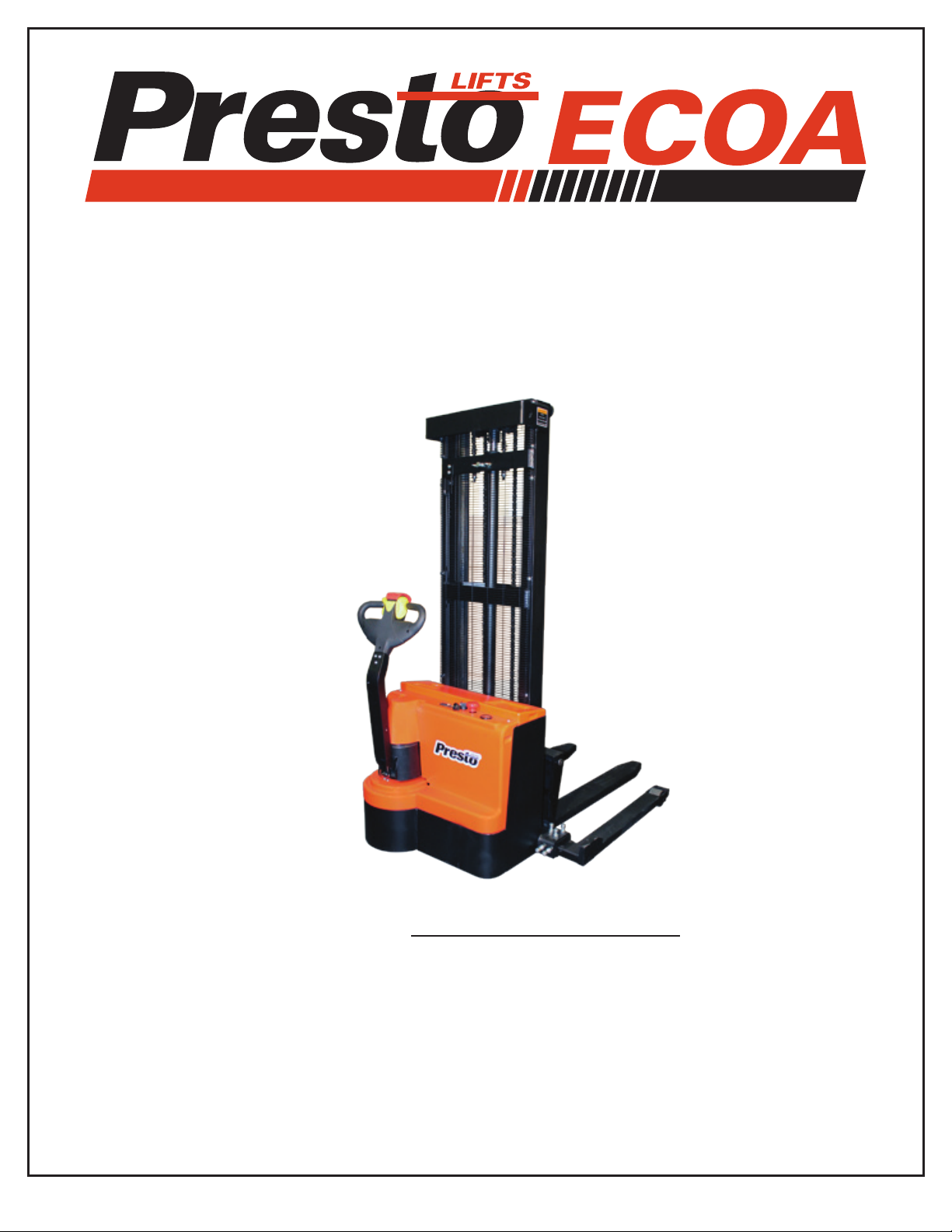

Presto Lifts PowerStak PPS2200-101AS, PowerStak PPS2200-150AS, PowerStak PPS2200-125AS Owner's Manual

PowerStak Owner’s Manual

PPS2200-101AS, 125AS, 150AS

For machines with frame numbers beginning with ST stamped into the mast.

Model:

Serial Number: __________________________

Date placed in

service:

50 Commerce Way, Norton, MA 02766

Email: service@prestolifts.com

__________________________

Presto Lifts Inc.

Phone: 800.343.9322

Fax: 888.788.6496

www.PrestoLifts.com

June 19 2019

Contents

1 Introduction ............................................................................................................. 4

1.1 Responsibilities of Owner and Users.................................................................................. 4

1.2 Responsibilities of Operators .............................................................................................. 5

2 Safety ....................................................................................................................... 7

2.1 Safety Alert Symbols ............................................................................................................ 7

2.2 Signal Words ......................................................................................................................... 7

3 Labeling ................................................................................................................. 10

3.1 Label Placement Diagram .................................................................................................. 10

4 Setup.......................................................................................................................11

4.1 Critical Procedure for Proper Wheel Traction ...................................................................11

4.2 Inspection ............................................................................................................................ 12

4.3 Removing From Pallet ........................................................................................................ 12

4.4 Preparation For Use ............................................................................................................ 12

5 Operation............................................................................................................... 13

5.1 To Raise and Lower ............................................................................................................ 13

5.2 Travel Function.................................................................................................................... 13

5.3 Turtle Speed Travel ............................................................................................................. 13

5.4 Electric Brake ...................................................................................................................... 14

5.5 Reversing Safety ................................................................................................................. 14

5.6 Horn ...................................................................................................................................... 14

6 Maintenance & Repair .......................................................................................... 14

6.1 Battery Maintenance ........................................................................................................... 15

6.2 Periodic Maintenance ......................................................................................................... 16

6.2.1 Weekly Maintenance ................................................................................................... 16

6.2.2 Monthly Maintenance ................................................................................................. 16

6.3 Ordering Replacement Parts.............................................................................................. 17

7 Troubleshooting ................................................................................................... 18

8 Stacker Body Components.................................................................................. 19

9 Control Pod ........................................................................................................... 20

10 Steering Assembly ............................................................................................. 21

11 Drive Wheel Assembly ....................................................................................... 22

12 Carriage Assembly ............................................................................................. 23

13 Mast Assembly ................................................................................................... 24

14 Hydraulic System ............................................................................................... 25

2Presto Lifts PPS2200-101AS,125AS,150AS Manual

15 Hydraulic Power Unit ......................................................................................... 26

16 Hydraulic Schematic .......................................................................................... 27

17 Control Panel ...................................................................................................... 28

18 Electrical Schematic........................................................................................... 29

19 Battery Connection ............................................................................................ 30

20 Warranty & Contact Information ....................................................................... 31

21 Daily Operator Checklist .................................................................................... 32

This label (part # 10095524)

is required by California law.

For more information visit

www.65Warnings.ca.gov.

This label (part # 10095524)

is required by California law.

For more information visit

www.P65Warnings.ca.gov.

3Presto Lifts PPS2200-101AS,125AS,150AS Manual

1. Introduction

This manual attempts to provide all of the information necessary for the safe and proper

installation, operation and maintenance of Presto Lifts Inc. battery operated, PowerStak. It is

important that all personnel involved with the installation, maintenance or operator of the stacker

read this manual. Additional manuals are available upon request or at www.PrestoLifts.com.

Each Presto stacker is equipped with nameplate, serial number and model identications. Please

refer to these numbers when ordering parts or requesting further information. The Presto stackers

are designed for lifting, lowering and positioning a wide variety of loads. WHERE UNIQUE

SITUATIONS ARISE, WHICH ARE NOT COVERED IN THIS MANUAL, CALL PRESTO LIFTS

FOR FURTHER INSTRUCTIONS.

The battery operated stackers are designed for in-plant/non-hazardous locations only. They can

be used in a 8’ or larger aisle. These units are not for personnel lifting.

This machine is designed for powered travel and should not be

manually moved by applying force to the Control Pod Handles. The

Control Pod and steering arm should only be moved side to side when

the machine is under power. The Control Pod and steering arm should

be lowered to the drive position and power, Forward or Reverse, is

engaged by moving the thumb wheel in the direction of desired travel

then the steering arm can be moved side to side for directional steering.

Pushing or pulling on the Control Pod Handles when the unit is not

powered can lead to damage and/or breakage

1.1 Responsibilities of Owner and Users

Basic Principles - Owners/users shall apply sound principles of safety, training, inspection,

maintenance, and expected operating environment. It shall be the responsibility of the owner/user

to advise the manufacturer where deection may be critical to the application.

Manuals - Owners/users shall keep and maintain a copy of the operating and maintenance

manual(s) and ensure its availability to operating and maintenance personnel.

Inspection and Maintenance - It shall be the responsibility of the users to inspect and

maintain the machine as required to ensure proper operation. The frequency of inspection and

maintenance shall be based upon the manufacturer’s recommendations and be compatible with

operating conditions and the severity of the operating environment. Machinery that is not in proper

operating condition shall be immediately removed from service until repaired. Maintenance and

repairs shall be made by a qualied person and the repairs shall be in conformance with the

manufacturer’s recommendations.

Maintenance Safety Precautions - Before adjustments and repairs are started on the machine,

the following precautions shall be taken as applicable:

1. Remove the load from the load enclosure.

2. Lower platform to the full down position.

3. Relieve system pressure from all circuits before loosening or removing any components.

4. All controls in the “off’ position and all operating features secured from inadvertent motion

by brakes, blocks, or other means.

5. Disconnect power and follow established owner/user lockout/tag out policies.

6. Follow precautions and directions as specied by the manufacturer.

4Presto Lifts PPS2200-101AS,125AS,150AS Manual

Replacement Parts - When parts or components are replaced, they shall be replaced with parts

or components approved by the original manufacturer.

Maintenance Training - The user shall ensure only qualied personnel inspect and maintain the

machine in accordance with the manufacturers recommendations.

Operator Training - An owner/user, who directs or authorizes an individual to operate the

machine shall ensure that the individual has been:

1. Trained in accordance with the manufacturer’s operating manual.

2. Made aware of the responsibilities of operators as outlined in section 1.4 of this manual.

3. Retrained, if necessary, based on the owners/user’s observation and evaluation of the

operator.

Modications and additions shall not be performed without the manufacturer’s prior written

approval. Where such authorization is granted, capacity, operation, and maintenance instruction

plates, tags, or decals shall be changed accordingly.

1.2 Responsibilities of Operators

Basic Principles - Operators shall apply sound principles of safety and good judgment in

the application and operation of the machine with consideration given to its intended use

and expected operating environment. Since the operator is in direct control of the machine,

conformance with good safety practices is the responsibility of the operator. The operator shall

make decisions on the use and operation with due consideration for the fact that his or her own

safety as well as the safety of other personnel on or near the machine is dependent on those

decisions.

General Training - Only personnel who have received general instructions regarding the

inspection, application and operation of machine, including recognition and avoidance of hazards

associated with their operation, shall operate the machine. Such topics covered shall include, but

not necessarily be limited to, the following issues and requirements:

1. A pre-start inspection

2. Responsibilities associated with problems or malfunctions affecting the operation of the

machine.

3. Factors affecting stability

4. The purpose of placards and decals

5. Workplace inspection

6. Safety rules and regulations

7. Authorization to operate

8. Operator warnings and instructions

9. Actual operation of the machine. Under the direction of a qualied person, the trainee shall

operate the machine for a sufcient period of time to demonstrate prociency in actual

operation of the machine.

Pre-start Inspection - Before use each day or at the beginning of each shift, the machine shall be

given a visual inspection and functional test including but not limited to the following:

1. Operating and emergency controls

2. Safety devices

3. Hydraulic system leaks

5Presto Lifts PPS2200-101AS,125AS,150AS Manual

4. Electrical cables and wiring harness

5. Loose or missing parts

6. Nameplates, precautionary and instructional markings and/or labeling

7. Guarding system

8. Items specied by the manufacturer

Problem or Malfunctions - Any problems or malfunctions that affect the safety of operations shall

be repaired prior to the use of the machine.

Before Operations - The operator shall:

1. Read and understand the manufacturer’s operating instruction(s) and user’s safety rules or

have them explained

2. Understand all labels, warnings, and instructions displayed on the machine or have them

explained.

Workplace Inspections - Before the machine is used and during use, the operator shall check

the area in which the machine is to be used for possible hazards such as, but not limited to:

1. Bumps, oor obstructions and uneven surfaces

2. Overhead obstructions and electrical hazards

3. Presence of unauthorized persons

4. Other possible unsafe conditions as noted in the operating manual.

Operator Warnings and Instructions - The operator shall ensure the operation of the machine

is in compliance with the following:

1. Guarding system - Guarding shall be installed and positioned, and access gates or

openings shall be secured per the manufacturer’s instructions (If applicable).

2. Distribution of load - The load and its distribution on the platform shall be in accordance

with the manufacturer’s rated capacity for that specic conguration.

3. Maintaining overhead clearance - The operator shall ensure that adequate clearance is

maintained from overhead obstructions and energized electrical conductors and parts.

4. Point of Operation - The operator shall not place any part of their body under the platform.

5. Precaution for moving equipment - When other moving equipment or vehicles are

present, special precautions shall be taken to comply with the safety standards established

for the workplace.

6. Reporting problems or malfunctions - The operator shall immediately report to a

supervisor any problem(s) or malfunction(s) that become evident during operation. The

operator shall ensure all problems and malfunctions that affect the safety of operations are

repaired prior to continued use.

7. Capacity limitation - Rated capacity shall not be exceeded when loads are transferred to

the load enclosure.

8. Work area - The operator shall ensure the area surrounding the machine is clear of

personnel and equipment before lowering the load enclosure.

9. Securing the machine - The operator shall comply with the means and procedures

provided to protect against use by an unauthorized person(s).

6Presto Lifts PPS2200-101AS,125AS,150AS Manual

10. Altering safety devices - Safety devices shall not be altered or disabled.

A BCD

11. Modications or alterations of the machine or the fabrication and attaching of frameworks

or the mounting of attachments to the machine or the guarding system shall only be

accomplished with prior written permission of the manufacturer.

12. Assistance to the operator - If an operator encounters any suspected malfunction or any

hazard or potentially unsafe condition relating to capacity, intended use or safe operation

the operator shall cease operation of the machine and request further instruction from the

owner/user.

13. Problems or malfunctions - Any problem(s) or malfunction(s) that affect the safety of

operations shall be repaired prior to the use of the machine.

2. Safety

All personnel installing, operating, and maintaining this machine shall read and understand this

manual. For questions or concerns contact the manufacturer.

All operators of this machine must be trained, by their employer, in accordance with OSHA

standard 1910.178 29QFR-7-1-06 before being permitted to operate this machine.

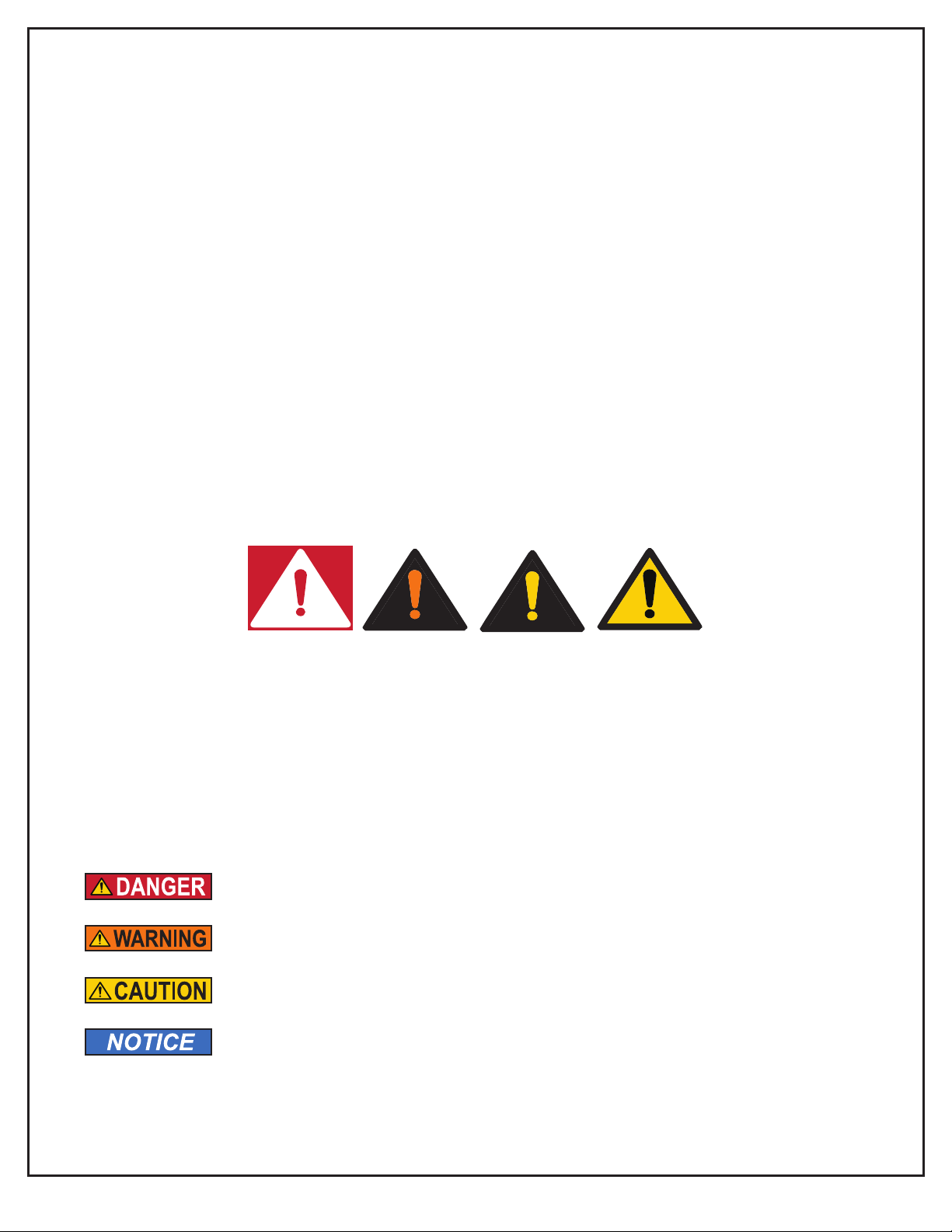

2.1 Safety Alert Symbols

A symbol that indicates a hazard. It is composed of an equilateral triangle surrounding an

exclamation mark. The safety alert symbol is only used on hazard alerting signs. It is not used on

safety notice and safety instructions signs.

A – For use with DANGER signal word; (safety white triangle, safety red exclamation mark, safety

red background)

B – For use with WARNING signal word; (safety black triangle, safety orange exclamation mark)

C – For use with CAUTION signal word; (safety black triangle, safety yellow exclamation mark)

D – For use with DANGER, WARNING, or CAUTION signal words; (D is a safety yellow triangle

with a safety black border and safety black exclamation mark;

2.2 Signal Words

DANGER Indicates a hazardous situation that, if not avoided, will result

in death or serious injury.

WARNING Indicates a hazardous situation that, if not avoided, could

result in death or serious injury.

CAUTION Indicates a hazardous situation that, if not avoided, could

result in minor or moderate injury.

NOTICE Indicates information considered important, but not hazardrelated (e.g., messages relating to property damage).

7Presto Lifts PPS2200-101AS,125AS,150AS Manual

DO NOT OPERATE THESE LIFTS WITHOUT CAREFULLY READING THIS MANUAL. In order

to provide for the safe operation of these stackers, Presto Lifts Inc. has identied certain hazards

that may occur during the maintenance and use of these lifts. For safety reasons these units are

designed to be serviced or repaired in the fully lowered position. If performed properly, this will

greatly reduce the possibility of injury.

When servicing the unit:

1. Key should be in “OFF” position.

2. E-stop should be depressed.

3. Disconnect the batteries at the terminals.

Do not perform any repair work on lifts if there is a load on the forks or

platform.

Do not perform any repair work if the forks or platform is in the raised

position.

All personnel must stand clear of the lift while in motion.

Do not put hands or feet under the forks or platform.

Do not stand underneath the forks or platform.

Do not stand in front of the stacker while in motion.

Do not stand, sit or climb on the lift.

Do not use the lift on soft, uneven or unstable surfaces.

Do not exceed the load center or capacity.

8Presto Lifts PPS2200-101AS,125AS,150AS Manual

To avoid death or serious injury:

• Always be alert to the area around you and watch where you are walking. Be careful

that you don’t get pinned or crushed between the stacker and a xed object such as

a wall or post.

• Watch your hands and feet. A foot or hand caught between the stacker and a xed

object will be crushed or even cut off.

• If traveling forks rst, keep both hands on the control handle and be careful when

changing direction of travel. Keep your feet clear of the stacker.

• Keep the stacker under control at all times. Operate at a speed that allows you to

stop safely. Be even more careful on slippery or uneven surfaces. Do not run over

objects on the oor.

• Perform all stacker movements smoothly and at a speed that will give you time to

react if an emergency occurs.

• Tip-overs and falls are very serious accidents; you can be crushed or even killed. To

prevent injury, know where you are at all times and follow the rules of safe stacker

operation.

• Be careful when working around docks, dock boards and trailers. Stay away from

the edge of docks and ramps. Check to make sure the wheels of truck or trailers are

chocked.

• Travel with the load or forks close to the ground. Watch for overhead obstructions.

Perform all stacker movements smoothly and at a speed that will give you time to

react in an emergency. DO NOT travel with forks or platform in an elevated position.

• Keep your hands and feet away from all moving parts such as masts, chains, forks or

wheels.

• Never stand on or under the forks, or allow anyone else to stand on or under them.

Never ride on the stacker or allow anyone else to ride.

• Before you leave your stacker, be sure to lower the forks to the oor. Shut the

stacker off with the key.

• DO NOT use this stacker until you have been trained and authorized to do so.

• DO NOT operate until you have read all warnings and instructions.

• DO NOT exceed load center or load weight capacities (check capacity plate).

• DO NOT operate until you have checked the conditions of the stacker: lift systems,

forks, chains, and cables.

• DO NOT use if any part is damaged, worn or not working properly.

• DO NOT use on ramps or inclines. Only smooth level surfaces.

• DO NOT use for lifting or carrying people.

• DO NOT handle unbalanced, unstable, loosely stacked, or loads that exceed the

rated capacity.

• DO NOT operate when parts of anyone’s body may be close to mast structure or any

moving parts.

• DO NOT drop loads on platform or forks.

• DO NOT alter or modify this stacker in any way.

9Presto Lifts PPS2200-101AS,125AS,150AS Manual

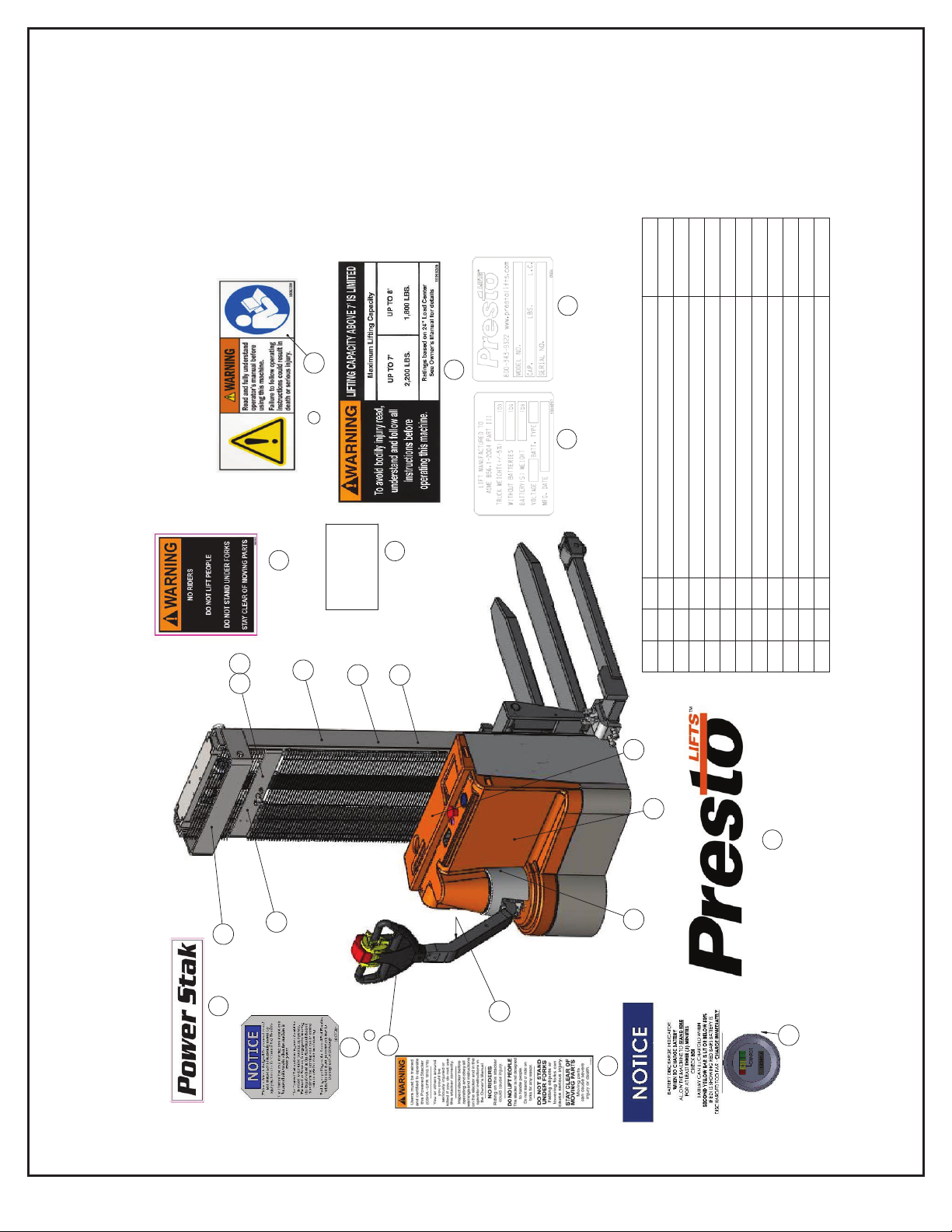

3. Labeling

This machine has labeling to indicate potential hazards this machine may pose when operating

and/or maintaining the machine. All labels must be legible. If any label is missing, damaged, or

otherwise illegible contact the manufacturer for replacement labels.

3.1 Label Placement Diagram

77893001KATS REWOP 00.02X00.3 LCD DL-KBAE12

87893001SREDIR ON 00.3X00.3 LCD DL-KBAE23

10079930

6*

ITEM #

8

ITEM # 11C

ITEM #

FRAME UNDER COVER

*LOCATE (1) ITEM #6 ON MACHINE

5ITEM #

.ON TRAPNOITPIRCSEDM/U.YTQ

3*ITEM #

2200 LBS

CAPACITY

11

5

2*

*PLACE DECAL HORIZONTAL

ON CROSS BAR

8*

SIDE OF WIDE MAST

*LOCATE (1) ON EACH

6*

7ITEM #

AT 24"

LD DCL 2.00X3.00 PRESTO SERIAL ID BLANK

LOAD CENTER

9 1 EA LD DCL 3.00X3.50 NOTICE: THIS MACHINE I 10076204

8 2 EA BK-LD LBL 3.00X7.00 DANGER 10055255

11 1 EA LD DCL 1.50X3.00 READ AND FULLY UNDERSTA 10082709

7

3*

SIDE OF WIDE MAST

*LOCATE (1) ON EACH

10 1 EA LD DCL 3.00X3.00 NOTICE BATTERY DISCHARG 10085658

10

6*

4

7 1 EA

4 1 EA BK-LD DCL 12.00X3.00 PRESTO ALPHA C155N

6 2 EA LD DCL 2.00X3.25 CAPACITY 2200 LBS AT 24 10046160

5 1 EA LD TAG LIFT MANUFACTURED TO ANSI/ITSDF B 10040297

1 1 EA BK-LD DCL 2.25X8.50 ! WARNING USERS MUST 10039876

ITEM

4

ITEM #

2*

B

ITEM #

9

ITEM # 9

1*

*PLACE UPSIDE DOWN

ON INSIDE OF HANDLE

1

ITEM #

10

ITEM #

10Presto Lifts PPS2200-101AS,125AS,150AS Manual

Loading...

Loading...