Page 1

INSTALLATION MANUAL

Four-way Cassette Type

PCM123HX

PCM183HX

Page 2

Install according to this installation instructions strictly.

If installation is defective, it will cause water leakage,

CONTENTS PAGE

CONTENTS PAGE

PRECAUTIONS......................................................................

INSTALLATION INFORMATION.............................................

ATTACHED FITTINGS............................................................

INSPECTING AND HANDLING THE UNIT.............................

INDOOR UNIT INSTALLATION..............................................

OUTDOOR UNIT INSTALLATION..........................................

INSTALL THE CONNECTING PIPE.......................................

CONNECT THE DRAIN PIPE................................................

CONNECTIVE DIAGRAM .....................................................

WIRING...................................................................................

TEST OPERATION.................................................................

1

2

3

4

4

11

15

18

19

20

21

1. PRECAUTIONS

Keep this manual where the operator can easily find them.

Read this manual attentively before starting up the units.

For safety reason the operator must read the following

cautions carefully.

The safty precautions listed here are divided into two categories.

WARNING

If you do not follow these instrutions exactly, the unit may

cause property damage, personal injury or loss of life.

CAUTION

If you do not follow these instrutions exactly, the unit may

cause minor or moderate property damage, personal

After completing the installation, make sure that the unit operates

properly during the start-up operation. Please instruct the customer

on how to operate the unit and keep it maintained.Also, inform

customers that they should store this installation manual along with

the owner's manual for future reference.

WARNING

Be sure only trained and qualified service personnel to

install, repair or service the equipment.

Improper installation, repair, and maintenance may result in

electric shocks, short-circuit, leaks, fire or other damage to

the equipment.

electrical shock and fire.

When installing the unit in a small room, take measures

against to keep refrigerant concentration from exceeding

allowable safety limits in the event of refrigerant leakage.

Contact the place of purchase for more information.

Excessive refrigerant in a closed ambient can lead to oxygen

deficiency.

Use the attached accessories parts and specified parts

for installation.

otherwise, it will cause the set to fall, water leakage,

electrical shock and fire.

Install at a strong and firm location which is able to

withstand the set' s weight.

If the strength is not enough or installation is not properly

done, the set will drop to cause injury.

The appliance must be installed 2.3m above floor.

The appliance shall not be installed in the laundry.

Before obtaining access to terminals, all supply circuits

must be disconnected.

The appliance must be positioned so that the plug is

accessible.

The enclosure of the appliance shall be marked by word,

or by symbols, with the direction of the fluid flow.

For electrical work, follow the local national wiring

standard, regulation and this installation instructions. An

independent circuit and single outlet must be used.

If electrical circuit capacity is not enough or defect in

electrical work, it will cause electrical shock or fire.

Use the specified cable and connect tightly and clamp

the cable so that no external force will be acted on the

terminal.

If connection or fixing is not perfect, it will cause heat-up or

fire at the connection.

Wiring routing must be properly arranged so that control

board cover is fixed properly.

If control board cover is not fixed perfectly, it will cause

heat-up at connection point of terminal, fire or electrical

shock.

If the supply cord is damaged, it must be replaced by the

manufacture or its service agent or a similarly qualified

person in order to avoid a hazard.

An all-pole disconnection switch having a contact

separation of at least 3mm in all poles should be

connected in fixed wiring.

When carrying out piping connection, take care not to let

air substances go into refrigeration cycle.

Otherwise, it will cause lower capacity, abnormal high

pressure in the refrigeration cycle, explosion and injury.

Do not modify the length of the power supply cord or use

of extension cord, and do not share the single outlet with

other electrical appliances.

Otherwise, it will cause fire or electrical shock.

Carry out the specified installation work after taking into

account strong winds, typhoons or earthquakes.

Improper installation work may result in the equipment falling

and causing accidents.

installation manual

1

Page 3

If the refrigerant leaks during installation, ventilate the

area immediately.

Toxic gas may be produced if the refrigerant comes into the

place contacting with fire.

The temperature of refrigerant circuit will be high, please

keep the interconnection cable away from the copper

tube.

After completing the installation work, check that the

refrigerant does not leak.

Toxic gas may be produced if the refrigerant leaks into the

room and comes into contact with a source of fire, such as a

fan heater, stove or cooker.

CAUTION

2. INSTALLATION INFORMATION

To install properly, please read this "installation manual" at

first.

The heat pump must be installed by qualified persons.

When installing the indoor unit or its tubing, please follow

this manual as strictly as possible.

If the heat pump is installed on a metal part of the building,

it must be electrically insulated according to the relevant

standards to electrical appliances.

When all the installation work is finished, please turn on

the power only after a thorough check.

Ground the heat pump.

Do not connect the ground wire to gas or water pipes,

lightning rod or a telephone ground wire.Inappropriate

grounding may result in electric shocks.

Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in

electric shocks.

Connect the outdoor unit wires , then connect the indoor

unit wires.

You are not allowed to connect the heat pump with the power

supply until the wiring and piping is done.

While following the instructions in this installation

manual, install drain piping in order to ensure proper

drainage and insulate piping in order to prevent

condensation.

Improper drain piping may result in water leakage and

property damage.

Install the indoor and outdoor units, power supply wiring

and connecting wires should be at least 1 meter away

from televisions or radios in order to prevent image

interference or noise.

Depending on the radio waves, a distance of 1 meter may not

be sufficient enough to eliminate the noise.

The appliance is not intended for use by young children

or infirm persons without supervision.

Regret for no further announcement if there is any change

of this manual caused by product improvement.

INSTALLATION ORDER

Select the location;

Install the indoor unit;

Install the outdoor unit;

Install the connecting pipe ;

Connect the drain pipe;

Wiring;

Test operation.

Don't install the heat pump in the following

circumstance:

There is petrolatum existing.

There is salty air surrounding (near the coast).

There is caustic gas (the sulfide, for example) existing

in the air (near a hot spring).

The Volt vibrates violently (in the factories).

In buses or cabinets.

In kitchen where it is full of oil gas.

There is strong electromagnetic wave existing.

There are inflammable materials or gas.

There is acid or alkaline liquid evaporating.

Other special conditions.

installation manual

2

Page 4

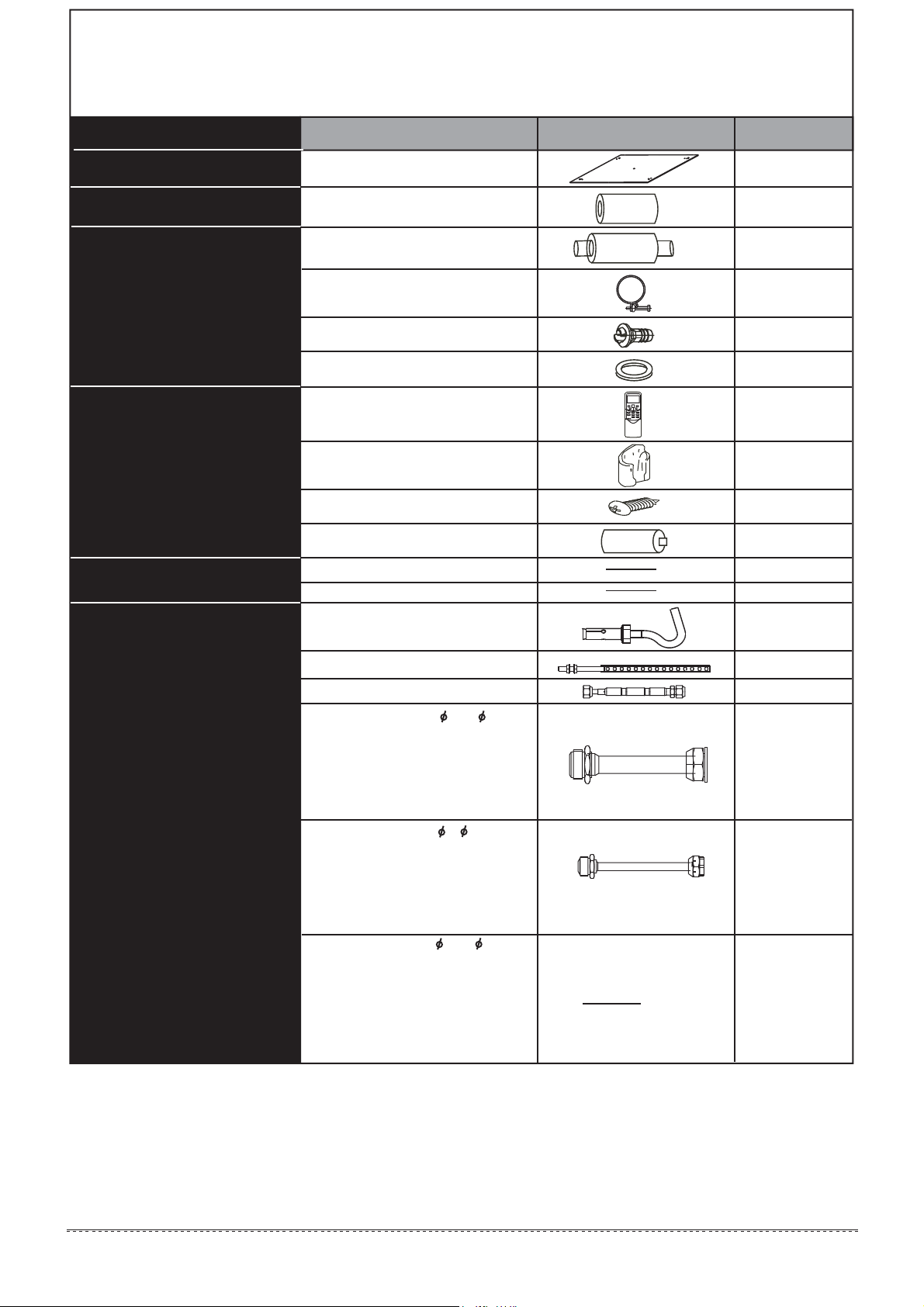

3. ATTACHED FITTINGS

Please check whether the following fittings are of full scope. If there are some spare fittings , please restore them carefully.

Installation Fittings

Tubing & Fittings

Drainpipe Fittings

Remote controller & Its Frame

(The product you have might not be

provided the following accessory)

NAME

1. Installation paper board

(on some models)

2. Soundproof / insulation sheath

(on some models)

3. Out-let pipe sheath

(on some models)

4. Out-let pipe clasp

(on some models)

5. Drain joint(on some models)

6. Seal ring(on some models)

7. Remote controller

8. Remote controller holder

9. Mounting screw(ST2.9×

10. Alkaline dry batteries (AM4)

11. Owner's manual

12. Installation manual

10-C-H)

SHAPE

QUANTITY

1

1

1

1

1

1

1

1

2

2

1

1

Installation accessory

(The product you have might not be

provided the following accessory)

13. Expansible hook

14. Installation hook

15 .Orifice

16 .Transfer connector( 12.7- 16)

(Packed with the indoor unit )

(NOTE: Pipe size differ from appliance

to appliance.To meet different pipe size

requirement, sometimes the pipe

connections need the transfer connector

to install on the outdoor unit .)

17 .Transfer connector( 6- 9.52)

(Packed with the indoor unit )

(NOTE: Pipe size differ from appliance

to appliance.To meet different pipe size

requirement, sometimes the pipe

connections need the transfer connector

to install on the outdoor unit .)

18 .Transfer connector( 9.52- 12.7)

(Packed with the indoor unit ,used for

multi-type models only)

(NOTE: Pipe size differ from appliance

to appliance.To meet different pipe size

requirement, sometimes the pipe

connections need the transfer connector

to install on the outdoor unit .)

4

4

1

1

(on some models)

1

(on some models)

1

(on some models)

installation manual

3

Page 5

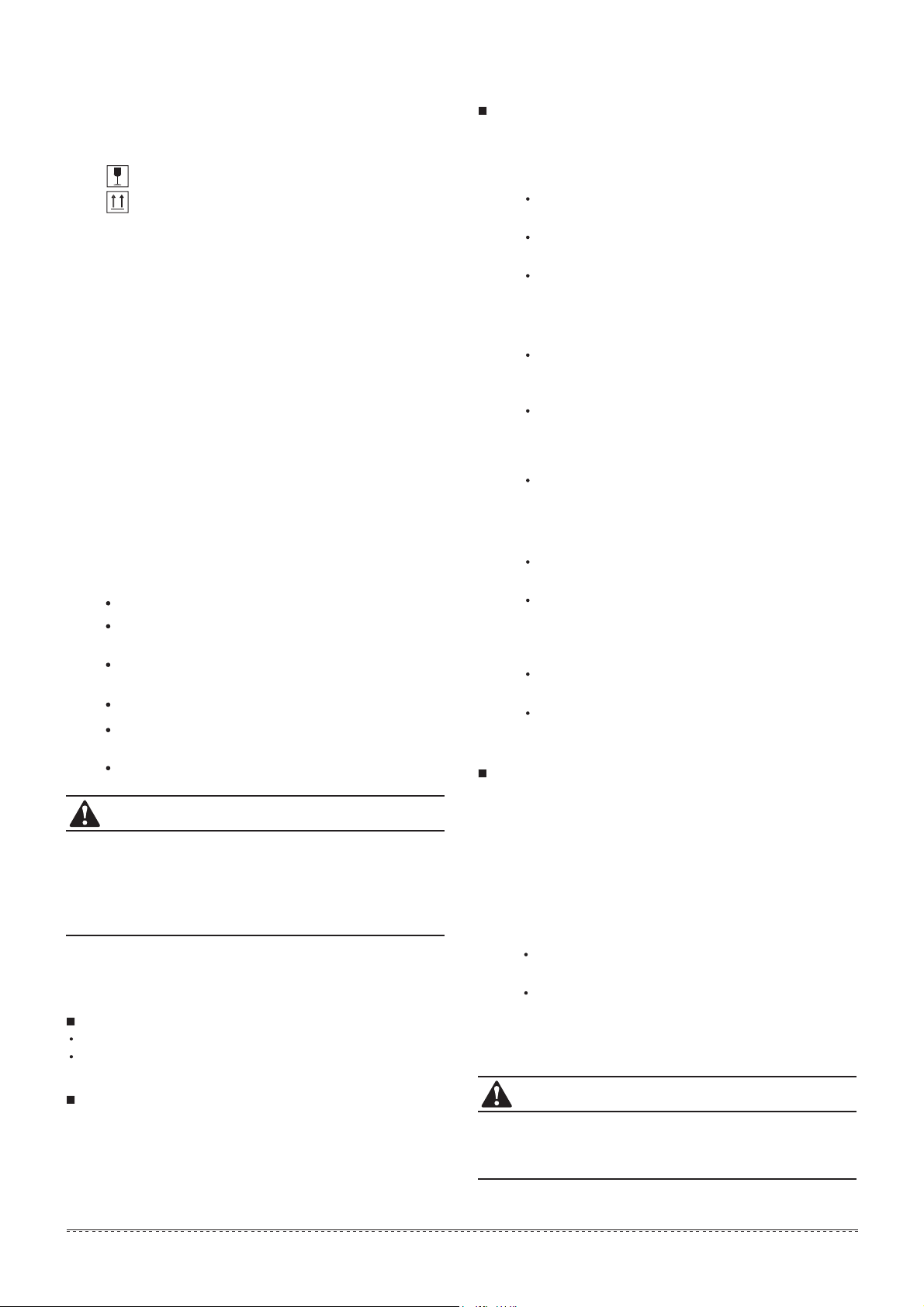

4. INSPECTING AND HANDLING THE UNIT

At delivery, the package should be checked and any damage should

be reported immediately to the service agent.

When handling the unit, take into account the following:

Fragile, handle the unit with care.

1

Keep the unit upright in order to avoid compressor

damage.

Choose on before hand the path along which the unit is to be

2

brought in.

Move this unit as originally package as possible.

3

4

When lifting the unit , always use protectors to prevent belt

damage and pay attention to the position of the unit’s centre

of gravity.

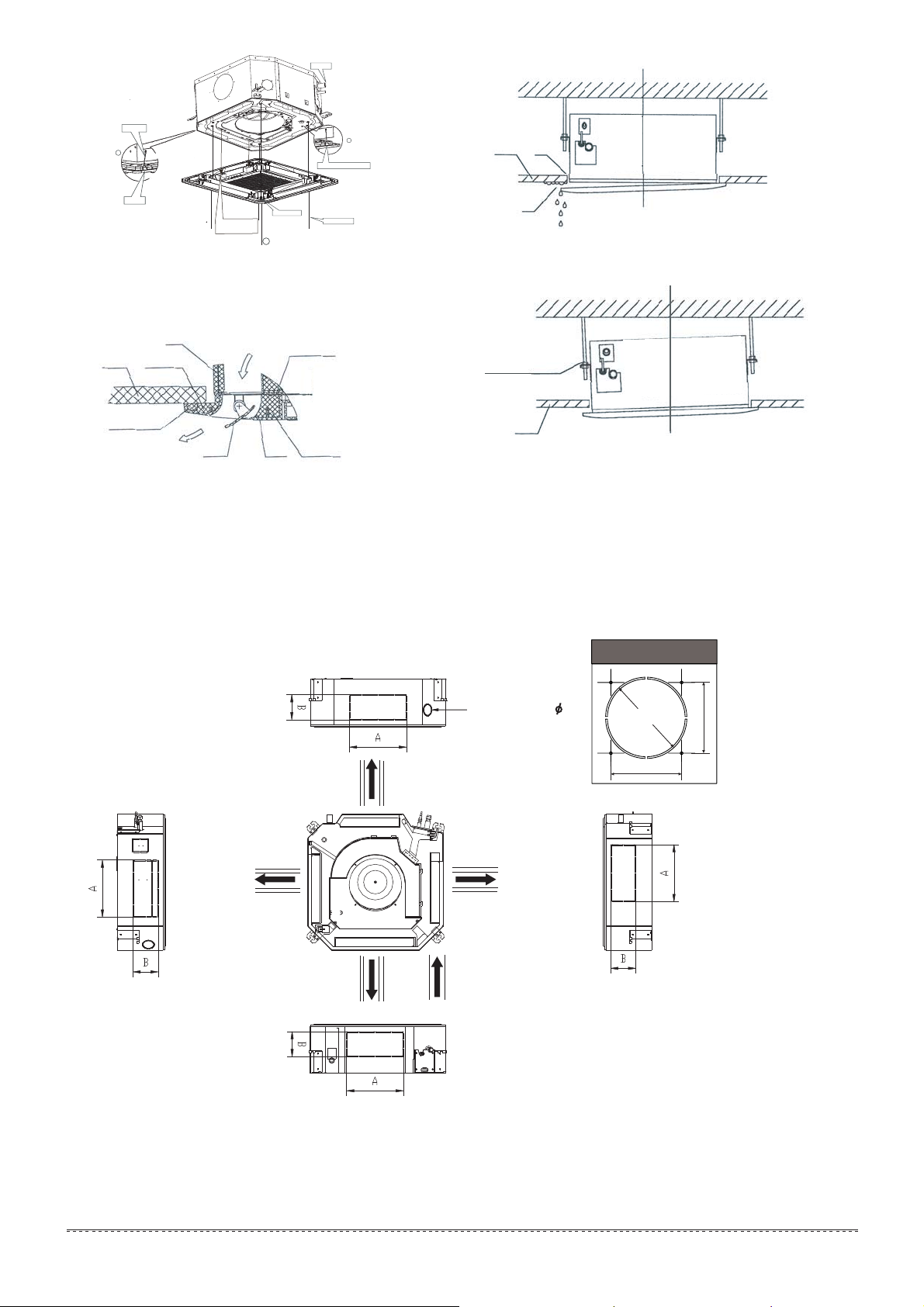

5. INDOOR UNIT INSTALLATION

5.1 Installation place

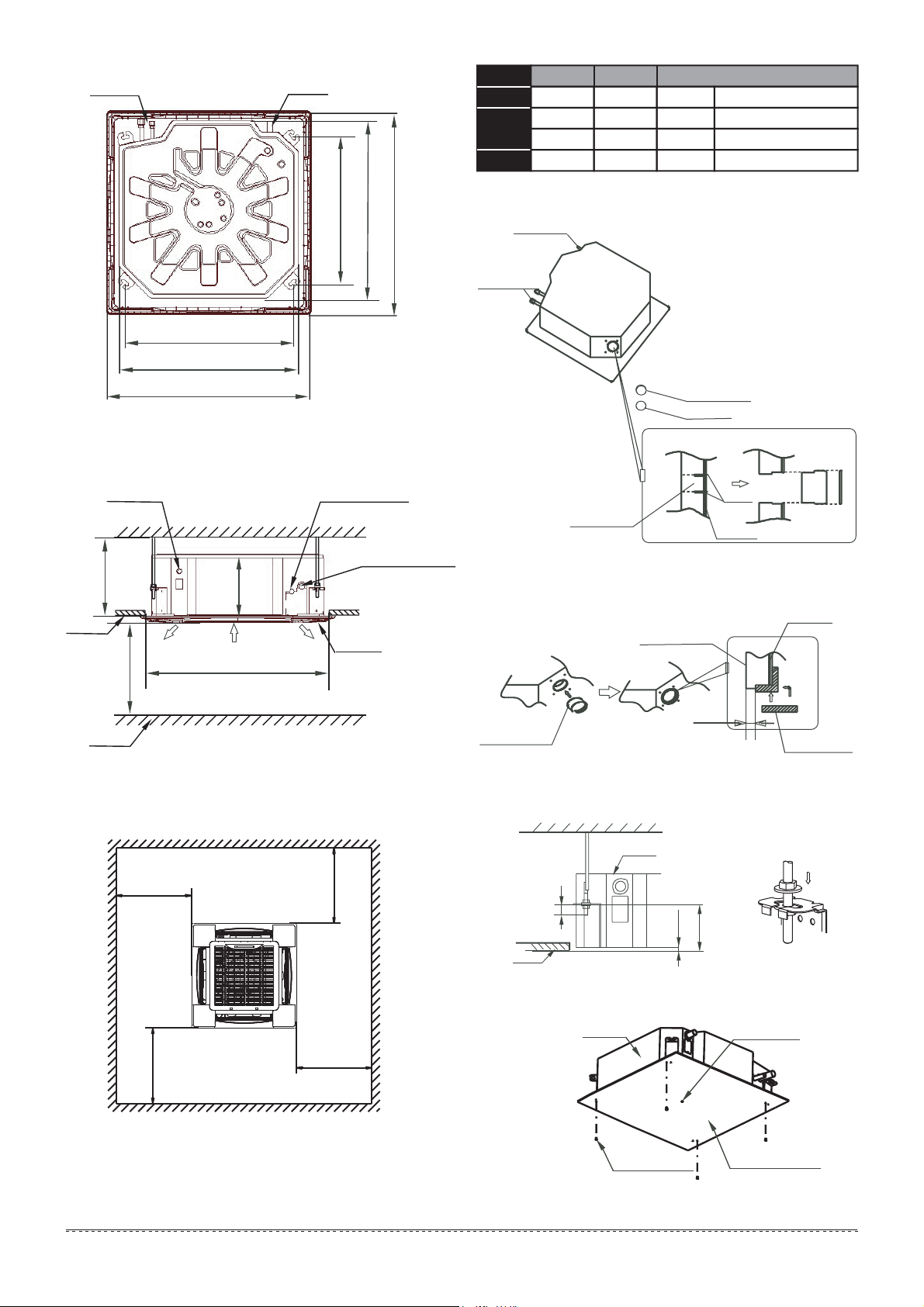

(Refer to Fig.5-1,Fig.5-2,Fig.5-3 and Table 5-1 for specification.)

The indoor unit should be installed in a location that meets

the following reauirements:

There is enough room for installation and maintenance.

The ceiling is horizontal, and its structure can endure the

weight of the indoor unit.

The outlet and the inlet are not impeded, and the

influence of external air is the least.

The air flow can reach throughout the room.

The connecting pipe and drainpipe could be extracted out

easily.

There is no direct radiation from heaters.

5.3.1 Install the main body(cassette type

heat pump)

The existing ceiling (to be horizontal)

1

Cut a quadrangular hole of 880x880mm in the ceiling

according to the shape of the installation paper board.

(Refer to Fig.5-2)

The center of the hole should be at the same position of

that of the heat pump body.

Determine the lengths and outlets of the connecting pipe,

drainpipe and cables.

To balance the ceiling and to avoid vibration, please

enforce the ceiling when necessary.

2

Select the position of installation hooks according to the

hook holes on the installation board.

Drill four holes of Ø12mm, 45~50mm deep at the selected

positions on the ceiling. Then embed the expansible

hooks (fittings).

Face the concave side of the installation hooks toward the

expansible hooks. Determine the length of the installation

hooks from the height of ceiling, then cut off the

unnecessary part.

If the ceiling is extremely high, please determine the

length of the installation hook according to facts.

3

Adjust the hexangular nuts on the four installation hooks

evenly, to ensure the balance of the body.

If the drainpipe is awry, leakage will be caused by the

malfunction of the water-level switch.

Adjust the position to ensure the gaps between the body

and the four sides of ceiling are even. The body's lower

part should sink into the ceiling for 10~12 mm (Refer to

Fig.5-6).

In general, L is half of the screw length of the installation

hook.(Refer to Fig.5-6)

Locate the heat pump firmly by wrenching the nuts after

having adjusted the body's position well.(Refer to Fig.5-7)

New built houses and ceilings

CAUTION

Keep indoor unit, outdoor unit, power supply wiring and

transmission wiring at least 1 meter away from televisions

and radios. This is to prevent image interference and

noise in those electrical appliances. (Noise may be

generated depending on the conditions under which the

electric wave is generated, even if 1 meter is kept.)

5.2 Installation procedures for fresh air

intake duct connection

Preparing the connection hole

Cut off the knockout hole on the side plate with a nipper.

Cut the inner insulation of the hole portion with a cutter.

(Refer to Fig.5-4)

Placing the insulation

Put the insulation tightly around the hole of the unit as

shown.

The ends of the side plate and the inner insulation must be

completely adhered without leaving any clearance along the

circumference of the hole.

Make sure the inner surface of insulation tightly contacts the

inner insulation edge and the side plate. (Refer to Fig.5-5)

installation manual

4

1

In the case of new built house, the hook can be embedded

in advance (refer to 2 mentioned above). But it should be

strong enough to bear the indoor unit and will not become

loose because of concrete shrinking.

After installing the body, please fasten the installation paper

2

board onto the heat pump with bolts(M6X12) to determine in

advance the sizes and positions of the hole opening on

ceiling.(Refer to Fig.5-8)

Please first guarantee the flatness and horizontal of

ceiling when installing it.

Refer to 1 mentioned above for others.

3

Refer to 3 above for installation.

4

Remove the installation paper board.

CAUTION

After installing the body, the four bolts(M6x12)must be

fastened to the heat pump onto ensure the body is

grounded well.

Page 6

Tubing side

780(Hook-location)

840(Body)

950(Panel)

Connecting point of drain pipe

H

Table 5-1

Drain side

) n o i t a c o l -

k

o o H ( 0 8 6

(Unit: mm)

) l e n a P

) y d o B ( 0 4 8

(

0 5

9

MODEL A H

18

24

30~60

piping

230

300

300

Drain piper

Fig.5-1

Connecting point of

refrigerant pipe

(Liquid side ØC)

Connecting point of

refrigerant pipe

A

(Gas side ØB)

Inner insulation

>260

>260230

>330

>330

mm

Remark

R410A &R22 Cooling/Cooling & Heating

R410A &R22 Cooling/Cooling & Heating

R410A &R22 Cooling/Cooling & Heating

R410A &R22

Inner insulation

Side plate

Cooling/Cooling & Heating

Slit

Side plate

Fig.5-4

Ceiling

Ground

m

Outlet

m 0 0 5 2 >

>1000mm

m m 0 0 0 1 >

Inlet

880mm (ceiling hole)

Outlet

m m 0 0 0 1 >

>1000mm

Panel

Fig.5-2

Insulation(local)

Ceiling

Side plate

Inner insulation

±10mm

Insulation(local)

Fig.5-5

Body

L

m

m

m

2

m

1 -

6

0 1

3

1

Fig.5-7 Fig.5-6

Body

Central hole

Fig.5-3

Bolt M6X12

Installation

paper board

Fig.5-8

installation manual

5

Page 7

Leakage

Ceiling

Grid switch

Pollution

Fig.5-9

4

Gap not allowed

Water condensation

Fig.5-14

Loosen upper nut

Adjust lower nut

Fig.5-10

Fig.5-15

Fig.5-11

Installation cover’s rope

Tap Screw

Slide the four sliders

in the corresponding

channel when installing

the cover

Swing Motor

Ceiling

panel sponge

panel

Tubing joint

Outlet joint

Hook-bolt

Cross-screwdriver

body

panel foam1

air out

Hook panel

Fan

Water-receiver

Fig.5-12

outlet foam

panel foam 2

Fig.5-16

<200mm

1-1.5m

Pump-pipe clasp

(the fittings)

m

m 0 5 7

<

Lean over 1/50

Fig.5-17

Pump joint

Test mouth

m

m 6

4

Body

Water-receiver

Test cover

Stow tube

installation manual

6

Fig.5-13

Drain plug

Fig.5-18

Page 8

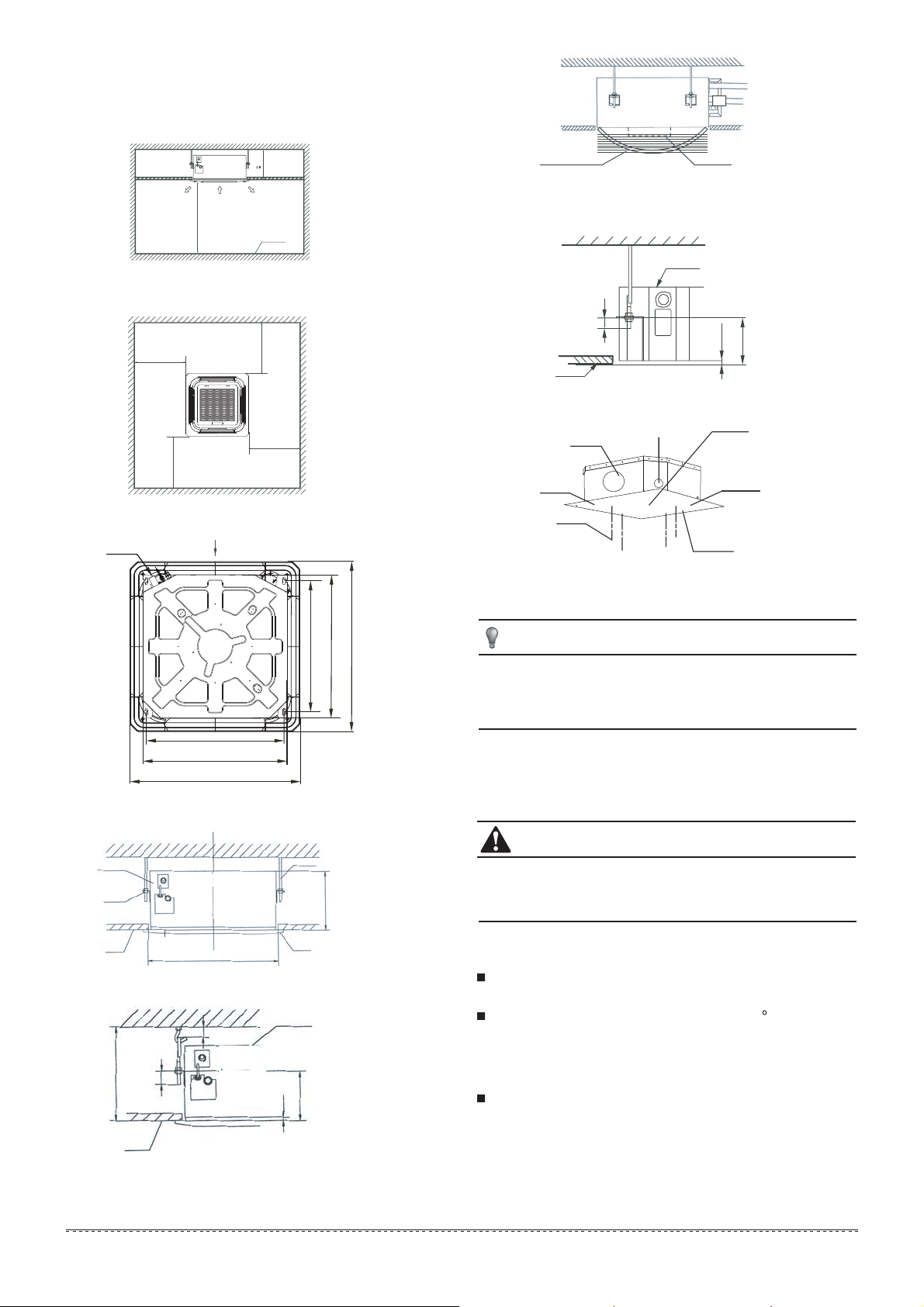

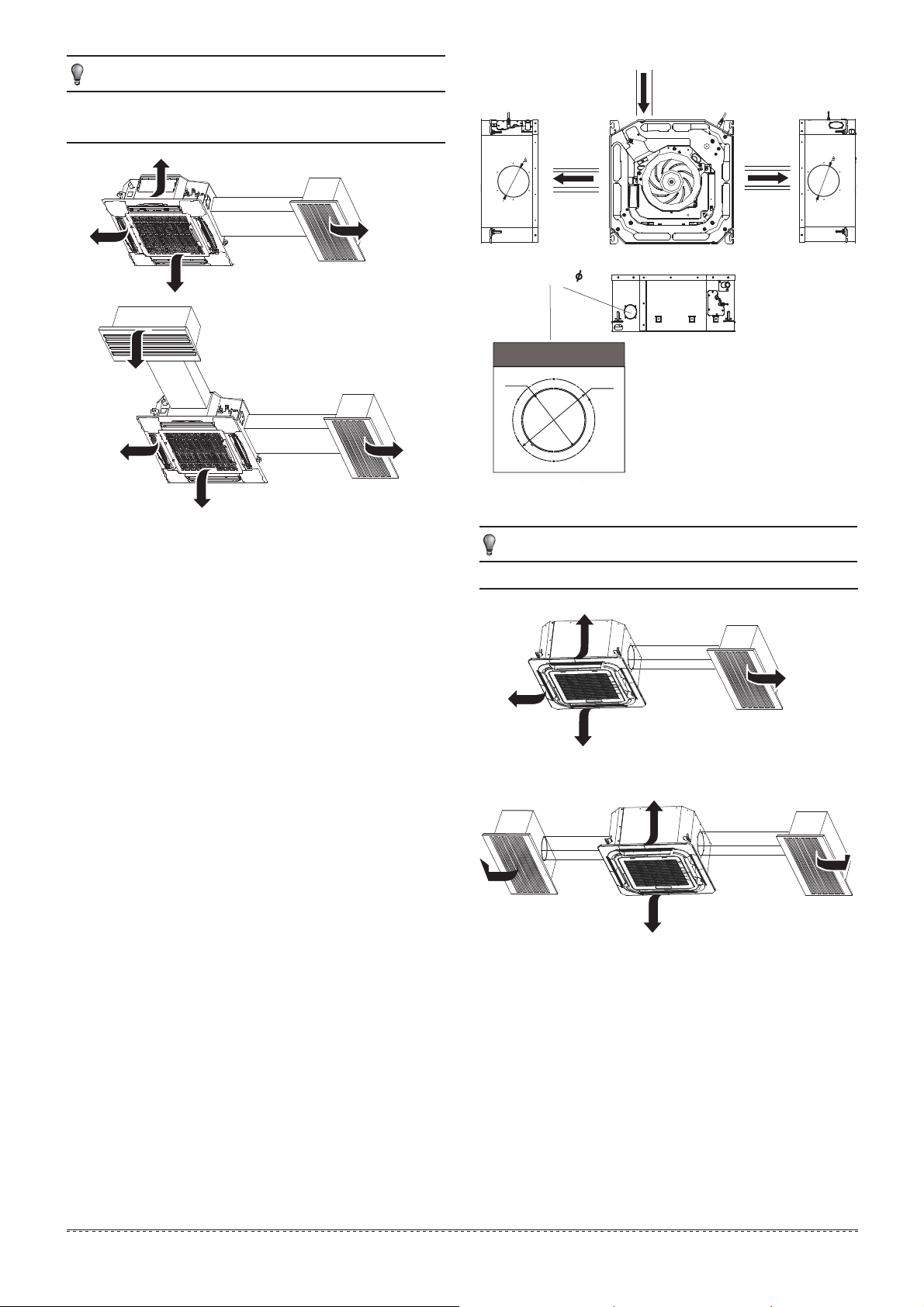

5.3.2 Install the main body(small cassette

type heat pump)

Necessary room

0

8

2

A

Outlet

Inlet

Outlet

0 0 3 2 >

Ground

Fig.5-19

Colourless

trans parent pipe

Body

Horizontal

indicator

Fig.5-24

Drain side

Body

Nut

>1000

0

0

0

1 >

545(Hook-location)

570(Body)

647(Panel)

A

L

>1000

Ceiling

m

m 2

m

m

1 -

6

0 1

3

1

Fig.5-25

Body

1 >

0

0

0

Fig.5-20

A

Fixing hole

installation paper board

Screw M5x16

(Accessory)

Fresh air intake (ф65)

Central hole

Hook hole

Installation paper board

Fig.5-26

NOTE

570(Body)

647(Panel)

523(Hook-location)

All the pictures in this manual are for explanation purpose only.

They may be slightly different from the heat pump you

purchased(depend on model).The actual shape shall prevail.

(Unit: mm)

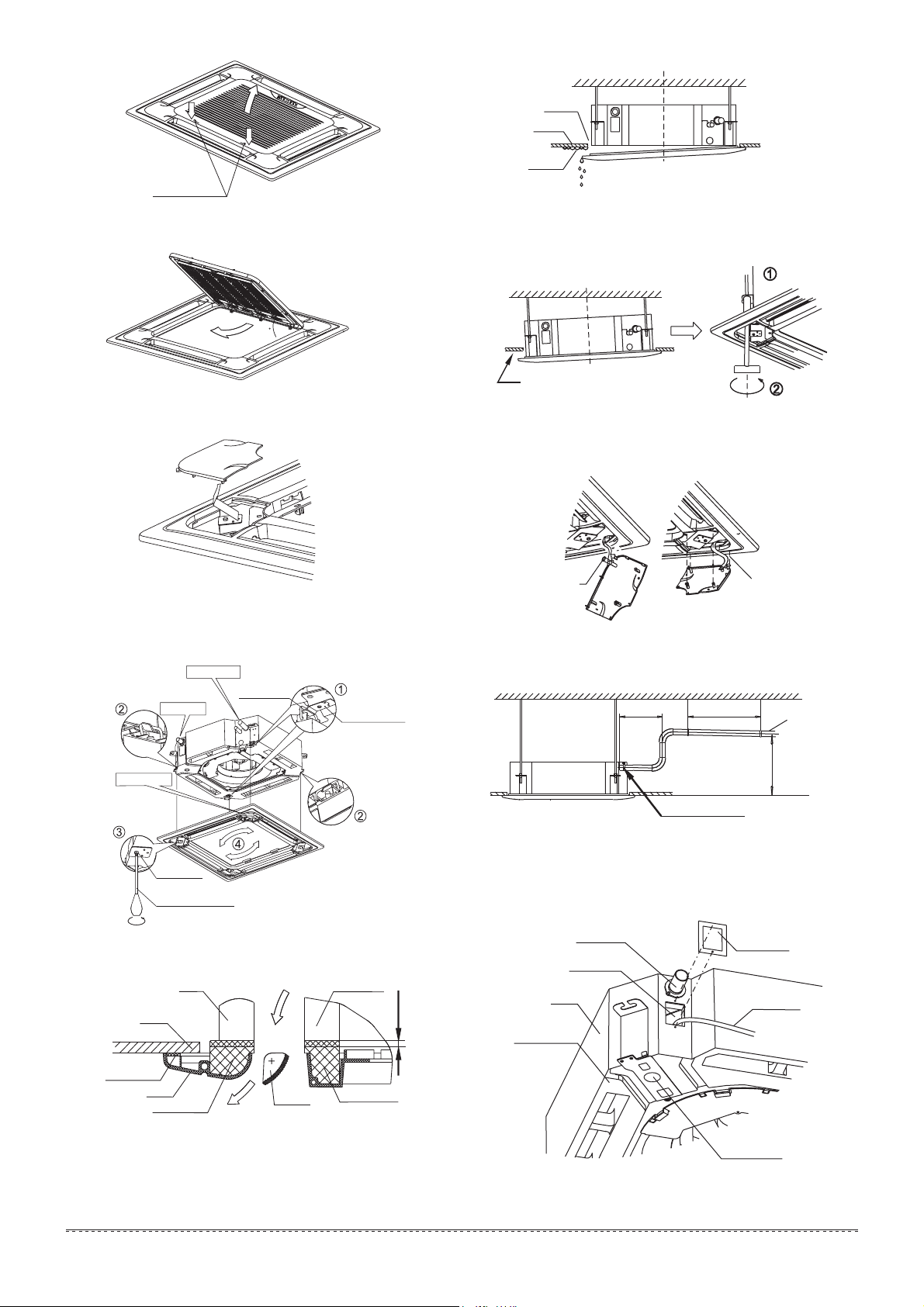

5.4.1 Install The Panel(cassette type heat

pump)

Fig.5-21

CAUTION

Hook

0

6 2

Never put the panel face down on floor or against the

wall, or on bulgy objects.

Never crash or strike it.

Ceiling

) t h g i e h g n

i l

i

e

c ( H

Ceiling

50

600

Panel

Remove the air-in grill.

1

Slide two grill switches toward the middle at the same time,

Fig.5-22

4

3

L

Body

2

1 - 0 1

6 7 1

and then pull them up. (Refer to Fig.5-9)

Draw the grill up to an angle of about 45, and remove it.

(Refer to Fig.5-10)

Remove the installation covers at the four corners

2

Wrench off the bolts, loose the rope of the installation covers,

and remove them. (Refer to Fig.5-11)

Fig.5-23

installation manual

7

Page 9

Install the panel

3

Align the swing motor on the panel to the tubing joints of the

body properly. ( Refer to Fig.5-12)

Fix hooks of the panel at swing motor and its opposite sides

to the hooks of corresponding water receiver. ( Refer to

Fig.5-12.1) Then hang the other two panel hooks onto

corresponding hangers of the body. ( Refer to Fig.5-12.2)

CAUTION

Do not coil the wiring of the swing motor into the seal

sponge.

Adjust the four panel hook screws to keep the panel

horizontal, and screw them up to the ceiling evenly. ( Refer to

Fig.5-12.3)

Regulate the panel in the direction of the arrow in Fig.5-12.4

slightly to fit the panel's center to the center of the ceiling's

opening. Guarantee that hooks of four corners are fixed well.

Keep fastening the screws under the panel hooks, until the

thickness of the sponge between the body and the panel's

outlet has been reduced to about 4~6mm. The edge of the

panel should contact with the ceiling well. (Refer to Fig.5-13)

Malfunction described in Fig.5-14 can be caused by

inappropriate tightness the screw.

If the gap between the panel and ceiling still exists after

fastening the screws, the height of the indoor unit should

be modified again. ( Refer to Fig.5-15-left)

You can modify the height of the indoor unit through the

openings on the panel's four corners, if the lift of the

indoor unit and the drainpipe is not influenced (Refer to

Fig.5-16-right).

Grid switch

4

5

Install the panel

2

Align the swing motor on the panel to the tubing joints of the

body properly. ( Refer to Fig.5-29)

Hang the four fixed rope of the main body to the installation

cover and the other three covers of the swing motor: (Refer

to Fig.5-29

and )

CAUTION

The installation cover of the swing motor must sink into

the corresponding water receiver.

Fig.5-27

Fig.5-28

Hang the air-in grill to the panel, then connect the lead

4

terminator of the swing motor and that of the control box

with corresponding terminators on the body respectively.

Relocate the air-in grill in the procedure of reversed order.

5

Relocate the installation cover.

6

Fasten the rope of installation cover on the bolt of the

installation cover. (Refer to Fig.5-16-left)

Press the installation cover into the panel slightly. (Refer to

Fig.5-16-right)

5.4.2 Install The Panel(samll cassette type

heat pump)

CAUTION

Never put the panel face down on floor or against the

wall, or on bulgy objects.

Never crash or strike it.

Remove the air-in grill.

1

Slide two grill switches toward the middle at the same time,

and then pull them up. (Refer to Fig.5-27)

Draw the grill up to an angle of about 45, and remove it.

(Refer to Fig.5-28)

Install the panel on the main body with bolt (M5×16) and

washer. (Refer to Fig.5-29

Adjust the four panel hook screws to keep the panel

horizontal, and screw them up to the ceiling evenly.

Regulate the panel in the direction of the arrow in Fig.5-29.

slightly to fit the panel's center to the center of the ceiling's

opening. Guarantee that hooks of four corners are fixed well.

Keep fastening the screws under the panel hooks, until the

thickness of the sponge between the body and the panel's

outlet has been reduced to about 4~6mm. The edge of the

panel should contact with the ceiling well. (Refer to Fig.5-30)

Malfunction described in Fig.5-31 can be caused by

inappropriate tightness the screw.

If the gap between the panel and ceiling still exists after

fastening the screws, the height of the indoor unit should

be modified again. ( Refer to Fig.5-32-left)

You can modify the height of the indoor unit through the

openings on the panel's four cor ners, if the lift of the

indoor unit and the drainpipe is not influenced (Refer to

Fig.5-32-right).

4

Hang the air-in grill to the panel, then connect the lead

terminator of the swing motor and that of the control box

with corresponding terminators on the body respectively.

5

Relocate the air-in grid in the procedure of reversed order,

install the air-in grid.

)

installation manual

8

Page 10

Drain side

1

Ceiling

Panel foam

Steel rope

Cover

Panel foam2

Outlet air

Body

Steel rope

1

3

Cover

Please operate according

to the direction of the arrow,

or it can not be disassembled

when it is necessary.

Air plate

Inlet air

2

3

3

Swing motor installation cover

Swing motor side

4

Panel sealing foam

Panel

Panel foam1

2

Swing motor installation cover

Bolt, washer

Fig.5-29

Fig.5-30

Ceiling

Leakage

Dew

Hexagon nut

Horizontal adjust ment

Ceiling

Fig.5-31

Fig.5-32

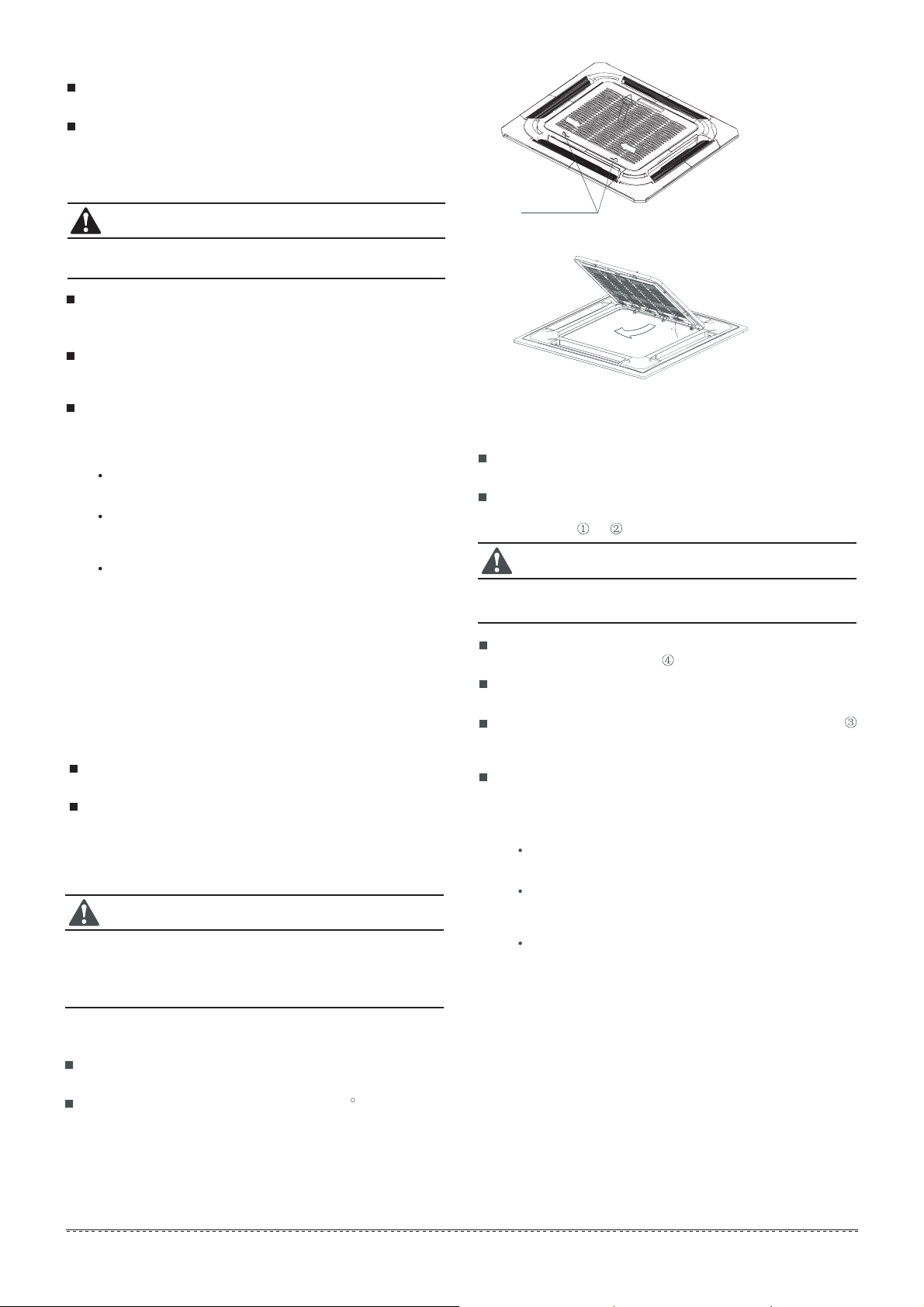

5.5.1 Install the distribution duct(cassette type heat pump)

Conditioned air can be distributes by means of a distribution duct.

Fresh air intake ( 75)

Distribution duct

Distribution duct

Distribution duct

Distribution duct

Fresh air

MODLE

Ø75mm

80mm

(18-60)

80mm

Fig.5-33

installation manual

9

Page 11

NOTE

model 18 to 24 Series A=350mm; Series B=85mm

model 36 to 60 Series A=350mm; Series B=155mm

Distribution duct

Fresh air

Distribution duct

One-way

Two- way

In case of one duct connection

The air volume in duct is around 300-360m3/h for model 18

to 24 unit.

The air volume in duct is around 400-640m3/h for model 36

to 60 unit.

The max. length of duct is 2m.

The original air outlet with the same direction of duct should

be sealed In case of two duct connection.

In case of two duct connection

The air volume in one duct is around 200-260m3/h for model

18 to 24 unit.

The air volume in one duct is around 300-500m3/h for model

36 to 60 unit.

The max. length of duct is 1.5m for one duct.

The original air outlet with the same direction of duct should

be sealed.

Fig.5-34

Fresh air intake ( 75)

MODLE (12-18)

Ø65mm

Ø75mm

NOTE

model 12 to 18 Series A=150mm

One-way

Fig.5-35

5.5.1 Install the distribution duct(small

cassette type heat pump)

Conditioned air can be distributes by means of a distribution

duct.

In case of one duct connection

The air volume in duct is around 180-300m3/h for model 12

to 18 unit.

The max. length of duct is 1m.

The original air outlet with the same direction of duct should

be sealed In case of two duct connection.

In case of two duct connection

The air volume in one duct is around 100-200m3/h for model

12 to 18 unit.

The max. length of duct is 0.75m for one duct.

The original air outlet with the same direction of duct should

be sealed.

installation manual

10

Two- way

Fig.5-36

Page 12

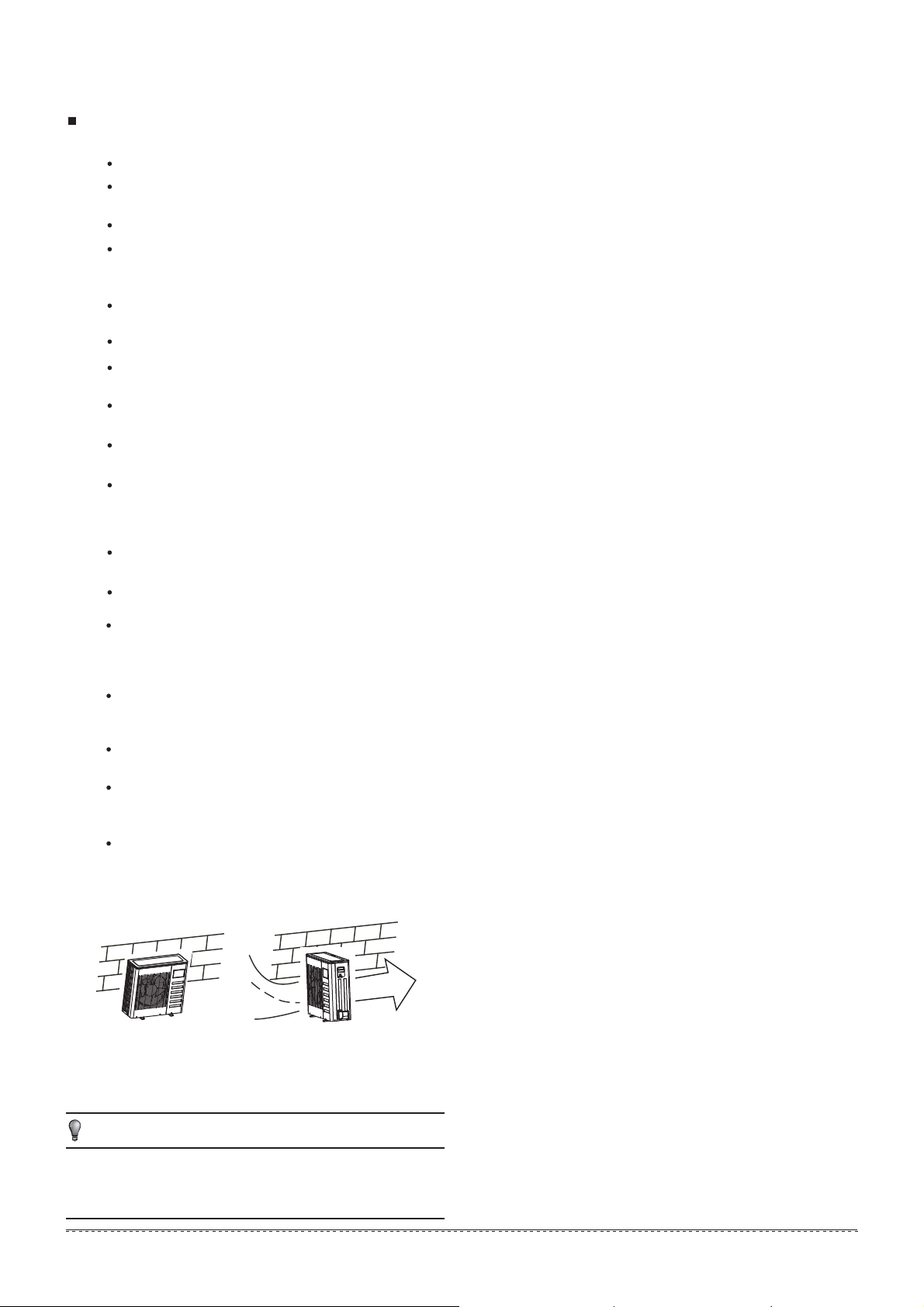

6. OUTDOOR UNIT INSTALLATION

6.1 Installation Place

The outdoor unit should be installed in the location that

meets the following requiements:

There is enough room for installation and maintenance.

The air outlet and the air inlet are not impeded, and can

not be reached by strong wind.

It must be a dry and well ventilating place.

The support is flat and horizontal and can stand the

weight of the outdoor unit. And will no additional noise or

vibration.

Your neighborhood will not feel uncomfortable with the

noise or expelled air.

It is easy to install the connecting pipes or cables.

Determine the air outlet direction where the discharged

air is not blocked.

There is no danger of fire due to leakage of inflammable

gas.

The piping length between the outdoor unit and the indoor

unit may not exceed the allowable piping length.

In the case that the installation place is exposed to strong

wind such as a seaside, make sure the fan operating

properly by putting the unit lengthwise along the wall or

using a dust or shield.(Refer to Fig.6-1)

If possible, do not install the unit where it is exposed to

direct sunlight.

If necessary, install a blind that does not interfere with the

air flow.

During the heating mode, the water drained off the

outdoor unit ,The condensate should be well drained

away by the drain hole to an appropriate place, so as not

to interfere other people.

Select the position where it will not be subject to snow

drifts, accumulation of leaves or other seasonal debris. If

unavoidable, please cover it with a shelter.

Locate the outdoor unit as close to the indoor unit as

possible.

If possible, please remove the obstacles nearby to

prevent the performance from being impeded by too little

of air circulation.

The minimum distance between the outdoor unit and

obstacles described in the installation chart does not

mean that the same is applicable to the situation of an

airtight room. Leave open two of the three

directions.(Refore to Fig.6-4, Fig.6-5)

Strong wind

O

X

Fig.6-1

NOTE

All the figures in this manual are for explanation

purpose only. They may be slightly different from the

heat pump you purchased.The actual unit shall prevail.

installation manual

11

Page 13

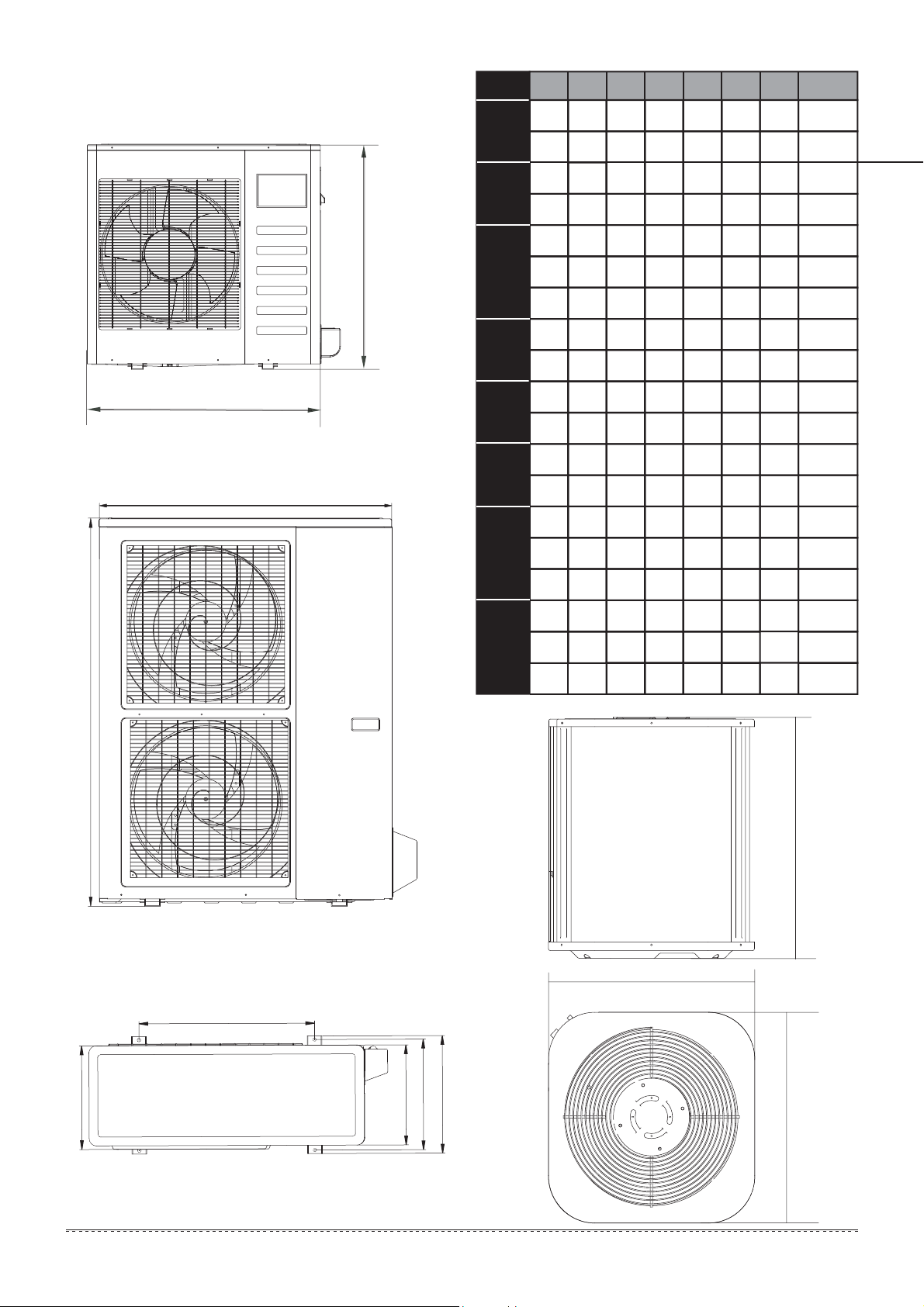

6.2 Figure of body size

1. Split type outdoor unit

Table 6-1 mm

MODEL A B C D E H F

762 530 290 315 270 593 282

12

780 548 266 300 241 547 250

Fig.6-2

Fig.6-2

695

Fig.6-2

Fig.6-2

Fig.6-2

762 530 290 315 270 593 282

18

842

560

335

360

852 582 368 390 328 660 340

312

324

H

24

895 590 333 355 302 862 313

990 624 366 396 340 966 354

990 624 366 396 340 966 354

30

895 590 333 355 302 862 313

A

Fig.6-2

A

990 624 366 396 340 966 354

36

940 600 376 400 340 1245 360

990 624 366 396 340 966 354

42

940

600

376

400

340

360

990 624 366 396 340 966 354

600

376

400

340

48

360 940

590 378 400 330 1167 340 900

600 376 400 340 1245 360 940

60

590 378 400 330 1167 340 900

1245

1245

Fig.6-2

Fig.6-2

Fig.6-2

Fig.6-2

Fig.6-2

Fig.6-3

Fig.6-2

Fig.6-3

Fig.6-2

Fig.6-3

Fig.6-3

Fig.6-3

Fig.6-3

F

H

B

Fig.6-3

E

C

643 404 448 368 1369 392 938

2. Vertical discharge type outdoor unit

D

Fig.6-3

A

Fig.6-5

C

B

installation manual

12

Fig.6-4

Fig.6-6

Page 14

Table 6-2 mm

DIMENSIONS

MODEL

REMARK

B A C

18

636 554 554

2. Vertical discharge type outdoor unit

(Wall or obstacle)

t e

m

l t u

m

0

O r

0

2 1

i

A

>

24

36

48

60

636 554 554

840

852

843 740 740

3. Centrifugal fan outdoor unit

I

A

B

C

G

Table 6-3

A

B

MODEL

C

554 554

740 740

J

D

E

H

D

E

F

G

H

Refore to

Fig.6-5

Fig.6-6

F

Fig.6-7

mm

I

J

>300mm

Air inlet

(Wall or obstacle)

m m

t

e

l

0

n i r

0

i A

3

>

Fig.6-9

>300mm

Air inlet

18

1174

1120

680

720

750

475

300

430

265

24

1174 1120 680 720 750 475 300 430 265 393

30

1381

1328

702

740

770

520

336

500

296

36

1381 1328 702 740 770 520 336 500 296 443

1394

1338

783

820

850

568

398

574

48

60

1338 783 820 850 568 398 574 342 463

1394

342

6.3 Space of installation and maintenance

1. Split type outdoor unit

(Wall or obstacle)

m

m

0

0

3 >

Maintain channel

>600mm

P

Fig.6-8

Air inlet

>300mm

N

Air inlet

m

m

0

M

0

0

2

>

Air outlet

393

443

463

m

t

e

m

l

0

n

i

0 3 >

r

i A

Fig.6-10

3. Centrifugal fan outdoor unit

a) In case that suspending in the ceiling

≥

4

m 0 0

m

m m 0 0

3

≥

m

m

0 0 3 ≥

Fig.6-11

installation manual

13

Page 15

b)In case that installing on the floor

3 ≥

0

m m 0

m

0 0 4 ≥

To change air outlet is necessary to interchange panels too.

Fan outlet panel is attached to fan structure, which must be

mounted as follow .

≥

3

m

m 0 0

m

Fig.6-12

NOTE

All the figures in this manual are for explanation

purpose only. They may be slightly different from the heat

pump you purchased.

The actual unit shall prevail.

6.4 Available configuration

Four different configuration are available for oudoor unit only

changing the panels and fan position.

NOTE

Keep in mind that fan unit weight is aprox 30kg ,the unit as

well as relevant equipment covered with the vinyl cover

during installation work.

Air inlet modification

To change air inlet is only necessary to interchange the

indicated panels position. Both panels use screws to be fixed

to unit chas s is.

Fig.6-14

6.5 Moving and installation

Since the gravity center of the unit is not at its physical

center, so please be careful when lifting it with a sling.

Never hold the inlet of the outdoor unit to prevent it from

deforming.

Do not touch the fan with hands or other objects.

Do not lean it more than 45, and do not lay it sidelong.

Make concrete foundation accoding to the sepecifications of

the outdoor units.

Fasten the feet of this unit with bolts firmly to prevent it from

collapsing in case of earthquake or strong wind.(Refer to

Fig.6-15)

≥60cm

Fix with bolt

installation manual

14

Fig.6-15

NOTE

All the figures in this manual are for explanation

purpose only. They may be slightly different from the

heat pump you purchased.The actual unit shall prevail.

Change Panel

Fig6-13

Page 16

Concrete Foundation

Foundation could be on flat and is recommended be 100-300mm

1

higher than ground level.

Install a drainage around foundation for smooth drain

2

When installing the outdoor unit fix the unit by anchor bolts of

3

M10.

When installing the unit on a roof or a veranda,drain water

4

sometimes turns to ice on a cold morning. Therefore, avoid

draining in an area that people often use because it is slippery.

0

0

3

≥100

0

0

1

Fig.6-16

Table 6-4

No Description

1 Outdoor Unit

2 Vibration-proof rubber

3 Anchor Bolt M10

4 Drainage (Wide 100×Depth 150)

5 Drainage

7. INSTALL THE CONNECTING PIPE

Check whether the height drop between the indoor unit and

outdoor unit, the length of refrigerant pipe, and the number of

the bends meet the following requirements:

(The number of the bends less than 15.)

Table 7-1

The type of models

50Hz T1 condition/R22

Split type heat pump

50Hz Vertical discharge heat pump

/60Hz T1 condition/R22 Split type

heat pump and Vertical discharge

heat pump

R410A inverter Split type heat pump

and Centrifugal fan outdoor unit

R410A Split type heat pump

and and Centrifugal fan outdoor

unit

50Hz/60Hz T3 condition

(outdoor unit down)

50Hz/60Hz T3 condition

(outdoor unit up)

the unit with quick joint

Model

12K

18K-24K

30K-42K

48K-60K

12K

18K-24K

30K-60K

12K

18K-24K

30K

36K

48K-60K

12K

18K-30K

36K

48K-60K

18K-24K

30K

36K

42K-60K

18K-24K

30K

36K

42K

48K-60K

12K-18K

The length of

refrigerant pipe

15

30

50

50

15

30

30

10

25

25

30

50

15

25

30

50

25

30

30

50

25

30

30

50

50

5

unit: m

The max

height drop

8

10

20

25

8

10

20

5

12

15

20

25

8

15

20

25

10

15

20

25

15

20

25

30

35

5

6 Mortar Hole (Φ100×Depth 150)

Table 6-5

MODEL

Unit

18~24

30~36

48

BC

1120 720

1328 740

1338 820

mm

Suspended unit

1. Suspend the unit as the drawing indicates.

2. Ensure that ceiling can resist the Outdoor unit weight indicated

in specification label plate.

Sling Bolt

Suspension Bracket

CAUTION

All field piping must be provided by a licensed

refrigeration technician and must comply with the

relevant local and national codes.

Prevent let air, dust, or other impurities enter the pipe

system during installation.

Insulation pipe shall be used to the gas piping and the

liquid piping. Otherwise, the condensate may happen

The Procedure of Connecting Pipes

7.1

Drill a hole in the wall (suitable just for the size of the wall

1

conduit), then set on the fittings such as the wall conduit and

its cover.

R410A

Fig.6-17

installation manual

15

Page 17

Bind the connecting pipe and the cables together tightly with

2

binding tapes.

Pass the bound connecting pipe through the wall conduct

from outside. Be careful of the pipe allocation to do on

damage to the tubing.

Connect the pipes. Refer to "How to Connect the pipes" for

3

details.

4

Expel the air with a vacuum pump. Refer to "How to expel the

air with a vacuum pump" for details.

open the stop values of the outdoor unit to make the

5

refrigerant pipe connecting the indoor unit with the outdoor

unit in fluent flow.

6

Check the leakage. Check all the joints with the leak detector

or soap water.

Cover the joints of the connecting pipe with the soundproof /

7

insulating sheath (fittings), and bind it well with the tapes to

prevent leakage.

CAUTION

Be sure to with insulating materials cover all the exposed

parts of the flare pipe joints and refrigerant pipe on the

liquid-side and the gas-side. Ensure that there is no gap

between them.

Incomplete insulation may cause water condensation.

3

Remove the protection cover of stop valve

Liquid Valve

Gas Valve

Connect the indoor unit at first, then the outdoor unit.

4

Bend the tubing in proper way. Do not harm to them.

Bend the pipe with thumb

min-radius 100mm

The bending angle should not exceed 90.

Bending position is preferably in the middle of the

bendable pipe. The larger the bending radius the better it

is.

Do not bend the pipe more than three times.

When connecting the flare nut, coat the flare both inside

and outside with either oil or ester oil and initially tighten

by hand 3 or 4 turns before tighting firmly.

Fig.7-3

Fig.7-4

How to Connect the pipes

Flaring

1

Cut a pipe with a pipe cutter. (Refer to Fig.7-1)

Lean crude burr

90

Insert a flare nut into a pipe and flare the pipe.

Refer to Table 4 for the dimension of flare nut spaces.

Table 7-2

Pipe gauge

Ø6.4 8.3 8.7

Ø9.5 12.0

Ø12.7 15.4

Ø15.9

Ø19.1

2

Tightening torque

15

~16 N.m

~163 kgf.cm)

(153

25

~26N.m

(255

~265 kgf.cm)

35~36 N.m

(357

~367 kgf.cm)

~47 N.m

45

~480 kgf.cm)

(459

65~67N.m

~684 kgf.cm)

(663

Remove the Cycle Service Panel and the Cover

Board, unscrewing the screws which secure it to

the structure

Cycle Service Panel

Cover Board

Flare dimensin A

(mm)

min max

12.4

15.8

18.6

22.9

19.0

23.3

Fig.7-1

Flare shape

°

4

±

90

45

°

±

2

A

R0.4~0.8

Fig.7-2

Fig.7-5

Be sure to use both a spanner and torque wrench

together when connecting or disconnecting pipes to /from

the unit.

Fig.7-6

CAUTION

Too large torque will harm the bellmouthing and too small will cause

leakage. Please determine the torque according to Table 7-2.

After the connecting work is finished, be sure to check that there is

no gas leak.

How to expel the air with a vacuum pump

Stop valve operation introduction

1. Opening stop valve

1.

Remove the cap and turn the valve

counterclock-wise with the hexagon wrench.

2.

Turn it until the shaft stops.Do not apply excessive force

to the stop valve. Doing so may breakthe valve body, as

the valve is not a backseat type. Always use the special

tool.

3.

Make sure to tighten the cap securely.

2. Closing stop valve

1.

Remove the cap and turn the valve clockwise with the

hexagon wrench.

Securely tighten the valve until the shaft contacts the

main bodyseal.

2.

Make sure to tighten the cap securely.

For the tightening torque, refer to the table below.

installation manual

16

Page 18

Table 7-3

Tightening torque N M (Turn clockwise to close)

Stop

Valve size

Ø6.4

Ø9.5

Ø12.7

Ø15.9

Ø19.1

Shaft (valve body)

Hexagonal

wrench 4 mm

7~9

9~11

11~13

Hexagonal

wrench 6 mm

Hexagonal

wrench 6 mm

Cap

(Valve lid)

13.5~16.5 5~7

18~22

23~27

35~40

Maintenance nut

11.5~13.9

CAUTION

Always use a charge hose for service port connection.

After tightening the cap, check that no refrigerant leaks

arepresent.

7.2

Additional Refrigerant Charge

CAUTION

Refrigerant cannot be charged until field wiring has been

completed.

Refrigerant may only be charged after performing the leak

test and the vacuum pumping.

When charging a system, care shall be taken that its

maximum permissible charge is never exceeded, in view of

the danger of liquid hammer.

Charging with an unsuitable substance may cause

explosions and accidents, so always ensure that the

appropriate refrigerant is charged.

service port

maintenance nut

cap

hexagon holeshaftseal

Using the vacuum pump

Loosen and remove the maintenance nuts of stop valves A

1

and B, and connect the charge hose of the manifold valve to

the service port of stop valve A. (Be sure that stop valves A

and B are both closed)

2

Connect the joint of the charge hose with the vacuum pump.

Open the Lo-lever of the manifold value completely.

3

Turn on the vacuum pump. At the beginning of pumping,

4

loosen the maintenance nut of stop valve B a little to check

whether the air comes in (the sound of the pump changes,

and the indicator of compound meter turns below zero). Then

fasten the maintenace nut.

When the pumping has finished, close the Lo-lever of the

5

manifold valve completely and turn off the vacuum

pump.Make pumping for 15 minutes or more and check that

the compound meter indicates -76cmHg(-1X10 Pa)

6

Loosen and remove the cap of stop valves A and B to open

stop valve A and B completely, then fasten the cap.

Disassemble the charge hose from the service port of stop

7

valve A, and fasten the nut.

Outdoor

unit

Stop valve

A

B

Manifold valve

Gas side

Liquid side

Pressure meterMulti-meter

5

Indoor

unit

C

D

Fig.7-7

Fig.7-8

Refrigerant containers shall be opened slowly.

Always use protective gloves and protect your eyes when

charging refrigerant.

The outdoor unit is factory charged with refrigerant. Calculate

the added refrigerant according to the diameter and the

length of the liquid side pipe of the outdoor unit/indoor unit

connection.

Table 7-2

Brass tube(mm)

orifice in the indoorunit

Ø6.35

orifice in the outdoorunit

orifice in the indoorunit

Ø9.53

orifice in the outdoorunit

orifice in the indoorunit

Ø12.7

orifice in the outdoorunit

orifice in the indoorunit

Ø15.9

orifice in the outdoorunit

orifice in the indoorunit

Ø19.0

orifice in the outdoorunit

R410A R22

0.022kg/m×(L-5)

0.011kg/m×(L-5)

0.060kg/m×(L-5)

0.030kg/m×(L-5)

0.110kg/m×(L-5)

0.060kg/m×(L-5)

0.170kg/m×(L-5)

0.085kg/m×(L-5)

0.250kg/m×(L-5)

0.125kg/m×(L-5)

0.030kg/m×(L-5)

0.015kg/m×L

0.065kg/m×(L-5)

0.030kg/m×L

0.115kg/m×(L-5)

0.060kg/m×L

0.190kg/m×(L-5)

0.095kg/m×L

0.290kg/m×(L-5)

0.145kg/m×L

NOTE:the table above refer to the liquid tube.

NOTE:The number of bends is up to the length of the max

height drop.Usually for each 10m need a bend.

NOTE

If a negative result is gotten for R from Table 7-4, no

refrigerant needs to be added nor removed.

Additional refrigerant will be twice of R from Table 7-4 if

the indoor unit installed throttle assembly.

Outdoor unit is equiped with a drain piping. Its position is

shown figure below.

-76 cmHg

Lo-lever

Charge hose Charge hose

Hi-lever

Vacuum pump

Lo-lever

Fig.7-9

Drain Piping

Fig.7-10

installation manual

17

Page 19

Table7-6

MODEL

A B

Unit

mm

18~24 595 1200

30~36 624 1381

48 646 1385

Prepare a polyviny chloride with 21mm inner diameter

Fasten the tube to the drain hose with an adhesive and the

field-supplied clamp. The drain piping must be performed with

a DOWN-SLOPE pitch of 1/25 to 1/100

Connect a siphon, as shown in figure below

75

Slope 2 %

Plug

Fig.7-11

Drainage test Drainage test

Check whether the drainpipe is unhindered.

New built house should have this test done before paving

the ceiling.

Remove the test cover, and stow water of about 2000ml to the

1

water receiver through the stow tube. ( Refer to Fig.5-18 in the

figure page)

2

Turn on the power, and operate the heat pump under the

"COOLING" mode. Listen to the sound of the drain pump.

Check whether the water is discharger well (a lag of 1min is

allowed before discharging, according to the length of the drain

pipe), and check whether water leaks from the joints.

3

Stop the heat pump, turn off the power, and reset the test cover

to its original position.

NOTE

The drain plug is used to empty the water-receiver for

maintenance of the heat pump. Please stuff it imposition

at all times during operation to avoid leakage.

Install the drain joint of the outdoor unit

8. CONNECT THE DRAIN PIPE

Install the drainpipe of the indoor unit

You can use a polyethylene tube as the drainpipe

(out-dia.37-39mm, in-dia.32mm). It could be bought at local

market or from your dealer.

Set the mouth of the drainpipe onto the root of the body's

pump-pipe, and clip the drainpipe and the out-let pipe sheath

(fittings) together firmly with the out-let pipe clasp (fitting).

The body's pump pipe and the drainpipe (especially the

indoor part) should be covered evenly with the out-let pipe

sheath (fittings) and be bound tightly with the constrictor to

prevent condensation caused by entered air.

To prevent water from flowing backwards into the heat pump

while the heat pump stops, please lean the drainpipe down

toward outdoor (outlet-side) at a degree of over 1/ 50. And

please avoid any bulge or water deposit. ( Refer to Fig.5-17.a

in the figure page)

Do not drag the drainpipe violently when connecting to

prevent the body from being pulled. Meanwhile, one

supportpoint should be set every 1~1.5m to prevent the

drainpipe from yielding (Refer to Fig.5-17a in the figure page).

Or you can tie the drainpipe with the connecting pipe to fix

it.(Refer to Fig.5-17.c in the figure page)

In the case of prolonged drainpipe, you had better tighten its

indoor part with a protection tube to prevent it from loosing.

If the outlet of the drainpipe is higher than the body's pump

joint, the pipe should be arranged as vertically as possible.

And the lift distance must be less than 200mm, otherwise the

water will overflow when the heat pump stops. (Refer to

Fig.5-18 in the figure page)

The end of the drainpipe should be over 50mm higher than

the ground or the bottom of the drainage chute, and do not

immerse it in water. If you discharge the water directly into

sewage, be sure to make a U-form aquaseal by bending the

pipe up to prevent the smelly gas entering the house through

the drain pipe.

Fit the seal into the drain joint, then insert the drain joint into the

base pan hole of outdoor, rotate 90° to securely assemble them.

Fit the seal into the drain joint, then insert the drain joint into the

base pan hole of outdoor, rotate 90° to securely assemble them.

Connect the drain joint with an extension drain hose (Locally

purchased), in case of the condensate draining off the outdoor

unit during the heating mode.

Seal

Drain joint

The base pan

of outdoor unit

The base pan hole

of outdoor unit

Seal

Drain

joint

Fig.8-1

NOTE

All the figures in this manual are for explanation

purpose only. They may be slightly different from the

heat pump you purchased.The actual unit shall prevail.

installation manual

18

Page 20

9. CONNECTIVE DIAGRAM

2. Cooling only

Liquid side

Gas side

Liquid side

Orifice

NOTE

For ensuring throttled efficiency , Please mount the Orifice

assembly as horizontally as possible; and anti-shock rubber

should be wrapped at external of the Orifice for denoise.

CAUTION

Mark the data plate with the Orifice installed(for some

models).

Please purchase the fittings according to the requirements in

the manual strictly.

Refer the diagram when installing.

1. Cooling&heating

Liquid side

Fig. 9-1

Indoor

Indoor

Indoor

Outdoor

Liquid side

Outdoor

Liquid side

Outdoor

X

Fig. 9-3

Indoor

Indoor

Indoor

X

X

Outdoor

Liquid side

Outdoor

Liquid side

Outdoor

Fig. 9-2

installation manual

19

Page 21

10. WIRING

The appliance shall be installed in accordance with

national wiring regulations.

The heat pump should use separate power supply with

rated voltage.

The external power supply to the heat pump should have

ground wiring, which is linked to the ground wiring of the

indoor and outdoor unit.

The wiring work should be done by qualified persons

according to circuit drawing.

An all-pole disconnection device which has at least 3mm

sepaaration distance in all pole and a residual current

device (RCD) with the rating of above 10mA shall be

incorporated in the fixed wiring according to the national

rule.

Be sure to locate the power wiring and the signal wring

well to avoid cross-disturbance.

Do not turn on the power until you have checked

carefully after wiring.

1. Split type outdoor unit

Cover

Protection board

Fig.10-1

2. Vertical discharge type outdoor unit

The power cord type designation is H07RN-F.

NOTE

Remark per EMC Directive 2004/108/EC

For to prevent flicker impressions during the start of the

compressor (technical process),following installation

conditions do apply.

1

The power connection for the heat pump has to be done

at the main power distribution. The distribution has to be

of a low impedance, normally the required impedance

reaches at a 32 A fusing point.

2

No other equipment has to be connected with this power

line.

For detailed installation acceptance please refer to your

3

power supplier, if restrictions do apply for products like

washing machines, heat pumps or electrical ovens.

For power details of the heat pump refer to the rating

4

plate of the product.

For any question contact your local dealer.

5

Connect the cable

10.1

Dissemble the bolts from the cover.(If there isn't a cover on

the outdoor unit, disassemble the bolts from the maintenance

board, and pull it in the direction of the arrow to remove the

protection board.)

Connect the connective cables to the terminals as identified

with their respective mached numbers on the terminal block

of indoor and outdoor units.

Protection Board

3. Centrifugal fan outdoor unit

Protection Board

All the figures in this manual are for explanation

purpose only. They may be slightly different from the

heat pump you purchased.The actual unit shall prevail.

Fig.10-2

Fig.10-3

NOTE

Re-install the cover or the protection board.

The Specification of Power

10.2

(Refer to Table10-1~Table 10-8)

Wiring figure

10.3

(Refer to Fig.10-1~Fig.10-6)

installation manual

20

Page 22

11. TEST OPERATION

1

The test operation must be carried out after the entire

installation has been completed.

Please confirm the following points before the test operation:

2

The indoor unit and outdoor unit are installed properly.

Tubing and wiring are correctly completed.

The refrigerant pipe system is leakage-checked.

The drainage is unimpeded.

The heating insulation works well.

The ground wiring is connected correctly.

The length of the tubing and the added stow capacity of

the refrigerant have been recorded.

The power voltage fits the rated voltage of the heat pump.

There is no obstacle at the outlet and inlet of the outdoor

and indoor units.

The gas-side and liquid-side stop valves are both opened.

The heat pump is pre-heated by turning on the power.

According to the user's requirement, install the remote

controller frame where the remote controller's signal can

reach the indoor unit smoothly

3

4

Test operation

Set the heat pump under the mode of "COOLING" with the

remote controller, and check the following points. If there is

any malfunction, please resolve it according to the chapter

"Troubleshooting" in the "Owner's Manual".

1) The indoor unit

a. Whether the switch on the remote controller works well.

b. Whether the buttons on the remote controller works

well.

c. Whether the air flow louver moves normally.

d. Whether the room temperature is adjusted well.

e. Whether the indicator lights normally.

f. Whether the temporary buttons works well.

g. Whether the drainage is normal.

h. Whether there is vibration or abnormal noise during

operation.

I. Whether the heat pump heats well in the case of the

HEATING/COOLING type.

2) The outdoor unit

a. Whether there is vibration or abnormal noise during

operation.

b. Whether the generated wind, noise, or condensed of by

the heat pump have influenced your neighborhood.

c. Whether any of the refrigerant is leaked.

CAUTION

A protection feature prevents the heat pump from being

activated for approximately 3 minutes when it is restarted

immediately after shut off.

installation manual

21

Page 23

The Specification of Power(indoor power supply)

Table 10-1

MODEL

POWER

CIRCUIT BREAKER/FUSE(A)

Table 10-2

POWER

CIRCUIT BREAKER/FUSE(A)

FREQUENCY AND VOLT

MODEL

PHASE

PHASE

FREQUENCY AND VOLT

18 24 60 30~36 42~48

1Phase 1Phase

208-240V 208-2 40V

20/16 40/25 50/30 60/45 60/50

30~36 30~36

3Phase

380-420 V

25/20 25/20 40/25 45/35

42~60 42~60

3Phase 3Phase

380-420 V

The Specification of Power(outdoor power supply)

Table 10-3

MODEL

24 60 30~36 42~48

1Phase

208-240V

208-240V

1Phase

208-240V

3Phase

208-240V

1Phase

208-240V

POWER

CIRCUIT BREAKER/FUSE(A)

Table 10-4

POWER

CIRCUIT BREAKER/FUSE(A)

FREQUENCY AND VOLT

MODEL

PHASE

PHASE

FREQUENCY AND VOLT

1Phase

208-240V

40/30 60/40 70/55 70/60

30~36 30~36

3Phase

380-420 V

25/20 25/20 40/25 45/35

1Phase

208-240V

1Phase

208-240V

1Phase

208-240V

42~60 42~60

3Phase 3Phase

380-420 V

208-240V

3Phase

208-240V

installation manual

22

Page 24

The Specification of Power(independence power supply)

Table 10-5

MODEL

POWER

(indoor)

CIRCUIT BREAKER/FUSE(A)

POWER

(outdoor)

CIRCUIT BREAKER/FUSE(A)

Table 10-6

POWER

POWER

(indoor)

(indoor)

CIRCUIT BREAKER/FUSE(A)

POWER

POWER

(outdoor)

(outdoor)

CIRCUIT BREAKER/FUSE(A)

FREQUENCY AND VOLT

FREQUENCY AND VOLT

MODEL

FREQUENCY AND VOLT

FREQUENCY AND VOLT

PHASE

PHASE

PHASE

PHASE

18 24 60 30~36 42~48

1Phase 1Phase

208-240V 208-2 40V

20/16 20/16 20/16 20/16 20/16

1Phase 1Phase

208-240V 208-2 40V

1Phase

208-240V

1Phase

208-240V

1Phase

208-240V

1Phase

208-240V

1Phase

208-240V

1Phase

208-240V

20/16 40/25 50/30 60/45 60/50

30~36 30~36

1Phase

208-240V

20/16 20/16 20/16 20/16

3Phase

380-420 V

42~60 42~60

1Phase

208-240V

3Phase 3Phase

380-420 V

1Phase

208-240V

208-240V

1Phase

208-240V

3Phase

208-240V

25/20 25/20 40/25 45/35

The Specification of Power for the invert type heat pump(independence power supply)

Table 10-7

MODEL

POWER

(indoor)

CIRCUIT BREAKER/FUSE(A)

POWER

(outdoor)

CIRCUIT BREAKER/FUSE(A)

Table 10-8

POWER

POWER

(indoor)

(indoor)

CIRCUIT BREAKER/FUSE(A)

FREQUENCY AND VOLT

MODEL

FREQUENCY AND VOLT

PHASE

PHASE

FREQUENCY AND VOLT

PHASE

18 24 60 30~36 42~48

1Phase 1Phase

220-240V 220-2 40V

15/10 15/10 15/10 15/10 15/10

1Phase 1Phase

208-240V 208-2 40V

1Phase

220-240V

1Phase

208-240V

1Phase

220-240V

1Phase

208-240V

1Phase

220-240V

1Phase

208-240V

30/20 30/20 40/30 40/35 50/40

30~36 30~36

1Phase

220-240V

15/10 15/10 15/10 15/10

42~60 42~60

1Phase

220-240V

1Phase

220-240V

1Phase

220-240V

POWER

POWER

(outdoor)

(outdoor)

CIRCUIT BREAKER/FUSE(A)

FREQUENCY AND VOLT

PHASE

3Phase

380-420 V

3Phase 3Phase

380-420 V

208-240V

3Phase

208-240V

30/20 30/25 50/40 50/40

installation manual

23

Page 25

CAUTION

The power supply is included in the power supply above mentioned can be applied to the table.

Wiring figure

Fig.10-4

Power supply

Switch/Fuse

(Available locally)

Power wiring (indoor)

Power linking wiring (Outdoor)

Indoor

Unit

Outdoor

Unit

Ground wiring

Gr ound wiri ng

Strong elec-signal link wiring

Weak elec-signal link wiring

Ground the heat pump properly in case to affect its anti-interference function

Fig.10-5

Power supply

Power linking wiring (Outdoor)

Indoor

Unit

Outdoor

Unit

Switch/Fuse

(Available locally)

Power wiring (indoor)

Ground wiring

installation manual

24

Gr ound wiri ng

Strong elec-signal link wiring

Weak elec-signal link wiring

Ground the heat pump properly in case to affect its anti-interference function

Page 26

Fig.10-6

Power supply

Power supply

Switch/Fuse

(Available locally)

Power wiring (indoor)

Power linking wiring (Outdoor)

Indoor

Unit

Out door

Unit

Gr ound wiring

Gr ound wiring

We ak elec-signal link wiring

Ground the heat pump properly i n case to affect its

anti-interference function

CAUTION

A disconnection device having an air gap contact separation in all active conductors should be

incorporated in the fixed wiring according to the National Wiring Regulation.

When wiring, please choose the corresponding chart, or it may cause damage.The signs of the

indoor terminal block in the some of following fugures may be replaced by L N L1 N1.

installation manual

25

Page 27

QSQ4I-017AEN

The design and specifications are subject to change without prior notice for product

improvement.Consult with the sales agency or manufacturer for details.

2012.12.20

202000192506

Page 28

Page 29

Page 30

installation manual

29

Page 31

installation manual

30

Page 32

installation manual

31

Page 33

installation manual

32

Page 34

installation manual

33

Page 35

installation manual

34

Page 36

installation manual

35

Page 37

installation manual

36

Page 38

installation manual

37

Page 39

installation manual

38

Page 40

installation manual

39

Page 41

installation manual

40

Loading...

Loading...