Page 1

1

PAP3400DUO Service Manual V1.0

Page 2

2

Contents

1. PAP3400DUO overview ............................................................................................................... 3

1.1 PAP3400DUO brief introduction ........................................................................................ 3

1.2 Function diagram ................................................................................................................ 4

1.3 Mainboard component distribution diagram ....................................................................... 4

1.4 Main IC Names ................................................................................................................... 7

2. RF .................................................................................................................................................. 7

2.1 RF Overview ....................................................................................................................... 7

2.2 RF part service analysis .................................................................................................... 11

2.2.1 Launch part ............................................................................................................ 11

2.2.2 Receive access ........................................................................................................ 12

3. Baseband section ......................................................................................................................... 15

3.1 Outline ............................................................................................................................... 15

3.2 Common Failure Analysis and Maintenance ........................................................... 17

3.2.1 Power failure Check ............................................................................................... 17

3.2.2 Audio faults ............................................................................................................ 19

3.2.3 USB serial port malfunction ................................................................................... 23

3.2.4 LCD Fault .............................................................................................................. 23

3.2.5 FM .......................................................................................................................... 24

3.2.6 Bluetooth and wifi .................................................................................................. 25

3.2.7 Camera fault ........................................................................................................... 26

3.2.8 SIM card failure ..................................................................................................... 27

3.2.9 Motor test is invalid ............................................................................................... 27

3.2.10 Triaxial Gsensor ................................................................................................... 28

3.2.11 T-Flash fault.......................................................................................................... 29

3.2.12Touch Panel function ............................................................................................. 30

3.2.13Distance sensor fault ............................................................................................. 31

3.2.14 Cannot boot failure ............................................................................................... 31

3.2.15 Auto Powe r On ..................................................................................................... 32

Page 3

3

1. PAP3400DUO overview

1.1 PAP3400DUO brief introduction

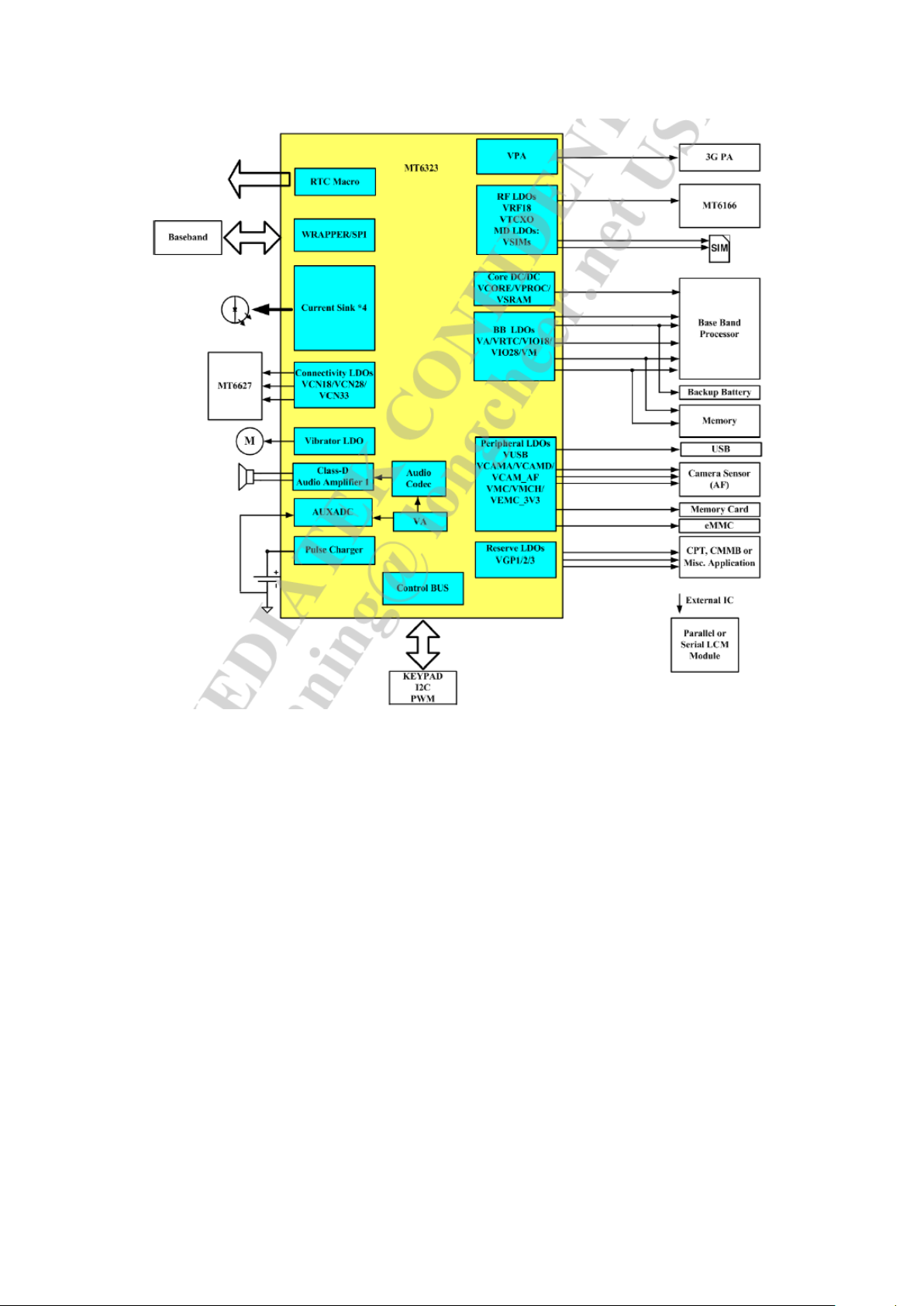

The development and design of the PAP3400DUO PCBA is based on MTK MT6572

platform. The mainboard system mainly consists of the chip

MT6572A/W+MT6166A+MT6323A, which are responsible for t hree part functions, namely,

baseband, radio frequency and power management chip. PAP3400DUO PCBA is an all-in-one

phone mainboard, w hich supports GSM, WCDMA, and covers Bluetooth, WIFI, Camera, FM

functions, GSensor and so forth.

The maintenance of mainboard is one of the important links among mobile products

rear-end producing. The speed and quality of maintenance relate to the rate of good products,

production efficie ncy, and cost control throug hout the pr oducing. In the case of a reasonable

design of product, in the end-producing, finding the significant proportion in the bad board

should be SMT bad and component incoming material ba d. So, whe n maintaining, first, start

with the two aspects. The principal means of fault diagnosis are: (1) find that bad welding spots

or components b y microscopic examination and visua l inspection; (2) guess fail ure positions

from the fault phenomena; (3) confirm the fault units by signal detection.

Page 4

4

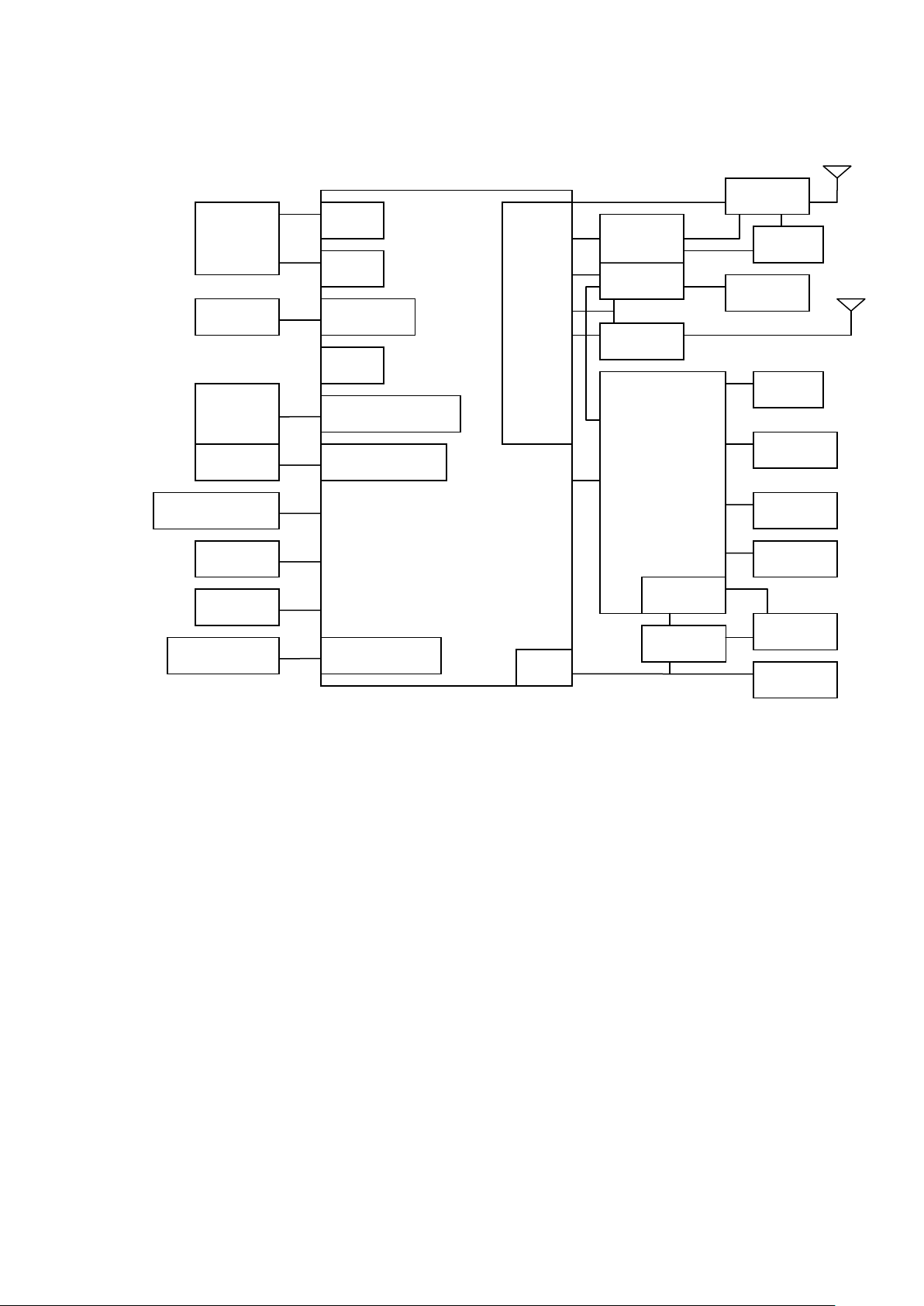

1.2 Function diagram

EMI

SPI

CAM(parallel)

LCD(MIPI)

JTAG、UART

USB

LCD

CTP

Keypad

Debug port

MT6166

FEM

Filter

26M

Charge

VIB

Memory

MCP

TF

Back

CAM

三轴 Gsensor

NFI

MSDC1

MT6572

ABB

26M

MT6627

MT6323

BJT

32K

Audio

SIM

BAT

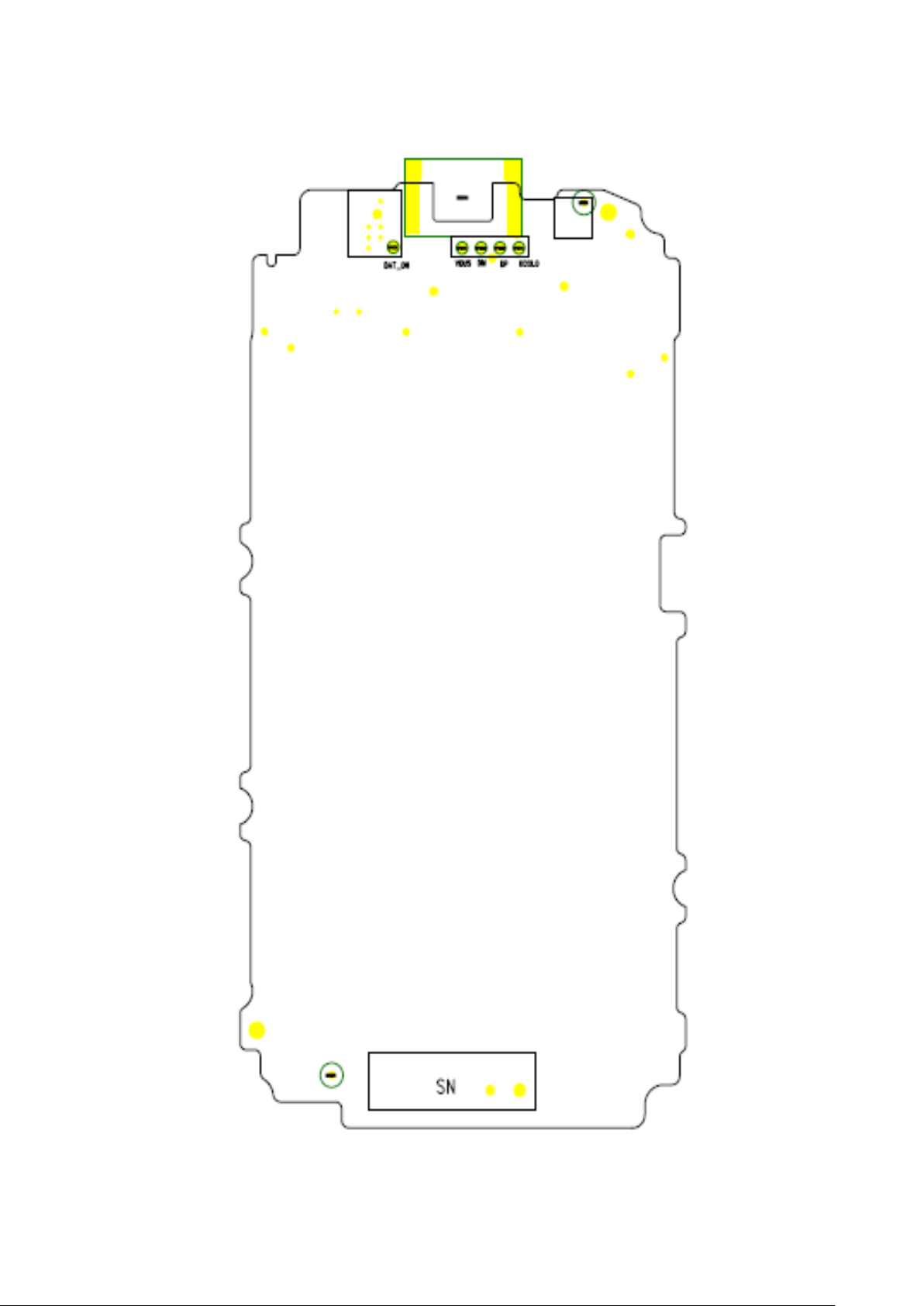

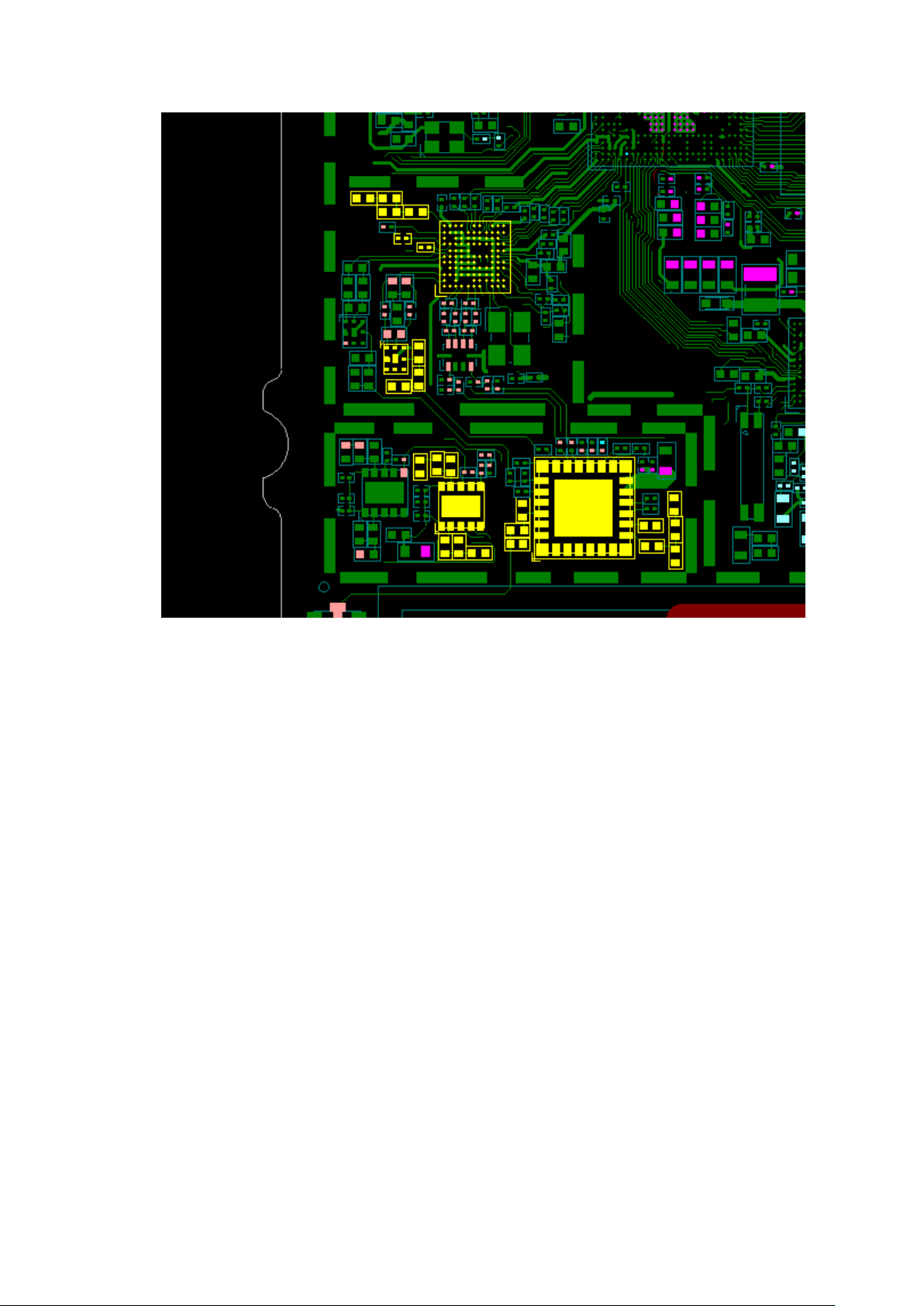

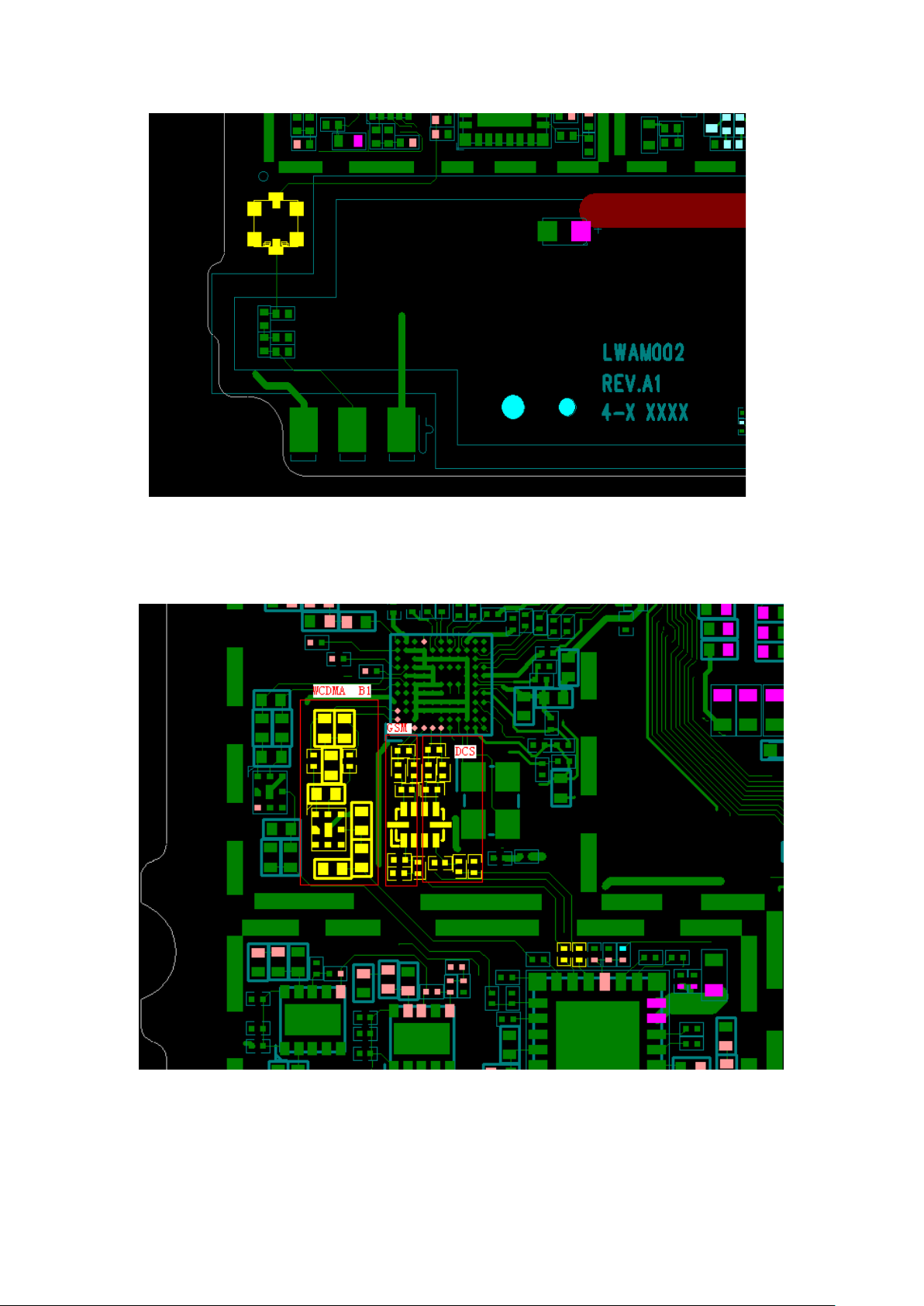

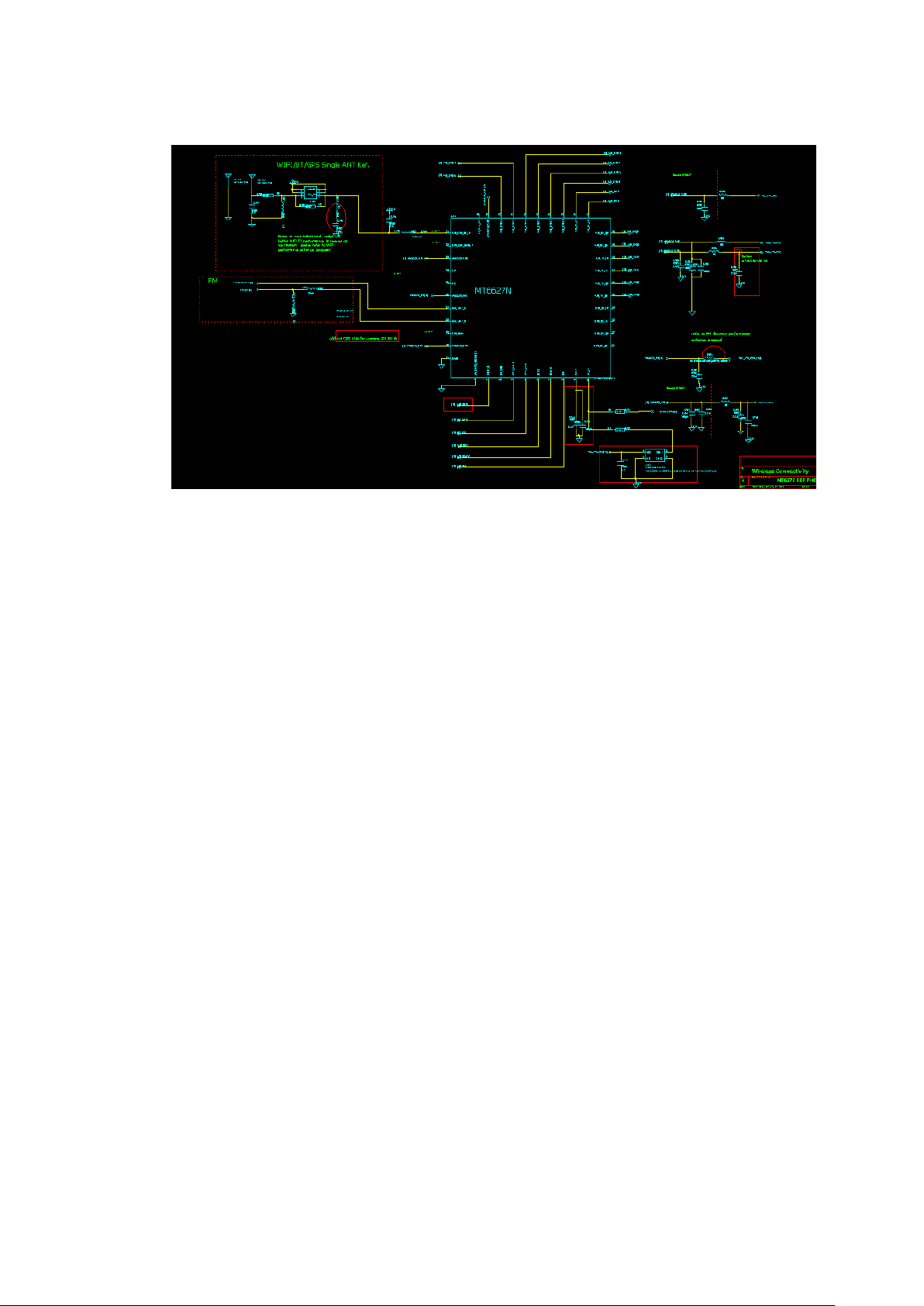

1.3 Mainboard component distribution diagram

Mainboard TOP

USB

Page 5

5

Mainboard BOTTOM

Page 6

6

Page 7

7

1.4 Main IC Names

IC,MT6572W,GSM/EDGE/WCDMA/HSDPA/HSUPA BB+AP

CHIP,1.3G,DC1318

IC,MT6323,Power Management Unit MT6323A U301

MT6572A/W U101

IC,MT6166,TD-SCDMA/HSDPA and GSM/GPRS/EDGE

dual-mode Transceiver

IC,eMMC+LPDDR2,4GB+4Gb,1.8V/3.3V,x8/x32,19ns,TLC KMN5U000ZM-B203 U402

IC,MT6627N,WIFI/BT/FM/GPS 4 in 1 MT6627N U800

IC,SY7301,40V Step-Up LED Driver, PWM control SY7301ADC U801

IC,HRPF88183B,PA+4*TRX WCDMA ASM,Tx-Rx FEM for

Quad-Band GSM/GPRS

IC,SKY77761,RF PA Module,LTE Band1/CDMA

IMT,1920-1980MHz,3x3

TRANS,PNP,30V,3A WPT2F30 U303

MOSFET,N-Channel,-40V,-180mA,4.5Ω PNM723T703E0-2 U305

Schottky diode 1PS79SB30,115 D301,D302,D801

DIODE,ZENER,5.1V,500mW PZ3D4V2H D305

32.768KHz Crystal

26MHzCrystal(3225) X1E000021043400 X600

X-CAP,3.3V,0.01mAh,Φ3.8,1.5H XH311HG IV07E GB301

MT6166A//MT6166V U600

HRPF88183B U700

SKY77761 U703

Q13MC1461000200//

Q13MC1462000200

X301

IC,MC3430,3-Axis Acceleration Sensor,Digital,8bit MC3430-I5 U1400

FILTER,BALUN,GSM,GSM850/PCS1900 OR

EGSM900/DCS1800,2012

DUPLEXER,WCDMA BAND1,

1950MHZ/2140MHZ,BALANCED,2016

RFBLN2012090BM5T25 U602

PJ D6PE2G140P3AW-Z U609

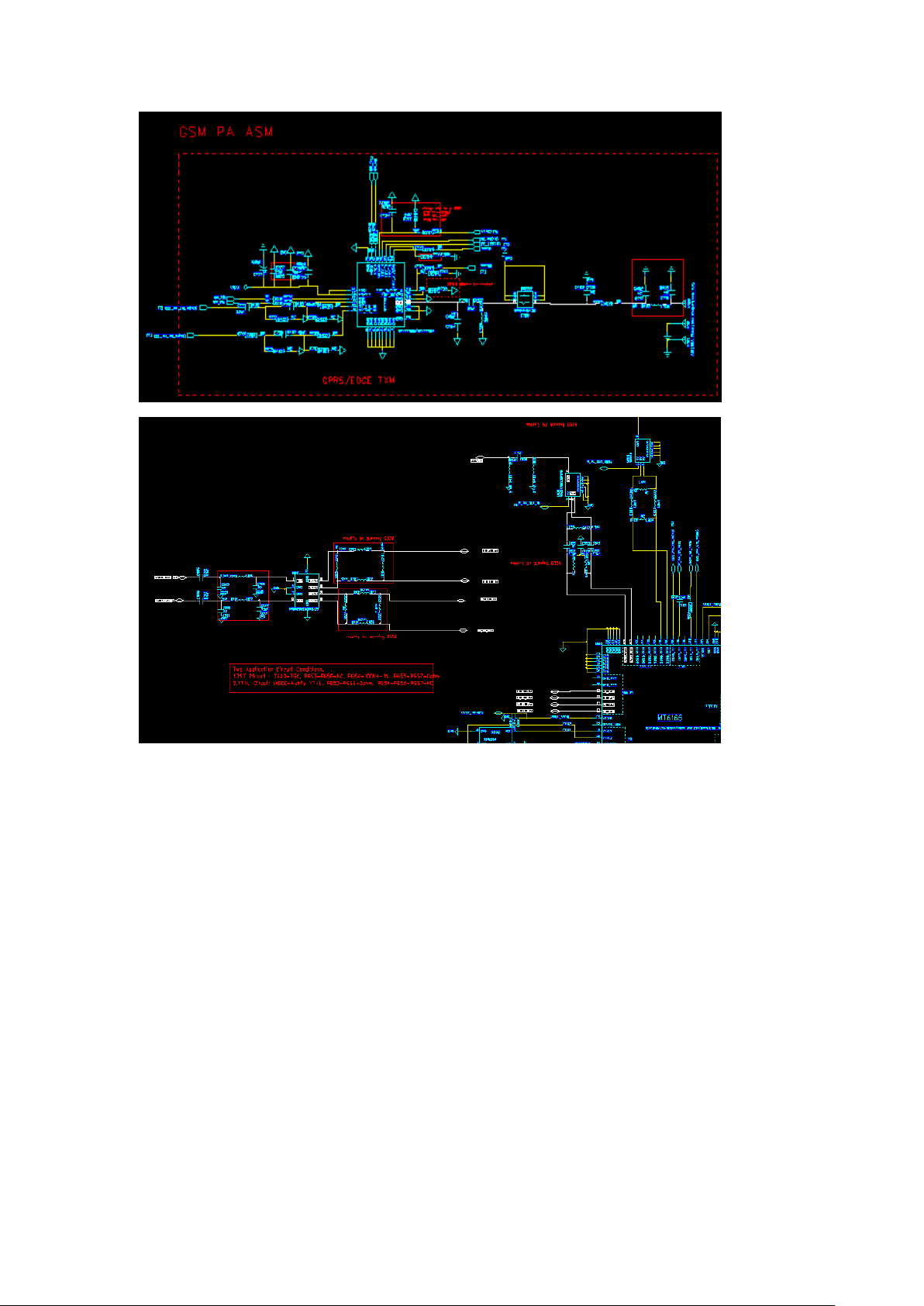

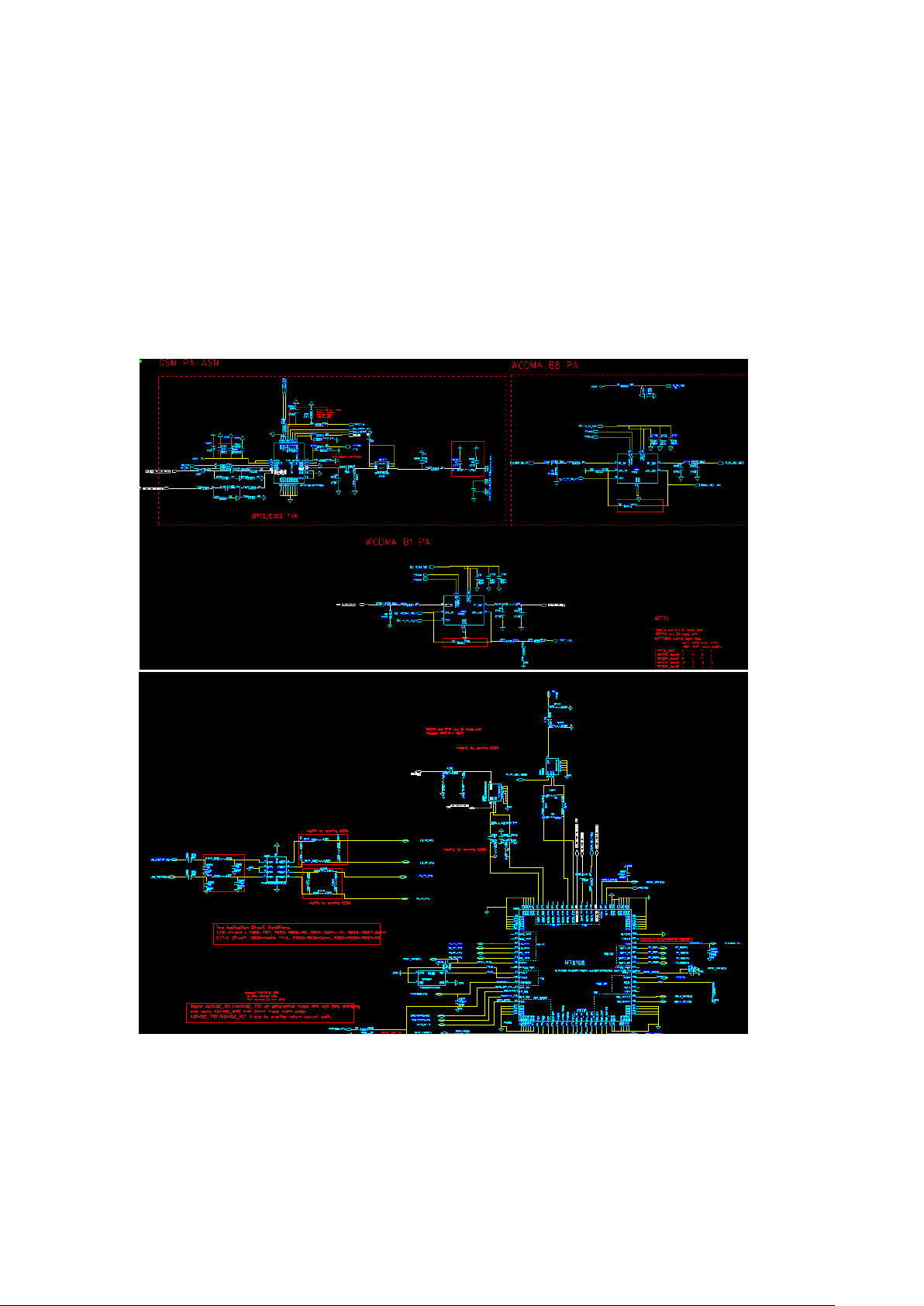

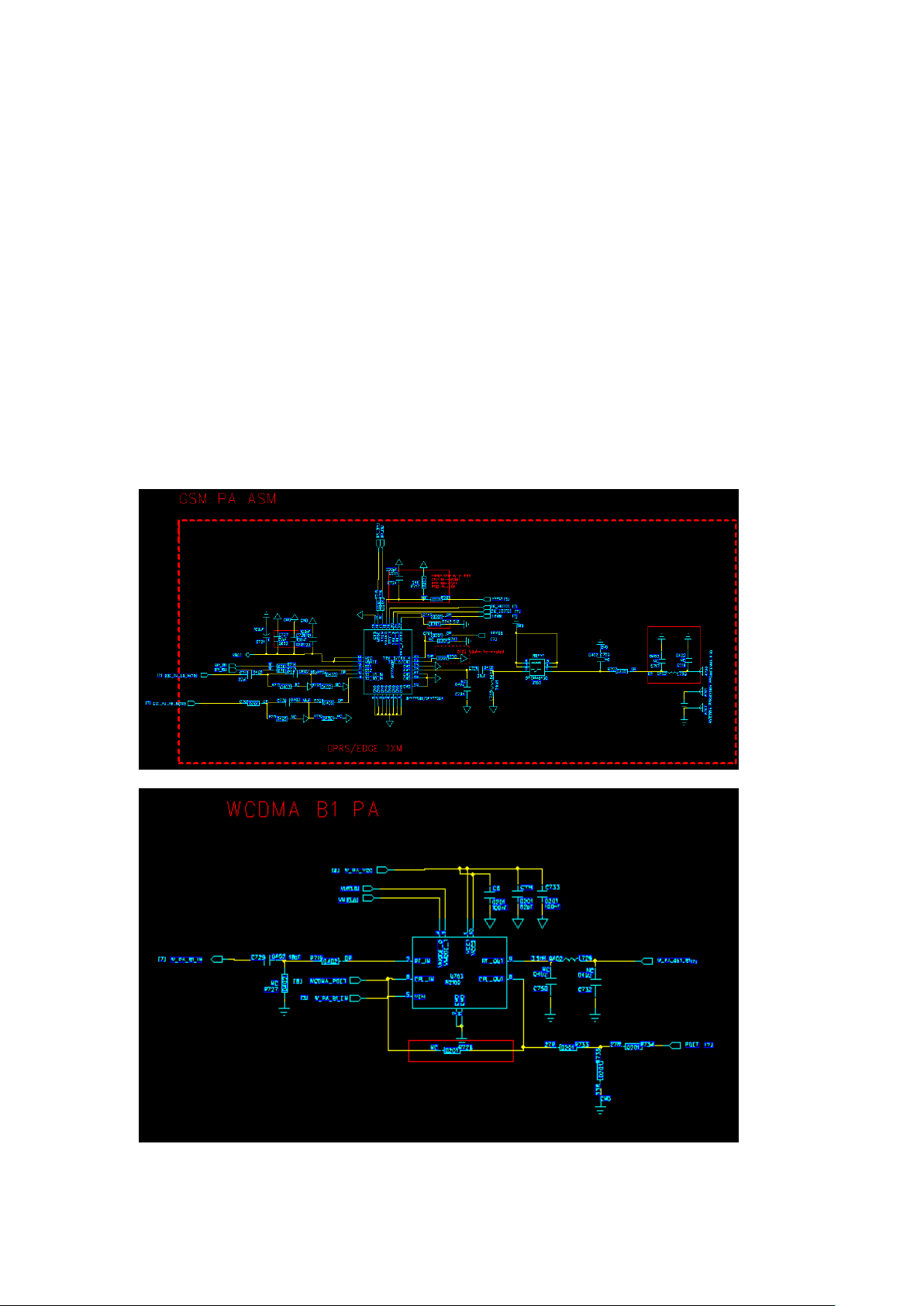

2. RF

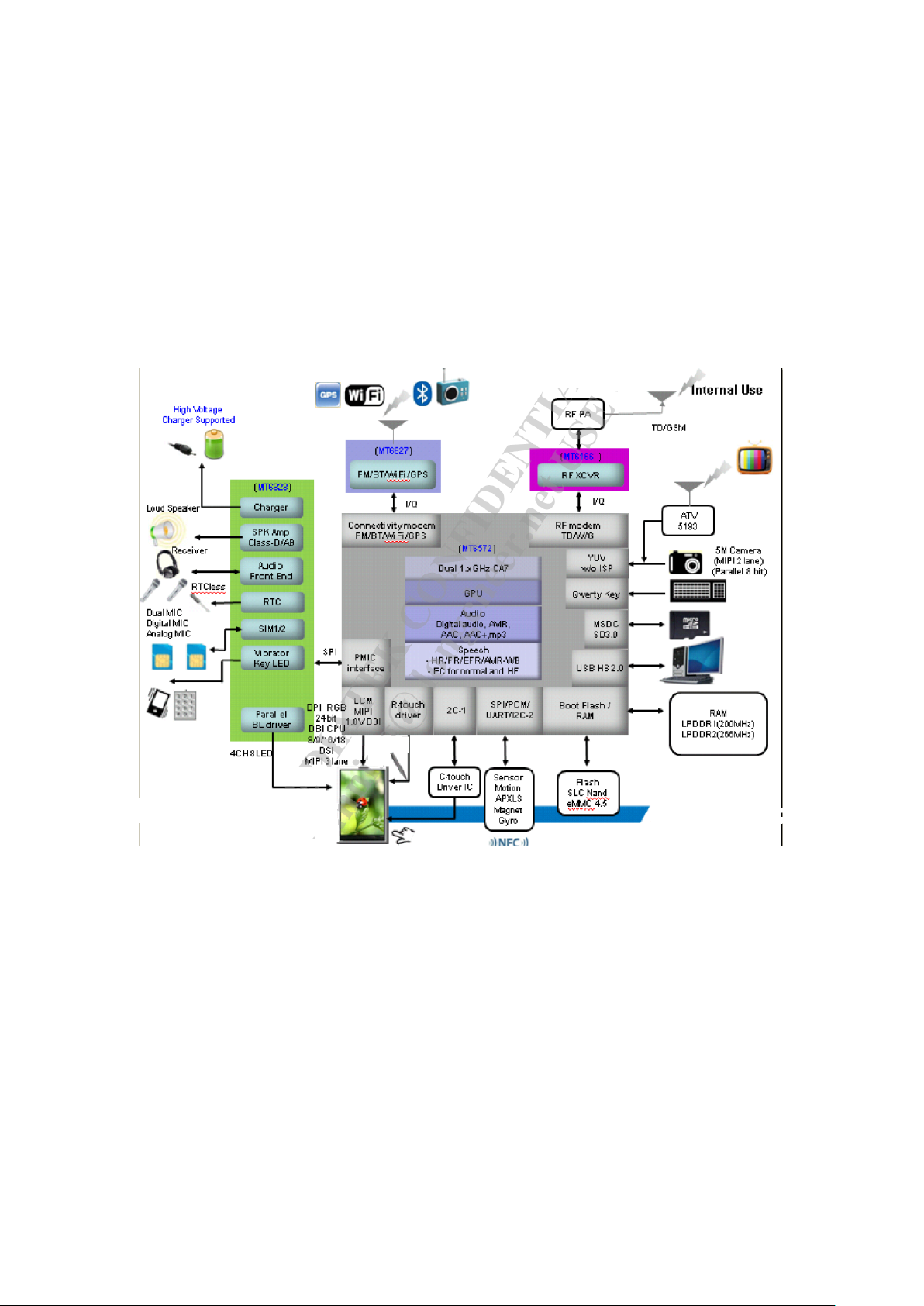

2.1 RF Overview

MT6166 is MTK's multi-mode and multi-frequency transceiver chip, supporting GSM/

GPRS/EDGE, WCDMA dual-band mobile phone.

The circuit description of Receiving part

Page 8

8

Receiving part functional block diagram

It can be seen from the schematic diagram, first, signal is received through antenna, reach RF

coaxial switch (J700) through antenna matching, and then enter RF PA module U700.

Choose GSM signal through PA module (U700) inner switch, output from PIN20, into receiving

filter U602, passing matching circuit, into MT6166 U600’s C1&D1 port, into MT6166 (U600)

inner LNA;

Choose DCS signal through PA module (U700) inner switch, output from PIN19, into BALUN

FILTER U602, passing matching circuit, into MT6166 U600’s E1&F1 port, into MT6166 (U600)

inner LNA;

Page 9

9

Choose WCDMA B1 signal through PA module(U700) inner switch, output into antenna

diplexer (BAND1-single-end RX) U609, divided into TX and RX two ways. RX passes the match,

into MT6166 U600’ A2&A3 port, into the inner LNA.

The each ways’ signal above pass the inner down-conversion, amplification, and after ADC

converting, into baseband.

The description of transmit part

Transmit part is the other way around,

GSM baseband signal within passes up-conversion and amplification, then output from

U600.A11, through outputting and matching, into PA module U700’ PIN10, through signal

amplification, and output into antenna port.

Page 10

10

DCS/TD(A/F) baseband signal within passes up-conversion and amplification, then output

from U600.B8, through outputting and matching, into PA module U700’ PIN9, through signal

amplification, and output into antenna port.

WCDMA B1 baseband signal within passes up-conversion and amplification, then output

from U600.A8, passes matching circuit into WCDMA power amplifier. The power amplifier has

in-built coupler, can coupling one part of signal to MT6166, to detect output signal. After PA

signal amplification, output to the PA module(U700)inner switch, TX’s input foot, and then

outputs to antenna transmit.

PA introduction

PA:HRPF88183B supports 2G four-band, the phone supports GSM/DCS two bands.

SKY77761 supports WCDMA’s BAND1

Page 11

11

2.2 RF part service analysis

2.2.1 Launch part

Test conditions 1:Vbatt=3.8v~4.2v

Test Equipment

Agilent8960, oscilloscope, frequency spectrograph, voltage-stabilized power,

multimeter

If BT, F T find output power low or no power output, can follow the order below to

check launch access by using multimeter, and also can choose middle some grade

to confirm whether its front grade or rear grade has problems.

GSM/WCDMA Launch

1、 To check whether the RF test socket J700 is welded well b y visual inspection? Whether

the female polarity is correct? Whether the center of the female seat has foreign matter?

2、 To check whether the components of U700&U703&600&U609 transmit circuit are

patched abnormal by visual inspection

Page 12

12

3、 If the visual inspections above have no abnormality, replace U700(for 2G&3G) test

4、 If has no improvement by replacing U700, replace the U600(for 2G&3G) test

5、 If remains no improvement, replace the U703(for 3G) test

6、 If remains no improvement, replace the U609(for 3G) test

2.2.2 Receive access

Can follow the procedure below to check

1、 To check whether the RF test socket J700 be welded well by visual inspection? Female

polarity is correct? The center of the female has foreign body?

Page 13

13

2、 Whether filter U602(for 2G)&U609(for 3G) on the receive path, and matching circuit

welded well?

Page 14

14

WiFi/BT/FM Part

WIFI and BT share RF access, signal is entered by antenna. The clock uses 26M clock

provided separately. Data transfer interface and audio interface are directly connected to the CPU.

WIFI main problems:

1. MT6627 chip has been calibrated before out of factory, production line directly do FT test.

The probability that it appears problems by WiFi test is ve ry low, the FT failure problems,

please power off and restart the phone, first retest.

2. WIFI test EVM fail. This major and power, as well as the freq error, if the power is too high

or the freq too big EVM may also lead to excessive, please re-test.

3. WIFI RX fail, main receiving sensitivit y fai ls to pass, Generally, production line testing has

not shielded box, RX vulnerable to external signal interference, If come across such problems,

can change the channel to do the test.

Bluetooth main problem:

Bluetooth does not need calibration, only need to check the function, if unable to search the

device or Bluetooth cannot be opened, check whether the J800 is welding bad or body bad.

Page 15

15

3. Baseband section

3.1 Outline

Baseband circuit completes main functions: the procedure data storage, keyboard

input, and the communication between the RF module, RF power control, the control

of the power management module, RUIM card interface, serial download interface,

Camera, T-flash, G-Sensor, and MMI (man-machine interface, such as the display,

backlight, buzzer, speaker, microphone, motors, etc.).

3.1.1 Memory

The baseband part has an eMMC+LPDDR2 MCP. Wherein the amount of eMMC storage

4Gb, it stores a communication protocol layer and application layer software, and

storing various system parameters, calibration parameters, such as RF control

correction value of an audio signal, the IMEI number, and other important information

and store user settings data such as phone number, CALL volume, and tone; LPDDR memory

512MB, temporary variables stored phone program run。

3.1.2 Power Management

Page 16

16

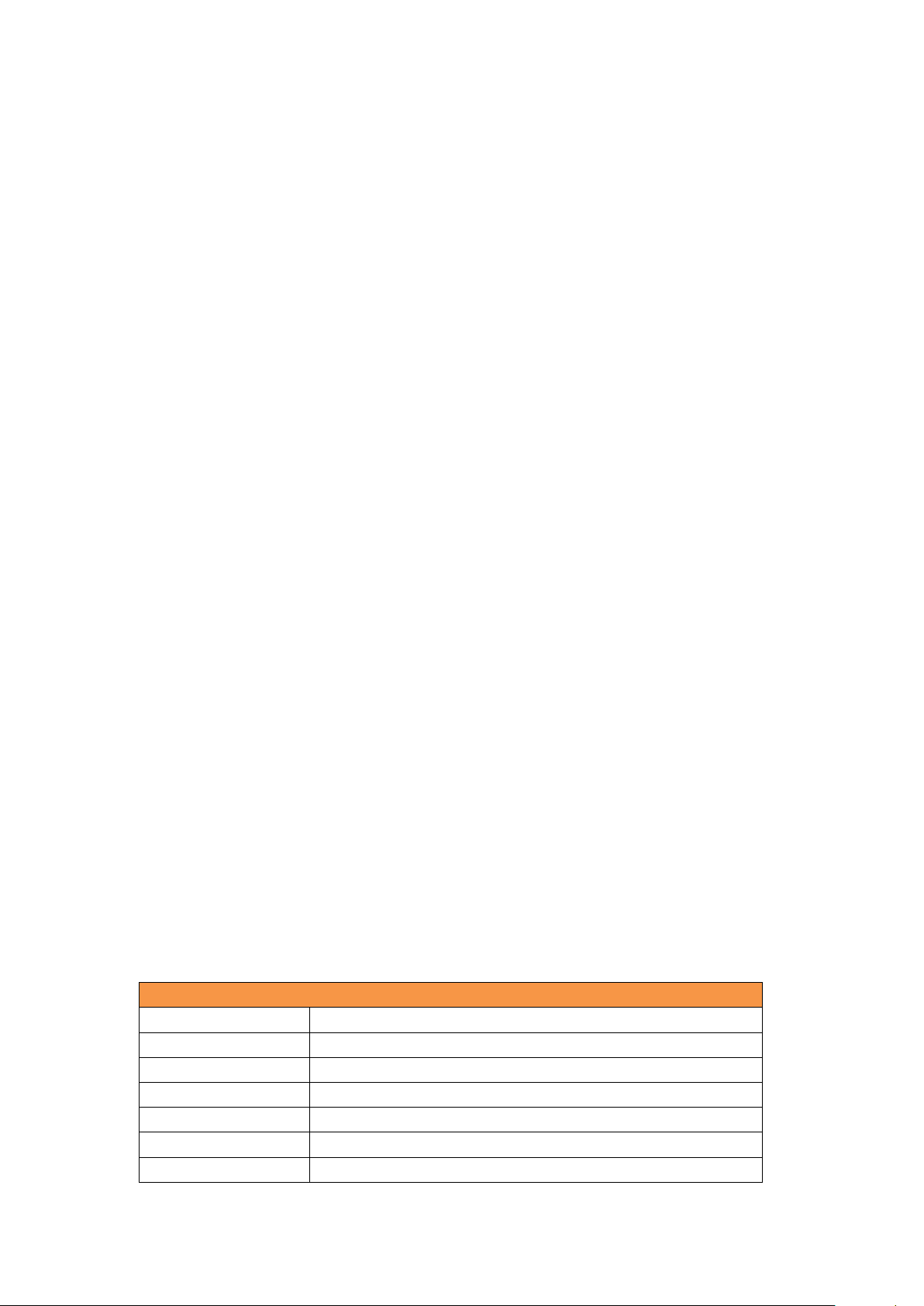

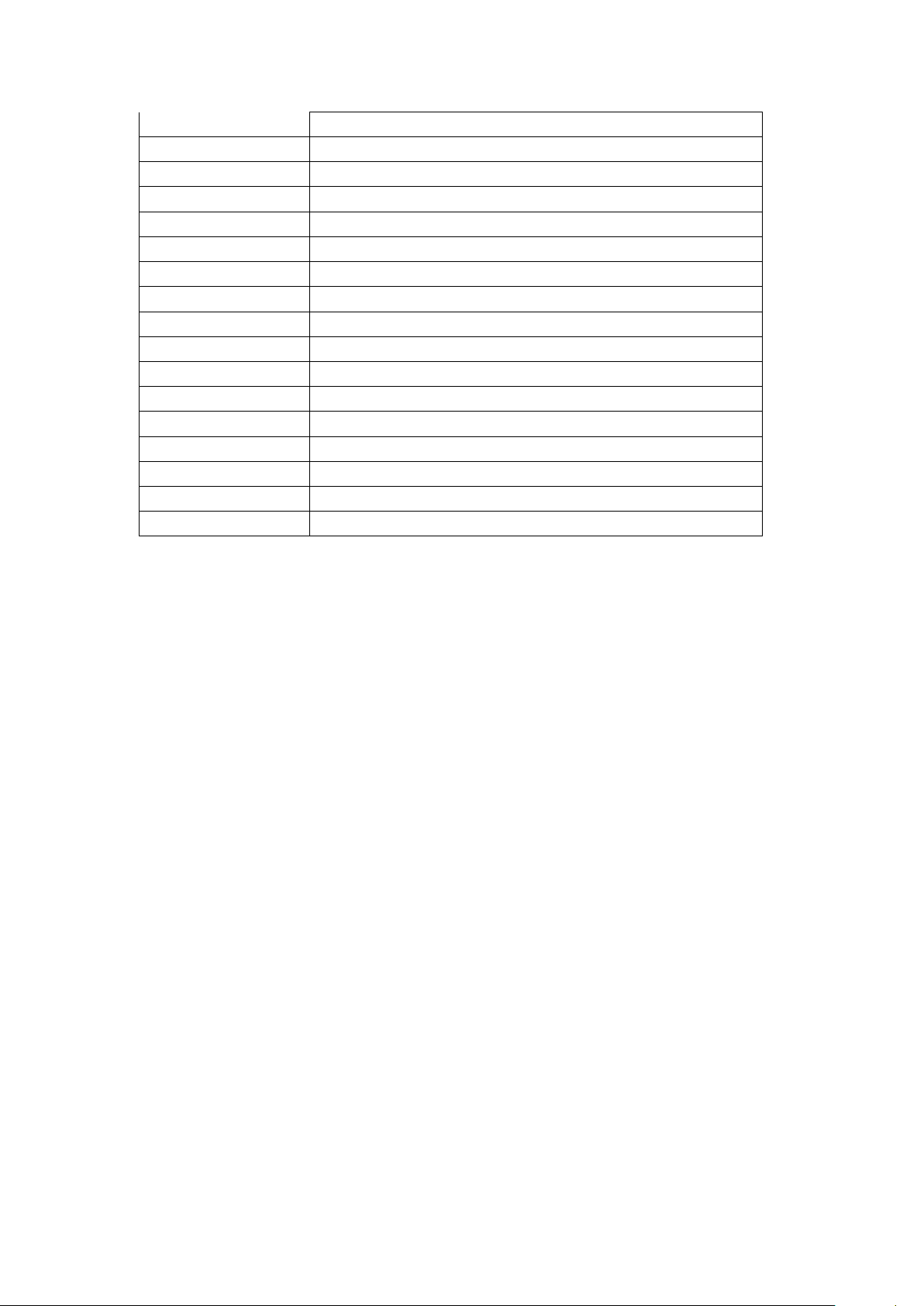

PMU chip is MT6323,which contains 3 DC-DC and 23 LDO, one 0. 7W class D audio

frequency power ampl ifier, 4-way current sink, SIM card level shift, and s o on.

3.1.3 Battery

1500mAh 3.7V lithium-ion battery.

3.1.4 32KHzCrystal

32KHz crystal is used for power-saving mode and real-time clock.

MT6572 platform supports 32K-less mode, PAP3400DUO does not adopt at present.

3.1.5 SIM Card

SIM card level shift integrates in MT6323, card 1 supports WCDMA and GSM dual modes.

3.1.6 Audio frequency

The largest impedance is 2.2KΩ.

Headset as a standard 3.5mm jack port, the nominal resistance 32Ω.

Speaker adopts 2014 specification, Receiver adopts 1506 specification.

3.1.7 I/O Interface

I/O Connector MICRO USB interface standard. Mainly used for software, download

Page 17

17

picture messages.

3.1.8 Display

The main screen is 4.0 TFT color screen 480*800(WVGA).

3.2 Common Failure Analysis and Maintenance

Before cutting board after the completion of the production line SMT X-RAY inspection,

according to the actual situation, X-RAY examination cannot be found 100% badness, X-RAY

inspection may omissions some fault plate flow down. If found fault plate in the testing process,

the first step is to re-check of the X-RAY and carefully to see if there is even welding, lap welding,

Weld, if normal, analyze the situation following the positioning。

3.2.1 Power failure Check

The failure phenomenon caused by a power failure: cannot boot, shutdown leakage current boot

large current.

The main reason for the problem: Weld, electrical the original filtering or ESD device to

short-circuit, burning with the device is connected to a power source.

Positioning as well as steps to solve this type of problem is as follows:

1, Troubleshoot and connected to the power supply components of the welding, Weld, or the

peripheral devices even tin.

2, with a multimeter rule out whether there is power to short-circuit, and step by step to

troubleshoot the cause of the short (mainly: even tin, IC burned ESD protection device

breakdown, capacitor breakdown).

3, boot to test the power output is normal.

If a power output value is not normal, whether the view filter capacitor welding problems,

whether the breakdown, filter capacitor is broken, replace; excluded one by one, and finally you

can navigate to the main chip damage.

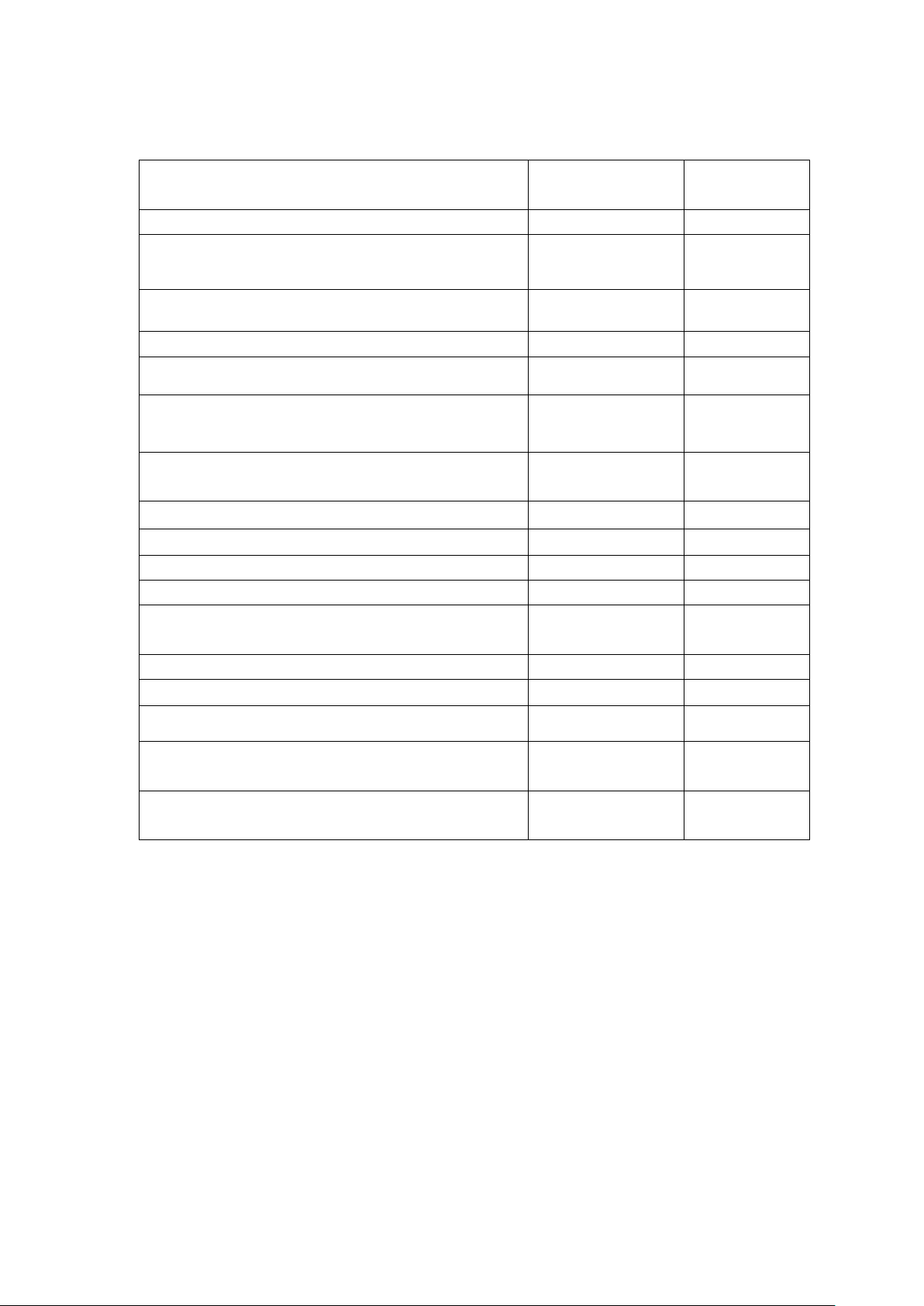

Each the power test position and the normal boot value is shown in the following table

power

VPROC_PMU for BB VCCK,VCCK_CPU

VSYS_PMU for PMU AVDD22_BUCK

VA_PMU for PMU AVDD28_ABB,AVDD28_AUXADC

VCN_2V8_PMU for 4 in 1

VTCXO_PMU for BB AVDD28_DAC,for MT6166

VCAMA_PMU for cam AVDD 2.8V

VRTC for back up bat

Page 18

18

VM_PMU for BB VCCIO_EMI,for memory

VRF18_PMU for MT6166

VIO18_PMU for 1.8V PERIPHERAL

VIO28_PMU for 2.8V PERIPHERAL

VCN_1V8_PMU for 4 in 1

VCAMD_PMU for cam DVDD 1.8V

VCAMD_IO_PMU for cam DOVDD 1.8V

VEMC_3V3_PMU /

VMC_PMU for BB DVDD3_MC1

VMCH_PMU for TF card

VUSB_PMU for BB AVDD33_USB

VSIM1_PMU for SIM1

VSIM2_PMU for SIM2

CTP_2.8V_PMU for CTP 2.8V

VIBR_PMU for VIBR

VGP2 /

CTP_1.8V_PMU for CTP 1.8V

Page 19

19

3.2.2 Audio faults

The audio part has main four parts including the speaker, receiver, mic and

headphone. First undesirable phenomena distinguish what part of the problem, and

then analyzed according to the following respective module.

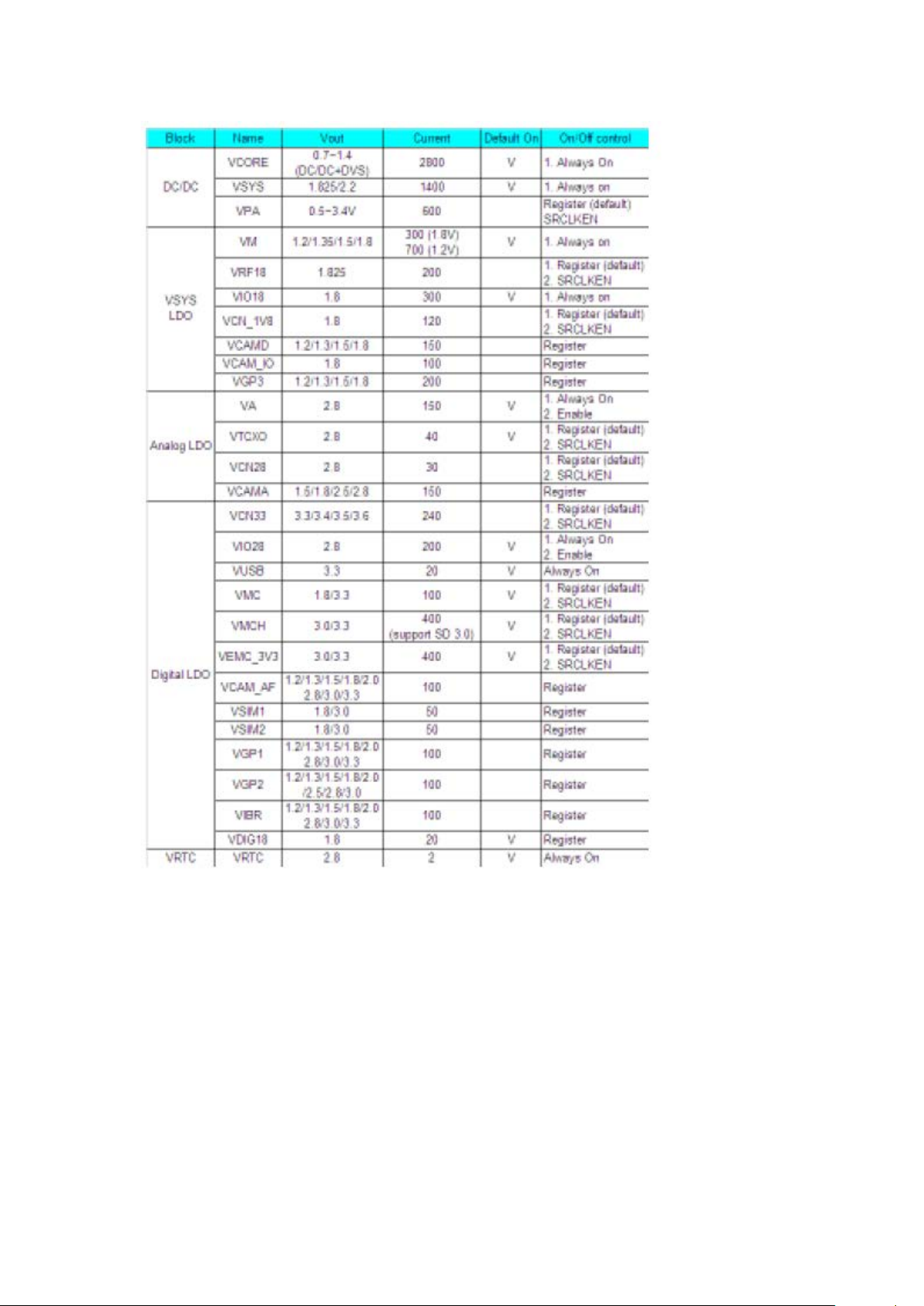

(1)Speaker loop

The PAP3400DUO phone’s speaker circuit is as follo w. Speaker audio output diagram is

as follows:

Page 20

20

Speaker Common faults and reasons:

1, SPK Ringtones reasons: 1) light board, SPK itself is bad, or the connection FPC

problem, the whole observation board board PFC Cartridge is skew, not in

place 2) B503、B504、R504、R518 relevant component there is dry welding 3 )

software problems

2: SPK ringtones or murmur: 1) software volume settings 2) SPK ontology reasons

Page 21

21

3. Switch machine ringtones, but engineering tests SPK OK: 1) scene mode is set to switch

machine ringer off 2) software problems, itself boot ringtones;

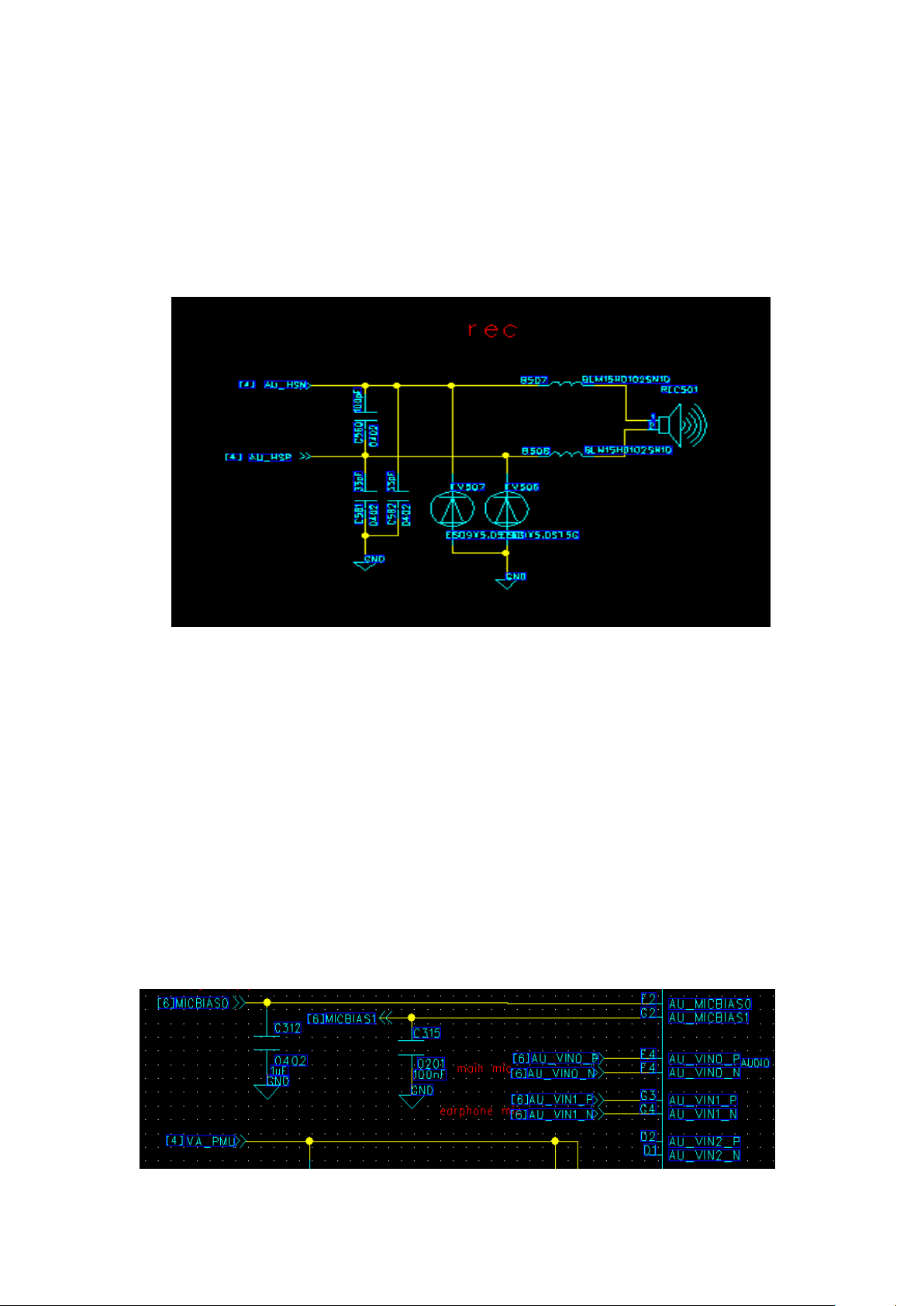

(2) Receiver circuit

PAP3400DUO phone receiver is embedded in the mobile phone front shell through shrapnel

and motherboard connection. Mainly used for the call. Receiver circuit diagram as shown below.

Receive Loop

Receiver Common faults and reasons:

1, Receiver without sound: 1) Receiver assembly adverse, the shrapnel and board

poor contact 2) Receive ontology bad 3) the volume settings or software problems

2, Receiver noise or volume: 1) Receiver incoming material, whether caused by

pad short circuit 2) relevant components have solder skips 3) software problems

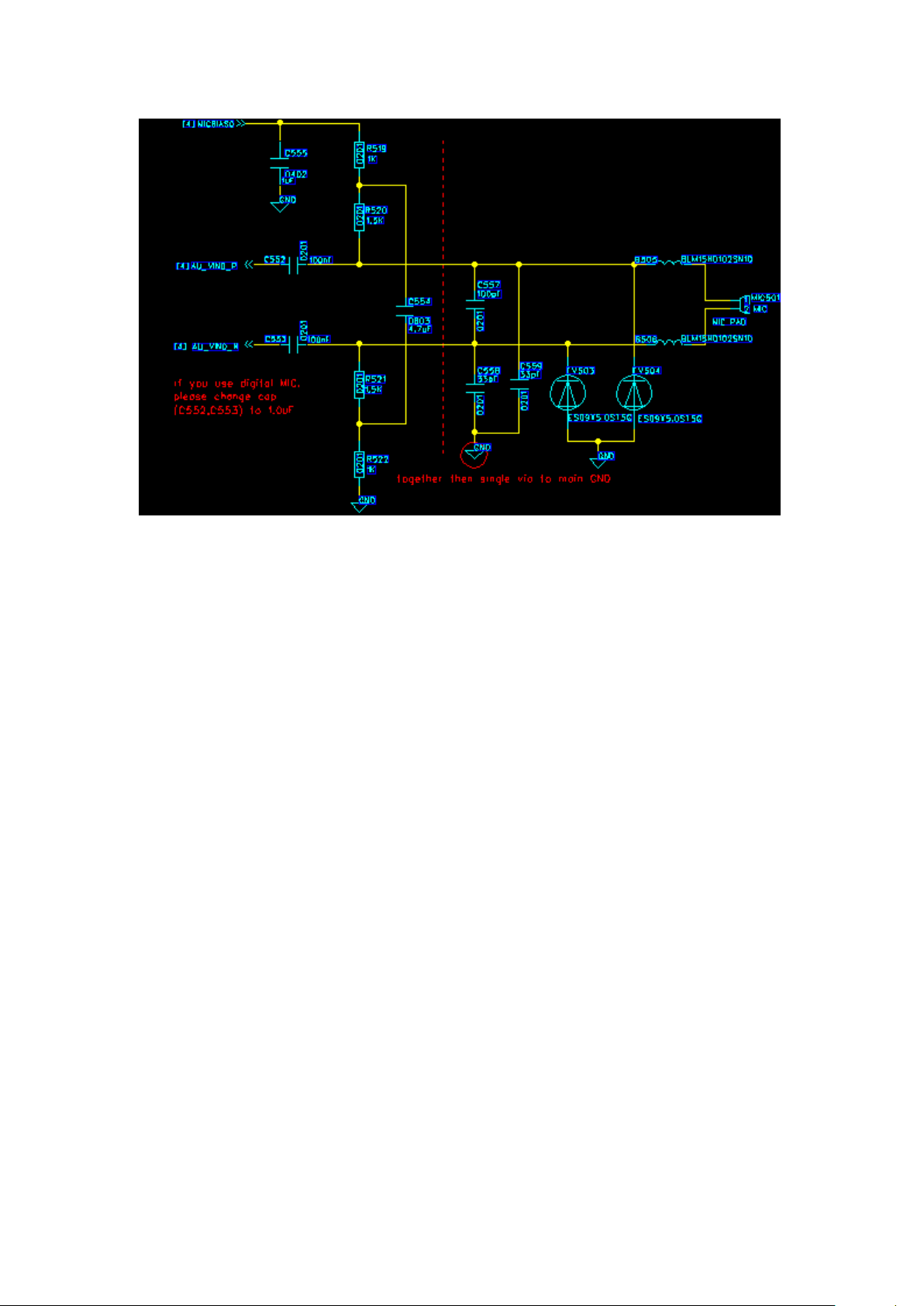

(3) Mic loop

The PAP3400DUO contains two MIC circuits, the main MIC and headphone MIC. The main

MIC was inserted needle. Loop schematic diagram as following:

Main MIC common faults and causes

1 MIC unable to send words or recording: 1) MIC poor welding 2) MIC body bad

2 MIC noise or sound: 1) MIC ontology bad 2) software problems.

Page 22

22

Main MIC

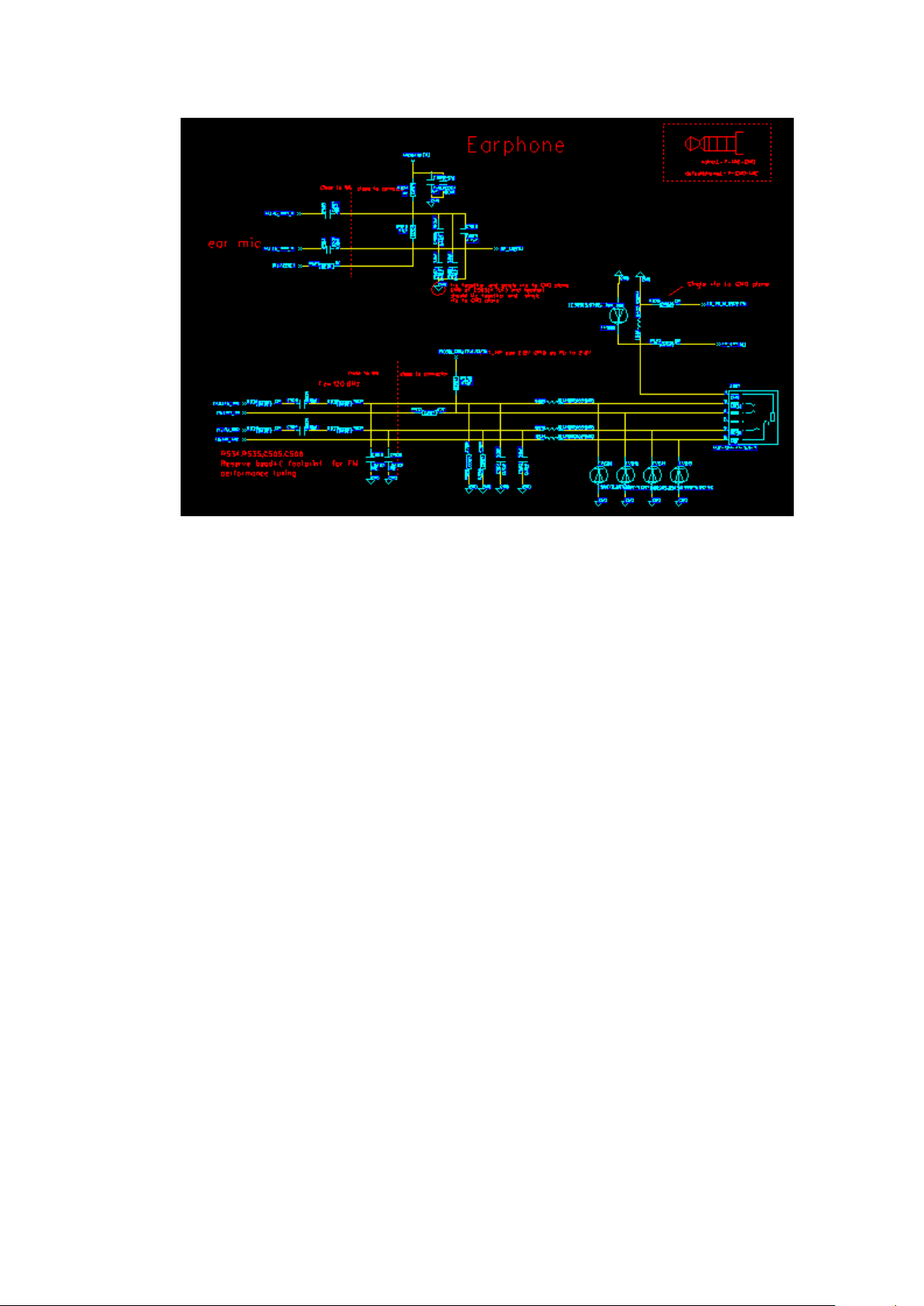

(4)Headphone loop

PAP3400DUO phone use headphones with a standard 3.5mm headphone. Its circuit

diagram is as follows:

Headphones common faults and reasons:

1, headphones only one channel sound: 1) the headset is not inserted in place 2) R534、

R535、C503、C504、R532、R533、B509、B510 Relevant component Weld. 3) R528、

R529、C501、C502、FV509、FV511 Relevant component breakdown shorted to ground;

2 headphone left and right channels are no sound: 1) the headset is not inserted in place 2)

Relevant component breakdown on the short circuit;

3, unplug the headphones bank borrowing does not recognize: 1) R530、R531 Relevant

component Weld; 2) whether headphones Block shrapnel and motherboard good contact 3)

software reasons

4 headset MIC no transmitter: 1) the headset is not inserted in place 2) B511、C565、R524、

R525、C563、C564 Relevant component Weld 3) FV512、C567、C568 Relevant component

breakdown on short-circuit;

Page 23

23

Headset MIC AND 3.5mmHeadphone jack circuit

3.2.3 USB serial port malfunction

During the test, "open serial port failure" will often occur. Main reasons are:

1) phone is unable to power on, Please refer to the fail to power on malfunction

maintenance

2) USB test points are oxidized, not contacting with fixture well

3) USB connectors J1001 is bad welding

4) USB circuit problems

3.2.4 LCD Fault

PAP3400DUO adopts 4.0-inch TFT LCD, The part of the circuit schematic as shown below.

Common problems and causes of the LCD module:

1, LCD screen is blank. 1) LCD is not installed or and fixture poor contact)

LCD backlight circuit is bad, check backlight so that the foot is pulled, check

whether welding problems 3) LCD itself fault.

Page 24

24

2, LCD blurred screen and white screen. Description LCD backlight circuit OK, just

shows abnormal. The cause of the malfunction is usually: 1) LCD connector poor

contact, poor welding and fixture poor contact 2) related components Weld or even

tin short circuit 3) software problems

3. LCD black spots, bright spots, black lines, stripes Failure: LCD ontology bad.

3.2.5 FM

When FM is working, should insert headphone as its antenna. FM outputs audio

signal to the CPU Codec, ampl ify playing or record. FM common faults and causes:

1, FM cannot search frequency or less frequency reason: 1) headphone without

Page 25

25

inserting or not insert goo d 2) sur r ounding environment is bad, such as plant, garage, etc.

FM signals itself is weak or no FM signals source 3) FM antenna circuit exists poor

soldering or short circuit, lead to unable to receive FM signals or FM signals leak 4)

software reason

2,FM without sound reasons or murmur 1) this FM radio frequency is invalid 2) FM

weak si gnal 3)related component bad-welding 4) headphone

whether headphone s ocket s hrapnel cont acts with t he m ainboard wel l 6) wheth er headph one

socket welding is OK

3,FM module operation failed. 1)Check whether the I2C and CL K signal ar e nor mal

or not 2)Software fault

was not put in place; 5)

3.2.6 Bluetooth and wifi PAP3400DUO BT and wifi adopt MT6627 chip. Data transfer interface and audio

interface are directly connected to the CPU. Common failures are:

1, Bluetooth function failure, you need to check the Bluetooth is turned on, the

Bluetooth Visibility settings are correct. The Bluetooth power supply and clock circuit

the existence of the phenomenon of short circuit or Weld.

2, Bluetooth effective distance is short, easily disconnected. Need to check

whether Bluetooth antenna circuit soldered or short circuit, Bluetooth antenna and

motherboard contact well.

Page 26

26

3.2.7 Camera fault

Camera common fault and why:

1, Camera initialization failed, could not enter the Camera the main interface. 1) Camera poor

welding or poor contact 2) the Camera Ontology failure 3) Camera Power supply is not normal

(Weld, or short-circuit led to) 4) related components welding problems

2, Camera Preview shows blurred screen or color is not normal. 1) Camera poor welding or

poor contact. 2) related components welding

Page 27

27

3.2.8 SIM card failure

PAP3400DUO SIM card module circuit is connected directly with PMU through four-path signal

from SIM slot. The major failure of the module does not know the card, the reason usually: 1)

SIM card GSM card and SIM deck poor contact 2) poor SIM card socket welding 3) software

problem cause the phone to pick a card, change the card to confirm. 4) SIM card holder exist Weld;

5) card exceeds the itinerary or inserted upside.

3.2.9 Motor test is invalid

PAP3400DUO adopts columnar motor, with simple circuit. As shown below. Common motor

failures and the reasons are:

1, the motor without vibration 1) motor and motherboard contacted poor

2, the motor was felt as weak 1) motor ontology bad) the cause of the software settings

3 motor vibration sometimes 1) motor and motherboard poor contact

Page 28

28

3.2.10 T riaxial Gsensor

PAP3400DUO triaxial GSensor circuit is provided power by VGSENSOR_PMU, supply

voltage 2.8V,1.8V I2C is imitated by GPIO. Triaxial GSensor common faults and reason:

1, Sensor sensitivity is low, response is slow: Software problems.

2, Triaxial GSensor function NG, check whether Triaxial GSensor module circuit has

welding or short-circuit faul t .

Page 29

29

3.2.11 T-Flash fault

PAP3400DUO T - Flash circuit is connected with CPU through the special SDIO bus, circuit

diagram shown below. T - Flash the common faults and reasons are:

1, T–Flash read-write test is failure. 1) T - flash for fault card or and T kaka seat have had no

contact with good 2) below the resistance there may be short circuit, or virtual welding

phenomenon. Capacitance may on short circuit. (using a multimeter to test whether T card signal

and ground and VMCH short circuit can eliminate) 3) software reason

2, T card not to know card: T holder PIN feet virtual welding, on MLV welding reverse and

capacitance breakdown

3, T - Flash can't through the USB for transmission. 1) T - Flash itself, speaking, reading and

writing test failure fault 2) software fault 3) USB fault

Page 30

30

T card circuit

3.2.12Touch Panel function

Touch Panel common fault and reasons are:

1. TP sensitivity low, slow reaction: software problem;

2. Touch Panel function NG, at present is mainly due to FPC itself partial long cause, the I2C

initialization failed;

TP circuit

Page 31

31

3.2.13Distance sensor fault

PAP3400DUO distance sensor is realized through the TP. During the call, when a certain

superficial TP sensor has reaction, realize off- screen app, etc.. If no reaction, should check

whether the TP firmware is the newest and has any problems or not.

3.2.14 Cannot boot failure

Can't boot failure is the phone fault with highest probability of occurrence. Software

problems, welding problem, device failure is the main factor causing failing to boot. Maintenance

process can cooperate with LCD and startup current, as well as the keyboard and so on to orientate

approximately.

1, Power off leak current is large. The main failure reason is VBAT connected components

had to earth short circuit problem. Usually radio frequency PA burned or welding problem cause.

The simpler method is looking for is a hot devices, general such devices have larger may on short

circuit.

2, Boot without current, LCD no display, keyboard, etc not bright. 1) boot key SMT bad 2)

battery connector bad contact (through the plug charging machines)

3, Crashed when boot, 1)can try to re-download the software, 2)replace memory

4, Current is large when boot. LCD displays normally, even can enter the IDIE interface,

single board is very hot 1) The individual power circuit short circuit to ground phenomenon exists

in the phone, which is usually the problem that ESD protective devices of module circuit

breakdown short circuit to ground or weld problems.

Page 32

32

3.2.15 Auto Power On

1, Connect the power , po w er on, insert USB don't turn on, sof tware decides to need to

connect to the power, and then power on.

2, W hether Power on key has incoming materials problem, whether welding is short

circuit.

Page 33

PAP 3400

service manual

Page 34

content

1、 Product introduce..………..p3-p4

2、 Disassembly guide ……….p5-p17

3

4

、Structure parts diagram…..p18

、 Repairing guide …………...p19-p29

2

Page 35

Product introduce

3

Page 36

Product introduce

Model :

Product size

Platform

Memory

System

Frequency band: WCDMA:900/2100,GSM:900/1800MHz

Battery

charger: Travel charger

USB cable: MICRO 5PIN

earphone

LCD&TP

Camera

: 4GB+512MB (Nand&sdram+RAM)

:Android 4.2

: 1500mAh

:0.3M and 2.0M CMOS

:123×63.5×11.9mm

:MTK6572,dual-core 1.2GHz

: 3.5jack

: 4.0 FWVGA TN, 480*800, Capacitance TP

Support

Support

:BT4.0,WIFI,FM。

:3D graphics accelerator,accelerator sensor

4

Page 37

Disassembly guide

1. Tools list

Tweezer /Cr oss scr ew driver/ Solder/Tommy bar/hot gun

Tommy bar

Tweezer

Cross Screw driver

Solder iron

Hot gun

5

Page 38

Disassembly guide

2. Battery caver disassembly

open the battery cover

,

as the Fig. 1

Battery

cover

Fig. 1

6

Page 39

Disassembly guide

3. Back caver disassembly

1)

Unscrew 10 screws in back cover ,as the Fig.2;

Fig. 2

7

Page 40

Disassembly guide

2) Disassemble back cover with Tommy bar ,as the Fig.3;

Back

cover

SPK

Fig. 3

8

Page 41

Disassembly guide

4.Main board an d front cover di sas sem bly

1)The main components of distribution,as the fig.4;

TP con.

Earphoe

con.

USB con.

Back CAM.

Front

CAM con.

Battery con.

SIM con.

Main PCBA

MIC

T card

con.

LCD con.

Fig.4

9

Page 42

Disassembly guide

2)remove two screws and open the LCD con.& TP con. ,and remove the

volume key FPC & power key FPC as the fig.5;

TPcon.

LCDcon.

Fig.5

10

Page 43

Disassembly guide

3) Disassemble the main board.as the FIG.6

Fig.6

11

Page 44

Disassembly guide

5. Front and Back camera & Flash FPC & Side key FPC & MIC &Camera

bracket disassembly

)disassembly the Camera bracket ,as the fig.7;

1

Fig.7

Camera

bracket

12

Page 45

Disassembly guide

5. Front and Back camera & Flash FPC & Side key FPC & MIC &Camera

bracket disassembly

)disassembly the Front and Back camera & Flash FPC & Side key FPC &

2

MIC ,as the fig.8;

Fig.8

13

Page 46

Disassembly guide

6. Speaker & receiver & Vibration disassembly

remove the Speaker and receiver and Vibration,as the FIG.9;

Fig.9

14

Page 47

Structure parts diagram

3in1 module

(LCD, TP & front cover

Back

cover

Battery

cover

15

Page 48

Structure parts diagram

receiver

front camera

Volume FPC

MIC

back

Main

PCBA

camera

Flash FPC

Camera

bracket

SPK

Power FPC

Vibration

16

Page 49

Repairing guide

1. LCD

a. Check if the SW is correct, otherwise to upgrade the SW;

b. Check the LCD if is ok, other wise change a new LCD;

c. If that the LCD loose, re-assemble the LCD and tes t;

d. Checking the LCD connector if is ok, otherwise re-solder it or change a new one;

e. Checking the circuit around the LCD connect or.

LCD

connector

17

Page 50

Repairing guide

2. Camera

a. Checking the camera is assemble ok, re-assemble t he camera and t est;

b. Using the good camera to do cross test, it can check if the camera is ok;

c. Checking the camera connector if is ok as below picture, otherwise to

re-solder or change a new one;

d. Checking the circuit around the camera connector.

Back Camera

connector

Front Camera

connector

18

Page 51

Repairing guide

3. TP

a. Checking the SW and upgrade the SW;

b. Checking the FPC of TP and re-assemble it;

c. Using the good TP to do cross t est;

d. Checking the TP connector, otherwise re-solder or change a new one;

e. Checking the circuit around the TP connector.

TP Connector

19

Page 52

Repairing guide

4.Ring

a. Checking the shrapnel of speaker if is ok;

b. Checking the resistance of speaker if is ok, otherwise to change a new

one;

c. Checking the F PC if is ok;

d. Checking SPK-FPC if connector with sub-board is ok.

20

Page 53

Repairing guide

5.receiver

a. Checking the shrapnel of receiver if is ok;

b. Checking the resistance of receiver if is ok, otherwise to

change a new one;

c. Checking the connector point on t he main board if is ok, as

below picture;

c. Checking the receiver circuit if is ok.

21

Page 54

Repairing guide

6.MIC and Vibrator

a. Checking the MIC and Vibrator is cold soldering, re-solder it;

b. Change the MIC and Vibrator;

c. Checking the circuit of MIC and V ibrator;

d. Checking the FPC if connect ok.

MIC con.

22

Page 55

Repairing guide

7. Earphone

a. Checking the shrapnel of earphone if is ok;

b. Checking the connector point on the main board if is ok, as below

picture;

c. Change earphone connector;

c. Checking the circuit of earphone.

earphone

23

Page 56

Repairing guide

8.No Power On

a. Checking the voltage of battery if is 3.8-4.2V and connect ok;

b. Upgrade the SW;

b. Checking the power on key and circuit around it.;

24

Page 57

Repairing guide

9.No charging

a. Checking the voltage of battery if is over 3.4V;

b. Checking the charger and USB cable if is ok;

c. Checking the USB connector and circuit if is ok.

USB Connector

25

Page 58

Repairing guide

10.No SIM card and No memory card

a. Checking the connector of T –card and SIM card;

b. Change the connector of T –card and SIM card;

T-card

connector

SIM

Connector

26

Page 59

Repairing guide

11.Signal

a. Checking RF line if that is broken;

b. Checking RF line assem ble if is ok;

27

Page 60

End

Q&A

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Loading...

Loading...