Pressol Rotary Drum Pump Operating Instructions & Parts Manual

G Operating Instructions & Parts Manual for Polypropylene Rotary Drum Pump

IMPORTANT: READ BEFORE USING

1. Description

2. Technical data

Pump Type Rotary - Vane

Flow 8 oz / Stroke

Maximum Fluid Temperature 130°F / 54°C

Bung Adapter 2” Male

Suction Tube Length 40” Maximum

Inlet 1-¼” O.D.

Outlet 1” O.D. Curved Spout

Wetted Materials of Construction PP, PVDF & Phenolic

Maximum Viscosity 2,000 SSU

3. General Safety Information

Always carefully read, thoroughly understand and follow the pump operating instructions. Use this

pump correctly and with care for the purpose for which it is intended. Failure to do may cause damage

or personal injury, and will invalidate the warranty. Retain instructions for future reference.

Contact your chemical or uid supplier to check for compatibility with pump prior to installation and

operation.

Prior to use, always carefully and thoroughly read and understand the OSHA information contained in the

Safety Data Sheet supplied for the chemical which is to be pumped.

Wear protective clothing (goggles, face masks, long sleeves, long pants, gloves, aprons, etc.) as set forth in

the OSHA Safety Data Sheet when pumping any hazardous chemicals.

When using ammable liquids, pump containers should be grounded to avoid static electricity.

Any pump used for transferring ammable liquids must be stored in a ventilated area after use.

Pump should be washed out before it is used since processing lubricants may contaminate the uids.

Prior to use, inspect your pump thoroughly verifying its proper assembly.

If pump is removed from drum, it should be thoroughly rinsed in a liquid that is compatible with both the

pump and uid.

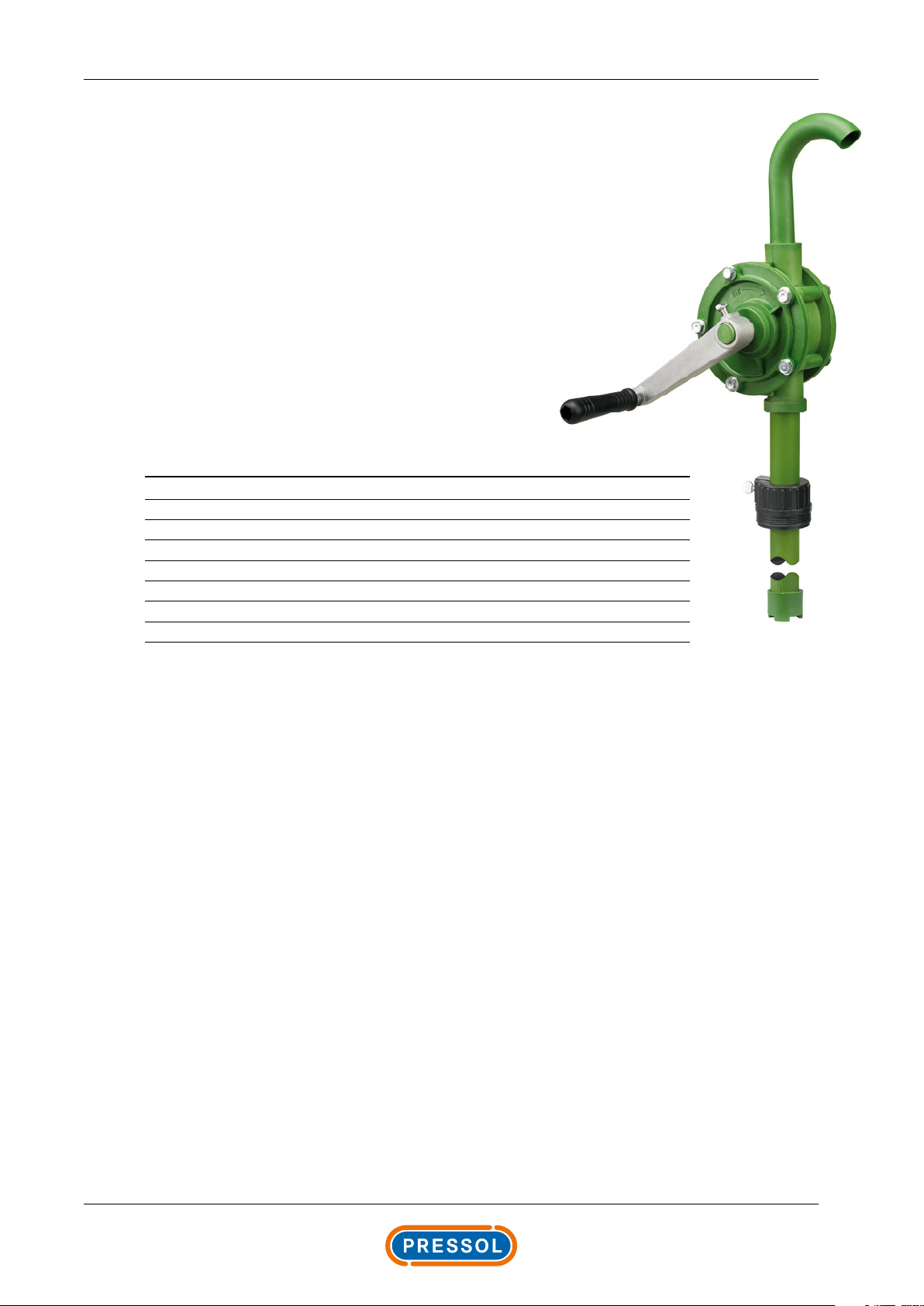

Polypropylene Rotary Drum Pump is designed for

transferring AdBlue®, organic acids, organic alcohols,

detergents, screen cleaners and other water soluble

inorganic chemicals. For exact media resistance see

stability list.

Supply with 2“ bung adapter and a 3-piece PP suction

tube to t most 15, 30 and 55 gallon drums.

G Operating Instructions & Parts Manual for Polypropylene Rotary Drum Pump

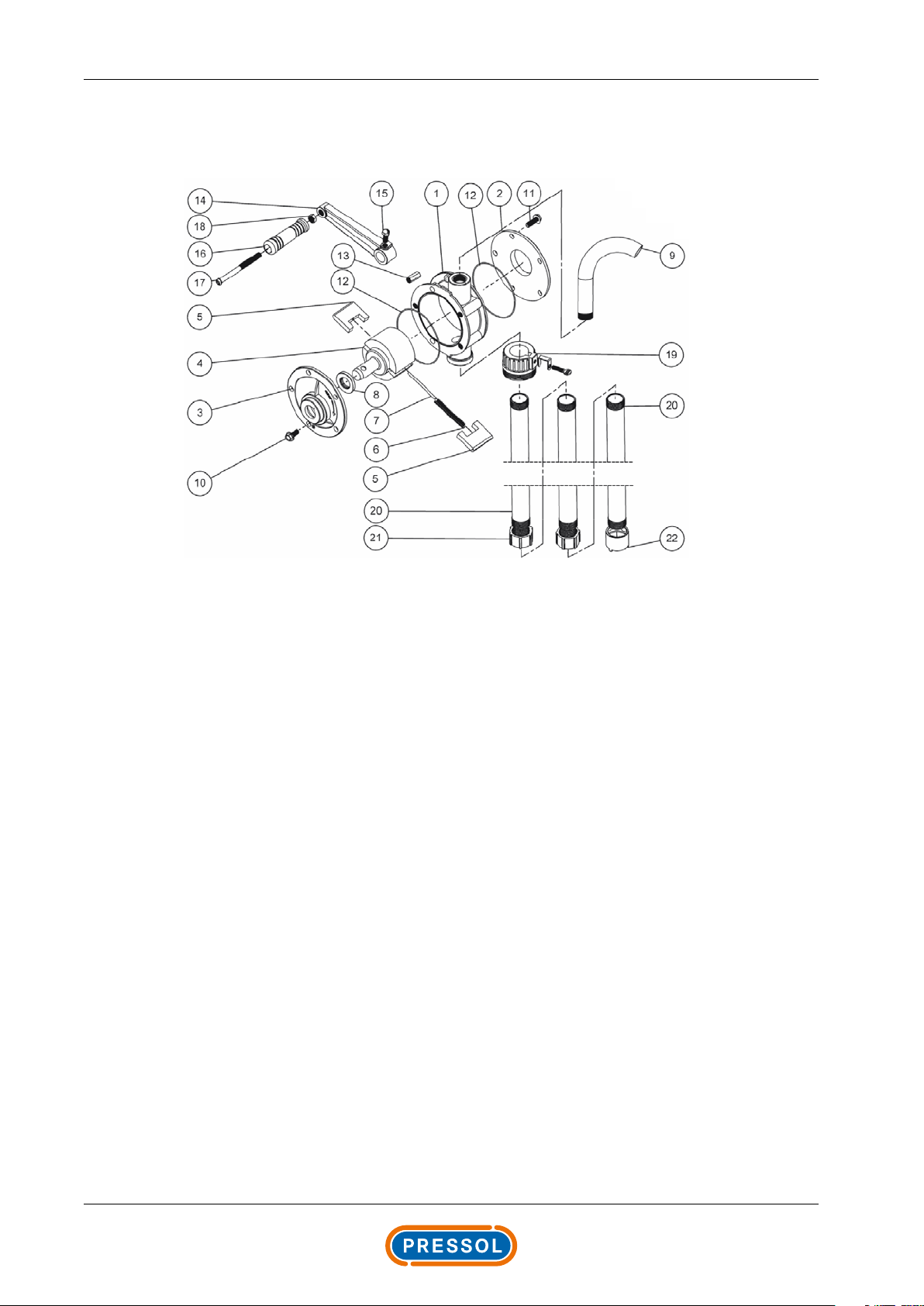

4. Repair Parts Illustration

Repair Parts List

Ref No. Qty Description

1 1 Pump Body

2 1 Rear Cover

3 1 Front Cover

4 1 Rotor

5 2 Vane

6 1 Spring

7 1 Spring Rod

8 1 Lip Seal

9 1 Discharge Spout

10 4 Cap Screw

11 6 Cap Screw

12 2 O-Ring

13 2 Hex Bridge

14 1 Crank Arm

15 1 Set Screw

16 1 Handle

17 1 Handle Shaft

18 1 Hex Nut

19 1 Bung Adapter

20 3 Suction Tube

21 2 Connector

22 1 Suction Filter

Loading...

Loading...