Price UMC3 Series Manual

MANUAL – INSTALLATION + SERVICE

Underfloor ModuFlex Controller

UMC3 Series

v100 – Issue Date: 09/20/17

© 2017 Price Industries Limited. All rights reserved.

UNDERFLOOR MODUFLEX CONTROLLER

TABLE OF CONTENTS

Product Overview

Introduction ................................................................... 1

General Safety Guidelines..............................................1

Safety Precautions .......................................................1

Safety Symbols ............................................................. 1

Underfloor Systems Control Zones ................................ 2

General Description ....................................................... 3

Features of the UMC3 ................................................... 4

Operation ...................................................................... 4

Installation & Mounting Instructions

Installation ..................................................................... 5

Price Flow Response Chart ........................................... 5

Input/Output Description ............................................... 6

Wiring ........................................................................... 7

Thermostat Installation .................................................. 8

How to use Thermostats ............................................... 9

Display Navigation

Initial Startup ............................................................... 10

Service Menu .............................................................. 11

Balancing Menu .......................................................... 12

VVT Menu ................................................................... 13

Setpoint Menu ............................................................. 14

Input Menu .................................................................. 15

Output Menu - Aux Binary ........................................... 16

Output Menu - Analog Outputs ................................... 17

Stat Setup Menu ......................................................... 18

Info Menu .................................................................... 19

Address Menu ............................................................. 20

Networking & Setup

BACnet Networking and Setup ................................... 21

Setting the Device Instance ......................................... 22

LINKER - USB Service Tool ......................................... 23

Maintenance

Troubleshooting ........................................................... 24

Hardware Specifications .............................................. 25

UNDERFLOOR MODUFLEX CONTROLLER

PRODUCT OVERVIEW

Introduction

In this manual, you will find technical descriptions and

diagrams of underfloor system components along with

their installation instructions. Practical guidelines and

recommendations are also provided. If more information is

required about this equipment, please contact a Price sales

representative.

General Safety Guidelines

This document is intended for use by owner-authorized

operating/service personnel who are expected to possess the

required training to enable them to perform their tasks properly

and safely. This individual must have read and understood this

document and any referenced materials prior to performing any

task on this equipment. Also, it is essential that this individual

be familiar with and comply with all applicable governmental

standards and regulations pertaining to the task in question.

This individual must also verify that installation and connections

comply with local building codes. It is the obligation and

responsibility of the operating/service personnel to identify and

recognize these inherent hazards, protect themselves, and

proceed safely in completing their tasks. Failure to comply

with any of these requirements could result in severe personal

injury or death to themselves and people at the site, as well as

serious damage to the equipment and the property in which it

is situated.

The equipment discussed in this manual is relatively

complicated apparatus and must be handled with the

necessary precautions. Individuals may be exposed to certain

components or conditions such as refrigerants, oils, materials

under pressure, rotating components, and both high and low

voltage during installation, operation, maintenance or service

of this equipment. If misued or mishandled, each item has the

potential to cause bodily injury or death.

Safety Precautions

When using electrical appliances, basic safety precautions

should always be followed including the following:

1. Read all instructions.

2. Do not touch hot surfaces.

3. To protect against electrical shock do not immerse cord,

plugs, or Control Box in water or other liquids.

4. Unplug the unit when not in use and before cleaning.

5. Do not operate any appliance with a damaged cord or

plug or after the appliance malfunctions or has been

damaged in any manner. Return appliance to the nearest

authorized service facility for examination, repair or

adjustment.

6. The use of accessory attachments not recommended by

the appliance manufacturer may cause injuries.

7. Do not use outdoors.

8. Do not let cord hang over edge of a table or counter, or

touch hot surfaces.

9. Do not place on or near a hot gas or electric burner, or in a

heated oven.

10. Always attach plug to appliance first, then plug into the

power source. To disconnect, turn any control to “off”,

then remove plug from power source.

11. Do not use appliance for other than intended use.

12. Save these instructions.

Safety Symbols

The following symbols are used in this document to alert the

reader to areas of potential hazard:

WARNING

Failure to observe may result in personal injury, death or

equipment damage.

CAUTION

Failure to observe may result in equipment damage.

NOTE: Used to highlight additional information helpful to the reader.

priceindustries.com | UNDERFLOOR MODUFLEX CONTROLLER - Manual

1

UNDERFLOOR MODUFLEX CONTROLLER

Product overview

Underfloor Systems Control Zones

INTERIOR ZONES

Constant Air Volume - Cooling Only

Typically, interior zones have relatively stable loads hence

constant volume supply is often employed. A typical interior

zone consists of contant volume or constant pressure turbulent

floor twist outlets installed in a large, common plenum space.

In this method the entire plenum space is treated as one zone

and, under fluctuating loads, the amount of air delivered to

the space is regulated by the relative pressure in this plenum,

modulated by a single point of control. Manual face-adjustable

diffusers (MFD) provide occupant control of airflow volume.

Variable Air Volume - Cooling Only

In the case an open plenum is desired to be divided into

several zones, variable air volume control is possible with the

use of devices installed under the diffuser or with the use of a

variable volume basket. The variable volume diffusers would

be controlled by the UMC. The UMC would open and close

the diffusers releasing air from the pressurized plenum. The

variable volume (VAV) diffusers require a 24 VAC signal which is

provided by the UMC to modulate the actuators. Meanwhile,

the UMC accepts a 0 to 10 VDC cooling signal either from

a manual control signal or from a thermostat. The UMC

modulates the airflow from 0% to 100%.

CONSTANT AIR VOLUME - COOLING ONLY

VARIABLE AIR VOLUME - COOLING ONLY

PERIMETER ZONE

Trough Heating and Cooling

Use of linear floor grilles with integrated heating elements offer

a system with heightened flexibility and efficiency as it omits

the use of fan terminal units and ducting. In cooling mode,

dampers on the LFGH modulate open to the plenum allowing

more airflow into the space to satisfy the cooling demand.

When a call for heat arises, the hot water or electric coil

energizes and the diffusers either open to the plenum or to a

perimeter cavity to allow air to pass over the heating element.

LFGHs are controlled by the UMC3 where up to 12 LFGHs can

be daisy chained.

TROUGH HEATING AND COOLING

2

UNDERFLOOR MODUFLEX CONTROLLER - Manual | priceindustries.com

UNDERFLOOR MODUFLEX CONTROLLER

PRODUCT OVERVIEW

General Description

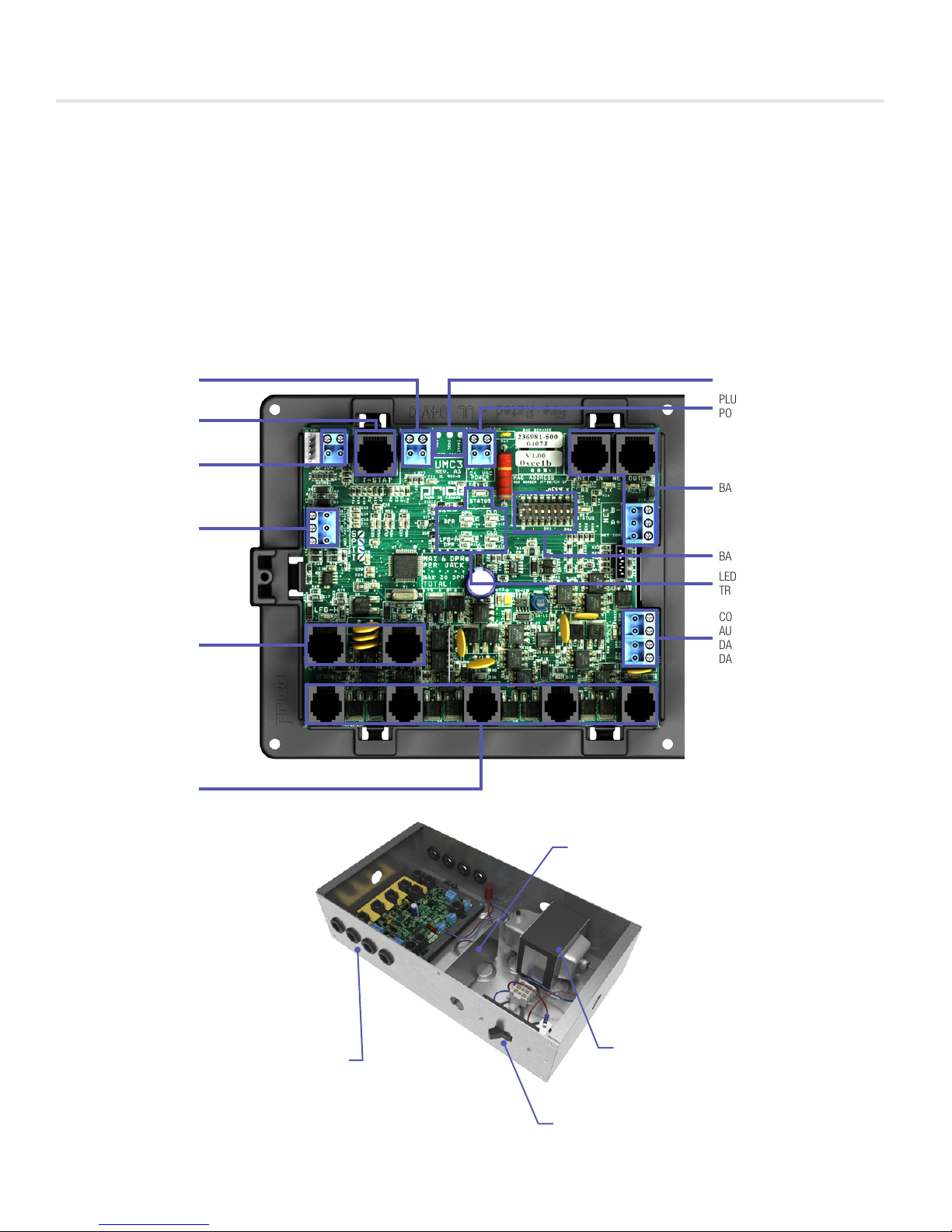

The Third Generation Underfloor ModuFlex Controller (UMC3) is a direct digital controller for pressurized underfloor plenum cooling

zones. It can control up to 30 underfloor damper/diffusers – 12 of which can be the LFGH with integrated reheat. Auxiliary inputs

and outputs add to the UMC3’s flexibility.

The UMC3 offers cutting edge zone control by combining the accuracy of direct digital control with the flexibility of an individual

zone control system; providing maximum control and efficiency. An advanced and configurable proportional integral controller

allows for exceptional user comfort and energy efficiency. Installation of the controller and thermostat is simple and error proof with

RJ-45 (network type) connections to the thermostat and BACnet network.

The UMC3 comes factory mounted in a rugged galvanized enclosure complete with a 96VA transformer and disconnect switch.

THERMISTOR INPUT

(MONITORING ONLY)

RJ-45 T-STAT PORT FOR

THERMOSTAT CONNECTION

ANALOG INPUTS

PIN 1 – COOLING

PIN 2 – HEATING

ANALOG OUTPUTS

HEAT

AUX

COM

LFGH OUTPUTS

CONNECT UP TO 6 LFGH UNITS

PER JACK FOR A TOTAL OF 12

LFGH UNITS

MODULAR DAMPER OUTPUTS

CONNECT UP TO 6 UNDERFLOOR

DAMPERS/DIFFUSERS PER JACK

FOR A TOTAL OF 30 DAMPERS/

DIFFUSERS (INCLUDING LFGH)

VOLTAGE TEST POINTS

PLUGGABLE 24VAC

POWER TERMINAL

BACNET MS/TP CONNECTIONS

BACNET MAC ADDRESS

LED INDICATORS FOR

TROUBLESHOOTING

COMMON BINARY OUTPUTS

AUX

DAMPER CLOSED

DAMPER OPEN

METAL SAFETY GUARD

SEPARATING HIGH AND

LOW VOLTAGE AREAS

OPENINGS FOR MODULAR

8 GROMMETED

CABLE CONNECTIONS

96 VA MULTI-TAP

TRANSFORMER WITH

CIRCUIT BREAKER

DISCONNECT SWITCH

priceindustries.com | UNDERFLOOR MODUFLEX CONTROLLER - Manual

3

UNDERFLOOR MODUFLEX CONTROLLER

Product overview

Features of the UMC3

• Control up to 30 underfloor dampers.

• Modular connections to dampers – Use RJ-12 cables

included with dampers to connect underfloor dampers to

UMC3. LFGH dampers use RJ-45 connections.

• Outputs protected by self-resetting thermal fuses – Prevents

damage to circuit board in the event of a damaged cable.

Fault LED lights when dampers are trying to drive on an

output with damaged cable.

• Auxiliary 24VAC Binary Output – Use for reheat, room lights,

signal to other equipment, etc. Rated for a maximum output

of 0.5A (12VA).

• Auxilary Analog Outputs (2) – Use to connect to other

equipment, BAS, etc. Output range fully configurable (210VDC, 0-10VDC, 10-2VDC, etc.). Rated at a maximum

output of 10mA each.

• Analog Inputs (2) – Configurable to allow control of the

UMC3 from a source other than a Price Thermostat (BAS,

third party thermostat, etc.). Accepts the standard dual

0-10VDC signal for cooling/heating. (if not using LFGH or

other heaters connected to UMC3, only the 0-10V cooling

signal is needed).

• Input (1) 10K type J thermistor – Can be used to monitor a

temperature over the network. Can also be used for heat/

cool changeover.

• Thermostat port - For RJ-45 connection to thermostat from

the UMC3 controller.

• Native BACnet MS/TP communication – Connect using RJ45 cable, or use discrete twisted-pair wire to terminal block.

Available speeds: 9600, 19200, 38400, 76800 (default).

• LED Indication – For ease of troubleshooting – displays

status, damper directions, BACnet status, and output fault.

• Pluggable terminal blocks – For easy installation.

• High-Voltage disconnect switch.

• 96 VA multi-tap transformer with circuit breaker.

• Metal safety guard separating high and low voltage areas.

• 8 grommeted openings for modular cable connections.

• Temperature sensor input (for monitoring).

• Disconnect switch.

• Pluggable 24VAC power terminal.

Operation

The UMC3 controller is an advanced and fully configurable

underfloor ModuFlex cooling controller. It is typically interfaced

with one of four Price Thermostats to determine room load and

allow for setup functions. With a variety of output configurations,

the UMC3 can control up to 30 underfloor dampers, as well as

auxiliary equipment using its auxiliary 24VAC binary outputs, and

analog 0-10V outputs.

Upon an increase in space temperature the controller regulates the

dampers open to increase the flow of cool air. On an increase

of space temperature greater than the proportional band,

the dampers’ positions are maintained at their pre-selected

maximum setting.

On a decrease in space temperature the controller regulates the

dampers closed to decrease the flow of cool air. If connected to

LFGH floor grills with integrated damper and reheat, the UMC3

will energize or modulate the heat proportionally to the room

demand. If the space temperature decreases to less than the

proportional band, the dampers’ positions are maintained at

their pre-selected minimum setting.

The UMC3 can also be configured to accept 0-10V input signals

from a BAS system or third party thermostat for room load

calculations, instead of data from the thermostat.

The UMC3 can be used as a stand alone unit, or can be

interfaced into a BAS with the MS/TP BACnet network.

The UMC3 offers four thermostat options that provide a range

of control from room temperature sensing, all the way to motion

sensing. With the use of the LCD Thermostat, balancing and

system setup can be achieved. Further, with the use of the LCD

Thermostat with Motion, the UMC3 can be used as a motionoccupied zone and lighting controller. The LCD Thermostat with

Motion offers different levels of sensitivity and still performs all

the functions of the regular LCD Thermostat.

4

UNDERFLOOR MODUFLEX CONTROLLER - Manual | priceindustries.com

UNDERFLOOR MODUFLEX CONTROLLER

INSTALLATION & MOUNTING INSTRUCTIONS

Installation

1. Place the UMC3 in the underfloor plenum in the center of

the controlled zone using a 35 ft. cable.

2. Supply power and ground to terminal per wiring diagram.

NOTE: This task must be completed by a certified and

licensed electrician.

3. Connect underfloor dampers using modular cables

supplied with dampers. Follow these general rules:

A. Connect no more than 30 dampers total

B. Daisy chain up to 6 dampers per output – no more

C. Do not connect standard dampers (with RJ-12 plug) to

LFGH outputs (which use RJ-45 plug)

D. LFGH dampers (up to 12) count towards the maximum

of 30 dampers per controller

Price Flow Response Chart

4. Run thermostat wire to thermostat, and plug into “T-Stat”

port on the UMC3. (For thermostat installation reference

the Installation & Mounting Instructions Thermostat

Installation section.)

5. Connect BACnet network (if used). For more detailed

information on networking with UMC3 reference the

Display Navigation Address Menu section.

6. Flip the UMC3’s power switch to the ON position.

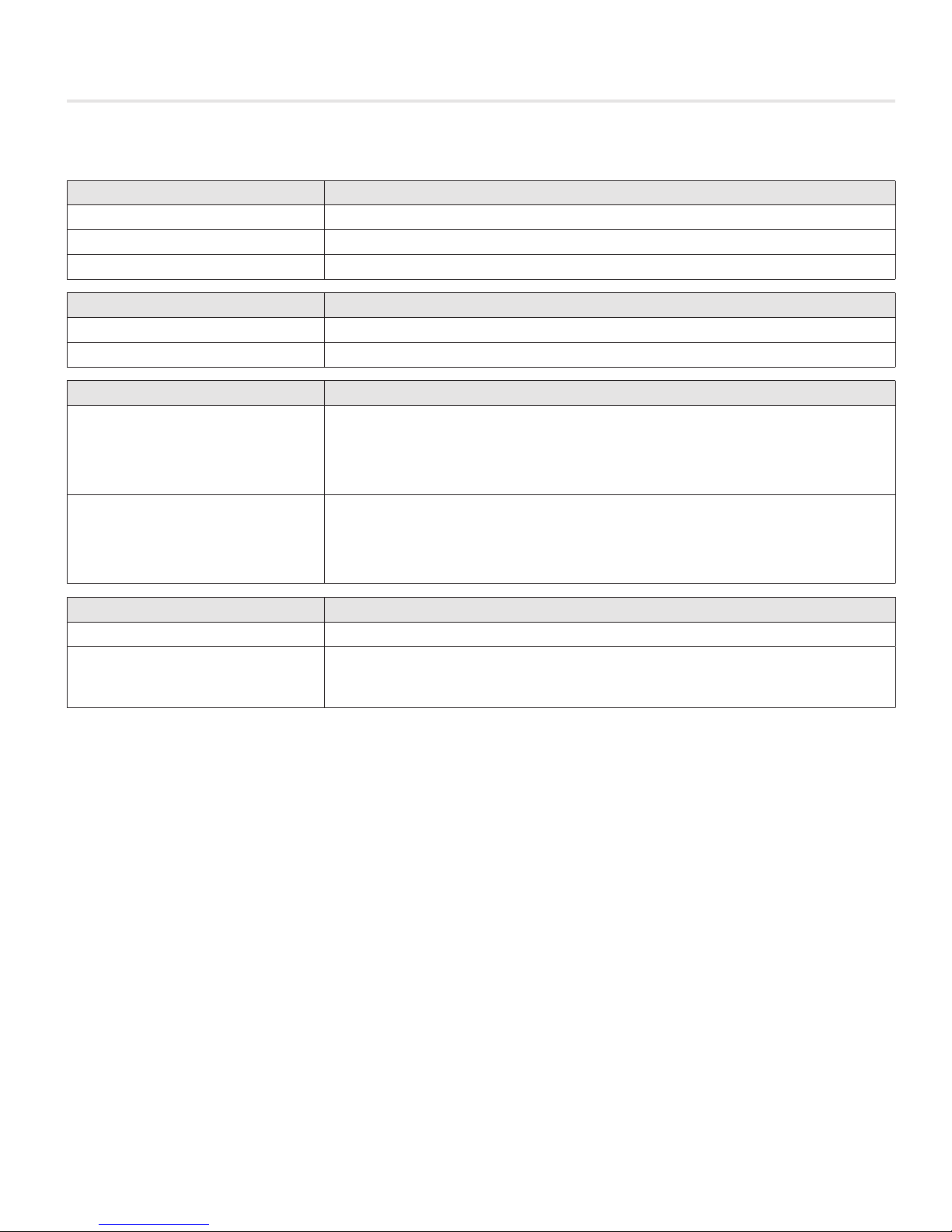

HCCO Response

PI = Cooling

PI = Heating

PI = Neutral

PI = Cooling

PI = Heating

PI = Neutral

PI = Cooling

PI = Heating

PI = Neutral

“D” indicates the target of the regular dampers and “L” represents the target of the LFGH dampers (with integrated reheat)

NOTE 1: By default the UMC3 is shipped configured for cold supply air only. This can be changed to enable HCCO with

thermistor probe (however this will almost never be the case).

NOTE 2 : PI = Proportional Integral = room load (either cooling/neutral/heating)

Above is a flow response chart for the UMC3, showing the demand, duct air condition, and the controller’s output.

E.g.: PI = Cooling, Supply Air = Cold, Output = Cooling Flows. This indicates that the room demand is in cooling, the supply air is cold,

and the controller would modulate both the regular dampers and the LFGH dampers between the Cool Min and Cool Max values.

Supply air = Cold D L

Supply air = Cold D L

Supply air = Cold D L

Supply air = Hot D L

Supply air = Hot D L

Supply air = Hot D L

Supply air = Neutral D L

Supply air = Neutral D L

Supply air = Neutral D L

Cooling

Min

Cooling

Flows

Heating

Min

Heating

Flows

Neutral Supply

Air Flow

TECH TIP

Use the above table to determine what airflows are being chased in certain modes. Example: If UMC3 is trying to heat the room (PI = Heating)

and cool air is being supplied (Duct Air = Cold) it will chase its heating min flow.

priceindustries.com | UNDERFLOOR MODUFLEX CONTROLLER - Manual

5

UNDERFLOOR MODUFLEX CONTROLLER

INSTALLATION & MOUNTING INSTRUCTIONS

Input/Output Description

24VAC Binary Outputs Description

BO – DPR OPN Plenum damper open. Used for floating point actuators.

BO – DPR CLO Plenum damper closed. Used for floating point actuators.

BO – AUX Aux binary output available.

Analog Outputs

AO – Heat Signal sent to LFGH diffusers (0-10VDC)

AO – Aux Aux analog output available (0-10VDC)

Analog 0-10VDC Inputs

Can be configured (along with AI5) to control the UMC3 from a third party

AI4 – Cooling

AI5 – Heating

thermostat. In this configuration, AI4 is the 0-10VDC cooling load input.

Can also be used for simple voltage monitoring when analog

inputs are not configured as control source.

Can be configured (along with AI4) to control the UMC3 from a third party

thermostat. In this configuration, AI5 is the 0-10VDC cooling load input.

Can also be used for simple voltage monitoring when analog

inputs are not configured as control source.

Additional Inputs

AI1 – 5VDC Sensor Typically used for voltage monitoring over BACnet network.

Analog Input for temperature probe hookup with 10k Type J Thermistor.

THERM

Typically used for temperature monitoring over BACnet network.

Can also be configured for heat/cool changeover if required.

6

UNDERFLOOR MODUFLEX CONTROLLER - Manual | priceindustries.com

UNDERFLOOR MODUFLEX CONTROLLER

INSTALLATION & MOUNTING INSTRUCTIONS

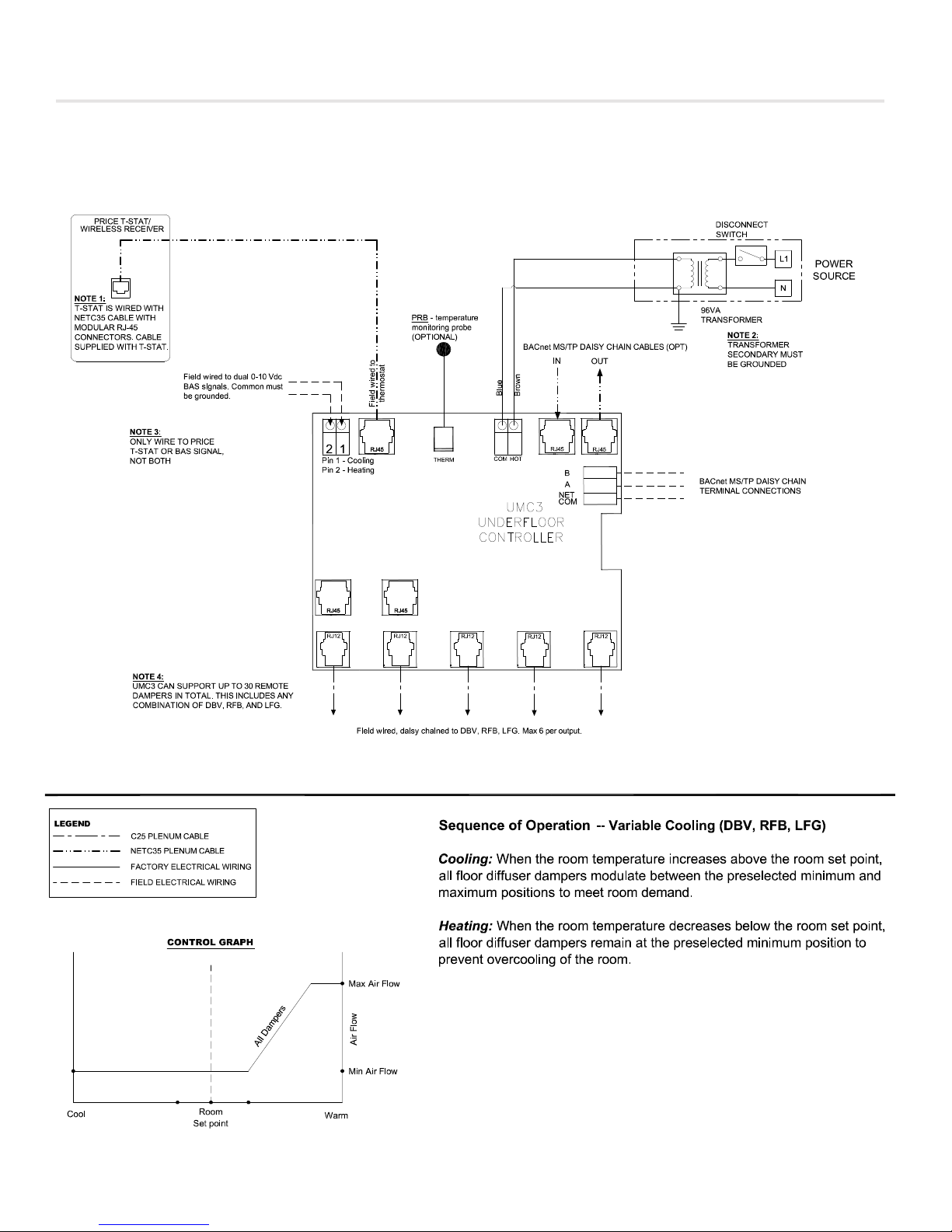

Wiring

Below is an example of a typical UMC3 layout.

priceindustries.com | UNDERFLOOR MODUFLEX CONTROLLER - Manual

7

Loading...

Loading...