Page 1

INSTALLATION MANUAL

Versatile Projector Mount

NORTH AMERICA EUROPE

3130 East Miraloma Avenue

Anaheim, CA 92806 USA

USA and Canada –

Phone: 800-368-9700

Fax: 800-832-4888

Other Locations – Phone: (001)-714-632-7100; Fax: (001)-714-632-1044

©Premier Mounts 2008

9530-009-011-05

PDS-PLUS

Model: PDS-PLUS

Swallow House,

Shilton Industrial Estate,

Shilton, Coventry, England CV79JY

Phone: +44 (0) 2476 614700

Fax: +44 (0) 2476 614710

AUSTRALIA, NEW ZEALAND, OCEANIA

(DISTRIBUTOR)

P.O. Box 295

Mordialloc Victoria 3195

Australia

Phone: 039586 6330

www.premiermounts.com.au

Page 2

PDS-PLUS

Congratulations on the purchase of your new Premier Mounts PDS-PLUS Versatile Projector Mount. The PDS-PLUS works

together with our exciting new PDS Base Box. The PDS-PLUS has multiple mounting configurations

to fit a variety of projectors. The PDS-PLUS is truly the most VERSATILE projector mount on the market

today.

Table of Contents

Warning Statements............................................................................................................................................- 2 -

Parts List .............................................................................................................................................................- 3 -

Installation Tools ................................................................................................................................................- 5 -

Optional Mounting Configurations.....................................................................................................................- 6 -

Ceiling Installation – Solid Surface ....................................................................................................................- 8 -

Concrete Mounting .............................................................................................................................................- 9 -

Attaching the PDS-PLUS to the Projector........................................................................................................- 10 -

Selecting the Proper Mounting Hardware.........................................................................................................- 10 -

Single Mounting Point Installation ...................................................................................................................- 12 -

Attaching the PDS-PLUS Base.........................................................................................................................- 12 -

Base Box Adjustment .......................................................................................................................................- 15 -

Technical Specifications ...................................................................................................................................- 16 -

Warranty ...........................................................................................................................................................- 17 -

Warning Statements

PREMIER MOUNTS DOES NOT WARRANT AGAINST DAMAGE CAUSED BY THE USE OF ANY PREMIER MOUNTS

PRODUCT FOR PURPOSES OTHER THAN THOSE FOR WHICH IT WAS DESIGNED OR DAMAGE CAUSED BY

UNAUTHORIZED ATTACHMENTS OR MODIFICATIONS, AND IS NOT RESPONSIBLE FOR ANY DAMAGES,

CLAIMS, DEMANDS, SUITS, ACTIONS OR CAUSES OF ACTION OF WHATEVER KIND RESULTING FROM,

ARISING OUT OF OR IN ANY MANNER RELATING TO ANY SUCH USE, ATTACHMENTS OR MODIFICATIONS.

THE CEILING STRUCTURE MUST BE CAPABLE OF SUPPORTING 230LBS. IF NOT, THE CEILING STRUCTURE

MUST BE REINFORCED. PROPER INSTALLATION PROCEDURE BY A QUALIFIED SERVICE TECHNICIAN, AS

OUTLINED IN THE INSTALLATION INSTRUCTIONS, MUST BE ADHERED TO. FAILURE TO DO SO COULD

RESULT IN SERIOUS PERSONAL INJURY, OR EVEN DEATH.

SAFETY MEASURES MUST BE PRACTICED AT ALL TIMES DURING THE INSTALLATION OF THIS PRODUCT. USE

PROPER SAFETY GEAR AND TOOLS FOR THE INSTALLATION PROCEDURE TO PREVENT PERSONAL INJURY.

THE MAXIMUM WEIGHT PROJECTOR THAT CAN BE USED WITH THIS MOUNT IS 75LBS. EXCEEDING THIS

WEIGHT LIMIT COULD CAUSE DAMAGE TO THE MOUNT, TO THE PROJECTOR OR TO YOURSELF.

PRIOR TO THE INSTALLATION OF THIS PRODUCT, THE INSTALLATION INSTRUCTIONS SHOULD BE READ AND

COMPLETELY UNDERSTOOD. THE INSTALLATION INSTRUCTIONS MUST BE READ TO PREVENT PERSONAL

INJURY AND PROPERTY DAMAGE. KEEP THESE INSTALLATION INSTRUCTIONS IN AN EASILY ACCESSIBLE

LOCATION FOR FUTURE REFERENCE.

Indicates that the power plug is to be disconnected from

the power outlet. Contact Premier Mounts with any questions –

Safety precautions must be taken at all times. Customer Service – (800) 368-9700

Do not install on a structure that is prone to vibration, movement or chance of impact. Failure to do so could result in damage to the

projector and/or damage to the mounting surface.

Do not install near heater, fireplace, direct sunlight, air conditioning or any other source of direct heat energy. Failure to do so may result

in damage to the projector and could increase the risk of fire.

A qualified person should perform the installation procedure. Injury and/or damage can result from dropping or mishandling the

projector

Technical Support – techsupport@mounts.com

.stnemetats noituaC dna gninraW

Page - 2 - Installation Manual

Page 3

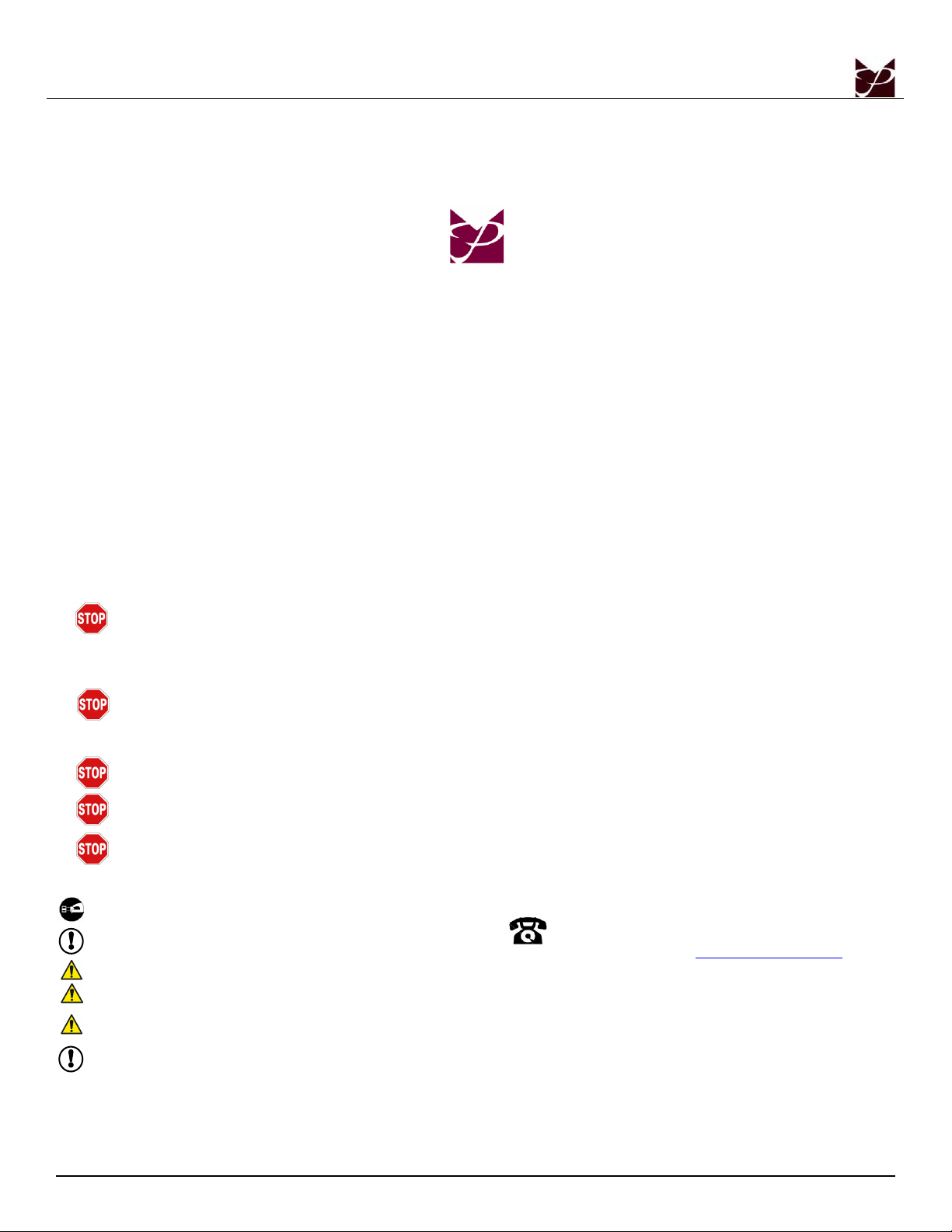

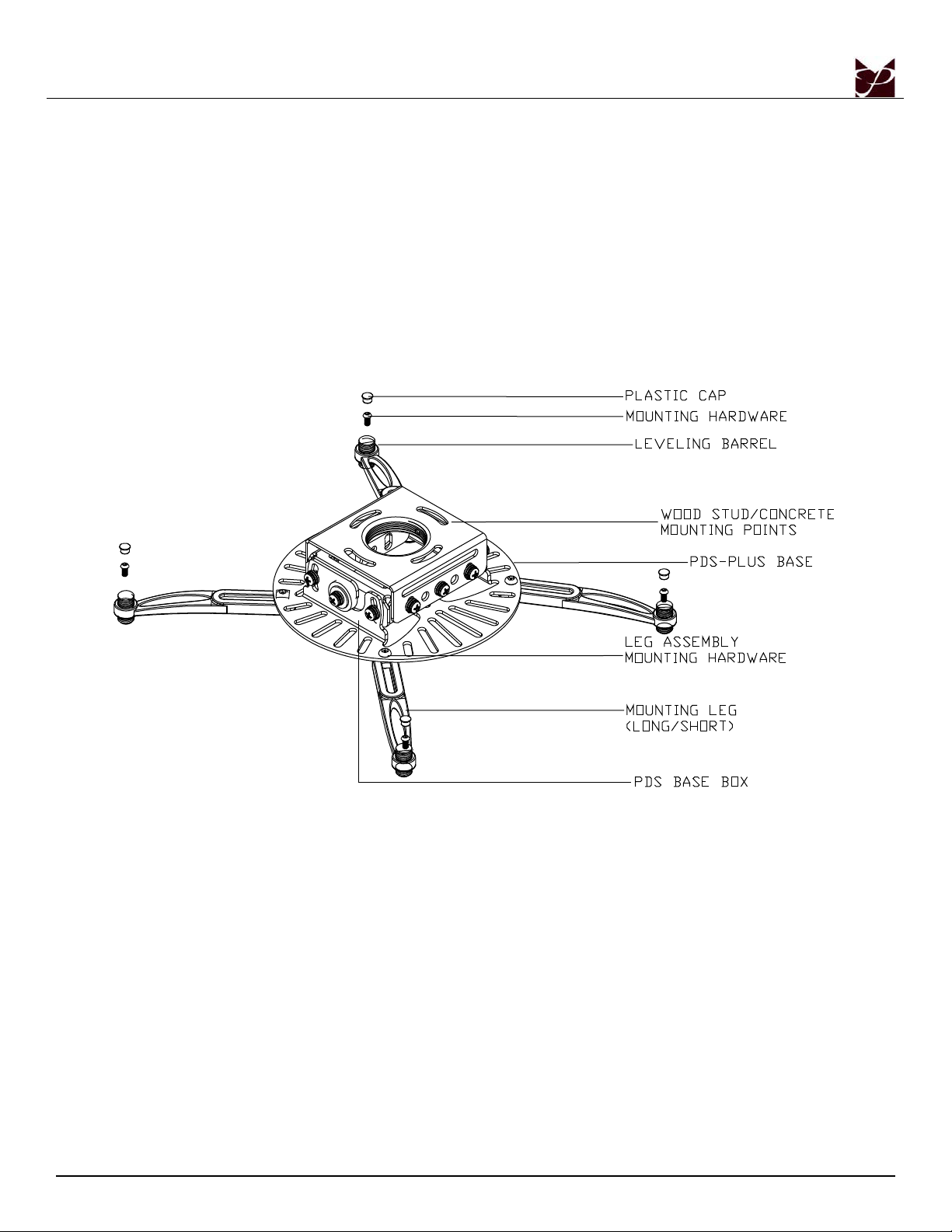

Parts List

Please familiarize yourself with all components contained herein.

PDS-PLUS

Please review all WARNING and CAUTION statements (see Page 2) before beginning the installation of the PDS-PLUS

PDS Base Box (Qty 1)

Nylon Spacer (Qty 2)

Flat Washer (Qty 2)

M6 x 8mm Socket

Head Set Screw

(Qty 1)

Mount.

M6 x 12mm Phillips

Pan Head w/

Integrated Split

Washer (Qty 12) – 6

come preinstalled on

the PDS Base Box

#14 x 2” Wood

Screws (Qty 2)

Lock-It™ Security System

M6 x 12mm Security

Escutcheon Ring

(Qty 1)

External Tooth Lock

Washers (Qty 4)

M5 Security Allen

Wrench (Qty 1)

Screw (Qty 12) -

Included in the

LOCK-IT™ packet

M6 x 8mm Security

Set Screw (Qty 1)

M3 Security Allen

Wrench (Qty 1)

Installation Manual Page - 3 -

Page 4

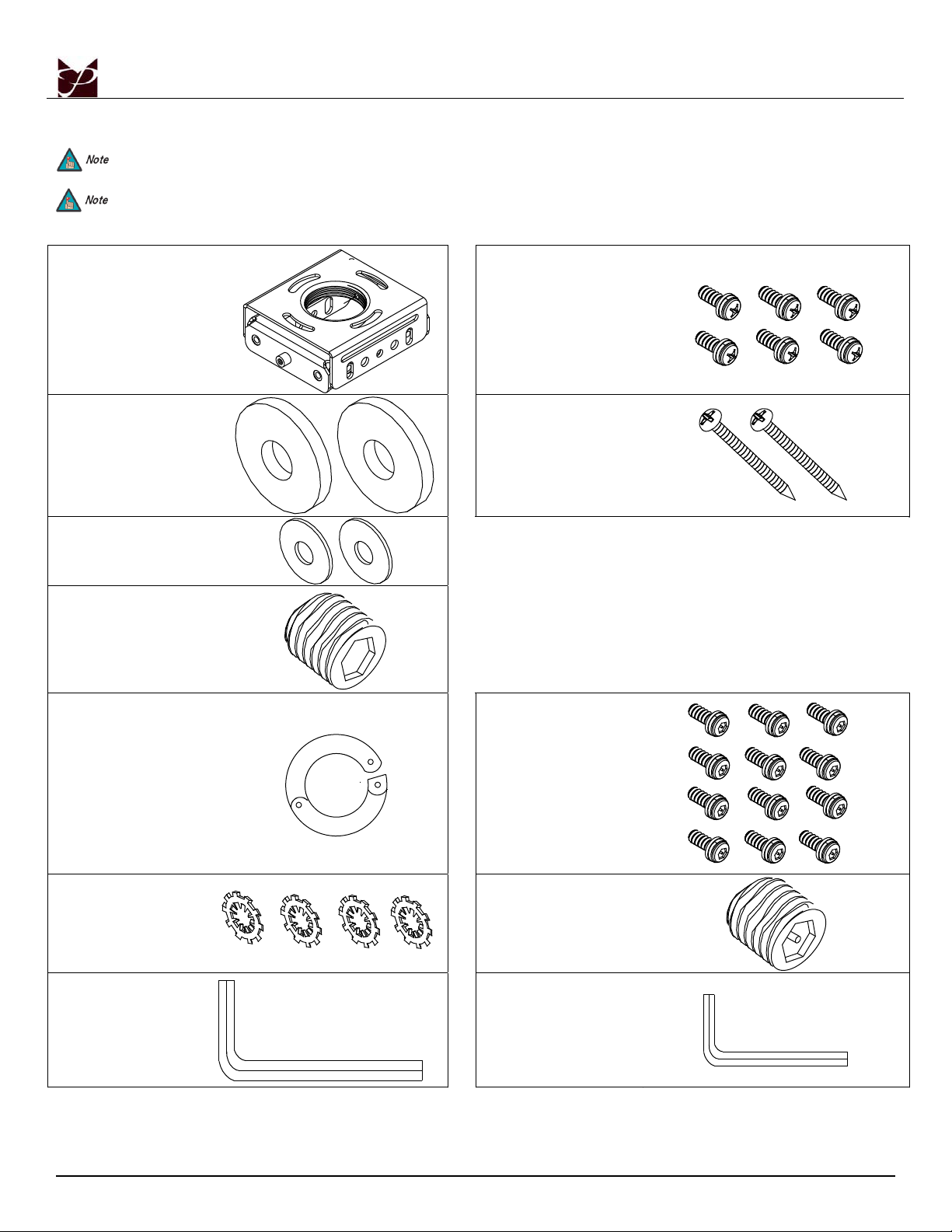

Parts List (cont.)

PDS-PLUS

PDS-PLUS

Base

(Qty 1)

Mounting Legs

– Long (Qty 4)

M2.5 x 12mm Phillips

Head Screw (Qty 4)

M3 x 16mm Phillips

Head Screw (Qty 4)

Plastic Barrel Caps

(Qty 8)

Mounting Legs –

Short (Qty 4)

ytiruceS ™tI-kcoL dradnatS

M2.5 x 12mm

Security Head

Screw (Qty 4)

M3 x 16mm

Security Head

Screw (Qty 4)

M3 Flat Washer

(Qty 10)

M4 x 12mm Phillips

Head Screw (Qty 4)

M5 x 12mm Phillips

Head Screw (Qty 4)

M6 x 12mm Phillips

Head Screw (Qty 8)

¼-20 x 5/16” Phillips

Head Screw (Qty 1)

M3 Flat Washer

(Qty 10)

M4 x 12mm

Security Head

Screw (Qty 4)

M5 x 12mm

Security Head

Screw (Qty 4)

M6 x 12mm

Security Head

Screw (Qty 8)

¼-20 x 5/16” Security

Head Screw (Qty 1)

Page - 4 - Installation Manual

Page 5

PDS-PLUS

Installation Tools

teknalB /lairetaM tfoS llirD elbatroP

erusaeM epaT licneP

Phillips Head Screw Driver M3 Security Allen Wrench (Supplied)

1/8” Drill Bit (Wood Installation – Commercially Available)

Masonry Bit (Concrete Installation – Commercially Available)

)deilppuS( hcnerW nellA ytiruceS 5M reddaL

Installation Manual Page - 5 -

Page 6

PDS-PLUS

Optional Mounting Configurations

This section will contain different configurations, if applicable, that the PDS-PLUS can be used with. The CLS adapter will be used in

conjunction with the PP-FCTA and the PP-FCMA. Please refer the Installation Instructions that come packaged with the following

products.

AMCF-PP ATCF-PP

Standard 1-1/2” NPT AST-2446 APP-2446 AST-1321

Page - 6 - Installation Manual

Page 7

PDS-PLUS

Ceiling Installation – Pipe

Unpack the PDS-PLUS Mount and familiarize yourself with the components. Please take time before you install the PDS-PLUS to

determine the location of where the PDS-PLUS will be mounted.

The PDS-PLUS may be attached to 1-1/2” standard thread ed pipe (NPT), to one of Premier Mount’s optional ceiling

adapters (see page 6), or to a single wood stud (see Page 8). If using an optional adapter, please refer to the installation

instructions that come with adapters.

1. After the pipe has been properly secured to the ceiling structure, thread the base box to the lower portion of the pipe.

PDS Base Box

M3 Allen Wrench

2. Secure the base box to the pipe with the M6 x 8mm set screw and tighten it down using the M3 Allen wrench (supplied).

Installation Instructions Page - 7 -

Page 8

PDS-PLUS

Ceiling Installation – Solid Surface

Upper Bridge

M6 x 8mm Set Screw

Base Box

1. Separate the Upper Bridge from the Base Box by removing the six (6) M6 x 12mm Phillips head screws (three on each side).

Wood Ceiling Stud

Ceiling Surface

Mounting Slot

Upper Bridge

#14 x 2”Wood Screws

2. Use the appropriate slot openings for single wood stud mounting, depending on your ceiling configuration. The adjustable

channel slots on the upper bridge plate will allow you to fine tune the final orientation of the projector.

3. Secure the Upper Bridge to the center of the stud on the ceiling structure at this time using two (2) #14 x 2” wood screws

(supplied).

Page - 8 - Installation Instructions

Page 9

PDS-PLUS

M6 x 12mm Phillips

Head Screw

Base Box

4. Attach the base box to the upper bridge and secure with the six (6) M6 x 12mm Phillips Head screws (above). DO NOT

OVERTIGHTEN THESE SCREWS AT THIS TIME.

Ceiling Wood Stud

Ceiling Surface

Concrete Mounting

The PDS-PLUS can be mounted to a ceiling with a minimum 6” thickness. Concrete wedge anchors must be used for

concrete installation. It is recommended that ¼” wedge anchors be used. A masonry bit must be used to drill the pilot hole.

These can be purchased at your local hardware store.

1. Begin by placing the upper bridge into position against the ceiling, keeping it level.

2. Mark off four holes to be used for securing the mount and place the upper bridge aside.

3. Next, drill holes using the appropriate masonry bit for your anchor.

4. Insert a concrete anchor into each hole.

5. If necessary, a hammer can be used to lightly tap each anchor into place so that they are flush with the ceiling.

6. Once all of the anchors are in place, move the upper bridge back into position.

7. Attach the nut onto the threaded shaft that is protruding from the ceiling.

8. Do not tighten until all nuts are in place.

Installation Instructions Page - 9 -

Page 10

Attaching the PDS-PLUS to the Projector

To truly show the versatility of the PDS-PLUS, the following pictures will show a variety of configurations that can be

achieved with the PDS-PLUS. Your individual application will depend on the purchased projector.

PDS-PLUS

To truly show the versatility of the ELE-UPROJB, the following pictures will show a variety of configurations that can be

achieved with the ELE-UPROJB. Your individual application will depend on the purchased projector.

1. Locate the mounting points on the bottom of the projector (see arrows above for sample mounting points).

Selecting the Proper Mounting Hardware

1. Turn the projector over and locate the mounting points.

2. Test each size of the screws provided.

3. The correct screws should thread easily into the mounting point and not pull out when pressure is applied.

DO NOT OVERTIGHTEN YOUR MOUNTING SCREWS TO THE PROJECTOR CHASSIS. USING THE

INCORRECT SCREW DEPTH MAY CAUSE DAMAGE TO YOUR PROJECTOR.

The optional M3 flat washers may be used to decrease the screw depth of either the M2.5 x 12mm screws or the M3 x

16mm screws. Place a M3 flat washer inside the leveling barrel and then insert the mounting screw. DO NOT

OVERTIGHTEN THIS SCREW.

Lock-It™ Security Hardware Pack (Optional)

The PDS-PLUS comes with the option of using Lock-It™ Security Screws. To use the security screws, simply replace

the M6 x 12mm Phillips Pan head screws with the M6 x 12mm security screws. Once the hardware has been changed,

adjust the PDS-PLUS and tighten down the M6 x 12mm security screws using the M5 Security Allen wrench (supplied).

Page - 10 - Installation Manual

Page 11

PDS-PLUS

Only attach to the projector manufacturer’s specified mounting points on the projector chassis with a minimum of three

mounting legs. Please follow all safety instructions specified by the projector manufacturer as well as the safety

instructions outlined in this manual.

Depending on your application, the long mounting legs and the short mounting legs may be used together. There are

multiple configurations that may be used combining the long mounting legs with the short mounting legs.

2. Attach the appropriate number of mounting legs to the projector using the corresponding mounting hardware (see Page 10, Selecting the Proper

Mounting Hardware).

3. If the mounting legs need to be leveled, rotate the leveling barrels to level the mounting bracket.

4. To raise the mounting legs, rotate the leveling barrel clock-wise. To lower the mounting leg, rotate the leveling barrel counter clock-wise.

5. When the desired position is achieved, tighten the mounting screws to the projector and then tighten the hex head leg screws with the M5 Allen

wrench.

Projector Plate

Mounting Leg

Square Nut

6. Position the legs accordingly for best configuration. You may raise or lower each leg independently by turning the leveling

barrels.

7. Secure the legs to the projector plate by screwing M6 x 12mm security screws into the M6 square nut (do not overtighten) on the

mounting legs.

Installation Manual Page - 11 -

Page 12

PDS-PLUS

Single Mounting Point Installation

Mounting Point

If your projector has only one mounting point, a ¼-20 x 5/16”

screw must be used to attach the mount to the projector. Please

refer to the following three steps:

1. Determine where the mounting point is located.

Attaching the PDS-PLUS Base

Hinge Pin

2. Place the projector plate over the mounting point.

3. Insert the ¼-20 x 5/16” security screw.

This screw will use a standard hole when mounting.

PDS Base Box

PDS-PLUS

Base

1. Raise the projector (with the mounting bracket attached) and hook the projector bracket over the hinge pins.

Installation Manual Page - 12 -

Page 13

PDS-PLUS

2. Slide the projector forward (see arrow above).

3. Make sure the bracket is resting on the Base Box before letting go of the projector.

Installation Manual Page - 13 -

Page 14

PDS-PLUS

Hinge Pin and

Nylon Spacer

4. Place the nylon spacer over the hinge pin.

M6 x 12mm Phillips

Head Screw

w/Integrated Washer

Hinge Pin Nylon

Spacer and Washer

5. Secure the PDS-PLUS to the PDS Base Box with two (2) M6 x 12mm Phillips Head screws w/Integrated Washers (one on each

side).

If using the optional Lock-It™ Security Hardware Pack, secure the PDS-PLUS to the PDS Base Box with two (2)

M6 x 12mm Security Head screws and two (2) flat washers (one on each side).

Installation Manual Page - 14 -

Page 15

M6 x 12mm Phillips

Head Screw

w/Integrated Washer

PDS-PLUS

Hinge Pin Screw

and Washer

6. Once the mount is safely attached, insert and tighten the four (4) M6 x 12mm Phillips Head Screw w/ Integrated

Washers.

7. Make all final adjustments at this time.

Base Box Adjustment

Roll

1. You can adjust the roll of the projector by loosening the three (3) front and rear M6 x 12mm screws.

Do not fully loosen the screws, as the mount may drop.

2. Set the desired roll and then tighten the screws. First tighten the center screws and work your way to the outside screws,

making any final adjustments prior to tightening the last two screws.

3. You can adjust the tilt of the projector by loosening the two (2) M6 x 12mm screws on each side of the Base Box.

4. Set the desired tilt and then tighten the screws, making any final adjustments prior to tightening the last two screws.

If your projector is not holding the tilt, install the four (4) internal/external tooth lock washers on the four

(4) M6 x 12mm Phillips head screws w/ Integrated Washers.

Tilt

5. Once all adjustments have been made, tighten all hardware.

Page - 15 - Installation Manual

Page 16

Technical Specifications

All measurements are inches (mm).

PDS-PLUS

Installation Manual Page - 16 -

Page 17

PDS-PLUS

Warranty

PREMIER MOUNTS

LIMITED LIFETIME WARRANTY

What and Who is Covered by this Limited Warranty and for How Long

Premier Mounts warrants this product to be free from defects in material and workmanship for the

lifetime of the original owner of this product. The limited warranty is valid only for the original

purchaser of the product.

What Premier Mounts Will Do

At the sole option of Premier Mounts, Premier Mounts will repair or replace any product or product part

that is defective. If Premier Mounts chooses to replace a defective product or part, a replacement

product or part will be shipped to you at no charge, but you must pay any labor costs.

What is Not Covered; Limitations

PREMIER MOUNTS DISCLAIMS ANY LIABILITY FOR DAMAGE TO MOUNTS,

ADAPTERS, DISPLAYS, PROJECTORS, OTHER PROPERTY, OR PERSONAL INJURY

RESULTING, IN WHOLE OR IN PART, FROM IMPROPER INSTALLATION,

MODIFICATION, USE OR MISUSE OF ITS PRODUCTS.

PREMIER MOUNTS DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. PREMIER MOUNTS IS NOT RESPONSIBLE FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO, INABILITY TO

USE ITS PRODUCTS OR LABOR COSTS FOR REMOVING AND REPLACING DEFECTIVE

PRODUCTS OR PARTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

What Customers Must Do for Limited Warranty Service

If you discover a problem that you think may be covered by the warranty you MUST REPORT it in

writing to the address below within thirty (30) days. Proof of purchase (an original sales receipt) from

the original consumer purchaser must accompany all warranty claims. Warranty claims must also

include a description of the problem, the purchaser’s name, address, and telephone number. General

inquiries can be addressed to Premier Mounts Customer Service at 1-800-368-9700. Warranty claims

will not be accepted over the phone or by fax.

Premier Mounts

Attn: Warranty Claim

3130 E. Miraloma Avenue

Anaheim, CA 92806

How State Law Applies

This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state.

Page - 17 - Installation Manual

Loading...

Loading...