Operator’s ManualOperator’s Manual

PS 100

Folder and Sealer

Telephone: +44 (0) 19 6273 5777

E-mail: service@pseal.co.uk

Website: www.pressure-seal.com

Pressure Seal Group

This manual is protected under the Copyright Laws of the United Kingdom. All rights

reserved. Reproduction of this material without the express written consent of Pressure

Seal Systems Ltd is prohibited.

PRESSURE SEAL SYSTEMS MAY MAKE IMPROVEMENTS AND OR CHANGES IN THE

PRODUCT DESCRIBED IN THIS MANUAL AT ANY TIME AND WITHOUT NOTICE.

This publication could contain technical inaccuracies or typographical errors. Changes

are periodically made to the information contained in this manual; these changes will be

incorporated in new editions of this publication.

Correspondence regarding this publication should be addressed directly to:

Pressure Seal Systems Group Ltd

Pressure Seal house

1 The Dean

New Alresford

Hampshire

England

SO24 9BQ

PS 100

Page intentionally blank

PS 100

Contents

1. Introduction

Introduction to the PS100 ...............................1

Which Side Is Which? .................................2

How to use this manual ................................3

Safety precautions...................................4

Operating environment.................................4

Power requirements ..................................5

If the machine is damaged...............................5

2. Features

General ........................................7

Folder components ..................................8

Form guides ...................................8

Feed roll .....................................8

In-feed tray....................................8

Folding plates ..................................8

Folding rollers ..................................8

Operator controls ...................................9

Batch counter ..................................9

Illuminated Power Switch.............................9

Run switch....................................9

Stop switch...................................10

Power and safety components ............................11

Mains lead ...................................11

Top cover....................................11

Sealing and stacking components ..........................11

Pressure bolts .................................11

Sealing rollers..................................11

Stacker .....................................11

PS 100

14-11-02 Iss. 1. Page v

3. Set-up

Setting up the PS100.................................13

Removing the top cover ...............................14

Removing the folding plates .............................15

Setting up the folder .................................16

Setting the document stop ..............................16

Setting the adjustable document guide ........................18

Replacing the folding plates .............................19

First fold plate..................................19

Second fold plate ................................19

4. Operation

Operating the PS100 .................................21

Loading documents .................................22

Verifying folder settings .............................24

Processing forms ..................................25

Interrupting operation ..............................25

5. Operation Errors

Error Conditions ...................................27

Clearing Mishandled Documents ...........................28

When the stop light flashes ...........................28

If it is in either the first or second fold plate: ..................28

If the form is jammed in the sealing rollers: ...................30

Pressure bolt adjustment ...............................31

Troubleshooting ...................................32

6. Cleaning the machine

Cleaning procedure..................................35

PS 100

Page vi 14-11-02 Iss. 1.

7. Specifications

Folder/Sealer Specifications .............................37

Construction ..................................37

Sealer......................................37

Size.......................................37

Weight .....................................37

Power .....................................37

Speed .....................................37

Environment ..................................37

Feeder Capacity .................................38

Colour .....................................38

Noise ......................................38

Document Specification ...............................38

Weights.....................................38

Sizes ......................................38

Fold Configuration ...............................38

Appendix A - Form Loading Guide

Appendix B - Form Curl

Service Visit Log

PS 100

14-11-02 Iss. 1. Page vii

Page intentionally blank

PS 100

Page viii 14-11-02 Iss. 1.

1. Introduction

Introduction to the PS100

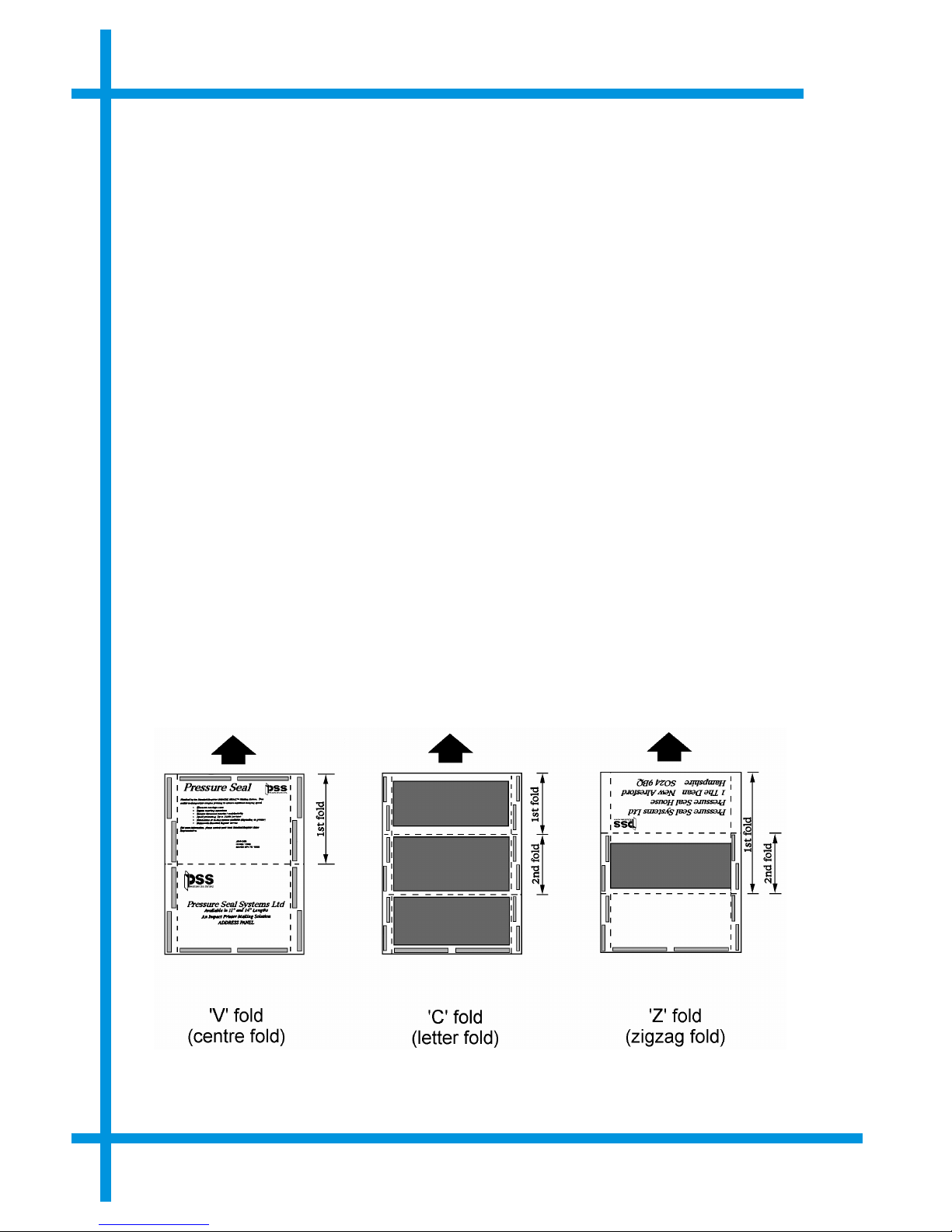

The PS100 folder/sealer produces finished mailable documents or “self-mailers” from

cut-sheet Pressure Seal documents. In one smooth operation the PS100 folds and seals

single sheets into self-mailers quickly and economically. Pressure activated cohesives

provide an instantly secure seal on the document, whether you use a “V”, “C” or “Z” fold.

Features of the PS100 folder/sealer include:

• Simple to load and operate

• Easy to change the fold style

• C, V, offset V and Z fold styles

• No adjustment required when changing the weight of forms used

• Automatic stop when the in-feed tray is empty

• In-feed forms counter with manual reset

• Paper flow error detection

This PS100 folder/sealer operator manual describes the set-up and operating instructions

for the PS100 folder/sealer. This manual is written as a reference for an operator who is

familiar with mailing operations and who has received some basic training in operating

the PS100.

14-11-02 Iss. 1. Page 1

Figure 1: Types of fold produced

Which Side Is Which?

The terms “infeed”, “outfeed” and “operator side” are used throughout this manual to

identify the sides of the PS100 (see fig.2 below).

• The infeed is the side into which the documents are fed.

• The outfeed is the side out of which the finished mailers exit.

• The operator side of the PS100 is the side on your right when you’re facing the infeed

of the PS100.

1. Introduction PS 100

Page 2 14-11-02 Iss. 1.

Figure 2: The sides of the machine

How to use this manual

Here is a summary of what is contained in this manual and where:

• Features (page 7) - describes the major components you use to set up and operate

the machine. New operators should read this section to gain a basic understanding of

how the machine works. Experienced operators should read this section when they

have a specific question about the function of a particular feature.

• Set-up (page 13) - outlines the tasks required to set up the machine. Provides easy

step procedures for removing the top cover and folding plates and setting up the

folder. New operators should read each procedure as they perform the task.

Experienced operators should refer to relevant parts of the procedure to find answers

to specific questions.

• Operation (page 21) - provides easy step-by-step procedures for loading and starting

the machine.

• Operation errors (page 27) - lists common operating problems and possible causes

and solutions.

• Cleaning (page 35) - provides details of the cleaning required to keep the machine in

the best possible condition.

• Specifications (page 37) - provides the technical details of the folder/sealer.

• Form loading guide (page 39) - explains how to load forms based on the form

design, type of fold, condition of forms (if they are curled or not - see Appendix B on

page ), and how the folded/sealed forms should be orientated when they reach the

conveyor.

PS 100 1. Introduction

14-11-02 Iss. 1. Page 3

Safety precautions

Although the design of your folder/sealer includes safeguards for set-up and operation,

you must adhere to the following precautions.

I No one should use the machine unless they have been trained to do

so. Pressure Seal Systems Ltd accept no responsibility for

unauthorized use.

Operating environment

• Dress safely. Loose clothing, long hair and jewellery can become tangled in moving

parts.

• Keep your work area and the machine clean and clear of dust or debris. Details of

how to clean the machine thoroughly are given in Chapter 6.

• Do not place the machine on an unstable stand or table. The machine may fall,

causing serious damage or injury.

I To avoid personal injury and damage to the machine, it should

always be lifted by two people.

• Do not allow anything to rest on the mains lead. Do not relocate the machine where

anyone will walk on the lead.

• Operate the machine only with the top cover in place; the forms properly loaded in the

in-feed tray and the out-feed tray/conveyor initially empty.

• Keep hands clear of the in-feed and out-feed areas when the machine is running.

I Except as explained elsewhere in this operator manual, do not

attempt to service the machine. Doing so may expose you to

dangerous voltages or other risks. Do not remove the protective

side covers from the machine. Refer servicing to qualified service

personnel. Only trained, authorised service personnel should

remove the protective side covers - and then only for servicing

purposes.

1. Introduction PS 100

Page 4 14-11-02 Iss. 1.

Power requirements

The PS100 must be operated from the type of power source indicated on the marking

label. If you are unsure of the type of power available, consult your Pressure Seal

representative or local power company.

If an extension lead is used with the PS100, make sure that the total of the ampere

ratings of the products plugged into the extension lead does not exceed the extension

lead ampere rating.

If the machine is damaged

Unplug the machine from the wall outlet and refer servicing to qualified personnel under

the following conditions:

q If the mains lead is damaged or frayed

q If liquid has been spilled into the machine

q If the machine has been exposed to rain or water

q If the machine has been dropped or damaged

q If the machine does not operate normally when the operating instructions are

followed. Adjust only those controls that are covered by the operating instructions,

since improper adjustment of other controls may result in damage.

q If the machine exhibits a distinct change in performance, indicating a need for a

service

PS 100 1. Introduction

14-11-02 Iss. 1. Page 5

Page intentionally blank

1. Introduction PS 100

Page 6 14-11-02 Iss. 1.

2. Features

General

This section guides you through the features of the folder/sealer. The component names

introduced in this section are used throughout this manual.

Please refer to Figure 3 below as you read about the features of the machine.

14-11-02 Iss. 1. Page 7

Figure 3: Features of the machine

Folder components

Form guides

The form guides keep the forms aligned so the feed roll feeds each one squarely. The

form guides on the machine are adjustable to accommodate various sheet widths.

Feed roll

The feed roll provides reliable single-sheet form feeding into the folding area. The feed roll

requires no adjustment.

In-feed tray

The in-feed tray holds the stack of forms allowing them to be fed by the feed roll. The

spring-loaded tray presses the forms against the feed roll, automatically providing the

correct pressure to allow only one form at a time to be fed into the folder.

Folding plates

These provide for simple "V" (centre or half) folds, "Z" (zigzag) folds or "C" (letter) folds.

The plates are adjustable to accommodate various form lengths.

Folding rollers

The folding rollers work in conjunction with the folding plates to produce folds. The

rollers feed the form into and out of the folding plates. The top roller is removable, which

aids recovery of mishandled forms (see page 28).

2. Features PS 100

Page 8 14-11-02 Iss. 1.

Operator controls

Batch counter

There are two types of batch counter available. The standard counter indicates the

number of documents in the current batch (since it was last reset) and has a push button

reset. There is an additional counter available for the cumulative total, and this may only

be reset by a service engineer.

Illuminated Power Switch

The power switch is illuminated when the PS100 is connected to the mains supply.

Run switch

The run switch lights when:

• All documents are properly loaded on the feed table, and there are no mishandled

documents anywhere in the PS100

• The safety cover is fitted

When the run switch lights:

• Momentarily pressing the run switch processes one document.

• Pressing and holding the run switch for two seconds processes all of the documents

PS 100 2. Features

14-11-02 Iss. 1. Page 9

Stop switch

Pressing the stop switch stops the PS100 after the document currently being fed is

processed. You can stop the PS100 at any time while documents are processing.

The stop switch flashes when there is an operating error. To clear an error condition:

• Remove the lid from the PS100

• Clear any mishandled documents

When the top cover is replaced, the PS100 automatically resets the error detection.

2. Features PS 100

Page 10 14-11-02 Iss. 1.

Figure 4: Operator controls

Power and safety components

Mains lead

The mains lead supplies electrical power to the PS100. There is a 5-amp fuse in the

three-pin plug.

Top cover

The top cover provides access to the folding and sealing components. The cover has two

safety switches that disable operation of the PS100 when it is removed.

Sealing and stacking components

Pressure bolts

These allow you to release the pressure on the sealing rollers for clearing mishandled

documents with the allen key that is provided.

Sealing rollers

The sealing rollers provide the pressure required to tightly seal the edges of the

document.

Stacker

This final component collects the self-mailers and stacks them for easy removal. It is

adjustable for different forms.

PS 100 2. Features

14-11-02 Iss. 1. Page 11

Page intentionally blank

2. Features PS 100

Page 12 14-11-02 Iss. 1.

3. Set-up

Setting up the PS100

This section provides instructions for:

• Removing the top cover

• Removing the folding plates

• Setting up the folder

Follow all the instructions in this section the first time you use the PS100 and whenever

you need to process a different style document. Refer to the first two topics in this

section when you need to access folding and sealing components.

I When any work is being carried out on the machine or any

adjustments are being made, the machine should be disconnected

from the mains.

14-11-02 Iss. 1. Page 13

Removing the top cover

Remove the top cover by placing one hand at the outfeed end and the other close to the

infeed of the PS100. The outfeed end should be lifted first as the top cover is held in

place by a retaining lip above the feed table.

When installing the top cover, make sure that it is firmly seated on top of the unit.

The safety switches for the top cover prevent the PS100 from operating if the cover is not

properly installed.

3. Set-up PS 100

Page 14 14-11-02 Iss. 1.

Figure 5: Removing the top cover

Removing the folding plates

1. Remove the top cover

2. Grasp each folding plate as shown in the below diagram and lift to disengage

the notches in the plate from the mounting studs. Pull the folding plate out of

the PS100 at approximately 45°.

PS 100 3. Set-up

14-11-02 Iss. 1. Page 15

Figure 6: Removing the fold plates

Setting up the folder

Once you’ve removed the top cover and folding plates, setting up the PS100’s folder

involves three steps:

• Setting the document stop on each folding plate

• Setting the adjustable document guide

• Replacing the folding plates and top cover

Setting the document stop

The location of the document stop along the scales on each folding plate determines

where the folds are made on the documents. The first fold plate controls the first fold,

and the second fold plate controls the second fold.

To set the document stop:

1. Measure the length of the document to each fold. Determine the settings for the

type of fold you want as shown in the diagram below.

3. Set-up PS 100

Page 16 14-11-02 Iss. 1.

Figure 7: Document fold lengths

2. For each folding plate, adjust the document stop to the settings you determined

in step 1. With the folding plates removed:

• Loosen the locking knobs at each end of the document stop.

• Using the knobs as handles, slide the stop along the rods until the stop

aligns with the correct settings on the scales. Make sure both scales are

showing the same settings otherwise the document will not fold squarely.

• Tighten the two locking knobs.

PS 100 3. Set-up

14-11-02 Iss. 1. Page 17

Figure 8: Document stop setting components

Setting the adjustable document guide

With the first fold plate removed, set the adjustable document guide on the feed table to

fit the width of the documents you’re processing.

To set the adjustable document guide:

1. Loosen the adjustment knob on the underside of the feed table. Move the

document guide to the right.

2. Place a document on the feed table, and align the left edge with the fixed

document guide. Hold the document in place.

3. Using your other hand, align the adjustable guide with the right side of the

document.

4. Secure the guide in place by tightening the adjustment knob.

When you finish there should be just enough clearance to allow the document to move

freely between the guides. Too much or too little clearance can cause mishandling.

3. Set-up PS 100

Page 18 14-11-02 Iss. 1.

Figure 9: Document stop setting components

Replacing the folding plates

The PS100 may be set for C, V or Z fold forms. The fold plates used determine the fold type.

First fold plate

Insert the fold plate by identifying the locating pins nearest the fold roller and hooking the

plate onto the pins, ensuring that both the hooks locate onto both the pins on either side

of the machine. Lay the fold plate flat and push the edge down until the fold plate clicks

firmly into position.

Second fold plate

For C and Z folds, locate the pins nearest the fold roller and hook the plate onto the pins,

making sure that both hooks locate onto each pin either side of the machine. Lay the fold

plate flat and push the edge down until the fold plate clicks firmly into position. For V

folds only, the second fold plate should be located with the hooks on the same pins near

the fold roller, but with the plate rotated through 180 . Lay the fold plate flat and push the

edge down until it locks firmly into position above the first fold plate.

PS 100 3. Set-up

14-11-02 Iss. 1. Page 19

Figure 10: Adjusting the form guides

Page intentionally blank

3. Set-up PS 100

Page 20 14-11-02 Iss. 1.

4. Operation

Operating the PS100

Operating the PS100 is a simple three-step process:

1. Verify that the machine is set for the fold style required by the documents.

2. Place the forms in the in-feed tray and adjust the forms width guide plate if

necessary.

3. Start the machine.

I It is not recommended that any internal adjustments be

made to the PS100. If adjustments are needed, contact an

authorised service representative.

This section explains in detail how to:

• Load documents

• Start up and test the PS100

• Process documents

Any problems that arise from the operation of the PS100 are addressed in the next

chapter, which includes a troubleshooting guide.

14-11-02 Iss. 1. Page 21

Loading documents

When you load documents make sure:

• There are no mishandled documents in the folder or sealer (the stop switch is not

flashing)

• All rubber and metal rollers are clean and free of foreign matter

1. Fan the stack of documents to make sure that they aren’t sticking together.

2. Align the stack so the documents feed correctly into the PS100. Document

orientation depends upon document design, the type of fold desired, presence

of curl, and how the folding plates are set up.

3. Align the stack of documents so that the ends and sides of the stack are

smooth and square.

4. Raise the feed table and feed the stack between the document guides and into

the PS100 until the stack meets resistance.

5. Lower the feed table.

The run switch lights, indicating the stack is properly loaded on the feed table.

Make sure that the stack of documents is flat and not bowed due to the document guides

being too tight.

4. Operation PS 100

Page 22 14-11-02 Iss. 1.

Starting up and testing the PS100

This procedure describes how to start up and test the PS100 to make sure

it’s ready to fold and seal your documents. Always perform this procedure at

the start of each document processing session to ensure the best results.

Before you start up and test the PS100, make sure all of the following

conditions are satisfied:

• The top cover is firmly seated on the top of the unit.

• The folding plates are adjusted and installed properly for the fold you

want.

• The document guides are set correctly to provide enough, but not too

much, clearance at the sides of the document stack.

• The power switch is illuminated.

• Documents are properly loaded and the run switch is lit.

PS 100 4. Operation

14-11-02 Iss. 1. Page 23

Verifying folder settings

1. Momentarily press the run switch. The PS100 processes one document.

2. Check the document for proper fold and seal. Check that the folds are in the

proper place.

• If the first fold is in the wrong place, adjust the first folding plate.

• If the second fold is in the wrong location, adjust the second folding plate.

4. Operation PS 100

Page 24 14-11-02 Iss. 1.

Figure 11: First and second folds

Processing forms

Before proceeding, make sure you’ve started up and tested the PS100 and that the test

document is properly folded and sealed.

1. Reset the counter (if required).

2. Press and hold the run switch until the next document is processed.

The PS100 processes the documents loaded on the feed table.

The PS100 automatically stops after the last document is processed. The run

switch light turns off indicating the feed table is empty.

3. Remove the sealed documents from the stacker.

4. When you have finished processing documents, disconnect the PS100 from the

mains power supply.

Interrupting operation

Press the Off/Stop switch at any time to cease processing. Do not stop the machine by

removing the lid as this may damage the machine.

PS 100 4. Operation

14-11-02 Iss. 1. Page 25

Page intentionally blank

4. Operation PS 100

Page 26 14-11-02 Iss. 1.

5. Operation Errors

Error Conditions

The red flashing error light indicates a problem. It is possible that a form is resting

between the folder and the sealer, there is a misfeed or slipping of the folding mechanism

or there is a form resting between the folding and sealing mechanisms or in the sealing

mechanism.

The following section describes how to clear mishandled documents, and also includes a

simple troubleshooting guide.

14-11-02 Iss. 1. Page 27

Clearing Mishandled Documents

When the stop light flashes

To clear a flashing error condition:

• Switch off the mains power and unplug from the mains.

• Remove the lid and locate the form that is jammed.

If it is in either the first or second fold plate:

Remove the fold plate in question by using the following procedure:

• Lift off the first fold plate as follows:

a) Lift up the left hand edge of the plate until it releases from the left hand holding clips.

b) Pull it clear of the hook pins located under the right hand edge of the plate.

• Remove the second fold plate as follows:

a) Lift up the right edge of the plate until it releases from the holding clips

b) Pull it clear of the hook pins under the left edge of the plate.

• Lift the two snap levers holding the top-folding roller in place, (see figure 12) and lift

out the roller.

• Remove the jammed form.

5. Operation Errors PS 100

Page 28 14-11-02 Iss. 1.

• Replace the top-folding roller. Note that the flat faces on the two end bearings must be

held vertically for them to drop into the housing slots. Close the two snap levers to

hold the roller in place.

• Replace the first and second fold plates.

• Replace the top cover and restore mains power.

• Reload and restart the PS100.

PS 100 5. Operation Errors

14-11-02 Iss. 1. Page 29

Figure 12: Removing the top folding roller

If the form is jammed in the sealing rollers:

a) Remove all documents from the in-feed tray.

b) Momentarily press the run switch to eject the mishandled document out of the

rollers.

• If the document doesn’t eject, repeat step b. It may take several attempts.

• If, after several attempts, the mishandled document doesn’t eject, continue with

the next procedure.

P It may be necessary to stabilise the forms before folding and sealing them.

This can be achieved by allowing them to rest in the same room as the

PS100 for an hour or more after printing.

When the jammed form is removed from the sealer, check the sealer rollers for any form

particles that may have become stuck with adhesive.

5. Operation Errors PS 100

Page 30 14-11-02 Iss. 1.

Pressure bolt adjustment

1.

Using the 8mm allen key provided, turn the four adjustment screws

anticlockwise to relieve the sealing roller pressure. (The allen key is situated on

the lip above the in-feed tray, beneath the lid.)

2. Install the top cover, reconnect the power and switch the machine on.

3. Press the run switch momentarily to clear any mishandled forms.

4. When you are sure that all mishandled forms have been cleared, unplug the

mains lead from the wall outlet.

5. Remove the top cover and tighten each adjustment screw down until you feel a

significant increase in resistance. This is a predetermined stop.

I Do not overtighten the adjustment screws! Stop tightening

the screws as soon you feel a significant increase in

resistance.

6. Install the top cover and power up the machine.

PS 100 5. Operation Errors

14-11-02 Iss. 1. Page 31

Figure 13: Relieving the sealing roller pressure

Troubleshooting

The table below lists the possible causes and any corrective actions required

for conditions that may occur with your PS100. For conditions not covered

below, contact your Pressure Seal Systems distributor.

Condition Possible Cause Corrective Action

The illuminated power

switch does not light.

Mains lead not plugged into

an AC outlet.

Plug mains lead into an

AC outlet.

Board fuse blown. Contact your Pressure

Seal distributor for advice.

The PS100 does not

operate when the run

switch is pressed (power

switch illuminated.)

Document misfeed, jam

detected: stop switch is

flashing.

Clear mishandled

documents (p. 24).

Top cover not firmly seated

on top of the unit.

Firmly seat the top cover

on the unit (p. 12).

No documents loaded. Load documents (p.19).

Board fuse blown. Contact your Pressure

Seal distributor for advice.

Documents are

mishandled in the folder

or damaged during

sealing.

Fold plate document

stop(s) adjusted

improperly.

Check and adjust the

position of the fold plate

document stop(s) (p.14).

Documents have excessive

curl due to moisture,

excessive toner or poor

storage.

Store documents in area

with low humidity; de-curl

by placing documents on

a flat surface with a heavy

weight for several hours.

Debris in folding plates;

folding plates not installed

properly; fold plate

document stop(s) adjusted

improperly.

Remove debris; properly

install fold plates; check

position of the fold plate

document stop(s).

5. Operation Errors PS 100

Page 32 14-11-02 Iss. 1.

Condition Possible Cause Corrective Action

Documents are

mishandled in the folder

or damaged during

sealing.

Dirty folding rollers. Clean rollers with cleaning

solution.

Folding roller adjusted

improperly or worn; sealing

rollers adjusted improperly.

Contact your Pressure

Seal distributor for advice.

Documents not sealing. Pressure on sealing rollers

is relieved.

Reset pressure on the

sealing rollers (p.27).

Documents are older than

their shelf life (one year).

Use fresh documents.

Fold plate document

stop(s) adjusted improperly

causing poor registration of

adhesive strips.

Check and adjust position

of the fold plate document

stop(s) (p.14).

Sealing rollers adjusted

improperly.

Contact your Pressure

Seal distributor for advice.

Documents are

misfeeding.

Feed table document

guides are set too tight.

Set the guides so there is

just enough clearance to

allow the document to

move freely between the

guides (p. 16).

Debris in folding plates;

folding plates not installed

properly; fold plate

document stop(s) adjusted

improperly.

Remove debris; properly

install folding plates;

check and adjust the

position of the fold plate

document stop(s).

Worn feed roll. Contact your Pressure

Seal distributor for advice.

PS 300 5. Operation Errors

14-11-02 Iss. 1. Page 33

Condition Possible Cause Corrective Action

Documents are wrinkled

or badly folded.

Documents not feeding

squarely against document

stop(s).

Adjust the document

stop(s) to squarely deflect

the documents; ensure

the stop setting is identical

on both scales.

Dirty folding rollers. Clean folding rollers.

Feed table document

guides are set too tight.

Set guides to allow the

document to move freely

between the guides.

Fold plate document

stop(s) adjusted

improperly.

Check and adjust the

position of the fold plate

document stop(s) (p. 14)

Folding rollers adjusted

improperly or worn; sealing

rollers adjusted improperly.

Contact your Pressure

Seal distributor for advice.

Two or more documents

are feeding into the folder

together.

Documents in stack are

sticking together.

Fan document stack and

reload documents.

Worn feed roll. Contact your Pressure

Seal distributor for advice.

5. Operation Errors PS 100

Page 34 14-11-02 Iss. 1.

6. Cleaning the machine

Cleaning procedure

The machine’s folding and sealing mechanisms should be cleaned in the following

manner:

P To avoid leaving finger-marks on the machine’s internal rollers, it is recommended

that disposable gloves are worn during cleaning. People susceptible to dust allergies

may be more comfortable wearing a protective mask.

1. Be sure that the room is well ventilated.

2. Switch off the mains power and unplug or disconnect from the mains.

3. Lift off the top cover.

4. Remove the first fold plate.

5. Remove the second fold plate.

6. Lift the two levers holding the top folding roller (see Figure 12), and lift out the roller.

7. Remove as much paper dust as possible using a soft brush. Try to avoid letting

the dust drift down into the lower machinery.

I If compressed air is used to clear the paper dust, use only a

recommended canned air blower.

8. Moisten a clean, lint-free cloth with the cleaning solution.

I Avoid breathing the fumes or getting the solution in an open

wound or other sensitive areas such as the eyes or mouth.

Read the label on the container carefully before use.

14-11-02 Iss. 1. Page 35

9. Wipe clean the surface of all the folding and sealing rollers using the moistened

cloth. It will be necessary to rotate each roller, taking care not to let anything

get caught between them. A moderate amount of effort may be required to turn

the sealing rollers. Wipe off any fingerprints from the rollers as they are turned.

10. Replace the top-folding roller.

P The flat faces of the bearing holder must be held vertically for the roller to

drop into the holding slots.

11. Close the two snap levers to hold the roller in place.

12. Replace the first and second fold plates.

13. Replace the top cover and then restore the mains power.

6. Cleaning the machine PS 100

Page 36 14-11-02 Iss. 1.

7. Specifications

Folder/Sealer Specifications

Construction

Formed sheet metal steel side frames with ABS shell

Sealer

Integral four-roller system

Size

685mm(L) x 495mm(W) x 375mm(H)

(excluding output tray of 115mm)

Footprint 675mm x 495mm

Weight

80kg

Power

115/230V ac ±10%, 50/60Hz

Speed

4000 forms per hour (A4 Z fold)

Environment

Operating 10° - 40° C

5% - 50% humidity

Non-operating 5° - 50° C

5% - 80% humidity

14-11-02 Iss. 1. Page 37

Feeder Capacity

150 sheets

Colour

Graphite

Noise

72dB

Document Specification

Weights

60gsm minimum; 145gsm maximum

Sizes

W 175mm (6.9in) x L 100mm (4in) minimum

W 216mm (8.5in) x L 355mm (14in) maximum

Cut-sheet

Fold Configuration

Z, V and C folds

7. Specifications PS 100

Page 38 14-11-02 Iss. 1.

Appendix A - Form Loading

Guide

Many variables must be considered when setting up the folder/sealer, and loading forms

for processing. These include the form design, type of fold and how the folded/sealed

forms should be orientated when they reach the conveyor.

14-11-02 Iss. 1. Page 39

Settings Settings Settings

First folding plate:

Half of the form length.

First folding plate:

One third of the form length.

First folding plate:

Two thirds of the form

length.

Second folding plate:

Rotate through 180 degrees.

Second folding plate:

One third of the form length.

Second folding plate:

One third of the form length.

Feeding problems:

Rotate form 180 degrees.

Feeding problems:

Print backside of form first.

Feeding problems:

Flip form, then rotate 180

degrees.

Appendix B - Form Curl

Many variables must be considered when setting up the folder/sealer, and loading forms

for processing. These include the form design, type of fold, condition of forms (if they are

curled or not), and how the folded/sealed forms should be orientated when they reach the

conveyor.

Figure 14 shows acceptable (flat or curl down), and unacceptable (curl up) curl

conditions. In some cases, forms that are curled up can be processed by loading them

differently.

Page 40 14-11-02 Iss. 1.

Figure 14 Curled Documents

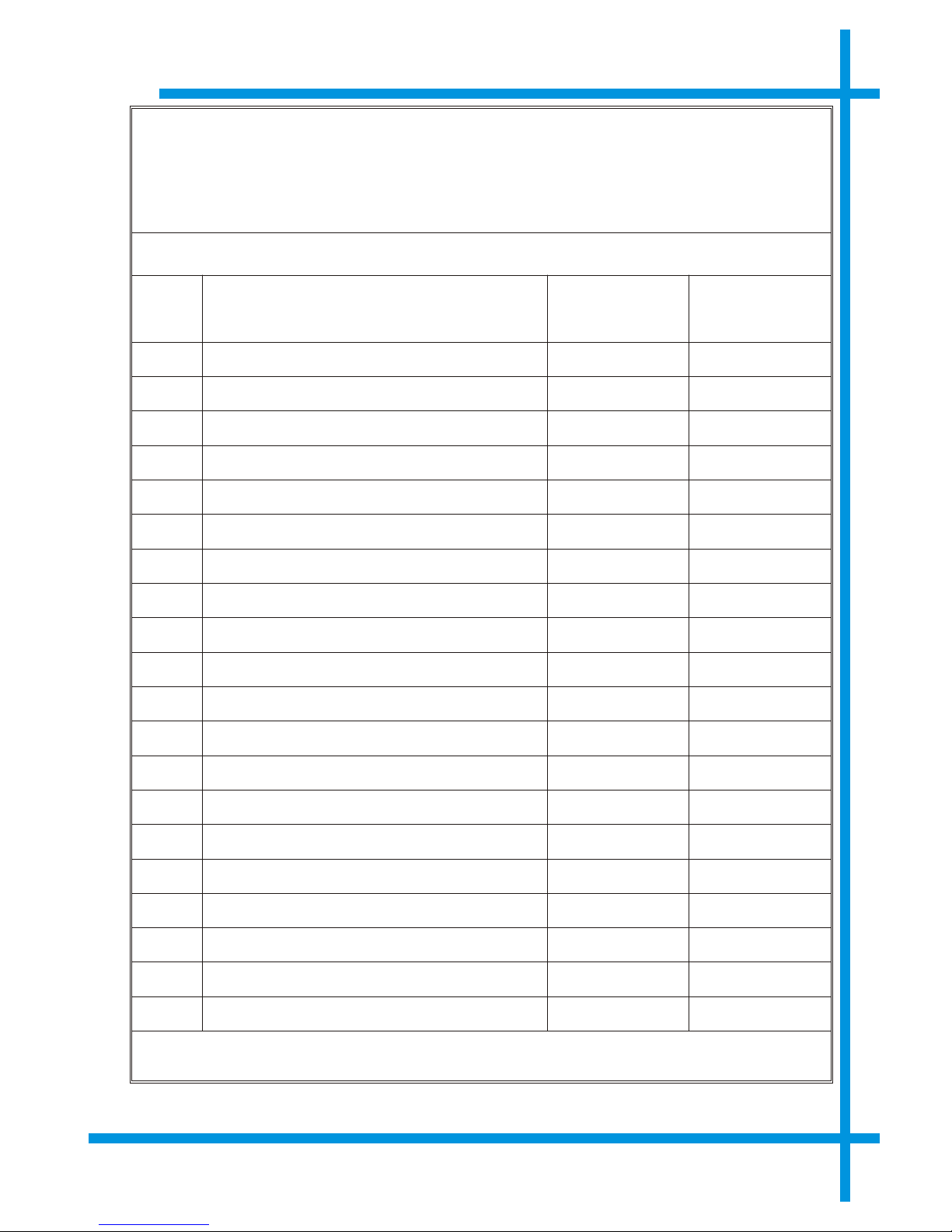

Service Visit Log

Serial number:

Date Work done and comments

Engineer’s

signature

Customer’s

signature

Head Office: Pressure Seal House, 1 The Dean, New Alresford, Hampshire, SO24 9BQ

Tel: +44 (0)19 6273 5777 Fax: +44 (0) 19 6273 4555 e-mail: service@pseal.co.uk

14-11-02 Iss. 1. Page 41

Loading...

Loading...