Premier Mounts XUT-3763 User Manual

INSTALLATION GUIDE: XUT-3763

Victory Tilt Screen Wall Mounting System

The Victory Tilt Screen Wall Mounting System is designed for secure installation of flat screen displays up

to 63”.

Warning Statements

THE WALL STRUCTURE MUST BE CAPABLE OF SUPPORTING AT LEAST A

MINIMUM WEIGHT OF 350 LBS. IF NOT, THE WALL MUST BE REINFORCED.

PROPER INSTALLATION PROCEDURE BY A QUALIFIED SERVIC E TECHNICIAN,

AS OUTLINED IN THE INSTALLATION INSTRUCTIONS, MU ST BE ADHERED T O.

FAILURE TO DO SO COULD RESULT IN SERIOUS PERSONAL IN JURY, OR EVEN

DEATH. DO NOT PLACE A UNIT WEIGHING MORE THAN 175LBS. ON THIS

MOUNT.

SAFETY MEASURES MUST BE PRACTICED AT ALL TIMES DURING THE

INSTALLATION OF THIS PRODUCT. USE PROPER SAF ETY GEAR AND TOOLS

FOR THE INSTALLATION PROCEDURE TO PREVENT PERSONAL INJURY.

PRIOR TO THE INSTALLATION OF THIS PRODUCT, THE INSTALLATION

INSTRUCTIONS SHOULD BE READ AND COMPLETELY UNDERSTOOD. THE

INSTALLATION INSTRUCTIONS MUST BE READ TO PREVENT PERSONAL

INJURY AND PROPERTY DAMAGE. KEEP THESE INSTALLATION

INSTRUCTIONS IN AN EASILY ACCESSIBLE LOCATION FOR FUTURE

REFERENCE.

A secure structure must support the weight, or load, of the display. When mounting to a

wall that contains wooden studs, dead center of the wooden stud must be confirmed prior to

installation.

Do not install on a structure that is prone to vibration, movement or chance of impact.

Failure to do so could result in damage to the display and/or damage to the mounting

surface.

Do not install near heater, fireplace, direct sunlight, air conditioning or any other source of

direct heat energy. Failure to do so may result in damage to the display and could increase

the risk of fire.

At least two qualified people should perform the installation procedure. Injury and/or

damage can result from dropping or mishandling the display.

Recommended mounting surfaces: wooden studs and solid-flat concrete. If the mount is to

be installed on any surface other than wooden studs, use suitable hardware (which is

commercially available).

Contact Victory Mounts with any technical/installation questions.

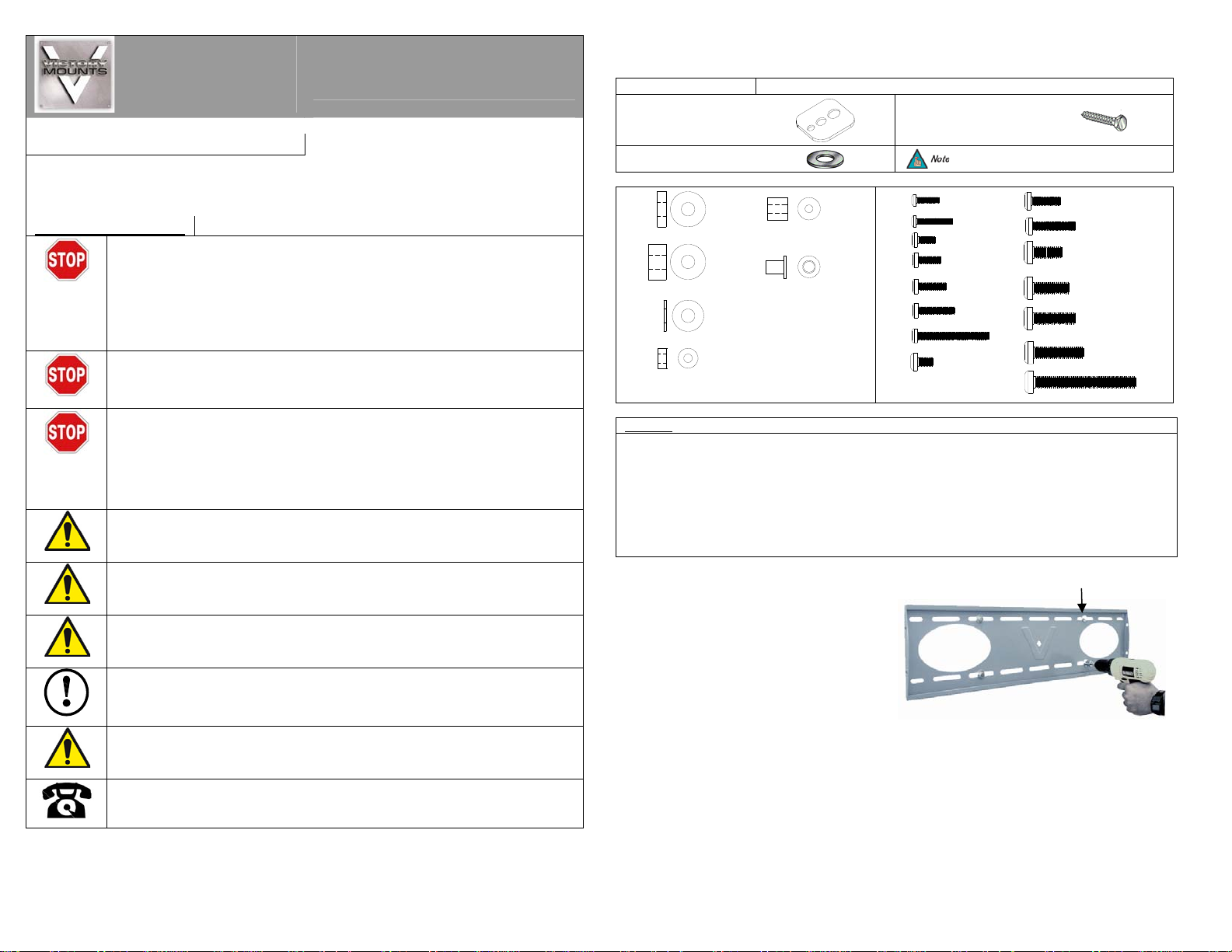

Included Hardware

Universal Washer

(Qty 8)

Flat Washers (Qty 6)

1/4" Nylon spacers

(large)

(Qty 6)

1/2" Nylon spacers

(large)

(Qty 12)

5/16" Flat washers

(metal)

(Qty 6)

1/4" Nylon spacers

(small)

(Qty 6)

Tool List

Phillips Head Screw Driver

Electronic Stud Finder

½” Socket and Wrench

Portable Drill

Masonry Bit for Concrete Installation

1/4” Drill Bit for Wood Installations

Level (Commercially Available)

Wood Stud Mounting

1. For secure wood stud mounting, the wall plat e must be

mounted to two studs at least 16” apart.

2. Use a high-quality electronic stud finder (commercially

available) to locate two adjacent studs and mark their

locations with a pencil.

3. With the help of an assistant, use a level (commercially

available) and position the wall plate agains t the wal l in

the desired mounting location.

4. Mark the right, upper and lower and the left (upper

and lower), positions of the small horizontal slots

that are in alignment with the studs.

5. You should mark four positions total.

6. Next, pre-drill a 1/4” hole in the wall stud at each

marked location.

9/16" Nylon spacers

(Qty 6)

Nylon sleeves

(Qty 4)

3” Lag Bolts

(Qty 6)

M4 x 16

M4 x 25

M5 x 12

M5 x 16

M5 x 20

M5 x 25

M5 x 50

M6 x 12

To correctly determine your hardware, please

refer to the hardware list below.

(Qty 8)

(Qty 8)

(Qty 8)

(Qty 6)

(Qty 6)

(Qty 4)

(Qty 4)

M6 x 20

M6 x 30

M8 x 20

M8 x 25

M8 x 30

(Qty 4)

M8 x 35

M8 x 70

(Qty 6)

(Qty 6)

(Qty 6)

(Qty 6)

(Qty 6)

(Qty 4)

Lag Bolt and Washer

Continued on back page

(Qty 4)

9531-015-122-06

Continued from front page

7. With the help of an assistant, position the wall plate against the wall and line up the mounting slots with

drilled holes.

8. For each location, insert a lag bolt and washer into the wall.

9. Tighten each bolt with an open ended socket wrench by turning clockwise until tight.

Do NOT over-tighten lag bolts when attaching the mount to the wall. Improper installation may

result in personal injury or damage to property.

Concrete Mounting

1. Begin by placing the wall plate into position against the wall, using the bubble guide to

keep it level.

2. Mark off six holes to be used for securing the mount and place the wall plate aside.

3. Next, drill holes using an electric drill and masonry bit.

4. Insert a concrete anchor into each hole.

5. If necessary, a hammer can be used to lightly tap each anchor into place so that they are flush with the

wall.

6. Once all of the anchors are in place, move the wall plate back into position.

7. Attach the nut onto the threaded shaft that is protruding from the wall.

8. Do not tighten until all nuts are in place.

Do not release the wall plate until it is properly mounted and secured to the wall.

The concrete anchors must be used for concrete installation. They can be purchased at your local

hardware store.

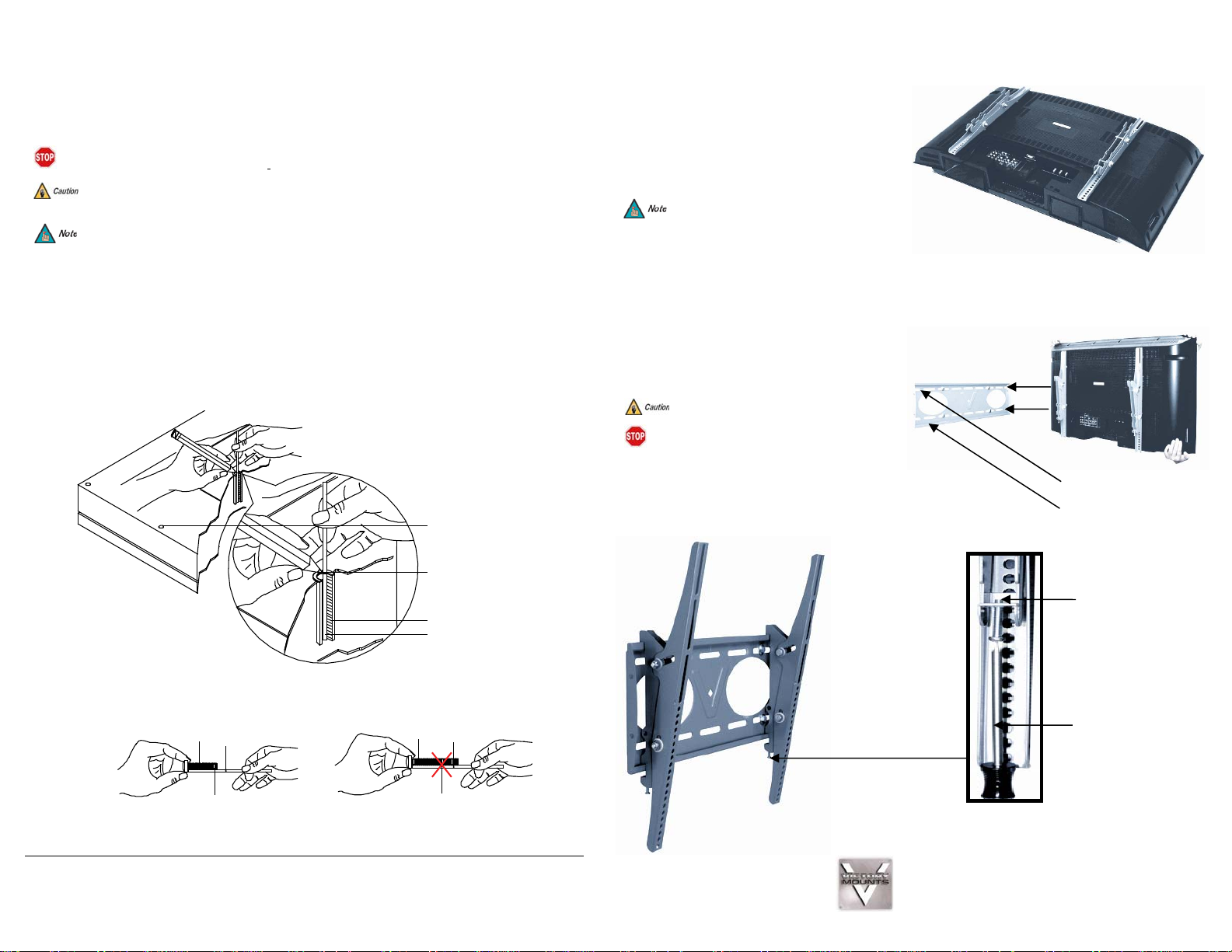

How to Determine Thread Depth

Inverted Flat

Panel Display

Marking the

Depth

Thread Insert

Thread Depth

Indicator

Figure 1

Screw

Screw

Figure 2

Marking

Stir Straw

or

Toothpick

Marking

Stir Straw

or

Toothpick

Figure 3

Display Bracket Installation

1. To ensure optimal installation, this kit includes various

screws of different diameters and lengths.

2. Place your flat panel screen down on a soft, flat surface,

and locate the threaded mounting points that are located

on the back of the display.

3. Determine which screw is the correct length by carefully

inserting a straw, o r toothpick, and mark how deep the

mounting point is.

4. If your display has a curved back or a recessed thread

mounting point, a spacer must be used.

5. Place the spacer between the mounting bracket and

the display.

6. If a smaller screw is being used (M4, M5, or M6)

please use a square griplate with each screw for

added stability.

7. Attach each bracket to the display by aligning the

holes on each bracket, with the threaded inserts on

the back panel of your display, inserting the screws

through both and turning clockwise until they are fully

inserted.

8. Tighten with a Phillips head screw driver.

Final Installation

1. To complete the installation of your new plasma

mount, carefully place the flat panel brackets over the

upper and lower mounting lips.

2. Use a Phillips head screwdriver to tighten the two (2)

security bracket screws (see inset below).

Select the spacer that is closest in depth to the

recess to keep your bracket as close to the display

as possible.

Two people are required for this step.

MAKE SURE THE LOCKING SCREW IS FLUSH

WITH THE LOCKING SCREW TAB BEFORE

INSTALLATION.

Upper Mounting Lip

Lower Mounting Lip

Progressive Marketing Products, Inc.

3130 E. Miraloma Ave.

Anaheim, CA 92806

800-368-9700

victory@mounts.com

Locking Screw

Screwdriver

Loading...

Loading...