Page 1

INSTALLATION MANUAL

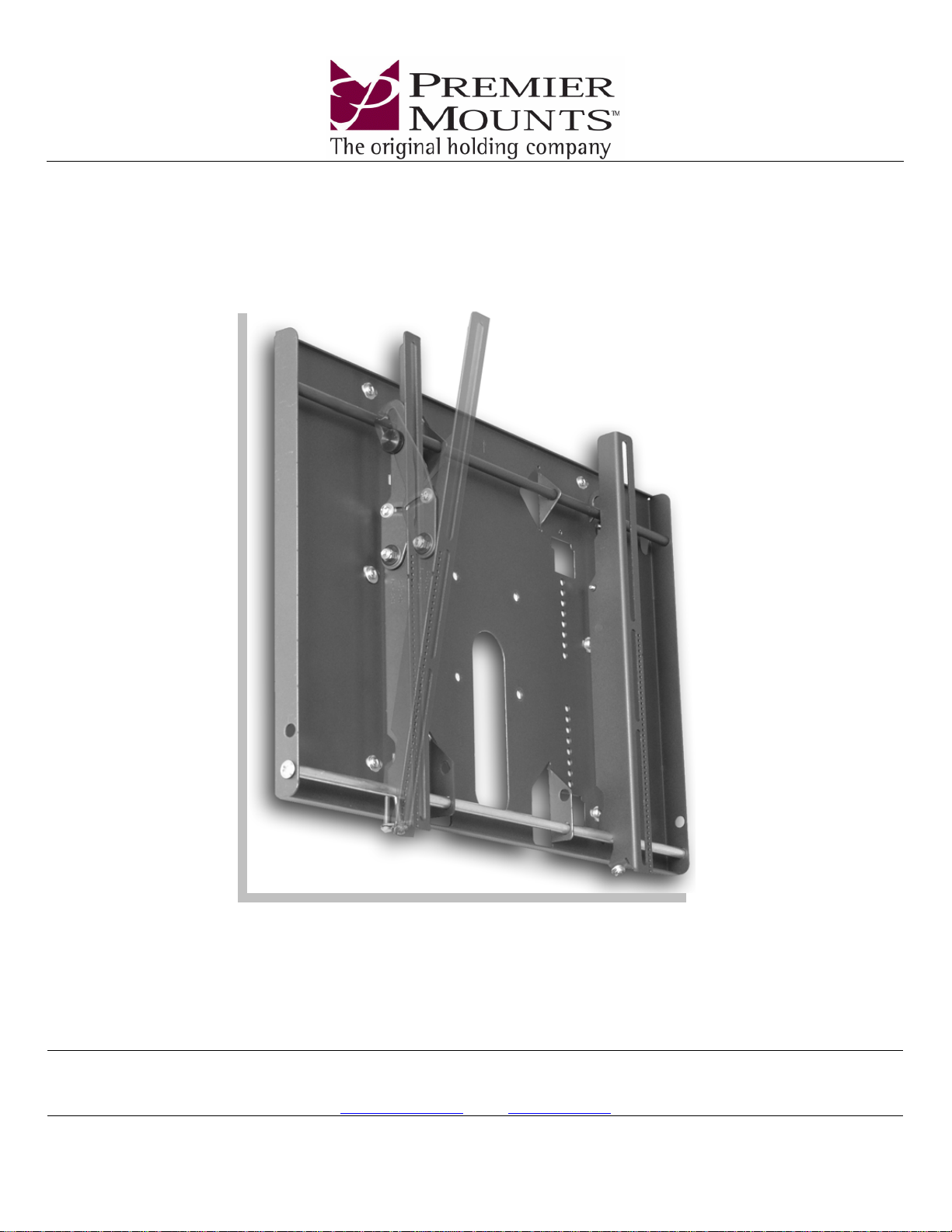

IN-CTMMS2.R2

CTM-MS2

Premier Mounts

3130 E. Miraloma Avenue

Anaheim, CA 92806

Phone: (800) 368-9700 Fax: (800) 832-4888

mounts@mounts.com

www.mounts.com

Page 2

PBL-110 Projector Mount

Page - 2 - Installation Manual

Page 3

CTM-MS2

Table of Contents

Warning Statements ........................................................................................................................................- 4 -

Parts List ...........................................................................................................................................................- 5 -

Installation Tools ..............................................................................................................................................- 5 -

Mounting Bracket Installation .......................................................................................................................- 9 -

CTM-MS2 Installation ..................................................................................................................................- 12 -

Installing the Flat Panel Display (CTM-MS2) ............................................................................................- 14 -

Technical Specifications ................................................................................................................................- 17 -

Warranty ........................................................................................................................................................- 18 -

Contact Premier Mounts ...............................................................................................................................- 18 -

Notes ................................................................................................................................................................- 19 -

Installation Manual Page - 3 -

Page 4

Warning Statements

WARNING:

WARNING:

WARNING:

THE WALL STRUCTURE MUST BE CAPABLE OF SUPPORTING 160 LBS. IF NOT, THE WALL

STRUCTURE MUST BE REINFORCED. PROPER INSTALLATION PROCEDURE BY A QUALIFIED

SERVICE TECHNICIAN, AS OUTLINED IN THE INSTALLATION INSTRUCTIONS, MUST BE

ADHERED TO. FAILURE TO DO SO COULD RESULT IN SERIOUS PERSONAL INJURY, OR EVEN

DEATH.

SAFETY MEASURES MUST BE PRACTICED AT ALL TIMES DURING THE INSTALLATION OF

THIS PRODUCT. USE PROPER SAFETY GEAR AND TOOLS FOR THE INSTALLATION

PROCEDURE TO PREVENT PERSONAL INJURY.

PRIOR TO THE INSTALLATION OF THIS PRODUCT, THE INSTALLATION INSTRUCTIONS

SHOULD BE READ AND COMPLETELY UNDERSTOOD. THE INSTALLATION INSTRUCTIONS

MUST BE READ TO PREVENT PERSONAL INJURY AND PROPERTY DAMAGE. KEEP THESE

INSTALLATION INSTRUCTIONS IN AN EASILY ACCESSIBLE LOCATION FOR FUTURE

REFERENCE.

Indicates that the power plug is to be

disconnected from the power outlet.

Safety precautions must be taken at all

Contact Premier Mounts with any

questions.

times.

Warning and Caution statements.

Do not install on a structure that is prone to vibration, movement or chance of impact. Failure to

do so could result in damage to the flat panel display and/or damage to the mounting surface.

Do not install near heater, fireplace, direct sunlight, air conditioning or any other source of direct

heat energy. Failure to do so may result in damage to the flat panel display and could increase the

risk of fire.

At least two qualified people should perform the installation procedure. Injury and/or damage can

result from dropping or mishandling the flat panel display.

CTM-MS2

Page - 4 - Installation Manual

Page 5

CTM-MS2

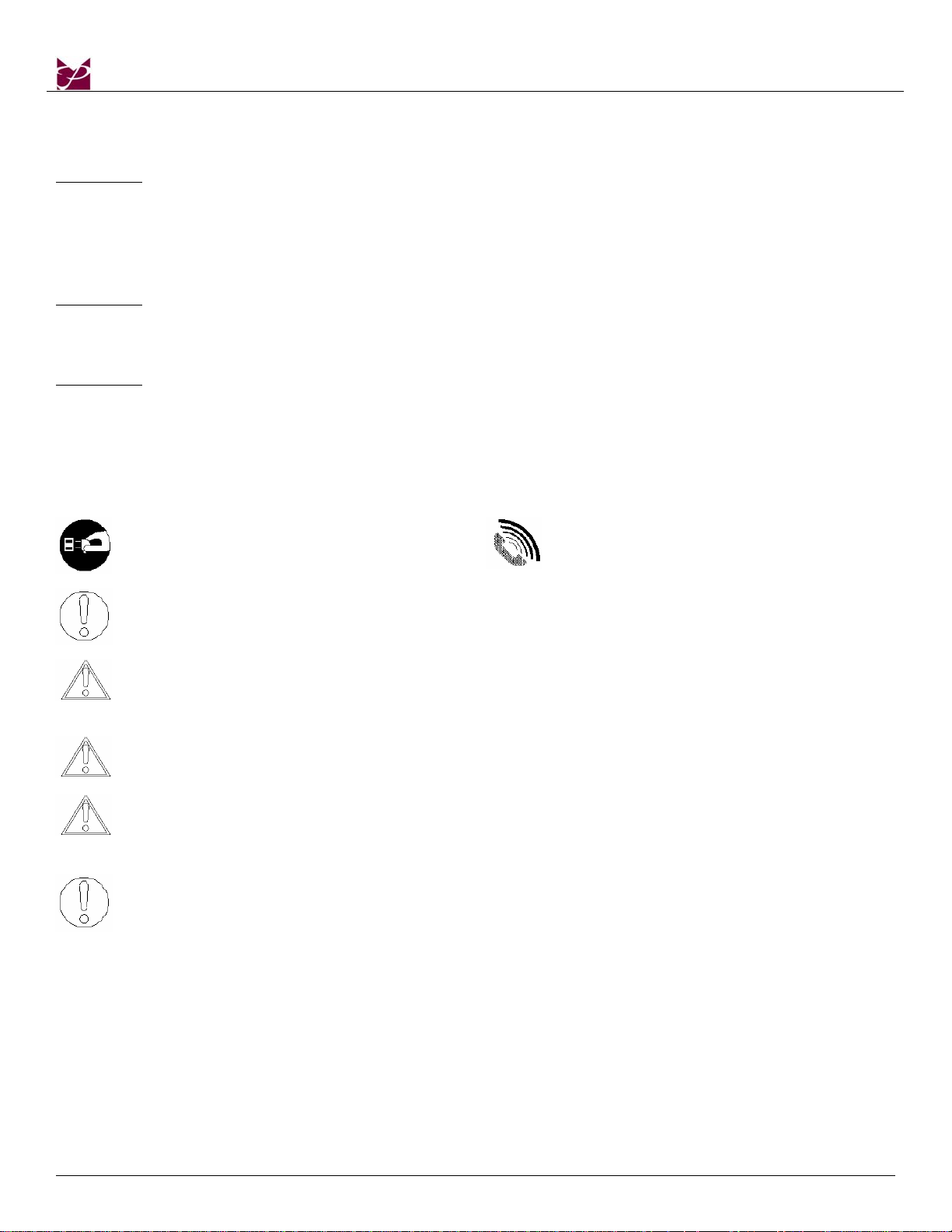

Parts List

NOTE: This wall mount is shipped with all proper installation hardware and components. Make sure that

none of these parts are missing and/or damaged before beginning installation. If there are parts

missing and/or damaged, please stop the installation and contact Premier Mounts

(800-368-9700).

WM4000 Wall

Plate (Qty 1)

Mounting

Brackets

(Qty 2)

5/16” Flat

Washers

(Qty 6)

5/16” x 3” Lag

Bolts (wooden

studs only) –

(Qty 6)

M6 x 30mm

Lateral Shift

Locking Screws

(Qty 2)

Griplates™

(Qty 8)

M6 x 12mm

Safety Knobs

(Qty 2)

Thread Depth

Indicator

Installation Tools

Phillips Head Screw Driver Soft Material/ Blanket 5/16” Socket and Wrench

Pencil Tape Measure Drill Gun

Level (Supplied)

Installation Manual Page - 5 -

Page 6

CTM-MS2

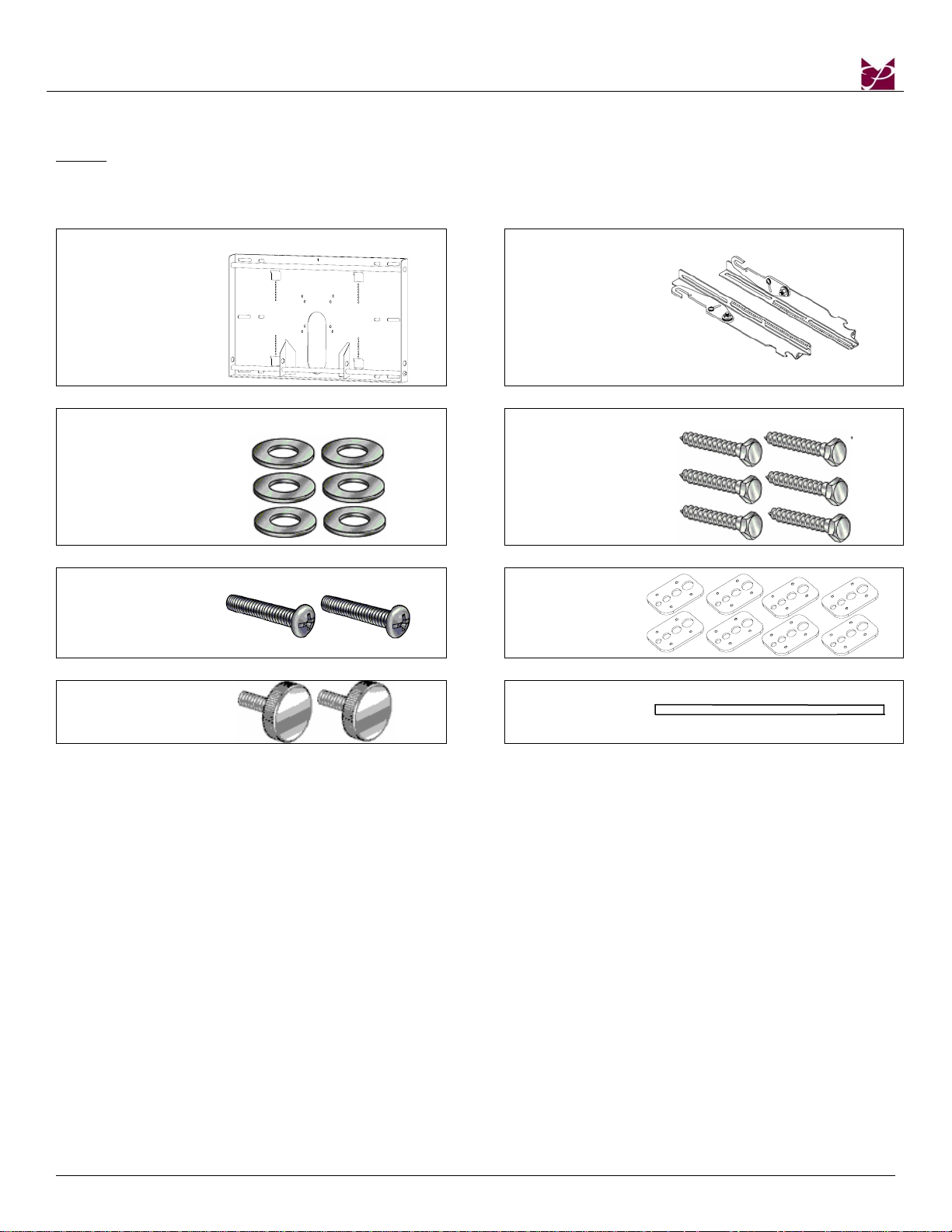

M4 x 16

M4 x 25

M5 x 12

M5 x 16

M5 x 20

M5 x 25

(Qty 8)

(Qty 8)

(Qty 6)

(Qty 4)

(Qty 6)

(Qty 4)

M6 x 20

M6 x 30

M8 x 20

M8 x 25

M8 x 30

(Qty 6)

(Qty 2)

(Qty 6)

(Qty 6)

(Qty 6)

M5 x 50

M6 x 12

(Qty 8)

(Qty 4)

M8 x 35

M8 x 70

(Qty 4)

(Qty 4)

Page - 6 - Installation Manual

Page 7

CTM-MS2

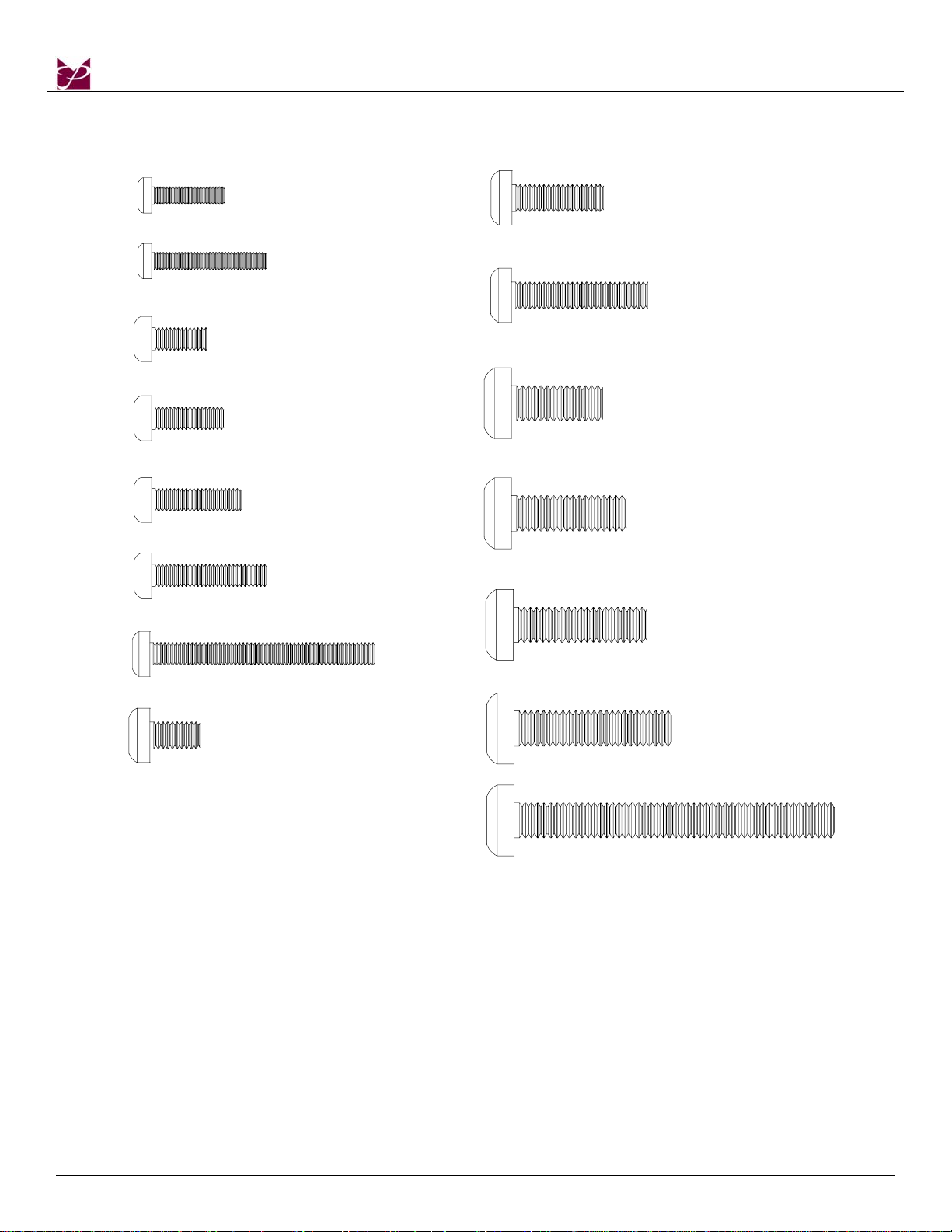

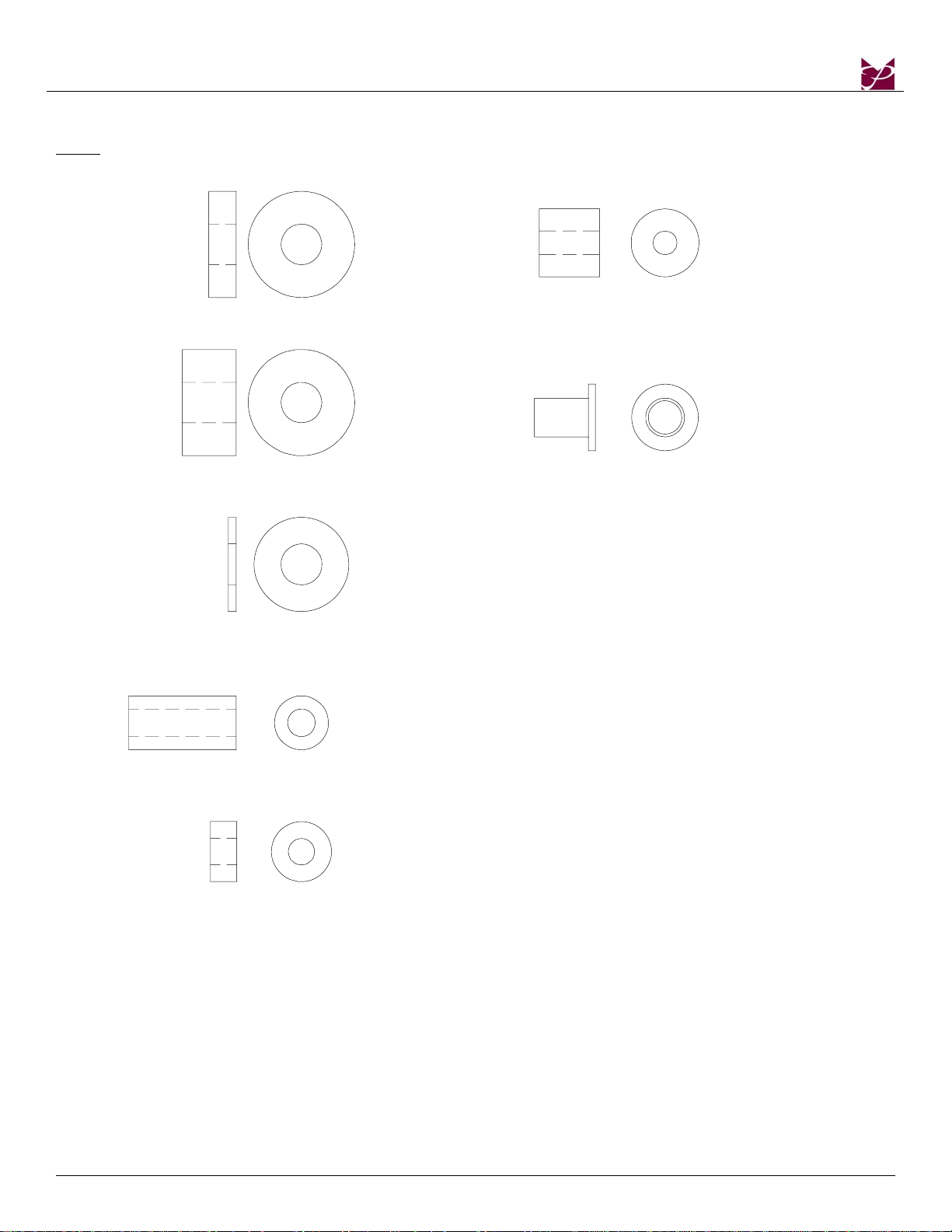

Nylon spacers and flat washers actual size

NOTE: The nylon spacers may be stacked to achieve proper spacing.

1/4" Nylo n space rs

(large)

(Qty 6)

1/2" Nylo n space rs

(large)

(Qty 12)

5/16" Flat washers

(metal)

(Qty 6)

9/16" Nylon spacers

(Qty 6)

Nylon sleeves

(Qty 4)

1" Nylon spacers

(Qty 6)

1/4" N ylon spacers

(small)

(Qty 6)

Installation Manual Page - 7 -

Page 8

CTM-MS2

Thread Depth Indicator

1. Insert the thread depth indicator (supplied) through the thread inserts found on the back of the flat

panel to make sure the inserts measure the same full depth and mark it (Figure 1).

2. Locate the correct diameter screw for the thread insert. Compare your marking to the screws (supplied).

3. If your selected screw is longer than the marking on the thread depth indicator, DO NOT USE this screw.

4. The screw length must not bypass the marking. Select another screw size (Figure 2 and 3), until you

find one that comes closest to your mark without going past.

Inverted flat panel

display

Marking the depth

Thread insert

Figure 1

Screw

Thread depth

indicator

Marking

Screw

Figure 2 Figure 3

Marking

Thread depth

indicator

Thread depth

indicator

Page - 8 - Installation Manual

Page 9

CTM-MS2

p

Mounting Bracket Installation

NOTE: Proper installation procedure by qualified personnel as outlined in the installation instructions must

be adhered to. Failure to do so could result in serious personal injury and possible damage to the

flat panel.

WARNING: INVERT THE FLAT PANEL PLACE IT ON A SOFT, FLAT SUFRACE TO PREVENT DAMAGE TO

THE FLAT PANEL. USE A BLANKET, FOAM, ETC. FAILURE TO DO SO WILL RESULT IN

DAMAGING THE FLAT PANEL. DO NOT LAY THE FLAT PANEL ON THE FLOOR WITHOUT ANY

PROTECTION TO THE GLASS. THE FLAT PANEL IS HEAVY AND FRAGILE. AT LEAST (2)

QUALIFIED PERSONNEL ARE STRONGLY RECOMMENDED FOR INSTALLATION OF THIS

PRODUCT. FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY AND POSSIBLE DAMAGE

TO THE FLAT PANEL.

1. Once the flat panel is inverted, use a measuring tape to find the center of your flat panel measuring

from outside to outside of the chassis (Figure 4).

2. Using a pencil lightly mark the center of your flat panel (Figure 5).

Measuring tape

Inverted flat panelBottom of flat panel

Top of flat panel

C

L

Mark the center

of the flat

anel

Inverted flat panel

C

L

Figure 4 Figure 5

Installation Manual Page - 9 -

Page 10

3. Install the nylon spacers (if needed) to the mounting points on the flat panel (Figure 6).

4. Lay the left and right mounting brackets (stamped arrows facing out) - (Figure 7).

CTM-MS2

Center Mark

Nylon Spacers, If Applicable

Inverted Flat Panel

Arrows Facing Out

Mounting Brackets

Bottom of Flat Panel

Figure 6 Figure 7

5. Match the center of viewing guide with the centerline you marked in Step 1 (Figure 8).

6. The mounting brackets are designed with a center of viewing guide on the outside (Figure 9).

Page - 10 - Installation Manual

Page 11

CTM-MS2

F

P

P

P

p

Mounting Bracket

C

L

Bottom of Flat

anel

Center of

Viewing Guide

Align the Mounting

Brackets

Bottom of the

lat Panel

Center of Flat

anel

Figure 8 Figure 9

7. The Griplates™ have M4, M5 M6 and M8 hole patterns to fit the hardware that your flat panel requires.

EXAMPLE: If your plasma uses M8 x 20 Phillip screws. Use the M8 mounting points (Figure 10).

8. Once the mounting brackets are aligned secure the Griplate™ to the flat panel. Use (1) Griplate™ per

mounting point (Figure 11).

NOTE: The dimples of the top plates have to be facing up and the bottom dimples must be facing down.

Dimples Facing

U

Screw Driver

DIMPLES

FACING UP

DIMPLES

FACING UP

DIMPLES

FACING DOWN

Bottom of Flat

anel

M4 M5 M8 M6

DIMPLES

FACING DOWN

Figure 10 Figure 11

Installation Manual Page - 11 -

Page 12

W

y

w

CTM-MS2

CTM-MS2 Installation

1. Using a (commercially available) wood stud finder, locate the 16" or 24" stud centers behind the wall

(Figure 12).

2. Once found, make a pencil marking on the center of the wood studs (Figure 13).

NOTE: The wall plates have 16" and 24" mounting slot positions.

3. Place the wall plate to the reference line and mark the nine (9) lag bolt mounting points through the

wall plate slots on the wall.

Wood Stud Finder

(Commerciall

available)

16"

Mark the wall

and the center

of the wood

studs.

ood studs

behind the

wall

structure.

16"

Measure and

mark the

viewing height

desired on the

all.

Figure 12 Figure 13

NOTE: Although not depicted in the illustrations shown above, the width of this wall mount will encompass

four wall studs (three studs if 24” apart).

Page - 12 - Installation Manual

Page 13

CTM-MS2

4. Level the wall plate with the reference arrow pointing up to the ceiling (Figure 15).

5. Drill six (6) ¼" pilot holes to the marked wall.

6. Secure the plate using the six (6) 5/16" lag bolts and flat washers (Figure 16).

Mark the six (6) mounting

slot openings

16"

Wall Plate

Wall Plate

Figure 15

5/16” x 3” Lag

Bolts

Figure 16. Wood Installation

NOTE

: Although not depicted in the illustrations shown above, the width of this wall mount will

encompass four wall studs (three studs if 24” apart).

Installation Manual Page - 13 -

Page 14

CTM-MS2

Installing the Flat Panel Display (CTM-MS2)

WARNING: AT LEAST (2) QUALIFIED PERSONNEL ARE STRONGLY RECOMMENDED FOR INSTALLATION

OF THIS PRODUCT. FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY AND POSSIBLE

DAMAGE TO THE FLAT PANEL.

1. Raise the flat panel with the LEFT and RIGHT mounting brackets secured to the flat panel and insert

the top hooks over the upper rod. The lower hooks should rest on the lower rod (Figure 17).

Wall Plate

Top

Bottom

Figure 17

NOTE: Although not depicted in the illustrations shown above, the width of this wall mount will

encompass four wall studs (three studs if 24” apart).

Page - 14 - Installation Manual

Page 15

CTM-MS2

W

L

2. Make any lateral shift adjustment and lock it by tightening the two (2) M6 x 30mm Phillips screws

found on the bottom of the mounting brackets. Use the foot leveler to adjust your plasma.

CAUTION: Do not over tighten the M6 x 30mm screws to the rods (Figure 18).

NOTE: To remove the display from the wall simply back off the M6 x 30mm screws using a Phillips

screwdriver and lift the unit of the wall carefully.

ateral Shift

all Plate

Figure 18

: Although not depicted in the illustrations shown above, the width of this wall mount will

NOTE

encompass four wall studs (three studs if 24” apart).

Installation Manual Page - 15 -

Page 16

CTM-MS2

3. Tilt the flat panel and secure the two (2) M6 x 12mm safety knobs to each of the mounting brackets

(Figure 19).

NOTE: To remove the display from the wall simply extend the display to its maximum tilt range, remove

the two 6 (mm) safety knurl knobs push the flat panel back to it’s flat position, loosen or remove

the two (2) M6 x 30 lateral shift screws and lift the unit of the wall.

Figure 19

NOTE: Although not depicted in the illustrations shown above, the width of this wall mount will

encompass four wall studs (three studs if 24” apart).

Page16 Installation Manual Page

Page 17

CTM-MS2

Technical Specifications

H

28.000

(171.2)

C

A

L

B

8.000

(203.2)

21.000

19.000

C

L

8.000

(203.2)

(482.6)

C

(533.4)

G

F

G

H

19.000

(482.6)

16.000

(406.4)

24.000

(616.97)

2.331

(59.21)

12°

E

1

2

D

A. Wall plate

B. Mounting brackets

C. Griplate™

D. Mounting hardware

E. M6 x 30 (mm) Phillip screws

F. Wood stud

G. 5/16” x 3” Lag screws and flat washers

H. Safety knobs

Figure 20

Installation Manual Page 17

Page 18

CTM-MS2

Warranty

Limited Lifetime Warranty

All Premier Mounts products carry a limited lifetime warranty from ship date against defects in materials and

workmanship. Premier Mounts is not liable for improper installation that results in damage to mounts,

adapters, display equipment or personal injury.

Contact Premier Mounts

In the event of missing and/or damage equipment, or technical questions, the following information can help

in the completion of the installation.

Customer Service – (800) 368-9700

Technical Support – techsupport@mounts.com

Page 18 Installation Manual

Page 19

CTM-MS2

Notes

Premier Mounts

3130 E. Miraloma Avenue

Anaheim, CA 92806

Phone: (800) 368-9700 Fax: (800) 832-4888

IN-CTMMS2.R2

mounts@mounts.com

www.mounts.com

Installation Manual Page 19

Page 20

AST-2446/2 Suspension Adapter

AST-2446/2 INSTALLATION INSTRUCTIONS

1. Separate the upper pipe and lower tube. Install the upper pipe to the ceiling structure using commercial

standards and commercially available suitable hardware (Figure 1).

2. Once the upper pipe has been properly secured to the ceiling structure. Screw the base box or any

ceiling adapters to the lower portion of the AST-2446 and secure it with the jam nut (supplied). Slide

the lower tube to the secured pipe, adjust the desired height and lock with the two (2) height adjustable

locking pins. Then screw in the three (3) thumbscrews to stabilize the pipes (Figure 2).

3. Install the mounting bracket into the projector (according to the mounting kit instructions) and raise

the projector to slide through the slot openings from the bracket into the base box. (Refer to the

mounting kit installations). Check all hardware for proper tightness and security).

4. The upper pipe has a duplicate set of thru holes. This allows you to change the normal 24" to 46"

adjustable range to 12" to 24" (Figure 3).

5. Adjustable range with a simple cut of the adapter. We recommend cutting 5/8" from the center of the

first hole of the second set of thru holes on the upper pipe. Cut between the 8th and 9th hole from the

mounting plate (Figure 3).

WARNING: The wall/ceiling should be capable of supporting a weight of at least five (5) times the plasma

displays. If not, the ceiling must be reinforced. Proper installation procedure by qualified

personnel as outlined in the installation instructions must be adhered to. Failure to do so

could result in serious personal injury.

Figure 1.

Installation Instructions Page 1

Page 21

AST-2446/2 Suspension Adapter

Figure 2. Figure 3.

Page 2 Installation Instructions

Page 22

PSD-S

PSD-S INSTALLATION INSTRUCTIONS

1. Separate the upper pipe and the lower tube.

2. Install the upper pipe in the ceiling structure using suitable commercial hardware.

3. Screw the lower portion of the PSD-S to the coupling and secure with the Allen screws.

4. Once the upper pipe has been properly installed, insert the lower tube (with the PSD-S attached) inside the upper

pipe.

5. Adjust the desired height and lock it with the two (2) through bolts.

6. Then screw in the (3) three thumbscrews to stabilize the pipe and tube.

Installation Instructions Page 1

Loading...

Loading...