Price AW-I Series, AW-I-3, AW-I-4 Installation Manual

MANUAL – INSTALLATION

AW-I

Gas Fired Make-Up Air Series

v200 – Issue Date: 09/07/18

© 2018 Price Industries Limited. All rights reserved.

AW-I

TABLE OF CONTENTS

Overview

General Safety Information ............................................ 1

Safety Notices ............................................................... 1

Unit Description ............................................................. 2

Unit Nameplate ............................................................. 2

Unit Inspection .............................................................. 2

Installation Instructions

Mechanical Installation .................................................. 3

Vent Stack and Combustion Air Opening ....................... 7

Electrical Installation ...................................................... 9

Gas Piping Connection ................................................ 13

Hot Water and Chilled Water Coil Connections ............ 15

Safety Shut-off Valve Leak Check ................................ 17

Installation Checklist .................................................... 18

Supply Fan Start-Up .................................................... 20

Typical Sequence of Operation .................................... 23

Maintenance

Maintenance ............................................................... 24

Service and Warranty Procedure ................................. 25

AW-I Start-Up Report Form ......................................... 26

Quality Assurance Report ............................................ 28

Limited Warranty .........................................................29

Appendices

Appendix A: Assembly of Split Units ............................ 30

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warning exactly could result in

serious injury, death or property damage.

Be sure to read and understand the installation, operation

and service instructions in this manual.

Improper installation, adjustment alteration, service or

maintenance can cause serious injury, death or property

damage.

• Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try and light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Leave building immediately.

• Immediately call your gas supplier from a phone

remote from the building. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire

department.

• Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

MANUFACTURED BY

Price Industries Limited

404 Egesz Street

Winnipeg, MB R2R 1X5

115 Turnbull Court

Cambridge, ON N1T 1C6

ANSI Z83.8

Commercial Industrial Gas Heating Equipment

CSA 2.6-2009

Industrial Package Gas Fired Package Furnaces

AW-I

OVERVIEW

General Safety Information

This manual provides information on installation, start-up and

maintenance for a gas fired unit. Improper installation can lead

to unsatisfactory operation or dangerous situations. This unit

should only be installed and maintained by qualified personnel.

Qualified personnel should have a clear understanding of

the contents of this manual prior to installation. Improper

installation may lead to electric shock, possible injury from

contact with moving parts and/or possible burns from contact

with heating components. Additional safety concerns can

arise from unit location such as a roof or inclement weather

(outdoor installations). Additional safety precautions may be

required.

Installer shall follow all national and local electrical code

requirements such as the National Electrical Code (NEC)

and the Canadian Electrical Code (CEC) in Canada. Where

applicable, follow National Fire Protection Association (NFPA)

requirements. The appliance must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70, and /or the

Canadian Electrical Code, CSA C22.1, if an external electrical

source is utilized.

The appliance installation shall conform to local building codes

or, in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1.

Safety Notices

Throughout this manual Caution and Warning notices are used

where additional safety information may be required. Warnings

are provided to alert personnel of a potential situation that

could result in personal injury or death. Cautions are provided

to alert personnel of a potential situation that could result in

personal injury.

In addition to Warnings and Cautions, Notices are used to

indicate a situation that may result in property damage.

WARNING

Indicates a potential situation that, if not avoided, could

lead to serious personal injury or death.

CAUTION

Indicates a potential situation that, if not avoided, could

lead to minor or moderate personal injury. Cautions may

also be used to indicate unsafe practices.

NOTICE: Indicates a situation or action that may cause

damage to the unit or the facility.

In addition to this manual, start-up and commissioning

videos are available at www.priceindustries.com. Additional

information on this unit can be found by scanning the QR code

sticker or by contacting Price Industries.

WARNING

The manufacturer’s warranty does not cover any

damage or defect caused by modifications to the

unit including unauthorized attachments of other

components. Such activity may lead to unsatisfactory

performance and may endanger life and property.

NOTE: This document is customer property and must be

retained by the unit’s owner for use by maintenance personnel.

priceindustries.com | AW-I - Manual

1

AW-I

OVERVIEW

UNIT DESCRIPTION TABLE

A B C D E F G H I

AW-I - 3 100 - S - AC DX - 010 - S - HR

Unit Description

The AW-I model is an indirect fired gas

heating unit with a drum and tube type

heat exchanger. The unit can be either

indoor or outdoor and may include

supplemental cooling and/or energy

recovery.

A: Unit Model

B: Furnace Passes

2 = Two furnace passes

3 = Three furnace passes

4 = Four furnace passes

C: Nominal heating output in kBtu/h

D: Efficiency

S = Standard efficiency

H = High efficiency

E: Cooling type

AC = Air cooled

WC = Water cooled

EC = Evaporatively cooled

F: Refrigeration design

DX = Cooling

HP = Heat pump

G: Nominal cooling capacity in tons. This

is based on nominal condensing unit

model.

H: Cooling efficiency

S = Standard efficiency

H = High efficiency

I: Single path heat recovery

Blank = None

HR = Heat Recovery

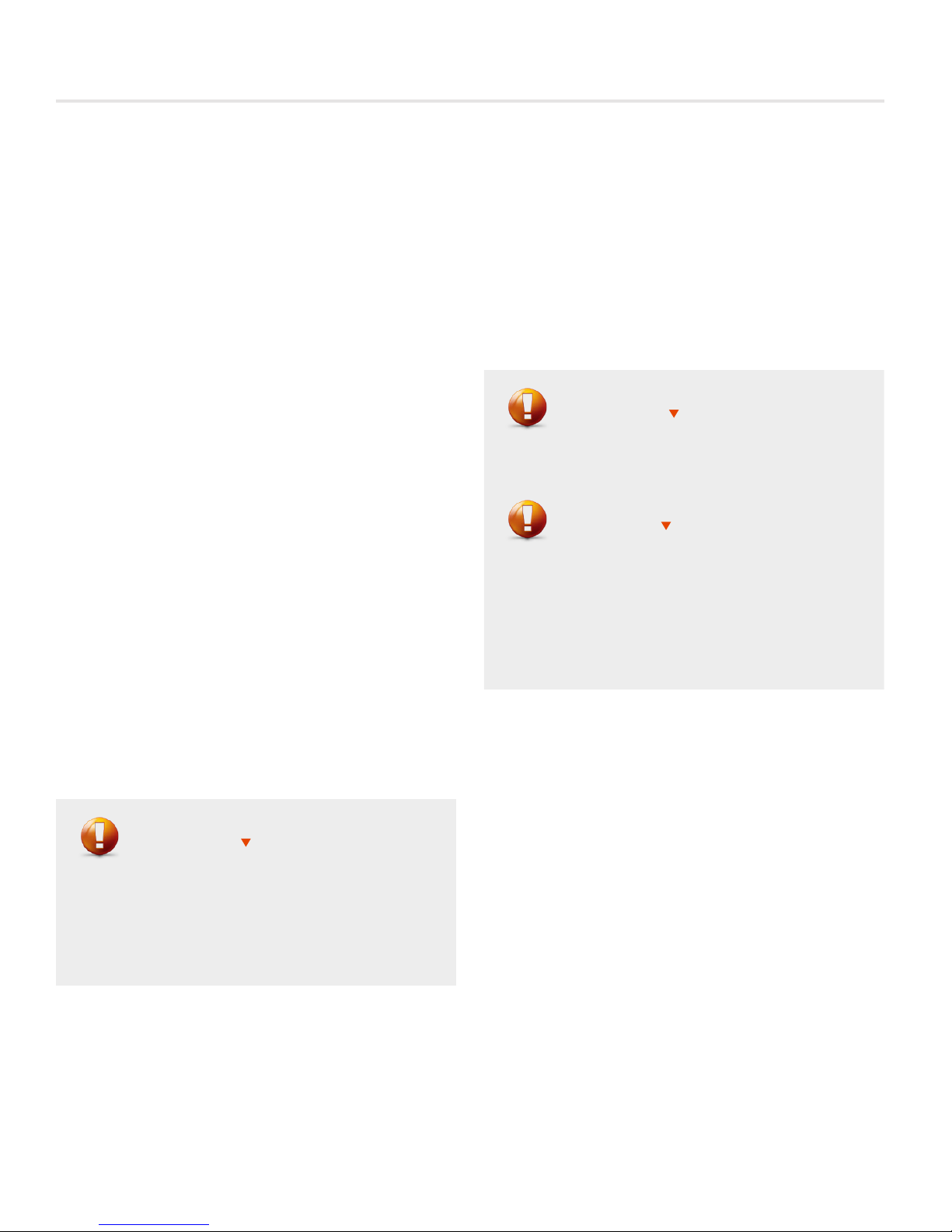

Unit Nameplate

Figure 1 shows a typical nameplate for

an AW-I unit. The nameplate is generally

located in the gas train weather housing.

The nameplate includes model number,

serial number, electrical characteristics

and other pertinent data.

Unit Inspection

This unit has been inspected and test

fired prior to shipment to make sure

the unit is free from defects from the

manufacturer. It is possible that damage

may occur during shipping, rigging and

installation.

Upon receiving the unit, check that

all items have been delivered by

comparing the Bill of Lading to the

equipment received. If anything is

missing or damaged, notify the carrier

immediately. The carrier should note

this on the packing slip or other form

of documentation and provide a

copy. Note: it is a good idea to take a

photograph of any possible damage for

record purposes.

Check the unit model number, heater

size and electrical characteristics to

make sure they are correct. If there

are any issues, do not proceed with

the installation. Contact your sales

representative.

Storage

If the unit is to be stored, take

precautions to prevent condensate

from forming inside the unit’s electrical

compartments. Make sure the

equipment is protected from weather and

dust from site conditions by temporarily

FIGURE 1: TYPICAL NAMEPLATE

sealing all openings to the air tunnel for

outdoor units and completely covering

indoor units.

Do not use the unit for temporary heat

without first completing the start-up

procedure. Price Industries will not

assume any responsibility for equipment

damage resulting from condensate

accumulation on the unit’s electrical and /

or mechanical components.

2

AW-I - Manual | priceindustries.com

ACCESS SIDE

30” (75 cm)

FLUE

9” (22 cm)

FLUE LOCATION

NO ACCESS SIDES

6” (15 cm) minimum

24” (60 cm) recommended

CONTROL CABINET

36” (1 m) minimum

48” (1.3 m) recommended

TOP

6” (15 cm) minimum

NO ACCESS BACK

20” (50 cm) minimum

24” (60 cm) recommended

ACCESS SIDE

30” (75 cm)

FLUE LOCATION

NO ACCESS SIDES

6” (15 cm) minimum

24” (60 cm) recommended

CONTROL CABINET

36” (1 m) minimum

48” (1.3 m) recommended

NO ACCESS BACK

20” (50 cm) minimum

24” (60 cm) recommended

ACCESS SIDE

30” (75 cm)

FLUE

9” (22 cm)

FLUE LOCATION

NO ACCESS SIDES

6” (15 cm) minimum

24” (60 cm) recommended

CONTROL CABINET

36” (1 m) minimum

48” (1.3 m) recommended

TOP

6” (15 cm) minimum

NO ACCESS BACK

20” (50 cm) minimum

24” (60 cm) recommended

ACCESS SIDE

30” (75 cm)

NO ACCESS SIDES

6” (15 cm) minimum

24” (60 cm) recommended

CONTROL CABINET

36” (1 m) minimum

48” (1.3 m) recommended

FLUE LOCATION

AW-I

INSTALLATION INSTRUCTIONS

Mechanical Installation

Location

Price AW-I units are approved for both indoor and outdoor

installations. The installation must conform with local building

codes or in absence of local codes, with the Natural Gas and

Propane Installation Code, CAN/CSA-B149.1, or with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

The unit is suitable for use in aircraft hangars, parking

structures and repair garages when marked and installed, as

applicable, in accordance with:

Standard for Airport Hangars, ANSI/NFPA 409

Standard for Parking Structures, ANSI/NFPA 88A

Standard for Repair Garages, ANSI/NFPA 88B

Natural Gas and Propane Installation Code, CAN/CSA-B149.1

No alterations are to be made on this unit.

Unit Clearances

WARNING

COMBUSTIBLE PRODUCTS: The unit must not be operated

in the presence of hazardous atmospheres containing

flammable vapors or combustible dust for risk of fire or

explosion. The use and storage of any flammable material

in the vicinity of the appliance is hazardous.

CORROSIVE PRODUCTS: The unit must not be operated

in the presence of chlorinated vapors, halogenated

hydrocarbons, cleaning solvents, refrigerants, swimming

pool exhaust or in application with airborne substances

containing silicone. When such vapor mixes with the

products of combustion, highly corrosive compounds

result causing premature failure of the heat exchanger and

other components. In such event, the warranty is void.

Exposure to these compounds can lead to personal injury

or death.

Before placing the unit, clearances to combustible materials

and obstructions should be considered.

FIGURE 2: TYPICAL UNIT CLEARANCES FOR AW-I-3 UNITS

FIGURE 3: TYPICAL UNIT CLEARANCES FOR AW-I-4 UNITS

Maintain minimum clearances to combustible materials as

indicated as shown in Figure 2 and 3.

For ease of service, it is also advisable to maintain a minimum

of 48" (1.2 m) clearance to the control side of the unit and 24"

(60 cm) or more on the side opposite of the controls.

If the unit is to be operated within a confined space or within a

building of tight construction, air for combustion and ventilation

must be obtained from outdoors or other spaces freely

communicating with the outdoors.

priceindustries.com | AW-I - Manual

3

AW-I

INSTALLATION INSTRUCTIONS

Roof Curb or Base

Price AW-I units can be installed on a concrete housekeeping

pad, sleepers or a roof curb. The entire perimeter base and

frame structure must be continuously supported with either

field supplied sleepers or structural steel. Make sure that the

sleepers or structural steel supports are the correct dimensions

for the unit and that it is flat and level.

NOTICE - CONTINUOUS STRUCTURAL SUPPORT REQUIREMENT:

The unit is designed to have continuous structural

support around its entire perimeter. Failure to provide

continuous structural support will damage the unit and

void the warranty.

Check that the housekeeping pad is the correct dimensions for

the unit and that it is flat and level. Check that there is enough

trapping height and that a floor drain is nearby where the

furnace condensate drain will be located.

Generally the curb is shipped in advance of the unit delivery.

It should be installed along with any required ductwork prior

to unit installation. Where a roof curb has been supplied

in knocked-down condition, absolute care must be taken

to make sure that all corners are square, and that finished

dimensions exactly match those provided on the drawings. If

this is not done, problems could arise with the seal of the unit

to the curb.

CURB INSTALLATION DETAIL

NOTE: To minimize sound transmission, only cut openings in

roof deck for ductwork penetrations. Do not cut out the entire

roof deck within in the curb perimeter.

If the unit is elevated, a field constructed cat walk around the

unit is strongly recommended to provide access for service.

Check diagonal dimensions prior to securing the curb to

ensure that dimensional integrity has been maintained during

shipping. Shim the curb to the deck as required and complete

roofing in accordance with accepted roofing practices.

Prior to the installation of the unit, check that the curb is the

correct dimensions for the unit and that the curb profile is

correct (this is especially important if the curb is not supplied

by Price Industries). Check that the curb is both level and

square. Curb ductwork that passes down through the

curb must be installed by installing contractor prior to unit

placement. Gasketing or other forms of sealant must be used

around the curb perimeter and at the duct connections. When

the curb is supplied by Price Industries, a neoprene gasket is

included. Prior to the installation of the unit, secure the gasket

to the mating surface of the curb by peeling the backing off the

gasket material and applying adhesive-side down.

4

AW-I - Manual | priceindustries.com

AW-I

INSTALLATION INSTRUCTIONS

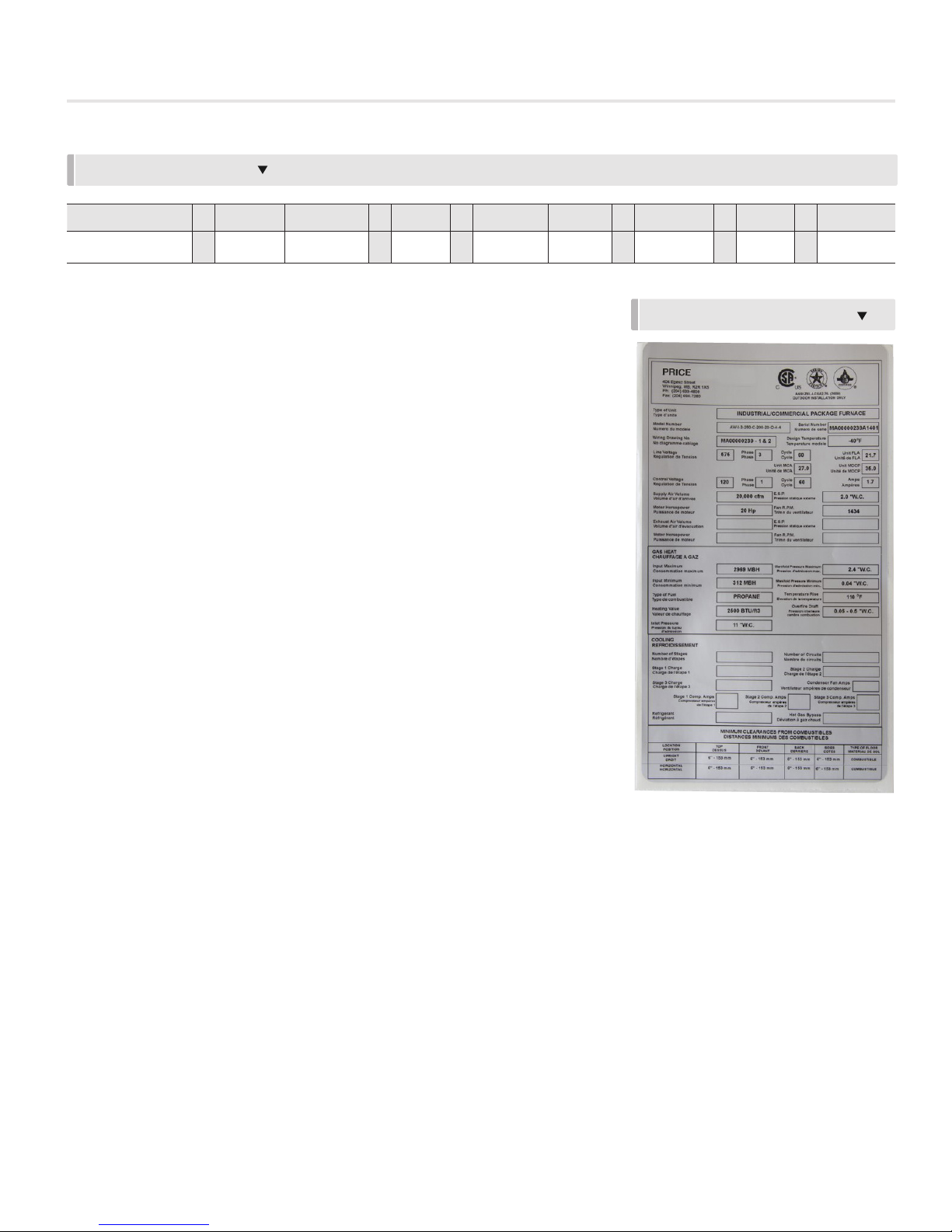

Unit Assembly

CAUTION

HEAVY COMPONENTS: The unit sections are very heavy

and significant force will need to be applied to cinch the

sections together. Make sure everyone is clear of the

sections prior to cinching to avoid injury.

SLIP UNITS: Price AW-I units may be shipped as a single

unit or in sections for field assembly by the installing

contractor. For proper assembly of split units, refer

to Appendix A of this manual. Failure to follow the

instructions in this manual may void your warranty.

Figure 4: Split unit sections shall only be pulled together using

the provisions on the base. Trying to pull sections together

from the cabinet walls or roof will damage the cabinet and void

the warranty. Refer to Appendix A.

Figure 5: Where sections join together, a flanged joining strip

with bolt holes is provided. Refer to Appendix A for detailed

instructions on how to attach these strips and all other

components needed to properly seal between the unit splits.

FIGURE 4: TYPICAL BASE CINCH POINTS

FIGURE 5: TYPICAL FLANGE JOINTS

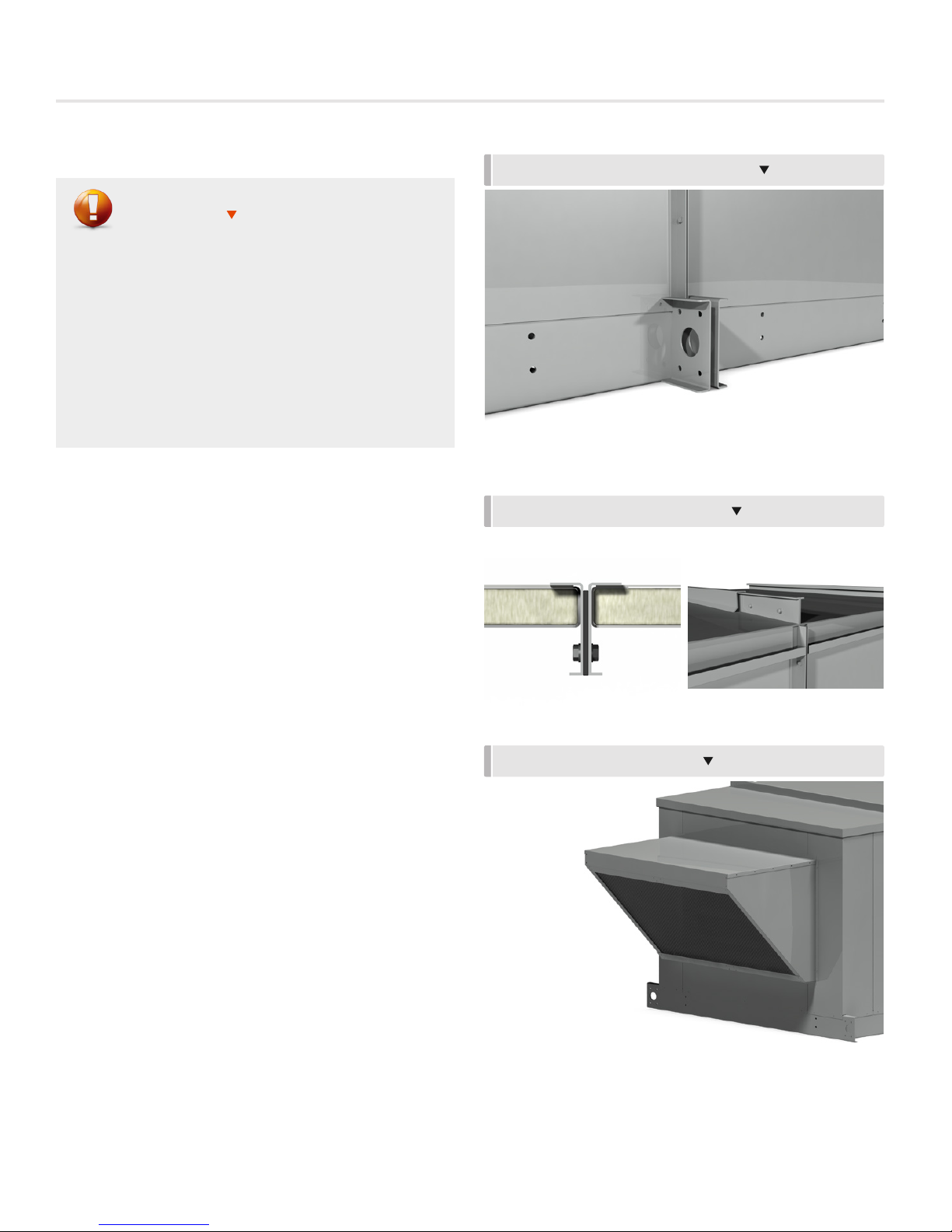

Figure 6: Mount any loose items such as intake hoods and

secure them to the unit with self-tapping fasteners.

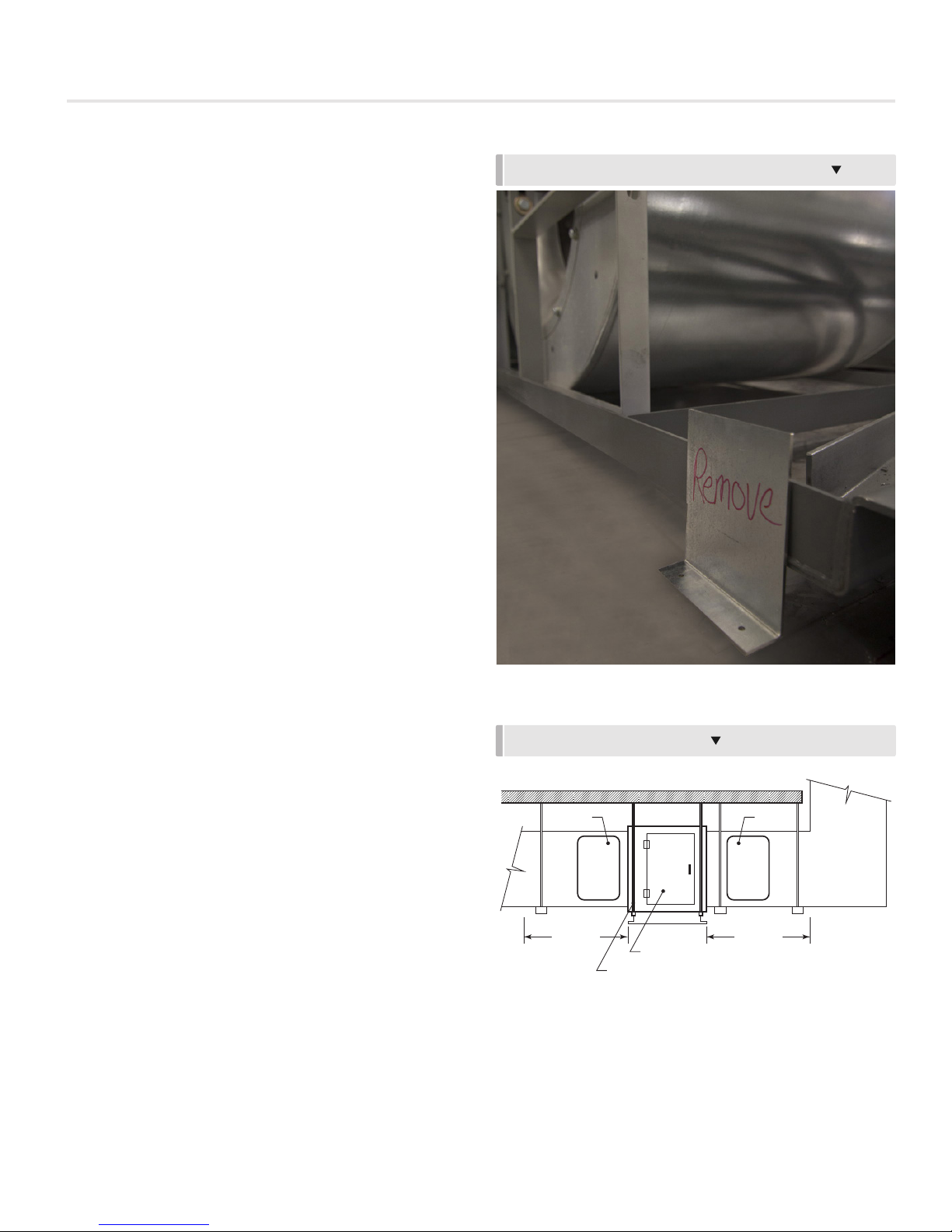

Figure 7 (on the next page): Remove all shipping braces, packing

etc. from the unit.

FIGURE 6: OUTDOOR AIR HOOD

priceindustries.com | AW-I - Manual

5

AW-I

INSTALLATION INSTRUCTIONS

Duct Connections

On outdoor units with ducting passing down through the

curb, the ducting will be installed prior to unit placement and

attached to the curb. For all other duct connections, the

ductwork will be connected to the unit casing using sheet

metal screws by the installing contractor. Unless indicated on

the submittal drawings, the weight of the ducting should not

be placed directly on the unit. The installing contractor should

provide an external means to carry the duct weight.

Access panels in the ducting near the unit are recommended.

Where no access to the unit inlet or discharge section is

provided as part of the unit (for example an access door in the

unit), access panels are strongly recommended for inspection

and service.

Duct Furnace Installation

Where AW-I furnaces are supplied as duct furnaces, the

following installation requirements apply:

1. Duct furnaces shall be installed on the positive pressure

side of the fan.

2. Duct furnaces shall be installed with an inlet duct which will

provide air distribution equivalent to a straight run of duct

having the same cross-sectional area as the inlet connection

and no less than two equivalent diameters in length.

FIGURE 7: TYPICAL FAN BASE SHIPPING BRACKET

3. Provide removable access panels on both upstream and

downstream sides of the duct furnace. These openings

shall be accessible when the appliance is in service, and

shall be of such a size that smoke or light may observed

inside the casing to indicate the presence of leaks in the

heating element. The access panels shall be attached in

such a manner as to prevent leaks.

4. High static packaged heaters must be adjusted to obtain

temperature rise, manifold pressure and air flow within

the range specified on the unit rating plate. Duct furnaces

must be adjusted to obtain an air flow rate within the

range specified on the appliance rating plate.

5. For altitudes of 2000 – 4500 feet (600 and 1350 m),

derate the maximum rated input by 10%.

6. The appliance shall not be installed downstream from

evaporative coolers, air washers or cooling units of

refrigerating systems unless the following optional

conditions are met.

a) if the heating element is made of corrosion resistant

material as per ANSI 83.8/CSA 2.6 clause 4.29.1 , it

can be installed downstream for evaporative coolers or

air washers.

DUCT FURNACE INSTALLATION

ACCESS

PANEL

2 diameters

DUCT FURNACE

HANG UNIT WITH ROD

CONNECTED TO BASE

ACCESS

PANEL

2 diameters

b) if the appliance complies with all of the optional provisions

outlined in ANSI 83.8/CSA 2.6 clause 4.29 and 5.30

the appliance may also be installed downstream from

refrigerated units supplying air below the dew point of the

ambient air surrounding the appliance.

6

AW-I - Manual | priceindustries.com

AW-I

INSTALLATION INSTRUCTIONS

Vent Stack and Combustion Air Opening

Outdoor Installation

AW-I units are certified as Category III appliances with positive

vent pressure and stack temperature not exceeding 500°F

(260 °C). Outdoor AW-I units are equipped with a factory

mounted exhaust stack. This stack is made especially for the

unit and should not be removed or altered in any way.

The gas train and burner vestibule is equipped with ventilation

and combustion air openings. The appliance must be installed

so that these openings are unobstructed. The unit must be

installed in a location with adequate clearances to provide

sufficient combustion air space, service, inspection and

clearance from combustible material as marked on rating plate

or as per local codes and authorities having jurisdiction.

Indoor Installation

WARNING

POISONOUS GASES: The products of combustion from any

gas appliance contain poisonous gases including Carbon

Monoxide. Failure to properly install the chimney for an

indoor installation could lead to dangerous gases being

released within the building that in turn lead to death or

serious injury. Follow the installation instructions carefully.

OUTDOOR EXHAUST STACK

NOTICE - CONDENSATE: Some chimney installations will

cause condensate to form in the chimney. Failure to

properly drain the condensate from the chimney could

lead to damage in both the chimney and the unit. This will

void the warranty.

Vent installation shall conform with local codes or, in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.1/

NFPA 54, or the National Gas and Propane Installation Guide,

B149.1.

The unit must be installed in a location with adequate clearances

to provide sufficient combustion air space, service, inspection

and clearance from combustible material as marked on rating

plate or as per local codes and authorities having jurisdiction.

The appliance shall be located in such a manner that it does not

interfere with the circulation of the air in the space being served.

Outdoor air must be introduced in accordance with National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the National Gas and

Propane Installation Guide, B149.1.

Install air openings that provide a total free area in accordance

with the following;

1. Air from inside the building – Opening of 1 square inch per

1000 Btu/h ( 22 cm² per kW) input but not less than 100

square inches (650 cm).

2. Air from outside ducted – Opening of 1 square inch per

2000 Btu/h ( 11 cm² per kW) input.

3. Air from outside, direct opening - Opening of 1 square

inch per 4000 Btu/h ( 6 cm² per kW) input.

The combustion products must be vented to the outdoors.

All venting installation shall conform with local codes or, in the

absence of local codes, the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or the National Gas and Propane Installation

Guide, B149.1. Indoor AW-I units are supplied with a round

flue connection as shown on the unit drawing. AW-I units are

certified as Category III appliances, with positive vent pressure

and stack temperature not exceeding 500°F (260 °C). Care

must be taken to avoid flue products from entering the space.

Only use vent material and components that are UL listed and

approved for Category III appliances.

priceindustries.com | AW-I - Manual

7

AW-I

INSTALLATION INSTRUCTIONS

Before starting installation, examine all components for

possible shipping damage.

1. Venting shall be installed in accordance with the appliance

manufacturer's instructions. Venting shall conform with

local codes or the National Fuel Gas Code, ANSI Z223.1/

NFPA S4, or the Natural Gas and Propane Installation

Code, CSA B149.1.

2. AW-I units are approved with type “A” vents.

3. Each unit must have its own individual vent pipe and

terminal. Do not common vent or connect more than one

appliance to the venting system.

4. All vent pipe joints must be sealed to prevent leakage.

The joints must be screwed with a minimum of five #10

stainless steel screws. Use approved high temperature

sealant to seal the joints.

5. The total equivalent length of vent pipe must not exceed

50 feet (15.25 m). Avoid unnecessary turns and any other

features that create resistance to the flow of flue gases.

6. Maintain the same vent diameter all the way to the end.

7. The vent shall be extended high enough above either

a building or the neighboring obstructions so that wind

from any direction will not create a positive pressure in the

vicinity of the vent termination. The vent shall extend at

least 18” (450mm) above the highest point where it passes

through the roof surface and any other obstruction within

a horizontal distance of 18” (450mm).

14. The vent shall terminate in accordance with the National

Fuel Gas Code, ANSI Z223.1/NFPA S4, or The Natural

Gas and Propane Installation Code, CSA B149.1. Provide

minimum vent termination clearances to the building as

shown below:

Structure Min. Clearances

Public paved driveway 7’ above (2.1m)

Grade/snow level 1’ (300mm)

Mechanical air supply inlet 6’ (1.8m)

Window, door or any other opening 3’ (900mm)

Meter/regulator

15. All horizontal runs shall include ¼” per ft (21 mm per m)

pitch and a maximum horizontal length of 10 ft. (3 m)

without a power vent.

16. Do not connect into any portion of mechanical draft system

operating under positive pressure.

3’ (900mm) horizontally

15’ (4.5m) vertically

TYPICAL CHIMNEY INSTALLATION

8. The venting system shall be firmly attached to flue collar

with stainless steel screws.

9. The venting system shall be securely supported by

noncombustible hangers suitable for the weight at a

minimum of 36” (1m).

10. When a vent penetrates a floor or ceiling and is not

running through the fire rated shaft, a fire stop and support

is required.

11. The vent system must be installed to prevent collection of

condensate. Use a condensation drain if necessary. The

heat exchangers are equipped with condensate drain(s)

and all the condensation must be disposed in accordance

with local codes.

12. Maintain a minimum of 9” (22 cm) clearance between the

vent pipe and combustible material. Insulate the pipe run

longer than 10’ (3m) for pipe routed through unheated

area with a minimum of ½” (12.5mm) thick foil face

fiberglass, 1 ½ lb. (680,4 g). density insulation.

13. Venting system must be accessible for inspection.

NOTE: Do not intermix vent parts from different manufacturers in

the same vent system.

8

AW-I - Manual | priceindustries.com

AW-I

INSTALLATION INSTRUCTIONS

Electrical Installation

WARNING

ELECTRICAL SHOCK HAZARD: Disconnect all electric power,

including remote disconnects before servicing. Follow

proper lockout/tagout procedures to ensure the power

cannot be inadvertently energized. Failure to disconnect

power before servicing could result in death or serious

injury.

NOTICE - USE COPPER CONDUCTORS ONLY: Unit terminals

are designed for copper conductors only. Failure to use

copper conductors may result in unit damage.

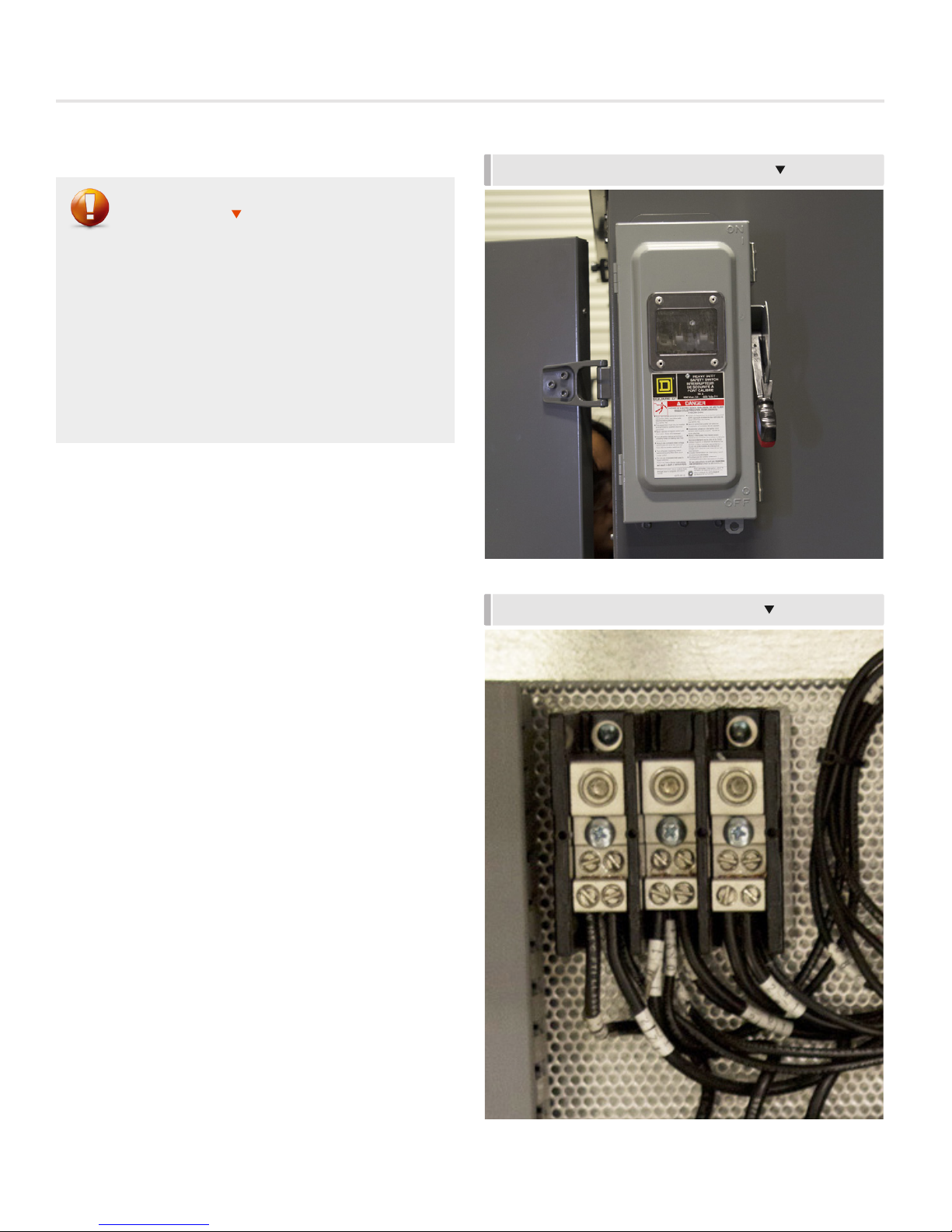

Main Power Connection

All connections to the unit and the main disconnect switch

must conform to the Canadian Electrical Code/National

Electrical Code and local codes.

1. Before proceeding with electrical connections, ensure that

the unit characteristics and the intended supply match.

The proper voltage for connection is listed on the rating

plate attached to the unit.

TYPICAL FACTORY SUPPLIED DISCONNECT

TYPICAL SPLITTER BLOCK TERMINATION

2. Unit must be electrically grounded in accordance with local

codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, and /or the Canadian

Electrical Code, CSA C22.1, if an external electrical source

is utilized.

3. Refer to the unit submittal drawing to determine the

suggested location of the field wired power supply. Where

a disconnect is supplied as part of the unit, the main

power connection will be the line side of the disconnect.

4. If the unit is not supplied with a factory mounted

disconnect, a field supplied disconnect must be installed

in accordance with local codes, or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA

70, and /or the Canadian Electrical Code, CSA C22.1.

Where a disconnect is supplied by others, the main power

connection to the unit will be the line side of the main

splitter block. Refer to unit electrical wiring diagrams for

details.

5. Ensure that the routing of the power supply wiring does

not interfere with removal of any unit access door, or in any

way hinder servicing of the unit.

priceindustries.com | AW-I - Manual

9

AW-I

INSTALLATION INSTRUCTIONS

6. Refer to the submittals for electrical service routing.

Unless indicated on the submittals, DO NOT penetrate

the floor of the unit to route electrical conduits to the unit

control panel. Provide a pitch pocket in accordance with

standard roofing practice.

7. For units that are shipped in multiple sections, some

electrical connections may have to be made by the

installer in the field. Field wiring to be done by the installer

appears as a dotted line on the wiring diagram. Wiring

to connect two sections of a unit will be marked by the

factory and a terminal block will be provided for such

connections.

8. Fuses are furnished and installed by the factory in

accordance with the National Electrical Code, ANSI/NFPA

70, and /or the Canadian Electrical Code, CSA C22.1.

Should the replacement of any fusing become necessary,

the replacement MUST be of the same amperage as

the original. Failure to use equivalent replacement fuses

may result in damage to components within the electrical

system of the unit and/or the building. If any of the original

wires need to be replaced, they must be replaced with

type TEW 105° or equivalent except where noted.

9. On units with three-phase power supplies, make sure that

motor rotation is correct as connected.

ELECTRICAL INSTALLATION W/PITCH POCKET

CONVENIENCE OUTLET AND LIGHTS

Auxiliary Power Connections

A separate 120/1/60 power supply may be required on

units with convenience outlets and lights. Refer to unit wiring

diagrams for wiring sizing details and connection points.

Controls Installation

All field wiring must be in accordance with local codes, or in

the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70, and /or the Canadian Electrical Code, CSA

C22.1.

Field controls wiring requirements will depend on the controls

provided with the unit. A basic unit will require controls by

others. Only the minimum safety controls are provided by

Price Industries. A controller or thermostat must be provided

by the installing contractor. Refer to unit electrical wiring

diagrams for details.

Units supplied with controls may require field wiring to a

remote sensor or control panel. Refer to unit electrical wiring

diagrams for details.

10

AW-I - Manual | priceindustries.com

Loading...

Loading...