Supplied By www.heating spares.co Tel. 0161 620 6677

·

·~

~

POTTERTON

30F, 40F, 50F, 60F,

balanced

flue

THIS APPUANCE

gas

IS

FOR

USE WITH NATURAL

80F

& 1

fired

OOF

boilers

GAS

(G20)

ONLY

'

-

fanned

Installation

LEAVE THESE INSTRUCTIONS

and

Servicing

ADJACENT

Instructions

TO THE

GAS

METER.

Supplied By www.heating spares.co Tel. 0161 620 6677

CE

SAFETY, PERFORMANCE & QUALITY

Prima F boilers have been assessed

of

'Essential Requirements'

The Directive

construction, and use

and monitored system of quality assurance.

BSI kitemark remains

The

performance and

POTTERTON

POTTERTON

POTTERTON

lays

down

quality (BS.5750) standards.

PRIMA

PRIMA

PRIMA

30F G.C.

40F

SOF

the European

requirements for the safety and efficiency of the appliance, together with its design,

of materials. It also requires

on

the product. demonstrating continued conformity with

No.

41.607.01

G.C.

No.

41.607.02

G.C.

No.

41.607.03

CONTENTS

General

Optional Extras

Accessories

Installation Data

Boiler Dimensions

Site Requirements

Technical Data

Installation Instructions

Commissioning

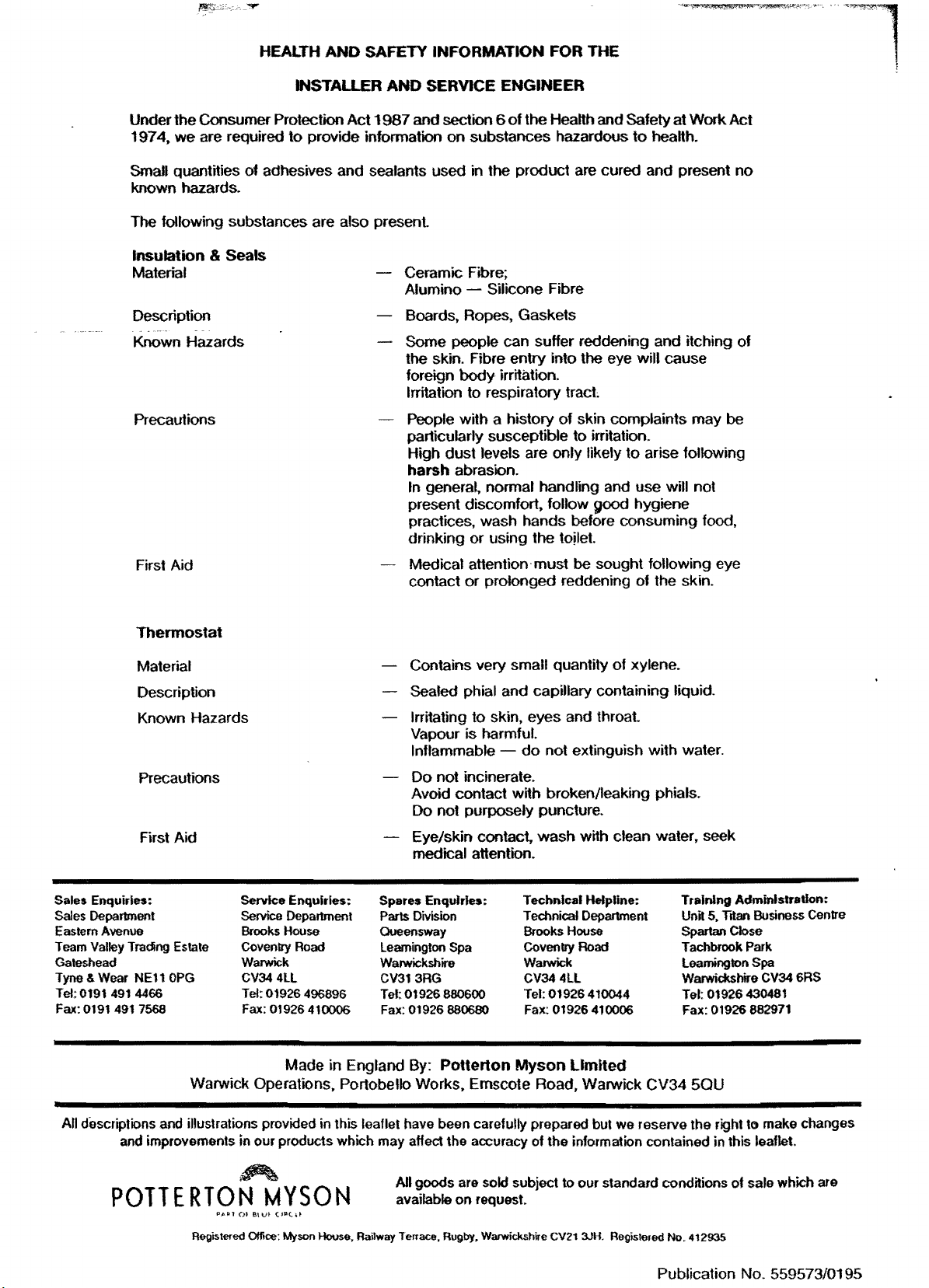

Health and Safety Information

Control

Wiring Guide

User's Instructions

Systems, Pipework and

Literature

by

a Government appointed Notified Body and

Gas

Appliance Directive.

the

production process to

POTTERTON

POTTERTON

POTTERTON

PRIMA

PRIMA

PRIMA

IMPORTANT

Page No. 2

Page No. 2

Page No. 3

Page No. 3

Page No. 3

Page No. 3

Page No. 6

Page No. 11

Page No.

Back Page

Supplied

18

in

Pack

The appliance

competent

(Installation and Use) Regulations 1984.

Prima F boilers (formerly

are certified

that no

economisers,

appliances

instructions

Any

approved

certificate and

external control devices (e.g. flue dampers,

direct

must

person

by

BSI

etc.)

unless

or

otherwise

connection

by

Potterton

the

normal warranty.

shown

be

covered

the

relevant BSI safety,

60F

G.C.

80F

G.C.

100F

G.C.

be

installed

as

stated

known

for

safety. it is therefore important

be

directly

covered

recommended

of a control

could

to

meet the

by

an approved

No.

41.607.04

No.

41.607.32

No.

41.607.33

and

serviced

in

the

Gas

as 'Profile Prima')

connected

by

these

invalidate

installation

in

device

to

the

by

a

Safety

these

writing.

not

BSI

GENERAL

Prima F boilers are fully automatically controlled, wall

mounted.

using a cast iron heat exchanger and are available in

outputs

six

100,000 Btulh).

The boilers which are designed

hot

INDIRECT FULL y PUMPED systems only, which may

be sealed

The boilers can

types of

Standard

for a

fan

powered,

ranging

water

and/or

or

flue system:

horizontal

wall thickness of 100mm {4in) to 510 (20in).

central

open vented.

be

supplied with either of the following

balanced

from

heating

flue

flue

5.86-29.3

to

provide domestic

must

system

appliances,

kW

be

which

(20,000-

is

used

suitable

on

PRIMA 100F MODEL ONLY

1

metre

maximum flue length of 955mm (37in).

Vertical

through a

980mm (38in) measured from the top

of

PRIMA 30F, 40F, 50F, 60F & 80F Models only

2

metre

maximum

Vertical

through a flat roof and terminate

1980mm (78in) measured from the top of boiler case.

of

OPTIONAL EXTRAS

The following are kits available as optional

lnternal Fitment Kit, which is suitable for a maximum

wall thickness of 510mm (20 in.) is

to

access

Pump

designed

valves installed above the boiler.

be fitted above

used).

Terminal

to the outside

after making good around the

the outside wall is impracticable.

Cover

Kits

located

to

conceal the pump, and/or any motorised

the

wan

Plate, where necessary can

wall face to improve the appearance.

boiler

on

if

to

top

(Note:

the

vertical

terminal.

extras:-

be used where

of

the

boiler

Pump cannot

flue

be

and

kit

fitted

is

Terminal

fitted less

above a flat roof

45°

flexibility (Prima

Vertex

flexibility

only).

Full

SEE PAGE

OPTIONS.

2

horizontal

Flue

system

flat roof and terminate at a maximum height

horizontal

flue length

flue

system

Guard,

than

and

90°

Flue

through

fitting instructions are provided with each kit.

10

flue

system

which allows

flue

system

of

1955mm (77in).

which allows

to

be

used

2m

above a balcony, above ground

to

which people have access.

Flue

Bend

Kits,

30F

to 60F only).

Kit,

giving

a roof

FOR PART Nos. OF FLUE KITS AND

space

which

which

at

a maximum height

when

giving greater flueing

greater

(Prima

provides

the

flue

of

boiler case.

provides

the

flue

the

vertical

to

to

terminal

30F

pass

pass

flueing

to

a

a

is

or

60F

Supplied By www.heating spares.co Tel. 0161 620 6677

ACCESSORIES

The following Potterton Myson controls are

recommended

Electronic Programmer EP2001,

Cylinder Thermostat PTT2

Room Thermostat PRT2

for

use with your boiler:-

or

PTI100

or

PRT100

EP300i.

or

EP6000

Frost Thermostat PRT100 FR

INSTALLATION

The installation

with

the

latest

Safety

{Installation and

building regulations, IEE Wiring Regulations and the

Byelaws

of

Detailed recommendations are

following British Standards and Codes of Practice.

BS6798, BS5440 Part1

of

the boiler must be

relevant

requirements

Use)

the

Local Water Undertaking.

in

accordance

of

the

Gas

Regulations, local

contained

in the

BOILER

RETURN

Motorised

Zone Valve MSV222

Motorised Diverter Valve MSV322

Thermostatic Radiator Valve

Data Sheets describing these products are available

on

request.

DATA

BS5440 Part 2 BS5449 Part1

BS5546 BS4814. BS6891.

BUILDING REGULATIONS.

MODEL

BRITISH

GAS

WATER BYELAWS.

GAS

SAFETY

REGULATIONS.

BUILDING STANDARDS (SCOTLAND)

REGULATIONS.

DIMENSIONS

or

MSV228

PUBLICATION DM2.

(INSTALLATION

·so

(60)

AND

USE)

srr

srr

FIG. 1

Boiler

Dimension 'A'

(mm)

Flow/Retum

Connections

'B'

'C'

'D'

30F

350

110

103

87 87

22mm

Copper

These boilers are not suitable for external installation

and should not

appliance. The boiler may

although particular attention is drawn

ments of

the

current

Scotland, the electrical provisions of the Building

Standards applicable in Scotland with respect to

40F

350 350

110

103

22mm

Copper

Copper

50F

110

103

87

22mm

60F

3SO

110

103

107

22mm

Copper

80F

425

150

143

107

28mm

Copper

SITE

be

fitted directly above a cooking

be

installed in any room,

to

the require-

l.E.E.

Wiring Regulations and

100F

425

150

143

107

28mm

Copper

REQUIREMENTS

installation

or

Where a room-sealed appliance is installed in a room

in

the

containing a bath or shower, any electrical switch or

appliance control, utilising mains electricity should

situated that it cannot

bath or shower.

3

600

I

1HE

100

I

BOltER

is

inverted).

*30

(40)

(40)

•NOTE:

IF

PIPEWORK

NORMAL CLEARANCE OF

ANDWALLCANBEINCREASEOT035mmlFDESIREDBYIN\/ERTINGTHE

BOILER MOUNTING

(Dimensions in

IS

TO BE RUN DOWN

25mm

PLATE DURING INSTAUATlON

brackets

apply

of

the appliance in a room containing a bath

THE

BACK OF

BElWEEN THE REAR OF THE BOILER

when the mounting plate

shower.

be

touched

by

a person using the

be

THE

so

Supplied By www.heating spares.co Tel. 0161 620 6677

FLOW

PIPE

RETURN PIPE

CONTROL

THERMOSTAT

PUMP OVER-RUN

THERMOSTAT

THERMOSTAT

CAPILLARY

RETAINING CLIP

~

/

FLUE

ELBOW

FAN

SUPPLY

LEADS

CONNECTOR

FAN

FLUE

HOOD

HEAT

EXCHANGER

OVERHEAT

THERMOSTAT

POCKET

BOILER DRAIN

CAP

ELECTRODE~

PILOT

GAS

COCK

COMBUSTION

CHAMBER

AIR

DEFLECTOR

CHANNEL

MAIN

BURNER

PUMP

OVER-RUN

THERMOSTAT

CONTROL

BOX

GAS

VALVE

CONTROL

FIG. 2 GENERAL

BURNER

TEST

POINT

PRESSURE

ARRANGEMENT

4

\

OVERHEAT

THERMOSTAT

CODE

CONTROL

THERMOSTAT

BADGE

Supplied By www.heating spares.co Tel. 0161 620 6677

Where

location, special

6798 gives detailed guidance

Ensure that the

enough for

the installation of the boiler will

procedures

gas

this

appliance

supply

may

on

pipe

and

be

this aspect.

and

any

run off the same meter. Reference

BS6891

Boiler

The boiler

of

to

local authorities

Mounting

must

combustible

take the

weight

Surface

be

mounted

material and

of

the boiler.

and

on

a flat wall,

must

The

the Building Regulations

be

adhered to.

IMPORTANT

TIMBER

If

the appliance is

it should

Publication

Framed Housing'.

from the local

Clearances

NOTICE:

FRAMED

to

be

fitted in

DM2

'Guide for Gas Installations in

Gas

Around

HOUSES

be

fitted in a timber framed building,

accordance

If

in doubt,

Region

the

advice

of

British Gas.

Boiler

The following minimum clearances

after installation, for correct operation

the boiler:

61

Omm (2 ft) at the front

Smm (0.2 in) each side

of

the boiler

of

the boiler

be

in an unusual

necessary

and

meter are large

others that

should

be

which

may

made

may

sufficiently

requirements

must

with

British Gas

must

be

must

be

maintained

and

servicing

BS

be

to

be

robust

of

the

be

Timber

sought

of

50mm

boiler case),

cover

(2 in)

is

to

at

the

except

be

fitted,

top

(measured from

where

when

the

178mm

optional extra

allowed.

100mm

Additional

installation for lifting

required at the

(4 in) at the

clearances

top

bottom

the

of

of

to

these are required during

boiler

the boiler for

the boiler.

and

connections.

Ventilation

If

the boiler is

a cupboard, the

must

be provided

each

of

TABLE

a compartment are given in

to

be

installed in a confined

space

at

the

which

should have a free area

1. Further details

will

need

top

and

for

installation

BS

ventilating.

bottom

6798.

TABLE 1

PRIMA

30F

40F

50F

60F

80F 43 277

100F

AIR

VENT

2

in

16 103

21

26 170

32 206

54

If the openings draw air from outside

free

areas

may

be

halved. Refer

for further guidance.

the

top

(7 in) should

127mm

access

to

space

Openings

of

the

cupboard

as

shown

of

a boiler within

AREAS

2

cm

135

349

the

building the

to

BS

5440

of

pump

(5

in) is

the

such

Part 2

the

be

pipe

as

in

Balanced Flue Terminal

The fresh air inlet

left, right, rear

the

terminal

on

and

the outside

The minimum spacings from the

and ventilation openings are

mation appertaining

reference should

be

flue

or

top

made

and

Ducting

ducts

can

be

run

from either

of

the

boiler

to

a miniature

of

the building.

terminal

shown

to

horizontal flue lengths

to

FIG.

to

obstructions

in FIG. 3. For infor-

4.

INFORMATION RELATING

PROVIDED

CAL

NOTE

Where a flue terminal is fitted less than 1000mm from a

plastic

an

underside of gutter

Any

If a terminal is fitted less than 2m above a balcony,

ground

then a suitable terminal

or

above a flat roof

to

which

guard

people

should

be

have

fitted.

above

access

(P.l.L

a roof

and

suspect and further

No. 205792).

Ref

er

to BS5440 Part 1

Under

Carport.

FIG. 3

THE

for

further

--~-~~-~~-·---!"--.+-

SITING

FLUE

TERMINALS

guidance.

'fo

1--"-o..£.

L~

OF

BALANCED

/

!G

POSITION MINIMUM DISTANCE

A. DIRECTLY BELOW

B.

C. BELOW EAVES

0. BELOW A

E FROM VERTICAL DRAIN PIPES ANO

/

F.

G.

H.

I.

J.

K.

L HORIZONTALLY FROM A TERMINAL ON

M.

5

TO

VERTICAL FLUING IS

IN

THE PACK CONTAINING THE VERTI-

FLUE SYSTEM.

or

painted gutter

aluminium shield

car

port

or

other

or

a roof

and

two

other walls - the installation shall

WINDOW,

VENTILATION OPENING.

BELOW

SOIL

FROM

ABOVE ADJACENT GROUND OR BALCONY

LEVEL

FROM A SURFACE FACING THE TERMINAL

FACING TERMINALS

FROM

CARPORT INTO DWELLING

VERTICALLY FROM A TERMINAL

THE SAME

THE SAME WALL

ADJACENT

AIR VENT,

GUTIER.

BALCONY

PIPES

INiERNAL

OPENING

WALL

TO

OPENING

or

500mm from painted eaves,

of

1000mm length

or

eaves.

add-on

one

advice

AN

OR

DRAIN/SOIL

OR

OR

(DOOR/WINDOW)

extension should consist

other wall. If it consists

sought.

OPENABlE

ANY

OlHER

PIPE

CAR PORT ROOF

EXlERNAL

CORNERS

IN

ON

should

be

be

fitted

of

a roof

treated

1.200

1.200

1.500

to

of

as

300

25

25

25

75

25

300

600

300

150

Supplied By www.heating spares.co Tel. 0161 620 6677

REAR OR SIDE FLUEING

MAXIMUM

LENGTH'X'

=

FIG. 4 FLUE LENGTHS

ELECTRICITY

A 240

fused

with

and

voHs-

to

the

any

current rating

3 amperes and have a cross sectional area

0.75mm2

The

supply to the boiler and its associated equipment

SUPPLY

50Hz, single

3 amperes, must

latest edition

other

local regulations

of

the wiring to the boiler must exceed

in

accordance with BS 6500. Table 16.

of

the

phase

be

provided

1.E.E.

electricity

in

Wiring Regulations

that

may apply.

accordance

of

at

supply

The

least

STANDARD

SYSTEM

1

METRE

SYSTEM

100F

2METRE

SYSTEM

30f.

MODELS

should be controlled

pole switch {having

in

both

poles)

supply

can

be achieved

RULE

MODEL

FLUE

40F.

50F'

ONLY

so

that

FLUE

by

at

be carried out in safety.

GAS

SUPPLY

A

gas

supply pressure

inlet

to

the appliance. Performance

·use of reference

gas

ONLY

60F & 80F

an

least

complete

to

of

G20.

1955mm

exclusive

3mm

contact separation

isolatron

enable

20

mbar

s1omm

(2Qin)

955mm

(37in)

(nin)

3A

fused

from

servicing

work

is required at

data

is based

double

the

to

the

on

Maximum working head

Minimum working head

Gas supply pressure

Maximum flow temperature

Electricity supply

Internal Fuse

Power Consumption

Gas supply connection

Appliance lift weight (min)

Appliance weight

installed

Water content

Row/Return connections

TECHNICAL DATA

30.Sm (100ft)

150mm.(6in}

20mbar

82°C

240v-50Hz fused at 3A

TypeT1A

80

Watts (excluding pump)

Re. 1h (%in BSP female)

30F, 40F, 50F & 60F Models

26.0kg

37.1

2.0 litre (0.44 gal)

(57.31bs)

kg

(81.81bs)

22m copper

80F & 100F Models

33.Skg

46.4kg

(73.871bs)

(102.31bs)

2.4 litre (0.53 gal}

28mm

copper

6

Supplied By www.heating spares.co Tel. 0161 620 6677

I

I

BOILER

SIZE

INJECTOR

SIZE

GAS RATE

m%

(ft%)

INPUT

kW(Btu/h)

OUTPUT

kW(Btu/h)

BURNER

mbar

PRESSURE

iowg

i

l

30

l

40

150

100

60

80

Min

Max

Min

Max

Min

Max

Min

Max

Min

Max

Min

Max

2.9mm 0.87(30.61) 9.29(31686)

3.1mm

3.5mm

3.6mm 1.89(66.84) 20.28(69182)

4.4mm

4.7mm 3.10(109.38)

0.71

(25.23) 7.65(26116)

1.03(36.23) 10.99(37500)

1.06(37.40)

1.21

(42.86)

1.37(48.31)

1.39(49.11)

1.54(54.35)

1.71

(60.39) 18.32(62500)

1.73(61.07)

2.05(72.46) 21.98(75000)

2.13(75.19) 22.81(77821) 17.58(60000)

2.43(85.94)

2.74(96.62)

2.78(98.09) 29.75(101523) 23.45(80000)

3.42(120.77) 36.64(125000)

11.35(38710)

13.00(44360)

14.65(50000)

14.90(50826}

16.49(56250)

18.53(63211) 14.65(50000)

26.07(88945) 20.52(70000) 8.7

29.31(100000) 23.45(80000)

33.18(113208) 26.37(90000) 9.9 4.0

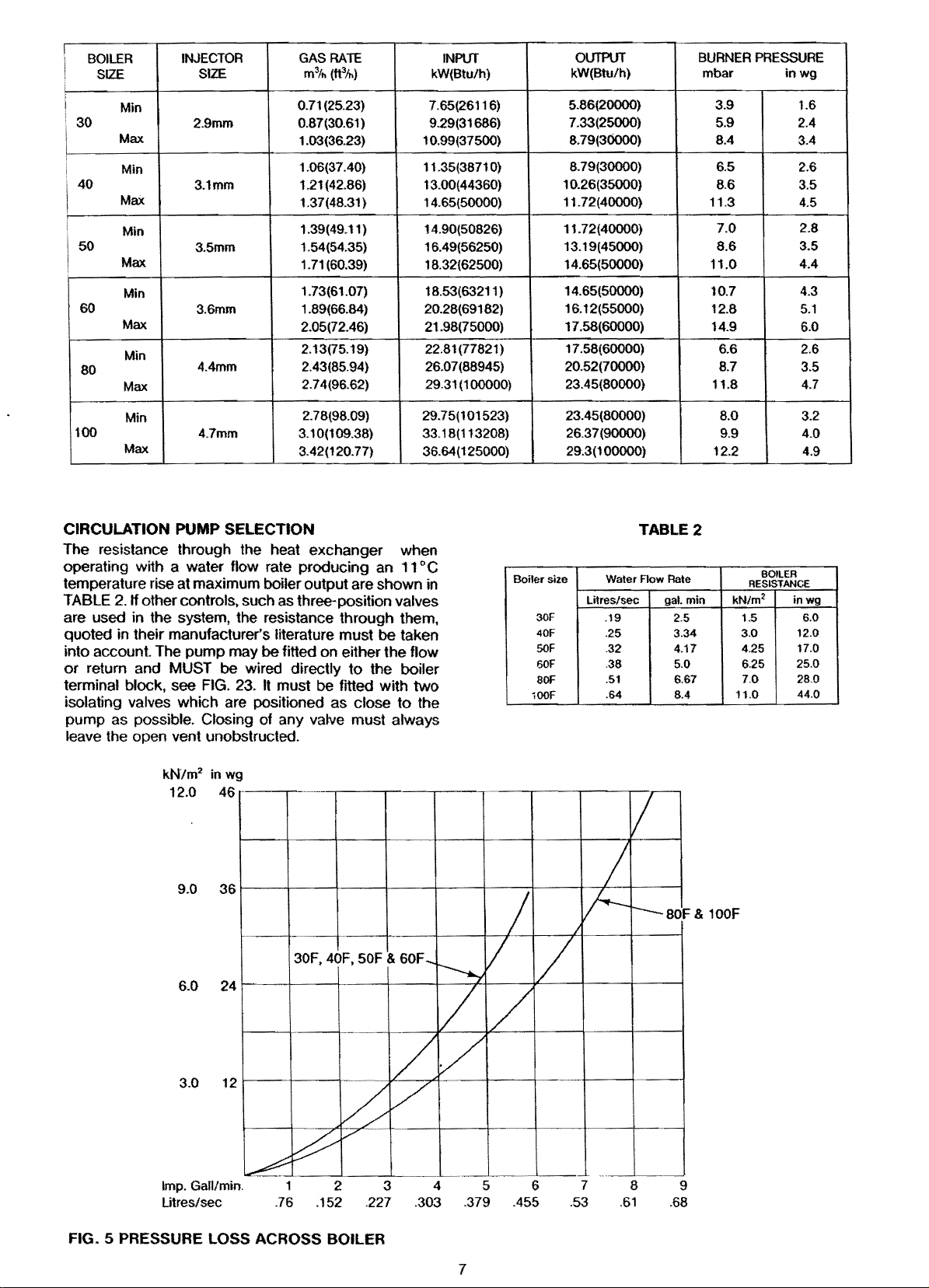

CIRCULATION PUMP SELECTION

The resistance through the heat exchanger when

operating with a water flow rate producing

temperature rise at maximum

TABLE

2.

If other controls, such as three-position valves

boiler output are shown in

an

11

° C

are used in the system, the resistance through them,

quoted in their manufacturer's literature must be taken

into account. The pump may be fitted on either the

or

return and MUST be wired directly

terminal block,

isolating

pump as

see

FIG.

23. It must be fitted with two

valves which are positioned as close

possible. Closing of any valve must always

to

flow

the boiler

to

the

leave the open vent unobstructed.

5.86(20000)

.33(25000)

7

8.

79(30000) 8.4

8.79(30000)

10.26(35000)

11.72(40000)

11.72(40000)

13.19(45000)

14.65(50000)

16.12(55000)

17.58(60000)

29.3(100000)

TABLE2

Boiler size Water Flow

Litres/sec

30F

40F

50F

60F

80F

iOOF

.19

.25

.32 4.17 4.25

.36 5.0 6.25

.51 6.67

.64

3.9

5.9 2.4

6.5

8.6

11.3

7.0

8.6

11.0

10.7

12.8

14.9

6.6 2.6

11.8 4.7

8.0

12.2 4.9

Rate

gal.min

2.5 1.5

3.34

6.4

BOILER

RESISTANCE

2

kN/m

3.0

7.0

11.0

1.6

3.4

2.6

3.5

4.5

2.8

3.5

4.4

4.3

5.1

6.0

3.5

3.2

inwg

6.0

12.0

17.0

25.0

28.0

44.0

kN/m2 in wg

12.0

Imp. Gall/min.

Litres/sec

46

·---r--··~·~--~·-~--~·~-~--~-~-r~

1 2 3 4 5 6

.76 .152 .227 .303 .379 .455

.53

BOF

& 100F

7

.61

8

9

.68

FIG. 5 PRESSURE LOSS ACROSS BOILER

7

Supplied By www.heating spares.co Tel. 0161 620 6677

The System

The

boiler

must

be

used

on

INDIRECT FULLY PUMPED

systems

The

static

minimum

On

tenninal block, it will

over-run thermostat.

continue

temperature b !1igh,

of

It is

valves are

when

with

heating

with a

within

If a three port divertervalve

a

open.

Where a

necessary. The total length

from

metres

lockshield

flow

FIGS

Systems fitted with

· operate

circuits are closed i.e.

static control valves,

capable of:-

1. Dissipating a

2.

A suggested

using a bathroom radiator fitted

valves

Additional system information

Control Systems, Pipework

Drain off

the

only,

which

system

head

should

does

of 150mm (6in).

all

systems

the

overheat thermostat.

important

the

controls

circuits

by-pass

the

by-pass

the

through

6.

7.

Maintaining a

boiler

is

boiler

the

to

run after

that

used

the

zone valves are closed. Also, systems

that

while

circuit

boiler.

is

not necessary since

pair

of

two

boiler

connections

of

22mm pipe. It

valve and

the

when

both

minimum

of

9 litres/min (2 gal/min).

method

shown

taps

and

in

should

in

may

be

designed

not

exceed

pump

then

This

boiler

thus

preventing nuisance operation

where

boiler

close

the

to

dissipate

port

be

adjusted

boiler

of

controls

the

mechanically

must

minimum

of

meeting

FIGS. 6, 7.

be

the

low

be

sealed

See

FIG 6.

should

be

will

ensure

electrically operated

is

wired

both

boiler

is

used

valves are used, a

of

the

should

should

4.5

litres/min

which

hot

water

be

fitted

of 1 kW

water

and

fitted

points

NOTE

Although

taps

empty

cap

the

system

installed

the

boiler

positioned

in

the

it

within

can

be

pipework

is

necessary

the

emptied

boiler

or

open

vented.

so

that

the

maximum

30.5m (100ft) and a

be

wired

to

the

controlled

shut

hot

is

still hot,

the

as

one

by-pass

to

with a by-pass

these

can

Wiring Guide.

in

the

of

around

to

case. See FIG. 2.

by

the

that

the

pump

down

if

the

so

it

does

not

water

and

must

residual heat

shown

be

maintain a

allow

and

(3400 Btu/h).

with

the

remove

in

FIGS. 6, 7

circuit

be

operated

flow

be

pipework

using

is

by-pass

circuit

greater

fitted with a

minimum

(1

gal/min)

the

central

through

requirements

two

lockshield

found

system.

the

the

system,

the

central.

be

always

than

boiler

heating

thermo-

close

drain

drain

boiler

pump

will

water

zone

cycle

fitted

fitted

from

taken

see

circuit

the

by

in

the

is

4

to

to

off

to

off

SEALED SYSTEMS

Installation

The installation

BS 6798 1987

"British Gas Specification

Heating

Systems"

must

and

comply

BS

5449

should

with the requirements

Part

1.

The B.G.

for

also

Domestic

be

consulted.

Wet

publication

Central

Safety Valve

A non-adjustable spring-loaded safety valve, preset

operate at 3

with

BS

It shall

or

vertically

valves are

valve. The valve

which

such

components

bar

(451bf/in

6759 Part 1 and

be

positioned

upwards

to

be

placed

should

permits

that

no

the

hazard

is

caused.

in

and

safe

to

2

shall

be

)

include

the

between

be

discharge

persons

a manual

flow

close

to

the

installed

used.

It

must

testing

pipe

either

honzontally

the

boiler.

No

boiler

and

into a discharge

of steam

or

damage

and

to

comply

device.

shut-off

the

safety

pipe

hot

water

electrical

Pressure Gauge

A pressure gauge incorporating a fi II

the

covering

system. It

the

same

at

should

be

range 0-4

should

point

visible from

bar

be

connected

as

the

the

(601bf

expansion vessel. Its location

filling point.

pressure

2

)

/in

shall

be

to

the

system, preferably

indicator,

fitted

to

Expansion Vessel

A diaphragm

shall

be

connecting

nominal). Pipework connecting

should

supporting

The nitrogen

vessel shall

of

the

vessel). To size

to

calculate

The

following

guide

to

Boiler Heat Exchanger: 6.5 litres

Small Bore Pipework: 1 litre

Micro

Bore Pipework:

Steel Panel Radiators:

Low Water Capacity Radiators:

Hot

water Cylinder:

type

expansion vessel

fitted

close

to

the

inlet side

pipework

not

incoporate valves of any sort.

the

or

not

top

point

the

volumes

calculating

should

vessel are supplied

air

charge

be

less

of

the

the

expansion vessel it

volume

the

not

pressure

than

the

hydrostatic

system above

of

water in

may

be

system volume.

be

less

the

by

the

used

system

7 litres

8 litres

system

2 litres

system

2 litres

to

BS4814 Part 1

of

the

pump.

than

15mm (%in

expansion

Methods

the

manufacturer.

of

the

expansion

head

the

expansion

is

first necessary

system

as

a conservative

per

kW

output

per

kW

output

per

kW

output

vessel

(height

in litres.

of

of

of

of

to

the

The

of

8

Supplied By www.heating spares.co Tel. 0161 620 6677

If the system is extended, the expansion vessel volume

may have to

been made for the extension. Where a vessel

calculated size is not

size should

boiler flow temperature is controlled at approx-

The

imately

The vessel size can now be determined from the follow-

ing table where V=System volume in litres.

Vessel Charge Pressure(bar)

Initial System Pressure (bar)

Expansion Vessel Volum.e (litres)

be increased unless previous provision has

available, the next available larger

be used.

82°C.

0.5

1.0

v x 0.11 v

of

the

1.0

1.0

x0.087

Cylinder

The hot water cylinder must be

cylinder fitted with an immersion calorifier suitable

direct

for operating at a gauge pressure

excess of safety

cylinders are not suitable for sealed systems.

valve setting. Single feed indirect

an

indirect coil type

of

0.3

bar

(51bf/in

or

2

)

a

in

Method

Provision shall be made for replacing water loss from the

system

i)

ii) where access to a make-up vessel would be difficult

Mains

There shall be

or

water even through a non-return

approval

of

Make-Up

either.from a make-up vessel

higher than the

ted through a non-return valve to

return side

all heat emitters.

or

by

using the mains

automatic pressurisation and make-up unit as

trated in FIG. 7 METHODS 1 and

top

of

hot water cylinder

or

tank mounted in a position

point

of

the system, and connec-

the

system

or

the return side

top

up

method

2.

or

a remote

on

Connection

no

connection to

to

the water storage tank which supplies domestic

of

the local Water Authority.

the

mains water supply

valve, without the

the

of

illus-

Filling Point

The system shall be fitted with a filling point at low level

which incorporates a stop

check valve (approved

be fitted in this order from the system mains, Refer to

FIG. 7. Method 1.

valve

to

BS 101 O and a double

by

the National Water Council) to

WATER

LEVEL

l--

TOP

OF

CASING

BOILER

I

BY-PASS

BALANCING

OPTIONAL

ZONE

OPTIONAL

3

PORT

·~---~--------<

I

VALVE

t

'

X-r

X-L

I

I

I

______

VALVES

~

~r

VALVE

~LJ

--.,

I

_j

ALTERNATIVE

ARRANGEMENT

BATHROOM

FITTED

VALVES

WITH

RADIATOR

XVENT

1 1

.-1...

1---1

..J

BY-PASS

USING

TWO

LOCKSHEILD

.---..

>--

t....

-

.J

THE

~

------------{.:>

FIG.

6 OPEN VENTED

Flrreo

WITH A COMBINED FEED AND VENT

FULLY

PUMPED SYSTEM

9

Supplied By www.heating spares.co Tel. 0161 620 6677

SAFETY

VALVE

A EXPANSION

u VESSEL

BOILER

PRESSURE

GAUGE

T---.

~

BY.PASS \

8AlANCINGVALVE

FILLING POINT

-----

OPTIONAL

ZONE VALVES

OPTIONAL~'

3PORTVALVE

~-~------~

' '

I I

X-L-

><VENT

~

~

~L

- J

,_,

L-J

<--J

·~\~~~---J.--~~

\

ALTERNATIVE BY-"ASS

ARRANGEMENT USING THE

BATHROOM RADIATOR

FITTED WITH

VALVES

CYLINDER

.__

·----c---------

TWO lOCKSHIELD

Y-KEUP

I VESSEL

I

I

I

I

--t>

Two methods

METHOD 1

MAINS TOPPING-UP

METHOD

NOTE:

This

system

to

the

method

may

only

Local

be

Water

Undertaking

HEATING

SYSTEM

'-='---+<lf-r-1KJ--------C><l-

of

filltng a

used

DOUBLE

CHECK

sealed

if

acceptable

VALVE

MAINS

WATER

SUPPLY

RV

ICE

!SE

VALVE HOSE

PIPE l

HOS(UNION

STOP TEMPORARY

FIG 7. FULLY PUMPED SEALED SYSTEM

FLUE KITS AND OPTIONS (See Page 2)

30F

Standard

1 metre

Flue

Flue

System

System

225540 225540 225540

NIA

2 metre Aue System 225543

Vertical

Flue

System 225157

40F

N/A

225543

225158 225159

of

filling a sealed

water system

j

SOF

NIA

225543

60F

225541

NIA

225544

225160

METHOD2

CISTERN FILLING METHOD

NOTE:

Cistern

to

be

temporary

pipe

or

cold

STOP VALVE

225541

225544

225161

connection

water

BOF

NIA

supplied

from

distributing

\

PRESSURE

REDUCING

llF

AEOVIREO)

100F

225542

225545

NIA

225162

a service

through

a

pipe

OVERFLOW]

CISTERN

;-

-t:><J--

PUMP

VALVE

STRAIGHT

FLUE

KITS

I

MAINS

WATER

SUPPLY

90"

Flue

Bend

45°

Flue

Flue

Elbow

(For

use with

Vertical

(For

use

1 metre

metre

2

Vertex

Flue

Vertex

Flue

Terminal

Terminal

Internal

Pump

Cover

Pump

Cover

Pump

Cover

Pump

Cover

Kit

Bend

Kit

Kit

Flue

Bends)

Flue

Terminal

with

Flue

Flue

System 225545

Flue

System 225544

Kit

Bends)

Kit

1 metre extension

Wall

Plate 212306

Guard 205792

Fitment

Kit

Kit

(Gin)

Kit

(7in

12in)

Kit

(13in

-18in) 225424

Kit

(19in -24in)

225600

225601

225602 225603

225606

225700

kit

84265

225183 225183

225422

225423

225425

225600

225600

225601 225601

225604

225607

225608

225545 225545

225544 225544

225701

84265

212306

225702

B4265

212306

205792 205792

225183

225422 225422

225423

225424

225423

225424

225425 225425

225600

225601

225605

225609

225545

225544

225703

84265

212280 212280

205792

225184

225422 225418

225423

225424

225425

10

NIA

NIA

NIA

NIA

NIA

NIA

NIA

NIA

205792

225184

225419

225420

225421

NIA

NIA

NIA

NIA

NIA

NIA

NIA

NIA

212280

205792

225184

225418

225419

225420

225421

FLUE

BEND

KITS

J_

VERTEX

FLUE KITS

OTHER

KITS

J_

Supplied By www.heating spares.co Tel. 0161 620 6677

INSTALLATION INSTRUCTIONS

It is the law that all gas appliances are installed and

serviced

Safety {Installation and Use) Regulations 1984.

For Health and Safety information see back page.

Electrical

competent

Wiring Regulations.

The boiler and its associated equipment will arrive

site in two cardboard cartons. The contents of each

carton is as follows.

CARTON 1

Boiler

Template

Literature Pack Containing:-

lnstallation and Servicing Instructions

User's Instructions

Control Systems Pipework and Wiring Guide

Auxiliary Pack Containing:-

Boiler Mounting Bracket

Gas

by

competent

testwork

person

:-

Boiler

Service Cock and Accessory Packs

SIDE

OF

REFERENCE

BOILER

persons

should

in

accordance

Pack

MARK

as stated in

be

carried

with

TOP

BOILER

out

the

OF

Gas

by

LE.E.

on

a

CARTON

Horizontal Flue Packs

Air/Flue Duct Assembly (length as ordered)

Flue Elbow Extension

Flue Terminal

Flue Sealing Collar

Rope Sealing Ring

Side Infill Panels-2 off

Vertical

Air/Flue Duct Assembly

Flue Terminal

Terminal

Vertical Flue

Accessory

Side Infill Panels-2

Flue

2:-

Flue

System

Flue Pack (2 cartons)

Cowl

Adaptor

Pack

Installation Instructions

Pack

off

HOLE WALL

FOR

'-....

A

D

0 '

FOLD

LINE

FOR

LH

FLUE

OUTLET

FIG.

8 TEMPLATE

Place template in proposed boiler position ensuring n

level (the minimum side clearances are automatically

allowed

REAR

Mark holes

boiler reference lines throught slots

SIDE FLUING

Mark hole positions 'A', 'D' and side

lines through

Mark large flue outlet hole and holes 'B' using the

thick lines on the template for minimum

the rear of

maximum

NOTE - Prima 30F, 40F

If

size

centrally

marking around the outside of the collar.

for)

FLUING

'A',

slots 'C'.

the

clearance. See note on Fig. 1.

a flue bend kit

is

obtained

over the marked flue outlet position, and

BOTTOM

'B', 'D', large flue outlet hole and side of

boiler and the

is

to be used. the correct flue hole

by

placing the

and

OF

50F

BOILER

thin

TEMPLATE

·c·.

of

boiler reference

clearance at

dotted lines for

only

wall

sealing collar

1s

SIDE

REF.MARK

SCREWS

FIG.

Remove template and carefully cut flue outlet

through wall. It necessary make good around hole to

enable holes 'B' to be drilled. (If internal flue fitment kit is

being used refer to instructions supplied with kit).

Drill holes 'A' using a 7 mm drill

Drill holes

Using wall plugs,

A)

level and the correct way up,

at

using the

Insert wall plugs into holes 'B' (accessory pack

hole 'D' (accessory pack

Insert flue sealing collar into wall and secure with screws

provided, (accessory pack

wall surface around flue sealing collar.

11

PLUG

FLUE

OUTLET

0

()

OF

BOILER

9 BOILER MOUNTING PLATE

attach boiler mounting plate to wall. Ensure that it

the rear of the boiler allowed for when marking out

-----

r;:::;.===~rT.e~---TOP

- - - -

C)

CUPWASHER

'B' and 'D' using a 5 mm drill

screws and washers {accessory pack

template. See also NOTE on

--

-a

.

L

-

0

i.e.

D).

B).

-~FIXING

REAR

"

to provide the clearance

Make good the internal

SEALING

COLLAR

FOR MIN.

CLEARANCE

FIG.

1.

SCREWS

hole

B)

and

is

Supplied By www.heating spares.co Tel. 0161 620 6677

FIG. 1

Oa

SIDE

i---

FLUE

·x·

-··~..;

I

CUTTING AIR/FLUE DUCTS

AG.

10b

REAR

FLUE

1. Measure from outside face

casing reference

2.

Take

air /flue duct assembly and measuring from the

flanged end, mark and cut the outer

flue duct to dimension 'x' plus 20mm. Ensure that

both ducts are cut squarely.

30F

to50F

FIG.

11

AIR/FLUE

line (dimension 'x').

TERMINAL

DUCT

of

wall to the side

INNER

DUCT

ASSEMBLY

duct

FLUE

of

and inner

boiler

1. Measure wall thickness (dimension 'Y').

2.

Take

air/flue duct assembly and measuring from

flanged end, mark and cut the outer air

flue duct to dimension

both ducts are cut squarely.

'Y', plus

duct

and inner

45

mm. Ensure that

NOTE

Cutting length remains the same for minimum or

maximum clearance at

AIR

DUCT

the rear of the boiler.

ROPE

SEALING

RINI'";

the

1.

Slide rope sealing ring on to air duct.

2.

Engage the terminal on

to

the ends

flue duct and press fully home.

FIG.

12

SECTIONAL

DUCT

ASSY THROUGH WALL

VIEW

OF

AIR/FLUE

of

the inner

3.

Engage four screws from accessory pack

the

pre-drilled holes in the terminal and screw fully

·c·

into

home.

These screws which are self drilling will pierce the

air duct and secure the terminal to air duct.

On models 30F

pilot holes in the air

4. Protect duct where it is likely to come into contact

with

mortar

(accessory pack E).

5.

Insert the assembly into

sealing ring along the air duct into the tlue sealing

collar.

Bend

inwards to retain the rope sealing ring. Ensure air

duct flange studs

onto mounting bracket.

to

50F, it is necessary to drill four

duct

by

using

the

adhesive

the

wall

six

tabs

on

flue

do

not obstruct lifting

tape

sliding the rope

sealing

provided

collar

of

boiler

12

Supplied By www.heating spares.co Tel. 0161 620 6677

FAN

FLUE OUTLET

SEALING

CONNECTOR

PLATE

DOOR

FIG.

13

PREPARING

COMBUSTION

CHAMBER FRONT

PANEL

THE

BOILER

BOILER

ASSEMBLY

MAIN

SECURING SCREW

ACCESS DOOR

The controls cover should have been removed

unpacking

opening the

underside

the

boiler,

door

of

controls cover, see

if

not remove controls cover

covering

the

securing screw

FIG

13.

when

on

the

by

Undo securing screw, pull controls cover forward 10 mm,

lower to release from four side fixings and

clear

of

thermostat knob.

Remove the

door

lift

Disconnect

Remove

remove

door

off

the

the

thumb

elbow

by

undoing

two

upper

two

flexible tubes from

the

lower fixing screws and

hinge brackets.

screw securing the flue

by

sliding forward

to

disengage

pull forward

the

flue elbow.

elbow

it

and

from its

rear retaining flange.

NOTE

The boiler

sealing plate removed.

required, remove

and transfer

is

supplied with the left hand flue outlet

If

another flue outlet direction

the

appropriate flue outlet sealing plate

it

to

the left hand position.

is

The boiler may now

if desired

the

by removing the fan/fluehood assembly also

be

lifted onto

its

appliance lift weight can

mounting bracket

be

further reduced

the

gas control assembly as follows.

1. Removing fan/fluehood assembly.

Disconnect

connector

the

fan

adjacent

supply

to

the

and earth leads from the

fan. Remove

the

two

nutssecuringthefluehoodtotheheatexchanger.Uft

out

fanlfluehood assembly.

2.

Removing burner/gas control assembly.

Remove

chamber

electrical

the

screws securing

the

combustion

front panel and remove panel. Unplug the

supply

leads

for

the

gas control valve from

the control box.

Remove

its

the

support

screw securing

bracket

the

gas

control valve

Disconnect electrode lead from electrode.

Remove

the

gas

two

screws securing

bottom

of

the boiler case and lift

control assembly.

the

burner assembly

out

the

or

burner/

wing

to

to

burner/

13

Supplied By www.heating spares.co Tel. 0161 620 6677

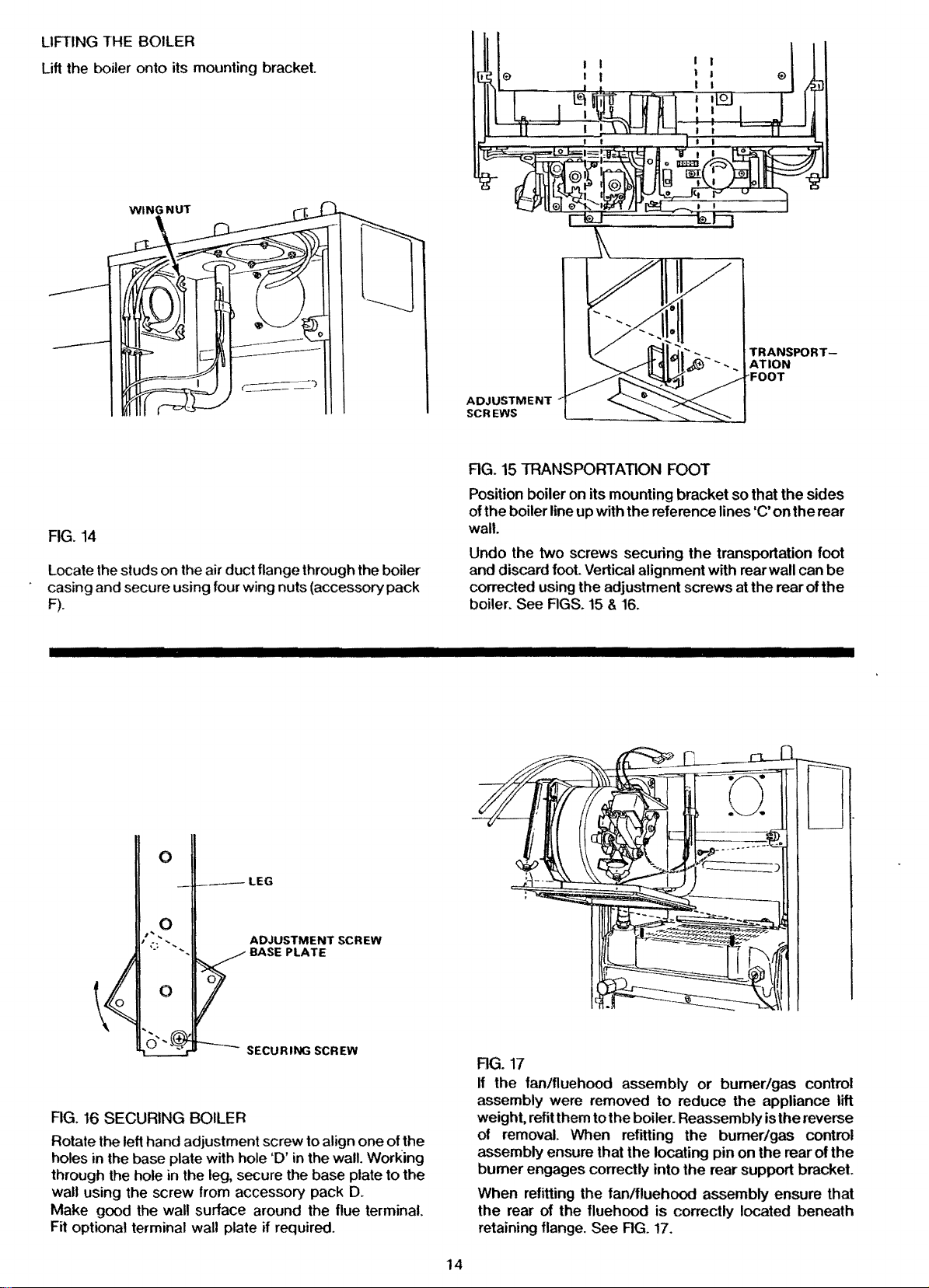

LIFTING THE BOILER

Lift the boiler

onto

its mounting

bracket

ADJUSTMENT

SCREWS

FIG.

14

Locate the studs on the air duct flange through the boiler

casing and secure using four wing nuts (accessory pack

F).

0

-LEG

AG.15

Position boiler on

of

wall.

Undo

and discard foot. Vertical alignment with rear

corrected using the adjustment screws at

boiler. See FIGS.

TRANSPORTATION FOOT

its

mounting bracket

the boiler line

the two screws securing

up

with

15 & 16.

the

so

reference lines

the

transportation foot

that

·c·

the

the

sides

on

the

wall can

rear

of

D

rear

be

the

ADJUSTMENT

BASE

PLATE

SECURING SCREW

SCREW

FIG.

If

the

assembly were removed

AG. 16 SECURING BOILER

Rotate the left hand adjustment screw to align one

holes in the base plate with hole 'D' in the

through the hole in the

wall using the screw from accessory pack D.

Make good the wall surface around the flue terminal.

Fit optional terminal

leg, secure the base plate

wall plate

if

required.

wall. Working

of

to

the

the

weight. refit them

of removal. When refitting

assembly ensure that

burner engages correctly into

When refitting the fan/fluehood assembly ensure that

the

retaining

14

17

fan/fluehood assembly

to

the

boiler. Reassembly is

the

rear

of

the fluehood

flange. See

FIG.

or

burner/gas control

to

reduce

the

locating

the

is

correctly located beneath

17.

the

appliance lift

the

reverse

burner/gas control

pin

on

the

rear of

rear support

bracket

the

Supplied By www.heating spares.co Tel. 0161 620 6677

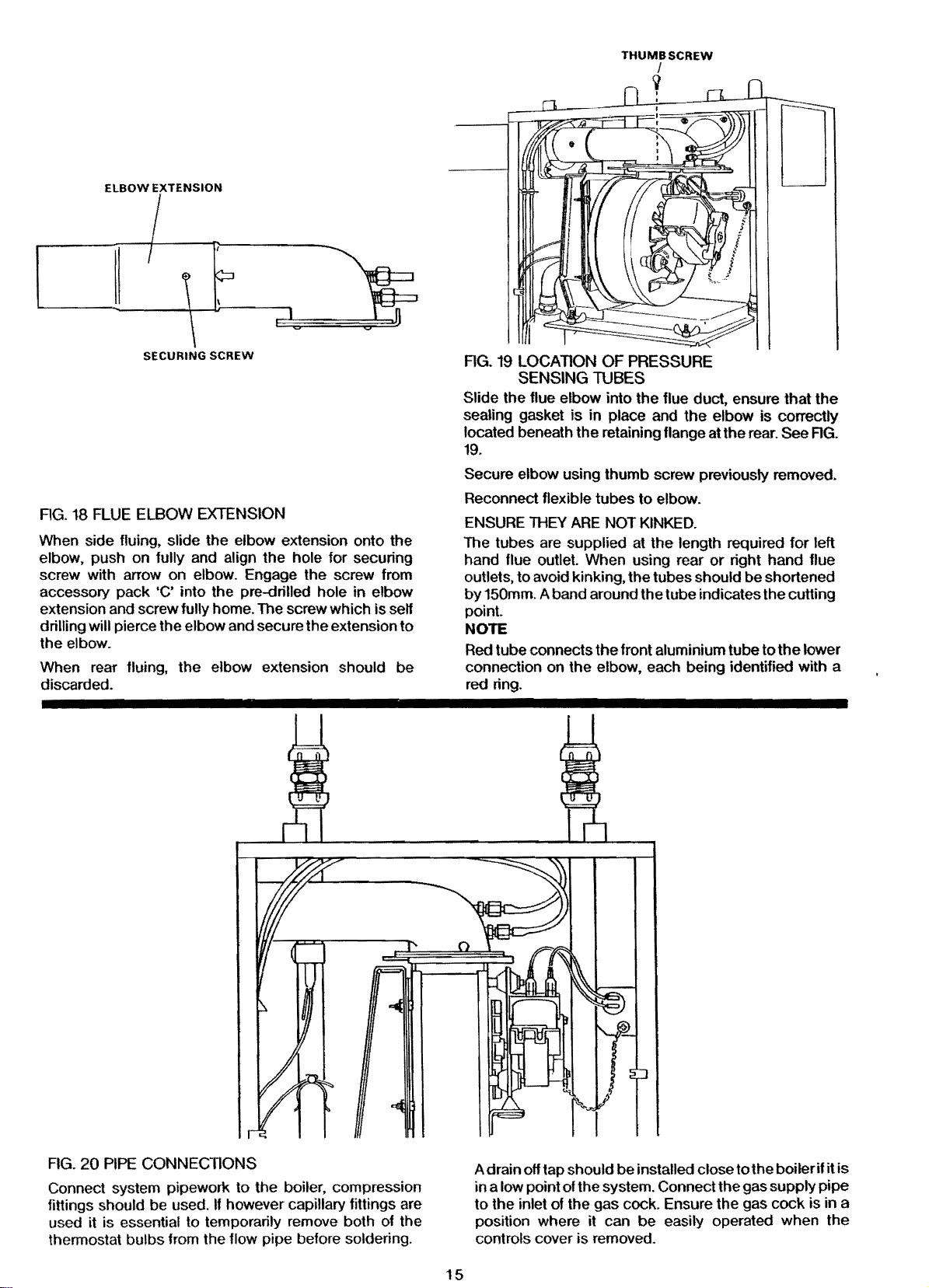

ELBOW EXTENSION

SECURING

AG.

18

FLUE

ELBOW

When side fluing, slide the elbow extension onto the

elbow, push on

screw with arrow on

accessory pack

extension and screw

drilling will

the elbow.

When rear

discarded.

fully and align the hole for securing

'C' into the pre-drilled hole

pierce the elbow and secure the extension

fluing, the elbow extension should be

SCREW

EXTENSION

elbow. Engage the screw from

in

elbow

fully home. The screw which is self

to

AG.

19

LOCATION

SENSING

Slide the flue elbow into the flue duct. ensure that the

sealing gasket is in place and the elbow is correctly

located beneath the retaining flange at the rear. See

OF

PRESSURE

TUBES

FIG.

19.

Secure elbow using thumb screw previously removed.

Reconnect flexible tubes to elbow.

ENSURE

The tubes are supplied at

hand flue outlet. When using rear

outlets,

by

point

NOTE

Red

connection on the elbow, each being identified with a

red ring.

THEY

ARE

NOT

KINKED.

the

length required for left

or

right hand flue

to avoid kinking, the tubes should be shortened

150mm. A band around the tube indicates the cutting

tube connects

the

front aluminium tube to

the

lower

FIG.

20

PIPE

CONNEGllONS

Connect system pipework to the boiler, compression

fittings

used it is essential to temporarily remove both of the

thennostat bulbs from the

should be used. lf however capillary fittings are

flow pipe before soldering.

A drain off tap should be

in a low point of the system. Connect the gas supply pipe

to the inlet of the gas cock. Ensure the gas cock is in a

position where it can

controls cover is removed.

15

installed close to the boiler

be

easily operated when the

if

it

is

Supplied By www.heating spares.co Tel. 0161 620 6677

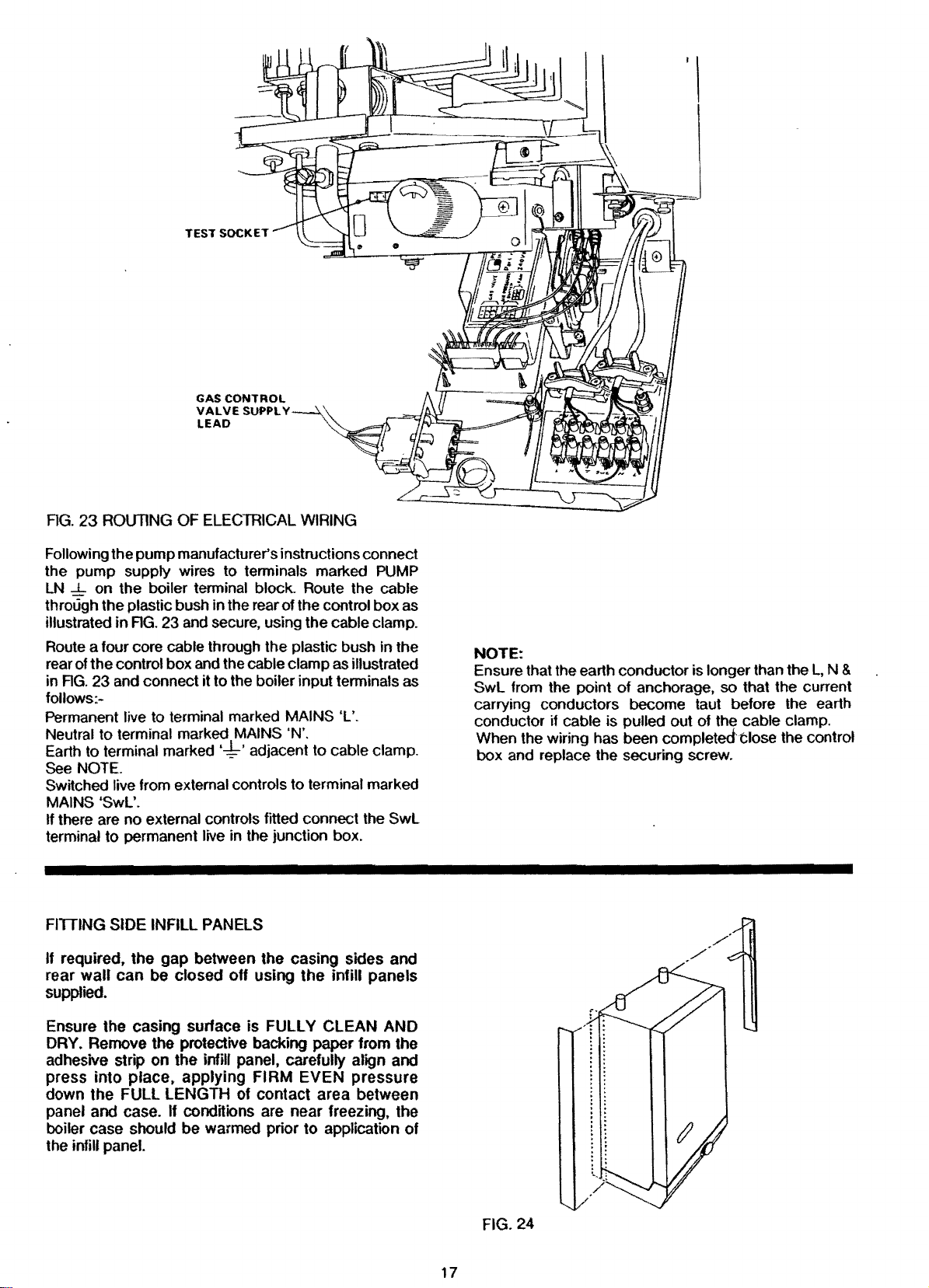

ELECTRICAL

The boiler and all external control circuit wiring must

supplied from the same single isolating switch

and

socket

Care must be taken

is kept clear

and should

of

sharp edges and hot surfaces.

be

fused at 3A.

to

ensure that all wiring to the boiler

or

plug

be

EX1'ERNAL

ELECTRiCTJY

SUf>f'LV

EXTlRPiAl 3 Con

~~~~00

FIG.

21

PROGRAMMER

S

to3Cott

CONlAOL

VAlVES

ETC.

PRINCIPLE

JUCTION BOX

OF

WIRING

ROOMANS)/OR

CYllNt>ER

'THERMOSTAT

BOtU:R

SECU::HNG

SCREW

AG. 22 ACCESS

TERMINAL

TO

THE

BLOCK

BOILER

ELECTRICAL

The boiler tenninal

block

which

is

situated

in

the control

box is not designed to accept wiring from all the on site

controls and therefore

the

installer will usually need

to

incorporate a suitable junction box. This may not be

required

this incorporates a junction

shown in AG.

if a Potterton Electronic Programmer is used as

box. The principle of wiring is

21.

Further infonnation on wiring of system controls can be

found in the

Remove control

control

Control System, Pipework and Wiring Guide.

box

securing screw and lower the

box

to gain access to

the

boiler tenninal block.

Remove packaging from rear of the control box.

16

Supplied By www.heating spares.co Tel. 0161 620 6677

TEST

SOCKET

GAS CONTROL

VALVE

SUPPL V

LEAD

I I

AG. 23

Following the pump manufacturer's instructions connect

the pump supply wires to

LN

through the plastic bush in the rear of the control box as

illustrated in

Route a four core cable through the plastic bush in the

rear of the

in

follows:Permanent live to terminal marked MAINS 'L'.

Neutral to terminal marked MAINS 'N'.

Earth to terminal marked'-:!:-' adjacent to cable clamp.

See

Switched live from external controls to terminal marked

MAINS

If there are no external controls fitted connect the

terminal

ROUTING

...L.

on the boiler terminal block. Route the cable

control box and the cable clamp as illustrated

AG.

23 and connect it to the boiler input terminals as

OF

ELECTRICAL

terminals marked

AG.

23 and secure, using the cable clamp.

WIRING

NOTE.

'Swl'.

to

permanent live in the junction box.

PUMP

Swl

FITIING SIDE INFILL PANELS

required, the gap between the casing sides and

If

rear

wall can be closed

off

using the infill panels

supplied.

NOTE:

Ensure that the earth conductor is longer than the

Swl

from the point

carrying conductors become taut before the earth

conductor

When the wiring has been completedt:lose the control

box and replace the securing screw.

if

cable is pulled out of the cable clamp.

of

anchorage, so that the current

L,

N &

Ensure the casing surface is

DRY.

Remove the protective backing paper from the

adhesive strip on the

press into

down the

place, applying FIRM EVEN pressure

FULL LENGTH of contact area between

panel and case.

boiler case

should be warmed prior to application of

infill

If conditions

FULLY CLEAN AND

panel, carefully align and

are

near freezing, the

the infill panel.

FIG. 24

17

Supplied By www.heating spares.co Tel. 0161 620 6677

COMMISSIONING

Open

Vented

Remove the pump and flush out the system thoroughly

with

cold

Examine for leaks.

Sealed

NOTE:

The system can

pump

approved

SYSTEM' section Page 8 in these instructions, also

BS

Remove

cold water. Refit the pump.

the pressure gauge registers

Examine for leaks. Raise the pressure until the safety

valve lifts. This should

preset

correct

water gauge to this

All

The whole

should

purged

BS 6891.

Electrical

competent

Wiring Regulations.

Test

Tum boiler thermostat

with a break tank

6798

lift pressure

Systems

pilot unions for gas soundness

Unplug

control box and plug

the boiler thermostat knob, See AG. 23.

on

Tum

Ensure that the time control if fitted is in an

and that the room

fitted are set to high temperatures.

Switch

Gas will

ignition system

Using a leak detection fluid, check pilot unions for

gas soundness.

Tum

off

service cock.

Remove gas control

refit

the

control box. See AG. 23.

Systems

water. Refit the pump. Fill and vent the system.

Systems

be

filled using a sealed system filler

or

by

any other method

by

the

Local Water Authority. Refer

1987.

pump

and flush out the system thoroughly with

RH

and vent the system until

1.5

bar

occur

within ±

of

3 bar. Release water

cold

fill pressure, and set the indicator on the

value.

of

the

gas

installation including the meter

be

inspected and tested for soundness and

in

accordance with the recommendations

testwork

person

the

gas

gas at the gas service cock.

on

the external electricity supply

flow

to

the pilot only.

the external electricity supply and

plug into the socket on the left hand side of

should

in

accordance

to

control valve supply lead from the

it

into the test socket adjacent

and/or

is

de-energised.

valve plug from

be

carried

with

as

the

'O'

position.

cylinder thermostats where

tt

will not

be

th~

test socket and

to

'THE

(21.5 lbf /in2}.

0.3

bar

of

to

attain the

out

by

the

l.E.E.

follows:-

ON

condition,

to

the boiler.

ignited

as

the

to

the

gas

the

of

a

Refit the combustion chamber front panel.

Fit

the

case door into position

hinge brackets and secure it with the lower

screws.

Remove the temporary label

appliance, having ensured compliance

warnings

First

on

the

Ughtlng

label.

by

lifting it onto

from

the

two

front

with

the

top

fixing

of the

the

WARNING: Before lighting the boiler.ensure that the

CASE

DOOR

the sealing strip fitted

seal with the main boiler casing. Before proceeding

light the boiler, check that the external electricity supply

to the

boiler

is

in

the

on

Tum

Ensure that the

are open.

Ensure that the time control, if fitted

and that the room and/or cylinder thermostats, where

fitted are set to high temperatures.

Switch on the external electricity supply

After installation of the appliance, preliminary electrical

system checks must

carried

HAS BEEN CORRECTLY FITTED and that

to

the case

is

switched off and that the boiler thermostat

'O'

position.

the gas service cock.

out

pump

are:-

and radiator isolating valves

be

carried

door

is

forming a tight

is

in an on condition,

to

out

The checks

to

the boiler.

to

be

A Earth Continuity

B.

Short Circuit

C.

Polarity

D.

Resistance

Refer

to

Fault

Tum the boiler thermostat on and

after a period

be

observed through the sight glass in the front cover

the boiler. The time period can vary upwards of

seconds, depending

pipework.

Test for

using leak detection fluid.

Tum

NOTE:

There

switched

gas

the

boiler thermostat

could

on

to

Earth

Finding

of

time the main burner will light, this can

soundness around the boiler components

be

a delay in lighting if

and off and then on again rapidly.

Chart

on

the amount

to

·o·.

FIG.

30

to

a high setting and

of

the

control knob

45

air in the

of

is

SETTING

With the controls cover removed.

Fit a pressure gauge to the pressure test

supply pipe.

Turn

burner

accordance with values stated under TECHNICAL

DATA.

The burner pressure is set to the maximum output at

the factory.

AND

CHECKING

See

FIG.

2.

on the boiler thermostat and ensure that the main

is alight. Check that the burner pressure is

OF

CONTROLS

nipple in burner

in

If

follows, referring

SIT

Remove the plastic

valve

clockwise

decrease the pressure.

HONEYWELL

Turn

increase the pressure

pressure.

18

burner pressure adjustment is necessary

to

AG. 25.

GAS

CONTROL

and

turn the pressure adjustment screw antito

increase

the pressure adjustment screw anti-clockwise

VAL

VE

cap

from beneath the gas control

the

pressure

GAS CONTROL

or

clockwise

VALVE

proceed

or

clockwise

to

decrease the

as

to

to

Supplied By www.heating spares.co Tel. 0161 620 6677

HONEYWELL

PILOT

SCREW

(For test purpose only)

SPACER

I

SEALS

PRESSURE

FIG.

25

MAIN

BURNER

With the burner set

given

rate

obtained

reading

been

replace the plastic

Shut down the boiler remove the pressure gauge and

refit the screw in the test nipple ensuring that a tight seal

is made.

Remove the self-adhesive arrow from the inspection

ticket tied

Data Plate inside the

appropriate burner setting pressure.

Refit the controls cover.

Relight the boiler

Check for water leaks, turn the

system

Refill the system and

correct

to

the system design pressure.

in

TECHNICAL

and

this

at

least 1 O minutes after the main burner has

lit.

When

whilst hot.

cold

the

to

the burner supply pipe and stick it

fill pressure. Set the pressure gauge pointer

ADJUSTMENT

PRESSURE

to

its correct pressure, the firing

should

pressure

cap

and

on

be

on

the

controls cover

heat the system

sealed systems adjust

SCREW

ADJUSTMENT

DATA

SIT

should

checked

and

rate are

gas

control valve.

to

indicate the

to

boiler off, drain the

also

be

by

meter

correct

to

the

maximum.

to

the

PRESSURE

The thermostat has been calibrated

no

attempt should

the thermostat

main burner shuts down.

Pump

Over-Run

Will keep the

down, as

is

above 80°C.

The thennostat

Overheat

The overheat thermostat is pre-set and no adjustment is

possible.

condition occurs. Access to the reset button is through a

hole in the underside of the controls cover, see

long

Thermostat

It will require manually resetting if an overheat

be

made to re-calibrate it

to

the 'O' ·position and

Thermostat

pump

running after

as

the

water temperature within

is

preset and no adjustment

ADJUSTMENT

by

the makers and

on

check

the

boiler has shut

the

is

SCREW

site. Turn

that the

boiler

possible.

FIG. 2.

Other

All boiler mounted controls are designed

fault should occur they will fail safe.

checking is necessary.

Boiler

Controls

so

No

further setting

that

if

any

or

If a by-pass circuit is fitted the by-pass valve should

adjusted with the boiler operating under minimum load

conditions

boiler

operate under

Pilot

The pilot is pre-set and

pilot flame envelope should cover the electrode tip and

spark earthing strip see

illustrated, remove and clean the pilot as described in

the

Page22.

Boiler

At its minimum and maximum settings, the thermostat

should control the water

mately

to

maintain suff1eient water flow through the

to

ensure that the overheat thermostat does not

normal operating conditions.

Burner

no

adjustment

FIG.

29.

If

Servicing Instructions Section

is

required. The

the pilot flame

4,

PILOT BURNER,

Thermostat

flow temperature at approxi·

55°C-82°C

(130°F-180°F).

is

not as

be

External

Check that any other external control connected in the

system, such as

boiler as required.

User's

A User's Instructions leaflet is provided with this boiler

but the householder must have the operation

boiler

householder must also be advised of the importance

annual servicing and of the precautions necessary

prevent damage to the system and building, in the event

of the system remaining out of commission in frost

conditions.

19

Controls

clocks

Instructions

and

system explained

and thermostats, control the

of

the

by

the Installer. The

of

to

Supplied By www.heating spares.co Tel. 0161 620 6677

PERMANENT

LIVE

PUMP

r-----+o+------1

BLACK

l "

B 8

PUMP

.,..___

EJ

SWITCHED

AG.

l!VE

26

FUNCTIONAL

PR

FLOW

OWN

TESl

SOCKET

DIAGRAM

fl

OVERKEAt

THERMOSTAl

BOiLER

THERMOSYAT

WHllE

a-

WHrTE

BLUE

BROWN

EL£C1R0"1JIC

CONlROL

llTlA

1----~----:::..+--:_::

11

12

Sl

S:I

____

13

T•

TS

16

T1

T8

WHITE

BLUE (

1

SLACK

_...

OftANGE IHO•

WP.UTE

9ROWN

____

BLUE

---, y

r

L--(

~~-~-~--I~

iE

GV2

r ---

GVI

'

!NCI

"

~=TROl

VAlVE

AIR

PRESSURE

SWITCH

!Cl

FANN

HONEYWELL

AG.

27

BOILER

WIRING

DIAGRAM.

20

Supplied By www.heating spares.co Tel. 0161 620 6677

SERVICING

Regular skilled servicing and cleaning

of

the

appliance

INSTRUCTIONS

is essential to ensure continued safe and efficient opera-

tion. The frequency

particular installation conditions, and the use to which

the

appliance is put, but in general, once per year

should be adequate.

It is the law that all gas appliances are installed and

serviced

(Installation and

For Health and Safety

Electrical installation and servicing should be carried

out

by

competent persons as stated in Gas Safety

by

a competent person

of

cleaning will depend upon

Use) Regulations 1984.

Information see back page.

in

accordance with the

the

l.E.E. Wiring Regulations.

Servicing is best arranged

Potterton Myson Limited and further

from the

The boiler

attached to the inside

CODE NUMBER

ing spares or requesting information

control box.

All parts likely to require servicing are readily accessible.

By

removing the front door from the

components are exposed. Remove the front of the

combustion chamber to gain access to the main and

pilot burner and the ignition electrode.

Removal of the

the flueways in the heat exchanger for cleaning.

The following notes

but it should be remembered that attention must

local Potterton Regional Service Office.

DATA

PLATE

which should be quoted when order-

See

FIG.

removing the cover from the boiler controls and

flue elbow, fan and fluehood will expose

apply to the boiler and its controls

by

a contract placed with

details are available

and WIRING DIAGRAM are

of

the controls cover. The boiler

is on the front

2.

boiler, most

of

the

also oe

paid to the heating circuit itself including radiator valves,

thermostats. the time control and the expansion

teea water system.

immediately after the end

In all cases prior to servicing, light up the boiler and

check that the

flame and that the gas rate and main burner pressure are

correctly set.

servicing

mation given

WARNING

Before

external electricity

plug at the socket

switch.

NOTE: After completing any servicing or replacement

components check for gas soundness and carry

functional checks.

1.

PREPARING THE BOILER FOR SERVICING

See RG.13.

NOTE:

elbow fitted to the fluehood.

The

flued boilers.

A Remove controls cover

B.

If the pilot flame is satisfactory,

of

the pilot burner

the

start of any servicing work, switch off

Tum

off the gas service cock.

Boilers with side or rear flues have a flue

elbow is replaced by an adapter on vertically

covering the securing screw on the underside

the controls cover, see AG.

screw,

to

release it from its four side fixings and pull

forward clear of the thermostat knob.

Remove door

and

lift door off the two upper hinge brackets.

tt

is

advisable to clean the boiler

of

the heating season.

pilot and main burners have a clean, even

is

necessary and the infor-

in

'4. PILOT BURNER' can be ignored.

supply

or

pull controls cover forward 1

by

disconnecting the supply

switching off the external isolating

by

opening the door

13.

Undo securing

Omm,

by

undoing the lower fixing screws

no

<lnd

further

at

the

of

out

lower it

of

GAS

CONTROL

VALVE

PLUG

~-----,

"""'

'

............

,

..

'\

'

...............

,

'\

',

__

'\

'--...

FIG.

28

BURNER AND GAS CONTROL ASSEMBLY

21

·-.,.............__

GAS

CONTROL

VALVE/SUPPORT

BRACKET

SCREW

7BLADESON

30F, 40F,

8BLADESON

80F

BURNER

SECURING

SCREWS

50f

& 100F

& 60F

Supplied By www.heating spares.co Tel. 0161 620 6677

C.

Remove screws securing

front panel and remove panel.

D.

Disconnect

E. Remove

withdraw

On

vertically flued boilers remove

and

slide the vertical flue adapter

duct.

F.

Disconnect

connector adjacent

nuts

out

Lift

Lower and

G.

Undo the union on

H.

Unplug

valve from control box. See

I.

Remove

its support

J.

Disconned

K Remove

the

bottom

and gas control assembly.

the

two flexible

thumb

securing the flue

fan/flue

the

the

two

screw securing

elbow. Take care

the

fan

supply

to

hood

lift

out vertical adapter.

the

electrical supply leads

screw securing

bracket

the

screws securing

of

See

electrode lead from electrode.

the boiler case

the

combustion

tubes

from

the

notto

damage

two

up

and earth leads from

the

fan. Remove

hood

to

the

heat exchanger.

assembly.

gas

service

FIG.

FIG.

cock

for

28.

the

gas control valve

28.

the

burner assembly

and

lift out

chamber

the

flue elbow.

flue elbow and

the

gasket.

thumb

the

screws

into

the

the

two

outlet.

gas control

the

burner

flue

the

wing

to

to

B. Unscrew

the

assembly

the

operation.

C.

Lightly brush

Remove

replace.

pilot

pilot

the

to

and

injector

the

NOTE

Do

not

use a wire brush

D.

Gently clean

E.

Refit

the

assemble

F.

Secure

two

the

hexagonal screws.

G. Fully tighten

to

the

pilot.

following

commissioning

18.

H.

Ensure that

two

the

pilot

any

pilot

the

pilot

the

Check

the

the

hexagonal

main

shield

does

the

pilot

injector

deposits from

injector

pilot

to

assembly

union

for

procedure described

sedion

spark gap

head

burner

where

and

fitted,

not fall out during

to remove

and

clean its orifice

or

pin

to

the

to

the

the

pilot

tube.

to

the

nut

connecting

gas soundness

of

these

is

as illustrated in

screws securing

remove pilot

be

careful

any