Price RDV Series, RDVQ Series, RDVQ 5000 Installation, Operation And Maintenance Manual

MANUAL – INSTALLATION, OPERATION, AND MAINTENANCE

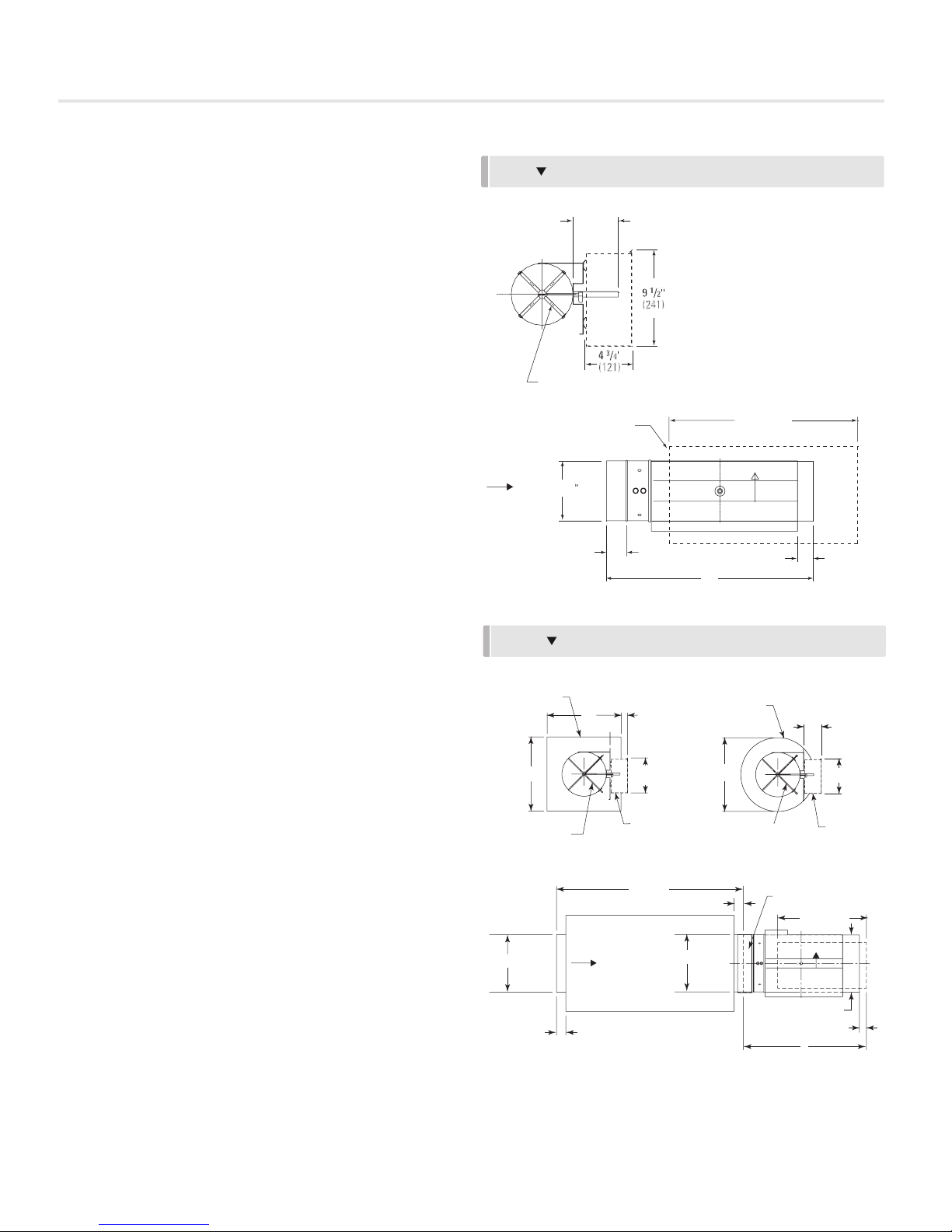

Air Volume Control Valve

RDV / RDVQ Series

v004 – Issue Date: 07/14/16

© 2016 Price Industries Limited. All rights reserved.

AIR VOLUME CONTROL VALVE

TABLE OF CONTENTS

Product Overview

General ......................................................................... 1

Receiving Inspection ..................................................... 1

Wiring ........................................................................... 1

Installation Instructions

Installing the RDV/RDVQ 5000 Terminal Unit ................. 2

Air Volume Ranges ........................................................ 2

SP300 Cal. Curves - RDV ............................................. 3

SP300 Cal. Curves - RDVQ w/Absorptive Silencer ........ 4

SP300 Cal. Curves - RDVQ w/Packless Silencer ........... 5

OPTIONAL

NEMA1

CONTROLS

ENCLOSURE

(SEE NOTE)

OPTIONAL

NEMA1

CONTROLS

ENCLOSURE

(SEE NOTE)

20”

(508)

MULTI-POINT SENSOR

C/W GAUGE TAPS

PACKLESS

SILENCER

20”

(508)

4

3

/4” (121)

9

1

/2” (241)

9

1

/2” (241)

MULTI-POINT SENSOR

C/W GAUGE TAPS

ABSORPTIVE

SILENCER

DIA = A + 8”

4

3

/4” (121)

DIA = A - 1/8” (3)

DIA = A -

1

/8” (3)

181/2” (470)

INLET SILENCER

SECTION

DIA = A - 1/8” (3)

AIR

FLOW

2”

(51)

B

2” (51)

36” (914)

CONNECTION COLLAR

UP

AIR VOLUME CONTROL VALVE

PRODUCT OVERVIEW

General

The RDV/RDVQ is supplied with the duct, damper, and airflow

sensor. The RDV/RDVQ assembly is designed to accept Direct

Digital Controls (DDC) for VAV pressure independent operation.

The terminal unit controls are supplied by the controls

contractor and either factory or field mounted and wired. For

information concerning controls, components, sequence of

operation, etc., please refer to the documentation provided by

the controls contractor.

Receiving Inspection

After unpacking the assembly, check it for shipping damage.

If any shipping damage is found, report it immediately to the

delivering carrier. During unpacking and installation do not

handle by the inlet velocity sensor, damper shaft, or tubing.

Damage may result.

Wiring

If controls have been factory mounted, a wiring diagram

will be included with the unit indicating the factory mounted

components. For field wiring of room sensors and other

accessories, refer to the controls contractor's documentation.

If the controls have been field mounted, refer to the controls

contractor's documentation for all wiring information.

Damper rotation is always clockwise to the open position.

An identification mark on the end of the shaft indicates the

damper position.

The factory supplied sensing lines are color coded. Red

indicates the total pressure or ”HI“ line which should be

located on the upstream side. Green indicates the static

pressure or ”LO“ line which should be located on the

downstream side.

An optional protective enclosure may be provided to house

the terminal unit control components. The enclosure cover is

removable with two sheet metal screws.

RDV

AIR

DIA = A - 1/8” (3)

FLOW

RDVQ

PACKLESS

SILENCER

20”

(508)

MULTI-POINT SENSOR

C/W GAUGE TAPS

DIA = A - 1/8” (3)

4 1/2” (114)

DAMPER SHAFT

MULTI-POINT SENSOR

C/W GAUGE TAPS

FOR PNEUMATIC CONTROLS

NEMA1 OPTIONAL

CONTROLS ENCLOSURE

20”

(508)

AIR

FLOW

2”

(51)

3

/4” (121)

4

1

9

/2” (241)

OPTIONAL

NEMA1

CONTROLS

ENCLOSURE

(SEE NOTE)

36” (914)

INLET SILENCER

SECTION

ABSORPTIVE

SILENCER

DIA = A + 8”

MULTI-POINT SENSOR

C/W GAUGE TAPS

2” (51)

DIA = A - 1/8” (3)

18 1/2” (470)

UP

CONNECTION COLLAR

DIA = A -

1 1/2” (38)

4

1

/2” (241)

9

OPTIONAL

NEMA1

CONTROLS

ENCLOSURE

(SEE NOTE)

181/2” (470)

UP

1

/8” (3)

3

/4” (121)

B

priceindustries.com | AIR VOLUME CONTROL VALVE - Manual

1

Loading...

Loading...