Pridiom Concealed Duct Installation Manual

INSTALLATION MANUAL

Middle Static Pressure Duct Type

Thank you very much for purchasing our air conditioner,

Before using your air conditioner , please read this manual carefully and keep it for future reference.

If used as MULTI unit, please refer to the Installation & operation manuals packed with outdoor unit.

CONTENTS PAGE

SAFETY PRECAUTIONS.......................................................................................1

INSTALLATION INFORMATION........................................................................... 2

ATTACHED FITTINGS.............................................................................................3

INSPECTING AND HANDLING THE UNIT.........................................................4

INDOOR UNIT INSTALLATION.................................................................................4

OUTDOOR UNIT INSTALLATION............................................................................11

INSTALL THE CONNECTING PIPE..................................................................15

REFRIGERANT PIPE..........................................................................................16

REFRIGERANT PIPE CONNECTION ...............................................................17

CONNECTIVE DIAGRAM......................................................................................18

CONNECT THE DRAIN PIPE..............................................................................18

FRESH AIR DUCT INSTALLATION.......................................................................19

CONTROL..............................................................................................20

WIRING.................................................................................................20

TEST OPERATION................................................................................................21

1. SAFETY PRECAUTIONS

Keep this manual where the operator can easily find them.

Read this manual attentively before starting up the units.

For safety reason the operator must read the following

cautions carefully.

Installation must be performed in accordance with the

requirement of NEC and CEC by authorized personnel only.

The safty precautions listed here are divided into two categories.

WARNING

If you do not follow these instrutions exactly, the unit may

cause property damage, personal injury or loss of life.

CAUTION

If you do not follow these instrutions exactly, the unit may

cause minor or moderate property damage, personal

injury.

After completing the installation, make sure that the unit operates

properly during the start-up operation. Please instruct the customers

on how to operate the unit and keep it maintained.Also, inform

customers that they should store this installation manual along with

the owner's manual for future reference.

WARNING

Be sure only trained and qualified service personnel to

install, repair or service the equipment.

Improper installation, repair, and maintenance may result in

electric shocks, short-circuit, leaks, fire or other damage to

the equipment.

Install according to this installation instructions strictly.

If installation is defective, it will cause water leakage,

electrical shock and fire.

When installing the unit in a small room, take measures

against to keep refrigerant concentration from exceeding

allowable safety limits in the event of refrigerant leakage.

Contact the place of purchase for more information.

Excessive refrigerant in a closed ambient can lead to oxygen

deficiency.

Use the attached accessories parts and specified parts

for installation.

otherwise, it will cause the set to fall, water leakage,

electrical shock and fire.

Install at a strong and firm location which is able to

withstand the set' s weight.

If the strength is not enough or installation is not properly

done, the set will drop to cause injury.

The appliance must be installed 2.3m / 7.5ft above floor.

The appliance shall not be installed in the laundry.

Before obtaining access to terminals, all supply circuits

must be disconnected.

The appliance must be positioned so that the plug is

accessible.

The enclosure of the appliance shall be marked by word,

or by symbols, with the direction of the fluid flow.

For electrical work, follow the local national wiring

standard, regulation and this installation instructions. An

independent circuit and single outlet must be used.

If electrical circuit capacity is not enough or defect in

electrical work, it will cause electrical shock or fire.

Use the specified cable and connect tightly and clamp

the cable so that no external force will be acted on the

terminal.

If connection or fixing is not perfect, it will cause heat-up or

fire at the connection.

Wiring routing must be properly arranged so that control

board cover is fixed properly.

If control board cover is not fixed perfectly, it will cause

heat-up at connection point of terminal, fire or electrical

shock.

If the supply cord is damaged, it must be replaced by the

manufacture or its service agent or a similarly qualified

person in order to avoid a hazard.

An all-pole disconnection switch having a contact

separation of at least 3mm/0.118in in all poles should be

connected in fixed wiring.

When carrying out piping connection, take care not to let

air substances go into refrigeration cycle.

Otherwise, it will cause lower capacity, abnormal high

pressure in the refrigeration cycle, explosion and injury.

Do not modify the length of the power supply cord or use

of extension cord, and do not share the single outlet with

other electrical appliances.

Otherwise, it will cause fire or electrical shock.

Carry out the specified installation work after taking into

account strong winds, typhoons or earthquakes.

Improper installation work may result in the equipment falling

and causing accidents.

installation manual

1

If the refrigerant leaks during installation, ventilate the

area immediately.

Toxic gas may be produced if the refrigerant comes into the

place contacting with fire.

The temperature of refrigerant circuit will be high, please

keep the interconnection cable away from the copper

tube.

After completing the installation work, check that the

refrigerant does not leak.

Toxic gas may be produced if the refrigerant leaks into the

room and comes into contact with a source of fire, such as a

fan heater, stove or cooker.

CAUTION

Ground the air conditioner.

Do not connect the ground wire to gas or water pipes,

lightning rod or a telephone ground wire.inappropriate

grounding may result in electric shocks.

Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in

electric shocks.

Connect the outdoor unit wires , then connect the indoor

unit wires.

You are not allowed to connect the air conditioner with the

power supply until the wiring and piping is done.

While following the instructions in this installation

manual, install drain piping in order to ensure proper

drainage and insulate piping in order to prevent

condensation.

Improper drain piping may result in water leakage and

property damage.

Install the indoor and outdoor units, power supply wiring

and connecting wires should be at least 1 meter away

from televisions or radios in order to prevent image

interference or noise.

Depending on the radio waves, a distance of 1 meter may not

be sufficient enough to eliminate the noise.

The appliance is not intended for use by young children

or infirm persons without supervision.

Don't install the air conditioner in the following

circumstance:

There is petrolatum existing.

There is salty air surrounding (near the coast).

There is caustic gas (the sulfide, for example) existing

in the air (near a hot spring).

The Volt vibrates violently (in the factories).

In buses or cabinets.

In kitchen where it is full of oil gas.

There is strong electromagnetic wave existing.

There are inflammable materials or gas.

There is acid or alkaline liquid evaporating.

Other special conditions.

The appliance shall be installed in accordance with

national wiring regulations.

Do not operate your air conditioner in a wet room such

as a bathroom or laundry room.

An all-pole disconnection device which has at least 3mm

clearances in all poles , and have a leakage current that

may exceed 10mA, the residual current device (RCD)

having a rated residual operating current not exceeding

30mA, and disconnection must be incorporated in the

fixed wiring in accordance with the wiring rules.

2. INSTALLATION INFORMATION

To install properly, please read this "installation manual" at

first.

The air conditioner must be installed by qualified persons.

When installing the indoor unit or its tubing, please follow

this manual as strictly as possible.

If the air conditioner is installed on a metal part of the

building, it must be electrically insulated according to the

relevant standards to electrical appliances.

When all the installation work is finished, please turn on

the power only after a thorough check.

Regret for no further announcement if there is any change

of this manual caused by product improvement.

INSTALLATION ORDER

Select the location;

Install the indoor unit;

Install the outdoor unit;

Install the connecting pipe ;

Connect the drain pipe;

Wiring;

Test operation.

installation manual

2

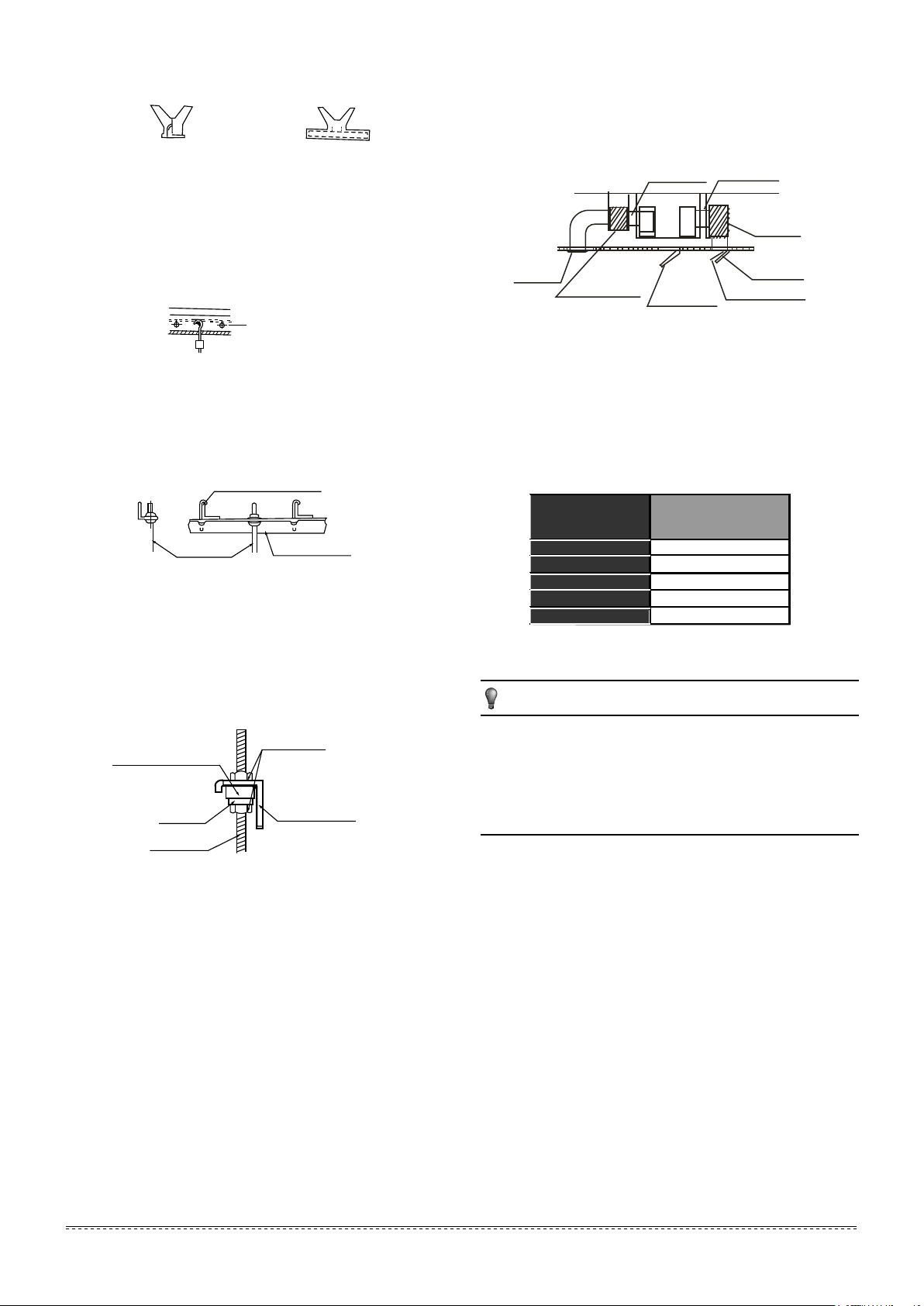

3. ATTACHED FITTINGS

Please check whether the following fittings are of full scope. If there are some spare fittings , please restore them carefully.

Table 3-1

Tubing & Fittings

Drainpipe Fittings

(for cooling & heating)

Remote controller & Its Frame

(Match with

remote controller )

Wire controller & Its Frame

(Match with wire controller )

EMC & Its Fitting

(for some models)

Others

NAME

1. Soundproof / insulation sheath

2. Binding tape

3.Seal sponge

4.Orifice

5. Drain joint

6. Seal ring

7. Remote controller

(on some models)

8. Frame

9.Mounting screw(ST2.9×10-C-H)

10.Alkaline dry batteries (AM4)

11. Remote controller manual

12. Wire controller

13. Magnetic ring

(twist the electirc wires L and N

around the magnetic ring to five

circles)

14. Owner‘s manual

15. Installation manual

16 .Transfer connector(Φ12.7-Φ15.9)/

( )

Φ0.5in-Φ0.63in

(Packed with the indoor unit )

(NOTE: Pipe size differ from appliance

to appliance.To meet different pipe size

requirement, sometimes the pipe

connections need the transfer connector

to install on the outdoor unit .)

17 .Transfer connector(Φ6.35-Φ9.52)/

( )

Φ0.25in-Φ0.375in

(Packed with the indoor unit )

(NOTE: Pipe size differ from appliance

to appliance.To meet different pipe size

requirement, sometimes the pipe

connections need the transfer connector

to install on the outdoor unit .)

18 .Transfer connector(Φ9.52-Φ12.7)/

( )

Φ0.375in-Φ0.5in

(Packed with the indoor unit,used for

multi-type models only )

(NOTE: Pipe size differ from appliance

to appliance.To meet different pipe size

requirement, sometimes the pipe

connections need the transfer connector

to install on the outdoor unit .)

19. Connecting wire for display (2M)

20. Cord protection rubber ring

SHAPE

QUANTITY

2

1

1

1

(on some models)

1

1

1

1

(on some models)

2

2

1

1

1

L

N

1

1

1

(on some models)

1

(on some models)

1

(on some models)

1

(on some models)

1

(on some models)

installation manual

3

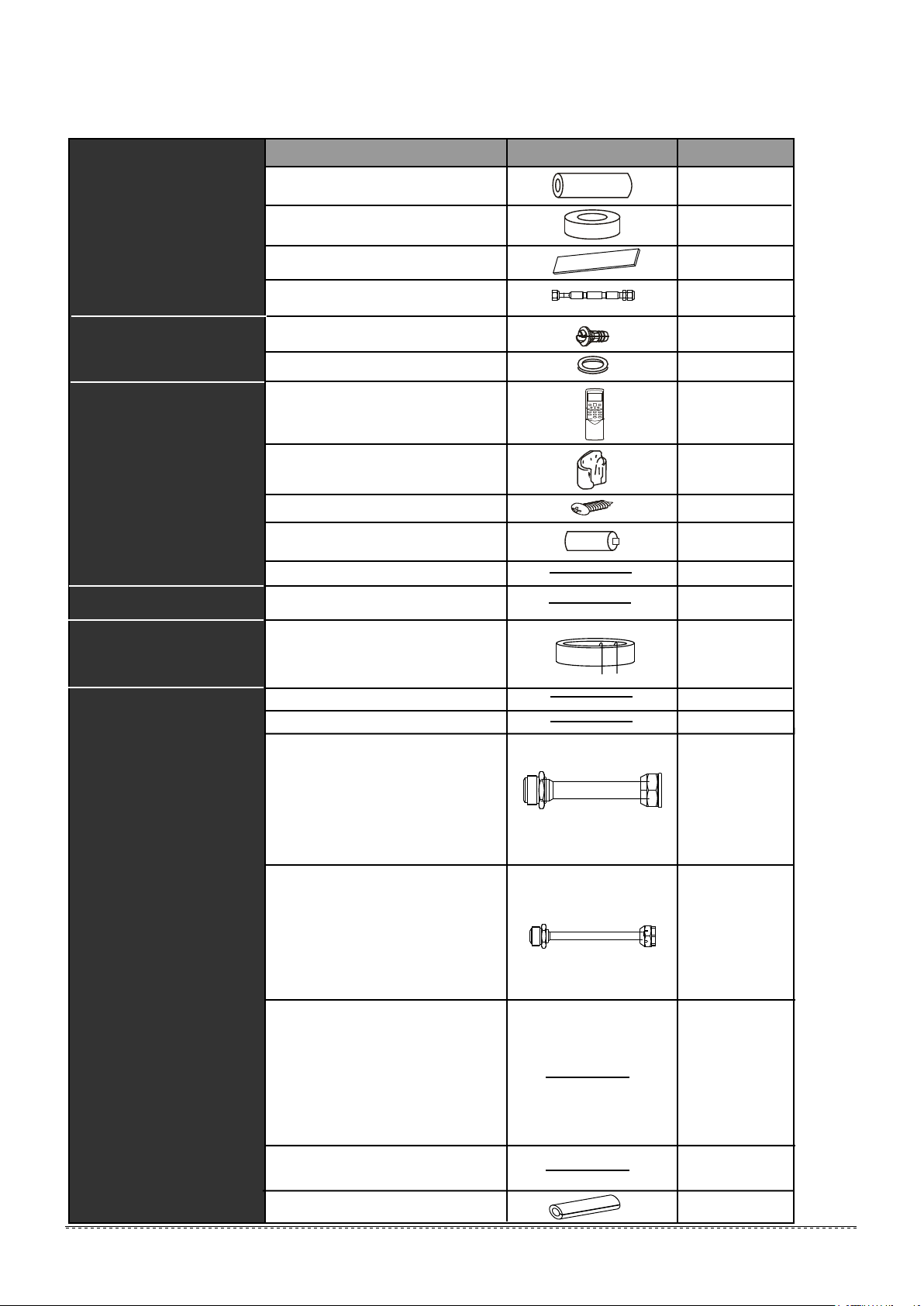

4. INSPECTING AND HANDLING THE UNIT

At delivery, the package should be checked and any damage should

be reported immediately to the service agent.

When handling the unit, take into account the following:

Fragile, handle the unit with care.

1

Keep the unit upright in order to avoid compressor

damage.

Choose on before hand the path along which the unit is to be

2

brought in.

Move this unit as originally package as possible.

3

4

When lifting the unit , always use protectors to prevent belt

damage and pay attention to the position of the unit’s centre

of gravity.

5. INDOOR UNIT INSTALLATION

5.1 Installation place

The indoor unit should be installed in a location that meets

the following requirements:

There is enough room for installation and maintenance.

The ceiling is horizontal, and its structure can endure the

weight of the indoor unit.

The outlet and the inlet are not impeded, and the

influence of external air is the least.

The air flow can reach throughout the room.

The connecting pipe and drainpipe could be extracted out

easily.

There is no direct radiation from heaters.

CAUTION

Keep indoor unit, outdoor unit, power supply wiring and

transmission wiring at least 1 meter away from televisions

and radios. This is to prevent image interference and

noise in those electrical appliances. (Noise may be

generated depending on the conditions under which the

electric wave is generated, even if 1 meter is kept.)

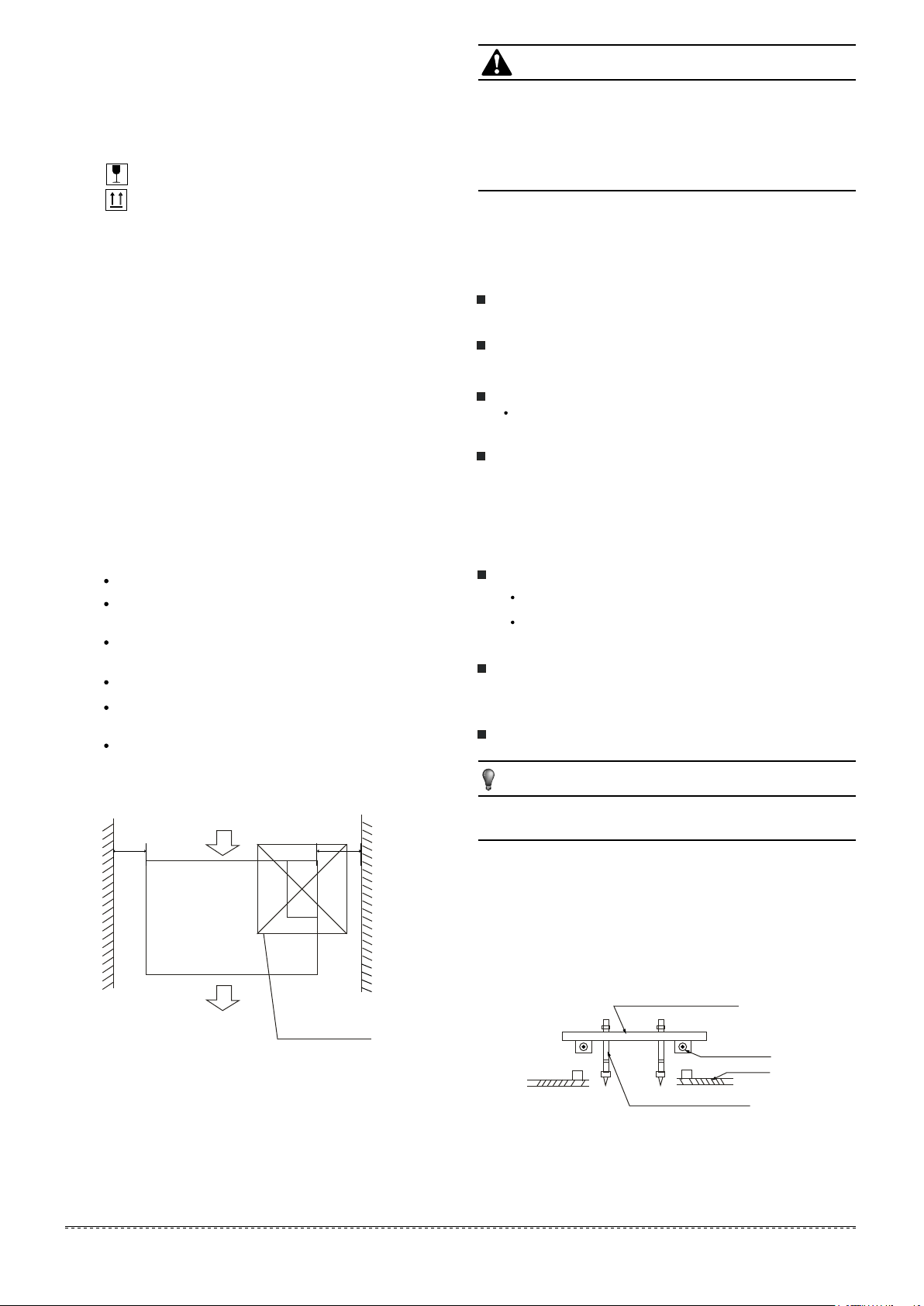

5.2 Install the main body

1 Installing Ø10/Ø0.394in hanging screw bolts. (4 bolts)

Please refer to the following figures for positioning 4 screw

bolts.

Evaluate the ceiling construction and please install with

Ø0.394in hanging screw bolts.

/

Consult the construction personnels for the specific procedures.

Do keep the ceiling flat. Consolidate the roof beam to avoid

possible vibration.

Carry out the pipe and line operation in the ceiling after finishing

the installation of the main body. While choosing where to start

the operation, determine the direction of the pipes to be drawn

out. Especially in case there is a ceiling, position the refrigerant

pipes, drain pipes,indoor & outdoor lines to the connection

places before hanging up the machine.

The installation of hanging screw bolts.

Cut off the roof beam.

Strengthen the place that has been cut off, and consolidatethe roof beam.

After the selection of installation location, position the refrigerant pipes, drain pipes,indoor & outdoor wires to the connection

places before hanging up the machine.

The installation of hanging screw bolts.

Ø10

Maintena nce roomage

200mm/7.874in or more

300mm/11.811in or more

600mmX600mm/23.622inX23.622in

checking orifice

Fig.5-1

NOTE

Confirm the minimum drain tilt is 1/100 or more

5.2.1

Wooden construction

Put the square timber traversely over the roof beam, then install

the hanging screw bolts. (Refer to Fig.5-2)

Timber over the beam

Roof beam

Ceiling

Hanging screw bolts

Fig.5-2

installation manual

4

New concrete bricks

5.2.2

Inlaying or embedding the screw bolts. (Refer to Fig. 5-3)

(Blade shape insertion)

For Original concrete bricks

5.2.3

(Slide insertion)

Fig.5-3

3.

Air inlet and air outlet duct should be apart far enough to avoid

air passage short-circuit.

Recommended duct connection

4.

Canvas tie-in Canvas tie-in

Isolation booth

Use embedding screw bold, crock and stick harness.

(Refer to Fig.5-4)

Steel bar

Embedding screw bolt

(Pipe hanging and embedding screw bolt)

Fig.5-4

5.2.4

Steel roof beam structure

Install and use directly the supporting angle steel. (Refer to Fig.5-5)

Hanging screw bolt

Hanging bolts

2

Overhanging the indoor unit

(1) Overhang the indoor unit onto the hanging screw bolts with

block.

(2) Position the indoor unit in a flat level by using the level indicator,

unless it may cause leakage.

Shockproof cushion

Washer

Hanging

screw bolt

Supporting

angle steel

Fig.5-5

Screw nut

Overhang part

Fig.5-6

Air outlet

5. Please refer to the following static pressure to install

Table.5-1

Change the fan motor static pressure corresponding to external

duct static pressure.

Isolation booth

MODEL

(Btu/h)

12

18

24

30~36

42~60

checking orifice

Static Pressure

(Pa)

30

70

70

80

100

Air inlet

Air dust filter

Fig.5-7

NOTE

Do not put the connecting duct weight on the indoor unit.

1.

2.

When connecting duct, use inflammable canvas tie-in to prevent

vibrating.

3.

Insulation foam should be wrapped outside the duct to avoid

condensate and internal duct underlayer shall be added to reduce

the noise for special requirement.

5.3 Duct and accessories installation

Install the filter(optional) according to air inlet size.

1.

2.

Install the canvas tie-in between the body and duct.

installation manual

5

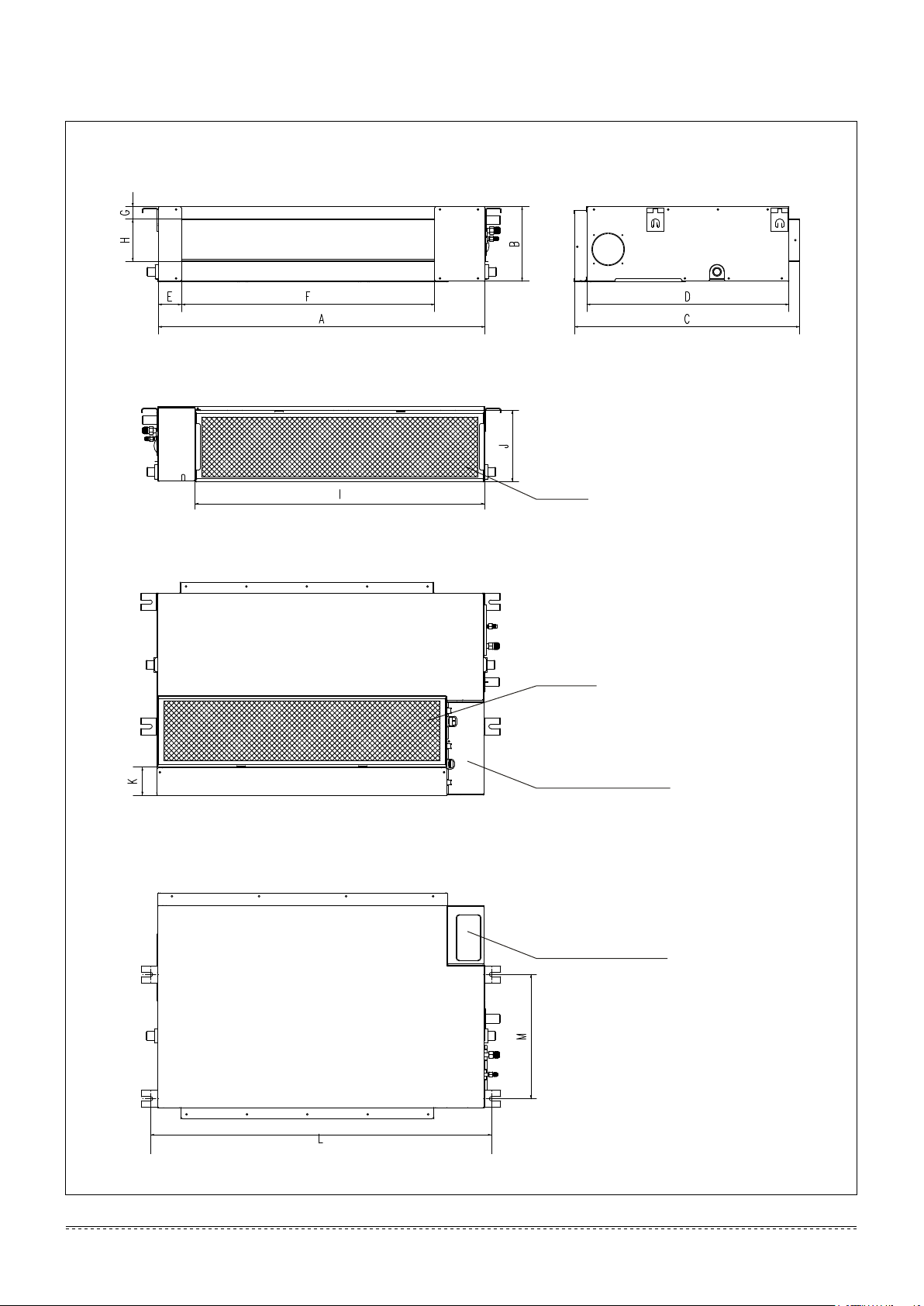

The positioning of ceiling hole, indoor unit and hanging screw bolts

Dimension and air outlet size

Air inlet size

Position size of descensional ventilation opening

Unit: mm

Air filter

Size of mounted hook

Air filter

Electric control box

Electric control box

installation manual

6

Fig.5-8

Table.5-2 mm

Outline dimension

air outlet opening size

air return opening size

Size of

mounted lug

A B C D E F G H I J K L M

12

12~18

24

36

(small model)

30~36

42~60

(in=mm/25.4)

700 210 635 570 65 493 35 119 595 200 80 740 350

920 210 635 570 65 713 35 119 815 200 80 960 350

920 270 635 570 65 713 35 179 815 260

920 270 635 570 65 713 35 179 815 260

1140 270 775 710 65 933 35 179 1035 260

1200

300 865 800 80 968 40 204 1094 288 45 1240 500

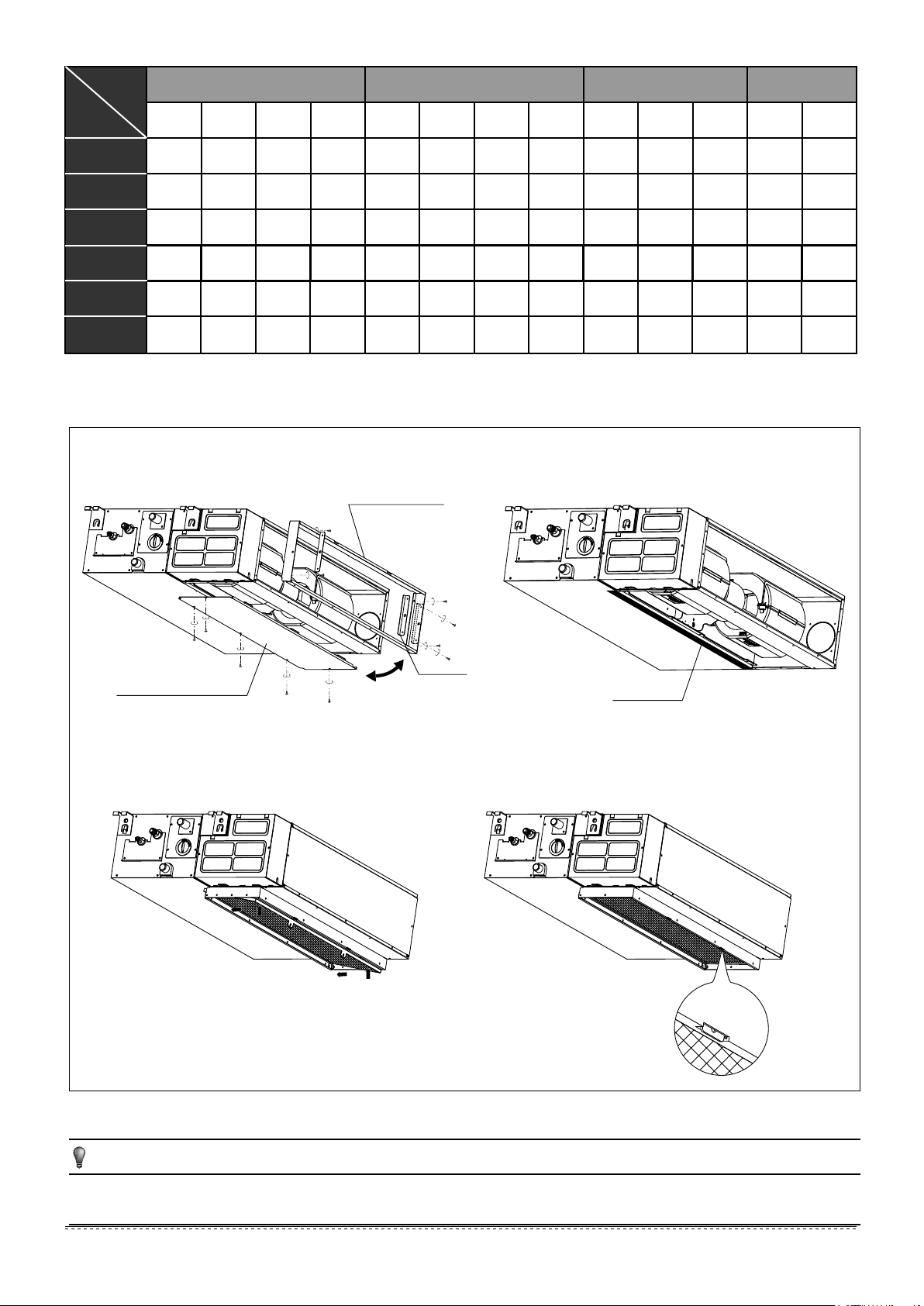

How to adjust the air inlet direction? (From rear side to under-side.)

1.

Take off ventilation panel and flange, cut off the staples at

side rail.

Air return flange

2.

Stick the attached seal sponge as per the indicating place in

the following fig, and then change the mounting positions of

air return panel and air return flange .

20 960 350

20 1180 490

45 1240 500

Dentilation panel

3.

When install the filter mesh, please plug it into flange inclined

from air return opening, and then push up.

Side rail

Seal sponge

4.

The installation has finish, upon filter mesh which fixing

blocks have been insert to the flange positional holes.

Fig.5-9

NOTE

All the figures in this manual are for explanation purpose only. They may be slightly different from the air

conditioner you purchased.The actual unit shall prevail.

installation manual

installation manual

7

Loading...

Loading...