Pressol PP PUMP, PPS PUMP Installation and operating instructions

G Installation and operating instructions

IMPORTANT: READ BEFORE USING

1. Technical data

PP (polypropylene) PUMP PPS (polyphenylene sulde) PUMP

Pump Type Lever Action Lever Action

Pump Body #1 Color Blue Black

Max. Flow 10 oz / Stroke 10 oz / Stroke

Max. Fluid Temperature 140° F 160° C 140° F 160° C

Bung Adapter 1-½“ & 2“ 1-½“ & 2“

Wetted Materials PP, Steel, Polyethylene (PE) PPS, SS304, SS316, PTFE, PVDF

Max. Viscosity 1,000 SSU 1,000 SSU

Application Diesel, Kerosene, Lubricant Gasoline, Diesel, Kerosene, Lubricant, Water,

2. Assembly and Installation

Alcohol, Acids, Alkali, Solvents, Chemicals

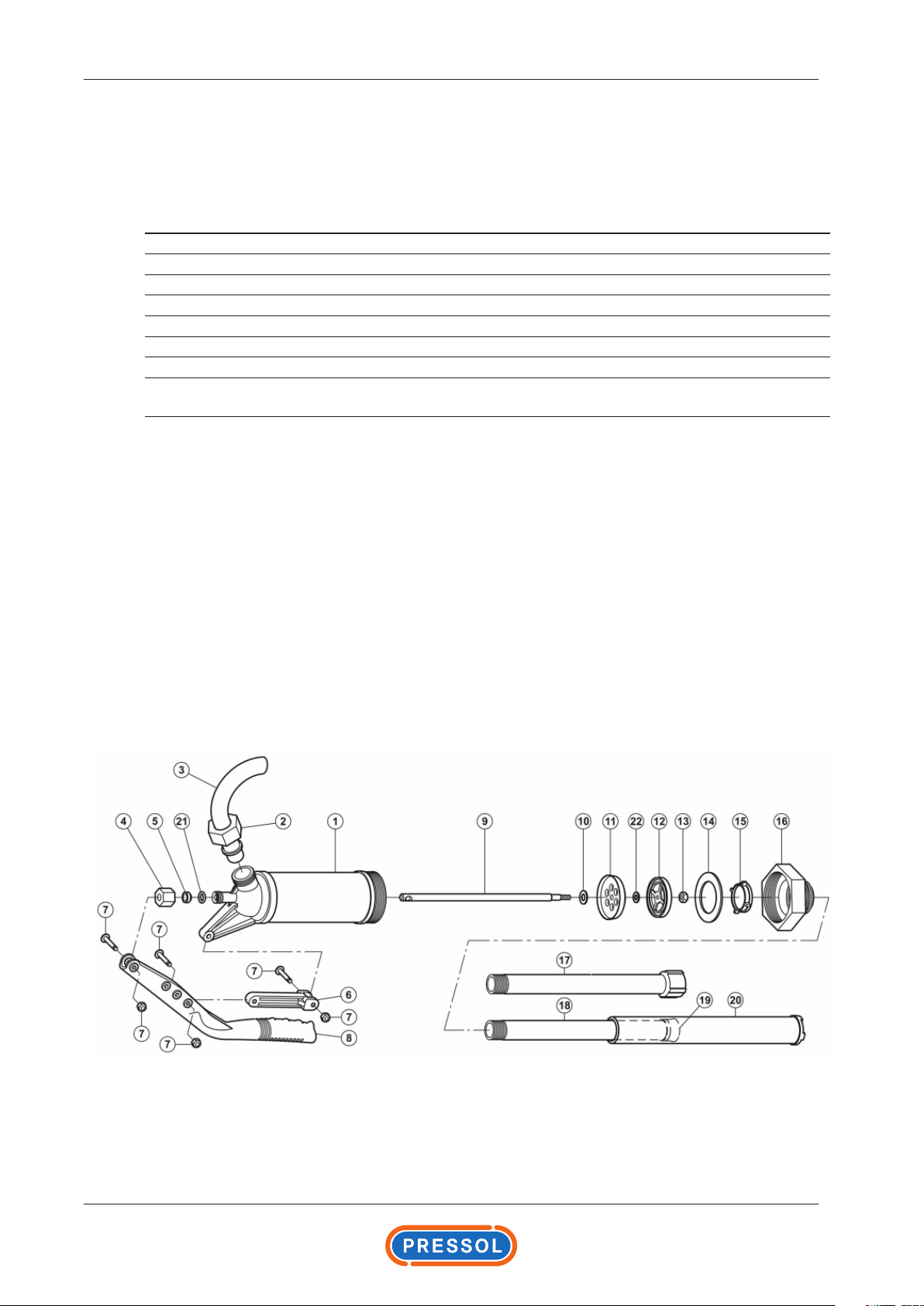

Check to see if all parts are included.

Install pump handle (Ref No. 8) to piston rod (Ref No. 9) with two sets of screws and nuts (Ref No. 7).

Install discharge spout (Ref No. 3) and screw the nut (Ref No. 2) tightly to the outlet thread of pump body

(Ref No. 1) and make sure discharge spout is secured.

Screw the assembled suction tube (Ref No. 17, 18 & 20) to inlet of pump body.

Insert this pump into the opening of drum. Then screw the bung adapter clockwise into drum.

The pump is now ready for operation. Liquid should begin to ow after several strokes. If any leakage

occurs, tighten piston rod nut (Ref No. 4) on top of pump carefully. Over tightening this nut will damage

seal, make the pump dicult to operate, and may strip nut.

G Installation and operating instructions

Parts List

Ref No. Description Ref No. Description

1 Pump Body 12 Rod Plate

2 Coupling Nut 13 Valve Nut

3 Spout 14 Foot Valve Seal

4 Piston Rod Nut 15 Base Plate

5 Piston Rod Seal 16 Base

6 Handle Lever 17 Tube

7 Nut & Screw 18 Telescopic Tube

8 Handle 19 Tube Seal

9 Piston Rod 20 Tail Telescopic Tube

10 Valve Plate 21 O-ring

11 Valve Base 22 Valve

3. General Safety Information

Always carefully read, thoroughly understand and follow the pump operating instructions. Inspect your

pump thoroughly to verify its proper assembly and then use this pump correctly with cara for tha purpose.

Failure to do may cause damage or personal injury, and will invalidate the warranty. Retain instructions for

future reference.

Prior to use, always carefully and thoroughly read and understand the OSHA information contained in the

Safety Data Sheet supplied for the chemical which is to be pumped. Contact your uid supplier to check

for compatibility with pump prior to installation and operation.

Pump should be washed out befor it is used since processing lubricants may contaminate the uids.

Wear protective clothing (goggles, face masks, long sleeves, long pants, gloves, aprons, etc.) as set forth in

the OSHA Safety Data Sheet when pumping any hazardous chemicals.

When pumping ammable liquids, pump containers should be grounded to avoid static electricity and

pump must be stored in a ventilated area after use.

To stop siphoning, rotate handle 1/4 turn (leave handle in horizontal position).

After using pump, position handle straight down, liquid will drain back to container.

If pump is removed from drum, rinse it thoroughly in a liquid that is compatible with both the pump and

the uid being pumped.

Regularly check pump and suction tubes for leaks. Leaks in the suction line or in pump housing will cause

inecient pumping and loss of prime.

Pressol Schmiergeräte GmbH

Parkstraße 7

93167 Falkenstein | Germany

Tel. +49 9462 17-0

Fax +49 9462 17-208

info@pressol.com

www.pressol.com

Loading...

Loading...