Presto Conti Compact Series, Conti Compact CC-13 V, Conti Compact CC-20 V, Conti Compact CC-40 V, Conti Compact CC-30 V Operating And Maintenance Instructions Manual

Page 1

Operating and

maintenance instructions

CHANNEL-TYPE BALING PRESS

TYPE

CONTI COMPACT

CC-13 V

CC-20 V

CC-30 V

CC-40 V

04/2012

Page 2

5.7 Funnel with safety circuit

1. Introduction

1.1 Introduction

1.2 Structure of the operating

instructions

1.3 Duties and information for

the machine operator

1.4 All rights reserved

2. Intended use

2.1 Improper use

2.2 Amendments at the supplied

device by the operator

2.3 Residual risks at the channel

type baling press

3. Safety

3.1 General information

3.2 Safety instructions

3.3 Safety marking

3.4 Protective devices

3.5 Organisational measures

3.5.1 General information

3.5.2 Location

3.5.3 Selection and qualification

of staff

3.6 Operation

3.6.1 Normal operation

3.6.2 Danger areas

3.6.3 Reference to special

dangers

3.6.4 Transport and loading

3.7 Maintenance/Repair

3.8 Liability and warranty

3.9 Product liability

3.10 Warranty

4. Technical data

4.1 Sound emission

1-1

1-1

1-2

1-2

1-3

2-1

2-1

2-1

2-1

3-1

3-1

3-3

3-3

3-4

3-5

3-5

3-6

3-6

3-7

3-7

3-9

3-9

3-10

3-11

3-12

3-12

3-12

4-1

4-4

5. Constructive description

5.1 General information

5.2 Basic construction

5.3 Press unit with channel

adjustment

5.4 Hydraulic unit

5.5 Electrical unit

5.6 Tie-off device

5.6.1 Fully automatic tie-off

device

6. Operating elements and

operation

6.1 General information

6.2 Operating elements

6.3 Works prior to initial

commissioning

6.4 Compacting process

6.4.1 Operation mode "Manual"

6.5 Control and program

description

6.6 Insert binding wire coils

6.7 Transport and loading

7. Maintenance

7.1 General information

7.2 Cleaning

7.3 Maintenance

7.3.1 Maintenance schedule

7.3.2 Description of the

maintenance works

7.3.3 Fuels, fuel quantities

8. Repair

5-1

5-1

5-2

5-3

5-4

5-6

5-8

5-8

5-8

5-10

6-1

6-1

6-1

6-2

6-4

6-5

6-11

6-15

6-19

7-1

7-1

7-2

7-3

7-3

7-6

7-19

8-1

04/2012

i

Page 3

9. Behaviour in case of trouble

9.1 Error messages

10. List of spare parts

11. Appendix

11.1 List of machine operators

and personnel in charge

11.2 Maintenance and revision

list

11.3 Special equipment

11.3.1 Funnel

11.3.2 Special equipment

11.4 Wiring diagrams

11.4.1 General

11.4.2 Wiring diagrams for the

channel type baling press

11.5 Disposal

9-1

9-2

10-1

11-1

11-1

11-3

11-4

11-4

11-5

11-5

11-5

11-5

11-6

04/2012

ii

Page 4

additional components the machine must

1 Introduction

be assembled before it is put into

operation. Until the machine has been

1.1 Introduction

Dear customer,

to assure a safe and efficient use of the

unit we would ask you to read the present

operating instructions carefully prior to

the initial start-up.

The operating instructions contain all

relevant information for the operation and

maintenance of the channel-type baling

press.

Chapter 1 to 10 will inform you about the

standard equipment. If installed, the

special equipment will be dealt with in

chapter 11.

These operating instructions form a

constituent part of the complete

documentation for the channel-type

baling press of the types CC-13, CC-20, CC30 and CC 40.

Other essential parts are:

• Electrical and circuit diagrams,

• Assembly or layout diagram

completely assembled, commissioning of

individual components is forbidden.

As a rule all safety instructions have to be

fulfilled prior to the commissioning of the

channel-type baling press.

Only qualified and trained personnel of

PRESTO or persons authorised by them

may work with the channel-type baling

press.

If maintenance works are neglected or

carried out improperly we will not be able

to fulfil our guarantee obligations

according to our terms of delivery.

Only original-PRESTO- spare parts ensure

quality and interchangability.

How to identify your machine:

These operating instructions serve for the

operation and maintenance and apply for:

Project: Channel-type baling press

Type: ______________________

(see type plate)

Mach.- No.: ______________________

(see type plate)

• Declaration of Conformity or

alternatively Declaration of

Incorporation

In principle, every machine is supplied

with a Declaration of Conformity. This

states that the machine fulfils the basic

safety and health requirements of the EC

Directive on Machines.

In the event that no Declaration of

Conformity is issued, the attached EC

Declaration of Incorporation for

incomplete machines states with which

04/2012 1-1

Page 5

PRESTO

GmbH & Co. KG

Bad Laer

Conformity with EC-directive 2006/42/EG

To observe upon delivery

The channel-type baling press left our

plant in a technically perfect and ready to

use condition. Please check the condition

of the machine immediately upon receipt

and carry out a functional check. Possible

complaints have to be reported to the

forwarding agent immediately.

1.2 Structure of the operating

instructions

The type plate is positioned at the

channel-type baling press as follows:

When contacting our service department

you should always have the information

ready which is given on the type plate.

Manufacturer: PRESTO GmbH & Co. KG

Customer:

______________________

Year of construction:

______________________

The operating instructions are laid down

in chapters according to the table of

contents.

The corresponding page number has been

assigned to each chapter.

The footnote contains the date of issue

and the page number.

04/2012 1-2

Page 6

PRESTO

GmbH & Co. KG

Bad Laer

Maintenance and repair instructions

1.3 Duties and information for the

machine operator

As the operator of this unit you have to

inform and instruct the operating staff

about prevailing legal regulations and

• Correct dealing with fuels

• Special experiences of the operator

for the cleaning and care,

maintenance and repair of the

machine

accident prevention rules as well as safety

and operating devices at the machine.

Ensure that your operating staff has

understood the instruction and follows it.

How to achieve a safety and danger

conscious operation by your staff:

In the following we have prepared some

items for you with respect to the

instruction subjects

With respect to safety

1.4 All rights reserved

All technical data, descriptions and photos

are valid on the day of the publication of

these instructions or its supplements. We

reserve all rights as well as amendments

by continuous further development.

The operating instructions serve for the

instruction of the customers. It may

neither in part nor fully be copied or

handed to third parties without the prior

written consent of PRESTO GmbH & Co.KG

• Accident prevention rules

• General legal regulations

• General safety instructions

• Measures in case of emergency

• Safety instructions for the

operation of the unit

• Dealing with the safety devices of

the machine

• Meaning of symbols and signs

With respect to the operation of the

machine

• Dealing with the operating

elements

• Explanation of the operating

instructions for the operating staff

• The use of aids and auxiliary

devices

• Experiences with regard to the use

of the machine

04/2012 1-3

Page 7

PRESTO

GmbH & Co. KG

Bad Laer

The channel-type baling press has been

constructed for the compaction of soft

materials as paper, cardboard, foils and

similar.

2.1. Improper use

Explosive materials or similar materials or

combustible materials may not be filled in.

It is also prohibited to charge rumble, wood,

form or bar racks from metal or other hard

materials, which can result in a jerky

jamming of the compressing die.

2.3. Residual risks at the channel-type

baling press

Danger by nonobservance of the

operating instructions

Danger by insufficient maintenance

and repair

Risks arising during maintenance,

servicing, and repair work through

the use of sharp-edged or

inappropriately compacted materials

(see note in chap. 7, Maintenance

and Inspection).

The operator is responsible for these residual

risks.

2.2. Amendments at the supplied device

by the operator

The declared conformity applies only to the

structural condition upon delivery of the

device in correspondence with the agreed

scope of delivery. Any installation or

equipment which is carried out by the

operator at a later time, however, has not

been developed or authorised by the

manufacturer of the machine, will result in

an expiry of the declared conformity.

This also includes unauthorised modifications

of the channel-type baling press with sheets,

wood, pasteboard or fabric of any kind by

the operator.

04/2012 2-1

Page 8

3. Safety

We wish to point out that the unit has to be

checked at least twice a year by a qualified

person with respect to the proper and safe

3.1. General

To safeguard the labour protection and the

on-the-job safety the following references

have to be adhered to:

Accident prevention regulations, in

particular:

BGV A1 General Regulations

BGV A2 Electrical systems and

operating resources

BGV A5 First Aid

BGV B3 Noise

BGV A8 Safety marking at the work

site

have to be adhered to.

The accident prevention rules of the country

where the unit will be used have to be

observed.

function in correspondence with the above

mentioned directives.

In addition to the above mentioned

regulations the following directives are

appropriate for the inspection as well:

Safety of machinery DIN EN 12100

Part 1 u. 2

Electrical equipment DIN EN 60204

EC- machinery

2006/42 EG

directive

During the operation of the machine the

laws and regulations applicable at the place

of use have to be observed. For the sake of a

safe work sequence the operator,

supervisory persons and machine operators

are responsible for observing the regulations.

The channel-type baling press may only be

used as directed. An improper use can result

in personal and property damages.

The PRESTO channel-type baling press has

been constructed for the compaction of soft

materials as paper, cardboard, foils and

similar.

04/2012 3 - 1

Page 9

It is prohibited to load explosive or similar

materials or inflammable materials

(according to §1 SprengG).

Materials that are subject to special

conditions of disposal according to the waste

disposal law must not be loaded.

Furthermore it is prohibited to fill with

rumble, timber or other such materials out of

metal or other hard materials. Only such

material may be compacted which can be

deformed by the given pressure and which

can be compressed in the compression room.

Glowing or burning particles must not be

loaded.

Another use or a surpassing use does not

comply with the intended purpose. PRESTO

GmbH & Co.KG will not be liable for damages

resulting from this. The risk will be borne by

the user of the machine.

DANGER!

The electric machines

and/or equipment are

production equipment for

use in industrial high

voltage systems. During

operation this production

equipment has dangerous

live parts which may

cause very serious injury

to health or damage to

property for instance as a

result of unauthorised

removal of coverings,

improper use, incorrect

operation or lack of

The staff responsible for the safety of the

unit has to safeguard that only qualified

persons

are instructed with work on the machinethat these persons always have the supplied

operating instructions available and that they

are obliged to strictly adhere to these

documents. Working at the unit or in the

proximity has to be prohibited for nonqualified personnel.

During filling the compactor with

material that may cause skin

damage wear gloves!

Pay attention to flying solids!

Use eye protection!

At places where there are solid airborne

particles or where dusts, caustic substances

or the like are processed or produced.

Residual risks with regard to the channeltype baling press:

• Endangering by failure to comply with

safety instructions

• Danger by insufficient maintenance and

repair

• Risks through hydraulic hoses

• Risks through sharp-edged casing corners

• Risks arising during maintenance,

servicing, and repair work through the

use of sharp-edged or inappropriately

compacted materials (see note in chap. 7,

Maintenance and Inspection).

The user will be responsible for these

residual risks.

maintenance.

04/2012 3 - 2

Page 10

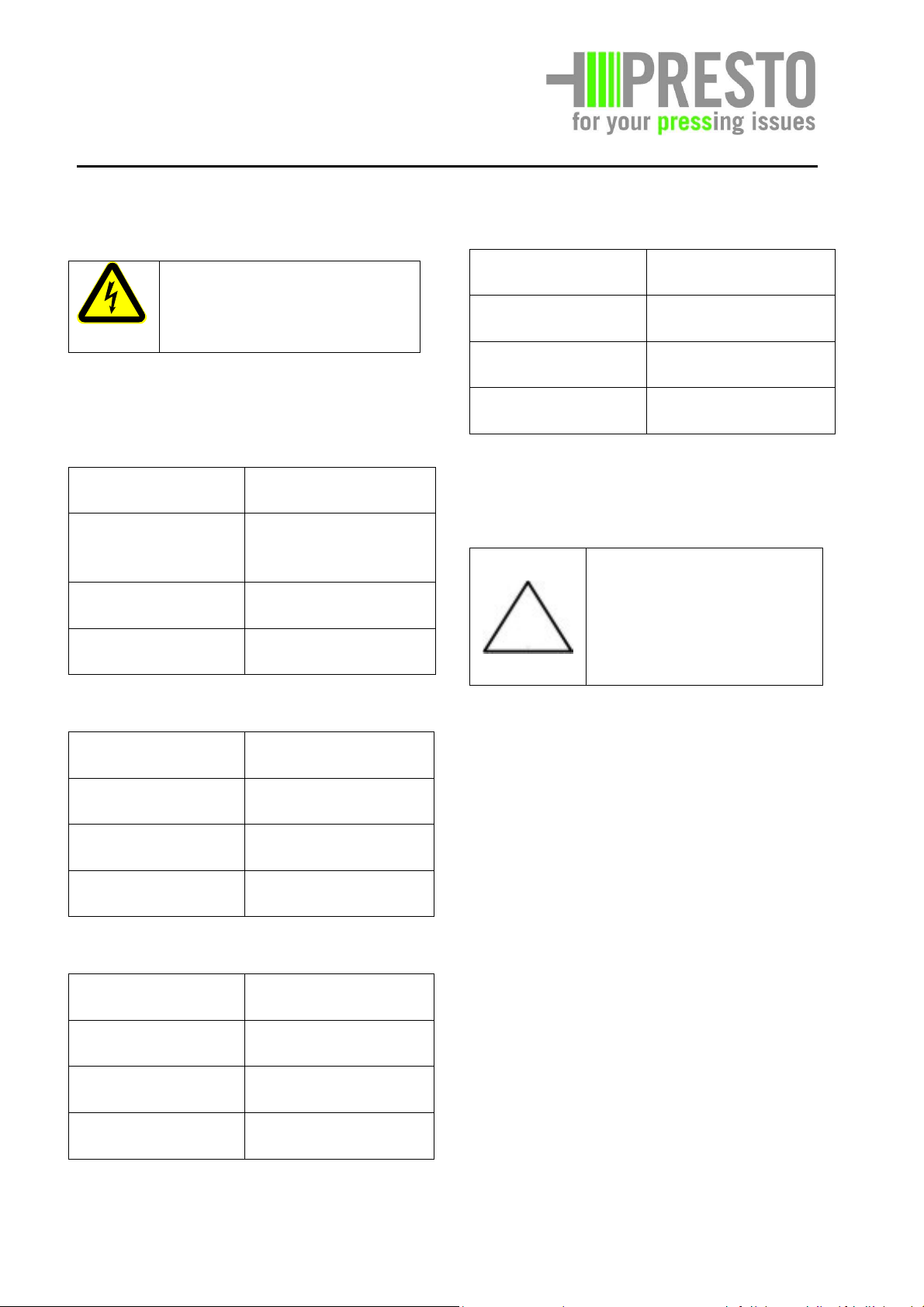

3.2. Safety instructions

The following symbols in these operating

instructions mean:

Risk to life and limb!

Caution!

This maintenance work may

only be carried out by skilled

personnel.

Additional important

information can be found here.

3.3. Safety marking

Safety instructions and the brief version of

the operating instructions are visible at the

machine

Note:

CAUTION!

NEVER CLIMB INTO THE

FEEDING OPENING!

DANGER!

Caution!

Risk of damage to or

destruction of the machine

or its parts.

Danger of crushing!

Do not reach into the

machine from the

bottom!

Caution!

Risk of crushing!

Read and understand

the manual!

Caution!

Risk from electric current!

04/2012 3 - 3

Page 11

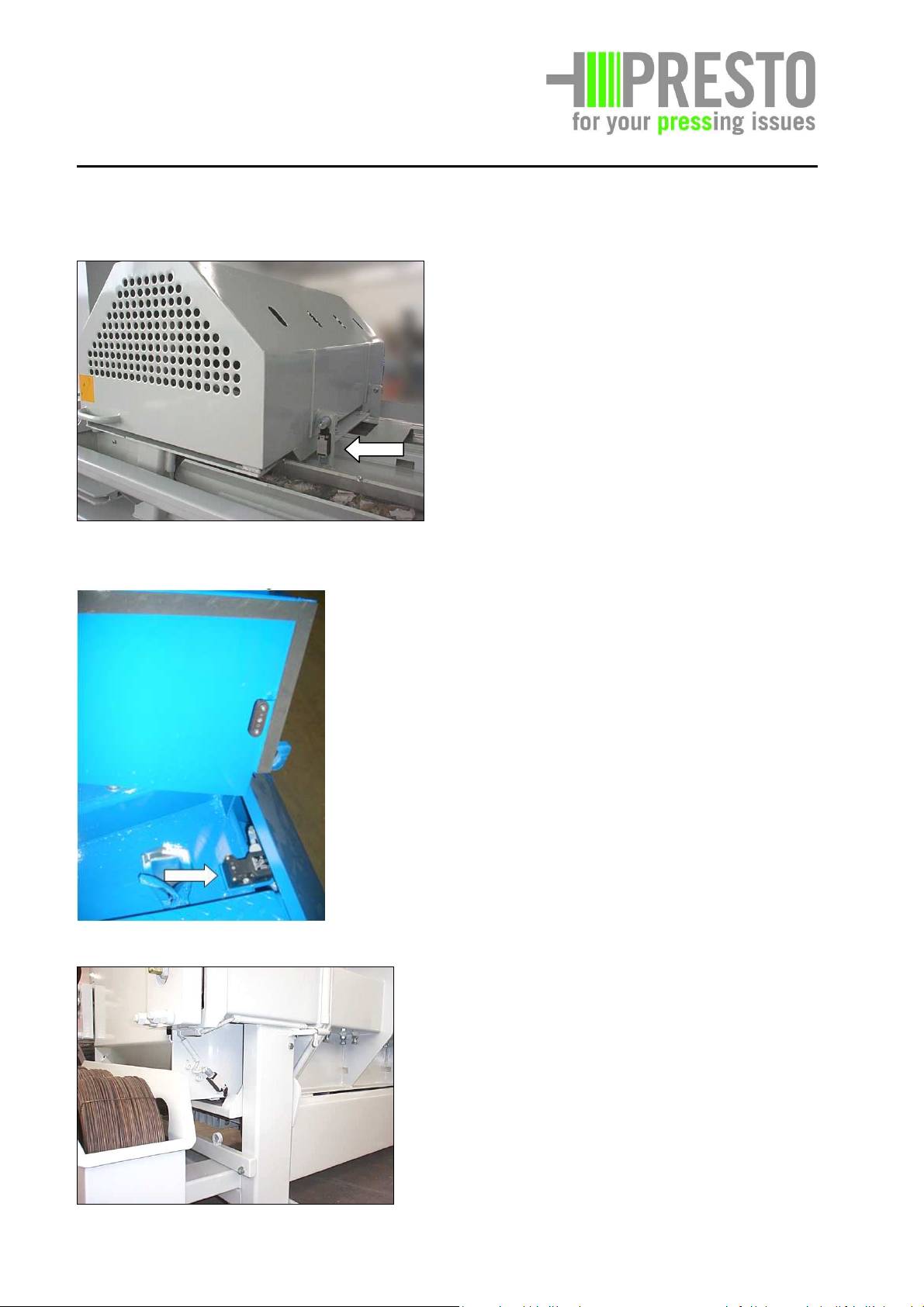

3.4. Protective devices

Safety switch, charging funnel

It is prohibited to put control, switching or

safety devices out of operation or to make

modifications. Non-compliance may result in

criminal prosecution.

Safety covers held in place by bolts which fit

through keyhole-shaped slots are removed

from the machine by loosening the bolts 3 or

4 turns. The bolts should remain in the drill

holes. The cover can now be slid along the

keyhole and removed by lifting over the bolt

heads which fit through the round, upper

keyhole aperture. The covers are replaced by

reversing the sequence.

Seals may not be destroyed and pre-set

Safety switch with rope release (1)

pressures may not be changed because this

would result in an expiration of the warranty

and criminal prosecution.

Equipment for the protection of the staff:

rgency-off switch, switch box

Emergency-off, key bar

04/2012 3 - 4

Page 12

Safety switch (Type CC-30 only)

3.5. Organisational measures

3.5.1. General

The operating instructions always have to be

kept at the intended place.

In case of multiple shift operation it has to be

determined who will be responsible to carry

out the maintenance works.

Cover, manual tie-off device

Check machine with regard to external

recognisable and/or audible damage and

defects, at least once per shift. Stop and

secure machine immediately if necessary.

Before starting the work the operational

tests at the emergency-off switch and the

safety switch and light barriers if necessary.

ATTENTION!

Any work such as taking into operation,

maintenance and repairs may be performed

by qualified staff only and have to be

checked by responsible experts. The user has

to notify any trouble or irregularities to his

person in charge immediately. This applies

for the mechanical and electrical devices.

The machine has to be stopped and secured

Safety switch needle flap

immediately in case of malfunctions or

safety-relevant changes of the behaviour of

the machine. Malfunctions have to be

corrected immediately.

It has to be seen to it that the operating

instructions, the maintenance and special

tools and devices, the oil cans and grease

guns as well as cleaning agents and

lubricants belonging to the channel-type

baling press container are always kept in the

intended receptacles.

04/2012 3 - 5

Page 13

with machinists who have been instructed

3.5.2. Location

The location has to be chosen that way that

the channel-type baling press stands on a

plain surface. The location must have a

concrete plain surface that corresponds to

the weight of the machine.

The unit may be operated in an electrical

network with the corresponding conditions

(see chapter "electrical system").

As a protective measure against indirect

touching the fault-current circuit breaker

according to VDE 0100 has to be used when

erecting the machine in the open. Only faultcurrent circuit breakers may be used with a

nominal fault current as specified in the

wiring diagrams of the manufacturer.

The provisions of the water household and

environmental protection law have to be

about the use of the machine according to

BGV A1 § 13. The above mentioned is only

valid for the Federal Republic of Germany.

The corresponding regulations and guidelines

of the country where the machine is used are

applicable.

Only qualified and reliable staff may work at

and with the machine.

Persons instructed with work at/with the

machine must have thoroughly read and

understood the operating instructions and

here especially the safety instructions and

they must be in a corresponding mental and

physical state.

Non-compliance with these instructions may

result in danger for life and limb and/or

danger for the machine or other physical

assets.

adhered to when setting up the unit and

taking it into operation.

3.6. Operation

Sufficient space has to be provided in front

of the channel-type baling press for the bale

which is pushed out. The access must be

possible for industrial trucks without

endangering persons.

The loading and starting area for industrial

trucks has to be marked.

The use in explosive areas and in an

explosive atmosphere is strictly prohibited.

The channel-type baling press is appropriate

for manual loading from ground level to the

loading space of the machine. If the loading

takes place from a ramp, PRESTO offers a

3.6.1. Normal operation

corresponding ramp funnel that guarantees

3.5.3. Selection and qualification of

staff

Only such persons selected according to BGV

A1 § 13, BGV A2 are authorised to operate

and maintain the channel-type baling press.

The user will be responsible for the

occupation of the channel-type baling press

the necessary minimum height with regard

to safety.

This means, that the location of the loading

level has to be designed in such a way that a

minimum height to the load opening and to

the laterally fixed loading door (if any) does

not fall below . If the loading level

04/2012 3 - 6

Page 14

varies PRESTO will supply the corresponding

funnel.

When using a lifting/tipping device to empty

the containers according to the dimensions

shown in the appendix, care has to be taken

that no person stays in the swivel area of the

device. Loading from other containers is

regarded as improper use. Using externally

manufactured loading or suction devices is

subject to the agreement of PRESTO.

The user must be aware of the

power supply of the channel-

type baling press as well as

their interrupting possibilities.

Beyond this the user has to be

familiar with the instructions

according to BGV A2.

According to the chapter "Operation" of the

operating instructions the dangerous zones

have to be paid attention to.

Attention!

To avoid malfunctions it is indispensable to

have the maintenance and inspection work

performed at regular intervals. Changes in

comparison with the normal operation

(increased power consumption,

To avoid malfunctions that may either

directly or indirectly result in serious

personnel or property damages, the

responsible maintenance personnel have to

be informed immediately..

Before taking the unit into operation all

protective devices have to be in protective

position and the locking devices and other

protective measures involved in the control

of the machine have to be in function. The

function of the operating elements has to be

checked.

The channel-type baling press must not be

used if the mains lead is not satisfactory.

Using electrical coupling devices and

adapters for the operation of the channeltype baling press is not allowed. Only

plugging devices according to VDE 0113 acc.

to DIN EN 60204 may be used.

The mains plug may be replaced by a

qualified electrician only. In case of a

replacement of the mains lead or equipment

connecting line it is not allowed to deviate

from the type stated by the manufacturer.

The mains plug may not be plugged before

the channel-type baling press has been

properly installed at the location.

temperatures or vibrations, extraordinary

noise or odours, response of control

instruments, etc.) show that the function is

impaired.

04/2012 3 - 7

Page 15

Entering the shaft of the

channel-type baling press is

strictly prohibited.

Before taking the unit into operation make

sure that nobody will be endangered.

Watch turn-on transient and turn-off

transient as well as control lamps according

to operating instructions.

User - decide responsibility.

Enable the user the refusal of instructions

from third parties that impair safety!

Ensure that only authorised persons are

working at the machine. Please keep persons

who are not involved in the work process in a

distance.

The staff may not wear long loose hair, loose

clothes or jewellery including rings. There is a

considerable danger to be injured, for

example by getting caught or being trapped.

Switch off machine when having finished the

work and secure against unauthorised

reclosure (lock main switch).

Comply with adjustment and maintenance

work instructions for the replacement of

parts / part equipment.

This work may be performed by skilled

personnel with sufficient knowledge and

corresponding tools, only.

As far as necessary or if required by legal

provisions use personnel protective

equipment!

Wear protective gloves!

Use eye protection!

at places where there are solid airborne

particles or where dusts, caustic substances

or the like are processed or produced.

It is prohibited to erect platforms, ladders or

other aids.

If there is no possibility of supervision, the

operation has to be locked by the actuation

of the main switch that can be locked by a

key.

The cover to the cylinder room may be

opened for the purpose of cleaning,

maintenance or repair only. For this purpose

the channel-type baling press has to be

disconnected from the power supply.

Additionally the main switch has to be put

into "0" position and be secured against

unauthorised interference by means of a

padlock. After having finished the work care

has to be taken that the flap is mounted

again correctly.

When using oils, grease and other

substances, adhere to the safety regulations

and legal provisions valid for the product!

An immediate interruption by the user is

absolutely necessary if defects occur, which

impair the safety.

Observe protection against accidental risks

(Guideline of the council 2001/45/EC).

04/2012 3 - 8

Page 16

These are:

• Failure of light barriers,

• Emergency-off switches and protective

devices

• • Damaging of electrical equipment and

lines as well as insulators.

In case of doubt immediately stop the

unit!

electrical information in the chapter

"Electrical unit"

Attention!

The rotational direction of the electric

motor of the hydraulic pump has to be

strictly observed. A short time wrong

running destroys the hydraulic pump.

The motor is running correctly when the

ventilator wheel at the electric motor rotates

in the direction of the arrow at the housing

indicating the rotational direction and the

3.6.2. Danger areas

The danger area of the machine is limited to

the horizontal distance measurement of 1 m

to the external dimensions of the channeltype baling press.

compressing die makes a movement

within 5 seconds.

If the compressing die does not make any

movement within this time turn off motor

immediately and change two phases of the

feed line by an electrical expert.

As the pump runs without oil flow in case of

a wrong rotational direction, the motor may

be turned on for a very short time only (5

seconds as a maximum).

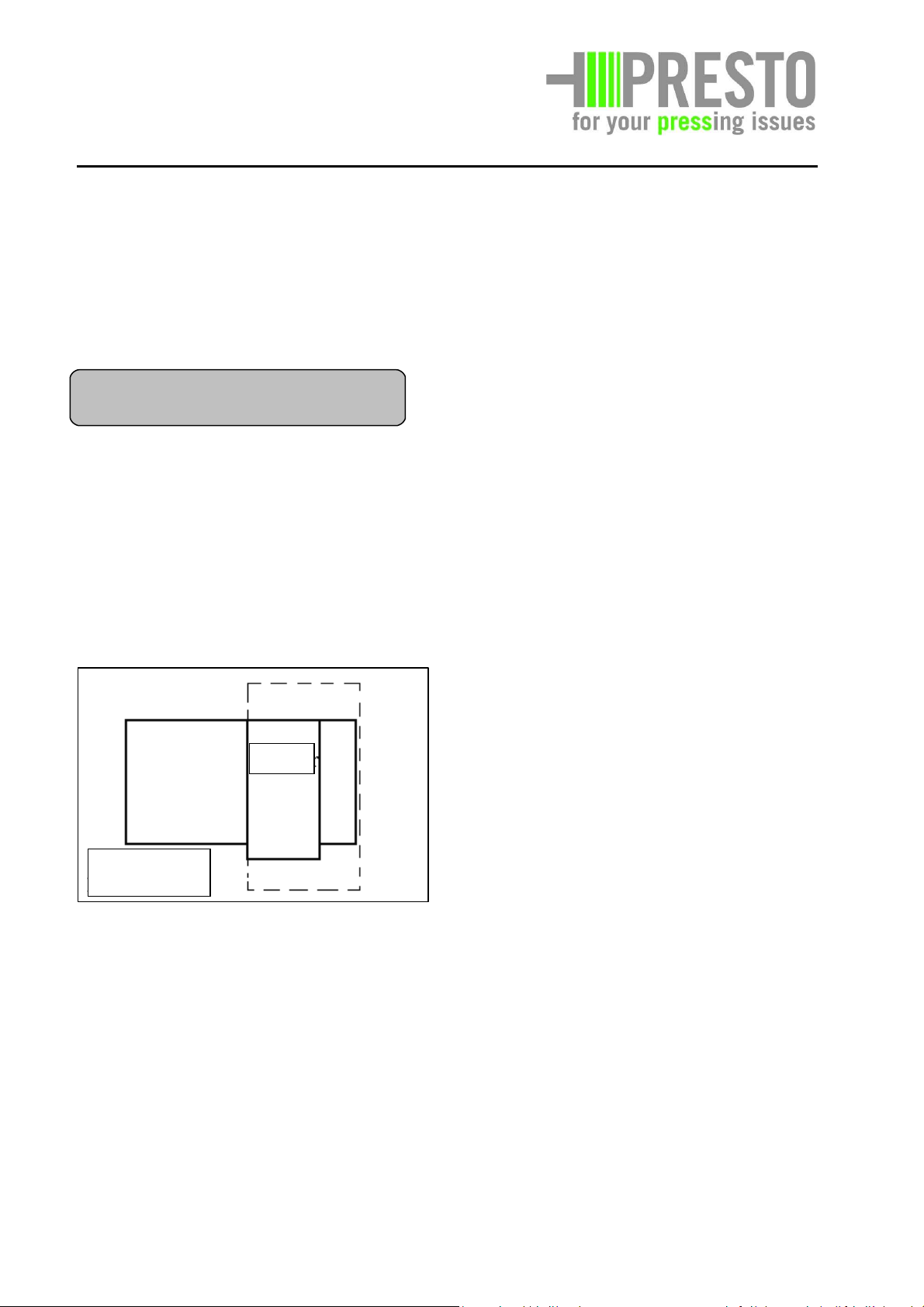

Funnel

Before working on electrical units or systems

these have to be switched dead.

The five safety rules before starting work:

Schematic

view

• Switch off

• Secure against reclosure (switch off main

switch and lock)

• Ensure dead circuit

• Grounding

• Cover or screen of adjacent live parts

3.6.3. Reference to special dangers

Electrical energy

The machine will be supplied ready for

operation.

The power connection has to be provided at

the side, doing this the electrical safety

instructions, the regulations and the

04/2012 3 - 9

Page 17

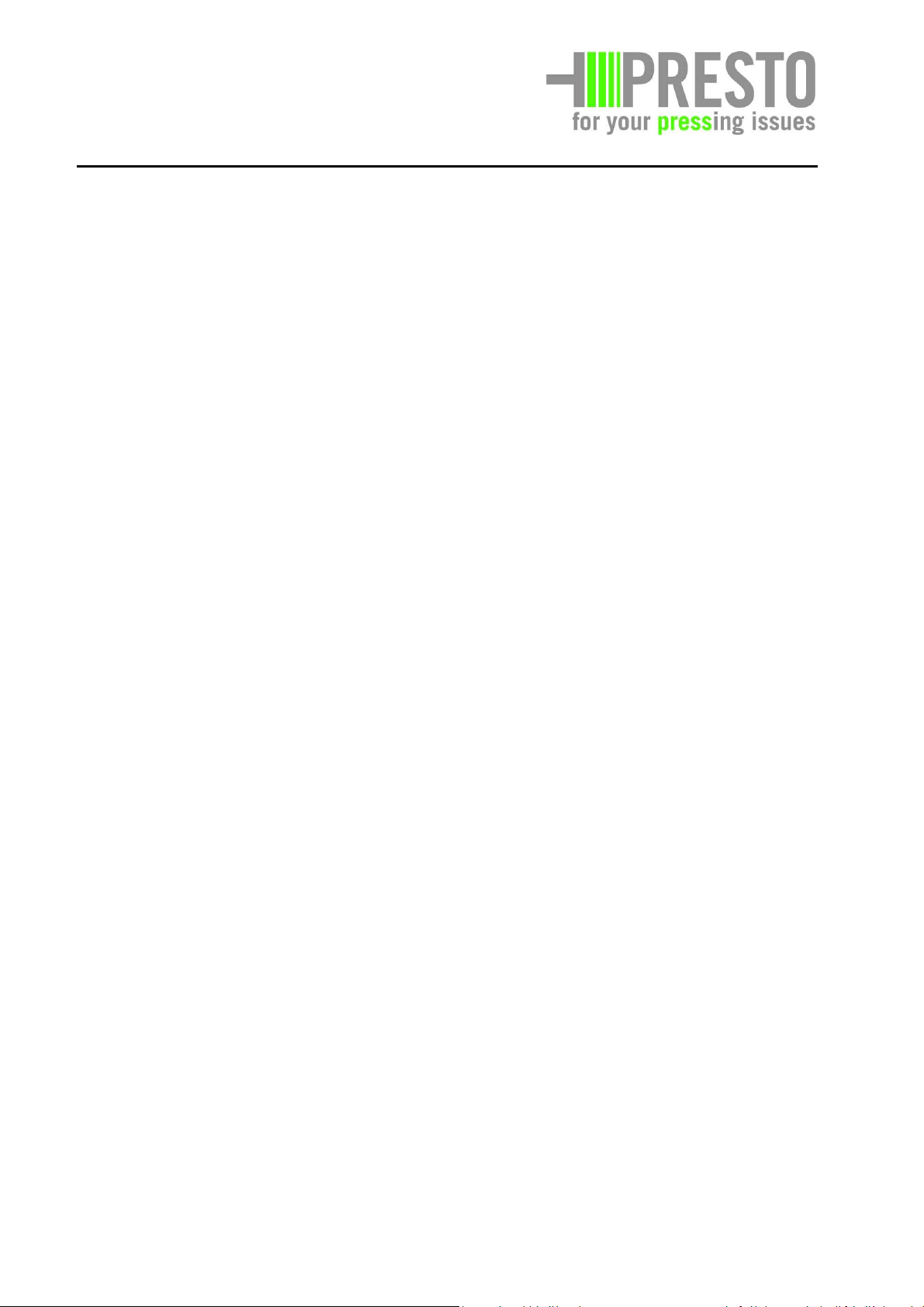

3.6.4. Transport and loading

Use corresponding hoisting equipment and

proper securing measures:

Lift machine at intended loading point only

or use forks of forklift truck only at bearing

parts! See schematic view!

The forks only in places marked by the

Following sign set.

CC 36, Points of notice forks

Secure load against unintended changes of

the position.

Parts that are removed during transit have to

be mounted and fixed again before taking

the machine into operation again!

Transport safety devices and transport aids

have to be removed.

The machine has to be separated from every

CC 13, Points of notice forks

external energy supply also in case of a slight

change of the location of the machine!

Before taking the machine into operation

again, the machine has to be connected to

the mains again properly!

CC 20, Points of notice forks

04/2012 3 - 10

Page 18

3.7. Maintenance / Repair

Staying in the dangerous zone

is allowed only during the

specially described work by

authorized personnel and/or

experts adhering to the

corresponding safety

instructions.

The maintenance of electrical equipment

may be performed by experts or instructed

persons only.

Before the inspection and cleaning of the

electrical equipment the unit must be dead

for the duration of the work.

The machine has to be turned off completely

during maintenance and repair work and be

secured against unauthorized reclosing (see

chapter "maintenance").

Before starting to work on electrical plants or

resources, de-energize them.

Inform operating staff about this point

before starting special and repair work!

Nominate a supervisory person!

Secure dangerous zone!

Tighten loosened connections properly again

during maintenance and repair work!

Dismantled protection- and safety devices

have to be properly mounted again and

checked regarding a tight seat before taking

the unit into operation again!

Use fuses in accordance with regulations and

current intensity only.

It is strictly forbidden to repair fuses!

Welding work on all supporting members are

prohibited.

Maintenance, cleaning and inspection work

may be performed during standstill and

turned-off machine and by authorized

personnel only. The padlock has to be

provided and locked at the main switch in

Do not switch. Work in progress

Place: Date:

This sign may only be removed by:

Attach a telltale sign prior and during work!

Danger!

Before taking the unit into

operation all safety

elements have to be

checked regarding their

function. All protective

covers and doors must be

order to avoid unintended turning on. The

key has to be kept in a safe place by the

supervisory staff or the nominated qualified

personnel.

Keys and tools by which the channel-type

baling press can be put into operation and/or

protective devices can be dismantled, must

be in possession of the instructed authorized

person or be kept in a safe place.

Electrical components or control elements

must not be directly splashed with water.

closed and locked.

04/2012 3 - 11

Page 19

The use of flammable materials (e.g. petrol is

forbidden – BGV A1 § 43 and 44! During

cleaning work, repairs, etc. the main switch

(1) always has to be locked in 0-position with

a padlock.

Operating fuels (e.g. gear lubricant oil) during

maintenance, repair work and oil changes

have to be collected in appropriate vessels

and disposed of according to the regulations

(EC guideline 75/439/EEC and decrees, 5a, 5b

AbfG and AltölV).

This requires the adherence to the applicable

regulations of the accident prevention and

the accepted

technical regulations for safety and proper

working and the operating instructions,

inspection and maintenance regulations valid

in the country of the user and at the location.

Modifications, extensions and

changes of the design of the

machine must not be made

without the approval of

PRESTO GmbH & Co.KG.

3.8. Liability and warranty

The completeness of the scope of delivery

according to the delivery note has to be

checked upon receipt of the machine.

If parts are missing or transport damages are

found, please inform PRESTO GmbH & Co. KG

immediately.

The supplied unit has been constructed

according to the latest state of the art and

the accepted safety standards (DIN 12100

part 1 and 2 and DIN EN 60204 T1 and

DIN ISO 13849).

In case of improper use and non-compliance

with the regulations, dangers to life and limb

and trouble of the machine or other tangible

assets might occur.

3.9. Product liability

If non-compliance/non-adherence to the

regulations and instructions of this operating

manual leads to accidents with personal

injury or property damage, PRESTO GmbH &

Co.KG will not be liable for any

damage and the compensation of indirect

damage as injuries of persons, damage to

goods, which do not form the subject of the

contract, loss of profits and production

failure which will be directed to PRESTO

GmbH & Co.KG under the title

"PRODUCT LIABILITY".

The PRESTO channel-type baling press

primarily serves for the compaction of soft

materials as paper, cardboard, foil, etc.

Another or surpassing use may be regarded

as improper use. PRESTO GmbH & Co.KG will

3.10. Warranty

PRESTO will accept the warranty for the unit,

provided that the operating and

maintenance manual is adhered to.

not be liable for damages resulting from this.

The risk will solely be borne by the user of

the machine.

Operate unit in a technically good order and

according to the regulations.

04/2012 3 - 12

Page 20

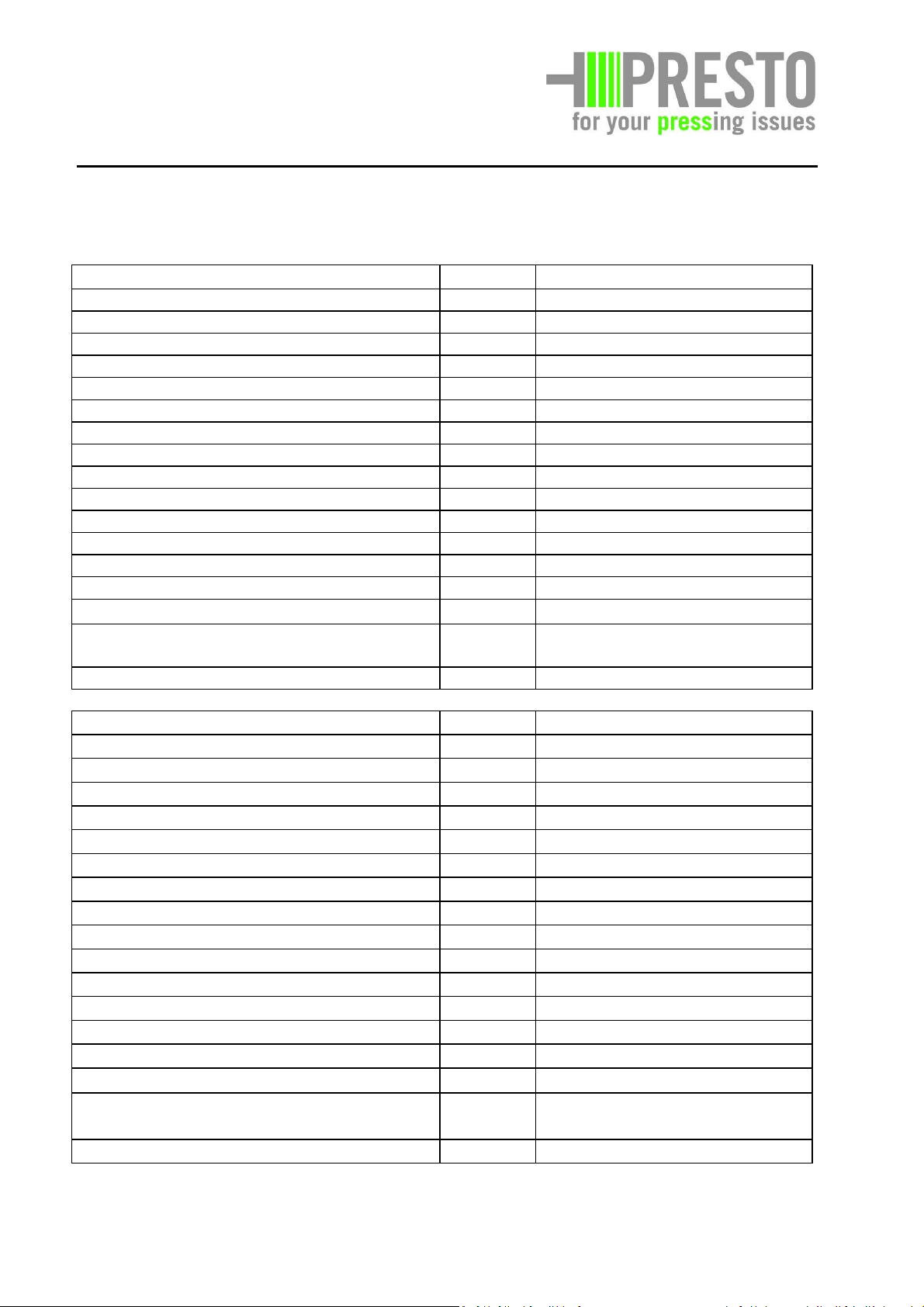

4. Technical data

Type CC-13 fully automatic

Pressing power kN 130

Spec. pressing power N/cm2 24,8

Channel cross section mm 700 x 750

Charging opening mm 750 x 750

Filling volume max. m3 0,39

Power kW 5,5

Volume in idle running m3/h 59

Volume under operating conditions m3/h 50

Weight related to the apparent density t/h

- 35 kg/m3 (department store) t/h 1,7

- 60 kg/m3 (mixed products) t/h 2,5

- 100 kg/m3 (collected products) t/h 3,8

Bale weight

Machine weight approx. t 1,9

Tie off – threefold vertically

Electric connection – standard plug CEE form, 5

pole, fuse protection

Lifting time s 24

Type CC-20

Pressing power

Spec. pressing power

Channel cross section

Charging opening

Filling volume max.

Power

Volume in idle running

Volume under operating conditions

Weight related to the apparent density

- 35 kg/m3 (department store)

- 60 kg/m3 (mixed products)

- 100 kg/m3 (collected products)

Bale weight

Machine weight approx.

Tie off – threefold vertically

Electric connection – standard plug CEE form,

5 pole, fuse protection

Lifting time

Depends on and bale length

wire ∅ 2,8

A 16

fully automatic

kN 200

N/cm2 38,1

mm 700 x 750

m3 1000 x 750

m3 0,53

kW 7,5

m3/h 80

m3/h 77

t/h

t/h 2,7

t/h 3,4

t/h 4,8

Depends on and bale length

t 2,7

A 32

s 24

wire ∅ 2,8

04/2012 4 - 1

Page 21

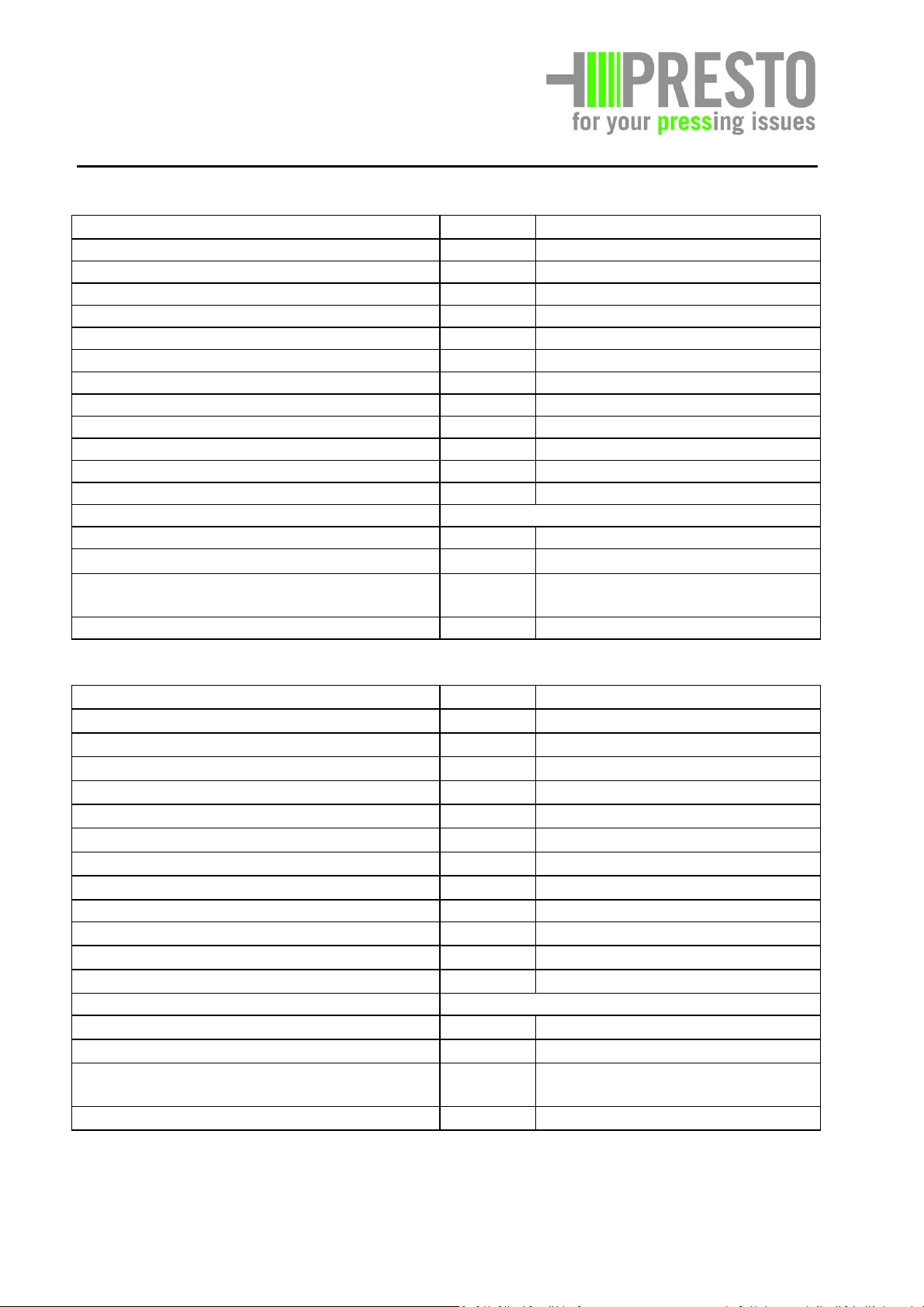

30 fully automatic

Pressing power kN 300

Spec. pressing power N/cm2 45,0

Channel cross section mm 700 x 950

Charging opening m3 1030 x 950

Filling volume max. m3 0,68

Power kW 11,0

Volume in idle running m3/h 72

Volume under operating conditions m3/h 58

Weight related to the apparent density t/h

- 35 kg/m3 (department store) t/h 2,0

- 60 kg/m3 (mixed products) t/h 3,2

- 100 kg/m3 (collected products) t/h 4,8

Bale weight

Machine weight approx. t 3,7

Tie off – threefold vertically

Electric connection – standard plug CEE form, 5

pole, fuse protection

Lifting time s 34

Depends on material and bale length

wire ∅ 3,1

A 35

Type CC-40 fully automatic

Pressing power kN

Spec. pressing power N/cm2

Channel cross section mm

Charging opening m3

Filling volume max. m3

Power kW

Volume in idle running m3/h

Volume under operating conditions m3/h

Weight related to the apparent density t/h

- 35 kg/m3 (department store) t/h

- 60 kg/m3 (mixed products) t/h

- 100 kg/m3 (collected products) t/h

Bale weight

Machine weight approx. t

Tie off – threefold vertically

Electric connection – standard plug CEE form, 5

pole, fuse protection

Lifting time s

Depends on material and bale length

A

400

48,5

750 x 1100

1030 x 1100

0,85

15

90

72

2,5

4

5,9

4,2

Wire 2,8-3,1

35

34

04/2012 4 - 2

Page 22

Dimensions (mm)

Typ A B C D E F G H L M

CC-13 V

CC-20 V

CC-30 V

CC-40 V

1225 1475 1830 380 1050 600 1560 1400 2800 750

1225 1475 2030 380 1135 700 1900 1650 3300 750

1225 1475 2130 380 1350 700 2540 1800 3700 950

1275 1575 2200 380 1640 750 2540 1800 4200 1100

M = Semiautomatic V = Fully automatic

04/2012 4 - 3

Page 23

4.1. Sound emission

The sound intensity level was measured according to EN 23744.

The sound intensity level is stated according to MRL Appendix I, point 1.7.5. f in a free sound

field in a distance of 1 m from the machine and a height of 1.6 m with the highest measured

value.

The sound intensity level measured at the channel-type baling press of the types

• CC-13,

• CC-20,

• CC-30 and

• CC-40 V

is < 75 dB(A).

04/2012 4 - 4

Page 24

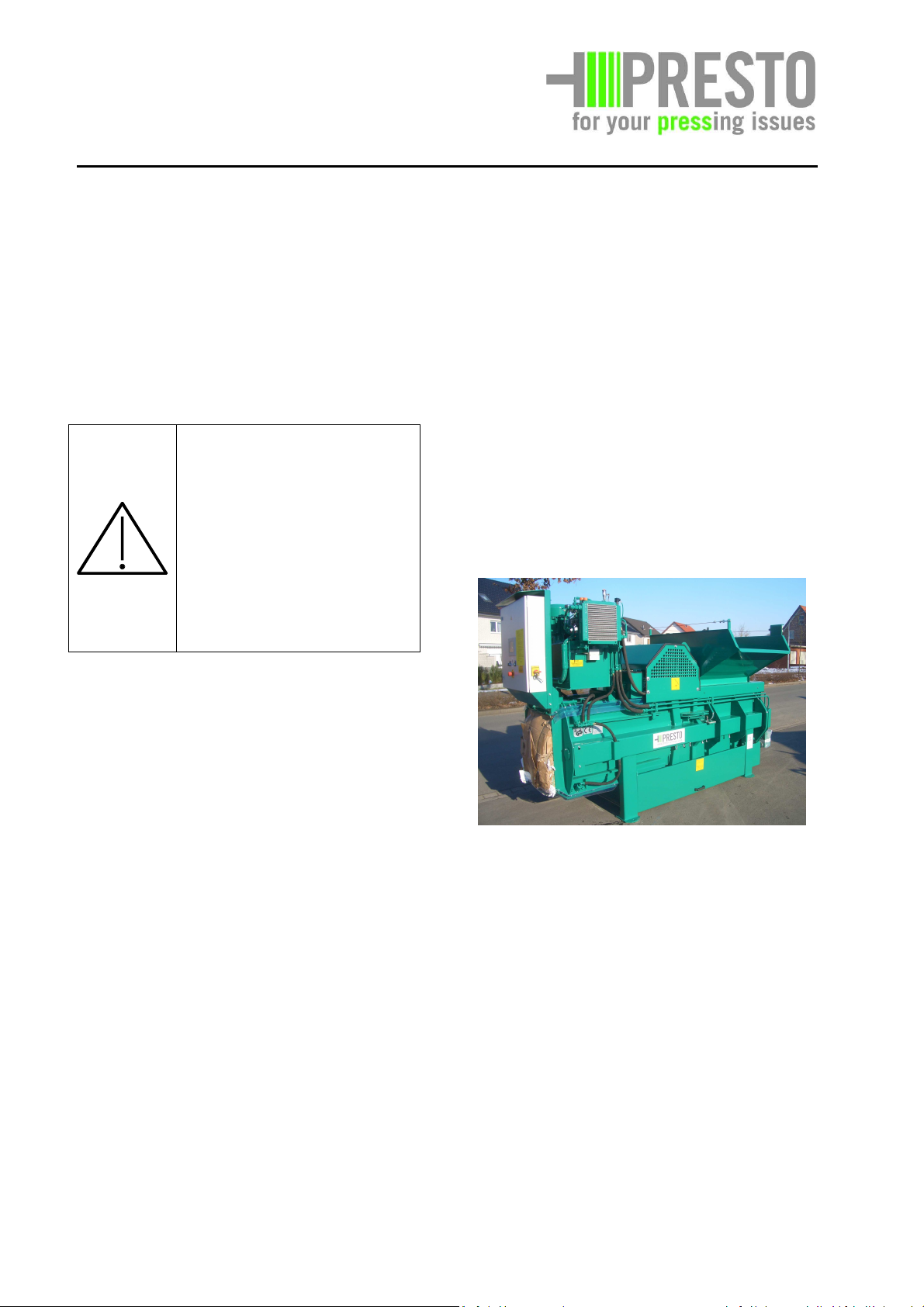

5. Constructive description

Glowing or burning particles must not be

loaded.

5.1. General

For a better representation of the components

we have dispensed with protective covers in

some cases.

Danger!

Before taking the unit into

operation it has to be

ensured that all protective

covers, flaps or sheets have

been duly mounted. They

serve for the protection of

The channel-type baling press is controlled

by a stored program control (SPC). The

compaction of the material is effected by a

compressing die which is moved in the

pressing channel by means of a hydraulic

cylinder. According to the design the pressed

material is tied up to a bale automatically (V).

These operating instructions generally apply

for all machine types of the channel-type

baling press Conti-Compact CC-13, CC-20, CC-

30 and CC-40 V.

the staff, however, also for

the proper function of the

machine.

The PRESTO channel-type baling press has

been constructed for the compaction of soft

materials as paper, cardboard, foil, etc.

It is prohibited to load explosive or

assimilated materials or inflammable

materials (according to §1 SprengG).

When erecting the unit and taking it into

operation the guidelines of the water

household and environment protection law

have to be adhered to.

Materials that are subject to special conditions

The above illustration only shows machine

type CC-20V.

In case of constructive deviations this is

stated extra. In order to simplify matters the

operating instructions refer to the channel-

type baling press.

for the disposal according to the waste disposal

law must not be loaded.

Furthermore it is prohibited to fill in rumble,

timber or other bar racks from metal or other

hard materials.

04/2012 5 - 1

Page 25

PRESTO

GmbH & Co. KG

Bad Laer

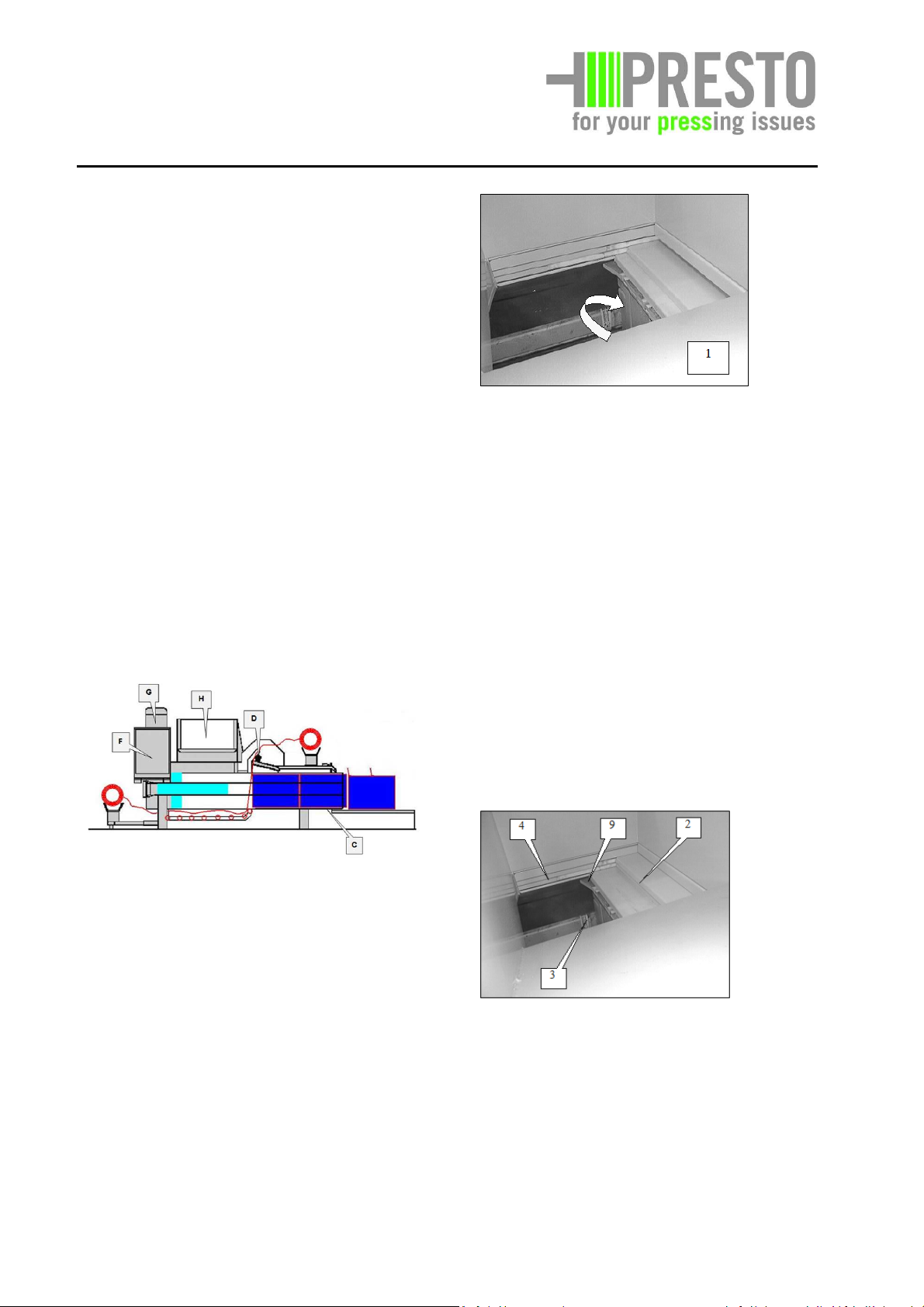

5.2. Basic construction

The basic construction is a steel construction

and, on the whole, it is the housing (A) for the

following components:

• the compressing unit (see section 5.3),

• the channel adjustment (C),

• tie-off device (D) with cover,

• the electrical unit (E), with

• the stored program control - SPC - (F),

• the hydraulic unit (G),

• the funnel with (H) safety circuit.

The components cannot be shown completely

in the following illustration. However these will

be dealt with more thoroughly in the individual

sub-chapters 5.3 to 5.7.

Baling channel with press body (1),

Telescope sheets (2),

Polyamide guide rails (3) for the press body,

Polyamide guide rails (4) for the telescope

sheets,

Hydraulic cylinder (5), see hydraulic unit,

Channel adjustment sheets (6) with

tightening elements (7), and plate for bale

rest.

The press body is moved in the baling

channel by means of two hydraulic cylinders.

The movement of the press body is guided

by polyamide rails. Telescope sheets, which

protect the space behind the press body

against material falling into it, are pulled out

during the pressing movement.

5.3. Compressing unit with channel

adjustment

This assembly is responsible for the compaction

of the material filled in the charging opening.

The assembly mainly consists of the following

components:

04/2012 5 - 2

Knives (9) are provided at the upper side of

the press body or the underside of the

channel entrance. At their cut edge the

knives cut the material filled in. They prevent

the pressure build-up on the upper side of

the press body and thus avoid excessive wear

at the polyamide guide rails.

Page 26

PRESTO

GmbH & Co. KG

Bad Laer

The material to be compacted is pushed into a

narrowing channel. The narrowing avoids that

length has been achieved, serves to tie up

the bale.

a back pressure is building up. A retaining

device avoids the compacted material from

getting back into the pressing channel.

Retaining device – on both sides

Four hydraulic cylinders are mounted at the

channel outlet.

5.3.1. Hydraulic channel adjustment

The material to be compacted is pushed into

a narrowing channel. Channel narrowing

causes counter-pressure to build up. A

retaining device (10) is used to keep the

compacted material in the press chamber

(see page 5-4).

Cylinder for hydraulic adjustment

As extra equipment the installation of a

hydraulic channel adjustment is possible. You

will find the corresponding description in

chapter 5.3.1.

Retaining device – from the inside.

While the compressing process starts, tie-up

material is fed by several rollers on the one

side of the forming bale. While the bale grows

both in volume and length tie-up material is

pulled over and under the bale. This tie-up

material later on, after the requested bale

04/2012 5 - 3

Page 27

PRESTO

GmbH & Co. KG

Bad Laer

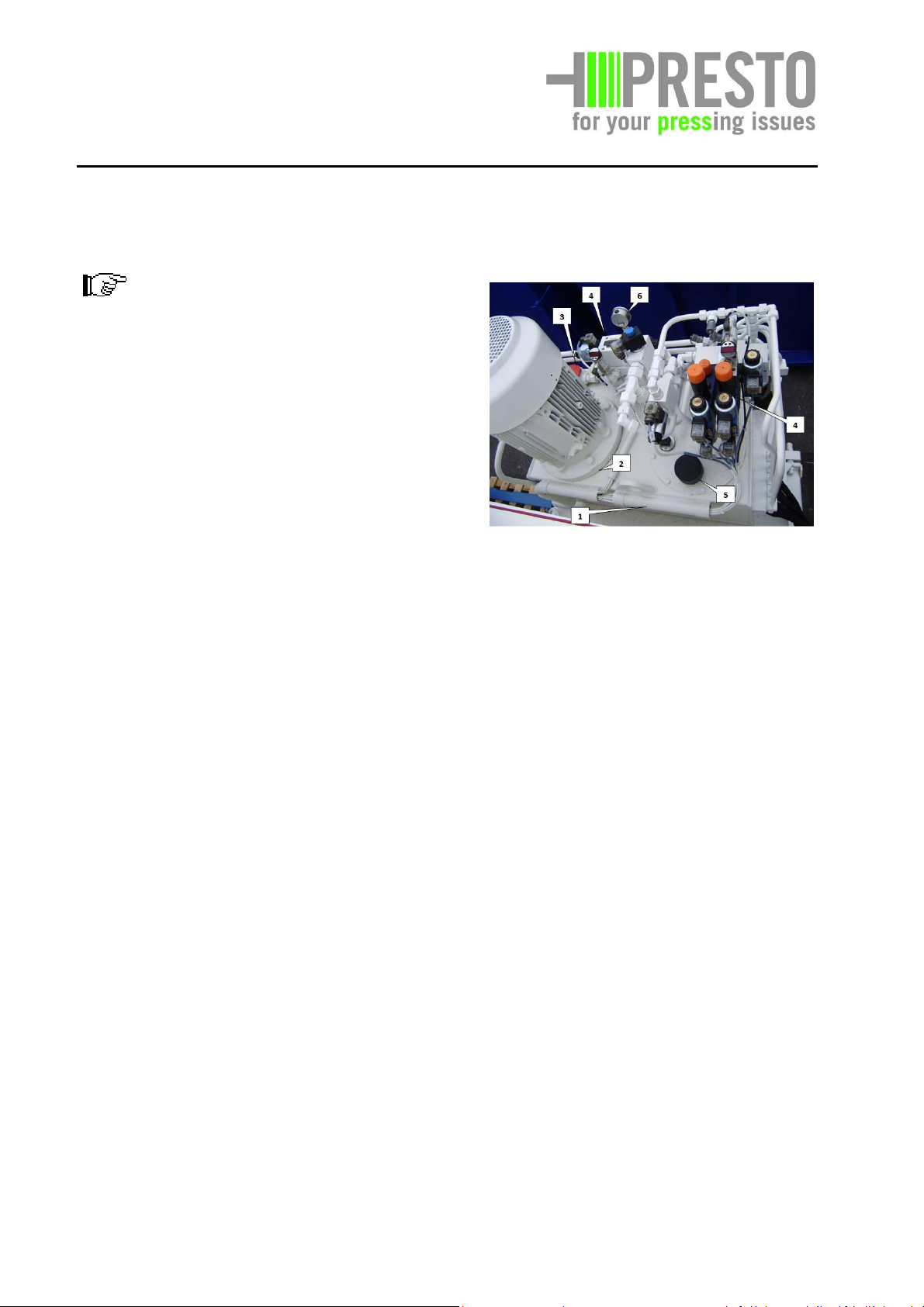

5.4. Hydraulic unit

The assembly "Hydraulic unit" mainly

consists of the following components:

The hydraulic unit of the channel-type

baling press generates heat that has to be

dissipated by the customer by corresponding

ventilation and/or waste air openings.

If the machine is erected in rooms with a

permanent temperature of more than 30° C

the installation of an oil cooler might be

necessary. Our sales or service department will

be glad to advise you correspondingly.

The assembly "Hydraulic unit" is responsible to

provide the hydraulic pressure which is

required for the compaction of the filled in

material.

(1) aggregate (hydraulic part)consisting of

the hydraulic pump in the hydraulic tank (2)

and filter unit (3 ), valve block (4) ,

exhauster (5), pressure gauge (6).

The electrically driven hydraulic pump, gear

pump design, provides the hydraulic unit with

the required operating pressure. A valve has

been installed as an overload protection which

protects the hydraulic unit against excessive

pressure.

04/2012 5 - 4

Page 28

PRESTO

GmbH & Co. KG

Bad Laer

• Switch - lack of oil/temperature (9).

Switch-lack of oil

• Two hydraulic cylinders (7),

• Hydraulic lines (10),

• Temperature display (8) – optional

8

The hydraulic pump of the aggregate cannot

be illustrated because it is positioned in the

hydraulic tank.

04/2012 5 - 5

Page 29

PRESTO

GmbH & Co. KG

Bad Laer

5.5. Electrical unit

The electrical works may be

carried out by an authorised

qualified electrician only!

Bauseitige Voraussetzung zur Installation der

Kanalballenpresse ist 400V und 50 Hz.

Type CC-13

Anschluss 3L, PE, 400 V, 50 Hz,

5,5 kW, Drehstrom

Netzanschlussleitung 4 x 2,5 mm2

Gummischlauchleitun

g

FI-Schutzschalter: 30 mA

Vorsicherung: 16 A, träge Sicherung

nach DIN 49462/63

Type CC-20

Anschluss 3L, PE, 400 V, 50 Hz,

7,5 kW, Drehstrom

Netzanschlussleitung 4 x 6 mm2

Type CC-40

Anschluss 3L, PE, 400 V, 50 Hz,

15 kW, Drehstrom

Netzanschlussleitung 4 x 10 mm2

FI-Schutzschalter: 30 mA

Vorsicherung: 35 A, träge Sicherung

nach DIN 49462/63

The a.m. fuse protection and FI-switches

must be observed even if larger plugs with

adapters are used.

Attention!

It is absolutely necessary to

ensure the correct rotation

of the electric motor. A

short time reverse run will

destroy the hydraulic pump.

The motor is running correctly when the

ventilator wheel at the electric motor rotates

in the direction of the arrow on the housing.

As the pump runs without oil flow in case of

wrong rotation, the motor may only be

FI-Schutzschalter: 30 mA

Vorsicherung: 32 A, träge Sicherung

nach DIN 49462/63

Type CC-30

turned on for a very short time (5 seconds as

a maximum).

The assembly "Electrical unit" controls the

machine and supplies it with electrical

energy.

Anschluss 3L, PE, 400 V, 50 Hz,

11 kW, Drehstrom

Netzanschlussleitung 4 x 10 mm2

FI-Schutzschalter: 30 mA

Vorsicherung: 35 A, träge Sicherung

nach DIN 49462/63

04/2012 5 - 6

Page 30

PRESTO

GmbH & Co. KG

Bad Laer

• Switch box (1) with relay (2) motor

protection switch (3), fuses (4) and

operating elements, stored program

control (5) and wiring,

B33

• Limit switch, press in front (B33)

B31

• Limit switch, press backwards (B31)

See fig. “Overview limit switches”, page 5-8

04/2012 5 - 7

Page 31

PRESTO

View from the right sight of the machine

View

from the

lef

t sight of the machine

GmbH & Co. KG

Bad Laer

Overview limit switches

B30 Puls generator bale length

B31 Stop position press backwards

B33 Stop position press in front

B34 Stop position needle down

(left side)

B35 Stop position needle down

(right side)

B36 Stop position needle up

B37 Puls generator drill

04/2012 5 - 8

Page 32

PRESTO

GmbH & Co. KG

Bad Laer

5.6. Tie-off device

5.6.1. Fully automaticl tie-off device

The assembly of the manual tie-off device

consists of the following components:

• Pulse generator (B37), drill

Drill and cutting device (15),

• Pulse generator (B30), bale length

• measuring wheel bale length (16)

See fig. “Overview limit switches” page 5-8

You will find information with regard to

maintenance and care in chapter 7.

Limit switch for needle down, operation

(B35),

limit switch for needle up (B36)

See fig. “Overview limit switches” page 5-8

04/2012 5 - 9

Page 33

PRESTO

GmbH & Co. KG

Bad Laer

If the desired bale length has been achieved

the compressing die will stop in the front final

position. The drilling discs make a half way

rotation and transport the upper wire in one

opening. The lower wire is led from the needle

as a loop upward and laid into the free opening

of the drilling disc (⇒). After a number of

rotations of the drilling disc the drilling process

is finished with a return rotation and the

subsequent cutting.

Drilling disc

You will find the detailed description with

regard to the operation and the sequence of

the tie-off process in chapter 6 "Operation".

04/2012 5 - 10

Page 34

PRESTO

25

GmbH & Co. KG

Bad Laer

The assembly mainly consists of the following

5.7. Attachable funnel with safety

circuit

Attention, danger of

crushing!

Do not climb or reach into

loading opening!

Danger!

This assembly is responsible to observe the

minimum safety height of the loading opening

of 1100 mm above the loading level. The

attachable funnel becomes necessary, if the

channel-type baling press is loaded by means

of a ramp.

components

• Charging funnel with installation

material,

• Light barrier (see chapter 11 "Appendix,

special equipment")

• Safety switch.

PRESTO will adapt the attachable funnel to

the local conditions. As a rule the channeltype baling press and the attachable funnel

have to be installed at the customer's

according to the enclosed project plans.

Attention!

The installation of the funnel

may be carried out be

S2

specialists only!

You will find further information in chapter

11, "Appendix / special equipment"

(A standard funnel with revision door (25) and

safety switch (S2) is shown.

04/2012 5 - 11

Page 35

PRESTO

GmbH & Co. KG

Bad Laer

6. Operating elements and operation

6.2. Operating elements

6.1. General

The channel-type baling press has left our

plant ready for operation. Please check

stationary compression unit for damages by

visual inspection and function test and

inform your forwarding agent immediately

about possible complaints.

Works at/with the unit may

only be carried out by

instructed, reliable staff

and/or by experts.

In general the function and operation of all

types of channel-type baling presses is

similar. There are, however, differences with

regard to the pressing power. This results in

considerable differences in the control and

work sequence.

Prior to the commissioning make sure what

kind of channel-type baling press you use

(see type plate and chapter 4 "Technical

data").

Any accessories, which form part of the

special equipment, are described in the

following point. You will find a more detailed

description with regard to this extra

equipment in chapter 11 "Appendix, special

equipment."

This section describes the operating

elements of the channel-type baling press

CC-13, CC-20, CC-30 and CC-40 with fully

automatic tie-off device.

With respect to all types of channel-type

baling presses the essential operating

elements necessary for the operation are

located centrally in the switch box. If

applicable there might be a Button bar in the

rear area of the unit.

Switch box for channel-type baling press

Type CC-13V, CC-20V, CC-30V and

CC-40V

>> fully automatic tie-off device <<

1. Main switch

2. "Start" Button

3. Illuminated switch "Operation"

4. "Emergency-off" switch

5. Button "Press forward"

6. Button "Press backward"

7. Button "Needle up"

8. Button "Needle down"

9. Selector switch "Twisting"

10. Selector switch "Cutting"

04/2012 6 - 1

Page 36

PRESTO

GmbH & Co. KG

Bad Laer

6.3. Works prior to initial commissioning

You will find information with regard to

transport and loading in section 6.6

"Transport and loading".

First check the unit for completeness of

supplied parts. Use the enclosed shipping

documents for this purpose.

The unit may be erected by

qualified staff with the

corresponding specialized

knowledge only (Explanation

see chapter 7, page 1).

Project documentation and wiring diagrams

of the manufacturer are enclosed to the unit.

The unit has to be installed and connected

according to these plans.

Place unit on a plain base. The base must be

capable of bearing the unit permanently. It

must be possible to screw the legs of the unit

with the base. In order to fix the unit you

should use heavy-duty dowels and

corresponding screws (see enclosed project

documentation).

For detailed description of adjustment

possibilities of the touch panel see page

6-11.

Leave sufficient space around the machine as

shunting area for industrial trucks.

Screw the sheet, i.e. the "bale slide" (50)

contained in the scope of supply with the

bottom side of the channel

(see fig. page 6-3).

04/2012 6 - 2

Page 37

PRESTO

GmbH & Co. KG

Bad Laer

In case of fire in the switch box

only use fire extinguishers

permitted for this purpose. NO

WATER!

Prior to the initial

commissioning the

operator of the unit must

have read and understood

A qualified electrician has to

provide and to check the

correct electrical connection.

Doing this the relevant VDE

regulations and/or the

regulations of the country

where the unit will be used

have to be observed.

Furthermore the wiring

diagrams of PRESTO have to be

observed.

When erecting and taking the unit into

operation the guidelines of the

environmental protection law and the water

household law have to be adhered to.

Carry out the following checks now:

• See to it that it is not possible to damage

the mains connection by running over,

crushing or dragging.

• check all hydraulic lines and screwing for

tight fit and obvious damages..

• Check whether all screwed connections

were properly tightened.

• Check the electric installation.

• Check function of all protective devices

(see chapter 7). Never bring into

commission without all security devices

working perfectly.

Carry out the following works every day

before taking the unit into operation:

• Visual inspection for obvious damages at

mechanical or electrical components. It is

prohibited to take the unit into operation

if one protective device does not work

properly.

• Check the protective devices in chapter 7

for correct function.

• In case of strong pollution the unit has to

be cleaned. Prior to cleaning put main

switch into "0" position and secure with a

padlock against unauthorised

intervention. Close and lock all protective

covers or doors or inspection flaps after

the cleaning.

• Check whether there is sufficient binding

wire on the coils.

• All further regular works have to be

carried out according to the maintenance

plan.

the operating

instructions.

It is possible to stop the

unit immediately in case

of danger by pressing the

emergency-off switches.

04/2012 6 - 3

Page 38

PRESTO

GmbH & Co. KG

Bad Laer

6.4. Compacting process

Attention! Danger of

crushing!

Never climb into charging

opening while the channel-

type baling press is in

operation.

Operation mode "Manual"

This operation mode is normally intended for

maintenance and repair works.

The unit is ready to use, i.e. the safety switch

is unlocked, the covers are closed.

Ensure that no persons are endangered.

• Switch on main switch, press button

operation, light “operation” is lighting.

• Put operation mode selector switch into

"Manual" position

• Press "Start" Button, the hydraulic pump

starts up.

• Move selector switch "Press

forward/back" into desired direction and

keep as long as the press is to be moved.

When running forward care has to be taken

that in the front final position there is not

cut-off by the limit switch. Observe the

pressure gauge. If the press is drawn back

manually the rear limit switch cuts off the

valve automatically when having reached the

limit switch.

Operation mode "Auto"

See to it that no persons are

endangered by the operation

of the unit!

For the fully automatic tie-off device you

should use coiled binding wire. In order to

safeguard a proper function you should use

binding wire which you can acquire through

our service department.

Properties:

• Binding wire for CC-13V and CC-20V on a

20 kg-coil, patent coiling, 2.8 mm

diameter, close annealed and oiled.

• Binding wire for CC-30V and CC-40 on 40

kg-coil patent coiling, 3.1 mm diameter,

close annealed and unoiled.

04/2012 6 - 4

Page 39

PRESTO

GmbH & Co. KG

Bad Laer

• The length of the bale permanently

Note:

Always use binding wire with the a.m.

properties. Binding wire that does not

increases. It is continuously collected by

the pulse generator and indicated.

correspond to the specification may lead to

trouble in the work sequence. You will find

the part numbers in chapter 10, spare parts.

• Throw the material into the charging

funnel. Fill the shaft up to slightly above

the counter knife.

6.4.1 Operation mode "Manual"

General

The manual operation modes

described in the following

assume that the operation

Make sure that no pressing strokes are

effected if the filled in material is not slightly

above the counter knife.

• Check whether there is sufficient binding

wire on the coils.

• Put operation mode selector in "Auto"

position.

• Switch on main switch, press "Operation"

key. The flashing of the control lamp

indicates the readiness for operation of

the unit.

• Press "Start" key (4). The unit starts up

and starts compressing.

• If the funnel has been filled up with

sufficient material and the compressing

die is in its end position, the machine

starts automatically via the installed light

• Switch on main switch, press button

operation, light “operation” is lighting.

• Put operation mode selector switch into

"Manual" position

• Press "Start" Button, the hydraulic pump

starts up.

• Move selector switch "Press

forward/back" into desired direction and

keep as long as the press is to be moved.

mode selector switch is put in

"Manual" position. The

operation mode "Manual"

has to be used for the

threading of a new binding

wire and for maintenance,

repair and adjustment works.

barrier.

The unit will check after the start

whether the compressing die is in the

rear position. The compressing die returns to

the back limit position and the pump is

switched off.

04/2012 6 - 5

Page 40

PRESTO

GmbH & Co. KG

Bad Laer

Needle upward / downwards

Condition: The final limit switch (B33)

"Press in front" is actuated. This is the case

when the compressing die is in the front final

position.

Needle from the "operating position" to

"threading position"

Conditions: The needles are in the basic

position, i.e. the limit switches "needle at the

bottom" (B34/B35) are actuated. The

compressing die is in the rear limit position,

i.e. the limit switch (B31) "Press at the rear"

is actuated.

B33

• Press key "Needle up" and hold. The

valve for” Needle up” is switched on as

long as the key is pressed.

The needle runs through the

compressing die upward until the limit switch

"needle up" (B36) switches. If the hydraulic

cylinder for the needle has fully extended and

if the switch is further kept in "needle

upward" position the pressure at the

hydraulic cylinder will increase to the

maximum pressure of 130bar.

Needle down

• Press key "Needle up" (7a) and hold.

The needle moves downward until the

limit switches "needle at the bottom" switch.

B31

• Press key (7b) "Needle down". This

process takes about two seconds.

The needle moves into the lowest

position, i.e. up to the limit stop. The

threading position has been reached. The

compressing die cannot be moved now. A

new lower wire can be threaded in now.

04/2012 6 - 6

Page 41

PRESTO

GmbH & Co. KG

Bad Laer

eading position" to

"operating position"

Twisting

• Press key "Twisting" (8a) and hold.

Conditions: The needles are in threading

position, i.e. the limit switches "needle at

the bottom" (B35) are not actuated. The limit

switch “Needle in threading position” (B34) is

actuated. The compressing die is in the rear

limit position, i.e. the limit switch (B31)

“press at the rear" is actuated.

• Press key (7b) "Needle up".

The drilling disc carries out a half

rotation. The pulse generator simultaneously

switches "Drill" (B37). Thereby the wires are

not cut.

Cutting

• Press key "Cutting" (8b) and hold.

The needle drives forward up to the

limit switch "needle at the bottom"

(B34/B35). The needle is in basic position.

The compressing die can be moved again.

The drilling disc carries out a half

rotation anticlockwise when drilling. The

cutting-off will not yet be made. The cuttingoff is possible when the cutting-off device is

held by the stop. The wires are cut off after a

new actuation of the key "Cutting" and a half

rotation of the drilling discs.

04/2012 6 - 7

Page 42

PRESTO

GmbH & Co. KG

Bad Laer

Visible only right side of the machine

04/2012 6 - 8

Page 43

PRESTO

GmbH & Co. KG

Bad Laer

Adjustment of pressing power

As a standard design the unit of CC13V and

CC20V are supplied with manual channel

adjustment. Optionally a hydraulic channel

adjustment with control can be supplied. You

will find the description of the hydraulic

channel adjustment in chapter 11.

The pressing power depends on the

backpressure of the material in the channel.

In order to achieve this back pressure the

cross section in the direction of the channel

outlet becomes smaller.

The back pressure of the material depends

on the following factors:

• Coefficient of friction of the channel walls

which slightly reduces after the runningin period of the unit,

• Coefficient of friction of the material to

be compacted. This can vary very strongly

(e.g. relatively high with respect to

cardboard and relatively low in case of

foils),

• The fill height in the fill in funnels by the

start of the press procedure. The fill in

funnels must be filled up to the upper

edge of the press body with material at

least, so that the channel discharge is

filled evenly.

• Adjustment of the tensioning elements

(10) on both sides of channel outlet

which must be changed especially during

the running-in period and in case of

material change.

The adjustment is correct if during the

forward stroke phase approx. 140 - 160 bar

are indicated at the pressure gauge. For this

reason the pressure gauge has to be

observed as a rule after material changes.

04/2012 6 - 9

Page 44

PRESTO

GmbH & Co. KG

Bad Laer

Attention!

Never fall short of the measurement of 65

mm (the spring package is almost completely

pressed together).

04/2012 6 - 10

Page 45

PRESTO

GmbH & Co. KG

Bad Laer

Adjusting the compaction pressure

hydraulically

The compaction pressure depends on the

counter-pressure of the material in the

channel. To achieve this counter-pressure,

the channel is narrowed by means of 4

hydraulic cylinders.

The counter-pressure of the material

depends on the following factors:

• Coefficient of friction of the channel

walls, which decreases slightly during the

plant running-in period;

• Coefficient of friction of the material to

be compacted, which varies highly (e.g. it

may be relatively high for cardboard

packaging and relatively low for plastic

films).

• The fill height in the fill in funnels by the

start of the press procedure. The fill in

funnels must be filled up to the upper

edge of the press body with material at

least, so that the channel discharge is

filled evenly.

6.4.2.1 Adjust bale length, twist

The unit must be switched on

during these adjustment

works. Therefore ensure that

no persons are endangered

during your activities. Visibly

fix a sign in order to point to

the adjustment works. Any

other procedure will be

pointed out extra.

Adjusting bale length (8)

Factory adjustment: 20

Potential range of adjustment:

13 counting pulses = about 0.65m

50 counting pulses = about 2.5m

(One counting pulse corresponds to about

0.05m)

If you want an adjustment that differs from

the factory value, proceed as follows:

04/2012 6 - 11

Page 46

PRESTO

GmbH & Co. KG

Bad Laer

6.5

Control- and programdiscription

Options

Main menu

Fig. 1: Main menu

Navigation and adjustments with Touch

Panel

With the button „Menu“ in the starting

picture you get to the window „main menu“.

In the main menu of the press different

menu entries can be chosen, e.g. show

„machine-data“. Adjustments can be edited

after entering a password in the menu entry

„settings“ (see “Settings”).

Key assignment in main menu:

F1-> display help

F2-> user login

F3-> language choice

F4-> show message buffer

F5-> lamp test

F6-> standard picture press

Fig. 2: Options

Pressing the button „Options“ the window

will open. Additional control and display for

the control of the conveyor (if existent) can

be found here.

A pre-selector for the limit position

disconnection of the compactor decides

whether the ram stops in front or rear

position after pressing.

Machine Data

Fig. 3: Machine data

Following menu entries can be found in

„machine-data“: bale counter, daily bale

counter and the graphics of the pressure at

the moment (shown in “bar”). The bale

counter indicates the total sum of wired

bales. The daily bale counter counts the

bales and can be reset to “0” after entering

the password.

04/2012 6 - 12

Page 47

PRESTO

GmbH & Co. KG

Bad Laer

Pre-selection pressure level

Menu Settings

Fig. 4: Preselection pressure level

With menu entry „pre-selection pressure

level“ the desired pressure level for the

material can be chosen. The values for the

different pressure levels are edited

separately in the menu „settings“.

Language choice

Fig. 5: Language choice

The menu entry „Language choice“ can be

activated out of the main menu or settings

menu.

Fig. 6: Settings

Via „main menu“ you get into the menu

entry „settings“ after entering the „User“

password (see entering password).

With the suitable function key you reach

further settings such as „time setting“ and

„system settings“. „System settings “ are

protected with a „PRESTO“ password (*see

entering of password).

Key assignment

„Settings“:

F1-> display help

F2-> login user

F3-> language choice

F4-> time settings

F5-> system settings

F6-> main menu

04/2012 6 - 13

Page 48

PRESTO

GmbH & Co. KG

Bad Laer

Entering the password

Setting of material pressure levels

Fig.: Entering the password

Some of the menus and functions are

secured with a password. Whenever a

password is needed, a window opens to

enter the password. Authorization is effected

by login of the user and the password.

Basically there are two levels of passwords.

First the „USER“ password level which is for

the operator and secures operation of the

press as well as settings of modification by

unauthorized persons. The second password

level „PRESTO“ secures system settings of

modifications by unauthorized persons and is

intended for the service technicians.

To login user and password the entry field of

the login screen has to be actuated (see fig.

password inquiry). The password or the user

name can now be entered with the touch

screen and has to be confirmed with enter

(fig.: entering password). The USER password

is „100“.

Next the user name and the password have

to be confirmed with the button „OK“ (see

fig.: Password inquiry). If the password is

correct the user has access to all

corresponding menu entries and functions.

Unless an error message appears.

Fig.: Pressure level „High“

Fig.: Pressure level „Middle“

Fig.: Pressure level „Low“

The values have to be set separately with the

corresponding buttons in the menu “settings.

Following pressure stages according to the

material:

Pressure level „High“ = Material: corrugated

board, paper, cardboard or similar.

Pressure level „Middle“ = Material: PET, PETbottles or similar.

Pressure level „Low“ = Material: Foil or

similar.

04/2012 6 - 14

Page 49

PRESTO

System

time

Input fields

GmbH & Co. KG

Bad Laer

Following values can be set:

Bale length 13 – 50 (1 = ca. 5-

6 cm.)

Half twist turnings 11 – 18 (1 = ½

twists)

Half backstroke in sec. 4 – 20 sec.

Relief pressure „nominal“ in

bar

Channelpressure „nominal“

in bar

10 – 260 bar

10 – 250 bar

System settings

Button „View right/left“

(press to choose)

Shut down

Touch Panel

Time setting

Button „Entering Input“ (press

longer than 1 sec.)

Whenever the time set does not correspond

to the actual time, time and date can be

changed via menu entry „time setting“..

Button „funnel door

yes/no“ (press to

choose)

Contrast

regulation

System settings include internal settings of

the touch panel and can only be modified

from our service technicians (fig.: system

settings).

04/2012 6 - 15

Page 50

PRESTO

Threading position

Operating position

Threading example for the lower wire for CCV

GmbH & Co. KG

Bad Laer

6.6 Insert binding wire coils

Inserting the lower wire

Loading the wire containers or the large roller stations with wire.

Master switch ON (13)

Selector switch to „Manual“ (8)

Press Operation button (9). System is ready for operation.

Press Start button (1). Electrical motor and hydraulic pump (20) are running.

Pressing ram backwards (button 3b). Press and hold button “ram backwards”. Ram

moves backwards until end position (B31) is reached and valve is closed.

Needle in threading position: Pressing ram must be completely retracted; press the

Needle down button (4b). Needle moves down and stops in Threading position

(only B34).

Pulling in the wire Straight align the wire and pull in.

1 through the spring winding at the end of the press

2 through the drill bushes at the rear support legs

3 through the needle profile above the needle head

4 pull wire through to the end of the channel

04/2012 6 - 16

Page 51

PRESTO

2

3

4 1

wheel

GmbH & Co. KG

Bad Laer

Retract needle to operating position. Pressing ram is retracted (rear). Press and hold the

Needle up button (4a). Needle moves up and stops in the Operating position (B34 + B35).

Inserting the upper wire

a) Pull the wire through the wire deflection pulley as shown below. Push the wire as far

as possible through the opening in the press shaft

b) Close all doors/covers

c) Select Automatic operating mode (8)

d) Press Operation button (9).

e) Perform approximately 2 – 3 press operations with the material until the upper wire

is tight.

f) During the subsequent extension of the pressing ram, rotate the bale length wheel

(B30) until Binding is indicated on the Touch panel (or if existent the light signal

Binding flashes).

Bale length

Binding signal

04/2012 6 - 17

Page 52

PRESTO

GmbH & Co. KG

Bad Laer

Once the binding process is completed, check the quality of the connection of the upper

and lower wire above the knotting device; make some improvements, if necessary (the

pre-tensioning of the wire, which occurs during normal operation, has not been applied

yet)

Good knot

Knot too loose

The processes 12 and 13 have to be carried out together at least twice with the

operating personnel.

04/2012 6 - 18

Page 53

PRESTO

GmbH & Co. KG

Bad Laer

6.7 Transport and loading

Before the transport and loading work take

place the following accident prevention rules

have to be adhered to:

BGV D8 Gear, lift- and draft devices

BGV D6 Load bearing facilities

BGV D27 Ground conveyors

BGV D29 Motor vehicles

BGV A8 Safety labelling at the

workplace

Remove transport safety devices and

handling systems

See to it that no persons

stay under the suspended

load.

Connect unit to the mains before taking the

unit into operation again.

Use corresponding lifting devices and proper

securing measures (for information

concerning the maximum permissible weight

see type plate or chapter 4 "Technical data"

in these operating instructions).

Lift device at the intended

lifting points only. Secure

load against unintended

changes of the position.

Separate unit from every external energy

supply also in cases of a slight change of the

position!

Parts that are removed for transport

purposes have to be mounted and fixed

before taking the unit into operation again!

04/2012 6 - 19

Page 54

PRESTO

GmbH & Co. KG

Bad Laer

Using a forklift truck

Adhere to accident prevention rules BGV D27

and D29. Empty the unit completely.

• Separate unit from mains and place

supply cable on the unit bound together.

• Disassemble all projecting parts or lead

the tie-up material over such parts.

• Only drive under bearing frame parts

with forks (directly under machine

housing), never drive under needle

guide and/or hydraulic cylinder.

Example: CC 30, Points of notice forks

• Tie-up unit on a transport vehicle by

diagonal attachment or make use of the

existing eyes.

• Disassemble all projecting parts at first

and/or do not lead tie-up material over

such parts.

Lift machine at intended loading point only

or use forks of forklift truck only at bearing

parts! See schematic view!