2. Turn Allan bolt on the top of valve, counterclockwise until all spring pressure is released

before proceeding to undo retaining nuts, to remove top of valve for diaphragm

replacement.

3. All working components ie. diaphragm, spring can be accessed by removing the four

retaining bolts located on the bottom of the valve (item # 9 of parts breakdown).

4. When replacing a PTFE coated diaphragm, ensure the PTFE coated side of the

diaphragm is facing down when viewed from the top of the valve. The installed

diaphragm also functions as the body seal. (Torque nuts to 40 inch pounds when

reassembling )

Installation and Maintenance of Pressure Relief Valves:

Pressure relief valves are installed on the discharge line of a pump and should be located as

close as possible to the metering pump. The valve is of an two port design and is required to

be installed on a branch tee for piping back to the supply tank or feed side of the pump.

Never install shut-off/isolation valves between pump discharge and in-line pressure relief

valves. When using in conjunction with a back pressure control valve, always install back

pressure valve downstream of pressure relief valve. The relief port on the pressure relief valve

should be piped back to the feed tank or suction side of the pump (see typical installation

schematics).

Caution: The plastic valve bodies have standard threads, which are tapered.

When installing pipe into the body, hand tighten only to avoid cracking.

Gauge Installation Instructions:

For the convenience of pressure setting and reading, there are two ports provided one on

either side of the valve body. These ports are normally not drilled or tapped unless initially

ordered that way. To drill and tap the ports it is recommended that you first disassembly the

valve so as to not leave any foreign particles in the valve. You will require a 1/8” or 3.264 mm

drill bit to drill out the centre point of the gauge port opening into the body of the valve. The

port is already the correct diameter for the tapping of a ¼” or M10 thread. It is recommended

that you use a regular tap then a bottoming tap to open the port up, this will allow for the

proper number of gauge threads.

5

Manual Air Release

The valve is shipped with a factory set pressure

of 50 psig. The diagram to the left shows a cut

away view of the position of the diaphragm on

the seat.

To adjust the valve to relieve air or gas

downstream:

1. Back off lock nut located beneath the

colour coded handle.

2. Turn handle counter clockwise until

approximately 1 inch of thread is exposed.

3. At this adjustment, the spring has relieved

all tension from the diaphragm allowing air

or gas to be vented downstream.

6

Typical Installations

The installations below are typical installation examples only. Consult your engineering department for

the appropriate installation for your application or call the factory for advice

Example A: Solenoid Driven Pumps Rated Under 150 psig

Example B: System arrangement for solenoid driven (above 150 psig) or motor driven pumps.

7

8

Parts Ordering Information

KEY

1 EVT-1CPVC- 51

2 EVB -2* * * - * *- * *

3 EVD-3- 51- * *

Connection:

A= NPT

B= BSPT

C= S/W N.A.

D= S/W Metric

E= Flg. ASME

F= Flg. DIN

G= Union Thr’d

Size:

110= 1” valve

125= 1 ¼” valve

150= 1 ½” valve

200= 2” valve

4 EVAB-4-51

5 EVS-5- 51

6 EVBD-6- 51

7 EVBD-7- 51

8 EVSB-8-51

8A EVSB-8A-*

9 EVBN-9- 51

10 EVBC-10- 51

11 EVGC-11- 51

12 EVTC-12-* *-51

13 EVO-13-51*

14 EVUN-14-* * -51

Material:

PTFE=TFE/EPDM

P =PVC

E =EPDM

V =viton

Size:

110 = 1” S/S valve

125 = 1 ¼” S/S valve

150 = 1 ½” S/S valve

200 = 2” S/S valve

Material:

PVC =polyvinyl chloride

CPVC=Corzan

PP =polypropylene

PVDF=polyvinyldene fluoride

S/S6 =316L stainless steel

Colour:

B= Blue =1” valve

S= Silver =1 ¼” valve

BL= Black =1 ½” valve

W= White =2” valve

“O” Ring seal:

V= viton

E= EPDM

T= PTFE encapsulated viton

Material:

PVC =polyvinyl chloride

CPVC=Corzan

15 EVUI- 15- * * - * *- * *

PP =polypropylene

PVDF=polyvinyldene fluoride

Material:

PVC =polyvinyl chloride

CPVC=Corzan

PP =polypropylene

PVDF=polyvinyldene fluoride

Connection:

NPT=NPT

BSPT=BSPT

SOC=S/W Imperial

SOC-M=S/W Metric

Size:

110= 1” valve

125= 1 ¼” valve

150= 1 ½” valve

200= 2” valve

9

Flow

Rates

Subject: Flow capacity through ECO VALVE, back pressure/pressure sustaining and pressure

relief valves.

Under continuous flow conditions: @ 100 PSI with ambient temperature water with the valve

set@ 50PSIG.

1” valve

35

USGPM

1 ¼” valve

38

USGPM

1 ½” valve

57

USGPM

2” valve

59

USGPM

Note: Capacities will increase with pressure.(if pressure is doubled, flow rate will

approximately double)

For capacities of valves with pulsating flow use approximately 1/3 of the above given flow

values.

TEMPERATURE EFFECTS: Thermoplastics and thermosets will decrease in tensile strength as the

temperature increases; therefore, the working pressure must be reduced accordingly. The following

factors will apply:

Temperature Correction Factors

Thermoplastics

Operating

Temperatures

{Factors}

F C PVC

CPVC

PP

PVDF

70

21

1.00

1.00

1.00

1.00

80

27

1.00

1.00

1.00

1.00

90

32

1.00

1.00

1.00

1.00

100

38

.90

1.00

1.00

1.00

110

43

.83

1.00

.91

1.00

115

46

.75

1.00

.87

1.00

120

49

.66

1.00

.83

1.00

125

52

.58

.97

.79

1.00

130

54

.50

.95

.75

1.00

140

60

.33

.90

.66

1.00

150

66

NR

.80

.60

.97

160

71

NR

.70

.53

.93

170

77

NR

.60

.43

.86

180

82

NR

.50

.33

.80

200

93

NR

.33

NR

.66

210

99

NR

NR

NR

.60

240

116

NR

NR

NR

.40

280

138

NR

NR

NR

.16

Example:

Maximum Pressure for PVDF valve at 280°F (138°C)

Factor = 0.16 x 150psig = 24psig max. pressure

Factor = 0.16 x 1034kPa = 165.44kPa max. pressure

The maximum pressure rating for valves regardless of size

is 150 PSIG (1034 kPa) at 73° F (22°C)

NR = not recommended

Primary Fluid Systems, Inc. takes no responsibility for the

enclosed data.

10

11

LIMITED WARRANTY

Primary Fluid Systems Inc. (Primary) warrants its products against defects in workmanship or materials for one (1) year under

normal use. Three-(3) year available when application card is completed and returned to factory.

Primary’s obligations and liabilities under this warranty shall be limited to replacement of the product, or a refund of an amount

not to exceed the purchase price of the product(s) to which such warranty claim is made. Repairs or replacements are made

subject to our inspection of the returned product(s). Primary’s decision of one of these alternatives shall be the buyer’s

exclusive remedy.

This warranty does not extend to damage by corrosion or other decomposition by chemical action. Primary does not warrant

damages caused by (a) improper use of the product, (b) unauthorized modification or attachment to product, (c) misuse,

abuse, accident or negligent handling or installation of product, or (d) alterations or repairs made by purchaser.

The materials of construction offered are recommendations only, subject in all cases to acceptance by purchaser. These

recommendations do not constitute any guarantee against corrosion or decomposition, but are based on previous experience

and best available information of the industry.

Statements and instructions set forth herein are based on the best information and practices known to Primary, but it should

not be assumed that every acceptable safety procedure is contained herein. Of necessity Primary cannot guarantee that

actions in accordance with such statements and instructions will result in the complete elimination of hazards and it assumes

no liability for accidents that may occur.

Except as specifically provided herein, Primary makes no warranty, representations, promise or guarantee, either express or

implied, statutory or otherwise, with respect to the product and technical information provided, including the products’ quality,

performance, merchantability, or fitness for a particular purpose.

In no event will Primary be liable for indirect, special, incidental, economic, covert or consequential damages arising out of the

use or inability to use the product, including without limitation, damages or costs relating to the loss of profits, business and

good will even if advised of the possibility of such damages. In no event shall Primary’s liability exceed the amount paid by you

for the product.

The warranty and remedies set forth herein are exclusive and in lieu of all others, oral or written, express or implied. No

Primary dealer, distributor, agent or employee is authorized to make any modification or addition to this warranty. This

warranty gives you specific legal rights and you may also have other rights which vary from state to state.

12

Notes

Loading...

Loading...