Page 1

USER GUIDE

Page 2

Page 3

Wlcome a

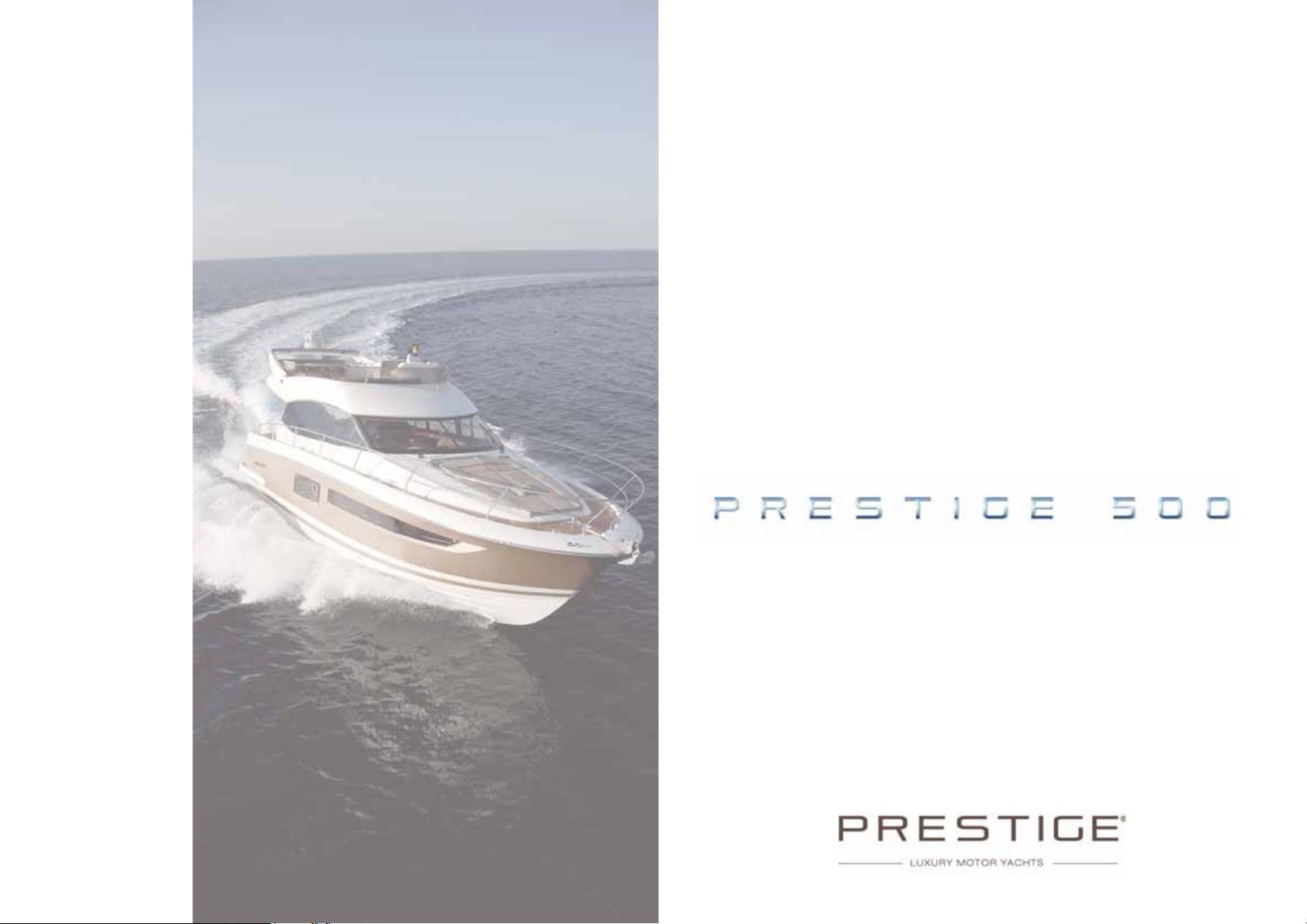

You have just taken delivery of your PRESTIGE 500 - congratulations!

Designed and built by Jeanneau professionals, your boat will be a source of great happiness.

The entire PRESTIGE team is now at your service.

Close to 300 dealers who share our values and love of boats have been selected from dealerships around the world.

They have been carefully trained in three essential areas: customer counselling, diagnostics and problem solving.

Threy are also equipped with an innovative logistical support service to ensure timely delivery of spare parts.

We are proud to sharing our passion for the sea with you and we will be there to assist you throughout the life of your boat.

To begin, we have developed this technical guide as a resource for you. Please read through it carefully to learn more about optimal

conditions for use of your boat and to ensure your full satisfaction.

As you take the helm of your new PRESTIGE, I wish you fair winds.

JP Chapeleau

GENERAL MANAGER

Page 4

Page 5

Preamble

This instruction guide is a tool that will enable you get to know your boat and apprehend the use of the components that

are necessary for running her. Some of the equipments mentioned in this guide are optional fi ttings.

A WAY TO MAKE THE MOST OF THIS INSTRUCTION GUIDE

In order to have an easier apprehension, this guide offers you two complementary reading levels:

. The pages with text on the right hand side of the document develop the different subjects dealt with in the chapters,

. The pages on the left hand side are given to the related photos, layouts or block diagrams.

The different warnings used throughout this guide are as follows:

RECOMMENDATION

Before you put out to sea, please read the owner’s manual (CE standard manual) delivered with your boat and please follow

the instructions.

Shows a piece of advice to do the appropriate actions or

manoeuvres adapted to what you are thinking of doing.

Draws your attention on dangerous ways of doing that may

bring about injuries to people or damages to the boat or her

components.

Warns you about the existence of a hazard that may have

serious or fatal consequences if the appropriate precautions

are not taken.

Page 6

Page 7

Contents

5

1 Specifications

1.1 I D of your boat

1.2 Technical specifi cations

1.3 Wheelhouse helm description

1.4 Flying bridge control house description

1.5 24 V - 230 V electrical panel description

2 Hull / deck

2.1 Construction

2.2 Careening

2.3 Deck fi tting

2.4 Access to the boat

2.5 Cockpit

2.6 Flying bridge

2.7 Access to the crew cabin

2.8 Retractable sun awning

2.9 Deck wash pump

2.10 Swim ladder

2.11 Deck searchlight

2.12 Underwater spotlights

2.13 Capstan

2.14 Anchoring

2.15 Gangway

2.16 Hydraulic platform

3 Accommodations

3.1 Saloon table

3.2 Floorboards

3.3 Portholes - Deck hatches

3.4 Windows

3.5 Cabins

3.6 Helm stations

Page 07

Page 17

Page 35

4 Utility aboard

4.1 Slot-in television

4.2 Flying bridge refrigerator

4.3 Flying bridge grill

4.4 Icemaker

4.5 Microwave oven

4.6 Stove unit

4.7 Induction cooktop

4.8 Extractor hood

4.9 Refrigerator / freezer

4.10 Dishwasher

4.11 Washer dryer

4.12 Safe

4.13 Heating

4.14 Air conditionning

5 Water systems

5.1 Bilge pump system

5.2 Grey waters

5.3 Black waters

5.4 Fresh water

6 Electricity

6.1 24 V circuit

6.2 Inverters

6.3 230 V circuit

6.4 Electronics

Page 41

Page 55

Page 65

7 Propulsion

7.1 Engines

7.2 Fuel

7.3 Dash boards

7.4 Steering system

7.5 Demister

7.6 Trim tabs

7.7 Propellers and anodes

7.8 Bow thruster

8 Winter storage

8.1 Laying up

8.2 Protection

9 Handling

9.1 Preparation

9.2 Crane lifting

10 Safety

10.1 Prevention

10.2 Gas system

10.3 Fire

10.4 Bilge pump system

10.5 Safety equipments

10.6 General remarks

11 Maintenance

11.1 Maintenance schedule

Page 81

Page 93

Page 97

Page 101

Page 115

Code 136497 - Indice C

Page 8

Page 9

Specifications

1.1 I.D. of your boat

1.2 Technical specifications

1.3 Wheelhouse helm description

1.4 Flying bridge control house description

1.5 24 V - 230 V electrical panel description

1

7

Page 10

Page 11

Your boat

9

1

NAME OF YOUR BOAT: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VERSION: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DELIVERY DATE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REGISTRATION NUMBER: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DOOR KEY NUMBER: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HULL NUMBER: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAKE OF THE ENGINES: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NUMBERS OF THE ENGINE KEYS: . . . . . . . . . . . . . . . . . . . . . . . .

SERIAL NUMBER OF THE STARBOARD ENGINE: . . . . . . . . . . . . .

SERIAL NUMBER OF THE PORT ENGINE: . . . . . . . . . . . . . . . . . . .

FURTHER INFORMATION: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OWNER’S NAME: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADDRESS: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E-MAIL ADDRESS: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LANDLINE PHONE NUMBER: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOBILE PHONE NUMBER: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BP 529 - 85505 LES HERBIERS CEDEX - FRANCE - TEL +33 (0)2 51 64 20 20 - FAX +33 (0)2 51 67 37 65 - www.prestige-yachts.com

Page 12

10

Design categories

CATEGORY A

The boat is designed for sailing in winds that may exceed force 8 on the Beaufort Scale and in waves of a signifi cant height of 4m and more and the boat is

to a large extent self-suffi cient.

Unusual conditions such as hurricanes are excluded.

You may meet with such conditions when you sail long crossings, for instance

across the oceans, or close to the shore when you are not protected from the

wind or waves over several hundreds of nautical miles.

CATEGORY B

The boat is designed for sailing in winds that do not exceed force 8 on the

Beaufort Scale and in the corresponding waves (waves of a signifi cant height

inferior or equal to 4m).

You may meet with such conditions when you sail offshore or close to the

shore when you are not protected from the wind or waves over several dozens

of nautical miles. You may also meet with such conditions in inland seas of a

suffi cient size to be able to give the wave height in question.

CATEGORY C

The boat is designed for sailing in winds that do not exceed force 6 on the

Beaufort Scale and in the corresponding waves (waves of a signifi cant height

inferior or equal to 2m).

You may meet with such conditions in exposed inland waters, in estuaries and

in coastal waters with mild weather conditions.

CATEGORY D

The boat is designed for sailing in winds that do not exceed force 4 on the

Beaufort Scale and in the corresponding waves (occasional 0.5m high waves

at a maximum).

You may meet with such conditions in sheltered inland waters and in coastal

waters in fi ne weather.

NOTE :

The signifi cant height of a wave is the average height of the upper third of the

waves; this corresponds more or less to the height of a wave an experienced

observer can assess.

Some waves will be twice as high as this value.

Page 13

Technical specifications

11

1

Length overall (L. O. A.) . . . . . . . . . . . . . . . . . . . . . . . . . . . 15,20 m / 49'10"

Hull Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14,92 m / 48'11"

Beam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,50 m / 14'9"

Air draft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5,23 m / 17'1"

Draft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,05 m / 3'5"

Light displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 14100 kg / 30080 lbs

Maximum load displacement . . . . . . . . . . . . . . . . . . . . 19862 kg / 43795 lbs

Manufacturer’s maximum recommended load . . . . . . . B/4900 kg - C/4950 kg

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B/10805 lbs - C/10915 lbs

Fresh water capacity . . . . . . . . . . . . . . . . . . . . . . . . 2 x 318 l / 2 x 84 US gal

Black water capacity . . . . . . 120 l / 32 US gal + 50 l / 13 US gal / crew cabin

Fuel capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 x 650 l / 2 x 172 US gal

Refrigeration unit capacity 24 V . . . . . . . . . . . 218 l/galley - 80 l/fl ying bridge

. . . . . . . . . . . . . . . . . . . . . . . . . . 58 US gal/galley - 21 US gal/fl ying bridge

24 V BATTERY CAPACITY

Domestic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 x 140 Ah

Engine system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 x 50 Ah

Bow thruster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 x 55 Ah

12 V BATTERY CAPACITY

CE CATEGORY Maximum number of persons

A .................................................................................

B .........................................................................12 persons

C .........................................................................14 persons

D .................................................................................

Bottom surface: 52,5 m2 / 565 sq ft

Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 x 50 Ah

Maximum engine power . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 x 435 HP (IPS)

Design category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B / C

Page 14

12

WHE ELHOUSE H ELM

2 3 4 51 7

1 1

6

8 9

10

11

12

13

14

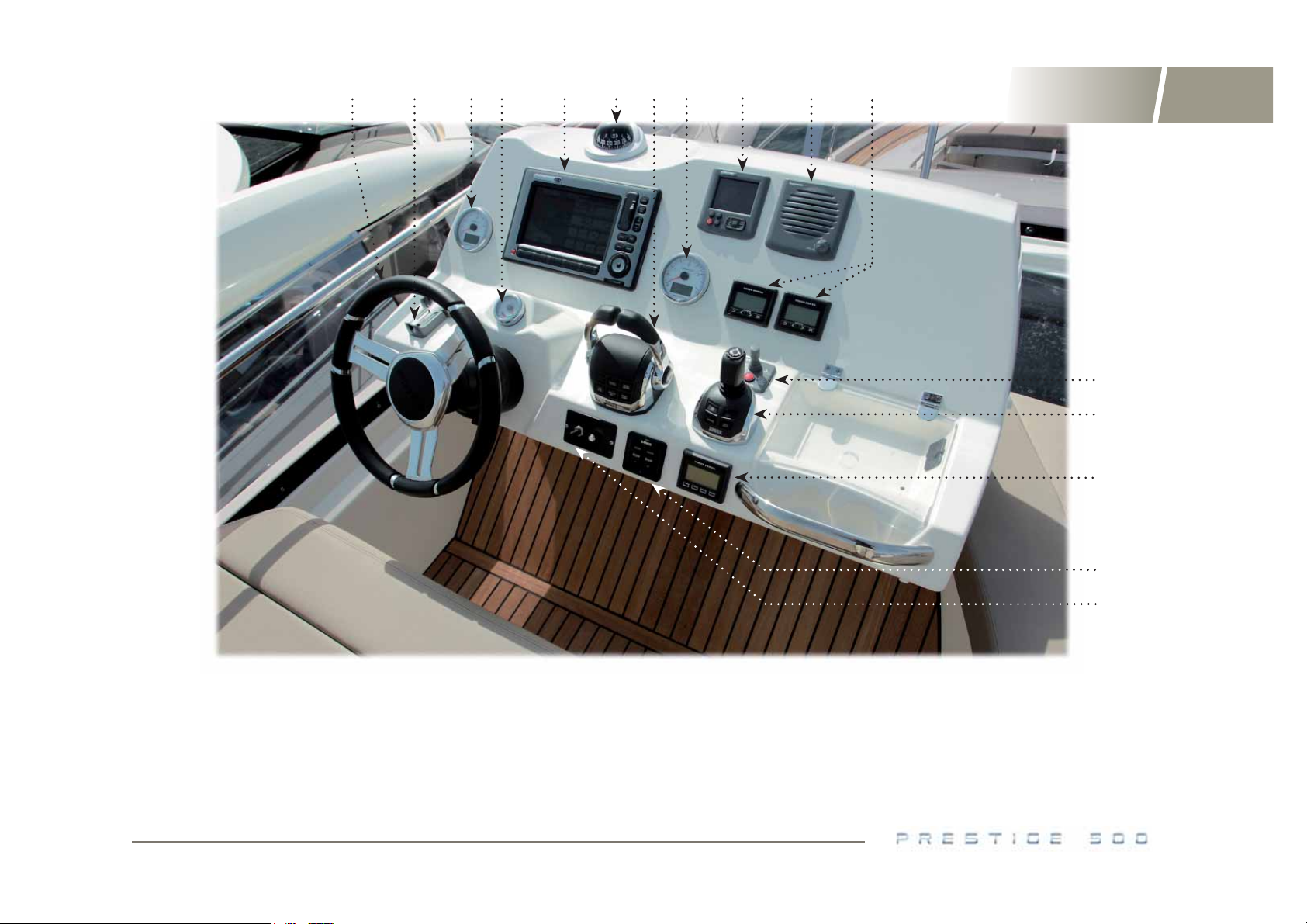

1 - Screen/ repeater for the electronic system

(optional fi tting).

2 - Compass.

3 - Port engine rev counter.

4 - Rudder angle indicator.

5 - Starboard engine rev counter.

WHEELHOUSE HELM

6 - Adjustable steering wheel.

7 - VHF radio (optional fi tting).

8 - Bow thruster control (optional fi tting).

9 - Trim tab control.

10 - Engine controls.

11 - Air conditioning control (optional fi tting).

12 - Deck searchlight control (optional fi tting).

13 - Release pull handle of engine extinguisher.

14 - 24 V switches (for more details about their

functionalities, see p.66).

Page 15

2 3 4 51 96

FLYING BRIDGE C ONTROL HOUSE

8

7

5

10

13

1

11

12

13

1 - Adjustable steering wheel.

2 - VHF radio (optional fi tting).

3 - Port engine rev counter.

4 - Rudder angle indicator.

5 - Screen/ repeater for the electronic system

(optional fi tting).

FLYING BRIDGE CONTROL HOUSE

6 - Compass.

7 - Engine controls.

8 - Starboard engine rev counter.

9 - VHF loudspeaker (optional fi ttin).

10 - Engine control screens.

14

15

11 - Bow thruster control (optional fi tting).

12 - Joystick / engine controls (optional fi tting).

13 - Engine start / stop control unit.

14 - Trim tab control.

15 - Deck searchlight control (optional fi tting).

Page 16

14

1

2

34

5

6 89

7

10

11

12 13

14 15

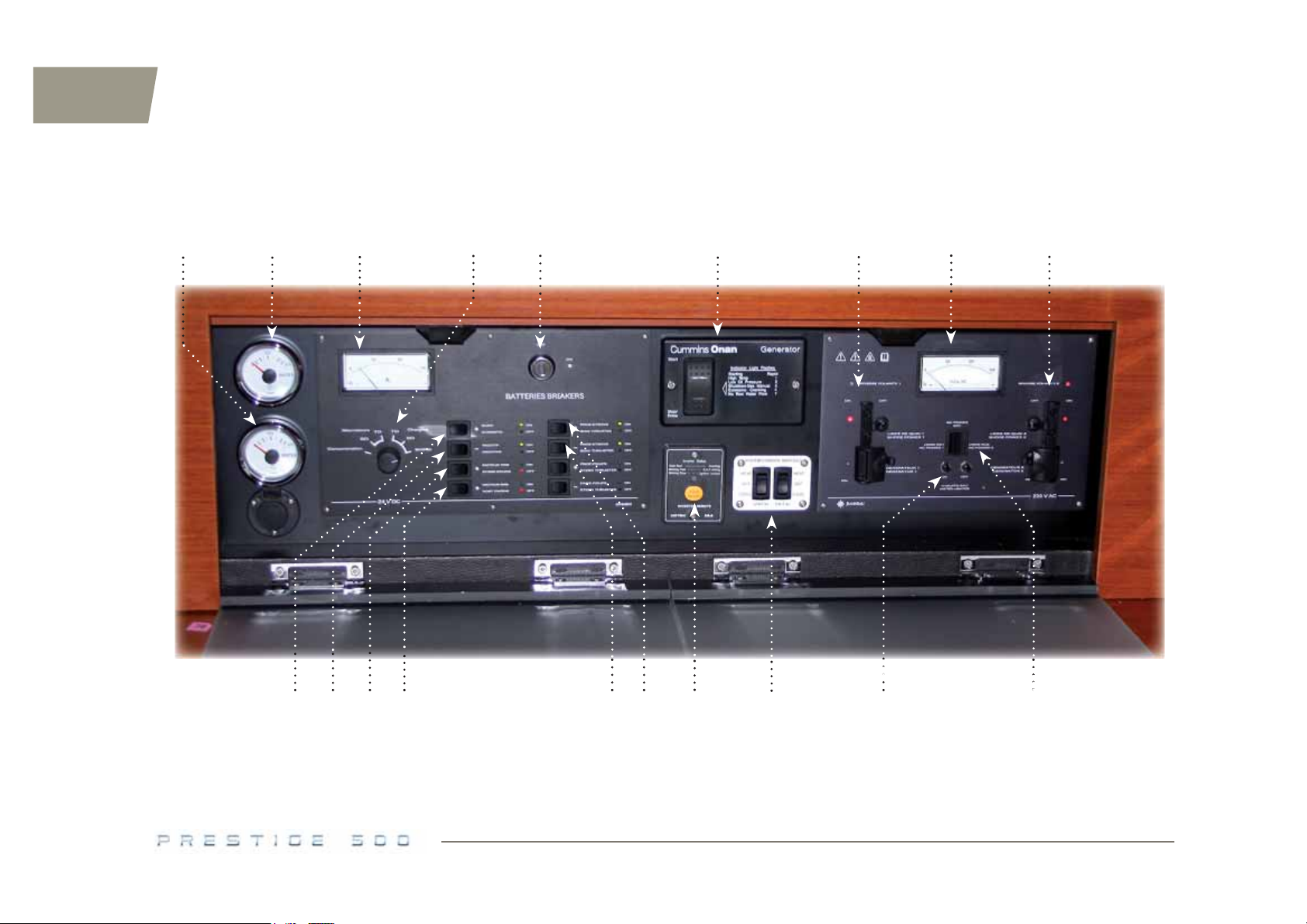

24 V - 230 V ELECTRICAL PANEL

16

17

18 19

Page 17

1

15

1 - Starboard water tank gauge.

2 - Port water tank gauge.

3 - Ammeter.

4 - Ammeter selector.

5 - General ON/OFF cut out.

6 - Generator control (optional fi tting).

7 - 230 V generator - shore supply selector / on board equipment.

8 - Voltmeter.

9 - 230 V generator - shore supply selector / air conditioning (optional fi tting).

LEGEND OF THE OPPOSITE PICTURE / 24 V - 230 V ELECTRICAL PANEL

10 - On board positive cut out.

11 - General negative cut out.

12 - Starboard engine positive cut out.

13 - Port engine positive cut out.

14 - Bow thruster positive cut out (optional fi tting).

15 - Bow thruster negative cut out (optional fi tting).

16 - 24 V / 230 V inverter control.

17 - Control to start the air conditioning.

18 - Water heater ON / OFF switches.

19 - 230 V selectors ON / OFF switches.

Page 18

Page 19

Hull / deck

17

2

2.1 Construction

2.2 Careening

2.3 Deck fitting

2.4 Access to the boat

2.5 Cockpit

2.6 Flying bridge

2.7 Access to the crew cabin

2.8 Retractable sun awning

2.9 Deck wash pump

2.10 Swim ladder

2.11 Deck searchlight

2.12 Underwater spotlights

2.13 Capstan

2.14 Anchoring

2.15 Gangway

2.16 Hydraulic platform

Page 20

18

Page 21

Hull / deck

2.1

Construction

The hull of the PRESTIGE 500 is made of laminate layers of fi breglass and

polyester resin with sandwich and an integrated osmosis barrier coat.

Frames and structural counter mould bonded and laminated to the hull, integrating supports for technical equipment: this is the way the structure of the

hull is.

The non structural areas maintain direct access to the hull.

The deck is made of laminate layers of fi breglass and polyester resin with

a sandwich composition suited to the different types of surfaces (fl at areas,

reinforced areas).

RECOMMENDATION

2.2

Careening

19

2

MAINTENANCE

The materials used to build your boat were selected for their high quality and

performances. Nevertheless they require a minimum maintenance to be protected from outside attacks (salt, sun, chafi ng, et...).

To keep her best look, besides her rinsing with fresh water after each trip, you

shall polish and shine the gel-coat periodically with cleaning products you will

buy at your dealer’s.

For possible stubborn stains or scratches, please contact your dealer; he will

be delighted to give you the proper advice.

A periodical careening of your boat will keep her original performances and

avoid any adhesion of marine vegetation.

The type of the water where you boat sails determines how to choose the

antifouling paint as well as how often to carry out these careenings.

Please contact a professional for advice.

Page 22

20

Fore deck - Access to the boat

OPEN CANOPY

SLIDING DOOR

STOPPING SYSTEM

SUNDECK

FOLDED CANOPY

SLIDING DOOR

LOCKING IT FROM THE OUTSIDE

GATE TO THE COCKPIT SUNDECK

SLIDING DOOR

LOCKING IT FROM THE INSIDE

Page 23

Hull / deck

2.3

Deck fitting

2.4

Access to the boat

21

2

FORE DECK

A sunbathing platform with a reclining back is integrated in the front desk,

protected by a foldable canopy.

Fasten the sundeck cushions and fold the canopy before you put out to sea.

PULPITS

Regularly rinse the stainless steel parts with fresh water.

LIFELINES

Inspect the metallic lifelines for "hairy wires".

Check for corrosion, particularly on the connections.

OUTSIDE WOODWORK

Regularly rinse and brush the outside woodworks with fresh water.

There are teak cleaners products on sale.

We advise you against using a pressure washer on teak.

AFT GATE

To come into the cockpit from the aft platform, lift the gate then push it to the

inside of the cockpit.

Be sure you closed the gate before you put out to sea.

WHEELHOUSE SLIDING GLASS DOOR

The wheelhouse has two sliding glass doors and a fi xed central part.

Each part slides and automatically stops at the end.

Unlock the different parts from the inside of the wheelhouse.

A curtain, inside the wheelhouse, covers the sliding glass door.

Page 24

22

Cockpit locker - Flying bridge closing system

COCKPIT LOCKER COCKPIT SHOWER FLYING BRIDGE HATCH

ACCESS TO THE FLYING BRIDGE

FLYING BRIDGE

DESK HATCHES AND SUN DECK

ACCESS TO THE

CREW CABIN

Page 25

2.5

Cockpit

Hull / deck

2.6

Flying bridge

23

2

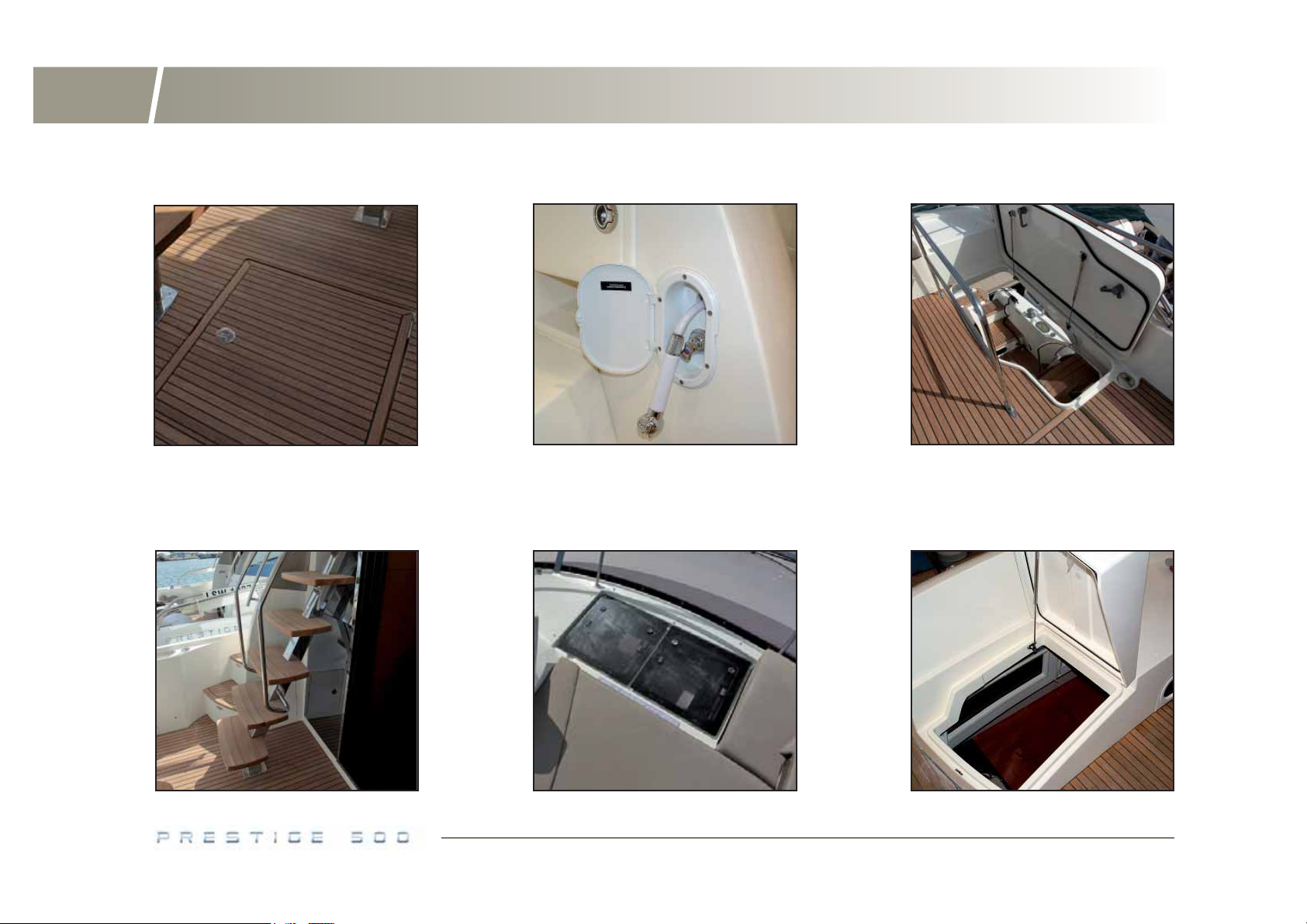

COCKPIT LOCKER

The cockpit is fi tted with a large locker with a companionway ladder.

You can reach the technical room and the engines using the ladder.

To open the cockpit locker, unlock it using the key, give the handle a quarter

turn then lift the latter.

COCKPIT SHOWER

The cockpit shower supplied with hot and cold water is located on the aft

starboard side of the cockpit.

Before using it, switch on the domestic 24 V circuit and the pressure water

pump using its switch on the dashboard.

ELECTRICAL AIR PUMP

The boat may optionally be fi tted with a portable electrical air pump.

Regarding the use and the maintenance of the electrical air pump, please

refer to the user’s manual.

You can go from the cockpit to the fl ying bridge using the stairs.

The fl ying bridge is fi tted with a hatch closing system set on jacks.

It is advisable to close the hatch cover when sailing.

FLYING BRIDGE SUNDECK

Fasten the cushions before going sailing.

FLYING BRIDGE HATCHES

Do not walk on the hatches.

Lock the hatches before going sailing.

2.7

Access to the crew cabin

The cockpit aft locker may be transformed into a crew cabin (optional fi tting).

You can reach the crew cabin from the cockpit through the cockpit seating

starboard side.

You can reach the pods through the fl oor in the crew cabin.

You can reach the battery chargers technical room through the back of the

cupboard.

Page 26

24

Retractable sun awning - Deckwash pump

RETRACTABLE

1

1 - Inlet to connect hose.

2 - Sea water supply valve.

3 - 3-way sea/fresh water selector valve.

4 - Deckwash pump.

SUN AWNING

1

UPPER COCKPIT LOCKER AWNING AND PUMP

SWITCHES

3

4

2

3

4

1

Page 27

Hull / deck

2.8

Retractable sun awning

2.9

Deckwash pump

25

2

The boat may optionally be equipped with a retractable sun awning fi tting in

the cockpit ceiling.

The retractable sun awning can be used only after having turned on the on

board 24 V circuit and the Comfort switch on the instrument panel.

To unfold the sun awning:

- Check that the on board electrical circuit has been turned on the instrument

panel located in the cupboard on the starboard side of the entrance.

- Unfold and then fold the retractable sun awning using its switch located on

the starboard side of the cockpit.

UPPER COCKPIT LOCKER

To open the locker:

- Unlock the three latches.

- Support the locker while it goes down.

RECOMMENDATION

The boat may optionally be fi tted with a deckwash pump.

The deckwash pump is located behind the ladder in the aft cockpit locker or

the crew cabin.

It provides sea water or fresh water from the tanks.

Open the sea water inlet valve (access through the trap located in the port

side toilets).

Select sea or fresh water using the valve located behind the ladder in the aft

cockpit locker or the crew cabin.

You can turn on the deckwash pump using the switch located on the cockpit

starboard side.

Press the plastic rims of the water inlets (starboard locker of aft platform +

anchor locker) to connect or disconnect the “Gardena” type connector.

Page 28

26

Swim ladder - Deck searchligh - Underwater spotlights

DECK SEARCHLIGHT

1

2

3

2

1 - Deck searchlight switch.

2 - Deck searchlight control.

3 - Underwater spotlights switch.

SWIM LADDER

DECK SEARCHLIGHT

SWITCH

4 - Deck searchlight.

5 - Swim ladder.

6 - Underwater spotlights.

UNDERWATER

SPOTLIGHTS

DECK SEARCHLIGHT

CONTROL

SWITCH OF THE

UNDERWATER SPOTLIGHTS

4

5

6

Page 29

Hull / deck

27

2

2.10

A swim ladder is located in the quarterdeck portside locker.

Do not forget to lift up the swimming ladder before sailing.

2.11

The boat may optionally be fi tted with a deck searchlight.

After having turned on the 24 V on board circuit, light on the deck searchlight

using its switch located on the command post instrument panel.

Use the control on the wheelhouse helm station or the fl ying bridge helm

station to operate the deck searchlight.

Swim ladder

Deck searchlight

2.12

The boat may be fi tted with optional underwater spotlights.

The underwater spotlights are under the aft platform, below the water line.

After having turned on the 24 V on board circuit and the Comfort switch on the

command post instrument panel, turn on the underwater spotlights using the

switch located on the starboard side of the cockpit.

Underwater spotlights

Page 30

28

Electric windlass - Capstan

1 - Electric windlass.

1

2 - Windlass switch.

3 - Windlass control.

4 - Capstan automatic breaker.

5 - Windlass automatic breaker.

6 - Capstan foot control.

7 - Capstan.

8 - Windlass control.

2

3

3

4

5

6

7

6

7

2 75

2

8

4

4

1

6

Page 31

Hull / deck

29

2

2.13

The capstan foot control is located at the bottom of the cockpit starboard

side.

The capstan can be used after switching on the 24 V domestic circuit.

If it does not work, check its circuit breaker located in the locker of the starboard companion ladder.

For the use and maintenance of the capstan, please refer to its instruction

guide.

A second electric capstan can be chosen as an option.

2.14

The stem is fi tted with a stainless steel fi tting with a double roller which enables you to sail when the anchor is home.

The fore deck is fi tted with an electric windlass.

Capstan

Anchoring

ELECTRIC WINDLASS

The electric windlass can be used when one or two engines are operating.

Turn on the windlass using its switch located on the instrument panel.

Operate the windlass from the helm station in the wheelhouse or the fl ying

bridge or using the control in the anchor locker.

If the electric windlass does not work, check its circuit breaker located in the

locker of the starboard companion ladder.

ANCHORING WITH THE ELECTRIC WINDLASS

- Have your boat head wind and sail slowly.

- Operate the windlass downwards.

- Veer away the chain while moving back slowly.

- When the anchor holds, make the wrap fast on the cleat.

RECOMMENDATION

Once the boat is anchored, keep an eye on the swinging space.

Before you anchor, check the type of the sea bed, the depth of water and the

strength of the stream.

Slip the anchor at least 3 times the depth of water.

A quality anchoring depends on both the chain (its weight makes the boat

stabilize) and the anchor.

Page 32

30

Gangway

HYDRAULIC

GANGWAY

1 - Automatic breaker.

2 - Gangway control.

3 - Hydraulic pump.

4 - Gangway location.

2 31

1

GANGWAY

USED AS A CRANE

2

3

4

Page 33

Hull / deck

31

2

RAISING THE GROUND TACKLE

- Lock the grab brake.

- Check the chain is properly set on the grab.

- Activate the windlass setting it to the ‘upward’ position.

- Slowly go near the anchor using the engine (do not use the windlass force

to winch up the boat).

RECOMMENDATION

- Visually check the fi nal metres until the anchor gets into contact with the

anchor fairlead.

- Check the position of the anchor on the stem fi tting.

Rinse the windlass and the ground tackle with fresh water each time you

come back.

For the maintenance of the windlass, please refer to its instruction guide.

2.15

The boat may be fi tted with an optional hydraulic gangway.

After the domestic electrical system is switched on, the gangway can work.

The gangway control is located in the cockpit aft port side.

A remote control is also available on board the boat.

If it does not work, check its circuit breaker located in the locker of the starboard companion ladder.

If all else fails, it is possible to retract the gangway using the lever on its hydraulic pump (access through the aft cockpit locker or crew cabin, port side).

The gangway can also be used as a crane in order to lift a tender up to the

transom or to take it down to the water from the transom.

Gangway

For winter storage, release the windlass brake and make sure the grab turns

freely.

For the use and maintenance of the hydraulic gangway, please refer to its

instruction guide.

Page 34

32

Hydraulic platform

HYDRAULIC

PLATFORM

1 - Platform automatic breaker.

2 - Platform control.

3 - Hydraulic pump.

1

2

3

2 31

Page 35

Hull / deck

33

2

2.16

The aft swim platform can be equipped as an option with an hydraulic platform.

Hydraulic struts enable you to let it down under the boat waterline.

After switching on the domestic 24 V circuit, use the platform control located

in the cubby hole on the starboard side of the cockpit.

The control makes it possible to lower, raise the platform into any position or

stop it in the chosen position.

In order to keep the platform in good working order, set the load as close as

possible to its centre.

Hydraulic platform

If it does not work, check its breaker located in the cubby hole in the companionway down to the aft cabin.

If all else fails, it is possible to raise the aft platform using the lever on its

hydraulic pump located in the service compartment located under the bed in

the skipper’s cabin.

Nota : a specifi c gangway is provided for boats equipped with the optional

hydraulic platform. It supports a maximum weight of 150 Kg.

RECOMMENDATION

Page 36

Page 37

Accommodations

3.1 Saloon table

3.2 Floorboards

3.3 Portholes - Deck hatches

3.4 Windows

3.5 Cabins

3.6 Helm stations

35

3

Page 38

36

Saloon table - Windows - Blinds

SALOON TABLE

SHORT POSITION

BLIND + MOSQUITO SCREEN

DECK HATCH

SALOON TABLE

LONG POSITION

SALOON TABLE FLOOR

FASTENING

BLIND ON

WHEELHOUSE WINDOW

Page 39

Accommodations

3.1

Saloon table

3

3.3

Portholes - Deck hatches

37

The saloon table can articulate into two positions, a short one when folded, a

long one when unfolded.

To extend the table:

- Take out the leaf brackets located on both sides, under the table.

- Unfold the two table tops.

Follow the procedure in the inverse order to convert the table into short position.

The saloon table can be moved unscrewing the two bolts located in between

the table legs.

3.2

Floorboards

The cabin fl oorboards have hatches to have access to the different service

units onboard, such as the waste holding tank, the windscreen washer tank

under the front cabin fl oor or a fresh water tank under the passageway fl oor.

RECOMMENDATION

The portholes and deck hatch are fi tted with locking systems to keep them in

a closed position.

At anchor, intermediate opening positions allow for airing the boat.

The deck hatches are fi tted with a blind and mosquito screen system that can

be used even when the hatch is open.

Their handling shall be done carefully.

3.4

Windows

CURTAINS

The windows in the wheelhouse, cabins and heads have blinds.

The wheelhouse blind can be electrically controlled (optional fi tting).

The electric blinds are controlled independently whether they are on the port

on the starboard side.

Another optional fi tting allows to equip the boat with outside blinds, obscuring

then all the wheelhouse.

Page 40

38

Sliding window - Cabins - Windscreen washer

SLIDING WINDOW

CREW CABIN WET ROOM

SLIDING WINDOW

CONTROLS

ADJUSTABLE

STEERING WHEEL

TWO-BERTH

PORT SIDE CABIN

WINDSCREEN WASHER

AND WIPERS SWITCHES

DOUBLE BED

PORT SIDE CABIN

WINDSCREEN

WASHER TANK

Page 41

Accommodations

39

3

ELECTRICAL SLIDING WINDOWS

The wheelhouse has two electrical sliding windows located next to the command post.

After having turned on the on board electrical system and the Comfort switch

on the instrument panel, you can make the windows go up or down using the

switched located on the station on the left of the command post.

3.5

Cabins

FRONT CABIN

The berth in the front cabin can be divided into two separated berths.

Lift each part of the berth and slide them towards the hull.

PORT SIDE CABIN

The two berths of the port side cabin can be transformed into one double bed

only by adding cushions in between them.

3.6

Helm stations

WHEEL

The height of the wheel can be adjusted to ease steering when you are standing or sitting.

DASH BOARD

All the desks and switches necessary for the engine and comfort component

operation are on the dash board.

Please read the details about the switches in Chapter ELECTRICITY.

WINDSCREEN WIPERS

The boat is fi tted with two windscreen wipers with incorporate windscreen

washer.

Windscreen wipers can be used having turned on the Comfort switch.

Their control is located on the left part of the wheelhouse instrument panel.

CREW CABIN

As an optional fi tting, the aft technical room can be transformed into a crew

cabin.

The crew cabin is fi tted with a simple berth, a private wet room and marine

toilets.

WINDSCREEN WASHER

The windscreen washer tank is located under the fl oor in front of the bed in

the front cabin.

Operate the windscreen washer using its switch located on the command post

instrument panel.

Page 42

Page 43

On board utility

41

4

4.1 Slot-in television

4.2 Flying bridge refrigerator

4.3 Flying bridge grill

4.4 Icemaker

4.5 Microwave oven

4.6 Stove unit

4.7 Induction cooktop

4.8 Extractor Hood

4.9 Refrigerator / freezer

4.10 Dishwasher

4.11 Washer-dryer

4.12 Safe

4.13 Heating

4.14 Air conditioning

Page 44

42

Slot-in television - Flying bridge refrigerator and grill

SLOT-IN TELEVISION UP / DOWN TV SWITCH

1

2

3

1 - Television.

2 - Up / down television switch.

3 - Utility switch.

FLYING BRIDGE GRILL

4

5

6

4 - Flying bridge grill.

5 - Flying bridge refrigerator.

6 - Refrigerator compressor.

REFRIGERATOR

INVERTER CONTROL

UTILITY SWITCHFLYING BRIDGE

Page 45

On board utility

4.1

Slot-in television

4.2

Flying bridge refrigerator

43

4

According to the lay out, the saloon is fi tted with a slot-in television located in

the unit at the front of the saloon.

After having turned on the 24 V circuit, use the Utility switch on the instrument

panel and then the switch located in companion ladder next to the command

post to make the television go up or down.

RECOMMENDATION

The TV set is powered through a 24 V / 230 V converter located in the port

technical room (see chapter ELECTRICITY).

RECOMMENDATION

For the use and maintenance of the television, please refer to its instruction

guide.

Nota: front or back cabins can also be fi tted with TV sets. Each of them is

supplied with the 24 V / 230 V converter.

The boat is fi tted with a fl ying bridge refrigerator.

It can be used after having turned on the 24 V on board circuit and after having

activated the Comfort switch.

Start the refrigerator using the thermostat switch.

Defrost then drain the refrigerator before you stop the domestic 24 V circuit.

For the use and maintenance of the fl ying bridge refrigerator, please refer to

its instruction guide.

4.3

Flying bridge grill

The boat is fi tted with an electric grill on the fl ying bridge.

Check that its circuit breaker has been powered on the lower bus in the electrical panel located in the companion ladder, next to the aft cabin.

SUPPLY

Select the source of the supply (generator or shore power) using the left selector of the 230 V selection panel at the entrance of the wheelhouse.

Page 46

44

Icemaker - Microwave oven

230 V ELECTRICAL CABINET

1

2

3

1 - Microwave oven.

4

2 - 230 V electrical cabinet.

3 - Icemaker.

4 - 230 V electrical panel.

5 - Valve + fi lter of the icemaker.

ICEMAKER VALVE + FILTER

OF THE ICEMAKER

MICROWAVE OVEN

5

Page 47

On board utility

For the use and maintenance of the fl ying bridge electric grill, please refer to

its instruction guide.

4.4

Icemaker

The boat is optionally fi tted with an icemaker located in the wheelhouse starboard entrance cupboard.

It is supplied with water coming from the fresh water system (valve located

above the fi lter in the starboard technical room).

4

4.5

Microwave oven

The boat is fi tted with a microwave oven located in the galley.

Check that its circuit breaker has been powered on the lower bus in the electrical panel located in the companion ladder, next to the aft cabin.

SUPPLY

Select the source of the supply (generator or shore power) using the left selector of the 230 V selection panel at the entrance of the wheelhouse.

For the use and maintenance of the microwave oven, please refer to its instruction guide.

45

Check that its circuit breaker has been powered on the lower bus in the electrical panel located in the companion ladder, next to the aft cabin.

SUPPLY

Select the source of the supply (generator or shore power) using the left selector of the 230 V selection panel at the entrance of the wheelhouse.

For the use and maintenance of the icemaker, please refer to its instruction

guide.

Nota: The icemaker system is fi tted with a carbon fi lter which is in the service

room. Regularly change the carbon fi lter.

Page 48

46

Stove unit - Induction cooktop - Hood

1

2

1 - Stove unit or

3

induction cooktop.

4

2 - 230 V electrical cabinet.

5

3 - Gas valves.

6

4 - 230 V electrical panel.

5 - Extractor hood.

6 - Storage place for gas bottles.

STORAGE PLACE FOR

GAS BOTTLES

INDUCTION

COOKTOP

GAS VALVESSTOVE UNIT

EXTRACTOR HOOD

Page 49

On board utility

47

4

4.6

Stove unit

The boat standard features include a 3-burner stove unit.

The burners run on gas after having opened the dedicated valve located under

the microwave (access through the drawer under the oven).

After turning on the burners, a safety feature obliges you to keep the knobs

pressed during a few seconds.

The gas cartridges are located in a storage space which you can gain reach

on the starboard side of the stairs leading to the fl ying bridge.

4.7

Induction cooktop

According to the fi tting out, the boat may optionally be fi tted with a induction

cooktop located in the kitchen and replacing the stove unit.

For the use and maintenance of the induction cooktop, please refer to its

instruction guide.

4.8

Extractor Hood

The boat is fi tted with an extractor hood located in the galley.

Check that its circuit breaker has been powered on the upper bus in the electrical panel located in the companion ladder, next to the aft cabin.

SUPPLY

Select the source of the supply (generator or shore power) using the left selector of the 230 V selection panel at the entrance of the wheelhouse.

For the use and maintenance of the extractor hood, please refer to its instruction guide.

Check that its circuit breaker has been powered on the upper bus in the electrical panel located in the companion ladder, next to the aft cabin.

SUPPLY

Select the source of the supply (generator or shore power) using the left selector of the 230 V selection panel at the entrance of the wheelhouse.

Page 50

48

Refrigerator - Dishwasher - Washer-dryer

1

2

3

4

5

6

7

8

9

10

UTILITY SWITCH

1 - Washer-dryer outlet.

2 - Washer-dryer.

3 - Utility switch.

4 - Washer-dryer fresh water

supply valve.

5 - Dishwasher.

6 - Dishwasher fresh water

supply valve.

7 - 230 V electrical cabinet.

8 - Refrigerator / freezer.

9 - 230 V electrical panel.

10 - Diswasher outlet.

DISHWASHER DISHWASHER - FRESH

WATER SUPPLY VALVE

WASHER-DRYER WASHER-DRYER - FRESH

WATER SUPPLY VALVE

Page 51

On board utility

49

4

4.9

Refrigerator / freezer

The boat is fi tted with a refrigerator / freezer located in the galley.

After having turned on the 24 V on board circuit, activate the Comfort switch

on the instrument panel.

Start the refrigerator using the thermostat switch.

Defrost then drain the refrigerator / freezer before you stop the domestic 24 V

circuit.

For the use and maintenance of the refrigerator / freezer, please refer to its

instruction guide.

4.10

The boat is fi tted with an optional dishwasher located in the galley.

The fresh water system supplies it with water.

Check that the relevant fresh water inlet valve located in the bin locker next to

the dish washer is open.

The drainage is direct (valve located in the port side technical room).

Check that its circuit breaker has been powered on the lower bus in the electrical panel located in the companion ladder, next to the aft cabin.

Dishwasher

SUPPLY

Select the source of the supply (generator or shore power) using the left selector of the 230 V selection panel at the entrance of the wheelhouse.

RECOMMENDATION

For the use and maintenance of the dishwasher, please refer to its instruction

guide.

4.11

The boat may optionally be fi tted with a washing machine located under the

front companion ladder.

The fresh water system supplies it with water.

Check that the relevant fresh water inlet valve located behind the washing

machine is open.

The drainage is direct (valve located in the front bathroom).

Check that its circuit breaker has been powered on the lower bus in the electrical panel located in the companion ladder, next to the aft cabin.

SUPPLY

Select the source of the supply (generator or shore power) using the left selector of the 230 V selection panel at the entrance of the wheelhouse.

Washer-dryer

Page 52

50

Safe - Heating

HEATING CONTROL BOILER

1

2

1

1

2

3

1

4

5

6

1

1 - Forced air heater.

2 - Heating control.

3 - Safe.

4 - Fuel tank.

5 - Fuel valve.

6 - Boiler.

SAFE

1

2

1

2

1

Page 53

On board utility

51

4

RECOMMENDATION

For the use and maintenance of the washer-dryer, please refer to its instruction guide.

4.12

The boat may optionally be fi tted with an electronic safe, located in the aft

cabin, in the starboard locker.

For the use and maintenance of the safe, please refer to its instruction guide.

Safe

4.13

The boat may be fi tted with optional heating.

It is a system in closed circuit, that works with water circulation.

The heating works after switching on the 24 V circuit.

The boiler is located in the technical room, at the back of the port side fuel

tank.

It is fed from the port fuel tank.

- Check the fuel valve is open (access on the tank in the technical room to

port).

- Check and read the pressure on the manometer (please refer to the manufacturer’s guide).

Each part has a control and thermostat.

The front control cabin supplies the front cabin and the front bathroom.

The aft cabin control supplies the aft cabin and the aft bathroom.

For the use and maintenance of the heating system, please refer to its instruction guide.

Heating

Page 54

52

Air conditioning

1

2

3

2

1

3

2

3

1

1 - Outlet.

2 - Air conditioning control.

3 - Forced air heater.

4 - Automatic breaker of the

air conditioning components.

8

5 - Water inlet valves + fi lters.

6 - Air conditioning drain valves.

7 - Air conditioning unit.

8 - Hot / cold selector.

2

1

1

3

2

3

1

2

4

5

6

7

5

3 7

8

Page 55

On board utility

53

4

4.14

The boat may be fi tted with an optional reversible air conditioning system.

The air conditioning system requires 230 V with a cold water system.

Six air conditioning units (forced air heaters) work independently.

They are located:

- In the saloon, under the pilot seat and the port side aft saloon seating.

- In the front cabin (starboard locker).

- In the port cabin (wardrobe).

- In the aft cabin (starboard locker).

- In the crew cabin (locker located behind the companion ladder).

There are outlets in every cabin, in the galley and in the saloon.

Before you start the system:

- Open the seawater inlet valves in the technical room, behind the fuel tanks

(access through the cockpit locker).

- Open the seawater outlet valves located next to each group and in the technical room for the saloon groups.

Air conditioning

SUPPLY

Select the source of the supply (generator or shore POWER) using the right

selector of the 230 V selection panel at the entrance of the wheelhouse.

Check that the air conditioning group and the pump circuit breakers have

been powered on the upper and lower bus in the electrical panel located in

the companion ladder, next to the aft cabin.

After selecting hot or cold position using the switch in the electrical panel of

the chart table, start the air conditioning unit in the desired area then adjust

the temperature using its control switch.

Regularly clean the fi lter on the sea water suction valves.

For the use and maintenance of the air conditioning system, please refer to

its instruction guide.

The air conditioning units are called “reversible” as they can heat the boat if

the sea water temperature is over 10° C.

A dehumidifi er function can be preset on the air conditioning controls.

Page 56

Page 57

Water systems

5.1 Bilge pump system

5.2 Grey waters

5.3 Black waters

5.4 Fresh water

55

5

Page 58

56

Water system - Draining

1 - Electric bilge pump.

2 - Bilge pump outlet valve.

3 - Front wet room outlet valve.

4 - Aft wet room outlet valve.

5 - Shower pumps.

1

2

3

6 - Kitchen grey water outlet valves.

7 - Flying bridge sink drain valve.

8 - Manual bilge pump.

9 - Switches of the bilge pumps.

4

5

1

6

7

2

8

2

1

8

1

9

9 9

Page 59

Water systems

57

5

5.1

Bilge pump system

The boat is fi ttted with three electric bilge pumps:

- In the front cabin (under the fl oor in front of the door).

- In the aft cabin (under the trap under the starboard berth).

- In the crew cabin (under the berth).

A manual emergency pump is located on the starboard side of the cockpit in

front of the wheelhouse.

All the electric bilge pumps are switched on using the WATER PUMP switch on

the left on the dash board (They automatically start).

Each pump starts manually using the switches on the left on the dash board.

The pump automatically starts if the water level is low but the alarm does not

(Draining of the bilge pipes).

Then the alarm starts when the water level is higher.

Nota: the electric bilge pump located in the crew cabin functions automatically even when the 24 V circuit is turned off.

RECOMMENDATION

RECOMMENDATION

Nota: A valve is closed when its handle is perpendicular to the hose and it is

open when its handle is in line with the hose.

5.2

Grey waters

The grey waters coming from the showers, the washbasins and the sinks are

directly drained out via sea-cocks fi tted with valves.

Open the relevant valves before using the water equipment and close the

valve after use.

Page 60

58

Holding tank

1

2

3

4

5

1 - Holding tank.

2 - Drain valve of the tank.

3 - Gauge of the holding tank.

4 - Switch to drain the tank.

5 - Drain fi ller of the black waters.

6 - WATER PUMP switch.

7 - Device to switch on the pressure

water pump.

3 4 6 7

SWITCH OF

THE ELECTRIC TOILETS

5

1

2

HOLDING TANK

FRONT CABIN

HOLDING TANK

CREW CABIN

Page 61

Water systems

59

5

5.3

Black waters

The boat is fi tted with electric toilets and a 120 litres holding tank under the

fl oorboard, in front of the bed.

The WC working is based on a depression draining system and the use of the

domestic fresh water for rinsing (approximately 0,6 litre per rinse).

The crew cabin (optional fi tting) is fi tted with manual toilets and with a 50

litres black water tank located in the port side technical room.

USE OF THE MANUAL TOILETS (CREW CABIN)

- Open the water inlet and drain valves (under the wet room cabinet).

To empty the bowl:

- Set the control lever of the pump slantwise (FLUSH) and operate the pump.

To dry the bowl:

- Set the lever back vertical (DRY) and operate the pump.

In order to avoid clogging the toilets, use absorbent paper only and pump until

the emptying hose is completly empty.

Regularly rinse the toilets with fresh water.

Close the valves after each use.

USE OF THE ELECTRIC TOILETS

Check fi rst that the WATERPUMP and water group switches located on the

instrument panel are activated.

The FULL switch allows to fi ll up the bowl before use.

The QUICK FLUSH switch allows to rinse and fi ll up the bowl after light use.

The FLUSH switch allows to rinse and fi ll up the bowl twice after intense use.

The EMPTY switch allows to drain off the bowl only.

USE OF THE HOLDING TANKS

Watch the black water level using the gauge located next to the electrical

toilet, in the front wet room.

The black water tank in the front wet room is emptied by an electric pump.

The crew cabin black water tank is emptied by gravitational force.

Make sure the drain valve of the tank is closed in order to avoid any inadvertent discharge (the valve is closed when the handle is perpendicular to the

hose).

Tank drainage:

- In an authorized area, after switching on the domestic 24 V circuit and opening the drain valve located in the front wet room, drain the tank using the

switch located in the front wet room.

Concerning the tank located in the technical room, open the outlet valve.

Page 62

60

Fresh water system

1

2

3

4

5

1 - Fresh water tanks.

2 - Valves to select tanks.

3 - Pressure water pump.

4 - Deck fi ller.

5 - Tank gauges.

6 - Switch to start the pressure

water pump.

5

6

32

Page 63

Water systems

61

5

- In a marina equipped with an organic waste suction system, fi t the suction

hose into the tank through the deck fi ller located on the port side of the passageway, next to the wheelhouse door.

- Start the pump of the suction system.

Regularly rinse the holding tank.

RECOMMENDATION

5.4

Fresh water

FRESH WATER TANKS

The boat is fi tted with two 318 litres tanks located under the fl oor of the port

side cabin and of the fl oor.

They are fi lled by one single deck fi ller located in front of the port side deck.

Tank selector valves are located under the starboard berth of the port cabin.

During fi lling, avoid handling contaminants near the fi llers.

Open and close the fi ller caps with the right key.

Check the fi ller cap seals for condition during fi lling.

The tanks are fi tted with overfl ow outlets and vents.

Never insert the water fi lling hose deep down into the system in order to prevent any over-pressure in the systems.

RECOMMENDATION

Nota: the capacity of the fresh water tank(s) indicated on the page SPECIFICATIONS may be not completely usable depending on the trim and load of the

boat.

PRESSURE WATER PUMP

The water group is located under the starboard berth of the portside cabin.

Its starting is done by using a switch on the dash board.

RECOMMENDATION

To prevent any handling mistake, never fi ll the water and fuel tanks at the

same time.

Page 64

62

Shore fresh water supply - Water heater

SHORE FRESH

WATER SUPPLY

1

2

3

1 - Water heater.

2 - 230 V electrical cabinet.

3 - Switch of the water heater.

4 - Shore fresh water supply.

230 V ELECTRICAL CABINET

WATER HEATER

ON / OFF SWITCH

OF THE WATER HEATER

WATER HEATER

ENGINE VALVES

4

Page 65

Water systems

63

5

WATER GAUGE

Watch the level of the water in the tanks using the gauges located on the

electrical panel at the entrance of the wheelhouse.

The gauges work only after switching on the ‘Pressure Water Pump’ switch

on the dash board.

SHORE FRESH WATER SUPPLY

The fresh water inlet valve with pressure regulator is located in the starboard

aft cockpit locker.

To use the marina fresh water:

- Connect the shore supply.

- Set the pressure water pump switch to OFF.

RECOMMENDATION

WATER HEATER

The water heater has a capacity of 60 litres.

It is located under the aft cabin berth.

Check that its circuit breaker has been powered on the upper bus in the electrical panel located in the companion ladder, next to the aft cabin.

Two valves located ahead of the port engine make possible to leave the water

heater system apart from the engine one.

SUPPLY

If the engines are not running, Select the source of the supply (generator or

shore power) using the left selector on the 230 V selection panel at the entrance of the wheelhouse.

RECOMMENDATION

The hot water temperature is pre-set using the thermostatic tap located on

the water heater (access under the aft cabin berth).

The water heater works automatically once the engines are running, or on 230 V

supply after the shore power supply is plugged or after the generator started

and its switch on the electrical panel at the entrance of the wheelhouse is set

to ON.

Page 66

Page 67

Electricity

6.1 24 V circuit

6.2 Inverters

6.3 230 V circuit

6.4 Electronics

65

6

Page 68

66

24 V circuit location - Batteries - Electrical panel

1

2

3

4

5

6

7

8

9

10

BATTERY CHARGERS24 V ON BOARD

POWER UNIT

1 - Dash board.

2 - 230 V devices circuit breakers.

3 - Boat and engine cutouts.

4 - Electrical panel.

5 - 24 V / 230 V inverter.

6 - 24 V service power unit.

7 - Automatic breakers of the shore power sockets.

8 -

Engine 24 V batteries.

9 - Battery chargers.

10 - Shore power sockets.

ELECTRICAL PANEL

24 V CUTOUTS

31

2

1 - Ammeter.

2 - Domestic positive pole.

3 - Common negative pole.

4 - Starboard engine.

5 - Port engine.

6 - Bow thruster positive cut out.

7 - Bow thruster negative cut out.

45 67

Page 69

Electricity

67

6

6.1

24 V circuit

24 V CIRCUIT

TO SWITCH ON THE 24 V CIRCUIT

On the electrical panel at the entrance of the wheelhouse:

- Set the key to ON.

- Press the following switches: Board, Negative, Engines and Bow thruster.

- Keep them pressed two seconds.

The ON indicator lights are on.

TO SWITCH OFF THE 24 V CIRCUIT

On the electrical panel at the entrance of the wheelhouse:

- Press the following switches: Board, Negative, Engines and Bow thruster.

- Keep them pressed two seconds.

The OFF indicator lights are on.

- Set the key to OFF.

BATTERIES

The 24 V power unit supplying the board is located under the fl oor, port side,

in the technical room.

BATTERY RECHARGING

You recharge the battery bank either with two alternators (24 V / 80 Amp) or

with the battery charger (230 V / 24 V - 60 Amp).

Another battery charger (230 V / 24 V - 40 Amp) is dedicated to the bow

thruster battery park.

OPERATION

The battery chargers can be used with the shore power socket or the operating generator.

Check that the relevant circuit breaker has been powered on in the electrical

panel located in the companion ladder, next to the aft cabin or on the electric

panel in the starboard technical room for the thruster.

Select the source of the supply (shore power or generator) using the left selector on the 230 V selection panel at the entrance of the wheelhouse.

Nota: the battery chargers can remain in operation even when the boat is not

energized in 24 V.

CHECKING OF THE 24 V CONSUMING APPLIANCES

You can check the 24 V consuming appliances reading related data on the

dash board and the electrical panel at the entrance of the wheelhouse (read

details on the summary table at the end of this chapter).

Page 70

68

24 V switches - Shore power sockets - Inverter

6

54321 121110987

54321 9876 10

1 - Port side electric window.

2 - Navigation lights.

3 - Starboard side electric window.

4 - Mooring lights.

5 - Demister.

6 - Deck fl oodlight.

THE SHORE POWER SOCKETS

7 - Bilge pump.

8 - Lighting.

9 - Bilge pump.

10 - On board utility.

11 - Bilge pump.

12 - Water pump.

24 V / 230 V

INVERTER

1 - Klaxon.

2 - Pressure water pump.

3 - Anchor lights.

4 - Electric windlass.

5 - Navigation instruments.

INVERTER CONTROLAUTOMATIC BREAKERS OF

6 - Windscreen washer.

7 - Auxiliary.

8 - Port windscreen wiper.

9 - Auxiliary.

10 - Starboard windscreen wiper.

AUTOMATIC BREAKERS OF

THE INVERTER

Page 71

6.2

Inverters

Electricity

6.3

230 V circuit

69

6

24 V / 12 V INVERTER

The boat is fi tted with a 24 V / 12 V converter for the 12 V sockets, the CD/

DVD players and the GPS antenna (via the Auxiliary switch on the instrument

panel).

The converter is located in the starboard technical room, above the electric

boards. It is started switching on the Comfort switch on the instrument panel.

24 V / 230 V INVERTER

According to the fi tting out, the boat may optionally be equipped with a 24 V /

230 V - 700 Va or 2500 Va inverter located in the port side technical room.

The inverter works once the 24 V domestic system is on, after putting on the

switch on the electrical panel.

The inverter feeds the boat electrical sockets with 230 V and each television

(an optional extra) with 230 V as well.

RECOMMENDATION

SHORE POWER SOCKETS

The shore power sockets are both located in the starboard aft locker of cockpit.

The POWER shore sockets give supply to the POWER and AIR CONDITIONING

busbar components that work on 230 V.

The UTILITY shore socket gives supply to the UTILITY busbar components that

work on 230 V.

Before you plug in or unplug the boat / shore power supply cable, switch off

the shut off device connected to the shore supply.

Connect the boat / shore power supply cable in the boat before connecting it

to the shore supply socket.

Unplug the boat / shore supply cable on shore fi rst.

Close the protecting cover of the shore supply socket when you do not use

the plug.

Nota : use with caution the biggest electrical-consuming devices supplied

with 230 V (e.g. microwave) when they depend on the inverter.

Check the battery charge during the use of the inverter.

Page 72

70

Generator

1 2

1

2

3

4

5

6

7

8

9

10

3

1 - Fuel fi lter of generator.

2 - Generator circuit breaker.

3 - Generator.

4 - Water / gas separator.

5 - Fuel tank.

6 - Fuel / generator stop pull handle.

7 - Start battery of generator.

8 - Sea water inlet valve of generator.

9 - Sea water fi lter of generator.

10 - Drain valve of separator.

11 - Generator control.

8

7

11

Page 73

Electricity

71

6

GENERATOR / 12 V CIRCUIT

12 V CIRCUIT

The 12 V battery supplying the generator is located in front of this generator,

in the technical room.

The battery can be charged either by the generator alternator or 230 V / 12 V

- 25 Amp battery charger located next to its cut-outs.

The battery charger can be used with the shore power supply if in use.

Check that its circuit breaker has been powered on the upper bus in the electrical panel located in the companion ladder, next to the aft cabin.

Select the source of the supply (shore power or generator) using the left selector on the 230 V selection panel at the entrance of the wheelhouse.

GENERATOR

The generator is located in the technical room, between the fuel tanks (access

through the cockpit locker).

Its function is to re-supply the batteries via the chargers and supply 230 V

electricity on board.

The generator is supplied by the starboard fuel tank.

Make sure its fuel valve (access in the service room on the starboard tank)

and its sea water cooling valve (access in the technical room, in the front of

the generator) are open.

RECOMMENDATION

For the generator use and maintenance, please refer to its instruction guide.

OPERATION

After having turned on the relevant circuit breakers, the generator can be

turned on either on the generator or using the control on the panel located on

the starboard side of the wheelhouse entrance.

Page 74

72

Automatic breakers - Selectors - Lighting system

SHORE POWER / GENERATOR

SELECTORS

230 V DISTRIBUTION BOARD

A

SWITCH IN SALOON

1 2345 6

1 - Ceiling indirect lighting.

2 - Saloon wheelhouse lighting.

3 - Outside courtesy leds.

4 - Cockpit lighting

(1 touch: white, 2 touches: blue).

5 - Galley ceiling lighting.

6 - Starboard companion ladder two-way switch.

FRONT COMPANION

LADDER SWITCH

1 23 45

1 - Ceiling indirect lighting

2 - Passageway two-way switch.

3 - Television set up / down.

4 - Saloon ceiling lighting.

5 - Saloon ceiling lighting.

B

A - Upper bus.

B - Lower bus.

Page 75

Electricity

73

6

CHECKING OF THE 230 V CONSUMING APPLIANCES

110 V - 230 V ELECTRICAL PANEL (entrance of the wheelhouse)

This panel has sliders which enable you to choose the supply source for the

different 110 V - 230 V consuming appliances on board.

LEFT SELECTOR:

- allows to use the devices on board supplied with a 110 V - 230 V current

coming from the generator or the shore.

RIGHT SELECTOR:

- allows to use the air conditioning powered by a 110 V - 230 V current coming

from the generator or from the shore power.

110 V - 230 V PROTECTION PANEL (board in the passage way)

This area groups together 2 buses of automatic breakers of the 110 V - 230 V

appliances and equipments.

The UPPER bus is relevant for the POWER bus on board appliances.

The LOWER bus is relevant for the AIR CONDITIONING bus and the UTILITY bus

on board appliances.

Nota: all the automatic breakers of the 110 V - 230 V circuit are bi-polar

automatic breakers.

USE OF THE 110 V - 230 V POWERED APPLIANCES

TO SWITCH ON THE APPLIANCES

In order to be able to use the 110 V - 230 V powered appliances (dishwasher

grill, etc.), it is advisable:

- To make sure that the automatic breakers are turned to OFF on the 110 V

- 230 V selection panel.

- Switch on the 110 V - 230 V source (start the generator or connect the shore

power socket to shore).

- Select this source on the electrical panel so that this source can supply the

boat (110 V - 230 V Selection electrical panel).

- Push the automatic breaker of the appliance to be used (dishwasher, grill,

etc.) on the electrical panel.

Then start the appliance with its own controls.

To start 110 V - 230 V elements, wait for 10 to 15 seconds between the start

up of each new component (in order to allow the generator to become stabilized and be able to give the power necessary for the starting up).

Page 76

74

Sensors - Pilot compass - Electronic boxes

SENSORS - INSIDE ELECTRONIC BOXES

1

2

3

1 - Log + depth sounder sensors.

2 - Automatic pilot compass.

3 - Electronic boxes.

Page 77

Electricity

75

6

TO STOP THE 110 V - 230 V POWERED APPLIANCES

To stop the 110 V - 230 V powered appliances (dishwasher, grill, etc.) it is

advisable to do as follows:

- Stop the appliance with its own controls.

To stop 110 V - 230 V elements, wait for 10 to 15 seconds between the stop of

each new component (in order to allow the generator to become stabilized).

- On the electrical panel, turn off the automatic breaker of the appliance that

is used.

- Turn to OFF the 110 V - 230 V source selector (generator or shore power).

- Stop the generator or disconnect the shore power socket.

6.4

Electronics

The boat may be fi tted with an optional electronic pack and different navigation aid accessories.

For the use and maintenance of all these components, please refer to their

instruction guides.

The log and depth sounders can be reached under the fl oor, in front of the aft

cabin berth.

The auto pilot compass is located behind the aft cabin wardrobe partition.

Make sure you do not put close to the compass, objects susceptible to disturb

the magnetic fi eld of the compass (metal objects).

The control units are located in the portside technical room (access through

the cockpit locker).

Page 78

76

Technical room electric boards

FRONT ELECTRIC BOARD

TECHNICAL ROOM

1

2 3 5

1 - Relay - coupling of engine battery banks.

2 - On board fuse.

3 - Battery switch - negative.

4 - Starboard engine main switch.

5 - Board main switch.

6 - Port engine main switch.

4

6

CENTRAL ELECTRICAL BOARD

TECHNICAL ROOM

31 4 6

2 4

1 - Negative bus bar before cut-out.

2 - Negative bus bar after cut-out.

3 - Positive bus bar after cut-out.

4 - Negative bus bar before cut-out.

5 - Port side engine bus bar before cut-out.

6 - Starboard engine bus bar before cut-out.

AFT ELECTRIC BOARD

TECHNICAL ROOM

1 432

1 - Bow thruster battery park charger fuse.

2 - Starboard load divider.

3 - Load shunts.

4 - Port load divider.

Page 79

Summary for the 12 V and 24 V components

CHARGE AND ELECTRICAL CONVERSION

1 x 230 V / 24 V - 60 Amp charger 24 V Service and engine bank

1 x 230 V / 12 V - 25 Amp charger With optional generator

1 x 230 V / 24 V - 40 Amp charger Bow thruster battery park

2 x 24 V - 80 Amp alternators Recharge of engine and service bank

24 V / 12 V inverter VHF, 12 V sockets, radio and DVD player

BATTERIES / CONSUMING APPLIANCES

24 V CURRENT VOLTAGE START PROTECTION

Engine batteries 24 V - 55 Ah x 2

Service batteries 24 V - 140 Ah x 4

24 V - 80 Amp alternator / engine recharge + 1 x 230 V /24 V - 60 Amp charger

Navigation electronics 24 V Dash board 24 V electrical panel

Utility lighting 24 V Dash board 24 V electrical panel

Navigation lights 24 V Dash board 24 V electrical panel

Refrigerators (galley and fl ying bridge) 24 V Dash board 24 V electrical panel

Lighting 24 V Dash board 24 V electrical panel

Electric WC 24 V Dash board 24 V electrical panel

Deckwash pump 24 V Dash board 24 V electrical panel

Windlass 24 V 24 V board + engine running Starboard companion ladder locker

Capstans 24 V 24 V board Starboard companion ladder locker

Gangway 24 V hydraulic 24 V board Starboard companion ladder locker

Bow thruster 24 V Board automatic breakers Forward cabin

77

6

12 V CURRENT VOLTAGE PROTECTION

Generator battery 12 V - 55 Ah

Recharge of alternator generator + 230 V / 12 V - 25 Amp charger

VHF 24 V / 12 V inverter 24 V electrical panel

Radio DVD player 24 V / 12 V inverter 24 V electrical panel

12 V sockets 24 V / 12 V inverter 24 V electrical panel

Page 80

78

Summary for the 110 V - 230 V elements

24 V / 230 V - 700 Va or 2500 Va INVERTER

When they are not supplied by the shore power socket or the generator, the following appliances on the UTILITY busbar function automatically with the inverter if it is switched on

(switch in REMOTE position). The 24 V batteries provide the current which is converted to 230 V or 110 V (US version).

GENERATOR

Force 11 Kva 50 Hz

Force 13,5 Kva - 110 V 60 Hz

SHORE POWER SOCKETS

Shore power socket - High Load 230 V - 50 Hz 32 Amp simple shore power socket Connection of aft starboard shore power socket box

Shore power socket - Air conditioning 230 V - 50 Hz 63 Amp simple shore power socket Connection of aft starboard shore power socket box

ELECTRIC DISTRIBUTION

UPPER bus supplied by generator or shore power

LOWER bus supplied by generator or shore power

CHARGE

230 V / 24 V - 60 Amp charger Recharge of the service and engine bank by generator or shore power

230 V / 24 V - 40 Amp charger Bow thruster charger supplied by the generator or the shore

230 V ou 110 V charger With optional generator to recharge the generator 12 V battery

Page 81

Summary for the 110 V - 230 V elements

CONSUMING APPLIANCES VOLTAGE BOAT ELECTRICAL PANEL

Hifi 230 V or 110 V inverter

Television 230 V or 110 V inverter

Water heater 230 V UPPER bus

Induction cooktop 230 V UPPER bus

Battery park charger 230 V UPPER bus

Hood 230 V UPPER bus

Generator charger 230 V UPPER bus

Air conditioning 230 V UPPER + LOWER bus

Icemaker 230 V or 110 V LOWER bus

Microwave oven 230 V or 110 V LOWER bus

230 V sockets 230 V or 110 V LOWER bus

Dishwasher 230 V or 110 V LOWER bus

Washer-dryer 230 V or 110 V LOWER bus

Flying bridge grill 230 V or 110 V LOWER bus

79

6

Page 82

Page 83

Propulsion

7.1 Engines

7.2 Fuel

7.3 Dash boards

7.4 Steering system

7.5 Demister

7.6 Trim tabs

7.7 Propellers and anodes

7.8 Bow thruster

81

7

Page 84

82

Location of the engines

1 - Fuel shut off valve.

2 - Fuel tanks.

3 - Fuel tank deck fi llers.

4 - Bilge fan.

5 - Fuel fi lter.

6 - Engine water inlet valve.

7 - Sea water fi lter.

8 - Engine.

9 - Pod.

1

2

3

4

5

6

7

8

9

FUEL VALVES

POD

PULL HANDLES

OF FUEL VALVES

BATTERY COUPLING

CONTROL

Page 85

Propulsion

7.1

Engines

ACCESS

You can reach the engines through the cockpit locker.

The locker is raised on jacks and its opening automatically controls the lighting of the service room.

The transmission is made by Pods.

You can reach it through the aft locker or the crew cabin (optional fi tting)

under the berth.

STARTING

Before starting the engines:

- Check the fuel valves on the tanks are open.

- Check the valves of the engine cooling systems (on the base of the Pods)

are open.

- Turn on the electrical circuit using the engine cut-outs on the instrument

board located at the entrance of the wheelhouse.

- Do not declutch the engines nor invert them.

83

7

- Start the engines using the keys and do not speed up.

Please carefully read the engine instruction guide supplied with the boat; it

gives you detailed explanations as to the best use of the engines and relative

operations.

ENGINE START WITH BATTERY COUPLING

In case one of the engine start batteries cannot be used:

- Activate the switch allowing the coupling of the batteries.

- Keep the switch pressed until the engine starts.

- Start the engine concerned.

- Release the coupling switch.

Nota: in the standard confi guration, the engine batteries are recharged by

their respective engines.

MAINTENANCE OF THE ENGINES

Follow the instructions for maintenance appearing in the guide supplied with

the engines.

You can check the oil level of the pods through the aft cockpit locker or the

crew cabin (optional fi tting).

Page 86

84

Engine water inlet - Fuel gauge - Filters

ENGINE WATER INLET VALVE ENGINE WATER FILTER FUEL TANK DECK FILLERS

BILGE FAN OIL FILTERS

Page 87

Propulsion

85

7

ENGINE WATER INLETS

The engine water inlet valves are located on each side of the pod bases in the

aft cockpit locker or in the crew cabin (optional fi tting).

They shall absolutely be open before you start the engines.

The strainers of the engine water inlets are located on the base of the Pods.

Keep the strainers of the engine water inlet valves in the best possible state

of cleanliness.

Brush the strainers when the boat is careened.

Be careful: do not cover the strainers with antifouling paint.

Close the water inlet valves if the boat is left unattended for long.

Inspect and clean the water strainers regularly (access in the service room).

VENTILATION OF THE SERVICE ROOM

The service room fans start up automatically as soon as the engines start.

7.2

Fuel

FUEL TANKS

The boat is fi tted with two tanks of 650 litres each.

Each tank has its own fi lling cap.

You can see the gauge on the instrument panel.

Emergency closing pull rods are located in the starboard companion ladder

locker.

Fuel transfer valves, located in the technical room, in front of the tanks allow to

decant fuel from one tank to the other (keep the valves close when sailing).

FILLING

Fill the fuel tanks using both fi lling caps located under the trap in the starboard side passageway.

Open and close the fi ller caps with the right key.

To prevent any handling mistake, never fi ll the water and fuel tanks at the

same time.

Page 88

86

Fuel fi lter

FUEL FILTER

Page 89

Propulsion

During fi lling, avoid handling contaminants near the fi llers.

87

7

To know when you have to intervene and how frequently you have to change

them, please refer to the engine instruction guide.

Drain it by undoing the knurled screw on the base of the decantation bowl (but

do not remove it).

Allow to fl ow into a box till the fuel looks clean.

Do it several times a year.

MAINTENANCE OF THE TANKS

Regularly check the O rings of the fi llers for good condition (to prevent water

from entering the tanks).

Do not turn off the fuel taps after each use (except in case the boat is unattended for long).

Keep the fuel tanks as full as possible (to avoid condensation).

Every year check the fuel system for condition (hoses, valves, etc.).

Ask a professional to carry out any works on the damaged parts of the fuel

system.

Nota: the capacity of the tanks (that is indicated in the page SPECIFICATIONS)

may be not completely useable according to the trim and load of the boat.

Always keep 20% fuel as a reserve.

FUEL FILTERS

In order to prevent any water infi ltration, the fuel runs through two fi lters: the

fi rst one is on the pipe that links the tank to the engine (designed as a water

decanter and pre-fi lter), the second one is an integral part of the engine (designed to fi lter fuel fi nely).

Change the pre-fi lter at least once a year (access to it when you remove the

bowl).

7.3

Dash boards

On the dash boards (wheelhouse and fl ying bridge) you can fi nd all the functions to monitor the engines.

Please refer to the engine instruction guide supplied with the boat; it gives

you explanations about the indicator lights, dials and warning lights on the

dash boards.

REVERSING CAMERA

The boat may optionally be fi tted with a rear view camera.

Images are displayed on the command post screen of the wheelhouse when

manoeuvring backwards.

Page 90

88

Joystick - Trim tabs - Demister

OUTSIDE STEERING JOYSTICK TRIM TABS TRIM TAB CONTROL

DEMISTER CONTROL ANODES

Page 91

Propulsion

7.4

Steering system

7.6

Trim tabs

89

7