Page 1

Beforeusingyourairconditioner,pleaseread

thismanualcarefullyandkeepitforfuturereference.

INVERTERSPLITTYPE

-

ROOMAIRCONDITIONER

Pleasereadthisinstallationmanualcompletely

beforeinstallingtheproduct.

Ifthepowercordisdamaged,replacementwork

shallbeperformedbyauthorisedpersonnelonly.

Installationworkmustbeperformedinaccordance

withthenationalwiringStandardsbyauthorised

personnelonly.

Contactanauthorisedservicetechnicianfor

repair,maintenanceorinstallationofthisunit.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 2

CONTENTS

SAFETYPRECAUTIONS

Warning...........................................................................................................................................2

Caution............................................................................................................................................2

INSTALLATIONINSTRUCTIONS

Selectinginstallationplace...............................................................................................................3

Accessories.....................................................................................................................................4

Indoorunitinstallation......................................................................................................................5

Outdoorunitinstallation..................................................................................................................7

REFRIGERANTPIPECONNECTION

Refrigerantpipeconnection............................................................................................................8

ELECTRICALWORK

Electricalwork...............................................................................................................................9

Installationofthesolarphotovoltaicsystem.................................................................................12

AIRPURGING

Airpurgingwithvacuumpump......................................................................................................23

Safetyandleakagecheck.............................................................................................................25

TESTRUNNING

Testrunning..................................................................................................................................25

ReadThisManual

Insideyouwillfindmanyhelpfulhintsonhowtoinstallandtesttheairconditionerproperly.

CAUTION

Contactanauthorisedservicetechnicianforrepairormaintenanceofthisunit.

Contactanauthorisedinstallerforinstallationofthisunit.

Theairconditionerisnotintendedforusebyyoungchildrenorinfirmedpersonswithoutsupervision.

Youngchildrenshouldbesupervisedtoensurethattheydonotplaywiththeairconditioner.

Ifthepowercordistobereplaced,replacementworkshallbeperformedbyauthorisedpersonnelonly.

InstallationworkmustbeperformedinaccordancewiththenationalwiringStandardsbyauthorised

personnelonly.

1

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 3

SAFETYPRECAUTIONS

ReadthefollowSAFETYPRECAUTIONScarefullybeforeinstallation.

Electricalworkmustbeinstalledbyalicensedelectrician.Besuretousethecorrectrating

andmaincircuitforthemodeltobeinstalled.

Incorrectinstallationduetoignoringoftheinstructionwillcauseharmordamage.

Theseriousnessisclassifiedbythefollowingindications.

WARNING

CAUTION

Thissymbolindicatesthepossibilityofdeathorseriousinjury.

Thissymbolindicatesthepossibilityofinjuryordamagetoproperty.

Theitemstobefollowedareclassifiedbythesymbols:

SymbolwithbackgroundwhitedenotesitemthatisPROHIBITEDfromdoing.

WARNING

1)Engagedealerorspecialistforinstallation.Ifinstallationdonebytheuserisdefective,itwillcausewater

leakage,electricalshockfire.

2)Installaccordingtothisinstallationinstructionsstrictly.Ifinstallationisdefective,itwillcausewater

leakage,electricalshockfire.

3)Usetheattachedaccessoriespartsandspecifiedpartsforinstallation.otherwise,itwillcausethesettofall,

waterleakage,electricalshockfire.

4)Installatastrongandfirmlocationwhichisabletowithstandthesetsweight.Ifthestrengthisnotenough

orinstallationisnotproperlydone,thesetwilldropandcauseinjury.

5)Forelectricalwork,followthelocalnationalwiringstandard,regulationandthisinstallationinstructions.An

independentcircuitandsingleoutletmustbeused.Ifelectricalcircuitcapacityisnotenoughordefectfound

inelectricalwork,itwillcauseelectricalshockfire.

6)Usethespecifiedcableandconnecttightlyandclampthecablesothatnoexternalforcewillbeactedon

theterminal.Ifconnectionorfixingisnotperfect,itwillcauseheat-uporfireattheconnection.

7)Wiringroutingmustbeproperlyarrangedsothatcontrolboardcoverisfixedproperly.Ifcontrolboardcover

isnotfixedperfectly,itwillcauseheat-upatconnectionpointofterminal,fireorelectricalshock.

8)Whencarryingoutpipingconnection,takecarenottoletairsubstancesotherthanthespecified

refrigerantgointorefrigerationcycle.Otherwise,itwillcauselowercapacity,abnormalhighpressure

intherefrigerationcycle,explosionandinjury.

9)Donotmodifythelengthofthepowersupplycordoruseofextensioncord,anddonotsharethe

singleoutletwithotherelectricalappliances.Otherwise,itwillcausefireorelectricalshock.

,

CAUTION

1)Thisequipmentmustbeearthedandinstalledwithearthleakagecurrentbreaker.Itmaycauseelectrical

shockifgroundingisnotperfect.

2)Donotinstalltheunitatplacewhereleakageofflammablegasmayoccur.Incasegasleaksand

accumulatesatsurroundingoftheunit,itmaycausefire.

3)Carryoutdrainagepipingasmentionedininstallationinstructions.Ifdrainageisnotperfect,water

mayentertheroomanddamagethefurniture.

2

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 4

INSTALLATIONINSTRUCTIONS

Selectinginstallationplace

Selectaninstallationlocationwhichisrigidandstrongenoughtosupportorholdtheunit,andselecta

locationforeasymaintenance.Readcompletely,thenfollowstepbystep.

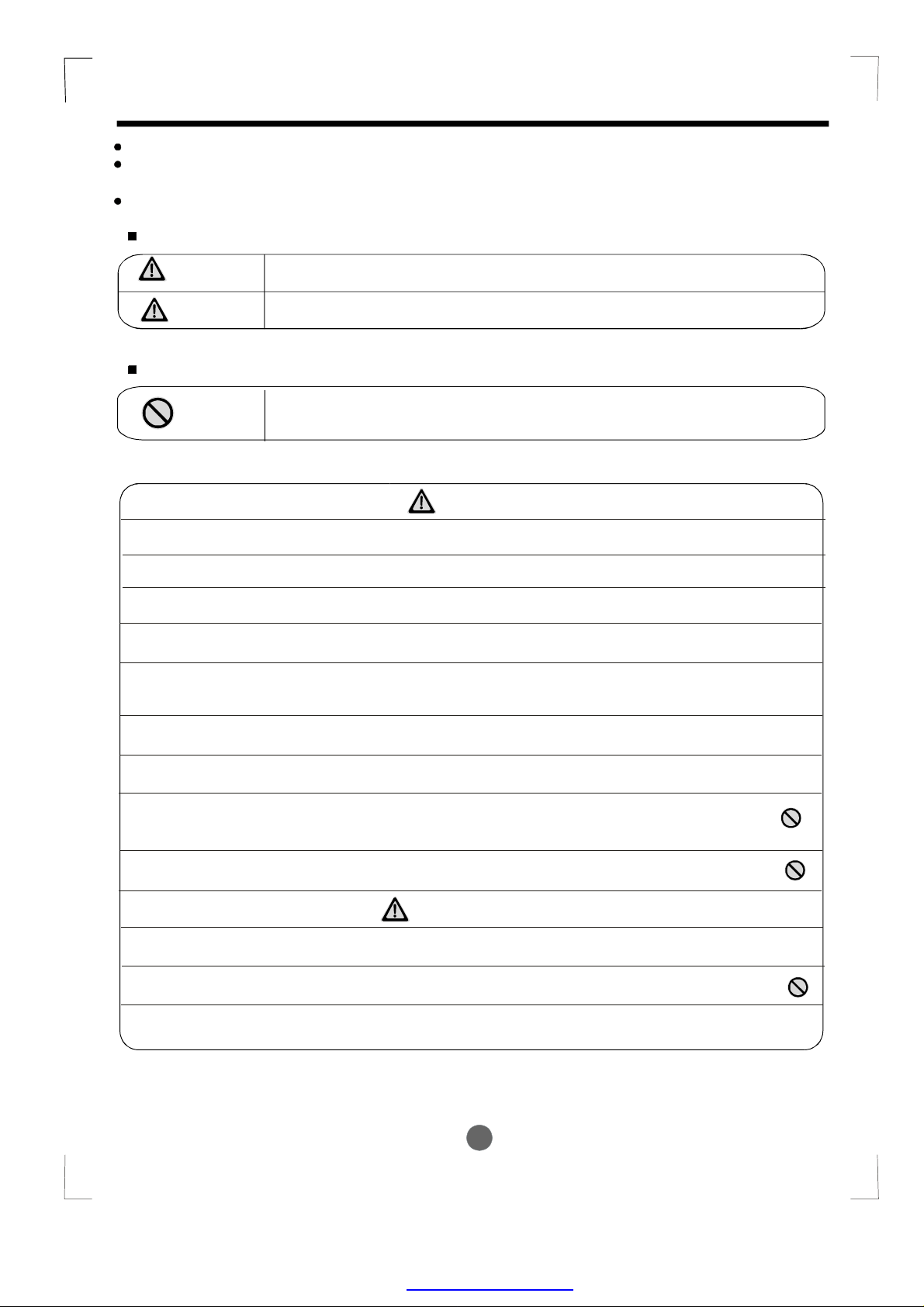

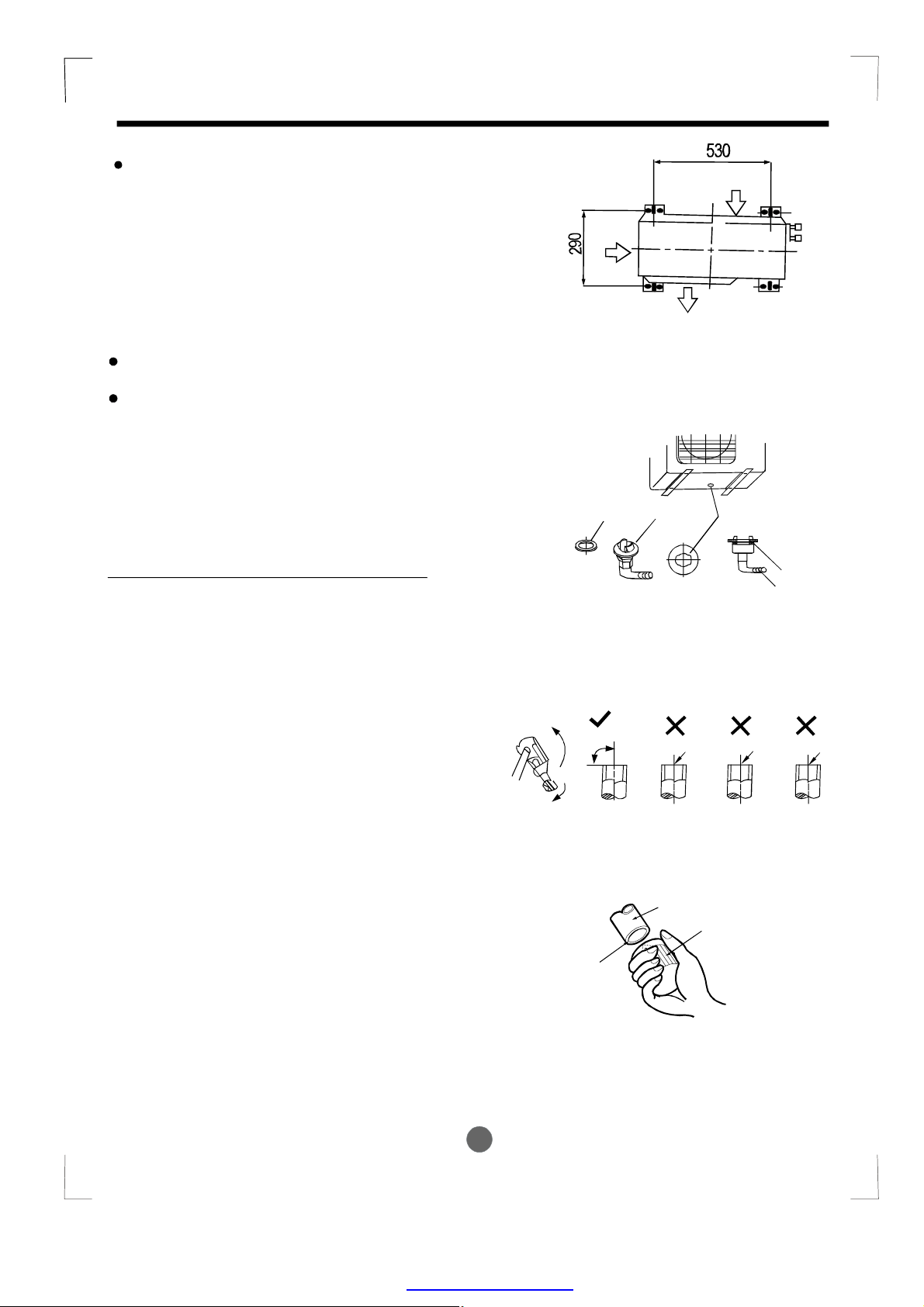

Indoorunit

Donotexposetheindoorunittoheatorsteam.

Selectaplacewheretherearenoobstaclesinfront

oraroundtheunit.

Makesurethatcondensationdrainagecanbe

convenientlyroutedaway.

Donotinstallnearadoorway.

Ensurethespacesindicatedbyarrowsfromthe

wallceilingorotherobstacles.

Aplacewherenoisepreventionistakenintoconsideration.

Aplace1mormoretoTVorradioinstrument.

Aplacewhereaircirculationintheroomisgood.

Thereshouldnotbeanydirectsunlight.Otherwise,thesun

willfadetheplasticcabinetandaffectitsappearance.If

unavoidable,sunlightpreventionshouldbetakenintoconsideration.

Outdoorunit

Ifanawningisbuiltovertheoutdoorunittoprevent

directsunlightorrainexposure,makesurethatheat

radiationfromthecondenserisnotrestricted.

Keepthespacesindicatedbyarrowsfromwallor

otherobstacles.

Donotplaceanimalsandplantsinthepathofthe

airinletoroutlet.

Taketheairconditionerweightintoaccountand

selectaplacewherenoise,vibrationandhotair

dischargedwillnotbeanissue.

Donotinstallinaplacefullofmachineoilorsulfide

gassuchashot-springresort.

Donotinstallinasalineplacesuchascoast.

Donotinstallinaplacewheretherearehighfrequency

machinessuchaswirelessequipment,welding

machineormedicalfacility.

Front

Fig.1

Fig.2

Rooftopinstallation:

Iftheoutdoorunitisinstalledonaroofstructure,besuretoleveltheunit.

Ensuretheroofstructureandanchoringmethodareadequatefortheunitlocation.

Consultlocalcodesregardingrooftopmounting.

Toolsneededforinstallation:

Levelgauge

Screwdriver

Electricdrill,Holecoredrill(65φ mm)

Flaringtoolset

Specifiedtorquewrenches:1.8kgf.m,

4.2kgf.m,5.5kgf.m,6.6kgf.m

(differentdependingonmodelNo.)

Spanner(halfunion)

Hexagonalwrench(4mm)

Gas-leakdetector

Vacuumpump

Gaugemanifold

Usersmanual

Thermometer

Multimeter

Pipecutter

Measuringtape

3

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 5

INSTALLATIONINSTRUCTIONS

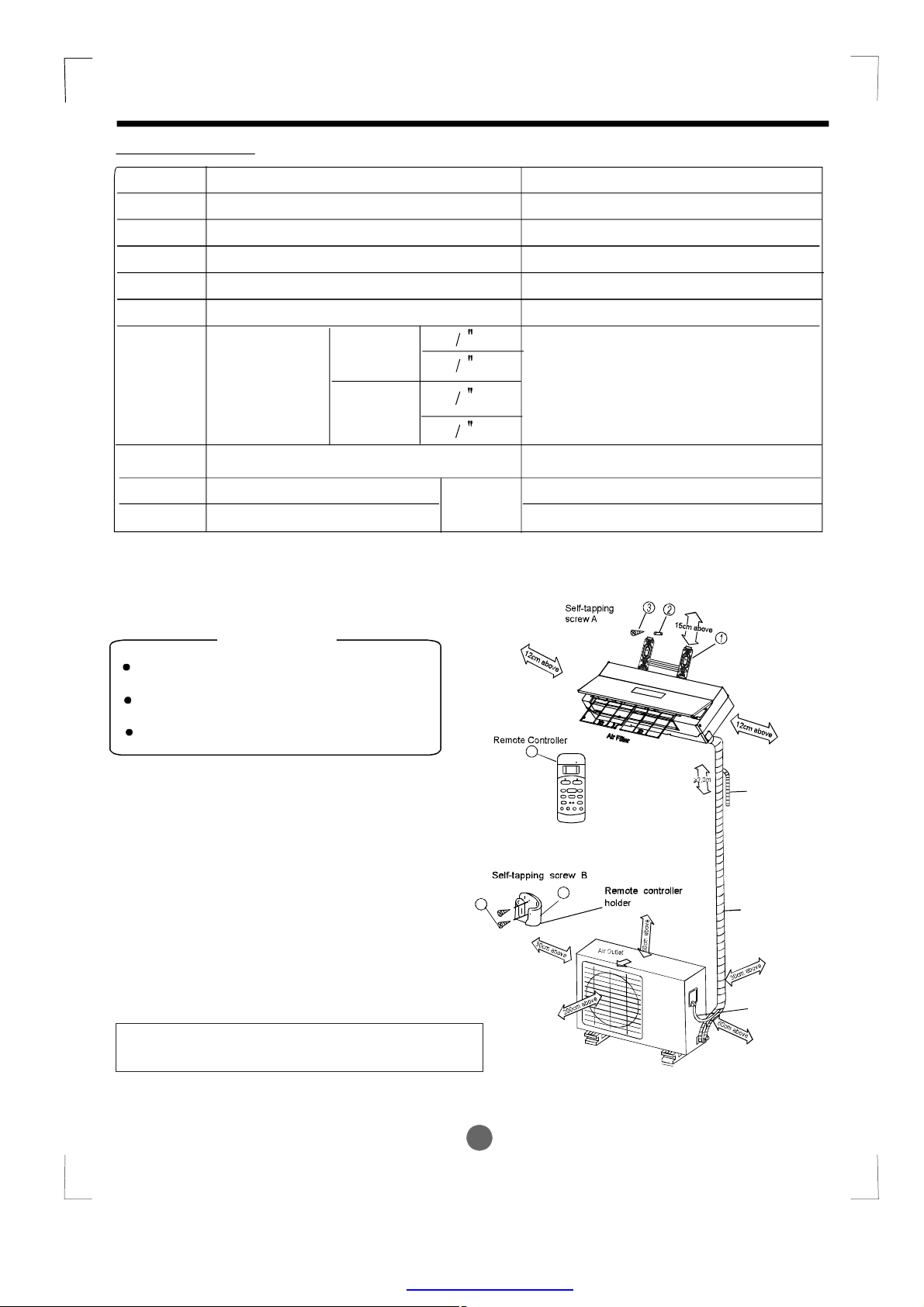

Accessories

Number

1

2

3

4

5

NameofAccessories

InstallationPlate

PlasticExpansionSheath

Self-tappingScrewAST3.9X25

Seal(Forcooling&heatingmodelsonly)

DrainJoint(Forcooling&heatingmodelsonly)

Qty’

1

5-8(dependingonmodels)

5-8(dependingonmodels)

1

1

14

Connecting

6

pipeAssembly

Liquidside

Gasside

38

12

Partsyoumustpurchase.Consult

thetechnicianfortheproper

pipesize.

58

7

8

9

Remotecontroller

Self-tappingScrewBST2.9X10

Remotecontrollerholder

Optional

parts

Note: Excepttheabovepartsprovided,theotherpartsneededduringinstallationyou

mustpurchase.

1

2

1

CAUTION

Useastudfindertolocatestudstoprevent

unnecessarydamagetothewall.

Aminimumpiperunof3metresisrequired

tominimisevibration&excessivenoise.

TwooftheA,BandCdirectionsshouldbe

freefromobstructions.

●

Thisillustrationisforexplanationpurposesonly.

●

Copperlinesmustbeinsulatedindependently

7

SETTEMPERATURE(C)

AUTO

FAN

COOL

HIGH

DRY

MED

HEAT

LOW

ADJUST

ON/OFF

MODE

FANSPEED

DIRECTION

/SWING

SLEEP

TIMERON

CLEAN

TIMEROFF

RESETLOCK

AIR

SELF

FOLLOW

LED

TURBO

CLEAN

ME

DISPLAY

8

9

A

B

Additionaldrainpipe

Wrappingtape

Loopthe

connective

cable.

C

.

Fig.3

4

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 6

INSTALLATIONINSTRUCTIONS

Indoorunitinstallation

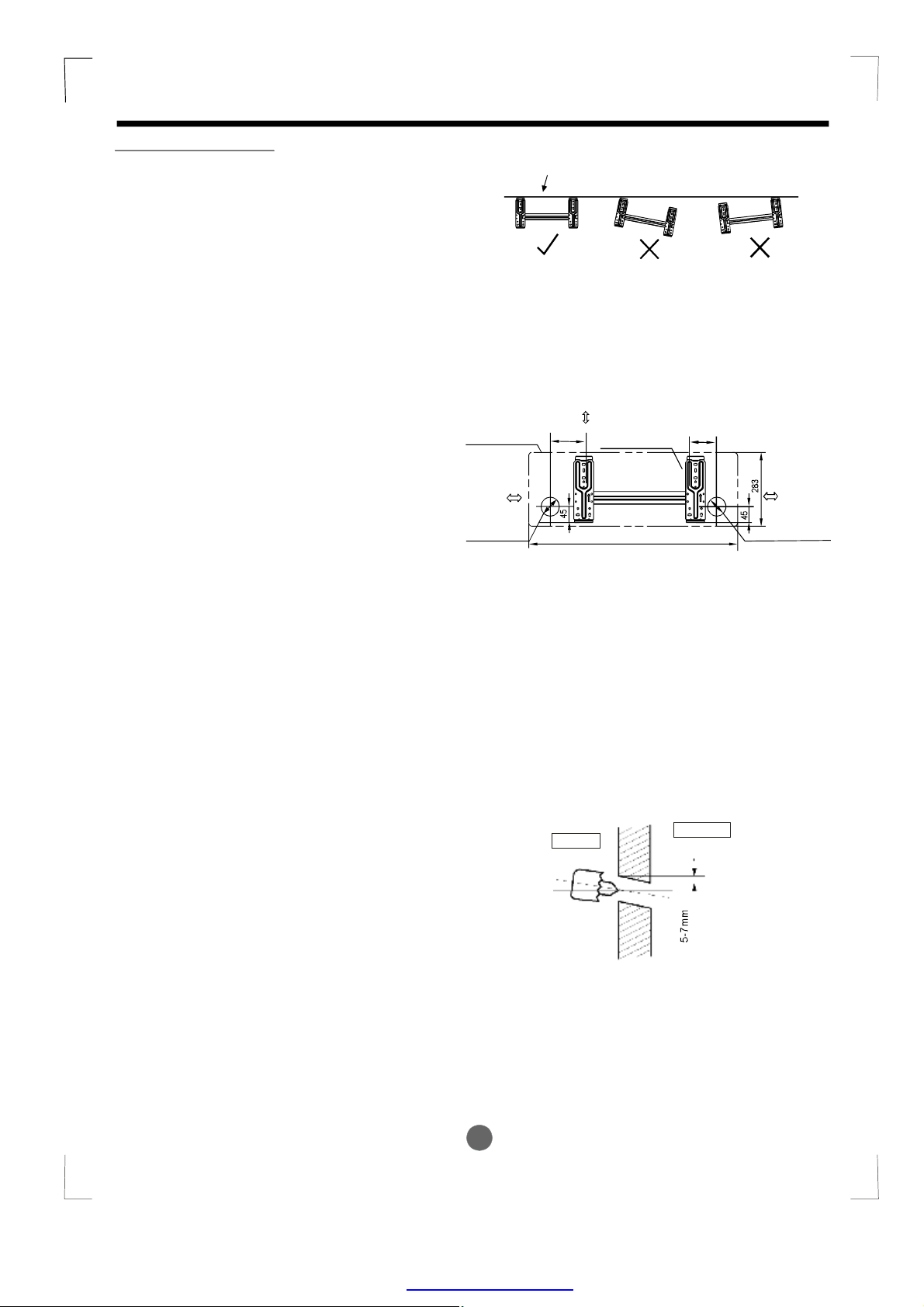

1.FittheInstallationPlate

1.Fittheinstallationplatehorizontally

onstructuralpartsofthewallwith

spacesaroundtheinstallationplate.

2.Ifthewallismadeofbrick,concrete

orthelike,drilleight(8)5mmdiameter

holesinthewall.InsertClipanchorfor

appropriatemountingscrews.

3.Fittheinstallationplateonthewall

witheight(8)type“A” screws.

Note:

FittheInstallationPlateanddrill

holesinthewallaccordingtothe

wallstructureandcorresponding

mountingpointsontheinstallation

plate.Theinstallationplateisdifferent

accordingtothemodels.

(Dimensionsarein“mm” unless

otherwisestated)

Indoorunitoutline

120mmor

moretowall

Leftrearside

refrigerant

pipehole65

φ

Correctorientation

ofInstallationPlate

Fig.4

150mmormoretoceiling

Installationplate

900

Fig.5

90150

120mmor

moretowall

Rightrearside

refrigerant

pipehole65

φ

2.Drillaholeinthewall

1.Determineholepositionsaccording

tothediagramdetailedinFig.5.Drill

one(1)hole(65mm)slantingslightly

φ

tooutdoorside.

2.Alwaysusewallholeconduitwhen

drillingmetalgrid,metalplateorthelike.

Wall

Indoor

Outdoor

Fig.6

5

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 7

INSTALLATIONINSTRUCTIONS

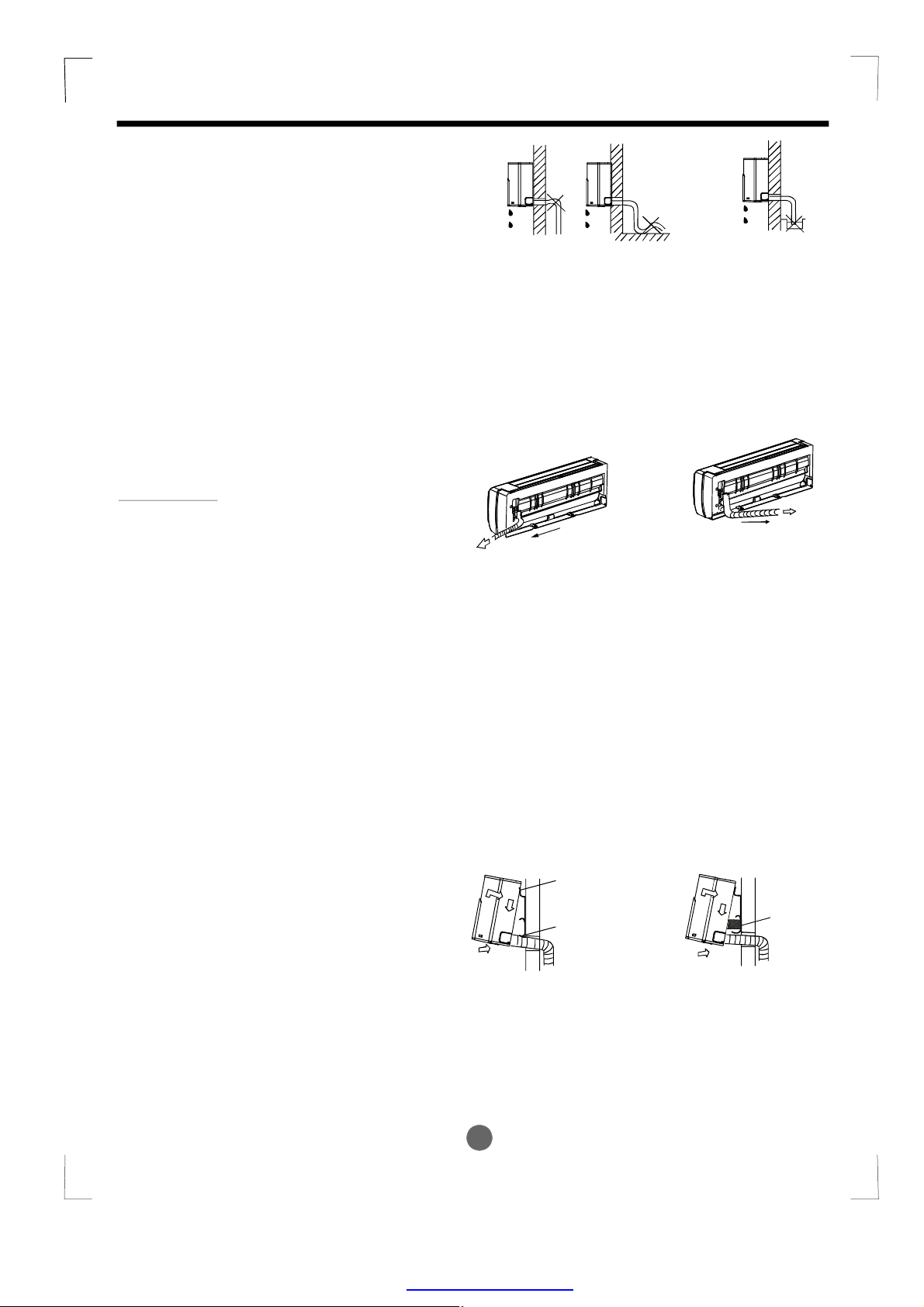

3.ConnectivePipeandDrainage

Installation

Drainage

1.Runthedrainhoseslopingdownward.

Donotinstallthedrainhoseas

illustratedinFig.7.

2.Whenconnectingextensiondrainhose,

insulatetheconnectingpartofextension

drainhosewithashieldpipe,donotlet

thedrainhoseslack.

Connectivepipeinstallation

IMPORTANT:

oftheindoorunit,theunitcanonlyuseRighthandpipingorRightrearpipingasshownin

Fig.8.

1.Removethecoverforright-handpipingfirst.

2.Fortherightrearpiping,installthepipingas

showninFig.8.

3.Fixtheendoftheconnectivepipe.(Refer

toTighteningConnectionin

REFRIGERANTPIPINGCONNECTION)

Forthebottomspacelimitation

Donotblockwaterflowbyarise.

Right-handpiping

Fig.8

Donotputtheendof

drainhoseintowater.

Fig.7

Rightrearpiping

4.Indoorunitinstallation

1.Passthepipingthroughtheholeinthe

wall.

2.Puttheupperclawatthebackofthe

indoorunitontheupperhookofthe

installationplate,movetheindoorunit

fromsidetosidetoseethatitissecurely

hooked(seeFig.9&Fig.10).

3.Pipingcaneasilybemadebyliftingthe

indoorunitwithacushioningmaterial

betweentheindoorunitandthewall.

Getitoutafterfinishpiping.

4.Pushthelowerpartoftheindoorunitup

onthewall,thenmovetheindoorunit

fromsidetoside,upanddowntocheck

ifitishookedsecurely.

UpperHook

Cushioning

LowerHook

Fig.9

Fig.10

material

6

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 8

5.Pipingandwrapping

Bundlethetubing,connectingcable,anddrain

hosewithtapesecurely,evenlyasshownin

Fig.12

Becausethecondensedwaterfromrearofthe

indoorunitisgatheredinpondingboxandis

pipedoutofroom.Donotputanythingelsein

thebox.

INSTALLATIONINSTRUCTIONS

Indoorunit

Connective

cable

Pondingbox

Piperoom

Drainhose

CAUTION

Connecttheindoorunitfirst,thenthe

outdoorunit.

Donotallowthepipingtoletoutfromthe

backoftheindoorunit.

Becarefulnottoletthedrainhoseslack.

Heatinsulatedbothoftheauxiliarypiping.

Besurethatthedrainhoseislocatedat

thelowestsideofthebundle.Locatingat

theuppersidecancausedrainpanto

overflowinsidetheunit.

Neverintercrossnorintertwistthepower

wirewithanyotherwiring.

Runthedrainhoseslopeddownwardto

drainoutthecondensedwatersmoothly.

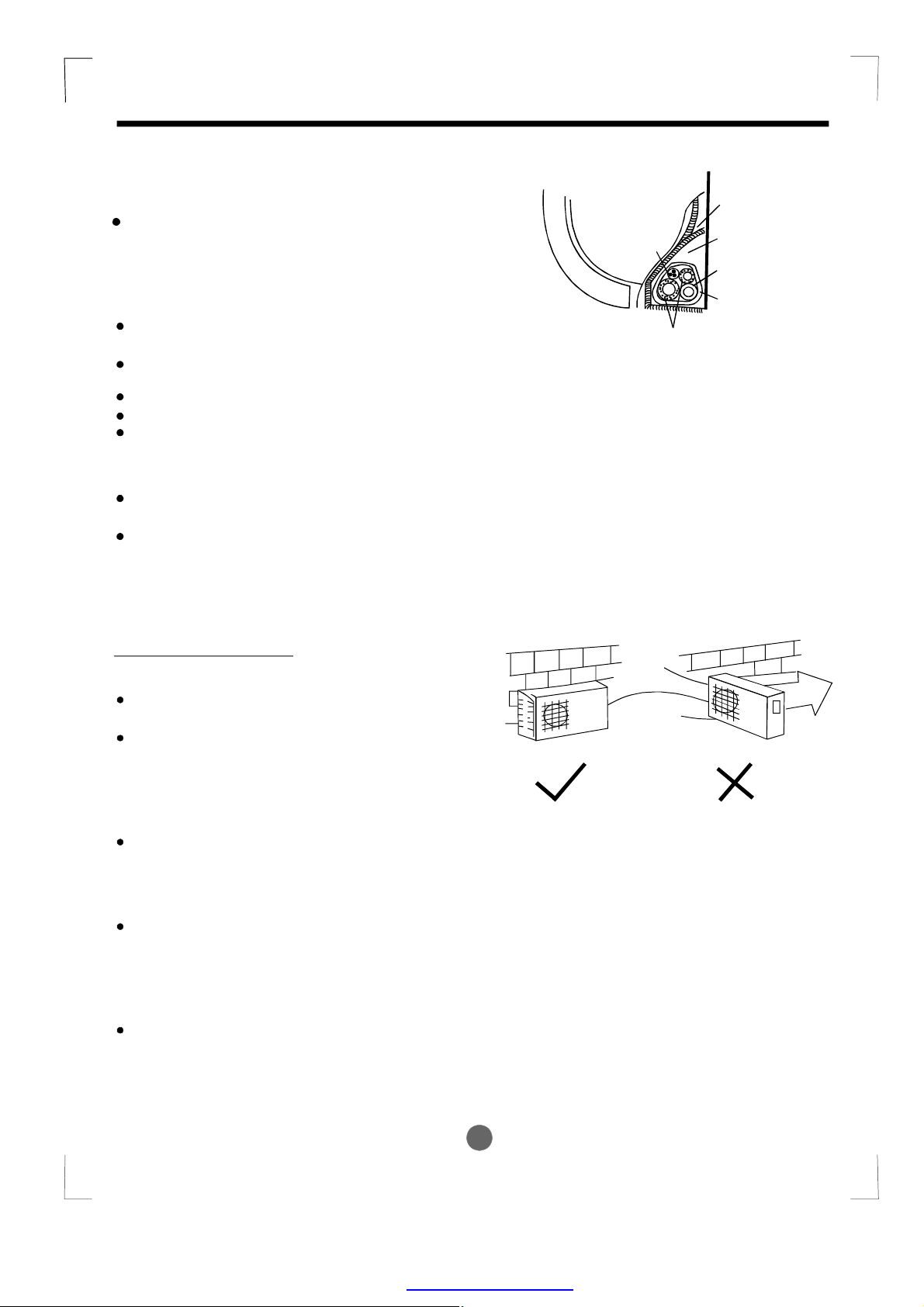

Outdoorunitinstallation

Outdoorinstallationprecaution

Installtheoutdoorunitonarigidbaseto

preventincreasingnoiselevelandvibration.

Determinetheairoutletdirectionwherethe

dischargedairisnotblocked.Inthecasethat

theinstallationplaceisexposedtostrongwind

suchasaseaside,makesurethefanoperating

properlybyputtingtheunitlengthwisealongthe

wallorusingadustorshieldplates.

Speciallyinwindyarea,installtheunittopreventtheadmissionofwind.Ifneedsuspending

installation,theinstallationbracketshould

accordwithtechniquerequirementinthe

installationbracketdiagram.

Theinstallationwallshouldbesolidbrick,

concreteorthesameintensityconstruction,or

actionstoreinforce,dampingsupportingshould

betaken.Theconnectionbetweenbracketand

wall,bracketandtheairconditionershouldbe

firm,stableandreliable.

Besurethereisnoobstaclewhichblock

radiatingair.

Wrappingbelt

Connectivepipe

Fig.11

Strong

wind

Fig.12

7

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 9

REFRIGERANTPIPECONNECTION

Settlementofoutdoorunit

Anchortheoutdoorunitwithaboltand

nut10or8tightlyandhorizontally

φφ

onaconcreteorrigidmount.

Airinlet

Airinlet

Airoutlet

Drainjointinstallation

Ifadrainelbowisused,theunitshouldbe

placedonastandwhichistallerthan3cm.

Fitthesealintothedrainelbow,theninsert

thedrainjointintothebasepanholeof

outdoorunit,rotate90tosecurelyassemble

。

them.Connectingthedrainjointwithan

extensiondrainhose(Locallypurchased),

incaseofthewaterdrainingofftheoutdoorunit

duringtheheatingmode.

Refrigerantpipeconnection

1.Flaringwork

Maincauseforrefrigerantleakage

isduetodefectintheflaringwork.

Carryoutcorrectflaringwork

usingthefollowingprocedure:

A:Cutthepipesandthecable.

1.Usethepipingkitaccessoryorpipes

purchasedlocally.

2.Measurethedistancebetweentheindoor

andtheoutdoorunit.

3.Cutthepipesalittlelongerthanthe

measureddistance.

4.Cutthecable1.5mlongerthanthepipe

length.

B:Burrremoval

1.Completelyremoveallburrsfromthecut

crosssectionofpipe/tube.

2.Puttheendofthecoppertube/pipeina

downwarddirectionasyouremoveburrsin

ordertoavoiddroppingburrsintothetubing.

Seal

。

90

Pointdown

Fig.13

Drainjoint

Fig.14

Oblique

Fig.15

Pipe

Basepanholeof

outdoorunit

Seal

Drainpipe

Roughness Burr

Reamer

8

PDF created with pdfFactory Pro trial version www.pdffactory.com

Fig.16

Page 10

ELECTRICALWORK

C:Puttingnuton

Removeflarenutsattachedtoindoorand

outdoorunit,thenputthemonpipe/tube

havingcompletedburrremoval.(notpossible

toputthemonafterflaringwork)

D:Flaringwork

Firmlyholdcopperpipeinadieinthe

dimensionshowninthetablebelow.

Max.

A(mm)

Min.

Outerdiam.

(mm)

6.35 1.3 0.7

9.52

12.7

12.7

1.6 1.0

1.8

1.8

1.0

1.0

TighteningConnection

Alignthecenterofthepipes.

Sufficientlytightentheflare

nutwithfingers,andthentighten

itwithaspannerandtorquewrench

asshowninFig.20&21.

Outer

diam.

14

38

12

Tightening

torque(N.cm)

1500

(153kgf.cm)

2500

(255kgf.cm)

3500

(357kgf.cm)

Additionaltightening

torque(N.cm)

1600

(163kgf.cm)

2600

(265kgf.cm)

3600

(367kgf.cm)

Coppertube

Bar

Copperpipe

Flarenut

Fig.17

Handle

Bar

Yoke

Cone

Clamphandle

Indoorunittubing Flarenut Pipings

Redarrowmark

Fig.18

Fig.19

Caution

Excessivetorquecanbreaknut

dependingoninstallationconditions.

Electricalwork

Fig.20

ElectricsafetyregulationsfortheinitialInstallation

1.Ifthereisserioussafetyproblemaboutthepowersupply,thetechniciansshouldrefuse

toinstalltheairconditionerandexplaintotheclientuntiltheproblemissolved.

2.Powervoltageshouldbeintherangeof90%~110%ofratedvoltage.

3.Thecreepageprotectorandmainpowerswitchwitha1.5timescapacityofMax.Current

oftheunitshouldbeinstalledinpowercircuit.

4.Ensuretheairconditionerisgroundedwell.

5.AccordingtotheattachedElectricalConnectionDiagramlocatedonthepaneloftheoutdoor

unittoconnectthewire.

6.Allwiringmustcomplywithlocalandnationalelectricalcodesandbeinstalled

byqualifiedandskilledelectricians.

7.Anindividualbranchcircuitandsinglereceptacleusedonlyforthisairconditionermustbe

available.Seethefollowingtableforsuggestedwiresizesandfusespecifications:

9

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 11

ELECTRICALWORK

Minimumnorminalcross-sectional

areaofconductors:

Ratedcurrent

ofappliance

(A)

>3and<6

>6and<10

>10and<16

>16and<25

NOTE

:Thecablesizeandthecurrentofthe

fuseorswitcharedeterminedbythemaximum

currentindicatedonthenameplatewhichlocated

onthesidepaneloftheunit.Pleaserefertothe

nameplatebeforeselectingthecable,fuseand

switch.

Connectthecabletotheindoorunit

NOTE:Beforeperforminganyelectrical

work,turnoffthemainpowertothesystem.

1.Thefrontpanelshouldberemovedbefore

connectingthecablebetweeninsideand

outside.

2.Pushthefrontpanelupstraightly,thenopen

ittoanangleof20(Fig.21&22).Totakedown

thefrontpanel,youshouldfirstreleasethetwo

lockleversonthebackofthepanel(Fig.23),

thenliftitupward.

3.Releasethecouplerplugsconnectedwiththe

frontdisplaypanelasshowninFig.24.

4.Aftertakingdownthefrontpanel,

electricalboxcoverbylooseningthescrew

asshowninFig.25.

5.Connectingcablebetweenindoorunitand

outdoorunitshallbeapprovedpolychloroprene

sheathedflexiblecord,typedesignation

H07RN-Forheaviercord.Ensurethecolourof

wiresofoutdoorunitandtheterminalNos.are

thesametotheindoorsrespectively,Fig.27.

6.Wrapthosecablesnotconnectedwithterminals

withinsulationtapes,sothattheywillnottouch

anyelectricalcomponents.Securethecable

ontothecontrolboardwiththecordclamp.

Connectthecouplerplugsconnectedwiththe

frontdisplaypanel.

Nominalcross-sectional

area

2

(mm)

0.75

1

1.5

2.5

O

removethe

,

Coupler

plugs

1 2

Fig.21

Backviewofthefrontpanel

Locklever

Removethe

frontpanel

Fig.22

Fig.23

Fig.24

Removetheelectrical

boxconverbyloosen

thescrew.

Fig.25

10

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 12

7.Reinstalltheelectricalboxcover,keepthe

whitebandjustunderthegrooveasshownin

Fig.26aandcurvethecableintothegroove.

MakesurethecableconnectedwithLED

displaywindowisfixedbytheelectricalbox

coverafterinstallation,Fig.26b.

ELECTRICALWORK

Groove

Connectthecabletotheoutdoorunit

1.Removetheelectricalcontrolboardcover

fromtheoutdoorunitbylooseningthescrew

asshowninFig.28.

2.Connecttheconnectivecablestothe

terminalsasidentifiedwiththeirrespective

matchednumbersontheterminalblockof

indoorandoutdoorunits,Fig.27.

3.Securethecableontothecontrolboardwith

thecordclamp.

4.Topreventtheingressofwater,fromaloop

oftheconnectivecableasillustratedinthe

installationdiagramofindoorandoutdoor

units.

5.Insulateunusedcords(conductors)with

PVC-tape.Processthemsotheydonot

touchanyelectricalormetalparts.

Cableconnected

withLEDdisplay

window

Terminalsonthe

outdoorunit

L1

Y/G

L1 L2

Topowersupply

Band

Fig.26a

L2

S L1

SL1L2

Terminalsonthe

indoorunit

Fig.27

Fig.26b

CircuitBreaker

L2

Tosolarpanel

Y/G

11

Cover

Screw

Fig.28

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 13

ELECTRICALWORK

Installationofthesolarphotovoltaicsystem

Thisguidecontainsinformationregardingtheinstallationandsafehandlingofsolarphotovoltaic

module.Allinstructionsshouldbereadandunderstoodbeforeattemptingtoinstall.Ifthereis

anyquestion,pleasecontactoursalesdepartmentforfurtherexplanation.Theinstallershould

conformtoallthesafetyprecautionslistedinthisguidewheninstallingthemodule.Localcodes

shouldalsobefollowedinsuchinstallations.

Thismanualdescribesseveraltypicalsystemsofsolarphotovoltaic,butdoesnotinvolvethe

specificstructuresandinstallationproceduresoftheinstallation.Pleaseconsultthesupplierfor

theinformationofthefollowingassemblys:

a)thespecificationsofthesolarphotovoltaicsystem;

b)cablematerial

c)connectingcomponents

d)bracketandsupport

e)supportingparts.

Beforeinstallingasolarphotovoltaicsystem,theinstallershouldbecomefamiliarwiththe

mechanicalandelectricalrequirementforsuchasystem.Keepthisguideinasafeplacefor

futurereference(careandmaintenance)andincaseofsaleordisposalofthemoduleatthe

endofitsusefullife.

General

Installingsolarphotovoltaticsystemsmayrequirespecializedskillsandknowledge.Installation

shouldbeperformedonlybyqualifiedpersons.

Allmodulescomewithapermanentlyattachedjunctionboxand#12AWGteminatedin

MuticontactPV-KBT4orPV-KST4connectors.Wecanprovidecustomerswithfittedcables

foreaseofinstallation,ifdesired.

Theinstallershouldassumetheriskofallinjurythatmightoccurduringinstallation,including,

withoutlimitation,theriskofelectricshock.

Thesolarphotovoltaticelectricalenergyproductionsystemmustcomplywiththefollowing

tableforsuggestedcurrentandvoltagespecifications:

MaximumPowerVoltage(W)

Optimumoperatingvoltage(Vmp)

Optimumoperatingvoltage(Vmp)

Open-circuitvoltage(Vmp)

Short-circuitcurrent(Vmp)

Maximumpowercurrent(Pmax)

OneindividualmodulemaygenerateDCvoltagesgreaterthan30voltswhenexposedtodirect

sunlight.ContactwithaDCvoltageof30Vormoreispotentiallyhazardous.Electricaljointssuch

asthewireterminalwillcausesparks,burningordeadlyelectricshock.Pleasedonottouchsuch

terminalsdirectlyunderanycircumstances.

<700W

<DC32V

>DC20V

<DC42V

<DC25A

<DC20A

Fig.29

12

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 14

ELECTRICALWORK

Whendisconnectingwiresfromaphotovoltaicmodulethatisexposedtosunlight,

anelectricarcmayresult.Sucharcsmaycauseburns,combustionandmayotherwisecreate

problems.Therefore,beextremelycareful!

Photovoltaicsolarmodulesconvertlightenergytodirect-currentelectricalenergy.Theyare

designedforoutdooruse.Modulesmaybegroundmounted,mountedonrooftops,vehicles,

orboats.Properdesignofsupportstructuresistheresponsibilityofthesystemdesignerand

installer.Properuseofmountingholesissuggestedinafollowingparagraph.

Donotattempttodiassemblethemodule,anddonotremoveanyattachednameplatesor

components.

Fig.30

Donotapplypaintoradhesivetomoduletopsurface.

Donotusemirrorsorothermagnifierstoartificiallyconcentratesunlightonthemodule.

Fig.31

Wheninstallingthesystem,abidewithalllocal,regionalandnationalstatutoryregulations.

Obtainabuildingpermitwherenecessary.Abidewithanylocalandnationalregulationswhen

mountingonvehiclesorboats.

Safetyprecautionforinstallingasolarphotovoltaicsystem

Wheninstallingthesolarmodulesorrepairingtheairconditioner,ensurethecircuitbreakeronthe

solarpaneloftheoutdoorunitisintheOFFstate(pushtheswitchtoposition).During

normaloperation,thecircuitbreakershouldbeinthestate(pushtheswitchtoposition).

""""

""""

ONON

Fig.32

12

13

OFF

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 15

ELECTRICALWORK

Solarmodulesproduceelectricalenergywhenlightstrikesontheirfrontsurface.TheDCvoltage

mayexceed30V.Ifmodulesareconnectedinseries,thetotalvoltageisequaltothesumofthe

individualmodulevoltages.Ifmodulesareconnectedinparallel,thetotalcurrentisequaltothe

sumofindividualmodulecurrents.

Fig.33

Keepchildrenwellawayfromthesystemwhiletransportingandinstallingmechanicaland

electricalcomponents.

Fig.34

Completelycoverthemodulewithanopaquematerialduringinstallationtokeepelectricityfrom

beinggenerated.Donottouchthecomponentsortheendoflivewires.However,if

protectionshasbeentakenduringtheoperation

accordingtothelocalsafetyregulations,the

aboverequirementisunnecessary.

appropriate

Fig.35

Donotwearmetallicrings,watchbands,ear,nose,lipringsorothermetallicdeviceswhile

installingortroubleshootingphotovoltaicsystems.

Useonlyinsulatedtoolsthatareapprovedforworkingonelectricalinstallations.

Fig.36

13

14

Fig.37

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 16

ELECTRICALWORK

Whenperforminginstallationindryconditions,pleaseensurethetoolsusedinthedry.

Fig.38

Abidewiththesafetyregulationsforallothercomponentsusedinthesystem,includingwiring

andcables,connectors,chargingregulators,inverters,storagebatteriesandrechargeable

batteries,etc.

Useonlyequipment,connectors,wiringandsupportframessuitableforuseinasolarelectric

systems.Alwaysusethesametypeofmodulewithinaparticularphotovoltaicsystem.

Themoduleframemustbeproperlygrounded.Thegroundingwiremustbeproperlyfastenedto

themoduleframetoassuregoodelectricalcontact.Usetherecommendedtype,oranequivalent,

connectorforthiswire.

Fig.39

Undermormaloutdoorconditionsthemodulewillproducecurrentandvoltagesthataredifferent

thanthoselistedinthedatesheet.Datasheetvaluesarevaluesexpectedatstandardtest

conditions.Accordingly,duringsystemdesign,valuesofshort-circuitcurrent(Isc)andopencircuitvoltage(Voc)markedonULseriesmodulesshouldbemultipliedbyafactorof1.25

whendeterminingcomponentvoltageratings,conductorampacity,fusesizeandsizeofcontrols

connectedtothemoduleorsystemoutput.

Theholeinthebackofthemoduleframeisusedtodrainthewater,ensurenottobeblocked.

Mechanicalinstallation

1.Selectinginstallationplace

Selectasuitableplaceforinstallationofthemodule.

timeoftheday.

Themoduleshouldbefacingduesouthinnorthernlatitudesandduenorthinsouthern

latitudesforbestpowerproduction.

Fordetailedinformationonthebestelevationtiltanglefortheinstallation,pleaseconsult

withthesolarphotovoltaticsystemsupplier.

Donotusemoduleneartheplacewheretheflammablegasmaybegeneratedorcollected.

Themoduleshouldnotbeshadedatany

15

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 17

ELECTRICALWORK

Fig.40

2.Selectingthepropersupportframe

Alwaysobservetheinstructionsandsafetyprecautionsincludedwiththesupportframetobe

usedwiththemodule.

Neverattempttodrillholesintheglasssurfaceofthemodule,itwillvoidthewarranty.

Donotdrilladditionalmountingholesintheframeofthemodule,itwillvoidthewarranty.

Fig.41

Modulesmustbesecurelyattachedtothemountingstructureusingfourmountingpointsfor

normalinstallation.Ifadditionalwindorsnowloadsareconsideratedfortheinstallation,additional

mountingpointsarealsoused.

Thesupportframemustbemadeofdurable,corrosion-resistantandUV-resistantmaterial.

Theheatexpansionandcoldcontractionofthesupportframeshouldhavenoaffectiontoits

usageandperformance.

3.Groundmount

Selecttheheightofthemountingsystemtopreventthelowestedgeofthemodulefrombeing

coveredbysnowforalongtimeinwinterinareasthatexperienceheavysnowfalls.Inaddition,

assurethelowestportionofthemoduleisplacedhighenoughsothatitisnotshadedbyplants

ortreesordamagedbysandandstonedrivenbywind.

Fig.42

1416

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 18

4.Roofmount

ELECTRICALWORK

Wheninstallingamoduleonarooforbuilding,ensurethatitissecurelyfastenedandcannotfall

asaresultofwindorsnowloads.

Fig.43

Provideadequateventilationunderamoduleforcooling(5cmminimumairspacebetweenmodule

andmountingsurface).

Fig.44

Wheninstallingmoduleonaroof,ensurethattheroofconstructionissuitable.Inaddition,any

roofpenetrationrequiredtomountthemodulemustproperlysealedtopreventleaks.

Insomecases,aspecialsupportframemaybenecessary.

Theroofinstallationofsolarmodulesmayaffectthefireproofingofthehouseconstruction,soit

isnecessarytouseanearthgroundfaultcircuitbreaker.Anyunproperinstallationmaycause

accidentalinjuries.

Fig.45

Wheninstallingthemoduleonarooforbuilding,dosoincalmwinds.Installingamoduleduring

strongwindsmaycauseaccidents.

5.Polemount

Wheninstallingamoduleonapole,chooseapoleandmodulemountingstructurethatwill

withstandanticipatedwindsforthearea.Thepolemusthaveasolidfoundation.

Roofmount

Groundmount

Fig.46

Polemount

17

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 19

ELECTRICALWORK

6.Generalinstallation

Modulemountingmustusethepre-drilledmountingholesintheframe.

Themostcommonmountingisachievedbymountingthemoduleusingthefoursymmetry

pointsclosedtotheinnersideonthemoduleframe.

Ifexcessivewindorsnowloadsareexpected,alleightmountingholesmustbeused.

Ifyouwanttoinstallthemodulewithoutusingthe

consultwiththesupplier.

Donotinstallintherainyweather,itmaycauseinsulationfailureduetomoisture,andthereis

ariskofelectricshock.

Fig.47

Donotattempttoliftthemodulebygraspingthemodulesjunctionboxwhilemoving.

pre-drilledmountingholesintheframe,please

,

Donotstandorsteponmodule.

Fig.48

Fig.49

Donotthrowthemoduleordropanythingonthemodule.

Fig.50

Toavoidgalssbreakage,donotplaceanyheavyobjectsonthemodule.

Donotsetthemoduledownhardonanysurface.

Inappropriatetransportandinstallationmaybreaktheglassofthemodule.

Fig.51

18

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 20

ELECTRICALWORK

Electricalinstallation

1.Generalinstallation

Donotusemodulesofdifferentconfigurationsinthesamesystem.

Thesolarphotovolaticarrayconsistsofmodulesconnectedinparallel,nomorethan3

modulescanbeusedinparallel.Modulesinparallelcanincreasetheoutputcurrentofthesolar

photovolaticsystem,especiallyforIfmodules

areconnectedinparallel,thetotalvoltagesisequaltothesumofindividualvoltages.

Ifmodulesusedinthesolarphotovolaticsystemarenotthespecifiedbrandofthemanufacturer,

itmustcomplywiththeelectricalrequirement.

ofconnectormustbeselectedtosuitthemaximumsystemshortcircuitcurrent,Otherwisethe

cableandtheconnectorwillbeoverheatedunderlargecurrent.

Modulesconnectedinparallelmustuseadesignatedswitchjunctionbox,pleasecontactthe

supplierforpurchasement.Themaximumcurrentofthesolarphotovoltaicsystemandthe

maximumcurrentandvoltagecapacityofthejointsandconnectivecablesshouldbeconsiderated

duringinstallation.

ConnectionmethodA:Thedistancebetweenthemodulesisclose,noneedtousetheextension

cord(3meters),seeFig.52a.

applicationsrequiringhighcurrents,lowvoltages.

Thecrosssectionareaofcableandthecapacity

Fig.52a

Outdoorunit

wireconnection

19

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 21

ELECTRICALWORK

ConnectionmethodB:Usinga3mextensioncordduringconnectionifthemodulesaredistant

apart,seeFig.52b.

Outdoorunit

wireconnection

Fig.52b

Ifyouwanttoconnectthephotovoltaicmodulesbyusingthecablespurchasedbyyourself,the

followingrequirementsmustbecomplied:

Cableinstallationshouldcomplywithalllocalregionalandnationalregulations.

Insomecountries,anindividualcircuitbreakerusedbetweenthesolarpanelandair

conditionermustbeinstalled.Soselectancircuitbreakerinaccordancewithlocalregulations,

andtheratedcurrentismorethan30A.

Cableinstallationneedtodistinguishthepositivepoleandnegativepole,reverseconnection

maycausepermanentdamagetotheairconditioner.

Usequalifiedphotovoltaiccablesonly.

ThecablecanresistUVraysandclimateofrapidchange.

Theratedvoltageofthecableismorethan600V.

Thecrosssectionareaofthecabledependsonthemaximumshortcircuitcurrentandthe

lengthofwire.

Beverycarefulwheninstallthecableatextremelylowtemperature.

Recommendedtousethecableofcrosssectionareaof4mmorgreater,andthewireshould

beasshortaspossibletoreducetheenergyconsumption.

Whenthemodulesareconnectedinparallel,cablesmustbesecurelyfastenedonthesupportframe

whichisusedformountingthemodulestoavoidwireslack.

Fig.53

20

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 22

Donotplacethecableonthesharpedgeofthethings.

Fig.54

Attentiontotheminimumbendingradiusofthewire.

Fig.55

Donotunplugtheconnectorwhenthepowerison.

ELECTRICALWORK

Fig.56

Theprotectingsheathmustbeusedonthecableifthereisapossiblefortheanimalsorchildrens

easytotouchit.

Fig.57

Themanufacturerofthesolarphotovoltaicsystemcansupplycablessuitableforuseinasolar

electricsystems.

21

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 23

ELECTRICALWORK

Ifyouwanttousetheconnectorpurchasedbyyourself,thefollowingrequirementsmustbecomplied:

Useonlyconnectorspecialdesignedforsolarelectricsystems.

Usetherecommendedorspecifiedtoolswheninstalltheconnectors.

Donotunplugtheconnectorswhenthepowerison.

Theconnectorsuitableforthesolarphotovoltaicsystemcanobtainfromthemanufacturer.

Electricalconnection:

Completelycoverthemodulewithanopaquematerialduringmechanicalinstallationandelectrical

installation.

Protectthecablesfrombeingdamaged.

Groundmountingmustabidewithalllocalregulations.

Storagebatterycannotbeconnectedwiththesolarphotovoltaicsystem.

Grounding:

Themoduleframemustbeproperlygrounded.Thegroundingwiremustbeproperlyfastenedto

themoduleframetoassuregoodelectricalcontact.

Ifthesupportframeismadeofmetal,thesurfaceoftheframemustbeelectroplatedandhave

excellentconductivity.Thegroundingwiremustbeproperlyfastenedtothesupportframe.

Therearetwopre-drilledmountingholesintheframe,usedtoinstallthegroundingcable.Each

moduleshouldconnectwiththegroundingcable.

Werecommendtheclosedlugwhengrounding.Firstinsertthegroundcableintothejackofthe

closedlugandweld,theninsertthestainlesssteelbolt(M3)intothetabofthelug,thegrounding

holeontheframeandfinallyanuttosecuretheentireassembly.Thespringwasherisrequiredin

ordertopreventscrewlooseningandcauseimpropergrounding.

Thegroundingresistancemustbelessthan10ohms.

Fig.58

Junctionboxinstallation:

Allmodulescomewithapermanentlyattachedjunctionboxandprovidewithfittedcables.

Thejunctionboxdonotneedthecustomertoinstall,pleasecontactthemanufacturerifthereis

anyproblemwiththemodule.

Disclaimerofliability

Becausetheuseofthismanualandtheconditionsormethodsofinstallation,operation,use

andmaintenanceofphotovoltaic(PV)productarebeyondourcontrol,wedonottakeany

reponsibilityandexpresslydisclaimsliabilityforloss,damage,orexpensearisingoutoforin

anywayconnectedwithsuchinstallation,operation,useormaintenance.Noresposibilityis

assumedbyusforanyinfringementofpatentsorotherrightsofthirdparties,whichmayresulted

byusingthePVproduct.Nolicenseisgrantedbymodificationorotherwiseunderanypatentor

patentrights.Theinformationinthismanualisbasedoncompanysknowledgeandexperience

andisbelievedtobereliable;butsuchinformationincludingproductspecification(without

limitations)andsuggestionsdonotconstituteawarranty,expressedorimplied.Wereserves

therighttochangethemanual,thePVproduct,thespecifications,orproductdatasheets

withoutpriornotice.

,

22

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 24

AIRPURGING

Aftercomplyingtotheaboveconditions,preparethewiringasfollows:

1)Neverfailtohaveanindividualpowercircuitspecificallyfortheairconditioner.Asforthe

methodofwiring,beguidedbythecircuitdiagrampostedontheinsideofcontrolcover.

2)Thescrewwhichfastenthewiringintheelectricalfittingcaseareliabletocomeloose

fromvibrationswhichtheunitissubjectedduringthecouseoftransportation.Check

themandmakesurethattheyarealltightlyfastened.(Iftheyareloose,itcouldcause

burn-outofthewires.)

3)Specificatioofpowersource.

4)Confirmthatelectricalcapacityissufficient.

5)Checkthestartingvoltageismaintainedatmorethan90percentoftheratedvoltage

markedonthenameplate.

6)Confirmthatthecablethicknessisasspecifiedinthepowersourcespecification.

7)Alwaysinstallanearthleakagecircuitbreakerinawetormoistarea.

8)Thefollowingwouldbecausedbyvoltagedrop:

Vibrationofamagneticswitch,whichwilldamagethecontactpoint,fusebreaking,

disturbanceofthenormalfunctionoftheoverload.

9)Themeansfordisconnectionfromapowersupplyshallbeincorporatedinthefixed

wiringandhaveanairgapcontactseparationofatleast3mmineachactive(phase)

conductors.

Airpurging

Airandmoistureintherefrigerantsystemhaveundesirableeffectsasindicatedbelow:

Pressureinthesystemrises.

●

Operatingcurrentrises.

●

Coolingorheatingefficiencydrops.

●

Moistureintherefrigerantcircuitmayfreezeandblockcapillarytubing.

●

Watermayleadtocorrosionofpartsintherefrigerationsystem.

●

Therefore,theindoorunitandtubingbetweentheindoorandoutdoorunitmustbeleaktested

andevacuatedtoremoveanynoncondensablesandmoisturefromthesystem.

Airpurgingwithvacuumpump

●

Preparation

Checkthateachtube(bothliquidandgassidetubes)betweentheindoorandoutdoorunits

havebeenproperlyconnectedandallwiringforthetestrunhasbeencompleted.Remove

theservicevalvecapsfromboththegasandtheliquidsideontheoutdoorunit.Notethat

boththeliquidandthegassideservicevalvesontheoutdoorunitarekeptclosedatthis

stage.

●

Pipelengthandrefrigerantamount:

Connective

pipelength

Lessthan5m

Morethan5m

Airpurging

method

Usevacuum

pump.

Usevacuum

pump.

Additionalamountofrefrigeranttobecharged

R22:(Pipelength-5)x30g/m

R410A:(Pipelength-5)x20g/m

23

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 25

AIRPURGING

Whenrelocatetheunittoanotherplace,

performevacuationusingvacuumpump.

Makesuretherefrigerantaddedintotheair

conditionerisliquidforminanycase.

(NotapplicabletotheunitsadoptfreonR22)

Cautioninhandlingthepackedvalve

Openthevalvestemuntilithitsagainstthe

stopper.Donottrytoopenitfurther.

Securelytightenthevalvestemcapwitha

spannerorthelike.

Valvestemcaptighteningtorque(See

Tighteningtorquetableinpreviouspage).

WhenUsingtheVacuumPump

Refrigerant

Outdoor

unit

Packedvalve Halfunion

A

B

Gasside

Liquidside

Fig.59

Indoor

unit

C

D

Flarenut

Stopper

Cap

(Formethodofusingamanifoldvalve,refer

toitsoperationmanual.)

1.Completelytightentheflarenuts,A,B,C,D,

connectthemanifold

valvechargehosetoa

chargeportofthelow-pressurevalveonthe

gaspipeside.

2.Connectthechargehoseconnectiontothe

vacuumpump.

3.FullyopenthehandleLoofthemanifoldvalve.

4.Operatethevacuumpumptoevacuate.After

startingevacuation,

oftheLovalveonthegaspipeside

slightlyloosetheflarenut

and

checkthattheairisentering(Operationnoise

ofthevacuum

commeterindicates0insteadofminus)

pound

pumpchangesanda

5.Aftertheevacuationiscomplete,fullyclose

thehandleLoofthe

manifoldvalveandstop

theoperationofthevacuumpump.Make

evacuationfor15minutesormore

thatthe

-76cmHg(-1x10Pa).

6.TurnthestemofthepackedvalveBabout

45counterclockwisefor6~7secondsafter

compoundmeterindicates

o

5

andcheck

thegascomingout,thentightentheflarenut

again.Makesurethepressuredisplayinthe

pressureindicatorisalittlehigherthanthe

atmospherepressure.

7.RemovethechargehosefromtheLow

pressurechargehose.

8.FullyopenthepackedvalvestemsBandA.

9.Securelytightenthecapofthepackedvalve.

Valvebody

Manifoldvalve

Compoundmeter

-76cmHg

HandleLo

Chargehose

Lowpressurevalve

Valvestem

Fig.60

Pressuregauge

HandleHi

Chargehose

Vacuumpump

Fig.61

24

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 26

TESTRUNNING

Safetyandleakagecheck

Electricalsafetycheck●

Performtheelectricsafecheckaftercompletinginstallation:

1.Groundingwork

Afterfinishinggroundingwork,measurethegroundingresistancebyvisualdetectionand

groundingresistancetester.Makesurethegroundingresistanceislessthan4.

2.Electricalleakagecheck(performingduringtestrunning)

Duringtestoperationafterfinishinginstallation,theservicemancanusetheelectroprobe

andmultimetertoperformtheelectricalleakagecheck.Turnofftheunitimmediatelyif

leakagehappens.Checkandfindoutthesolutionwaystilltheunitoperateproperly.

Gasleakcheck●

1.Soapwatermethod:

Applyasoapwateroraliquidneutraldetergent

ontheindoorunitconnectionoroutdoorunit

connectionsbyasoftbrushtocheckforleakage

oftheconnectingpointsofthpiping.Ifbubbles

comeout,thepipeshaveleakage.

Leakdetector

2.

Usetheleakdetectortocheckforleakage.

CAUTION

Indoorunit

checkpoint

Cover

Outdoorunit

checkpoint

Ω

DBC

A

A:LopackedvalveB:Hipackedvalve

CandDareendsofindoorunitconnection.

Fig.62

Testrunning

Performtestoperationaftercompletinggasleakcheckattheflarenutconnectionsand

electricalsafetycheck.

Checkthatalltubingandwiringhavebeenproperlyconnected.

Checkthatthegasandliquidsideservicevalvesarefullyopen.

1.Connectthepower,presstheON/OFFbuttonontheremotecontrollertoturntheuniton.

2.UsetheMODEbuttontoselectCOOL,HEAT,AUTOandFANtocheckifallthefunctions

workwell.

3.Whentheamienttemperatureistoolow(lowerthan17C),theunitcannotbecontrolledby

theremotecontrollertorunatcoolingmode,manualoperationcanbetaken.Manual

operationisusedonlywhentheremotecontrollerisdisableormaintenancenecessary.

PresstheManualcontrolbuttonontherightsideofthepanelframetoselecttheAUTOor

COOL,theunitwilloperateunderForcedAUTOorCOOLmode(seeUserManualfordetails).

4.Thetestoperationshouldlastabout30minutes.

Manualcontrol

button

25

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 27

Thedesignandspecificationsaresubjecttochangewithoutpriornoticeforproduct

improvement.Consultwiththesalesagencyormanufacturerfordetails.

CS0100I-SP(L)

202000192406

PDF created with pdfFactory Pro trial version www.pdffactory.com

Loading...

Loading...