Price FFU series, FFU-HE-RSR-FC Installation And Service Manual

MANUAL – INSTALLATION + SERVICE

Fan Filter Unit

FFU Series

v100 – Issue Date: 04/03/18

© 2018 Price Industries Limited. All rights reserved.

FAN FILTER UNIT

TABLE OF CONTENTS

Product Overview

Read & save these instructions .................................... 1

Before you start ............................................................ 2

Introduction ..................................................................3

Installation & Service Instructions

Diffuser Module Installation ...........................................4

Speed Controllers ......................................................... 6

PSCSC/WK Speed Controller

Installation & Operation .............................................. 6

ECMSC/WK Speed Controller

Installation & Operation ............................................... 7

ECMDX/WK Speed Controller

Installation & Operation ............................................... 8

BACnet Flow Controller (BFC)

Installation & Operation .............................................. 10

Filter Installation .......................................................... 11

Room Side Replaceable Filter (RSR) ........................ 11

Bench Top Replaceable Filter (BTR)) ........................ 13

Optional Accessories .................................................. 15

Aerosol Sample Port, Static Port and

Aerosol Injection Port (INJ).......................................15

Filter/Motor Indicator LED (ML/FL) – RSR ................ 17

Filter/Motor Indicator LED (ML/FL) – BTR ............... 19

Motor/Filter Indicator BAS (MBAS/FBAS) ................ 22

Service Introductions ..................................................23

Motor Change ............................................................ 26

Top Access Motor/Blower Assembly ....................... 26

Room Side accessible Motor/Blower Assembly ....... 28

Technical Note: Aerosol Sample and Static Port..........32

Room Side Replaceable (RSR) ................................ 32

Bench Top Replaceable (BTR) ................................. 33

Controls ...................................................................... 34

ECMSC ................................................................... 34

ECMDX ................................................................... 37

BFC ........................................................................ 39

Technical Note: Design with VAV/Constant Flow Boxes

and Ducted Applications ............................................. 41

Balancing ................................................................... 42

Un-ducted Supply Units .......................................... 42

Ducted Supply – Pressure Independent and

Dependent Airflow Control .......................................43

Ducted Supply – Pressure Independent and

Dependent Airflow Control .......................................45

Troubleshooting .......................................................... 46

Changing Motor Programs ...................................... 46

Tips ......................................................................... 47

BTR Unit Replacement Parts ...................................... 48

RSR Unit Replacement Parts ...................................... 49

Wiring Diagrams ......................................................... 50

Warranty ..................................................................... 61

Pre-Filter Cleaning ................................................... 23

RSR Filter Removal and Replacement ..................... 24

BTR Filter Removal and Replacement ..................... 25

ii

FAN FILTER UNIT

PRODUCT OVERVIEW

Read and Save These Instructions

Warning! To reduce the risk of fire, electrical shock, or injury to persons, observe the following:

A. Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and

standards, including fire-rated construction.

B. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

C. Use this unit only in the manner intended by the manufacturer. If you have any questions, contact the manufacturer:

In the United States

2975 Shawnee Ridge Court

Suwanee, Georgia USA 30024

Ph: 770.623.8050

Fax: 770.623.6404

In Canada / International Export Sales Office

638 Raleigh Street

Winnipeg, Manitoba Canada R2K 3Z9

Ph: 204.669.4220

Fax: 204.663.2715

D. Before servicing or cleaning unit, switch power off at service panel and lock service panel to prevent power from being

switched on accidentally.

E. To reduce the risk of injury to persons, install the unit at least 7ft above grade or in ceiling.

priceindustries.com | FAN FILTER UNIT - Manual

priceindustries.com | FAN FILTER UNIT - Manual

1

FAN FILTER UNIT

PRODUCT OVERVIEW

Before You Start

Inspect all cartons and boxes for flaws and shipping damages.

If anything is discovered to be damaged, contact the shipping company and file a freight claim.

Ensure that all HEPA/ULPA filters are stored in a clean, dry location in a vertical position, as labeled on the carton.

Ensure ductwork is balanced to scheduled flow prior to proceeding.

NOTE: Extreme caution should be taken to avoid contact with filter media. Touching filter media may result in filter failure. Damage

to filters can occur during installation or during leak qualification testing. The filters supplied by Price have been 100% tested

and certified by the manufacturer to be free of defects and leaks. Price cannot accept responsibility for damage that occurs after

shipment, whether through transit, handling or installation, and will not replace filters under Price standard warranty.

To ensure fan filter units are properly balanced, read Technical Note: Design with VAV/Constant Flow Boxes and Ducted

Applications prior to starting installation.

A minimum of two (2) people will be required to install the filters.

2

FAN FILTER UNIT

PRODUCT OVERVIEW

Introduction

Price Fan Filter Units (FFU) are ceiling module diffusers consisting of a fan/motor assembly and Roomside Removable (RSR), or

Bench Top Replaceable (BTR) filters. The module is designed to provide unidirectional vertical airflow of filtered, clean air over a

cleanroom space.

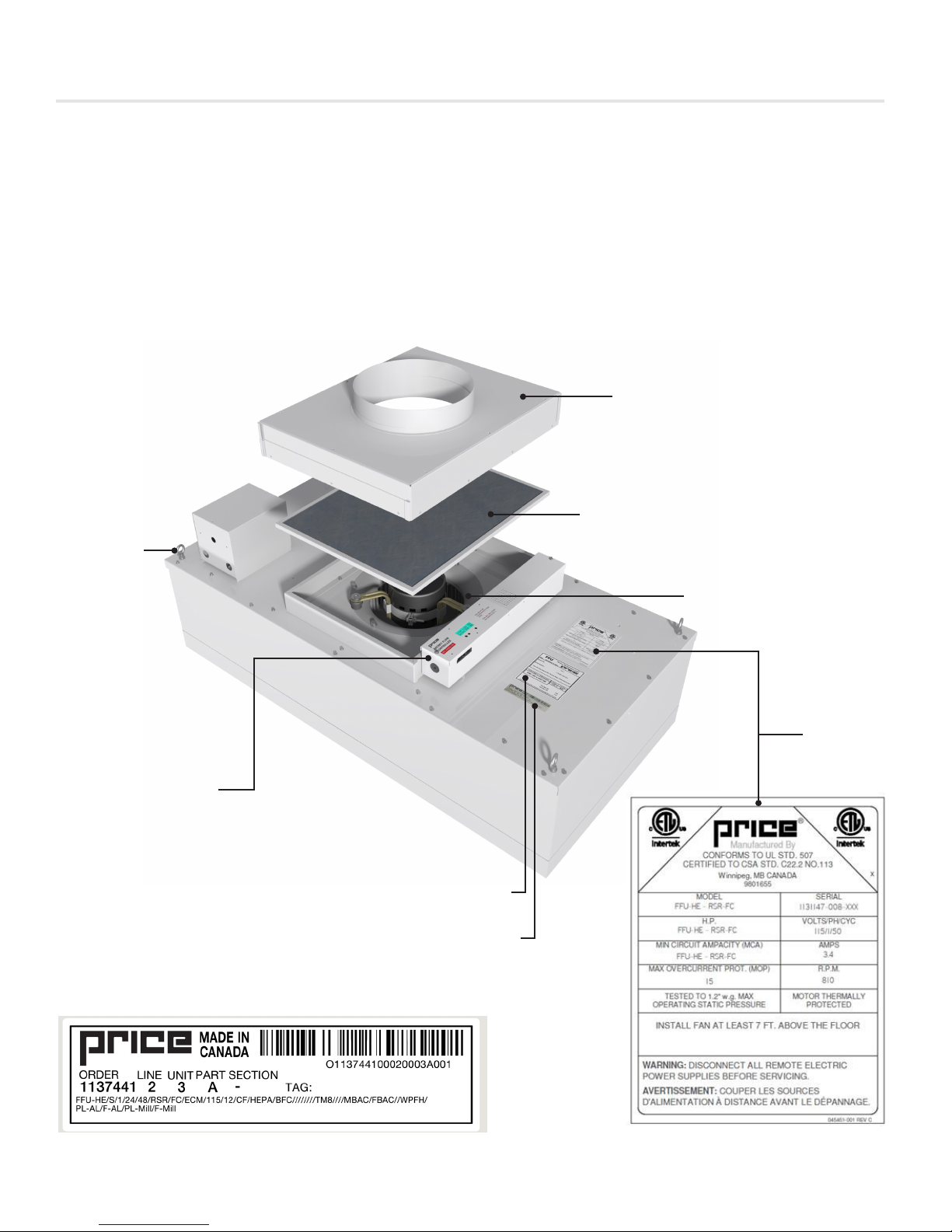

Fan Filter Units (FFU) models will have three (3) stickers located on the back of the plenum. For ease of troubleshooting assistance,

replacement parts, and general factory assistance, it is recommended that the order number, and model line string be used as

reference. This information can be found on the Factory Label.

OPTIONAL DUCT COLLAR

OPTIONAL PRE-FILTER

EYEBOLT

SPEED CONTROLLER

MOTOR/BLOWER ASSEMBLY

ETL LABEL

FACTORY PERFORMANCE LABEL

FACTORY LABEL

priceindustries.com | FAN FILTER UNIT - Manual

3

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

Diffuser Module Installation

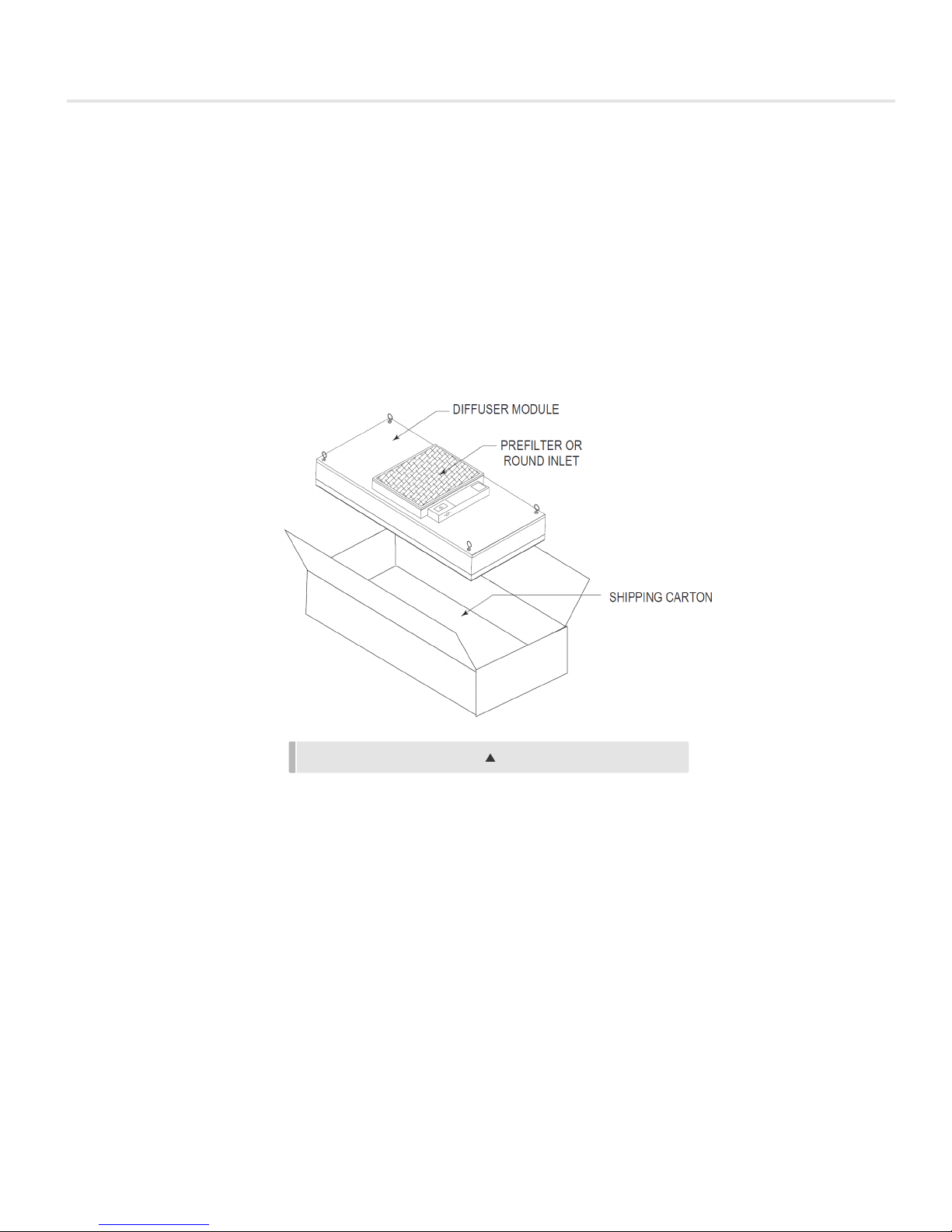

The Price FFU will come completely assembled from the factory with the exception of the HEPA/ULPA filters, which will ship in its

own carton, and the speed controller wall kits (if selected).

NOTE: Do not open the HEPA/ULPA filters until they are ready to be installed in the FFU units. All construction in the space should

be complete, the site and upstream air should be clean so as not to unnecessarily load the filter.

Sample line string for Room Side Replaceable filter:

FFU-1-X//I/24/48/RSR/FC/ECM/115/10//CF//HEPA//BFC////DSW-115////RMB/ASSP/INJ//FL+ML+BACnet///WPFH/PL-AL/FAL//PL-B12/F-B12

STEP 1: Remove FFU from shipping carton and inspect for any damage.

FIGURE 1: UNIT UNPACKING

NOTE: Ensure the HEPA/ULPA filter has been safely stored in a vertical position, per carton label, until ready for use.

STEP 2: If unit is Bench Top Replaceable (BTR) refer to page 13 for filter installation prior to proceeding. Once BTR filter is

installed, proceed to the next step. If unit is Room Side Replaceable (RSR), proceed directly to next step.

Sample line string for Bench Top Replaceable filter:

FFU-1-X//I/24/48/BTR/FC/ECM/115/10//CF//HEPA//BFC////DSW-115////TMB/ASSP///FL+ML+BACnet///WPFH/PL-AL///PLB12/

STEP 3: Raise the unit through the ceiling grid at an angle until entire unit is above the grid

STEP 4: Lower unit onto the backside of the tees.

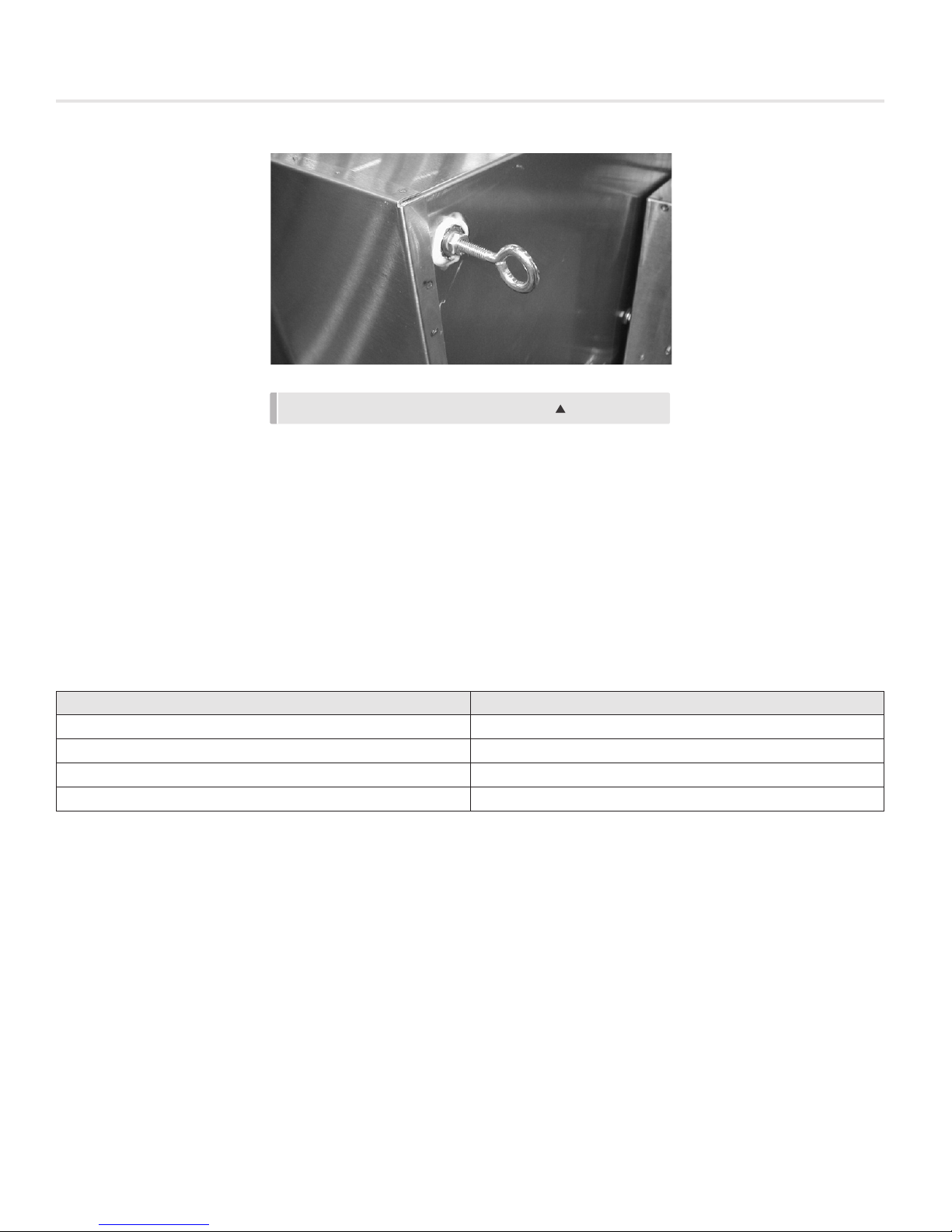

STEP 5: Secure the unit to the overhead structure using the eyebolts located on the back of the unit.

4

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

FIGURE 2: UNIT EYEBOLTS FOR MOUNTING

STEP 6: Adjust and level the unit so that it rests on the tees and there is adequate compression on the gasket to warrant a tight

seal.

Ensure that ceiling grid is properly gasket/sealed to prevent infiltration of unfiltered air from the ceiling plenum into the room side.

Above steps are manufacturer's suggested hanging techniques, always make sure to follow all local building codes, including

seismic, where applicable.

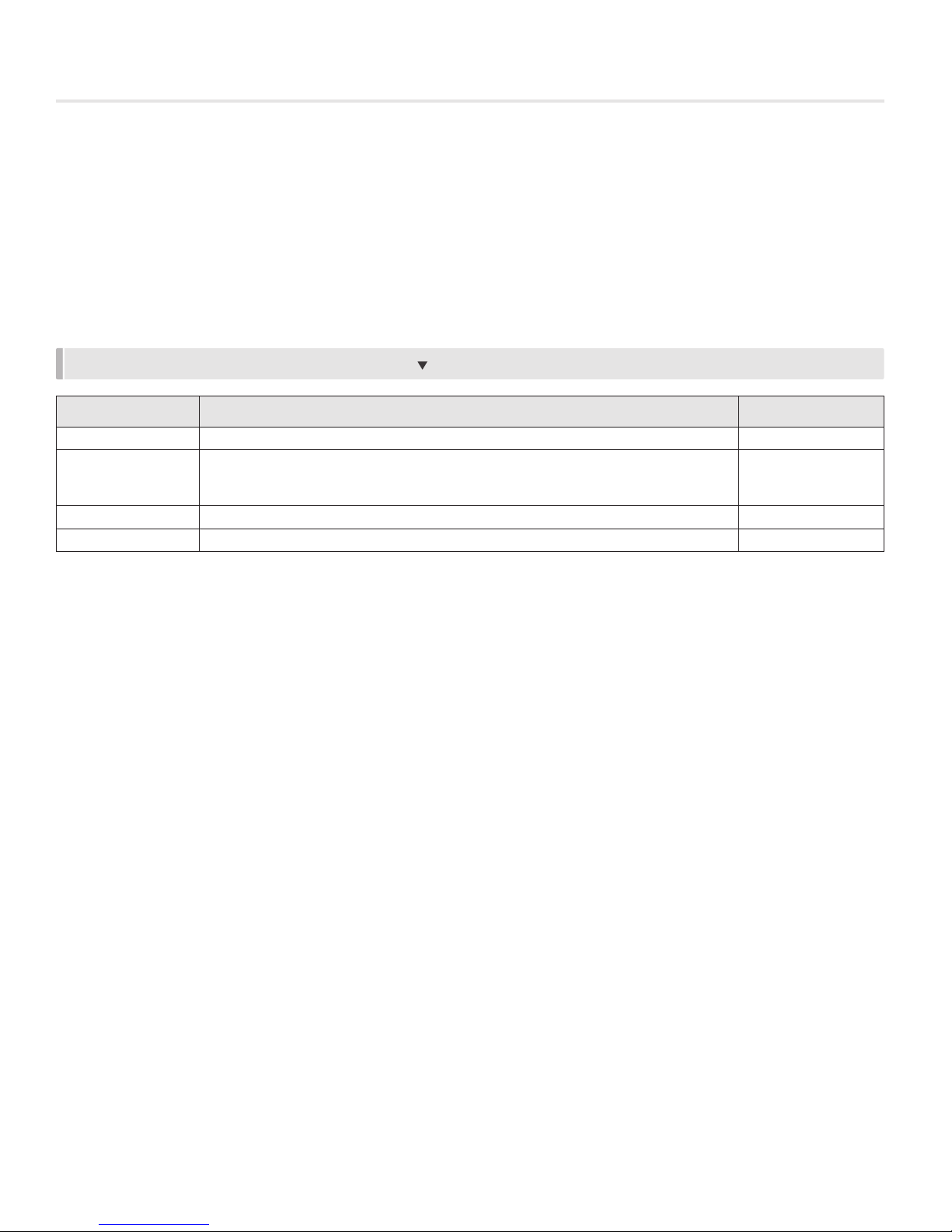

STEP 7: Refer to Factory Label to determine which speed controller is on the unit and use the following table for appropriate

reference page for the particular speed controller on your unit.

Sample line string:

FFU-1-X//I/24/48/RSR/FC/ECM/115/10//CF//HEPA//BFC////DSW-115////RMB/ASSP/INJ//FL+ML+BACnet///WPFH/PL-AL/FAL//PL-B12/F-B12

Speed Controller Page Reference

PSCSC/WK 6

ECMSC/WK 7

ECMDX/WK 8

BFC 10

NOTE: Depending on unit ordered, speed controller will be mounted on the unit itself, or, if a wall-kit option was selected, shipped

loose for field installation

priceindustries.com | FAN FILTER UNIT - Manual

5

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

Speed Controllers

PSCSC/WK Speed Controller Installation & Operation

Sample line string:

FFU-1-X//I/24/48/BTR/FC/PSC/115/10////HEPA//PSCSC//WK-PSC//DSW-115////TMB/ASSP//////WPFH/PL-AL///PL-B12/

FIGURE 3: PSC SPEED CONTROLLER WITH WALL KIT OPTION

If unit does not have the wall kit (WK) option, proceed to step 11A.

Sample line string:

FFU-1-X//I/24/48/BTR/FC/PSC/115/10////HEPA//PSCSC/////DSW-115////TMB/ASSP//////WPFH/PL-AL///PL-B12/

STEP 8A: Locate pre-installed electric box for wall-mounted speed controller.

STEP 9A: Wire speed controller according to wiring diagram found on page 57. Wall-mounted speed controller will be wired in

series with the motor.

NOTE: Wiring should be carried out by a certified electrician and meet national and local electrical codes.

STEP 10A: Attach the wall-mounted controls faceplate to the electrical box using the screws provided.

STEP 11A: Wire the unit according to appropriate wiring diagram. If Power Cord (PC) option is selected, simply insert plug end

into electrical socket.

Sample line string:

FFU-1-X//I/24/48/BTR/FC/PSC/115/10////HEPA//PSCSC/////DSW-115/PC-115///TMB/ASSP//////WPFH/PL-AL///PL-B12/

NOTE: Wiring should be carried out by a certified electrician and meet national and local electrical codes.

STEP 12A: If using RSR filter, refer to page 11 for filter installation instructions.

NOTE: Ensure that the space is clean, free of debris, and ducts are cleaned and ready for operation prior to installation of filter.

STEP 13A: Ensure proper voltage is hooked up to the unit.

STEP 14A: Proceed to controls and balancing section on page 42.

NOTE: Clockwise rotation will increase airflow, counter-clockwise rotation will decrease airflow.

NOTE: If unit is ducted, refer to Technical Note: Balancing Ducted Units on page 44 of this manual.

6

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

ECMSC/WK Speed Controller Installation and Operation

Sample line string below:

FFU-HE/24/48/RSR/BC/ECM/115/10//CT//HEPA//ECMSC// WK /DSW/PC/TMB/ATS/ML/FL/WPF/PL-AL/F-AL/PL-B12/F-B12

FIGURE 4: ECMSC/WK

If unit does not have the wall kit (WK) option, proceed to STEP 11B.

Sample line string:

FFU-1-X//I/24/48/RSR/FC/ECM/115/10//CF//HEPA//ECMSC/////DSW-115////RMB/ASSP//////WPFH/PL-AL/F-AL//PL-B12/F-B12

STEP 8B: Locate pre-installed electrical box for wall-mounted speed controller.

STEP 9B: Wire speed controller according to wiring diagram found on page 58 - 60. Motor speed controller will have color coded

wires and must be wired to the matching colors on the wall-mounted portion.

NOTE: Wiring should be carried out by a certified electrician and meet national and local electrical codes.

STEP 10B: Attach the wall-mounted controls faceplate to the electrical box using the screws provided.

STEP 11B: Wire the unit according to appropriate wiring diagram. If Power Cord (PC) option is selected, simply insert plug end

into electrical socket.

Sample line string:

FFU-1-X//I/24/48/RSR/FC/ECM/115/10//CF//HEPA//ECMSC//WK-ECMSC//DSW-115//PC-115/RMB/ASSP//////WPFH/PL-AL/FAL//PL-B12/F-B12

NOTE: Wiring should be carried out by a certified electrician and meet national and local electrical codes.

STEP 12B: If using RSR filter, refer to page 11 for filter installation instructions.

NOTE: Ensure that the space is clean, free of debris, and that ducts are cleaned and ready for operation prior to installation of filter

STEP 13B: Ensure proper Voltage is hooked up to the unit.

STEP 14B: Proceed to controls and balancing section on pages 42.

priceindustries.com | FAN FILTER UNIT - Manual

7

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

Speed Controllers

ECMDX/WK Speed Controller Installation and Operation

Sample line string:

FFU-HE/24/48/RSR/BC/ECM/115/10//CT//HEPA//ECMDX// /DSW/PC/TMB/ATS/ML/FL/WPF/PL-AL/F-AL/PL-B12/F-B12

If unit does not have the wall kit (WK) option, proceed to STEP 11C.

Sample line string:

FFU-HE/24/48/RSR/BC/ECM/115/10//CT//HEPA//ECMDX//WK/DSW/PC/TMB/ATS/ML/FL/WPF/PL-AL/F-AL/PL-B12/F-B12

STEP 8C: Locate pre-installed electrical box for wall-mounted speed controller.

NOTE: Wall kit must be mounted horizontally, as shown above.

FIGURE 5: ECMDX WALL KIT SPEED CONTROLLER

FIGURE 6: ECMDX WALL KIT SPEED CONTROLLER

STEP 9C: Wire unit according to wiring diagram found on page 58 - 60. Motor speed controller will have color coded wires and

must be wired to the matching colors on the wall-mounted portion.

NOTE: 24VAC and COMMON will need to be run from the terminal block in the control box to the terminals listed 24VAC HOT, and

COMMON on the wall-mounted portion.

NOTE: Wiring should be carried out by a certified electrician and meet national and local electrical codes.

STEP 10C: Attach the wall-mounted controls faceplate to the electrical box using the screws provided.

STEP 11C: Wire the unit according to appropriate wiring diagram. If Power Cord (PC) option is selected, simply insert plug end

into electrical socket

8

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

Sample line string:

FFU-HE/24/48/RSR/BC/ECM/115/10//CT//HEPA//ECMSC///DSW/PC/TMB/ATS/ML/FL/WPF/PL-AL/F-AL/PL-B12/F-B12

NOTE: Wiring should be carried out by a certified electrician and meet national and local electrical codes.

STEP 12C: If using RSR filter, refer to page 11 for filter installation instructions.

NOTE: Ensure that the space is clean, free of debris, and that ducts are cleaned and ready for operation prior to installation of filter

STEP 13C: Ensure proper Voltage is hooked up.

NOTE: ECMDX Speed Controllers have multiple modes, which are listed below:

TABLE I: ECMDX SPEED CONTROLLER DISPLAY CODES

Display Mode Range

L.SEt Local Set point – Manual speed adjust mode (use UP / DOWN to adjust) 0 - 100%

RPM – Shows current RPM of motor 1

rPn

bAS.r BAS Remote – BAS Mode – Voltage signal (Max reading is 9.99 VDC) 0 - 9.99 VDC

bAS.S BAS Set point – Current BAS set point 0 - 100%

If E001 – no RPM pulses are being read, check 6 position cable

If E002 – RPM reading is above 2000 RPM, check primary air

0 - 2500 RPM

STEP 14C: Proceed to controls and balancing section on page 42.

priceindustries.com | FAN FILTER UNIT - Manual

9

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

Speed Controllers

BACnet Flow Controller (BFC) Installation and Operation

Sample line string:

FFU-1-1//I/24/48/RSR/FC/ECM/115/10//CF//HEPA//BFC////DSW-115////RMB/ASSP/INJ//FL+ML+BACnet///WPFH/PL-AL/FAL//PL-B12/F-B12

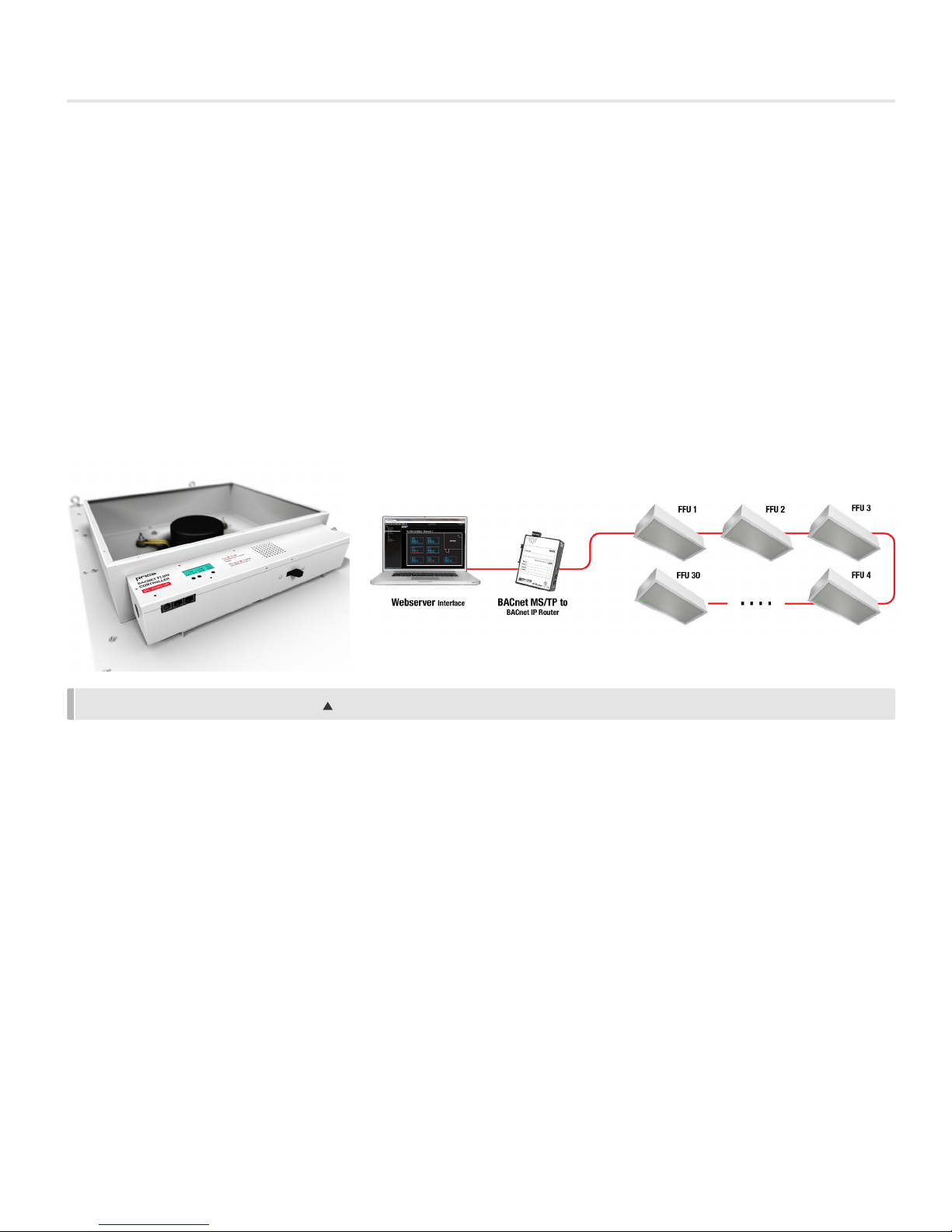

STEP 8D: Wire unit according to appropriate wiring diagram. If Power Cord (PC) option is selected, simply insert plug end into

electrical socket.

NOTE: Polarity is important and must be observed. It is also vital that the 24 VAC common side of the transformer be Earth

grounded.

STEP 9D: Hook up applicable BACnet, and/or local Building Automation System (BAS) according to wiring diagram found on

page 58 - 60. For multiple units, use provided cable to daisy chain units together. If using BAS or Local Set point, reference the

BFC controls section on page 39 for applicable instructions.

FIGURE 7: DAISY CHAINED FFU UNITS

NOTE: For additional information on BACnet, and the BFC controller, refer to the BACnet Wiring Guidelines, and BFC Manual which

are available on the Price Industries website @ priceindustries.com

STEP 10D: Wire the unit according to the appropriate wiring diagram found on page 58 – 60. If power cord option is selected,

simply insert the plug end into the electric socket.

Sample line string:

FFU-1-1//I/24/48/RSR/FC/ECM/115/10//CF//HEPA//BFC////DSW-115//PC-115//RMB/ASSP/INJ//FL+ML+BACnet///WPFH/PLAL/F-AL//PL-B12/F-B12

NOTE: Wiring should be carried out by a certified electrician and meet national and local electrical codes.

STEP 11D: If using RSR filter, refer to page 11 for installation instructions.

NOTE: Ensure that the space is clean, free of debris, and that ducts are cleaned and ready for operation prior to installation of filter.

STEP 12D: Ensure proper Voltage is hooked up to the unit.

STEP 13D: Proceed to controls and balancing section on page 42.

10

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

Filter Installation

Room Side Replaceable Filter (RSR)

Sample line string:

FFU-1-1//I/24/48/RSR/FC/ECM/115/10//CF//HEPA//BFC////DSW-115//PC-115//RMB/ASSP/INJ//FL+ML+BACnet/// WPFH/PLAL/F-AL//PL-B12/F-B12

NOTE: Extreme caution should be taken to avoid contact with filter media. Touching filter media may result in filter failure. Damage

to filters can occur during installation or during leak qualification testing. The filters supplied by Price have been 100% tested

and certified by the manufacturer to be free of defects and leaks. Price cannot accept responsibility for damage that occurs after

shipment, whether through transit, handling or installation, and will not replace filters under our standard warranty. shipment,

whether through transit, handling or installation, and will not replace filters under our standard warranty.

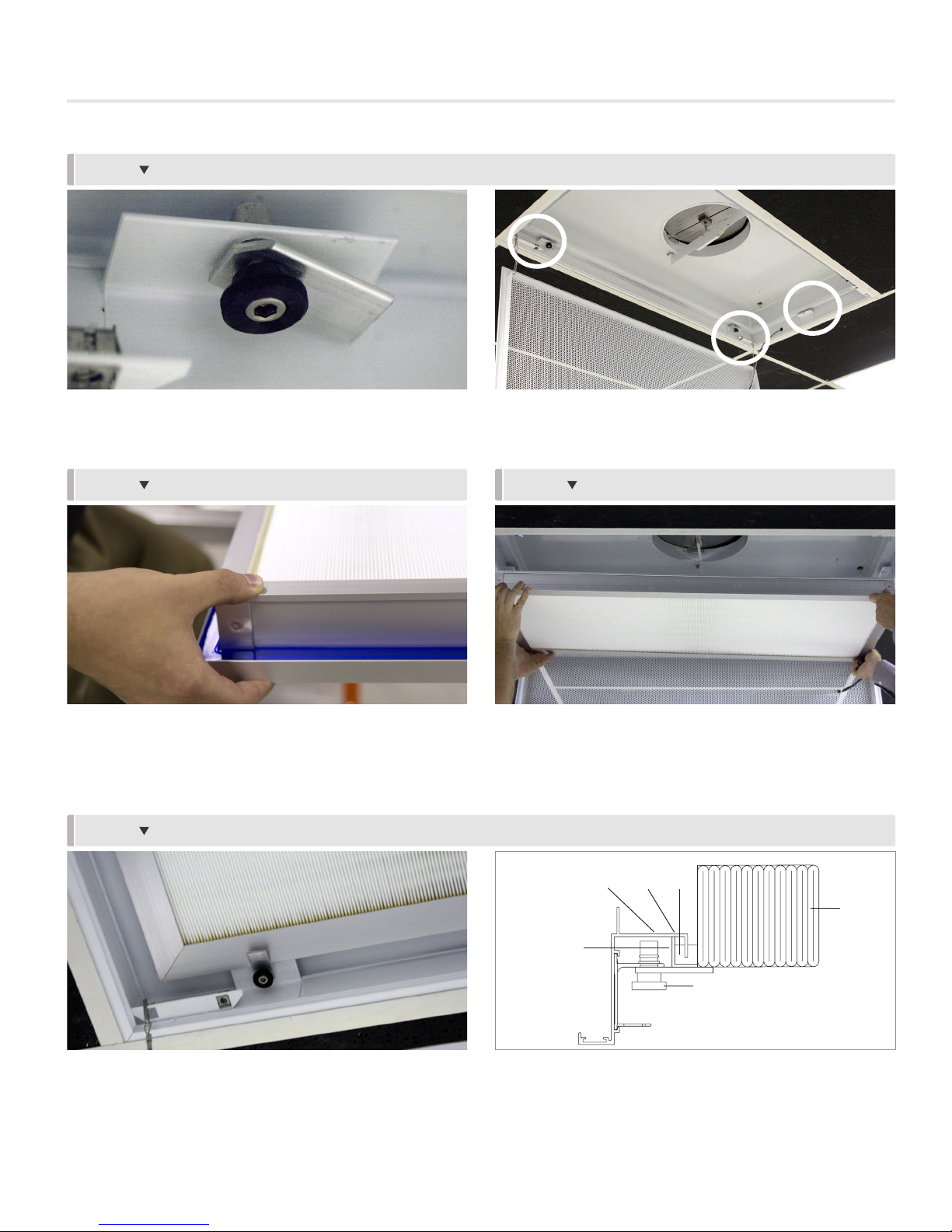

STEP 1

Remove filter from box using handles Place filter on flat surface or table.

STEP 3

STEP 2

STEP 4

Cut plastic bag and remove filter with care. To handle the filter, grasp by the frame only.

priceindustries.com | FAN FILTER UNIT - Manual

11

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

STEP 5

Loosen cam locks on diffuser to prepare filter for installation. Be sure latches are turned inwards so as not to interfere with filter frame.

NOTE: Note location of filter alignment guides (minimum one per side, dependent on size).

STEP 6

Raise the filter in place using two people and being careful not

to contact the filter media.

STEP 8

STEP 7

Using the alignment guides, raise the filter into place, ensuring

filter gel seal channel seat into knife edge of plenum.

NOTE: Do not bottom out gel seal in plenum knife edge. The gel

seal needs to ‘float’ in gel seal to ensure proper seal.

POINT

GEL

SEAL

FILTER

MEDIA

KNIFE

EDGE

CONTACT

Secure filter in place using the cam locks. Tighten until no

further rotations can be made. No tools are required to tighten,

and using one may cause damage to filter gel seal.

12

HEPA FILTER

OUTER FRAME

CAM

LOCK

Ensure HEPA filter outer frame is in contact with horizontal

knife edge of frame. Note that diffuser knife edge cannot

bottom out in HEPA filter gel seal.

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

Filter Installation

Bench Top Replaceable Filter (BTR)

Sample line string:

FFU-1-1//I/24/48/BTR/FC/ECM/115/10//CF//HEPA//BFC////DSW-115//PC-115//TMB/ASSP///FL+ML+BACnet/// WPFH/PLAL///PL-B12/

NOTE: Extreme caution should be taken to avoid contact with filter media. Touching filter media may result in filter failure.

Damage to filters can occur during installation or during leak qualification testing. The filters supplied by Price have been 100%

tested and certified by the manufacturer to be free of defects and leaks. Price cannot accept responsibility for damage that occurs

after shipment, whether through transit, handling or installation, and will not replace filters under our standard warranty.

NOTE: If ordered with Filter or Motor LED Indicator (ML/FL), refer to LED installation instructions which must be done at same time

as filter installation.

FFU-HE/24/48/BTR/BC/ECM/115/10//CT//HEPA//ECMDX//WK/DSW/PC/TMB///ML/FL/WPF/PL-AL///PL-MILL//

STEP 2 STEP 1

Place filter box on floor, careful to set box in correct orientation,

as per the arrow.

Place the filter gently on the floor, remove the tape, and take

the filter out of the bag.

Remove filter from box being careful not to touch filter media.

STEP 4 STEP 3

Place filter on a flat, clean, protecting surface with the

expanded face screen on the bottom. Make sure to protect

face LED if this has been selected as an option.

priceindustries.com | FAN FILTER UNIT - Manual

13

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

STEP 6 STEP 5

Place FFU top cap assembly onto filter’s gasket flange/ frame,

being careful to not damage the filter media.

Attach filter to top cap assembly by hooking and securing

latches. Gasket may need to be compressed to grab channel

with latch.

14

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

Optional Accessories

Aerosol Sample Port, Static Port and Aerosol Injection Port (INJ)

Sample line string below:

FFU-HE/24/48/RSR/BC/ECM/115/10//CT//HEPA//ECMDX//WK/DSW/PC/TMB/AT S/ML/FL/WPF/PL-AL/F-AL/PL-B12/F-B12

STEP 1: If unit has room side removable filter (RSR), remove diffusers perforated face by turning quarter turn fasteners holding

face in place.

FFU-HE/24/48/RSR/BC/ECM/115/10//CT//HEPA//ECMDX//WK/DSW/PC/TMB/ATS/ML/FL/WPF/PL-AL/F-AL/PL-B12/F-B12

NOTE: Safety cables will be attached to the diffuser face, but care should be taken to ensure that diffuser face does not swing and

injure anyone.

If unit is bench top removable (BTR), proceed to next step.

STEP 2: Remove threaded plug covering ATS port using a 5/16” hex screw driver.

KNIFE EDGE

ATS PORT

STATIC PRESSURE

PORT

DIFFUSER FACE

FRAME

UNIT PORT LOCATIONS

STEP 3: Insert aerosol test fitting or adaptor (the aerosol injection port has a 3/8” NPT internal thread) into Aerosol Injection port.

NOTE: An adaptor/test fitting that is longer than 1.5” and/or wider than 1” will not fit.

STEP 4: Inject aerosol test agent and measure particulate counts according to local codes.

NOTE: Aerosol Sample port can be used to measure upstream particle counts. Refer to page 15 for static pressure port details.

STEP 5: Disconnect test equipment, and reinstall plugs in the static pressure (if applicable) and aerosol injection ports. Reinstall

diffuser face (if applicable).

If the safety cables were also disconnected when removing the face, they must be reattached. When reinstalling the face, care

should be taken to tuck safety cables in place without damaging the filter.

NOTE: Airflow and aerosol challenge concentration should be kept uniform during the test. Static pressure and concentration may

be sampled through the static pressure port during the test, if required, to verify flow and concentration.

priceindustries.com | FAN FILTER UNIT - Manual

15

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

TABLE II outlines a few possible problems that may be encountered during leakage testing. This chart is intended as a quick

troubleshooting guide, and is not exhaustive. All local and applicable codes should be followed.

TABLE II: LEAKAGE TEST OUTCOMES & POSSIBLE SOLUTIONS

Display Mode Range

Leakage at the perimeter of the

filter

Pinhole leaks detected in filter

Leakage at the perimeter of the fan

filter unit

Particle Counter is beeping at

multiple locations, even away from

filter face

Improper filter installation

Improper handling of

filter/damage during installation

Improper seal between unit and

ceiling plenum

Possible leakage through

adjacent lights, diffusers, and/or

ceiling panels

Gently remove the filter, verify that the gel seal is intact and

undam- aged, and carefully reseat the filter in the knife edge

frame and latch in place.

Filter may be repaired by a trained technician.

Check seal between unit and ceiling plenum and seal as

required.

Isolate unit by placing cardboard or sheet metal to create

vertical 'walls' extending 2ft below the ceiling plane. If filter

passes, sealing of adjacent lights, diffusers, and/or ceiling

panels may be required.

16

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

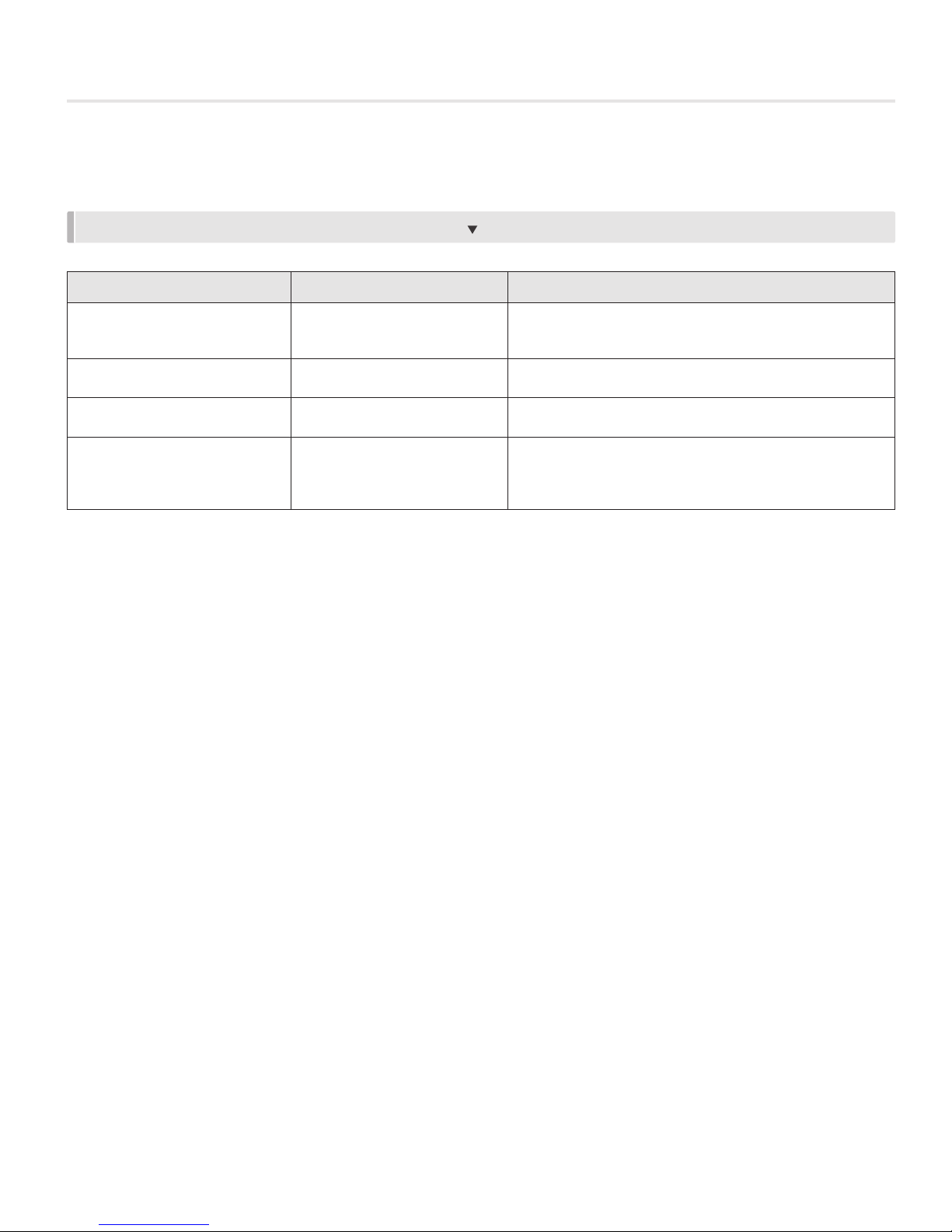

Filter/Motor Indicator LED (ML/FL) – RSR

Sample line string:

FFU-1-1//I/24/48/RSR/FC/ECM/115/10//CF//HEPA//BFC////DSW-115//PC-115//RMB/ASSP/INJ//FL+ML+BACnet/// WPFH/PLAL/F-AL//PL-B12/F-B12

LED Operation

Option Code

Filter LED FL

Motor

LED

ML

LED

Color

Green None

Yellow Change Filter

Green None

Red Troubleshoot Motor

Action Notes

Indicates normal operation until filter pressure drop exceeds

calibrated pressure drop (factory set at 1.5x clean filter pressure).

Indicates filter pressure drop has exceeded calbirated setting (factory

set at 1.5x clean filter pressure.

Indicates normal motor operation when the static pressure is above

0.2" w.g.

Indicates motor is not in operation, and that unit static pressure is

below 0.2" w.g.

Calibration

Filter LED will come factory set to activate at the pressure drops listed in the Table below.

Filter Pressure @ 90fpm [in w.g.] 1.5x Clean Filter [in w.g.]

HEPA 0.4 0.6

Filter Indicator Set Points

ULPA 0.6 0.9

If different set points are desired, they can be adjusted as follows:

FIGURE 9: PRESSURE SWITCH ADJUSTMENT SCREW.

STEP 1: Remove Loctite from adjustment screw hole.

priceindustries.com | FAN FILTER UNIT - Manual

17

FAN FILTER UNIT

INSTALLATION & SERVICE INSTRUCTIONS

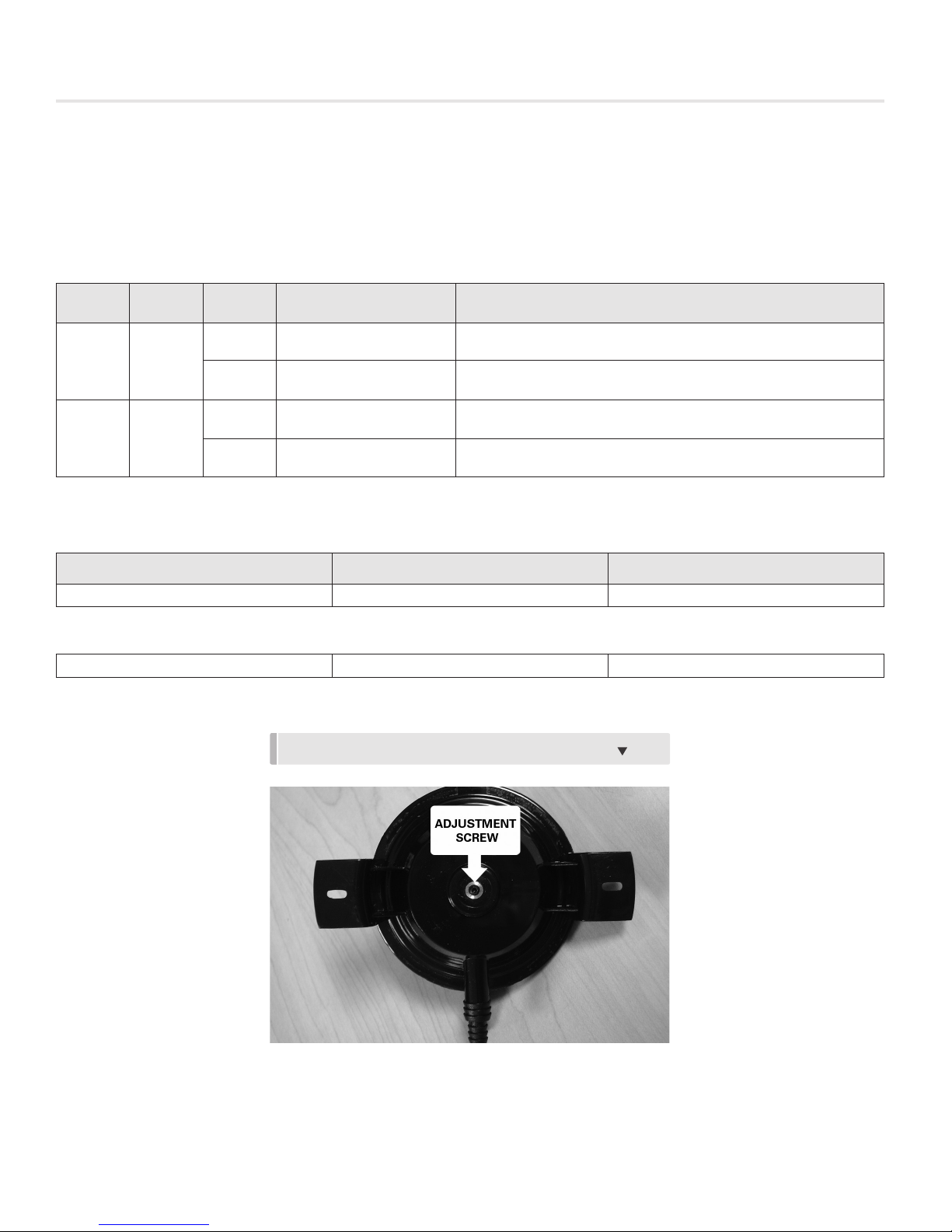

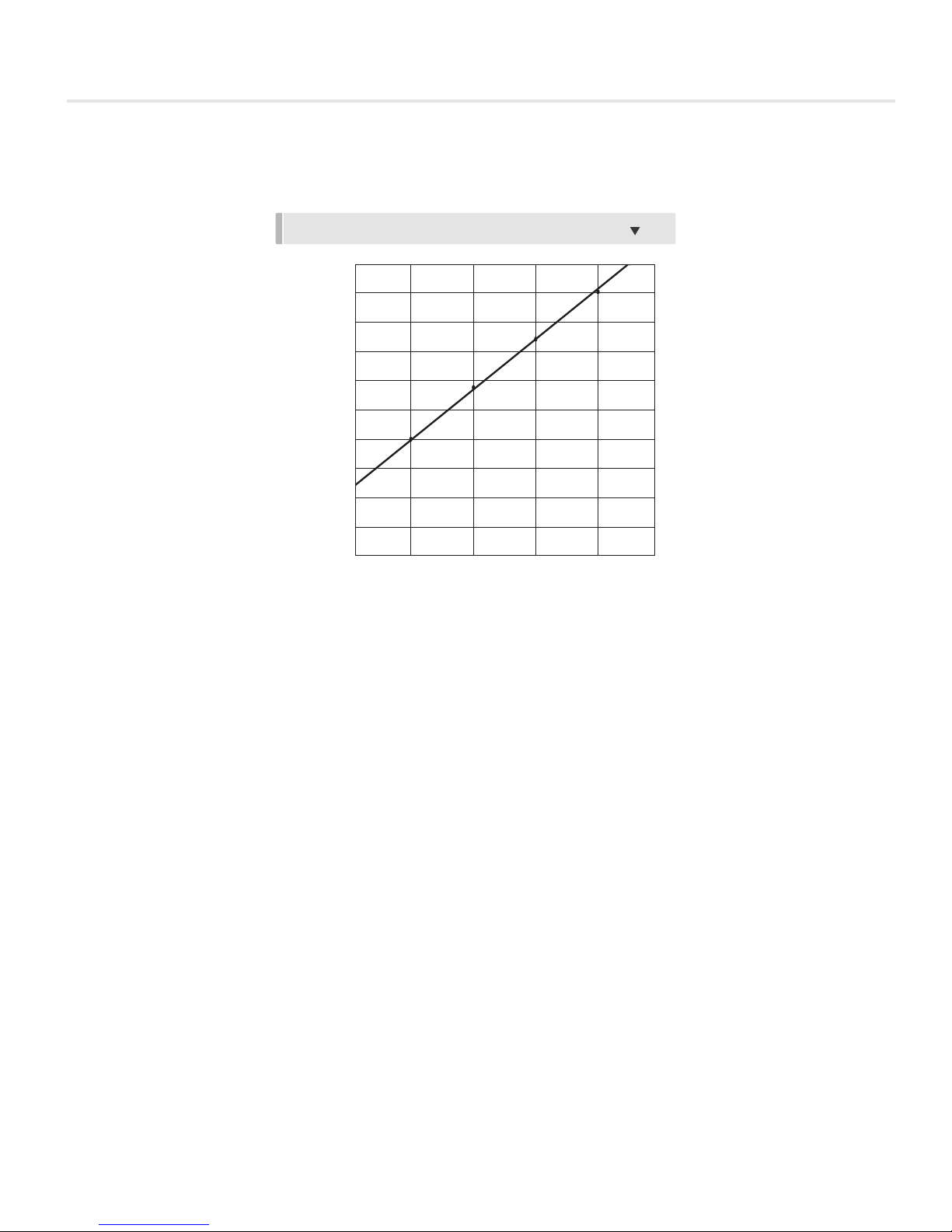

STEP 2: Calculate number of turns required based on difference between factory set point and desired set point using the

following chart.

FIGURE 10: RSR FILTER LED SET POINT ADJUSTMENT.

1.00

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

Set Point in Inches w.g.

0.10

0.00

0 1 2 3 4 5

Turns of Set Point Adjustment Screw

(from starting point at 0.25” w.g.)

Example:

HEPA filter with desired set point of 0.9 in w.g.

Number of turns at 0.9 in w.g. = 4

Number of turns at factory set point of 0.6 in w.g. = 2.2

Number of turns to field set = 4 – 2.2 = 1.8 (approximately)

NOTE: Maximum available pressure setting is 1.0” w.g. Do not exceed 4 ½ turns (total).

STEP 3: Turn screw clockwise the number of turns calculated above. You will need a 1.5mm hex Allen wrench

STEP 4: To check filter pressure set point and/or to fine tune, insert Magnehelic gauge into the static pressure port (located along

knife edge of diffuser – diffuser face must be removed to access).

STEP 5: Using an obstruction (piece of cardboard or equivalent), slowly increasing pressure on the unit by blocking off more and

more of the diffuser face until the LED turns from green to yellow.

STEP 6: Take pressure measurement at point the LED changed color and rotate the adjustment screw until desired pressure set

point is reached.

18

Loading...

Loading...