Price FHC, FHMX Installation Manual

MANUAL – INSTALLATION

Fume Hood Contoller/Monitor

FHC/FHMX Series

v300 – Issue Date: 05/31/17

© 2017 Price Industries Limited. All rights reserved.

Firmware Version: 1.6.0

FUME HOOD CONTROLLER / MONITOR

TABLE OF CONTENTS

Section 1 - Introduction

Product Overview .......................................................... 1

Features ........................................................................ 1

Fume Hood Interface (FHI) Features .............................2

Sidewall Sensor (SWS) Features .................................... 2

Sash Position Sensor (SPS) Features ............................2

Presence Sensor (PS) Features .....................................2

Section 2 - Installation & Mounting

Fume Hood Controller (FHC) Installation & Mounting .....3

Fume Hood Monitor (FHMX) Installation & Mounting ..... 4

Sash Position Sensor (SPS) Installation & Mounting ...... 5

Sidewall Sensor (SWS) Installation & Mounting .............. 7

Presence Sensor (PS) Installation and Mounting ........... 8

Wiring Diagram ............................................................. 9

Fume Hood Location Considerations .......................... 11

Section 3 - Sash, Sidewall & Hybrid Configuration

Control Settings ..........................................................12

Fume Hood Interface (FHI) .......................................... 13

FHI - Initial Start Up ..................................................... 13

Information Menu ........................................................ 14

Service Menu .............................................................. 14

IMPORTANT NOTES

CAUTION

This mark indicates an important point for the proper

function of the fume hood and the FHC. Improper

installation or setup may cause unit failure and

contamination of the laboratory space. Pay close

attention to all caution points throughout this manual.

Application Support

P: 204.654.5604

E: criticalcontrols@priceindustries.com

W: www.pricecriticalcontrols.com

Technical Support

P: 866.884.3524

E: pccfieldservice@priceindustries.com

Section 4 - Interface And Menus

Control/Monitor ........................................................... 15

Alarm Points ................................................................ 17

Occupancy ................................................................. 17

Input ........................................................................... 18

Output ........................................................................ 19

Network ...................................................................... 21

FHI Setup .................................................................... 21

Diagnostic ................................................................... 22

Section 5 - Setup Wizard

Setup Wizard .............................................................. 23

Section 6 - Balance And Verification

Balance & Verification .................................................. 25

Section 7 - BACnet Points List

BACnet Points List ...................................................... 26

pricecriticalcontrols.com | FUME HOOD CONTROLLER / MONITOR - Manual

FUME HOOD CONTROLLER / MONITOR

SECTION 1 - INTRODUCTION

Product Overview

Laboratory fume hoods serve as

ventilation systems that efficiently

exhaust chemical vapors, mist, and

fumes. Fume hoods also provide a

barrier protecting occupants from

certain reactions, spills, and even fires.

In most cases special fans exhaust the

fumes outside, which greatly dilute their

concentration and reduce their harmful

effects. In some cases a specialized

scrubber is also required to remove the

vapors from the exhaust air.

Fume hoods require constant exhaust

airflow to ensure that none of the air

entering the fume hood ever escapes

back into the laboratory space. This

ensures the safety of the user and of

any other occupants of the room or

building. The exhaust airflow, measured

in cubic feet per minute (CFM), creates

a face velocity across the sash opening.

This is the industry standard measure

of fume hood safety. Typically the

face velocity of a fume hood must be

between 80 – 100 feet per minute

(FPM), but this can vary based on local

codes or the fume hood design. It is

important to note the required face

velocity for the hood being used.

Features

The Fume Hood Controller (FHC) can ensure a safe working environment by

constantly monitoring and adjusting the exhaust to maintain the correct face velocity.

The main control inputs are sash sensors and sidewall sensors. Sash sensors use a

potentiometer attached to the sash to measure the current height. Face velocity in

feet per minute (FPM) is calculated in real time. Sidewall sensors use an extremely

sensitive, low pressure sensor to measure the negative pressure in the hood

compared to the lab space. The Fume Hood Monitor (FHMX) constantly monitors

the fume hood face velocity and can provide real-time fume hood information to

operators and to the building management system (BMS) over BACnet.

• 16 bit – high speed flash based microprocessor with watch dog timer, brown

out reset

• Multi-stage surge protection against voltage spikes on 24 VAC input

• 2 simple connections to sidewall sensors using RJ-12 jacks

• 3 Sash position inputs (10kΩ)

• 2 binary outputs rated at 0.5 amps each, protected with thermal fuse

(RED LED on trip)

• 1 binary output (dry contact)

• 2 analog outputs (0-10 VDC)

• 2 binary inputs

• Pluggable terminal blocks

• Mnet high-speed fume hood network port

• 1 potentiometer input

• 1 pressure port input

CAUTION

A higher face velocity is not always

safer. Turbulence in the fume hood

can be created by high face velocities

causing issues with spillage/blowback.

1

FUME HOOD CONTROLLER / MONITOR - Manual | pricecriticalcontrols.com

• LED’s for Mnet/Lnet data TX/RX, Mnet/Lnet wiring fault, and RS-45 termination

FUME HOOD CONTROLLER / MONITOR

SECTION 1 - INTRODUCTION

Fume Hood Interface

(FHI) Features

• Backlit 14x2 LCD Interface with true

character display

• LED side bars offer 180 degree

viewing of current fume hood status

• Variety of colors displayed to

indicate fume hood status

• Password protected setup menu

• Easy to use MENU system for fast

and simple setup of system

• Included RJ45 plenum rated cable

for fast, error free hookup

• Setup Wizard – walk through setup

of FHC when first powered up

Sidewall Sensor (SWS) Features

• Ultra Low flow digital temperature

compensated pressure transducer

• 25 ft. sensor cable with quickconnect installation

FUME HOOD INTERFACE

SIDEWALL SENSOR

• Sidewall assembly with easy-tomount hardware

Sash Position Sensor

(SPS) Features

• Ultra long life potentiometer (over

250,000 cycles)

• Stainless steel cable for stability

• Metal mounting ring for stable

installation and reliability

• Thick plastic cover for protection

against airborne chemical agents

Presence Sensor (PS) Features

• Low profile device

• Adjustable coverage pattern

• Sensitive response

SASH POSITION SENSOR

PRESENCE SENSOR

pricecriticalcontrols.com | FUME HOOD CONTROLLER / MONITOR - Manual

2

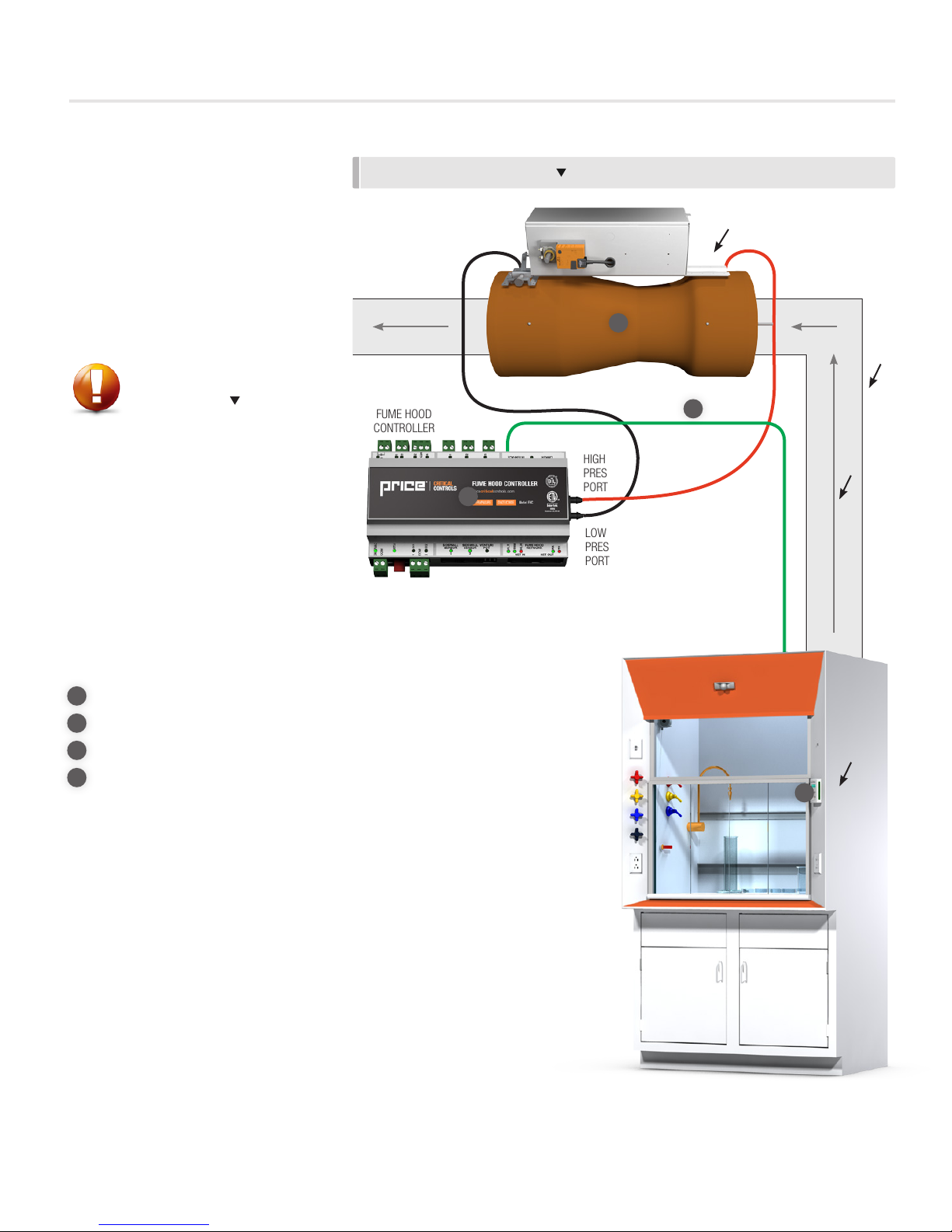

FUME HOOD CONTROLLER / MONITOR

SECTION 2 - INSTALLATION & MOUNTING

Fume Hood Controller (FHC)

Installation & Mounting

• Open the controls enclosure on the

Price Venturi Valve that is installed in

the fume hood exhaust duct.

• Follow the wiring diagram found

on page 10 for the FHC electrical

installation.

CAUTION

The Fume Hood Controller is factory

mounted on the valve when ordered

with a Price Venturi Valve. Only electrical

installation is required.

Ensure the valve is facing the correct

direction and is mounted in the correct

orientation (vertical or horizontal).

INSTALLATION & MOUNTING

FUME HOOD

CONTROLLER

2

1

HIGH

PRESSURE

PORT

LOW

PRESSURE

PORT

4

RJ-45 PLENUM

RATED FHI CABLE

VENTURI

VALVE

DUCT

AIRFLOW

DIRECTION

Required items:

1

Venturi Valve

2

Fume Hood Controller

3

Fume Hood Interface

4

RJ-45 Plenum Rated FHI Cable

FUME HOOD

INTERFACE

3

3

FUME HOOD CONTROLLER / MONITOR - Manual | pricecriticalcontrols.com

FUME HOOD CONTROLLER / MONITOR

SECTION 2 - INSTALLATION & MOUNTING

Fume Hood Monitor (FHMX)

Installation & Mounting

• The FHMX may arrive valve

mounted (see FHC Installation

& Mounting) or in a panel mount

controls enclosure. Open the

controls enclosure to access the

FHMX.

• Follow the wiring diagram found

on page 9 for the FHMX electrical

installation.

CAUTION

The Fume Hood Monitor is factory

mounted in an enclosure when ordered.

Only electrical installation is required.

Ensure that the panel-mount enclosure

is mounted in a location that can be

accessed for electrical installation.

INSTALLATION & MOUNTING

FUME HOOD

MONITOR

1

3

RJ-45 PLENUM

RATED FHI CABLE

DUCT

AIRFLOW

DIRECTION

Required items:

1

Fume Hood Monitor

2

Fume Hood Interface

3

RJ-45 Plenum Rated FHI Cable

FUME HOOD

INTERFACE

2

pricecriticalcontrols.com | FUME HOOD CONTROLLER / MONITOR - Manual

4

FUME HOOD CONTROLLER / MONITOR

SECTION 2 - INSTALLATION & MOUNTING

Sash Position Sensor (SPS)

Installation & Mounting

The sash sensor can be mounted in

one of four ways. Option A mounts

directly above the sash outside of the

fume hood. Options B and C mount to

the counter weight cable, and Option D

mounts directly in the hood.

Option A) Mount the sash sensor

above the sash as shown in Figure 1.

• Ensure the cable is free from

obstruction along the entire length

of sash movement.

• Ensure that the mounting position

of the end of the cable will not pass

above the sash sensor even at the

maximum sash height.

• Run the sensor cable back to the

FHC mounted on the venturi valve

or the FHMX.

Option B) Mount the sash sensor on

the top of the fume hood as shown in

Figure 2.

• Ensure the cable is free from

obstruction along the entire length

of sash movement.

FIGURE 1 FIGURE 2

FIGURE 3

• The sensor cable may be attached

directly to the counter weight.

This configuration may be desired

when the sash connects to the

counterweight with a belt and pulley

system.

• Run the sensor cable back to the

FHC mounted on the venturi valve

or the FHMX.

Option C) Mount the sash sensor on

the top of the fume hood as shown in

Figure 3 and 4.

• Ensure the cable clamp does not

pass around a pulley.

• Run the sensor cable back to the

FHC mounted on the venturi valve

or the FHMX.

• Ensure the sensor cable travels

parallel to the counter weight cable.

5

FUME HOOD CONTROLLER / MONITOR - Manual | pricecriticalcontrols.com

FIGURE 4

FUME HOOD CONTROLLER / MONITOR

SECTION 2 - INSTALLATION & MOUNTING

Option D) Mount the sash sensor on

the inside wall of the fume hood as

shown in Figure 5. This is the least

preferable mounting option, as the

sensor is directly in the exhaust air

stream.

• Ensure that the sensor and cable

to not interfere with the mechanical

operation of the fume hood sash.

• Ensure the sensor is as close to the

sash as possible so that the cable is

completely parallel to the sash in all

positions.

• Raise the sash to the fully open

position (not just the working

height). Screw the metal ring into

the sash. Ensure that the sensor is

mounted higher than the fully open

position of the sash.

• Once mounted, raise and lower the

sash several times to ensure that

the cable is clear of all obstructions

and moves freely with the sash.

FIGURE 5

• Run the sensor cable back to the

FHC mounted on the venturi valve

or the FHMX.

CAUTION

The sash position sensor cable must be

mounted as close to parallel as possible

with the direction of the sash movement.

Any angle can cause improper sash

height readings and result in poor

control.

CAUTION

If only one SPS is required, the

SPS must be wired into the SASH

POSITION SENSOR #1 port on the

FHC/FHMX.

pricecriticalcontrols.com | FUME HOOD CONTROLLER / MONITOR - Manual

6

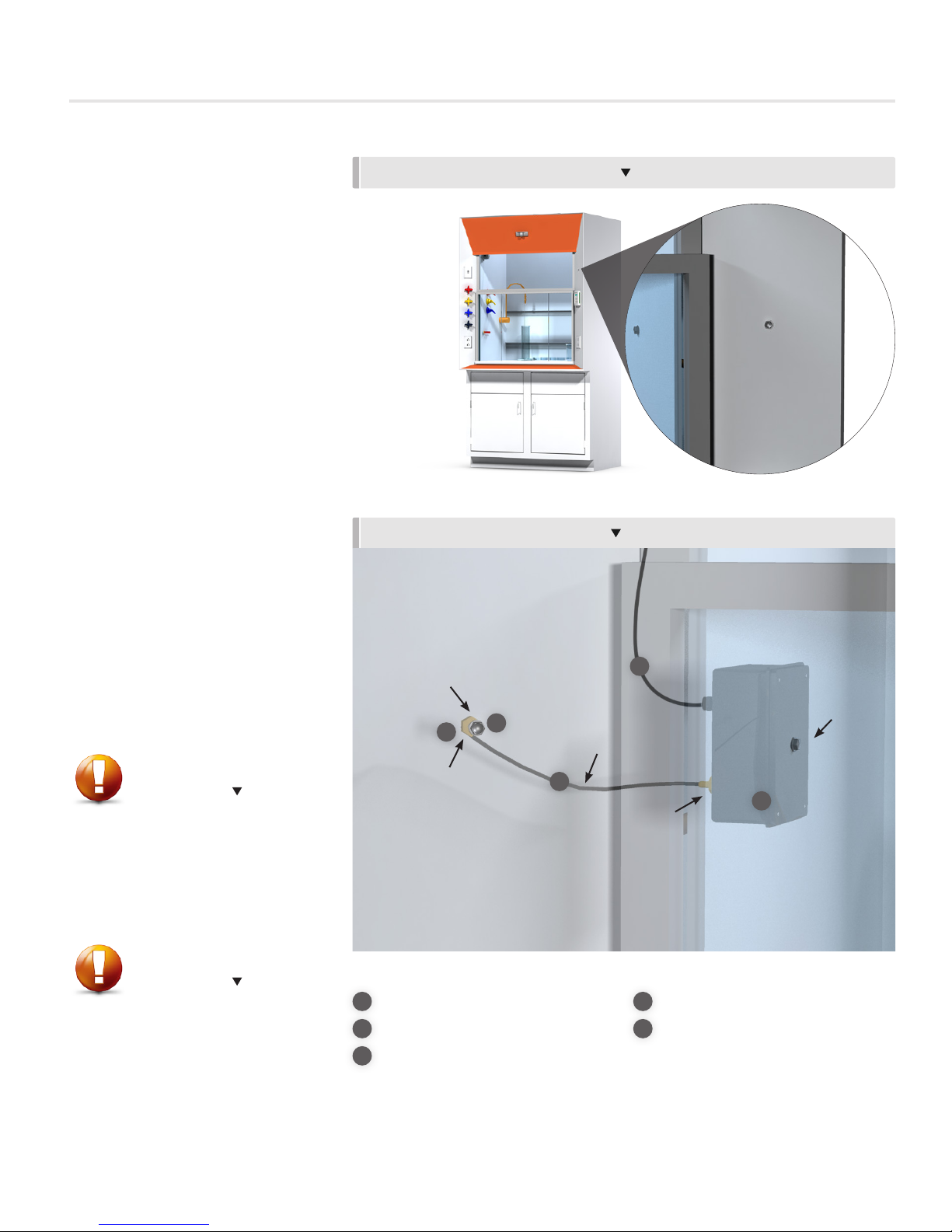

FUME HOOD CONTROLLER / MONITOR

SECTION 2 - INSTALLATION & MOUNTING

Sidewall Sensor (SWS) Installation

& Mounting

• The sidewall sensor consists of

multiple components: The Sidewall

Sensor, two hollowed bolts, a

male brass pressure port, and kink

resistant tubing.

• With the sash in the fully open

position, drill a 5/16” hole

5” above and 5” inward from

the base of the sash. Mount the

Sidewall Sensor behind the fume

hood wall, in the fume hood plenum

using one of the hollow bolts.

• To mount the exterior hollow bolt,

drill a 5/16” hole on the front of the

fume hood, no more than 12”

away from the Sidewall Sensor.

• Attach the provided male brass

pressure port to the exterior hollow

bolt.

• Use the kink-resistant tubing to

attach the brass pressure port from

the SWS to the brass pressure port

on the exterior hollow bolt.

• Attach the sensor cable to the SWS

and run the cable back to the FHC

mounted on the venturi valve or the

FHMX.

INSTALLATION & MOUNTING LOCATION

INSTALLATION & MOUNTING DETAILS

SENSOR

CABLE

HOLLOWED

BOLT #2

3

2

KINK

RESISTANT

TUBING

THE SIDEWALL SENSOR IS

MOUNTED BEHIND THE WALL, IN

THE FUME HOOD PLENUM, USING A

HOLLOWED BOLT PROVIDED.

4

HOLLOWED

BOLT #1

CAUTION

Mounting position is critical to ensure

the accuracy of the SWS. Ensure that

there are no sharp bends or kinks in the

tubing during the installation. Improper

installation will cause failure of the SWS.

CAUTION

If only one SWS is required, the SWS

must be wired into the SIDEWALL

SENSOR #1 port on the FHC/FHMX.

7

FUME HOOD CONTROLLER / MONITOR - Manual | pricecriticalcontrols.com

MALE BRASS

PRESSURE PORT

Required items:

1

Side Wall Sensor

2

Hollowed Bolt x2

3

Male Brass Pressure Port

5

1

BRASS

PRESSURE

PORT

4

Sensor Cable

5

Kink Resistant Tubing

SIDEWALL

SENSOR

FUME HOOD CONTROLLER / MONITOR

SECTION 2 - INSTALLATION & MOUNTING

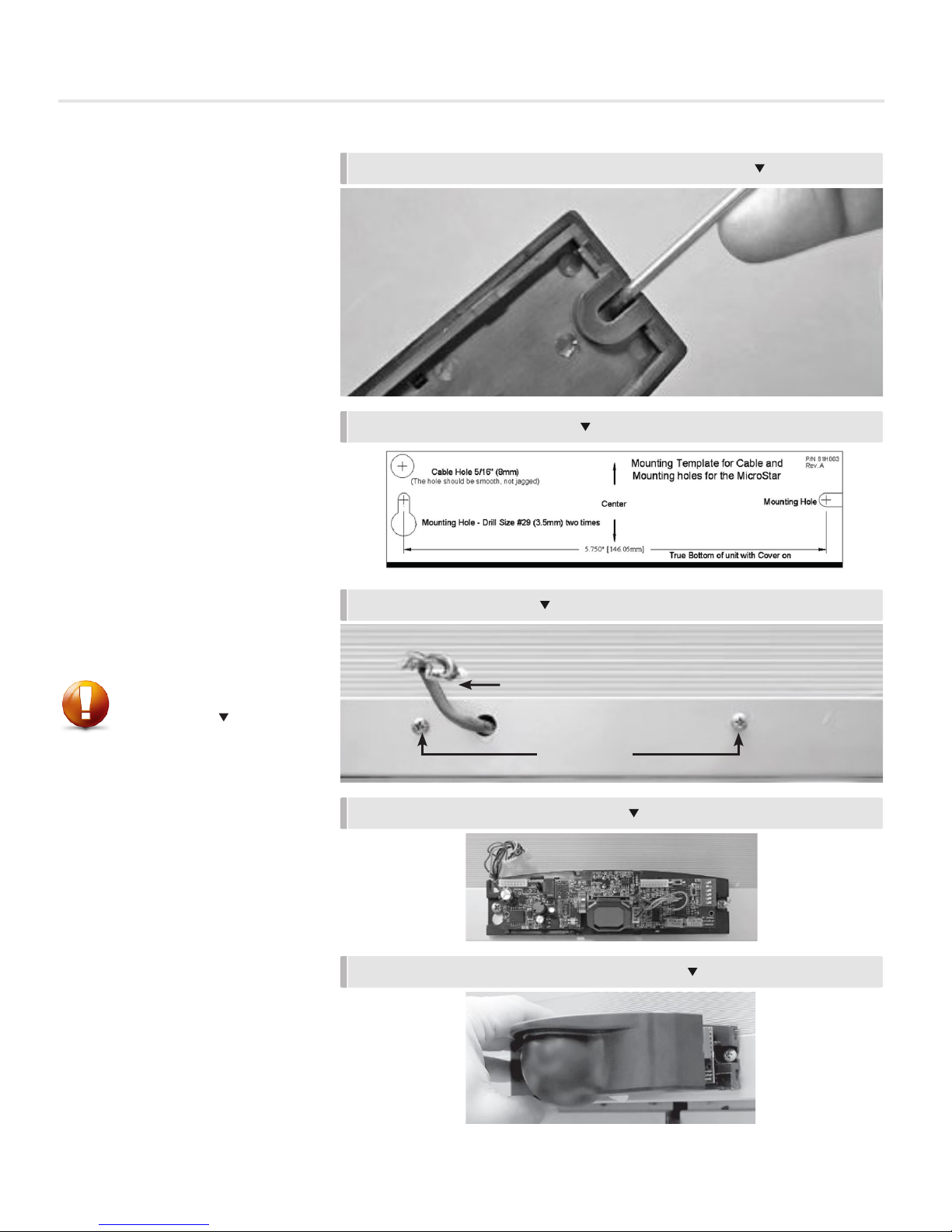

Presence Sensor (PS) Installation

and Mounting

1. Remove the cover of the presence

sensor by placing the blade of a

small screwdriver in the notch in

the right side of the cover as shown

(see Figure 1). Always remove the

cover in this manner.

2. Drill two screw pilot holes and one

wire passage according to the

template in Figure 2.

3. Insert mounting screws partially

into holes. Route the wire harness

through the wire passage hole as

shown in Figure 3.

4. Route the wire harness through

the hole in the presence sensor.

Install the presence sensor onto the

mounting screw and tighten.

5. Replace the cover by engaging

the left side first and then gently

snapping the cover into place

FIGURE 1 - INSERT SMALL SCREWDRIVER AND PRY UPWARDS

FIGURE 2 - MOUNTING TEMPLATE

FIGURE 3 - WIRE HARNESS

CAUTION

Remember to follow these safety

precautions:

• Shut off power to the FHC or

FHMX before wiring the sensor.

• Always ensure wiring is

located clear of any moving

parts to avoid damage.

POWER CABLE

MOUNTING SCREW

FIGURE 4 - MOUNTED PRESENCE SENSOR

FIGURE 5 - PRESENCE SENSOR FACTORY SETTINGS

pricecriticalcontrols.com | FUME HOOD CONTROLLER / MONITOR - Manual

8

Loading...

Loading...