Page 1

Prima 2e Re-transfer Printer

Printer Driver Manual

Page 2

Prima 2e Driver Manual

Page 2 of 77

Welcome to the high performance printer driver for the XID5xxi series printer. This manual will help

you to install, set-up and configure the driver to get the best results for your prints.

The driver runs on 32-bit Windows platforms and was successfully tested under Windows 2000

and Windows XP Professional.

This driver was designed for the best performance and stability. Additionally, all the necessary

features referring to different card materials, color ribbons etc., are included.

All document setting parameters can be controlled from the PC via the new Administration Center.

Technical Support

For technical assistance, please contact the company from which you purchased the printer.

Page 3

Table of contents

Prima 2e Driver Manual

Page 3 of 77

1. Legal and Copyright Information .........................................................................................................5

2. Installation..............................................................................................................................................6

2.1. Printer Driver Installation...................................................................................................................6

2.2. Advanced Printer Configuration ......................................................................................................14

3. Printing Preferences............................................................................................................................17

3.1. Introduction into driver and print technology...................................................................................17

3.2. Layout / Setup.................................................................................................................................18

3.2.1. Page Orientation.........................................................................................................................18

3.2.2. Set-up for Control of Printing / Encoding ....................................................................................18

3.2.3. Set-up for use of cards with magnetic stripe or smartchip (Card Type) .....................................19

3.2.4. Set-up for Layout Orientation......................................................................................................19

3.3. K/PO Panel .....................................................................................................................................20

3.3.1. Introduction .................................................................................................................................20

3.3.2. Default Settings ..........................................................................................................................20

3.3.3. Selection of text objects to be printed on K-plane ......................................................................20

3.3.4. Selection of black & white images to print on K-plane ...............................................................22

3.3.5. K Plane options...........................................................................................................................22

3.3.6. PO Panel Area Definition (Peel Off) ...........................................................................................28

3.4. Advanced ........................................................................................................................................32

3.4.1. Global Print Offset and K Plane Offset .......................................................................................32

3.4.2. Synchronization ..........................................................................................................................32

3.4.3. Track Formats.............................................................................................................................33

3.4.4. Card Output ................................................................................................................................33

3.4.5. Material Usage............................................................................................................................34

3.4.6. Sample of magnetic stripe Encoding ..........................................................................................35

4. Advanced Intelligent Printer Management (AIPM) ...........................................................................36

4.1. Introduction .....................................................................................................................................36

4.2. Dispatcher .......................................................................................................................................36

4.2.1. Printers........................................................................................................................................37

4.2.2. Material Capacity List .................................................................................................................37

4.2.3. Print Jobs ....................................................................................................................................37

4.2.4. Tools ...........................................................................................................................................38

5. Administration Center.........................................................................................................................40

5.1. Printer Settings................................................................................................................................40

5.1.1. Re-transfer settings ....................................................................................................................41

5.1.2. Bend remedy...............................................................................................................................41

5.1.3. Ink settings..................................................................................................................................41

5.1.4. Other settings..............................................................................................................................41

5.1.5. Print setting transfers..................................................................................................................42

5.2. Options............................................................................................................................................43

5.2.1. General Options..........................................................................................................................43

5.2.2. Printer Driver Profiles and Printer Grouping Definition...............................................................44

5.2.3. Setting up Printing Preferences and Managing of Printer Driver Profiles ..................................50

5.3. LUT / Password...............................................................................................................................51

5.3.1. Lookup Table Configuration........................................................................................................51

5.3.2. Password ....................................................................................................................................51

5.4. Driver Config ...................................................................................................................................52

6. Advanced Chip Encoding Framework (ACEF) .................................................................................53

6.1. Plugin architecture ..........................................................................................................................54

6.2. Software and Hardware Setup........................................................................................................55

6.2.1. Plugin Info ...................................................................................................................................55

6.2.2. Port Assignment .........................................................................................................................56

6.2.3. Format Templates.......................................................................................................................58

6.2.4. Configuration (Global Settings and Test) ...................................................................................60

6.3. Application Setup ............................................................................................................................61

6.4. Multi-printer encoding......................................................................................................................62

6.5. Printing and encoding over network................................................................................................63

6.6. Multiple encodings on one card ......................................................................................................63

Page 4

Prima 2e Driver Manual

Page 4 of 77

6.7. Precoding ........................................................................................................................................64

6.8. Encoding String...............................................................................................................................65

6.8.1. Encoding string examples...........................................................................................................68

7. Troubleshooting and known limitations ...........................................................................................70

8. Appendix A...........................................................................................................................................71

Page 5

1. Legal and Copyright Information

Prima 2e Driver Manual

Page 5 of 77

This product is provided on an "as is" basis, without any other warranties, or conditions, expressed

or implied, including but not limited to warranties of merchantable quality, merchantability or fitness

for a particular purpose, or those arising by law, statute, usage of trade or course of dealing. You

assume the entire risk as to the results and performance of the Software. Neither we, our dealers

nor our suppliers shall have any liability to you or any other person or entity for any indirect,

incidental, special or consequential damages whatsoever, including but not limited to loss of

revenue or profit, lost or damaged data or other commercial or economic loss, even if we have

been advised of the possibility of such damages or they are foreseeable; or for claims by a third

party. Our maximum aggregate liability to you, and that of our dealers and suppliers, shall not

exceed the amount paid by you for the product. Some jurisdictions do not allow the exclusion or

limitation of liability for consequential or incidental damages so the above limitation may not apply

to you.

Page 6

2. Installation

Prima 2e Driver Manual

Page 6 of 77

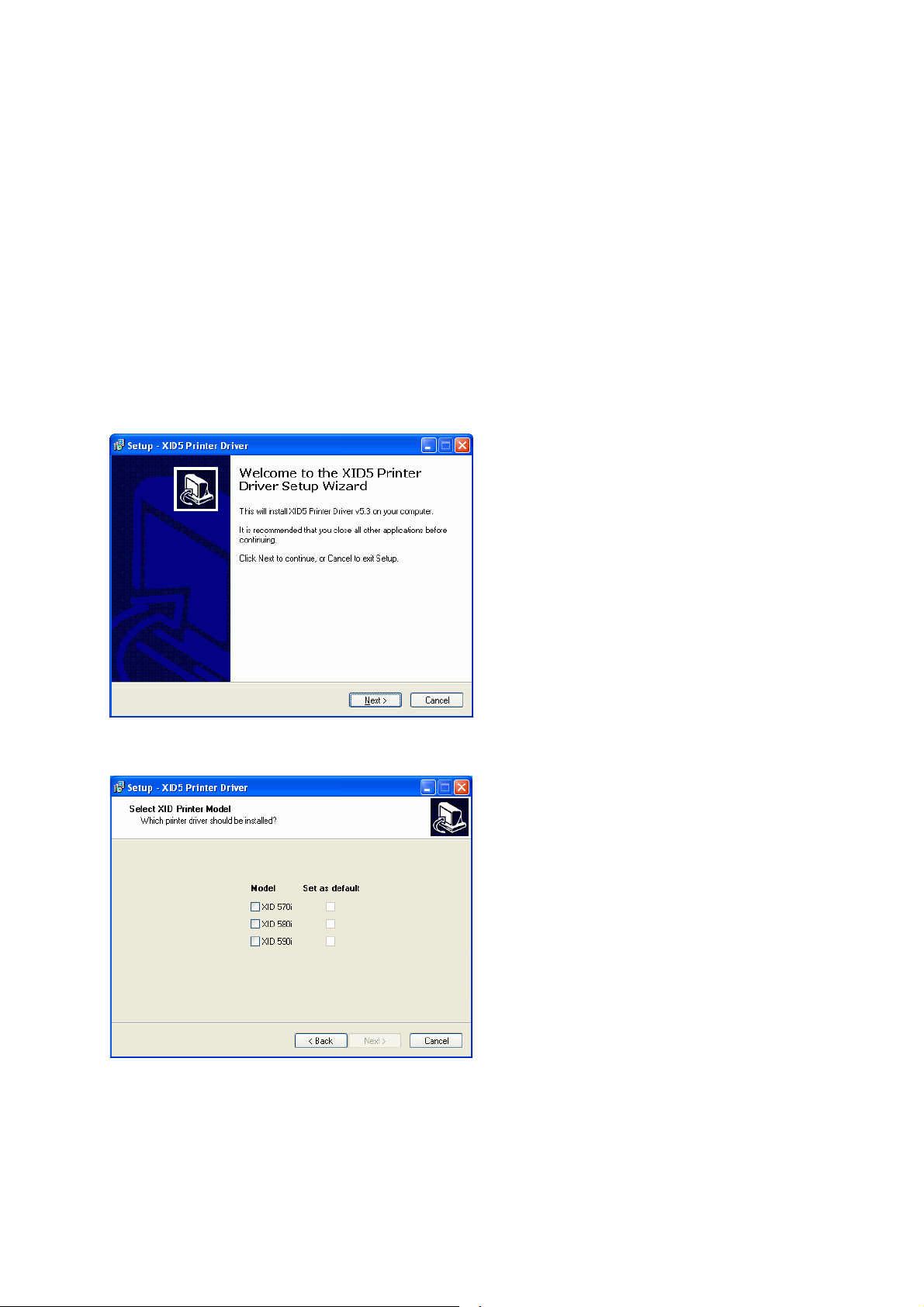

2.1. Printer Driver Installation

Note 1: It is recommended to install the driver before you connect the printer to the PC!

Note 2: System administrator privileges are required for driver installation!

Log on to Windows as system administrator.

Start the installer program "Setup XID5xx 5.3.exe" from your driver CD ROM. Follow the

instructions (See the following screen shots).

The installation itself contains two separate steps in one installation procedure: First the printer

device driver and second the printer driver itself.

Click "Next" to continue.

Please select your "DIGID XID5xx" model from the model list. In addition, you can decide to

specify the printer as the default printer on your system.

Then click "Next" to continue.

Page 7

Prima 2e Driver Manual

Page 7 of 77

Note: Please note that you have to choose the exact name of the delivered member of our XID

Printer Family. The wrong choice will result in a non-working printer!!!

An administrator password can be set during initial installation. This password grants access to the

Administration Center.

Note: It is possible to leave this field empty, but it is recommended to enter a password.

If both entries match,

click "Next" to continue.

Page 8

Prima 2e Driver Manual

Page 8 of 77

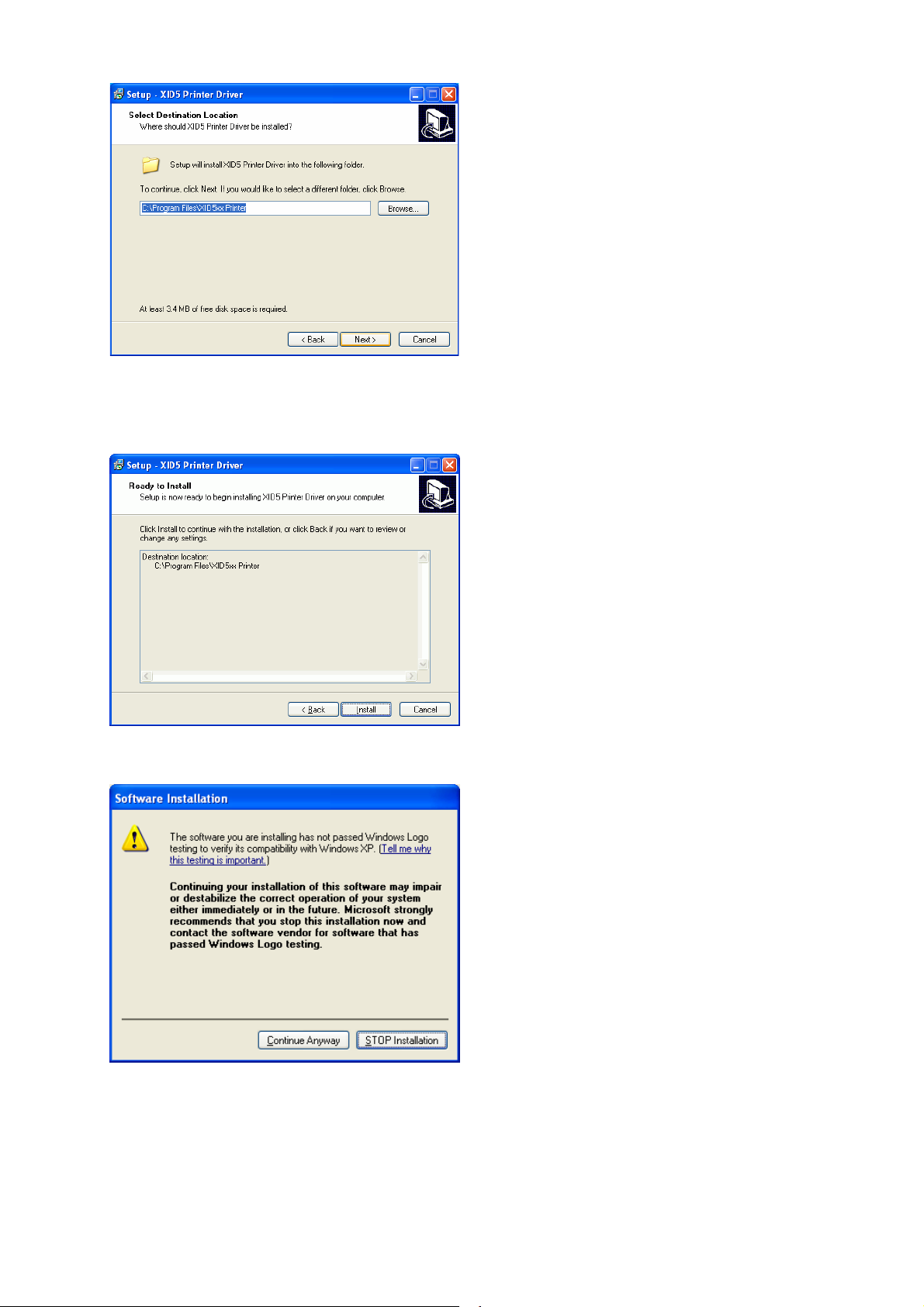

Note: It is recommended to use the proposed default path.

Please verify the path shown and click "Next".

Click "Install" to continue.

Click "Continue Anyway" to continue the installation.

Page 9

Prima 2e Driver Manual

Page 9 of 77

Click "Continue Anyway" to continue the installation.

Now the files will be installed.

Click on "Finish" to complete the installation.

Page 10

A reboot may be necessary, as shown below.

Prima 2e Driver Manual

Page 10 of 77

Please wait until the driver installation is completed, then click "Finish".

The selected printer should appear here (see arrow):

Under Start -> Programs -> XID5xx Printer, you should see the related modules

Page 11

By calling the printer properties, from the "General" tab, you can print a test page as follows:

Prima 2e Driver Manual

Page 11 of 77

After your test page has been printed successfully, click "OK".

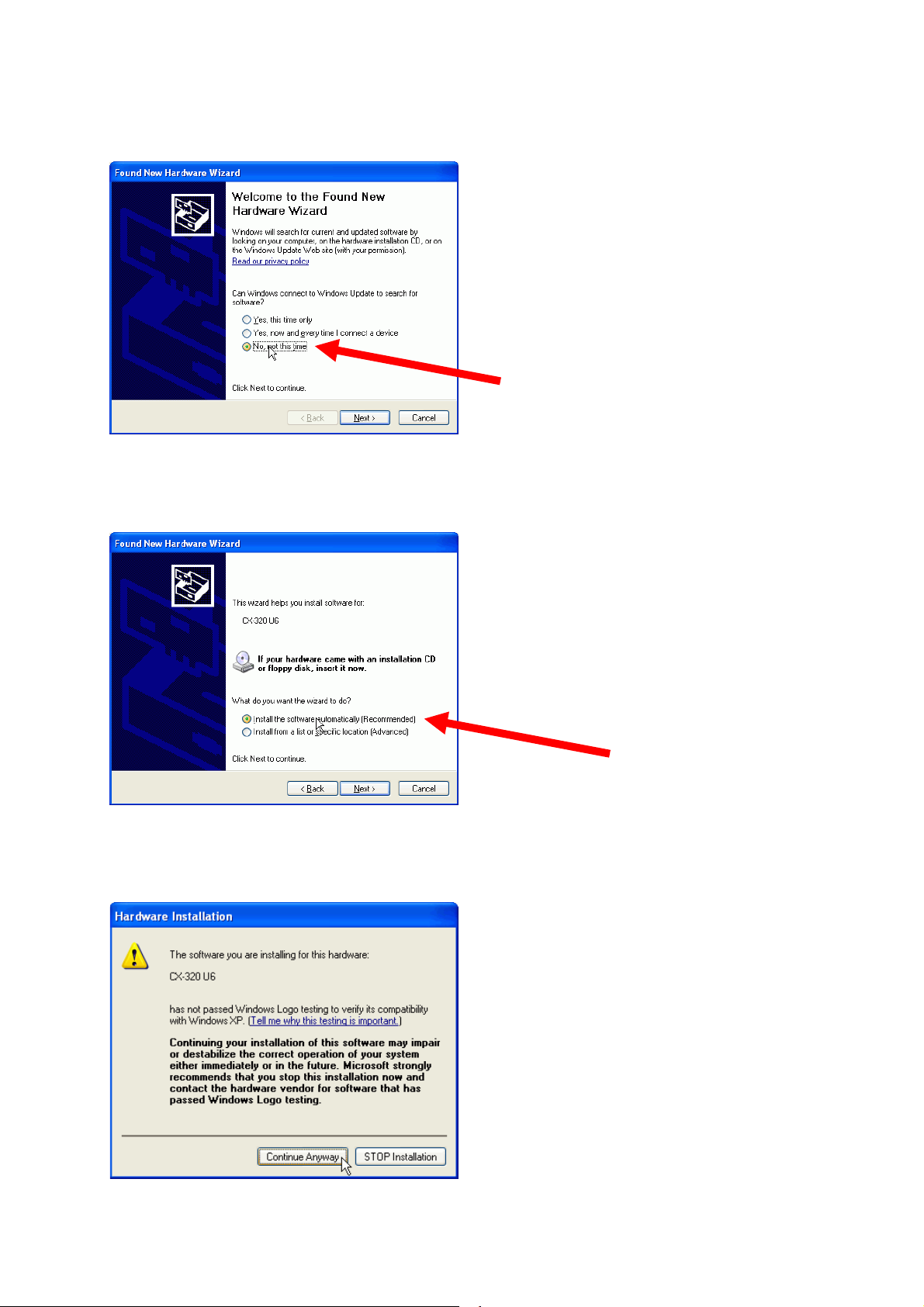

After the installation has been completed, connect the printer to the PC and power on. The

Hardware Wizard appears and shows a signature warning:

Click "Continue" to proceed.

Page 12

The Wizard will ask you to connect to Windows Update:

Prima 2e Driver Manual

Page 12 of 77

Choose "No, not this time" and click "Next".

Choose "Install the software automatically" and click "Next".

Note: The hardware name ("CX-320 U6") may differ depending on the firmware and the ID of the

printer.

The Hardware Wizard appears and shows a signature warning.

Click "Continue Anyway".

Page 13

Prima 2e Driver Manual

Page 13 of 77

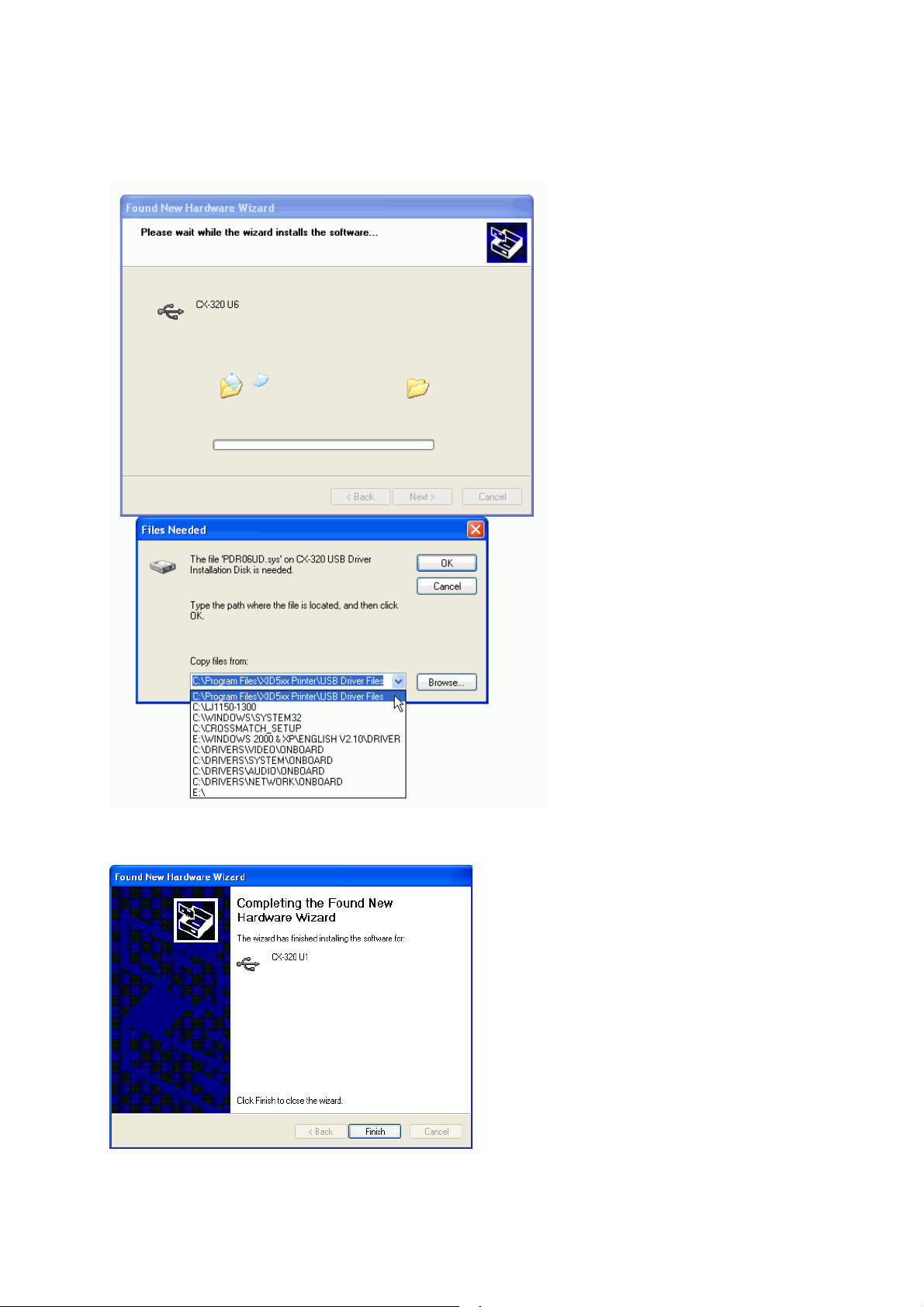

The wizard will ask you for the location of the driver files.

In the "Files Needed" window, click on the dropdown list box and choose the first entry. Click "OK"

to continue.

Click "Finish" to close the Hardware Wizard.

Congratulations! You have successfully finished the printer driver installation.

Page 14

2.2. Advanced Printer Configuration

Prima 2e Driver Manual

Page 14 of 77

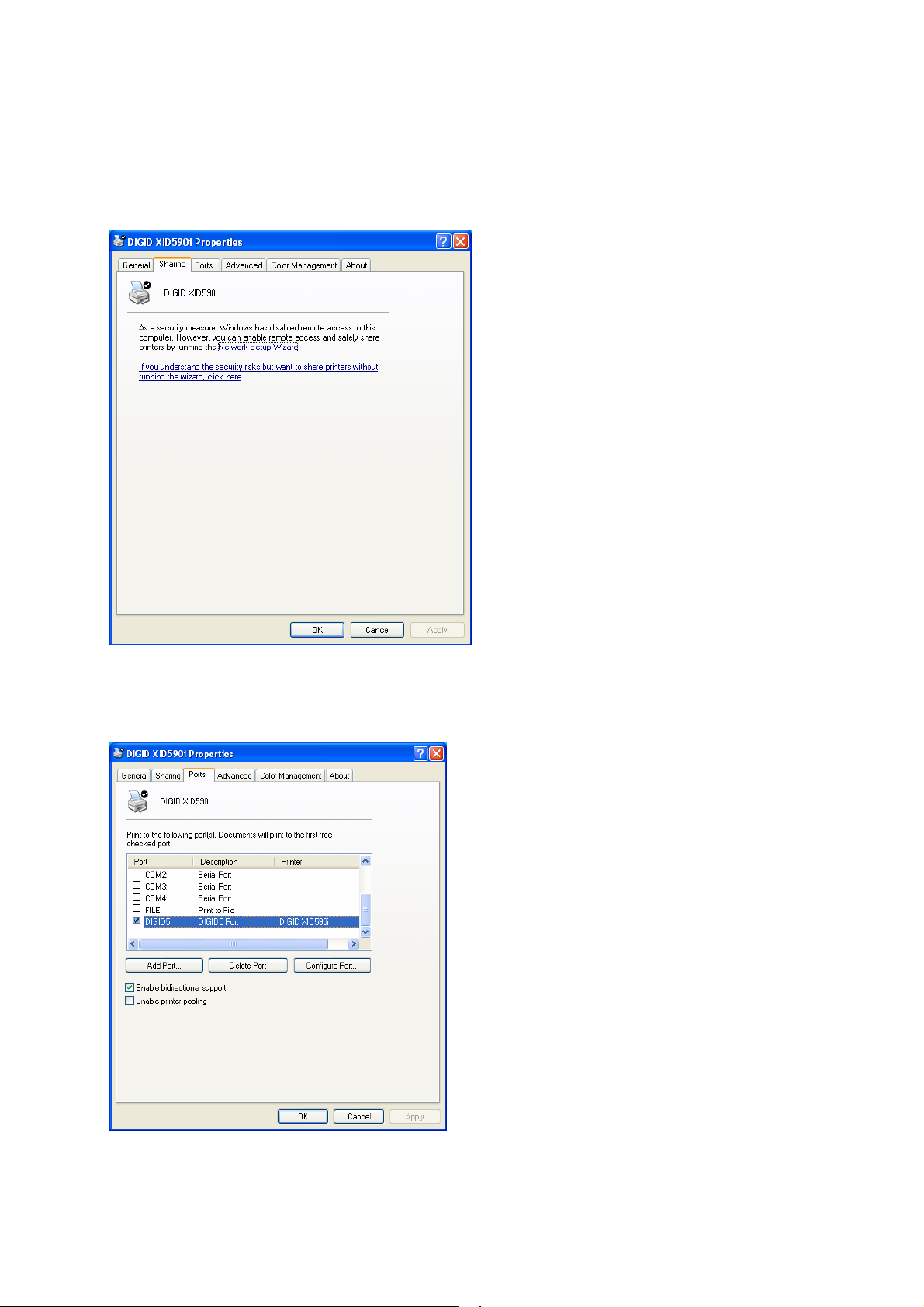

If the printer is used in a network environment and will be shared with other users, then click

"Shared as:" and name the printer. Afterwards other users can select this printer within the

network environment.

Note: The screenshot may differ depending on system configurations:

The required printer port will be linked automatically to DIGID5 port.

Do not change the following default settings unless you are an advanced user:

Page 15

Prima 2e Driver Manual

Page 15 of 77

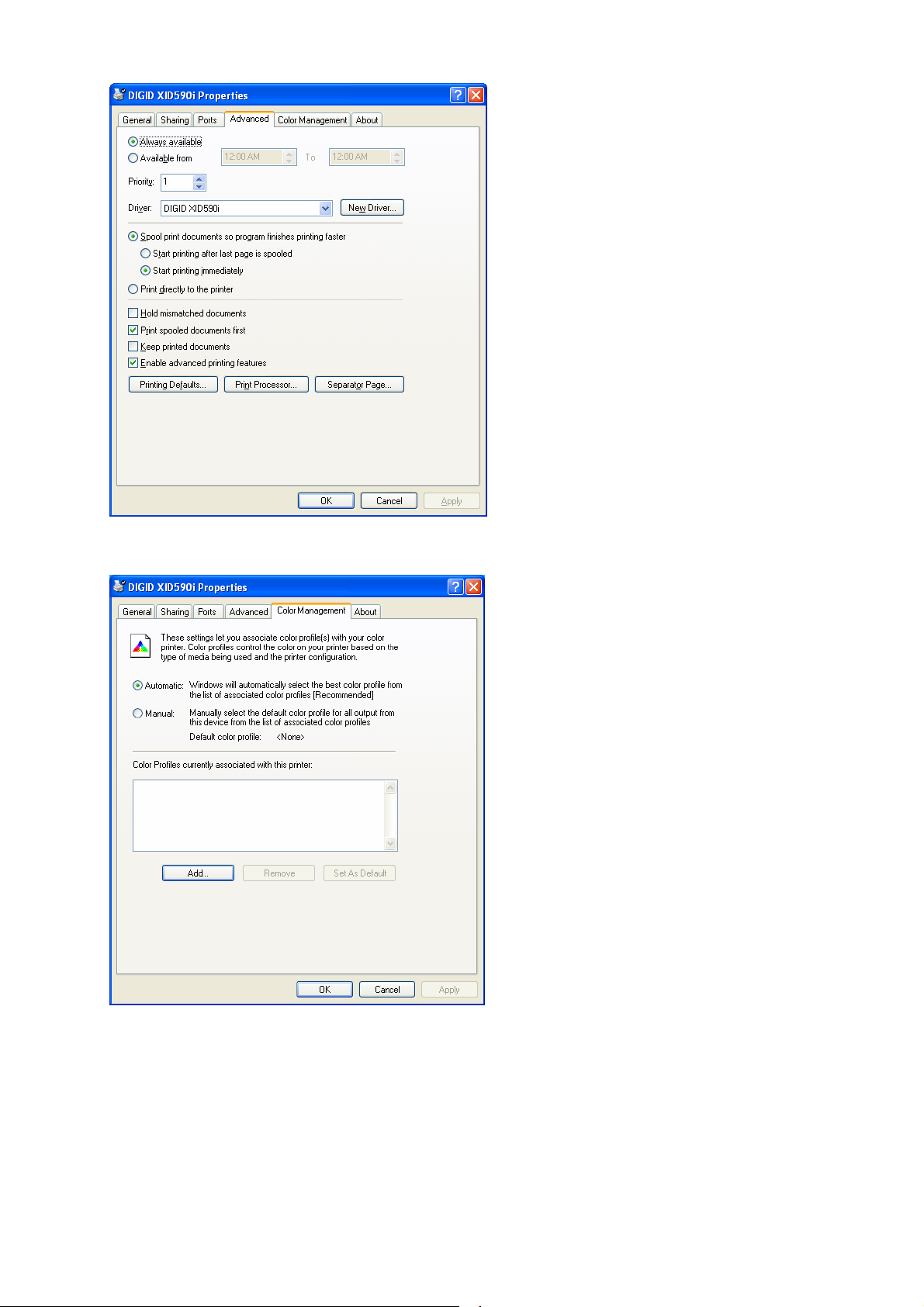

The Color Management settings should only be used by experienced users.

Page 16

Note: The screenshot may differ depending on system configuration:

Prima 2e Driver Manual

Page 16 of 77

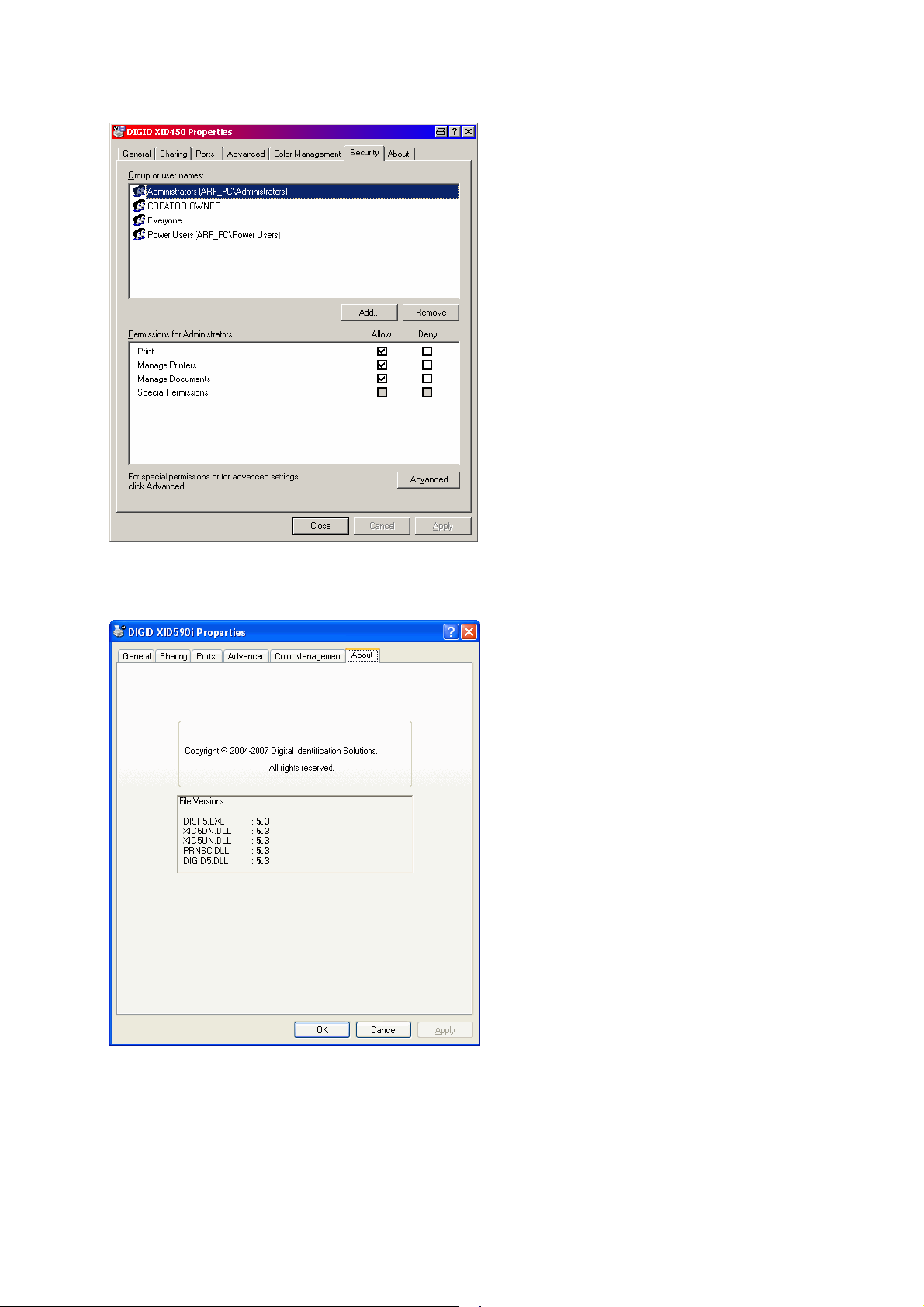

On the "About" tab you will find the version of the installed printer driver:

Page 17

3. Printing Preferences

Prima 2e Driver Manual

Page 17 of 77

3.1. Introduction into driver and print technology

In graphic user interfaces all options are shown dynamically as there are card feeding, loading card

in magazine, card leaving the printer etc.

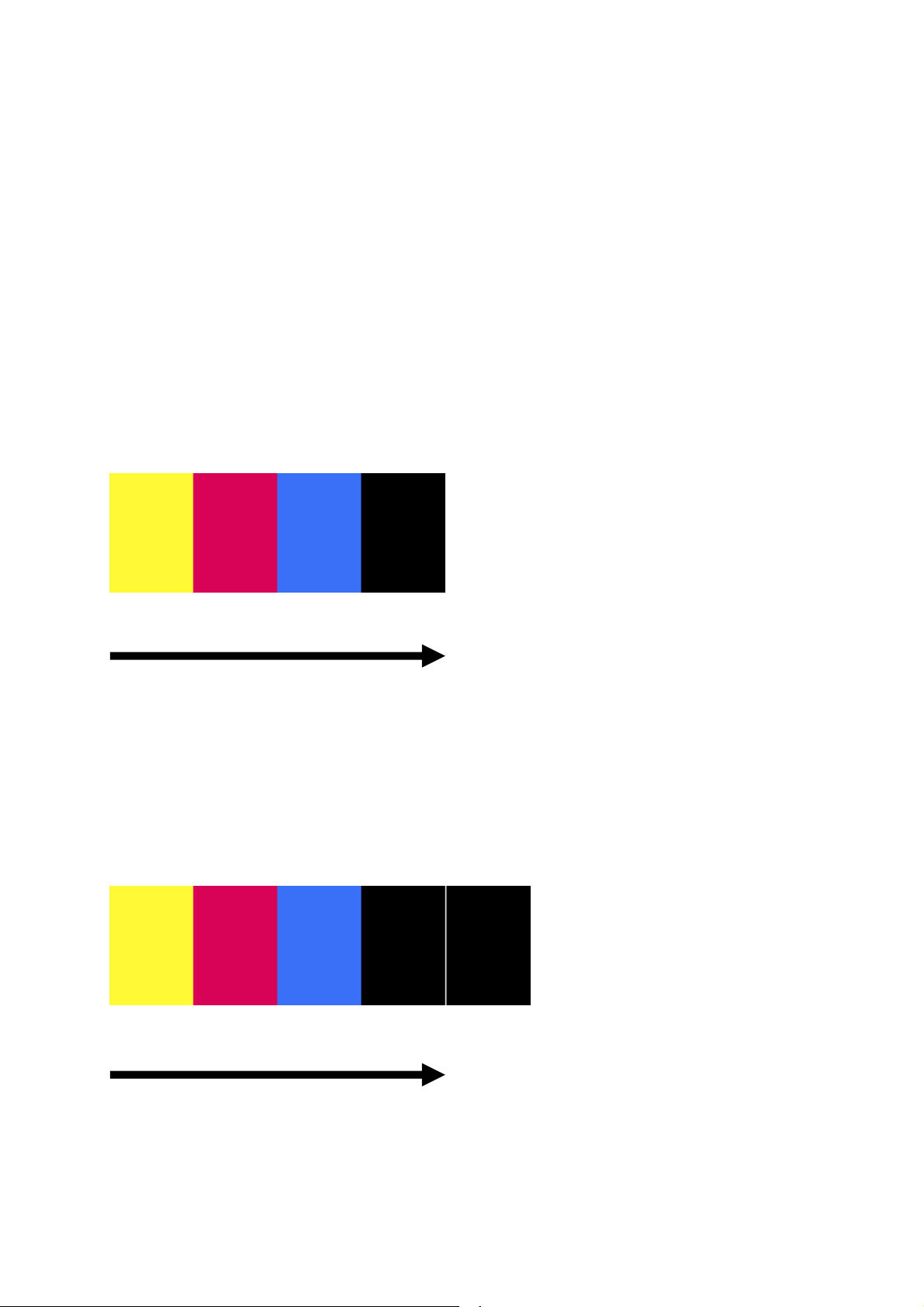

The printing technology contains printing of the colors as a mixture from Yellow, Magenta and

Cyan ("Y", "M", "C"). Black ("K"), also known as Carbon black or process black, is often available

on color ribbons. The reason for the use of Carbon ("K") black is that a full mixture of Yellow,

Magenta and Cyan results in a dark, but not pure black. As a consequence it is common to print

strings, barcodes etc. with Carbon ("K") black for achieving a better and sharper impression.

The print order per full color site with an YMCK ribbon appears as following:

Yellow Magenta Cyan Carbon (K)

P r i n t d i r e c t i o n

For special needs, we are also offering color ribbons with an additional K field. This is a useful

option if e.g. a customer needs to print the front of a card in YMCK while on the back of the card

has to be printed only some text information in K. The CMYKK ribbon enables this process without

the use of a double patch of YMCK and is very cost saving.

The print order per full color site with an YMCKK ribbon appears as following:

Yellow Magenta Cyan Carbon (K) Carbon (K)

P r i n t d i r e c t i o n

Page 18

3.2. Layout / Setup

Prima 2e Driver Manual

Page 18 of 77

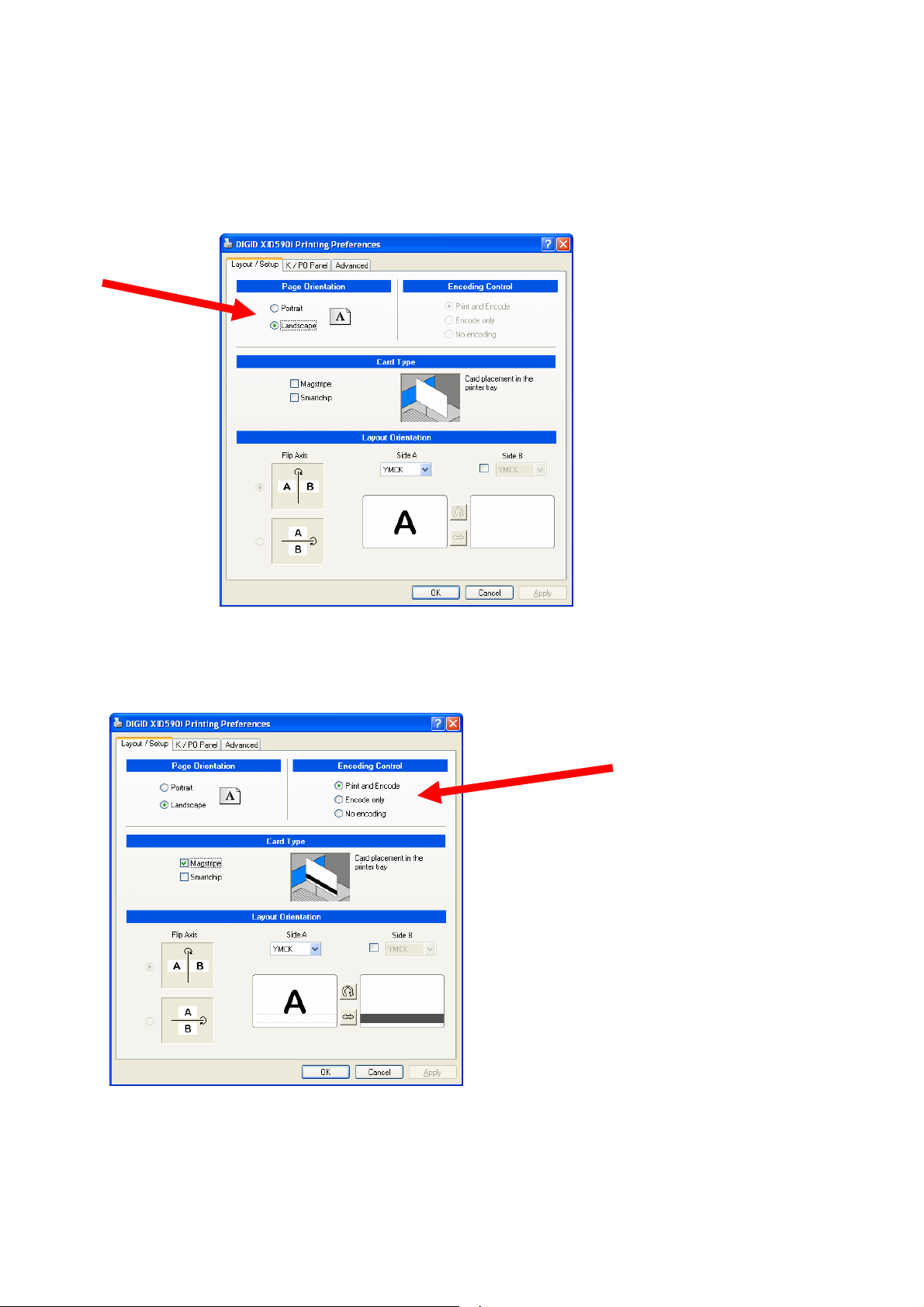

3.2.1. Page Orientation

This option will be used to setup the page orientation between Portrait and Landscape.

3.2.2. Set-up for Control of Printing / Encoding

This option sets up the control of "Print and Encode", "Encode only" or "No Encoding".

Page 19

3.2.3. Set-up for use of cards with magnetic stripe or smartchip (Card

Prima 2e Driver Manual

Page 19 of 77

Type)

If the "Magstripe" or "Smartchip" checkbox is enabled, all options regarding encoding and

positioning of card will be enabled. In addition, the "Card placement in the printer tray" shows

dynamically the correct images to the operator.

Please note that the magstripe function is for visualization AND activation.

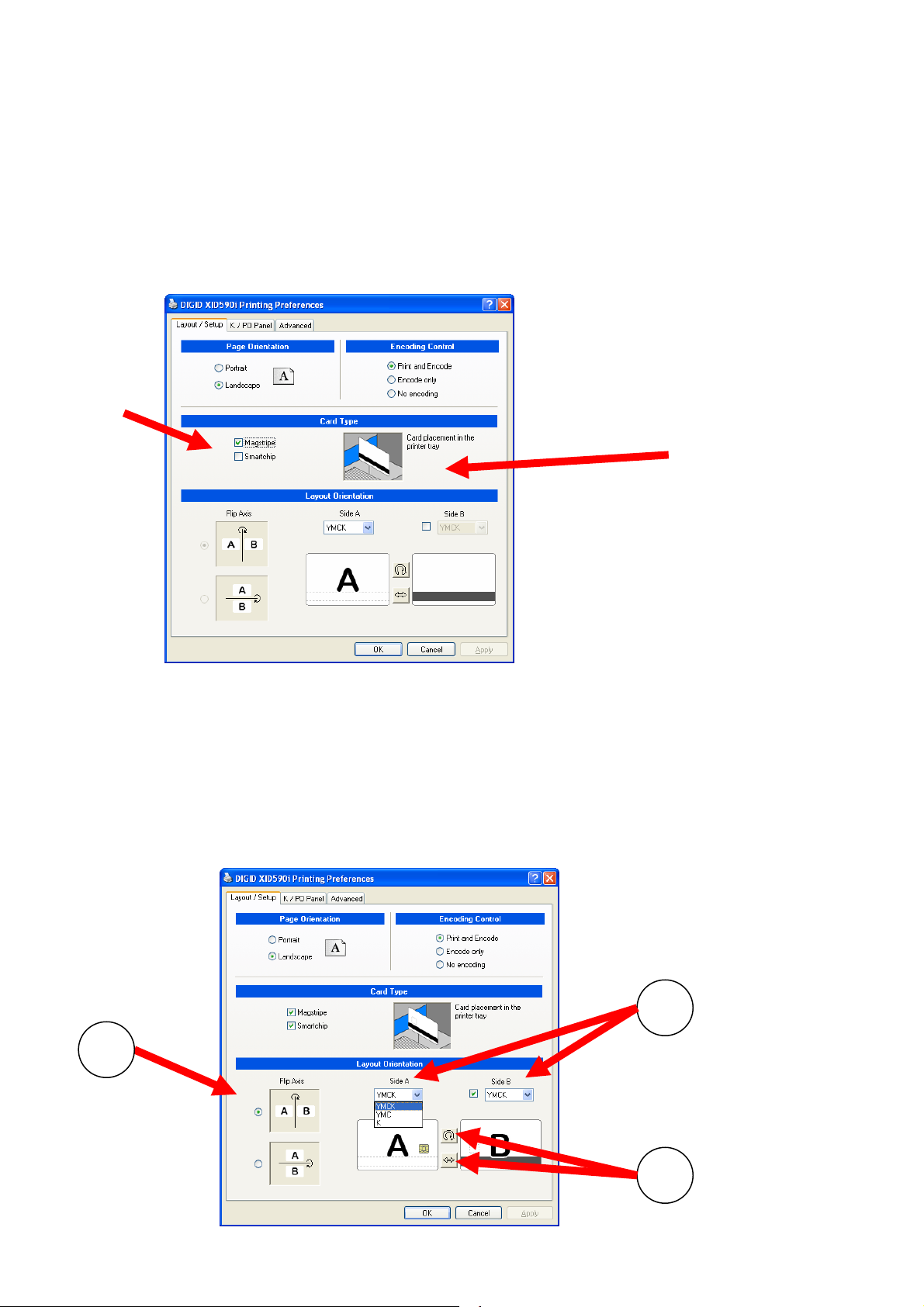

3.2.4. Set-up for Layout Orientation

The Setup for Layout Orientation is the "central point" of orientation definition of cards and usage

of ribbons. With a minimum of mouse clicks you can define every combination you need. By

default, the intelligent printer driver’s matrix calculates the fastest possible print out speed.

However, the operator can always decide between material usage vs. print speed.

B

A

C

Page 20

Prima 2e Driver Manual

Page 20 of 77

A

B

C

For more details, please refer to Appendix A at the end of this document!

Flip Axis: Here you can setup the orientation of the 'card body', which is the same as

the function as former 'Image Orientation'. The advantage is that you do not need to

imagine how the card will rotate. Just pick up a card and you will understand the idea

behind flipping the card horizontally or vertically.

Side A or B: Use the pull down menu to set up the patch usage of the color ribbon for

side A (Front side) and side B (Back side).

Rotation / Swap: The rotation button will rotate the full card 180°, while the swap button

will exchange the front and back of the layout.

3.3. K/PO Panel

3.3.1. Introduction

This tab allows you to both define the kind of extraction methods for placing different objects to the

K-plane (Carbon black) and to define inclusion areas for PO (peal-off) separately for front and

back.

3.3.2. Default Settings

Page 21

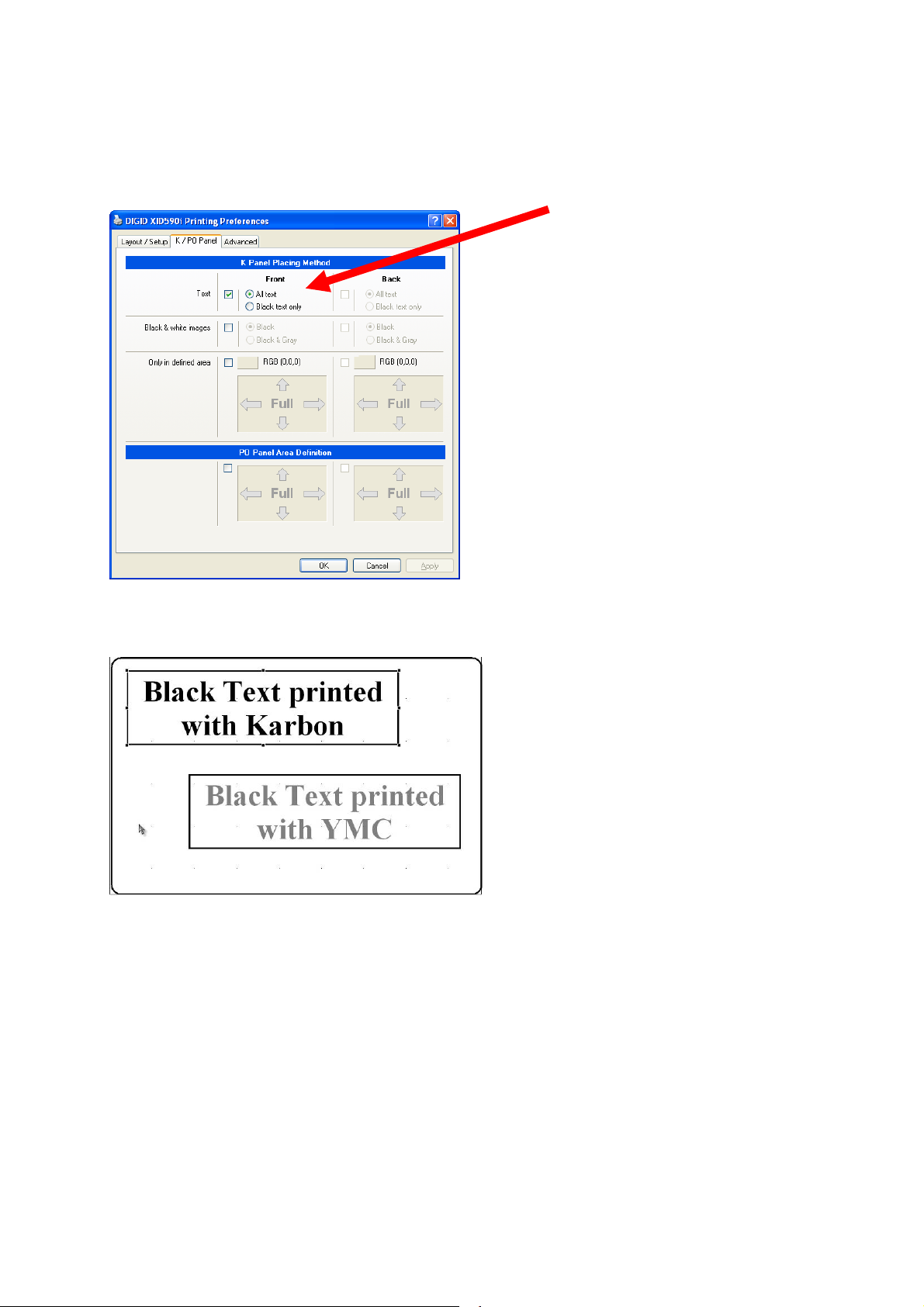

3.3.3. Selection of text objects to be printed on K-plane

Prima 2e Driver Manual

Page 21 of 77

By enabling "Text", you are able to specify if all text or only black text should be printed on

the K-plane.

Sample: The upper text box was printed with K and the lower box with YMC:

Page 22

3.3.4. Selection of black & white images to print on K-plane

Prima 2e Driver Manual

Page 22 of 77

By enabling "Black and White Images" you can specify if black or black & grey images

should be printed on the K plane.

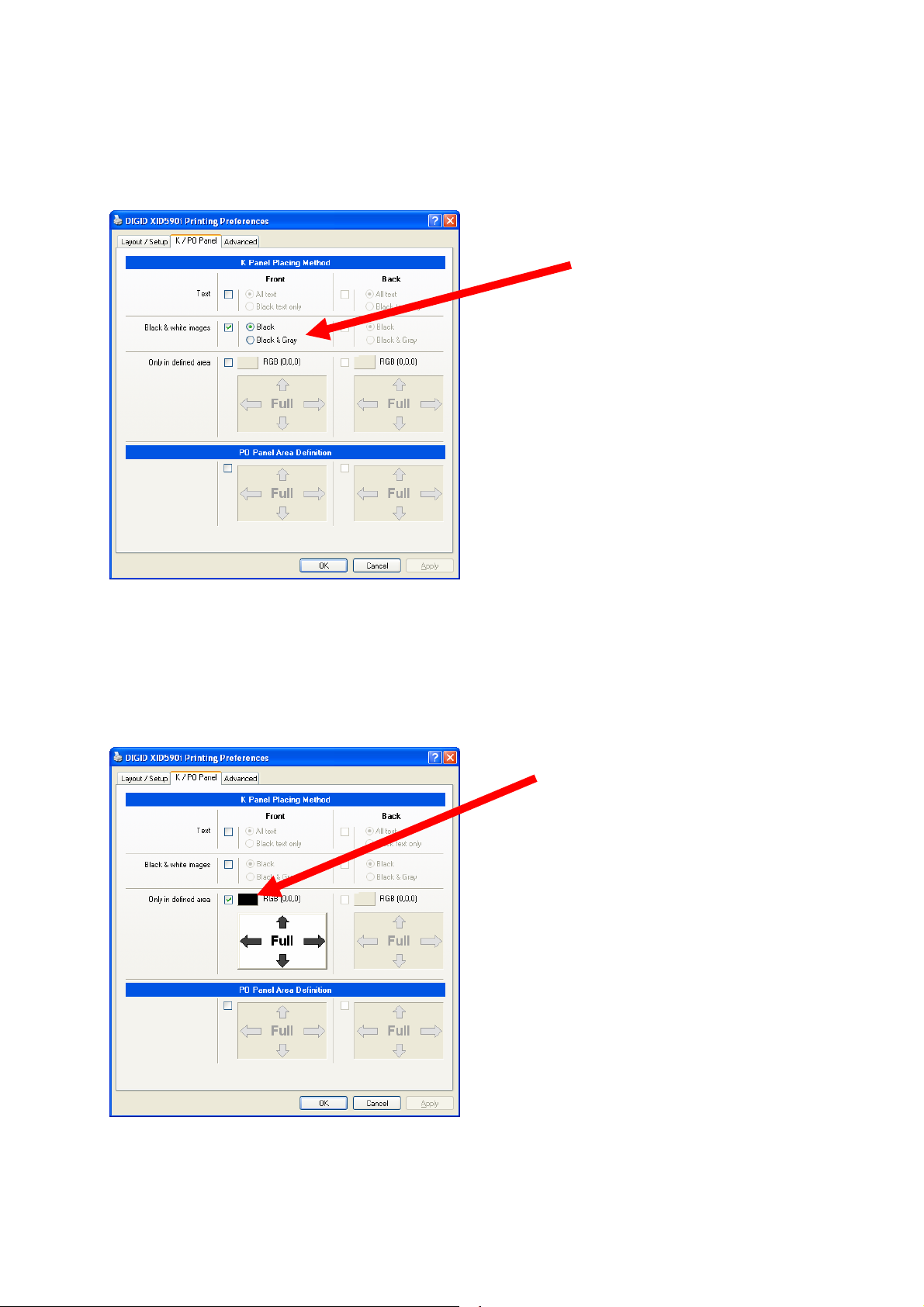

3.3.5. K Plane options

3.3.5.1. Definition of "special colors" for printing on K-plane

If you use special colors to match existing ones on your layout they will be printed on K-plane.

After clicking on the color button, pick up or define a new color as you need. Also, you can add this

color to the "Custom colors" as shown:

Page 23

Prima 2e Driver Manual

Page 23 of 77

It is recommended to choose either black or an extreme color, which will not be used in the rest of

the layout. Pure colors (like Magenta) will never appear in digital photos, so it is safe to use them

without introducing side-effects.

By clicking "OK" the color will be shown on the button.

Page 24

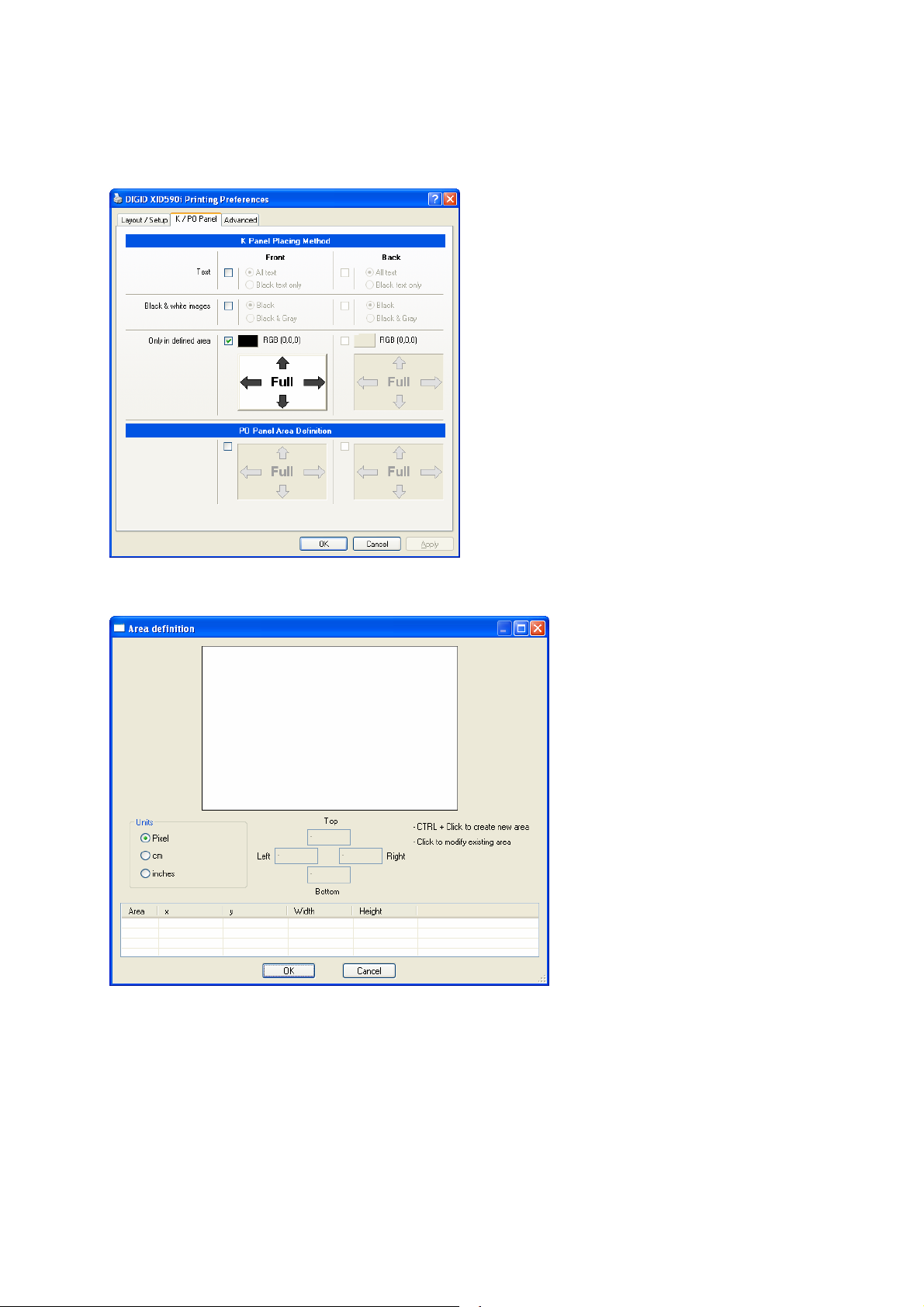

3.3.5.2. Definition of areas for printing on K-plane

Prima 2e Driver Manual

Page 24 of 77

In combination with the special colors (see chapter 3.3.5), you can define inclusion areas:

After clicking on the area button the following dialog window appears:

Page 25

To create a new area: Click and draw a rectangle area while pressing and holding down the

Prima 2e Driver Manual

Page 25 of 77

CTRL-key on the keyboard.

To edit an area: Select an area you want to move or resize by clicking on the area itself or choose

it from the list.

You can move the area pixel by pixel using the cursor-keys.

To Delete an existing area: Select the area you want to delete or choose the corresponding area

from the list, then either right-click on mouse button and click "Delete" or hit del Del-key on the

keyboard.

Page 26

Preview of defined sample K-Panel areas

Prima 2e Driver Manual

Page 26 of 77

Measurement changes

The following sample shows a change of units e.g. from Pixel to Inch

Page 27

Tip: Keeping values after disabling gives you the flexibility to design the areas before you enable

Prima 2e Driver Manual

Page 27 of 77

this setting.

Page 28

3.3.6. PO Panel Area Definition (Peel Off)

Prima 2e Driver Manual

Page 28 of 77

This function is designed to define areas which will be prevented from printing (e.g. signature

fields). The YMCK-PO looks like shown:

Yellow Magenta Cyan Carbon (K) Peel Off (PO)

Note: A special ribbon type is required to use this option.

Default Settings

Page 29

The peel off area is enabled by clicking the checkbox:

Prima 2e Driver Manual

Page 29 of 77

Warning: Use of full PO area results in non-visible printout. In each case you need to define

smaller areas (e.g. signature fields).

After clicking on the PO area button the following window appears:

Page 30

3.3.6.1. Definition of areas Peel Off

Prima 2e Driver Manual

Page 30 of 77

To create a new area: Click and draw a rectangle area while pressing and holding down the

CTRL-key on the keyboard.

To edit an area: Select an area you want to move or resize by clicking on the area itself or choose

it from the list.

You can move the area pixel by pixel using the cursor-keys.

To Delete an existing area: Select the area you want to delete or choose the corresponding area

from the list, then either right-click on mouse button and click "Delete" or hit del Del-key on the

keyboard.

Page 31

Preview of defined sample K-Panel areas

Prima 2e Driver Manual

Page 31 of 77

Tip: Keeping values after disabling gives you the flexibility to design the areas before you enable

this setting.

Page 32

3.4. Advanced

Prima 2e Driver Manual

Page 32 of 77

3.4.1. Global Print Offset and K Plane Offset

Global Print Offset:

Here you can shift the offset of the layout in horizontal and vertical direction by changing the

values; this influences the complete layout.

K-plane Offset:

The changing of the values for K-plane only influences the offset of the K-plane.

3.4.2. Synchronization

This is only required if the application controls the chip encoding. When encoding and printing

batch jobs without the built-in Advanced Chip Encoding Framework, the option "Wait for card

exit" must be checked:

Page 33

3.4.3. Track Formats

Prima 2e Driver Manual

Page 33 of 77

The track formats are shown for informational purpose. Only standard formats are allowed to be

encoded.

3.4.4. Card Output

By enabling the "Card Output" option, the user can force or override the default setting of the

printer driver. Independent from speed or material usage settings, the Card Output options "Front

up" or "Front down" will force the card orientation when leaving the printer.

This option should be used only if an external lamination unit is attached to the printer.

Page 34

3.4.5. Material Usage

Prima 2e Driver Manual

Page 34 of 77

The "Material Usage" area shows the expected usage of color and retransfer ribbon using the

currently selected options.

In some rare combinations, the "Save Material" option will become available and lets you enforce

material saving over production speed.

Page 35

3.4.6. Sample of magnetic stripe Encoding

Prima 2e Driver Manual

Page 35 of 77

Sending Track Information

Magnetic track data is sent in the form of text strings from the application software to the printer

driver, along with all of the other printable objects within your card design. For the printer driver to

differentiate between magnetic track data and the rest of the printable objects, the magnetic track

data strings must be uniquely "tagged" and formatted by using the "System" font. In other words,

specific characters must be added to the magnetic track data for the printer driver to know which

data is to be encoded, which tracks to encode, when the track data stops and starts and so on.

When using the Generic Printer Driver, you must manually add these characters to the string of

magnetic track data. If these characters are not added to the track data, the text intended for the

magnetic track will most likely appear as printed text on the card. To avoid this, track information

must be entered as described below.

When entering track data, the "~" character is entered first, followed by the track number (1, 2, or

3) on which you intend to encode the data. The data to be encoded should then follow. The first

character of this data string must be the track’s specific SS (Start Sentinel), and the last character

must be the specific ES (End Sentinel). The characters or data in between the SS and the ES can

include all of the valid characters specific to each track. The number of these characters, however,

is limited by each track’s maximum character capacity. When segmenting track data, the

appropriate FS (Field Separator) must be used. The following table shows the SS, ES, FS, and

valid characters defined for each track. (Track character limits are enforced by the TR-1, TR-2, and

TR-3/NNT format options selected in the Magnetic Encoding properties.)

Note: This data must always appear on the first page of your document.

The following example illustrates how track data should be entered for tracks 1, 2, and 3 under

following Windows OS:

Windows 2000/XP:

Track Start

Sentinel

~1 % ? ^ 0-9, A-Z, Dot., ASCII 32-95

~2; ; ? = ASCII 48-63

~3; ; ? = ASCII 48-63

~3;

for XP only

+ ? = ASCII 48-63

Sample for Windows XP:

Sending Data to Track 1: ~1%JULIE ANDERSON^623-85-1253?

Sending Data to Track 2: ~2;012345…89?

Sending Data to Track 3: ~3+012345…89?

End

Sentinel

Field

Separator

Valid Characters

Page 36

4. Advanced Intelligent Printer Management (AIPM)

Prima 2e Driver Manual

Page 36 of 77

4.1. Introduction

The "Advanced Intelligent Printer Management" was developed with a focus on giving the most

power and flexibility to the user. All necessary controls and settings are stored centrally in the

Dispatcher (DISP) application. The user has direct access to all setting parameters he needs.

The Dispatcher is a part of the printer driver and appears in the program group under the XID5xx

Printer folder or starts automatically when launching a print job.

Up to 7 printers (XID590i model only) can be connected to one PC.

The Dispatcher performs the following main tasks:

1. Showing of print job status in real time

2. Pause/Resume control for each printer

3. Showing the Re-Transfer-Film fill status

4. Showing the Color Ribbon fill status

5. Showing the Card Material fill status

4.2. Dispatcher

The Dispatcher is the management center for controlling the operations of the printer and print

jobs.

see 4.2.1

see 4.2.2

see 4.2.3

Page 37

4.2.1. Printers

Prima 2e Driver Manual

Page 37 of 77

The printer line shows the printer’s status: If the printer is connected and detected by the

Dispatcher and has no low level errors (e.g. 'No cards'), the printer’s related signs become active.

The 'LED' to the right of the printers ID shows with several colors the related state:

- Green Ready

- Green flashing Printing

- Yellow Initializing mode

- Red Fatal error

Every printer can be set into Pause Mode or continue individually. This function is very useful e.g. if

the user wants to change the ribbon or insert new cards into the tray.

4.2.2. Material Capacity List

For all three printer consumables the remaining capacity will be shown separately: Retransfer

Film, Color Ribbon and Cards in Tray. All values will be updated dynamically.

Note: The values shown are an approximation.

4.2.3. Print Jobs

All jobs handled by the dispatcher are shown in the "File List" area. Every time an application

sends print jobs to the spooler, the dispatcher will take them to its own job list. The problem of

hanging print jobs by the Windows spooler is reduced.

When a print job is started, DISP shows the status of every printer including the buffered print jobs

in the file list as shown in the sample. The group option will be described later in section 4.4.2.x.

The image sample below shows the action of seven printers connected.

Also listed is the main information regarding the print job:

- Job on printer

- Document Name

- Type of color printed on Front of card

- Type of color printed on Back of card

- Printer ID's assigned

- Timestamp of when the print was started

Page 38

Prima 2e Driver Manual

Page 38 of 77

During the run time of DISP the card counter shows the Cards for print and Cards printed.

Cards for print shows all jobs in the file list including copy prints.

In special cases, e.g. if a cleaning procedure is needed, an info line at the bottom shows the

related info message.

4.2.4. Tools

The tools from the pull down menu are designed to control following items

- Clear Spooler: If there is a reason to cancel running prints the clear statement deletes the

jobs from the Windows spooler.

- Reset Counter: Here the counter can be reset without closing and restarting DISP.

Page 39

Inside the Print Jobs list, the user can handle single jobs by right clicking with the mouse button as

Prima 2e Driver Manual

Page 39 of 77

follows:

- Delete (e.g. if unwanted after error recovery)

- Suspense (e.g. job can wait)

- Restart (e.g. after an error occurred)

- Move to top (prioritization)

Depending on the actual status of the print job, particular functions may not be available. In

addition, the user can multi-select several print jobs by hold CTRL or Shift and clicking on the

desired print jobs.

Page 40

5. Administration Center

Prima 2e Driver Manual

Page 40 of 77

The "Administration Center" is the central point for administrative management of hardware

related settings, printer driver and LUT/password control. Based on the innovative "Plug-In"

architecture, this framework allows you to implement administrative functions by copying new DLL

files to the Administration Center directory; no modification of the driver is needed. All

administrative functions like "Printer Settings", "Options" and "LUT/Password" are now shifted into

the Administration Center. The following Plug-In DLLs are included by default:

5.1. Printer Settings

The "Printer Settings" tab enables the user to set the printing parameters e.g. speed, temperature

etc. in a comfortable manner via PC separately for every detected printer. This involves the

following main parameters:

see 5.1.1 see 5.1.2

see 5.1.3

see 5.1.4

see 5.1.5

Page 41

5.1.1. Re-transfer settings

Prima 2e Driver Manual

Page 41 of 77

Ribbon Type Counts per roll (1000, 750)

Temperature -3 (Low) ..Standard + 2 (High)

Speed (Front/Back) -10 (Slow) .. Standard .. +2 (Fast)

5.1.2. Bend remedy

Temperature Off .. -5 (Low) .. Standard .. 0 (High)

Speed -2 (Slow) .. Standard .. +2 (Fast)

Cooling Time 0 sec .. 15 sec

Note: Cooling Time is only available if temperature is not Off.

5.1.3. Ink settings

Ribbon Type YMCK, YMCK + PO, YMCKK

Note: The auto detection function will always show the currently mounted type of color ribbon.

Resin Black -3 (Thin) .. Standard .. +5 (Thick)

Resin Black Mode Normal .. Fine

Special Ink: 1/2

(for future use)

-3 (Thin) .. Standard .. +3 (Thick)

5.1.4. Other settings

ISO Type HiCo or LoCo Magstripe Cards

Card Type Normal or Cybernetic Size (future use)

Printer Stand By No .. 60 minutes

Buzzer On or Off

Page 42

5.1.5. Print setting transfers

Prima 2e Driver Manual

Page 42 of 77

Load from File An already set file can be loaded

Save to File Actual settings can be saved to file

From Printer Settings will be read from printer’s memory

To Printer Settings will be downloaded and stored to the printers memory

Test Print Starts a test print

Card Material Predefined settings for several cards

Note: These settings are samples only and need to be checked with test material!

Page 43

Prima 2e Driver Manual

Page 43 of 77

5.2. Options

With the "Options" it is possible to enable / disable following items:

see 4.4.1

see 4.4.2

5.2.1. General Options

Start DISP with printers in paused mode

If enabled, the next time DISP is started (either by closing or rebooting PC) the printer will

stay in paused mode.

Dispatch copy print to all available printers

If enabled, all copy print jobs will be served to all available printers.

Save latest spool file

This new function was built in to enable saving the latest spool file for support purposes in

case of problems. This spool file will be stored in the Windows system printer directory by

default.

Show messages

Enabled by default. The user can suppress some error messages by deactivating this check

box. This makes sense if the customer does not like to confirm error messages on screen in

bigger production environments.

Redistribute print job

If enabled, in case of an error of daisy chained printers this new function will make sure that

every print job will be printed on the next available printer in the printer group.

Page 44

Prima 2e Driver Manual

Page 44 of 77

5.2.2. Printer Driver Profiles and Printer Grouping Definition

The Printer Group Definition is a unique technique powered by Digital Identification

Solutions to define several groups of "virtual" printers. If created, every Windows

application can print to one virtual driver shown in the Windows printer folder without

sending jobs individually. In addition, a single printer can be defined as a virtual

printer for routing the jobs to specific printer.

The following sample shows the technique of serving:

JOB 4

Printer. ID = 1

Windows Applications

Virtual Printer

(e.g. My printer group A)

JOB 1

Printer ID = 2

DISP

JOB 2

Send 4 print jobs

3 Physical Printers

assigned to the group.

JOB 3

Printer ID = 3

Page 45

5.2.2.1. Creation of Printer Groups

Prima 2e Driver Manual

Page 45 of 77

After clicking on "Add" in Printer Driver Profiles and Printer Grouping, the user needs to enter a

new group name and the ID of the printer which will belong to this group.

In the following window, the user can enter the following settings.

Note: Printer IDs will be enabled only by choosing XID590.

Page 46

The following two samples show how to enter the information:

Prima 2e Driver Manual

Page 46 of 77

Sample A:

1.

2.

3.

4.

As a result of this definition the printer appears in the list.

Page 47

Sample B:

Prima 2e Driver Manual

Page 47 of 77

When checking the maximum number of available printers you will get the maximum performance:

It is possible to add several groups including overlapping IDs, as shown in the sample two groups

named:

- "PrinterXID #2 to #4" with the IDs 2, 3 and 4 was added.

- "XID ARF's Printer Farm" with the IDs 1 - 7 was added.

After successfully adding a virtual printer with the same name, additional groups will be generated

and displayed automatically in the Windows' printer folder:

Page 48

5.2.2.2. Deleting of Printer Groups

Prima 2e Driver Manual

Page 48 of 77

There are two different ways of deleting Printer Groups: by Dispatcher or by use of the standard

procedure in the Windows printer folder. We strongly recommend using Dispatcher.

To delete Printer Groups the following steps have to be done:

1. Highlight a group by clicking the right mouse button and

2. Click button "Delete Group"

2.

1.

Remember: Deleting a printer group from within the Administration Center will automatically delete

the printer in Windows' printer folder.

5.2.3. Setting up Printing Preferences and Managing of Printer Driver

Profiles

5.2.3.1. Setting up Printing Preferences

Page 49

By clicking on the "Printing Preferences ..." button the user can view and setup the printer

Prima 2e Driver Manual

Page 49 of 77

settings out of the Dispatcher for the highlighted printer name as shown below:

5.2.3.2. Exporting of Printer Driver Profiles

By clicking on the "Export ..." button, a save dialog will be opened as shown below:

The printer profile

will be saved for

further use

Page 50

5.2.3.3. Importing of Printer Driver Profiles

Prima 2e Driver Manual

Page 50 of 77

If the customer needs to import the printer profiles he can do this by clicking on the 'Import ...'

button.

The Windows open dialog will be opened as shown below:

Page 51

5.3. LUT / Password

Prima 2e Driver Manual

Page 51 of 77

5.3.1. Lookup Table Configuration

Inside the Lookup Table Configuration the user has the possibility of using his own LUT tables.

LUT tables contain the color control values, which can be used instead of the internal printer LUT.

The Lookup Table contains the values to control the print density for every color separately. It can

be useful to get the same color impression if the customer needs to print on several materials with

backgrounds in different shades of white.

Remember: Using LUTs other than the printer’s internal ones requires deep knowledge in color

management and is recommended for special cases only!!

5.3.2. Password

The password option is designed for use in high security environments only. The user can set a

password to the printer to make sure only certified operators are able to use this protected printer.

Remember: This function is disabled by default and can only be enabled by contacting Digital

Identification Solutions!

Page 52

5.4. Driver Config

Prima 2e Driver Manual

Page 52 of 77

This page allows setting, changing and removing the password of the Administration Center.

When you click on "Reset" button, the following dialog appears.

If a password has been set during installation, it can be changed here. To do so, retype the old

password and type the new password twice to confirm. Click on OK to store the changes. If the

new passwords do not match or the old password is wrong, an error message appears.

To clear the password, the "new password" fields must be left empty.

To set a password, and no previous password has been set yet, the "old password" field must be

left empty.

Page 53

6. Advanced Chip Encoding Framework (ACEF)

Prima 2e Driver Manual

Page 53 of 77

Included in the printer driver is the Advanced Chip Encoding Framework, which is capable of

handling all card encoding itself. The mechanism is independent from the application, allowing

virtually any Windows based application to perform chip encoding.

The main features will be described in detail in the following chapters. These are:

- Plugin architecture

- Single-point and one-time software and hardware setup with the capability to test the setup from

within the driver, without the need of an external application

- Multi-printer printing and encoding (in combination with XID590i's Advanced Intelligent Printer

Management)

- Printing and encoding over network

- Precoding

- Application independency through the use of an Encoding String

The printer driver handles all of the synchronization and error scheduling of the jobs and initiates

the encoding sequence by calling the corresponding plugins.

The encoding itself, i.e. the communication with the encoder hardware and the chip card is done by

a small piece of external software that is loaded and executed by the driver. This software is fed

with all the necessary information which is needed to perform the encoding on the chip.

Since there is a large combination of different chips and customer requirements, Digital

Identification Solutions offers several options for the encoding plugins:

1.

Ready-made highly configurable encoding plugins for a diversity of chips on the market are

available for sale. The plugins have been developed to provide the most flexibility, while

maintaining a high level of security and user friendliness.

2.

Customized plugins can be developed, which meet the exact requirements of the encoding, in case

the ready-made plugins do not meet them or the chip or the encoder hardware is not yet

supported. This however must be discussed with your local dealer.

3.

Application developers can request a free development package, demonstrating the development

of a plugin. This option should be used if the ready-made plugins do not meet the requirements or

a yet unsupported chip or encoder hardware is used, or with high security applications where the

encoding secret may not be configurable in a user interface or in configuration file.

The configuration is done in the Administration Center's section "Plugin Manager".

Page 54

6.1. Plugin architecture

Prima 2e Driver Manual

Page 54 of 77

As the printer driver does not do the encoding itself but loads an additional piece of software that

know how to "talk" with a certain encoder hardware and chip card, it is not limited to chips and

encoders that are currently present on the market.

Such a piece of software is called "Plugin". The driver can handle an almost unlimited number of

these plugins.

Important

The base driver will come with no plugins installed. Therefore the Plugin Manager will show an

empty list in the Installed Plugins window, as shown below:

Plugin Manager after clean installation.

As the requirements on the chip type and encoder hardware differ, users can install the plugins

they need for their encoding requirements.

Plugin Installation

The installation of a customized plugin depends of the plugin itself. Plugins usually come with a

separate setup routine or will be installed by system integrators on customer-side when the printers

are setup.

After installation of a plugin, the list can be refreshed by

- clicking on the "Reload" button below the list of installed plugins

- changing to another Category in Administration Center, then going back to Plugin Manager

- restarting the Administration Center

Page 55

6.2. Software and Hardware Setup

Prima 2e Driver Manual

Page 55 of 77

6.2.1. Plugin Info

When a plugin is installed properly and appears in the list of Installed Plugins, clicking on it will

select and activate it.

The plugin is loaded and additional information of the plugin is displayed in the Plugin Info box as

shown below:

Encoder Position:

This shows whether a plugin encodes contact or contactless chips (this determines the position

where the card is moved in the printer, either to internal encoding position or to the right side of the

printer)

Can Precode:

This shows whether a plugin can perform a precode process (see chapter 6.7 for further

information about Precoding).

Multi Threaded:

If the plugin and the encoder hardware's driver is able to communicate with several devices

simultaneously, the encoding process on multiple printers will be faster. However, most encoder

manufacturers explicitly restrict the communication to one device at a time only, so the encoding

process for further devices must be delayed until the encoding for one device is finished. The

plugin must provide the information whether encoding in parallel is possible or not, and the printer

driver will delay the encoding on other devices with the same plugin on runtime until the one is

completely finished.

Note: This only affects the encoding process, which usually takes a fraction of a second. The

card positioning and printing are done in parallel, independent of the capability of the plugin.

Required CEF version:

The driver's internal chip encoding framework has its own, driver-independent version number.

Since additional functionality may be added in future, the Plugin Manager checks if the installed

framework is compatible with the plugin.

If a plugin uses functions of a later framework, the Plugin Manager will show a warning message

that a newer driver must be installed containing this framework version.

Page 56

This prevents plugins from crashing the driver by attempting to use unsupported functions of a later

Prima 2e Driver Manual

Page 56 of 77

driver release.

Plugin version

The plugin's version number is shown here. This is for support purposes to determine which

version of the plugin is installed on the system.

Unicode

Some applications require to encode Unicode characters on the chips. This shows whether the

plugin is capable of handling unicode data in the encoding string. If not, Unicode characters will be

converted to Ansi by the driver.

Description

The plugin developer can display a short description of what the plugin does here.

6.2.2. Port Assignment

General information

Each encoder hardware must be attached to a printer physically, either inside or outside.

As each printer has its own ID, there is a fixed relation between one specific encoder and one

specific printer.

Since each encoder is also attached physically to the computer (USB, COM or any other possible

port), a link of a "printer ID" and the "port" where the encoder hardware is attached on the PC must

be created. This link is called "Port Assignment".

In the Plugin Manager, the Port Assignment section shows two lists, one with all possible printer

IDs and one with the available ports. Initially, both lists are empty. Depending on the encoder

hardware and the ID of the printer to which the encoder is attached, the port names and IDs differ.

Encoder ports

The list is dynamically filled in real-time. That means as soon as a plugin is selected and an

encoder, which is supported by the plugin, is attached, the port list shows the port name as a new

entry immediately after Windows has recognized the device. For some encoders, it may be

necessary to install the manufacturer's device drivers first.

The same is true when a device is unplugged, i.e. the port disappears from the list.

Page 57

Prima 2e Driver Manual

Page 57 of 77

This mechanism allows easy recognition of the port name of each single encoder device in a

multiple printer (and encoder) environment by plugging them in one-by-one.

Creating the link between encoder and printer ID

When having identified the port name of an encoder that is connected to a specific printer, the link

between both must be created so the driver knows on which port the encoding must be performed

when printing on a certain printer ID.

This link is created by selecting the printer ID in the printer list, the encoder's port name in the port

list and then pressing the "arrow-up" button to create the link. This procedure must be repeated for

each encoder connected to a printer.

1.

3.

2.

To reset all assignments for the current plugin, click on the "Clear" button.

To reset the assignment of a single printer, either select the dash "-" from the port list and assign it

to a printer ID by clicking on the "arrow-up" button, or assign an already assigned port to another

printer ID.

Note: Ports cannot be assigned to two printers at once!

The names of the ports differ from plugin to plugin, especially with USB encoders, as USB ports do

not have common names.

Page 58

6.2.3. Format Templates

Prima 2e Driver Manual

Page 58 of 77

Some applications require different encodings, depending on the layout of the card, but use one

chip type.

Plugins can be developed to support multiple encoding styles, definitions, formats, and all in

combination.

In order to understand what "Format Templates" do, let's have a look at the following example.

Important

Keep in mind that there are several ways

requirement specification!!!

This is only an example demonstrating how a sophisticated plugin *could*

case. This does not work with all plugins and it requires the plugin to contain support for

Format Templates!

Assume we have two cards with different layouts:

The first one is a guest card that should contain only a sequential serial number, which must be

written to sector 0 using the key "1234", has 10 digits and should be filled with leading zeroes. We

call it the "SeqSerNumber".

The second card is an employee card that should contain the employee number, which must be

written to sector 0 using the same key as the guest card, and the first and last name of the

employee, along with his birth date, which must be written to sector 1 using a highly secure key.

The field names (and lengths) are "EmployeeNo" (10) and "Firstname" (20), "Lastname" (20),

"BDate" (YY-MM-DD).

Using the same chip cards for both layouts allows using the same plugin, just with different

"definitions" on what and how to encode.

For the two different encoding requirements, we would create two "Format Templates". Each of

them contains the description of each request, so Format Template 1 would contain the following

definition:

Format Template "Guest"

Fieldname Sector Key Len Filler Format

SeqSerNum 0 1234 10 0 Num

and Format Template 2 would contain the definition:

Format Template "Employee"

Fieldname Sector Key Len Filler Format

EmployeeNo 0 1234 10 leading 0 Num

Firstname 1

Lastname 1

BDate 1

scrambled-high-secure-key

scrambled-high-secure-key

scrambled-high-secure-key

to achieve this, depending on the plugin and the

handle the

20 trailing spaces Text

20 trailing spaces Text

- - Date

(yy-mm-dd)

Page 59

Each layout must then contain a "reference" to each format template, along with the encoding data,

Prima 2e Driver Manual

Page 59 of 77

and the plugin would be able to understand what, where and how needs to be encoded. For an

example how this reference looks like, please refer to section 6.8, keyword "ft".

Note that neither the contents nor the usage of "Format Templates" is defined or restricted by the

driver. It is purely handled by the plugin, so the format definitions, field names, storage of the keys

(unencrypted or encrypted, or none at all), format options and anything else depends only on the

plugin itself. A minimalist plugin does not need to provide support for format templates at all. The

lack of support may also be desired by the security requirements of the application.

According to the example, another plugin could also have an attribute "Position" so the position

inside the block could be specified, and another plugin could have all of the attributes hard-coded

so nobody could temper with the format templates and change them.

Format templates can be deleted using the "Delete" button next to the Format Templates list. A

confirmation dialog is shown to proceed with deletion.

Page 60

6.2.4. Configuration (Global Settings and Test)

Prima 2e Driver Manual

Page 60 of 77

The most important part in the chip encoding setup is to test the communication with the encoding

device and to test if the encoder can access, write to and read from the chip. Some encoders

require even global settings like authentication keys or the transfer speed, which is common for

COM ports.

Each plugin can optionally provide a user interface for both, the global settings and the encoding

test. If one of these or both are supported, the corresponding buttons "Settings..." and "Test..." will

be enabled.

If these options are provided by the plugin, clicking on either button will open a configuration or a

test dialog and show the corresponding functions that are necessary to configure the encoder

hardware and to test the encoding of the card.

The extent of the user interface depends on each plugin, i.e. there are no generic options from the

driver.

A sophisticated plugin should provide an easy-to-use user interface for both options and a way to

do encoding tests with real data in the test dialog, preferably with the same format templates that

have been set-up for the real encoding, as it is mandatory for the production that the hardware is

working correctly with the encoder software and the data is encoded properly on the chip.

Since both options are optional, a minimalist plugin does not need to provide these functions. The

absence of these options may also be desired by the security requirements of the application.

Page 61

6.3. Application Setup

Prima 2e Driver Manual

Page 61 of 77

The chip encoding features of the driver are application independent, i.e. the application does not

need to be set-up for the specific encoder hardware of the encoding plugins.

The entire encoder-specific configuration is done in the Plugin Manager, stored and handled

outside the printing application, as well as the encoding process itself.

However, there are application requirements that need to be fulfilled in order to process the

encoding data in the driver.

All of the encoding data is transported in a so called "encoding string" to the driver and later to the

plugin. The card layout must contain this string somewhere on the front page. This is especially

important to remember when using two-sided layouts.

If the driver recognizes the encoding string on the layout, it will not print it on the card but use it for

encoding. Therefore, the encoding string must be sent "as text" by the application.

The "switch" for the driver to find the encoding string is in the Card Type section of the document's

printer properties. If "Smartchip" is selected here, the encoding string will be captured and

processed.

Unfortunately, it cannot be determined in advance whether an application sends the string in the

correct format or not. The simplest way to check this is to print a layout containing a valid encoding

string. If the string is printed, the application does not support the way how the driver intercepts the

encoding string.

However, this has been tested thoroughly with many different applications and there are two rulesof-thumb that you have to know:

Pixel graphic drawing applications usually render text "as pixels" and are therefore not capable of

sending the encoding string "as text" to the driver.

Special transformations for shading, blending, winding, squeezing, skewing, twisting, outlining and

anything else do process the text "as graphic" and are therefore not suggested for the encoding

string.

Page 62

The font, however, is not relevant for parsing, as long as if it is a standard Windows font.

Prima 2e Driver Manual

Page 62 of 77

So to summarize all of the above:

Important

- The encoding string must be on front page of the layout!

- The encoding string must be in plain standard format with no special effects in the

layout!

6.4. Multi-printer encoding

By using multiple XID 590i printers in a printer group (see 5.2.2.1, Creation of Printer Groups), the

throughput of produced cards per hour can significantly increased.

The printer driver offers full support for printing and encoding on multiple printers simultaneously.

Note that the correct port assignment for each printer using an encoder is required before printing

and encoding in a printer group.

Page 63

6.5. Printing and encoding over network

Prima 2e Driver Manual

Page 63 of 77

Multiple workstations on the network can print on a PC that has one or more printers attached

locally and has shared the printers in Windows. Such a PC is called print server.

On the print server, it is mandatory that a user is logged on, otherwise the dispatcher will not be

able to process the jobs.

As the encoding string is embedded in the layout, the encoding string is transported inside the print

job (or spool job) over the network from the printing workstation to the print server.

The print server will properly process the job including the encoding, and distribute it to the

corresponding printers.

In an operator-less mode, it is even possible to re-encode and print failed jobs on other free

printers with the option "Redistribute print job" on the Options page of Administration Center.

This guarantees that all cards in the batch will be produced without user interaction - assuming that

enough printers are in the group for high availability.

6.6. Multiple encodings on one card

The driver is capable of handling multiple encoding strings in one layout, which might be

- different encoding format templates with one encoder

- contact encoding and contactless encoding

- combination with magstripe

Usually, the driver processes the strings in the order how they are sent from the printing

application. Since it is impossible to determine this, and since this differs for each application, a

special keyword allows specifying the processing sequence of multiple encoding strings. Using the

so-called "sequence order", the encoding and printing process can be tweaked to be performed in

the fastest possible way.

Page 64

6.7. Precoding

Prima 2e Driver Manual

Page 64 of 77

Introduction

A special preprocessing might be required by the application before encoding or printing the card,

or both.

In some cases, a serial number from a card needs to be processed and the card which has to be

produced is selected by this serial number, i.e. the card holder record is determined by the number

that is pre-encoded on the card.

Another example of the need to preprocess the card is when the card's pre-encoded serial number

must be printed on the card.

In both cases, a pre-processing needs to be done before the real print job is created:

- the card must be loaded to the encoder and some data from the chip is processed

- the layout is selected or adjusted and send to the print job queue

What is precoding?

In the time between the first and the second step, this printer must be locked for the second step,

which contains the data that needs to be encoded on the card or the layout that needs to be

printed, or both. (This is especially important in a multi-printer environment)

This first step is called "Precoding". In this step, the card will only be loaded to the encoder and

the printer will be locked for the second step and data from the chip is processed. No printing is

done at this step

What is done in the precode step?

In order to give the most flexibility, the plugin is completely free to decide what to do in the first

step. Examples of possible processings are:

- reading a serial number

- writing it to a database or log-file and

- report it to the application (to let it select the record for the printing layout and the encoding

string)

Precoding however does require the plugin to interact with the printing application so it can prepare

the second processing step when the precode step is finished.

Therefore, the plugin and the application must be customized to work together. As this requires the

adaptation of the printing application to the plugin, precoding will not work with most standard

applications, unless a special feedback interface is provided by the application out-of-the-box.

This should always be done in collaboration with your system integrator!

Important

Precoding always requires customization of the plugin together with the printing

application!

Page 65

6.8. Encoding String

Prima 2e Driver Manual

Page 65 of 77

In an encoding environment, there are many parameters that must be configured in order to the

encoding to be performed correctly.

We have seen above how to set-up the hardware, a way to configure the formatting and

positioning of the data with sophisticated plugins, and now there's one thing left:

The user data that actually needs to be encoded on the card.

Since this data is different for each printed card, it is placed directly on the layout.

The encoding string has a special format that can be recognized by the printer driver. There are

several keywords that are reserved and required by the driver to determine what needs to be done.

The basic syntax of an encoding string is:

{pi="<pluginname>" [ft="<formattemplatename>"] [so="<n>"] [pre] [pid="<n>"]

[[field1="abcd"] [field2="732894732984"]...] }

Attributes in square brackets [...] are optional.

Attributes in pointy brackets <...> are mandatory.

Double quotes "..." must be present in the string

Double-quotes inside encoding data must be escaped with a backslash before the character, e.g.

when encoding the string

John "Doe" Wood

the attribute must look like:

{ pi=... field1="John \"Doe\" Wood" ...}

The encoding string always starts and ends with the curly brackets {...}, containing the encoding

information for one

in 6.6.

User Data

The "field1" and "field2" attributes contain the user data that will be encoded and must be named

according to the plugin and the used format template. There is no fixed naming convention, so

field1 may be Firstname or EmployeeNo or anything else except the reserved keywords (see

table below for a description).

The number of user data attributes depends on the plugin and the template format that is used for

the encoding string.

Since the encoding string is fixed in the layout, it is the responsibility of the application to replace

the variable user data on runtime, when printing the layout.

Many card managements and even other standard applications allow the replacement of

placeholders when a job is sent to the printer.

Since almost every application handles variable data in a different way, it is far beyond the scope

of this document to give instructions on how to do this. It is recommended to look up the

encoding. There may be multiple encoding strings on the layout, as described

Page 66

corresponding section of the application's handbook on how to set up a text field with a string that

Prima 2e Driver Manual

Page 66 of 77

can hold both, fixed and variable data.

There are three types of applications that:

- recognize placeholders and replace them inside the fixed text encoding string

- require a temporary field and a script to build the full encoding string

- cannot replace user data at all

Usually applications belonging to the latter category will not be used at all for card production with

variable data per record because they cannot even print variable data.

Important

- Sophisticated plugins can provide a user interface to visually build and test a

syntactically correct encoding string that reflects the fields from the selected format

template!

- Applications should provide a way to replace data inside a text field per-record.

Page 67

The following keywords in an encoding string are reserved by the driver and processed in a special

Prima 2e Driver Manual

Page 67 of 77

way.

Keyword Option Format Description

pi mandatory Text plugin name

This name must match with the one shown in the Installed

Plugins list in Plugin Manager.

ft optional Text format template name

This name must match with one of the format templates

shown in the Format Templates list in Plugin Manager for

the plugin selected above (keyword "pi").

so optional Number sequence order

This specifies the sequence order and should only be used

when using multiple encoding strings on one card. The

numbers can be chosen freely.

The encodings will be processed in ascending order.

If two so-numbers are equal, the processing order of the

two is undefined and dependent on the application!

pre optional - precode step

This indicates that this is a precode step in which the card

will only be loaded but not yet printed.

This attribute must be present in the precode step and

must be omitted in the second (encode) step. It has no

value!

In addition, the printer will be locked for the precode-id

(see below).

pid optional Number precode id

The number must uniquely identify the precode step and

must be the same on the second (encode) step.

This attribute is mandatory in an environment where

precoding is done and must be present in both steps.

The application needs to take care that each card to be

printed and encoded gets a unique precode ID that is used

for both steps.

The printer is locked in the first step for this precode ID

and only a second job with the same ID can unlock the

printer. Therefore it is required that other cards have

different IDs.

Page 68

6.8.1. Encoding string examples

Prima 2e Driver Manual

Page 68 of 77

1. Simple encoding string

{pi="Contact" ft="Guest" ...encoding data... }

Uses the plugin "Contact" and the format template "Guest" to encode the encoding data, then

prints the card.

2. Multiple encoding strings

{pi="Mifare" ft="All Access" so="2" ...encoding data... }

{pi="Contact" ft="Payment" so="1" ...encoding data... }

First encodes with the plugin "Contact" and the format template "Payment", then encodes with the

plugin "Mifare" and the format template "All Access", then prints.

3. Precoding

Job 1: {pi="Contact" ft="Guest" pre pid="16457" ...encoding data... }

Job 2: {pi="Contact" ft="Guest" pid="16457" ...encoding data... }

Job 1 runs the plugin "Contact" using the format template "Guest" to read something from the card

and locks the printer for the second job with the precode id "16457".

Job 2 runs the same plugin and format template on the previously locked printer to encode the

data, then prints.

Page 69

4. Visual appearance of encoding strings

Prima 2e Driver Manual

Page 69 of 77

This example shows how an encoding string does appear in the application window and does not

appear on the printed card

Encoding string in the layout

Printed card

Page 70

7. Troubleshooting and known limitations

Prima 2e Driver Manual

Page 70 of 77

Print Errors

As a result of the enhanced error recovery capability of the AIPM driver, the user can decide in

case of an error to cancel, delete, recover, pause or re-print jobs.

In case the error persists, mostly due to a hardware error, please write down the error message

and contact the company from which you purchased the printer.

Known limitations

- Copy printouts depend on the applications used. In this case, use the "Collate" or "Sort" option

for printing copies.

- In some cases underlines will be printed in CMY instead in K.

Page 71

8. Appendix A

Prima 2e Driver Manual

Page 71 of 77

Layout placement on card

The printer driver uses a technology that allows you to quickly setup and adjust the document

properties for correct layout placement on the printed card.

This section describes the idea behind it and how to find the correct settings in six intuitive steps.

For first time users, take the card template that was used for designing the layout. Place it in front

of you to be able to look at it and to turn the card.

Open the printing preferences in the application you want to print (usually in menu File -> Print... -

> select printer -> click on Preferences...)

The numbers show the steps which are explained on the following pages.

Page 72

Step 1: One- or two-sided layout

Prima 2e Driver Manual

Page 72 of 77

Check if the design is a one or two-sided layout, i.e. if the layout has only a front side or a front

and back side.

One sided layout: Select

+ =

Front side of card Back side of card

or

Two sided layout: Select

+ =

Front side of card Back side of card

Page 73

Step 2: Landscape or portrait

Prima 2e Driver Manual

Page 73 of 77

Check if the design is a landscape or a portrait design.

Landscape Select

or

Portrait Select

=

=

Page 74

Step 3: Visible encoding features, Magnetic Stripe or Contact Chip

Prima 2e Driver Manual

Page 74 of 77

If the card is not blank, it is important to select the features so the driver knows in which order and

the sides must be printed.

Magnetic stripe card Select

=

or

Contact chip card Select

=

Note:

If the card has both encoding features, you need to select both types, Magstripe

and Smartchip.

Page 75

Step 4: Flip axis

Prima 2e Driver Manual

Page 75 of 77

The driver determines the rotation of the layout sides from the flip axis of the card, which is the axis

around which the card can be flipped and the layout stays in the correct orientation, not upsidedown.

The following illustration shows a vertical flip axis, i.e. the card is flipped along its short side edge:

Vertical flip axis Select

=

or

Horizontal flip axis Select

=

Rule of thumb:

If you turn the card around the short edge (vertical flip axis) and the back-side is upside-down,

select the horizontal flip axis.

Note:

For one-sided layouts, the flip axes are not selectable.

Page 76

Step 5: Rotation of the card

Prima 2e Driver Manual

Page 76 of 77

For non-blank cards, the layout design must cope with either the contact chip or the magnetic

stripe or both on each side of the card. In the layout, these areas are usually left blank and the

Rotation-button allows the print to match the layout, i.e. to place the elements in the correct

positions as they were intended during layout creation.

Magnetic stripe:

The stripe can either be on the top or the bottom of the layout.

Contact chip:

The chip can either be on the left or the right side of the layout.

Important:

The rotation button will rotate the card, so both, the position of either chip or magnetic stripe will

rotate on both sides of the layout.

The following illustrations show some examples of magnetic stripe and chip cards and a

combination of both types and the effect of the rotate-button.

Note:

Magnetic stripe Contact chip

The same applies for one-sided cards.

+

+

Magnetic stripe + contact chip

+

+

+

+

Page 77

Step 6: Exchange the card sides

Prima 2e Driver Manual

Page 77 of 77

As seen in the last step, for non-blank cards, the position of the magnetic stripe or contact chip or

both must be adjusted to fit the layout. While the Rotation-button rotated the card on both sides,

the Exchange-button allows to swap the front and back sides if the magnetic stripe or the chip are

shown at the wrong side of the layout.

Magnetic stripe:

The stripe can either be on the front or the back side of the layout.

Contact chip:

The chip can either be on the front or the back side of the layout.

The following illustrations show some examples of magnetic stripe and chip cards and a

combination of both types and the effect of the rotate-button.

Note:

Magnetic stripe Contact chip

The same applies for one-sided cards.

+

+

Magnetic stripe + contact chip

+

+

+

+

Loading...

Loading...