Prestige Medical 2100 Service manual

S ERV I C E M A N U A L

TTeecchhnniiccaall DDaattaa

MMeecchhaanniiccaall RReeppaaiirr

EElleeccttrriiccaall RReeppaaiirrss

CCaalliibbrraattiioonn

FFaauulltt DDiiaaggnnoossiiss

TToooollss aanndd TTeesstt EEqquuiippmmeenntt

PPaarrttss LLiisstt

Page 1 of 13

TTeecchhnniiccaall DDaattaa

Continuous operation, with intermittent use.

Electronic system is set to hold a minimum 121°C for 16 minutes (except 210006), 126°C for 11 minutes or 134°C for 3.5 minutes

when loaded with instruments.

On model 210006 the electronic system is set to hold 121 °C minimum, for 18 minutes when loaded with instruments.

All sterilizing times incorporate a safety margin between 0.5 and 1 minute depending on the operating temperature.

Nominal operating pressures are 1.05 Bar (15 psi) at 121°C, 1.6 BAR (23psi) at 126°C, and 2.2 BAR (32 psi) at 134°C.

Minimum vessel burst pressure is 7.8 Bar (115 psi).

Safety features

• Pressure release valve

• lid pressure interlock

• Gasket offset device (prevents pressure build up if lid not closed correctly)

• Body thermal fuse

• Boil dry detector

• Gasket extrusion slot for pressure relief

• End of cycle buzzer.

• Bi-metallic air bleed device fitted.

Pressure and temperature gauges available on some models (refer to price list).

Page 2 of 13

MMeecchhaanniiccaall RReeppaaiirrss

Depressurization Valve Kit (Part #KVK043-4084) (OEM Part #219711)

Fig 1.

To replace this valve, remove lock nut from inside the lid with a 13mm spanner and lift out complete valve

(Fig.1). Replace the valve with new one. Ensure cutouts in the aluminium valve body fit into notches on top

handle.

Always replace the seal when refitting the valve. These locate the valve in position.

Tighten nut to 10Nm.

Circlip in valve handle.

To replace the circlip,

remove the decal and

push up the valve stem.

The circlip may now be

removed / replaced

PRESSURE INDICATOR:

To remove this indicator, locate M16 hexagonal nut in a socket and use the specified tool to undo the red cap.

(For tool kit see 6: Tools and Test Equipment).

GASKET OFFSET DEVICE:

The gasket offset device (GOD spring) is a very important safety device. It ensures that if the lid is incorrectly fitted pressure cannot build up.The spring is forced away from the gasket by the body lug as the lid is rotated. The

spring allows the gasket to seal when the lid and body lugs are in a half lug engagement or better interlock position.

Gasket Offset Device Cover (Part #KVC019-4055) (OEM Part #219577)

This device must be inspected monthly

To work correctly the spring must be firmly riveted to the lid. It must protrude on the inside of the lid, past the

flange by a minimum of 1mm (with gasket removed). See figures 3 and 4.

A new spring cannot be fitted without the correct factory equipment, spring and riveter.

If the spring or rivet is damaged a new lid must be fitted.

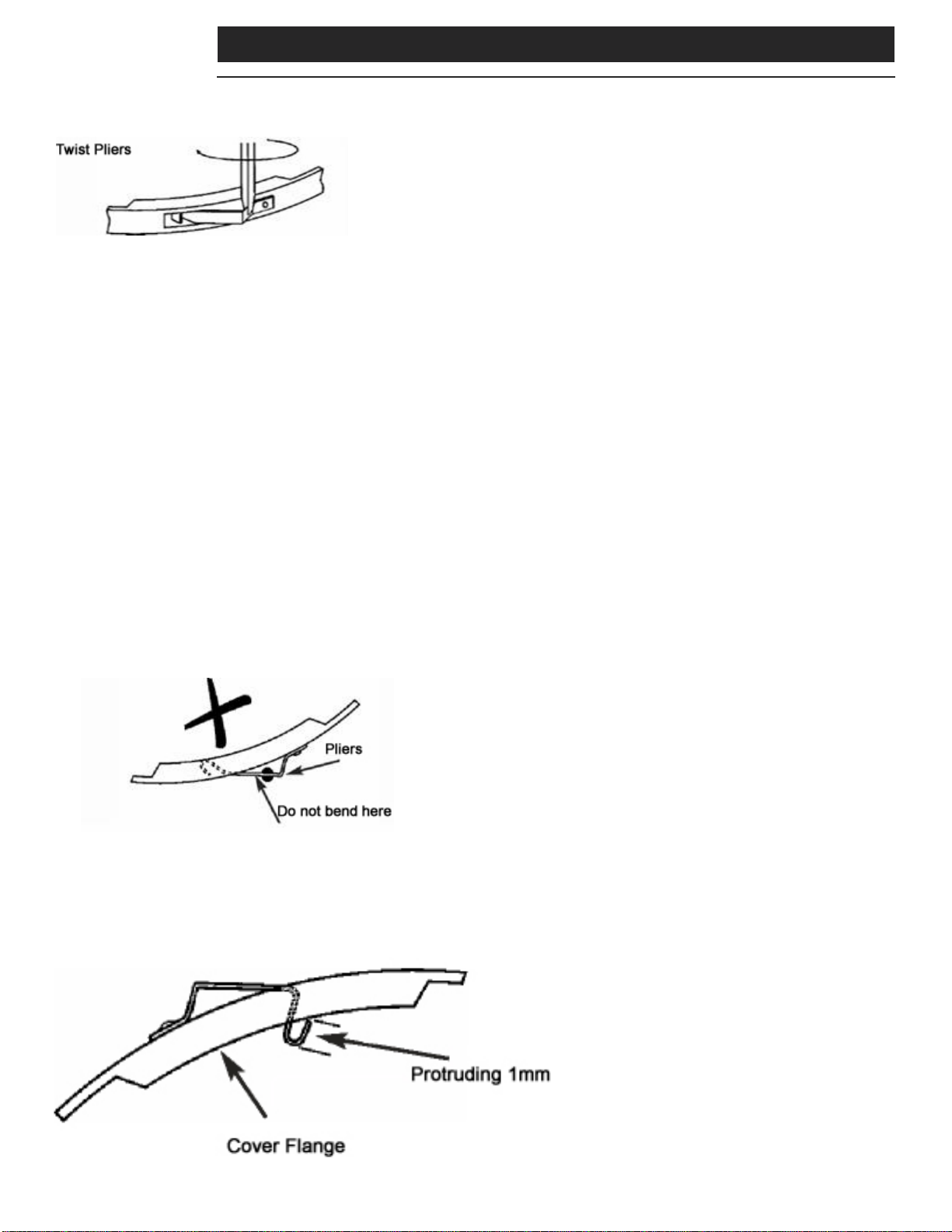

Procedure to correct GOD Spring setting

If the limits are outside the specification, then the GOD spring has to be adjusted using long nose pliers.

Page 3 of 13

Fig 2.

Fig 3.

MMeecchhaanniiccaall RReeppaaiirrss ((ccoonnttiinnuueedd))

Ensure the lid is flat and stable and apply the pliers vertically. Locate the pliers onto the back edge of the spring

and twist inwards carefully. Do not buckle the spring. Check visually and measure the distance again.

Fig 4.

Remove the lid and gasket to ensure that the spring is protruding from the edge of the flange by 1 mm. (Fig. 5.).

Fig 5.

Page 4 of 13

Loading...

Loading...