Prema DMM 5017 SC, DMM 5017 User Manual

_____________________________________________________________________________________________________________________________________

DIGITAL MULTIMETER 5017

7 ½ Digit Precision Multimeter with IEEE-488 and RS232 Interface

DMM 5017 / DMM 5017 SC

User´s Manual

PREMA Semiconductor GmbH

•

Robert-Bosch-Str. 6

Tel. +49-6131-5062-20

E-Mail: instruments @ prema.com

Internet: http: / / www.prema.com

D-55129 Mainz • Germany

•

Fax. +49-6131-5062-22

Subject to change without notice

AS5017-0045

_____________________________________________________________________________________________________________________________________

Table of Contents

Table of Contents

TABLE OF CONTENTS 1

1 INTRODUCTION 1-1

1.1 Features 1-1

1.2 Various Versions 1-1

1.3 Important Safety Instructions 1-2

Reading the User Manual 1-2

Further Safety Instructions 1-2

Predictability of Dangers 1-3

Proprietary Rights 1-3

Conformity Declaration 1-3

Proper Utilization as intended 1-3

Availability of the User Manual 1-5

2 GETTING STARTED 2-1

2.1 Delivery 2-1

2.2 Safety Guidelines 2-2

Utilization 2-2

2.3 Safety Symbols 2-3

2.4 Accident Prevention 2-3

2.5 Connecting the Unit to Main Power 2-3

2.6 Grounding 2-4

2.7 Warranty 2-5

2.8 Certificate 2-5

2.9 Turning it on 2-5

2.10 Connection of Measurement Leads 2-6

Operation with rear panel inputs and Scanner 2-8

2.11 Rack Mounting 2-8

2.12 Miscellaneous 2-9

Conforming to the Norm EN 61010 2-9

Scanner with Model 5017SC 2-9

3 QUICK START 3-1

3.1 Default Settings 3-1

3.2 Scanner (5017SC) 3-1

3.3 Measuring Voltage 3-2

3.4 Measuring Current 3-3

1

Table of Contents

_____________________________________________________________________________________________________________________________________

3.5 Measuring Resistance 3-4

3.6 Measuring Temperature 3-5

3.7 Frequency and Period Measurement 3-6

3.8 Continuity Test 3-7

3.9 Selecting Measurement Ranges 3-7

3.10 Setting the Integration Time / Resolution 3-8

3.11 Display 3-9

Display with Settings 3-9

Meaning of the Settings 3-9

Display with Mathematics 3-10

Display with Channel 3-10

Display with Time Counter 3-11

4 MANUAL OPERATION 4-1

4.1 Keypad 4-1

The Function Field 4-2

The Range / Menu Field 4-3

4.2 The Display Field 4-4

Display Elements 4-4

4.3 Measuring Inputs 4-5

Connecting the Measuring Cables 4-5

Limiting Data for the Measuring Inputs 4-6

4.4 Setting the Measuring Functions 4-7

4.5 Measuring Range Selection 4-7

4.6 Channel Selection for 5017SC 4-8

4.7 Offset Correction 4-8

4.8 Navigating in the Menu Structure 4-9

4.9 Mathematical Programs 4-11

Selection / Manual Control 4-11

Meaning of the Mathematical Programs 4-12

4.10 The Menu "Configure" 4-13

Start Mode / Trigger Mode 4-13

Filter 4-13

Automatic Filter (Auto Filter) 4-14

Fast Automatic Filter (Fast Auto Filter) 4-14

Moving Average Filter (Avg. Filter) 4-14

Filter Selection 4-15

Saving and Loading Instrument Settings 4-15

Power-Up Status 4-16

Calibration 4-16

4.11 The Menu "Device" 4-17

Setting the Contrast 4-17

Preselecting the Interface 4-18

2

_____________________________________________________________________________________________________________________________________

Table of Contents

Preselecting the Command Set for Remote Control 4-19

Selecting the Temperature Sensor 4-20

Activating the Loudspeaker 4-21

Setting the Display Formats 4-21

Setting the Scanner Mode 4-23

4.12 Error Messages 4-24

5 REMOTE CONTROL 5-1

5.1 Configuration 5-1

Select Interface 5-1

Configuring the RS232 Interface 5-1

Configuring the IEEE-488 Interface 5-2

Define the Command Set 5-2

5.2 General Information concerning Remote Control 5-3

5.3 Special Features for the RS232 Interface 5-3

5.4 Capabilities of the IEEE-488 Bus Interface 5-4

General IEEE-488.1 Messages 5-4

5.5 RS232 / IEEE-488.2 Common Commands 5-5

*CLS, Clear Status Command 5-5

*ESE Standard Event Status Enable Command 5-6

*ESE? Standard Event Status Enable Query 5-6

*ESR? Standard Event Status Register Query 5-6

*IDN? Identification Query 5-7

*OPC Operation Completed Command 5-7

*OPC? Operation Completed Query 5-7

*RST Reset Command 5-7

*SRE Service Request Enable Command 5-8

*SRE? Service Request Enable Query 5-8

*STB? Read Status Byte Query 5-8

*TST? Self Test Query 5-9

*WAI Wait-to-Continue Command 5-9

5.6 Structure of the Registers 5-10

5.7 Operation as Listener 5-11

5.8 Display Mode 5-14

5.9 String Length Selection 5-16

5.10 SRQ Mode 5-16

5.11 Operation of the Digital Multimeter as TALKER 5-16

Description of the Message Record Sent 5-17

Table of Device Messages sent by the Multimeter 5-18

Meaning of the Transmitted Characters 5-19

5.12 Error Messages 5-21

5.13 Compatibility 5-23

5017 as Listener 5-23

3

Table of Contents

_____________________________________________________________________________________________________________________________________

5017 as Talker 5-25

Difference between 5017 and 6001 concerning hardware 5-27

6 CALIBRATION 6-1

6.1 Calibration Periods 6-1

6.2 PREMA Calibration Service 6-1

6.3 Necessary Equipment 6-1

6.4 Automated Calibration 6-2

6.5 Important Steps prior to Calibration 6-3

6.6 PIN Number and Calibration Switch 6-4

Changing the PIN Number 6-5

6.7 Offset Correction 6-6

6.8 Calibrating DC Voltage 6-7

Offset Correction for DC Voltage 6-7

Calibration of DC Voltage 6-7

6.9 Calibration of Resistance Ranges 6-8

Offset Correction 6-8

Calibration of Resistance 6-8

6.10 Calibration of AC Voltage 6-9

6.11 Calibration of DC and AC Current 6-9

6.12 Calibration of Temperature 6-9

6.13 Storing Calibration Values 6-11

7 OPERATING INSTRUCTIONS 7-1

7.1 DC Voltage Measurement 7-1

Input Resistance in DC Voltage 7-1

Series Mode Suppression 7-2

Common Mode Suppression 7-3

Thermal Voltages 7-3

Noise Effects Through Inductive Interferences 7-4

7.2 Resistance Measurement 7-5

Two-Wire Resistance Measurement 7-5

Four-Wire Resistance Measurement 7-7

Power Dissipation in the Resistors 7-8

7.3 AC Voltage Measurement 7-8

7.4 DC and AC Current 7-9

7.5 Temperature Measurement 7-10

8 CONSTRUCTION 8-1

8.1 Input Circuit 8-1

8.2 Integrating A to D Converter 8-2

Mains Synchronization 8-3

4

_____________________________________________________________________________________________________________________________________

Table of Contents

Reference 8-4

8.3 Measurement of AC Voltage 8-5

Frequency, Period 8-5

RMS to DC Converter 8-5

8.4 Application of Microprocessors 8-6

Main Processor 8-6

Power Management 8-7

Other processors 8-7

8.5 Ports 8-8

Display 8-8

Memory 8-8

Serial Port 8-8

IEEE-488 Port 8-8

Trigger Port 8-8

8.6 Measurement Inputs 8-9

Front / Rear Measurement Connectors 8-9

8.7 Power 8-9

8.8 5017SC 8-10

Scanner 8-10

9 TECHNICAL SPECIFICATIONS 9-1

9.1 DC Voltage 9-1

9.2 Resistance 9-5

9.3 AC Voltage 9-7

9.4 DC Current 9-9

9.5 AC Current 9-11

9.6 Temperature 9-12

9.7 Frequency and Period 9-14

9.8 Special Functions 9-15

9.9 Scanner with Model 5017SC 9-16

Pin Assignment of the Scanner 9-17

9.10 IEEE-488 Interface 9-19

9.11 RS232 Serial Interface 9-21

9.12 Trigger Interface 9-23

9.13 EU Conformity 9-24

EMC Compliance Tests 9-24

Measurement of the EMI Emissions 9-24

Measurement of EMI Immunity 9-25

9.14 General 9-26

10 ACCESSORIES 10-1

10.1 Adaptercard (3110) 10-1

10.2 Mating Plug for Sub-D (6000/03) 10-2

5

Table of Contents

_____________________________________________________________________________________________________________________________________

10.3 Pt100 Temperature Probes (3011 and 3012) 10-2

10.4 Test Lead Set (3014) 10-2

10.5 Set of Short Circuit Plugs (3016) 10-3

10.6 Current Shunt (3017) 10-3

10.7 RS232 Cable (3018) 10-3

10.8 Carrying Case (4100) 10-3

10.9 Accessories for the IEEE488 Bus 10-3

10.10 19-inch Rack Mounting Kit (5021 G) 10-4

INDEX R-1

6

_____________________________________________________________________________________________________________________________________

1 Introduction

1 Introduction

With the Digital Multimeter 5017 you are now the owner of a 7 ½ digit measuring

instrument of the newest generation from PREMA.

This instrument is convincing by virtue of its outstanding measuring capabilities and

functional versatility.

1.1 Features

The following features of the 5017 are of special interest:

• Very good stability with only 4 ppm tolerance and annual drift of 20 ppm.

Additional measuring functions such as frequency and period duration.

•

• Temperature measurement with various Pt sensors

(Pt10, Pt25, Pt100, Pt500 and Pt1000)

• Good system capabilities with the RS232 and the IEEE-488 interface

• Large clearly readable liquid crystal display (LCD)

• Standard case dimensions: Half 19 inch width and 2 height units.

The 5017SC with built-in scanner for up to 80 measuring

•

points (80x1-pole, 40x2-pole, 20x4-pole)

1.2 Various Versions

In the standard version, the 5017 is fitted with banana safety sockets on the rear in

addition to the front panel sockets. A scanner is incorporated in the 5017SC. The

scanner connections are located on the rear panel in the form of 50-pole SubD sockets. An adapter card is available (see chapter ‘Accessories’) for connecting the scanner via screw terminals.

Prior to using the connections on the rear, a plug strip connector must be transferred

inside the instrument. The designator "Rear" is then lit in the display.

For the 5017SC current measuring ranges and the 1000V range can be selected only

when using the front panel sockets (maximum permissible voltage 125 Vpk at the

scanners rear input).

1-1

Important Safety Instructions

_____________________________________________________________________________________________________________________________________

1.3 Important Safety Instructions

Reading the User Manual

Proper working procedure with this instrument is possible only after reading all instructions, hints and procedure specifications attentively and understanding them.

Please get in touch with PREMA before commencing operation of the instrument if

you do not understand something in the user manual or the instructions, procedural

descriptions and safety regulations are unclear.

This user manual has been written to make the instrument understandable for operation in the manner intended. It contains important instructions for safe, correct and

efficient operation of the instrument.

Dangers are avoided, repair costs and downtime reduced and the service life of the

instrument is extended only when these instructions are observed. The user manual

should always be available at the place where the instrument is operated.

Incorrect manual control or failure to observe the instructions given here may endanger persons (also third parties) or cause material damage.

Personnel entrusted with operating this instrument must have read this user manual

attentively and must be familiar with all safety instructions.

In addition to the instructions given in this user manual, the local regulations for preventing accidents in force at the operating site apply, as well as the relevant rules for

safe and proper working procedure.

Further Safety Instructions

Further safety instructions are contained in the chapter headed "Getting

Started".Explanations and instructions are given there for the warning signs and symbols on the instrument for recognising specific sources of danger. It is essential to

observe and comply with all safety instructions. The warning symbols must be held

complete and in good readable condition.

1-2

_____________________________________________________________________________________________________________________________________

1 Introduction

Predictability of Dangers

The manufacturer cannot anticipate every conceivable danger.

If a task is not carried out in the manner recommended, the operator must make sure

that this does not entail any danger for himself and other persons.

He should also make sure that the instrument cannot be damaged or endangered by

the chosen manner of operation.

This user operating manual is not an instruction manual for making repairs.

The instrument should be returned to the factory for any necessary repairs.

Proprietary Rights

This user manual is protected by proprietary rights. No part thereof may be copied,

reproduced or distributed in any form without prior written permission.

Conformity Declaration

PREMA has issued an EC conformity declaration for this instrument. This declaration

certifies that the instrument complies with the relevant requirements of the EC directives.

Proper Utilization as intended

These instruments have been built conforming to the recognized technical safety principles, but nevertheless if it is not used and operated in the manner intended, dangers

may arise for body and life of the user or third persons, or damage may be incurred by

the instrument and other objects.

The instrument may therefore be operated only in technically perfect condition, in the

manner intended and with due awareness of safety considerations and dangers, observing the contents of the user manual and the regulations for the prevention of accidents. It should be used exclusively for the tasks described in this user manual.

All faults on the instruments which impair the safety of the user or third persons must

be remedied immediately.

PREMA accepts no liability for damage resulting from utilization of this instrument

in any manner other than the intended manner described in the user manual. The user

alone carries the risk and responsibility for any deviating utilization of the instrument.

1-3

Important Safety Instructions

_____________________________________________________________________________________________________________________________________

Availability of the User Manual

The user manual must always be available at the place where this instrument is operated. The personnel entrusted with operation of this instrument must be familiar with

all task procedures described in the user manual and with all safety instructions.

All warning and safety instructions attached to the instrument must be held complete

and in clearly readable condition.

No modifications, attachments or conversions of the instruments are permitted without consent and approval by PREMA, otherwise the conformity becomes void.

1-4

_____________________________________________________________________________________________________________________________________

2 Getting Started

2 Getting Started

2.1 Delivery

Every PREMA unit is thoroughly and carefully checked before it is shipped, to ensure

that it is in flawless condition, and that its technical characteristics are within specifications.

Consequently, upon receipt, the unit should be in perfect condition, mechanically and

electrically.

To make sure that the unit has not been damaged during transport, it should be thoroughly checked out immediately after receipt. If damage is detected, a damage claims

form should be completed with the shipping carrier.

Please use the following list to assure that delivery is complete:

)

1. Power Cable

2. User Manual, English

3. Calibration Certificate with Date and Signatures

4. Product Registration Card, which you should fill out and mail back to

PREMA

5. Any optional equipment ordered

Please ensure also, that the unit is set up for the right AC Voltage, with the right type

of fuse (see chapter “Connecting the Unit to Main Power”).

Important: Do not throw the box and packaging materials away!

If the unit has to be sent back to the factory for recalibration or repair,

only the original packaging materials will provide sufficient protection

against damage.

2-1

Safety Guidelines

_____________________________________________________________________________________________________________________________________

2.2 Safety Guidelines

Also refer to the safety guidelines in the “Introduction” chapter, please.

The multimeter may only be operated if it is in perfect and safe condition. Accident

prevention and environmental protection rules must also be followed.

All power-up and power-down procedures described next must be followed. Problems, such as loose connections, damaged or scorched cables, oxidized contacts, and

damaged fuses must be immediately removed by a professional.

A safe and ecologically sound disposal of operating and support materials, as well as

replacement parts, must be arranged. Only genuine replacement parts shall be used.

Otherwise, the manufacturer’s warranty and the multimeter’s conformity will be

voided.

Any changes to the multimeter, which cause any functional changes, may only be carried out by the manufacturer, or after discussion with and permission by the manufacturer.

Note: Switching operation to the rear panel connectors (or to the scanner) may

only be carried out by a professional (see “Connection of Measurement

Leads").

Utilization

The multimeter may only be utilized for the measurement functions that are described

in the Technical Specifications. It is especially important to adhere to the load limits

of the input connectors. PREMA accepts no responsibility for any damage arising

from improper operation.

2-2

_____________________________________________________________________________________________________________________________________

2 Getting Started

2.3 Safety Symbols

The signs and symbols on the multimeter, which provide guidelines for safety and

handling, are displayed and described below.

!

Please consult the manual (see “Connection of Measurement

Leads” and Chapter “Operating Instructions”).

This symbol makes the user aware, that a dangerous

voltage can be present at measurement connectors.

The CE mark means, that the manufacturer has issued an

EC Declaration of Conformity for this multimeter. This declaration

certifies, that this multimeter conforms to the pertinent requirements

of EC directives.

2.4 Accident Prevention

While using this measurement unit, precautions to prevent an accident should be

taken, appropriate to the use of a measurement device.

This symbol advises the user of a possible danger area.

It is especially important to observe , that during current measurement, a very low

impedance i.e. 0.1Ω exists between the Hi and Lo connectors, so that a current/voltage, which is applied to the Hi connector, can be contacted by a cable that is

connected to the Lo connector.

2.5 Connecting the Unit to Main Power

This PREMA measurement unit is designed to be connected to AC Main Voltage, at a

frequency of 50 Hz or 60 Hz. The rear panel of the unit is equipped with a standard

DIN grounded power connector.

2-3

Grounding

_____________________________________________________________________________________________________________________________________

Before connecting the unit to power, you should make sure that it is set to the right

voltage (indicator and fuse).

The voltage selection switch with integrated fuse is located right under the power

connector, where you can also read off the current voltage setting; a setting of

"220V" represents an AC voltage from 220V to 240V, "110V" represents a voltage

from 100V to 120V.

Switching the AC Voltage is done as follows:

)

1. Unplug the unit.

2. The clamp for the fuse is located between the plug and the power selector and

must be removed. For a setting of "110V" you will need a fuse rated at 0.4A;

for "220V" you’ll need a fuse rated at 0.2A.

3. Place the necessary fuse in the clamp and push the clamp back in.

4. Turn the cylinder with the voltage indicators once left or once right to the desired setting, so that the voltage that is currently set is indicated by the white

arrow on top.

The indicators are used as follows:

Setting Voltage Range

110 V 90 V

220 V 180 V

to 130 V

RMS

RMS

to 265

RMS

RMS

Table: Main Voltage Ranges

2.6 Grounding

In order to protect the user, the unit’s case is grounded through the grounding lead of

the power cable. To ensure proper grounding, the power cable should always be connected to a properly grounded power connector.

The unit case is galvanically separated from the measurement connectors and interface ports.

The back of the unit is equipped with a grounded screw, identified by the

bol, where the user can connect a separate ground line (rack mounting bracket).

sym-

2-4

_____________________________________________________________________________________________________________________________________

2 Getting Started

2.7 Warranty

PREMA warrants the reliable function of the unit for a period of two years from the

date of delivery.

Repairs that need to be carried out during the warranty period are not billed to you.

Damage caused by inappropriate use of the unit, or by surpassing specified limits,

does not fall under PREMA’s warranty obligations.

Please be aware, also, that PREMA will not be held liable for damages, incidental or

coincidental, associated with the use of this measurement device.

2.8 Certificate

Each Digital Multimeter 5017 is provided with a calibration certificate at the factory,

certifying the location, date, and traceability of the unit’s calibration to the user.

Please look for this certificate at delivery time. It can also be useful as a control for

yearly recalibrations, since PREMA warrants that the unit will remain within specifications for one year, and recommends recalibration after that time.

2.9 Turning it on

The multimeter can be switched on with the

STANDBY KEY

cable. A device setting with measurement function, range and time can be stored as a

power-on setting in the "Configure Menu, Settings, Save Settings".

Switch off the instrument also with the

STANDBY KEY

The 5017 is then in standby mode. The red LED at the bottom left of the front panel

lights up.

The analog board of the unit is provided with power, even in standby mode, so that no

warm-up time needs to be taken into account when the unit is turned on.

Otherwise, warm-up times, as provided in Chapter “Technical Specifications”, should

be heeded.

after connecting the power

.

Note: The transformer is not disconnected from Mains Power in standby

mode.

The instrument starts automatically with power-on after switchingoff the unit by pulling the power cord.

2-5

Connection of Measurement Leads

_____________________________________________________________________________________________________________________________________

2.10 Connection of Measurement Leads

The measurement inputs are implemented as safety connectors. PREMA strongly recommends the use of safety banana plugs with contact protection (see Appendix A,

“Accessories, Safety Lead Set”).

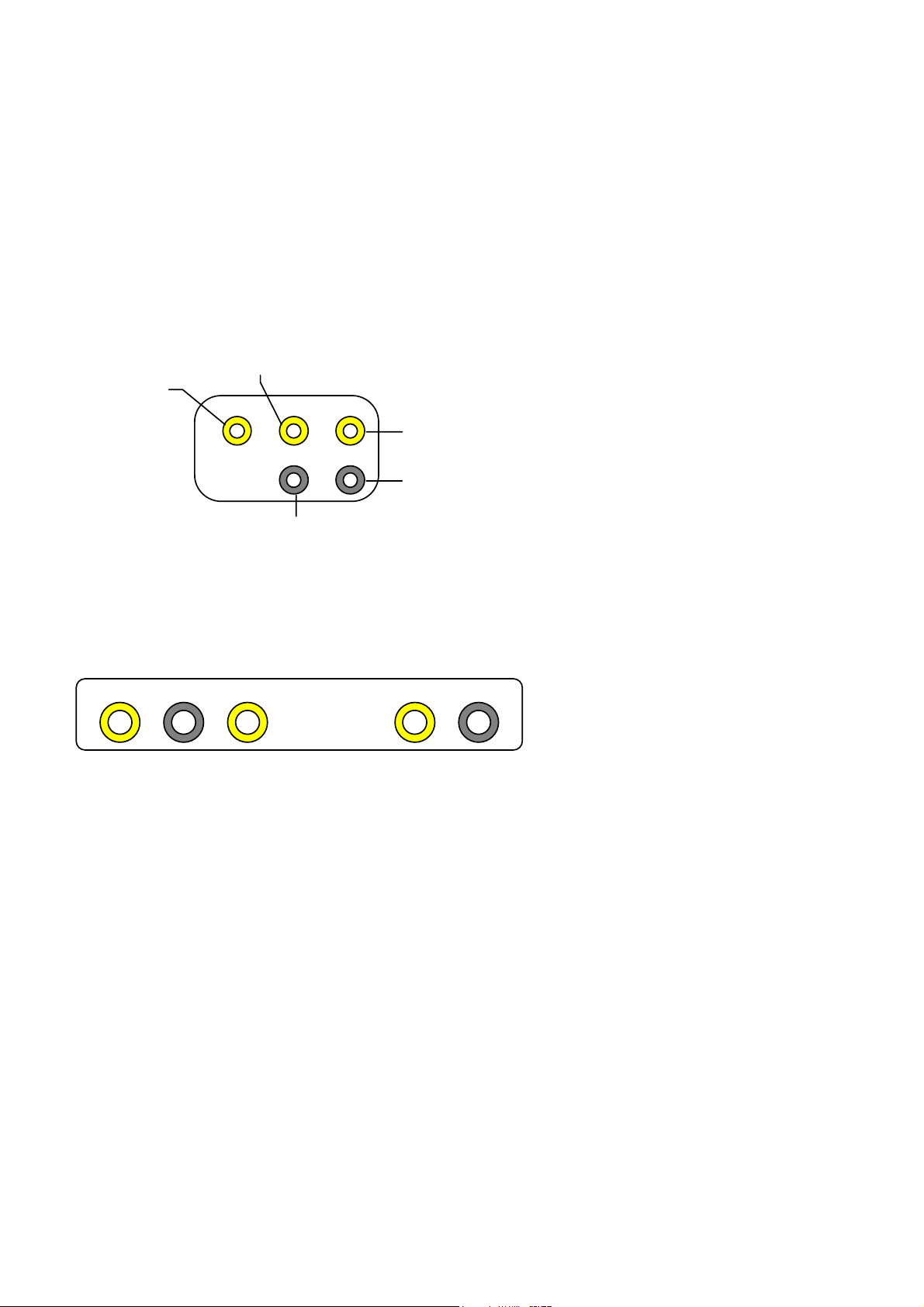

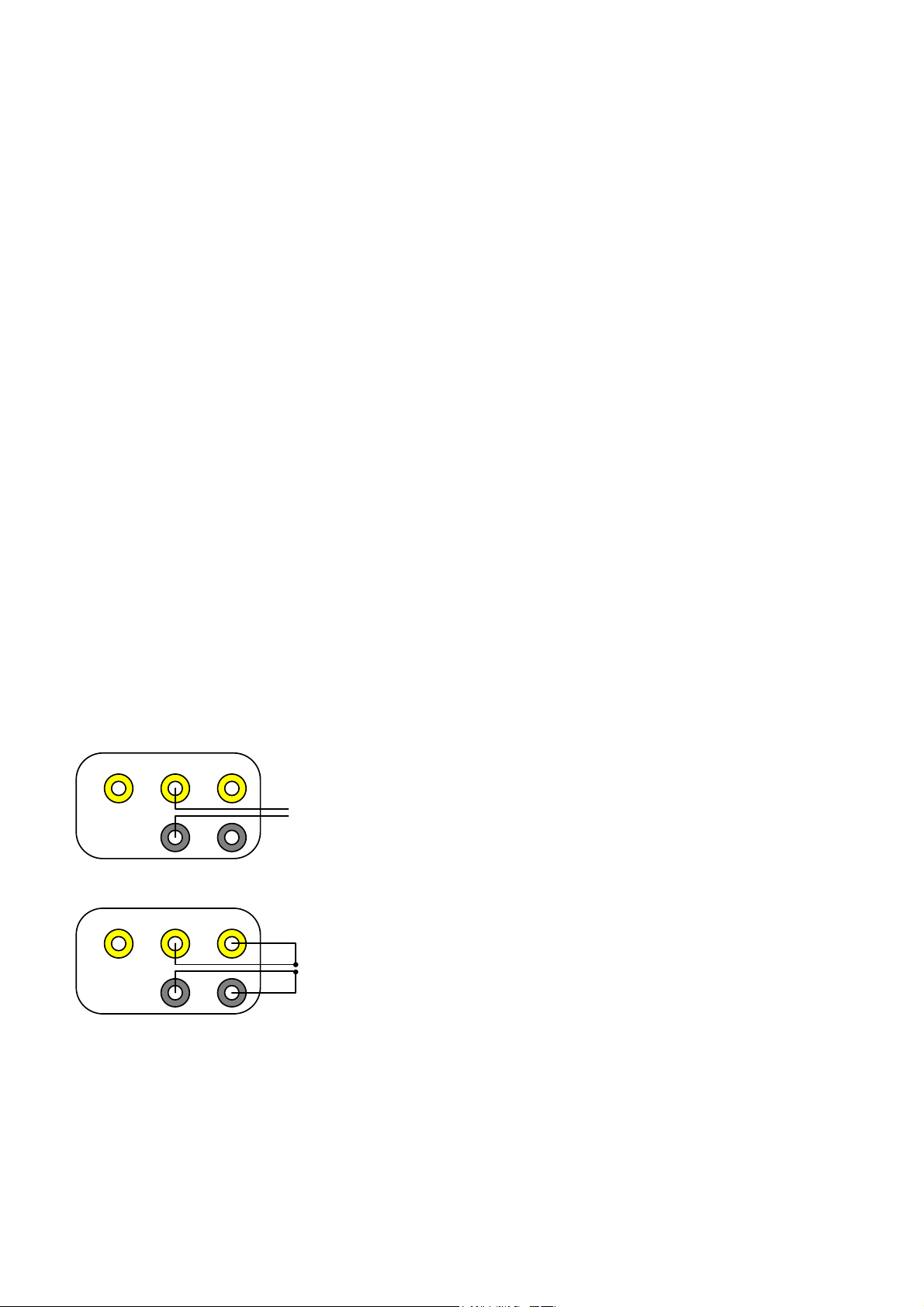

V-Hi Connector

Amps-Hi

Connector

SenseHiConnector

Sense-Lo

Connector

V-Lo Connector

Figure: Measurement Connectors

If the 5017 is not equipped with the Scanner option, safety input connectors are also

installed on the rear panel of the unit.

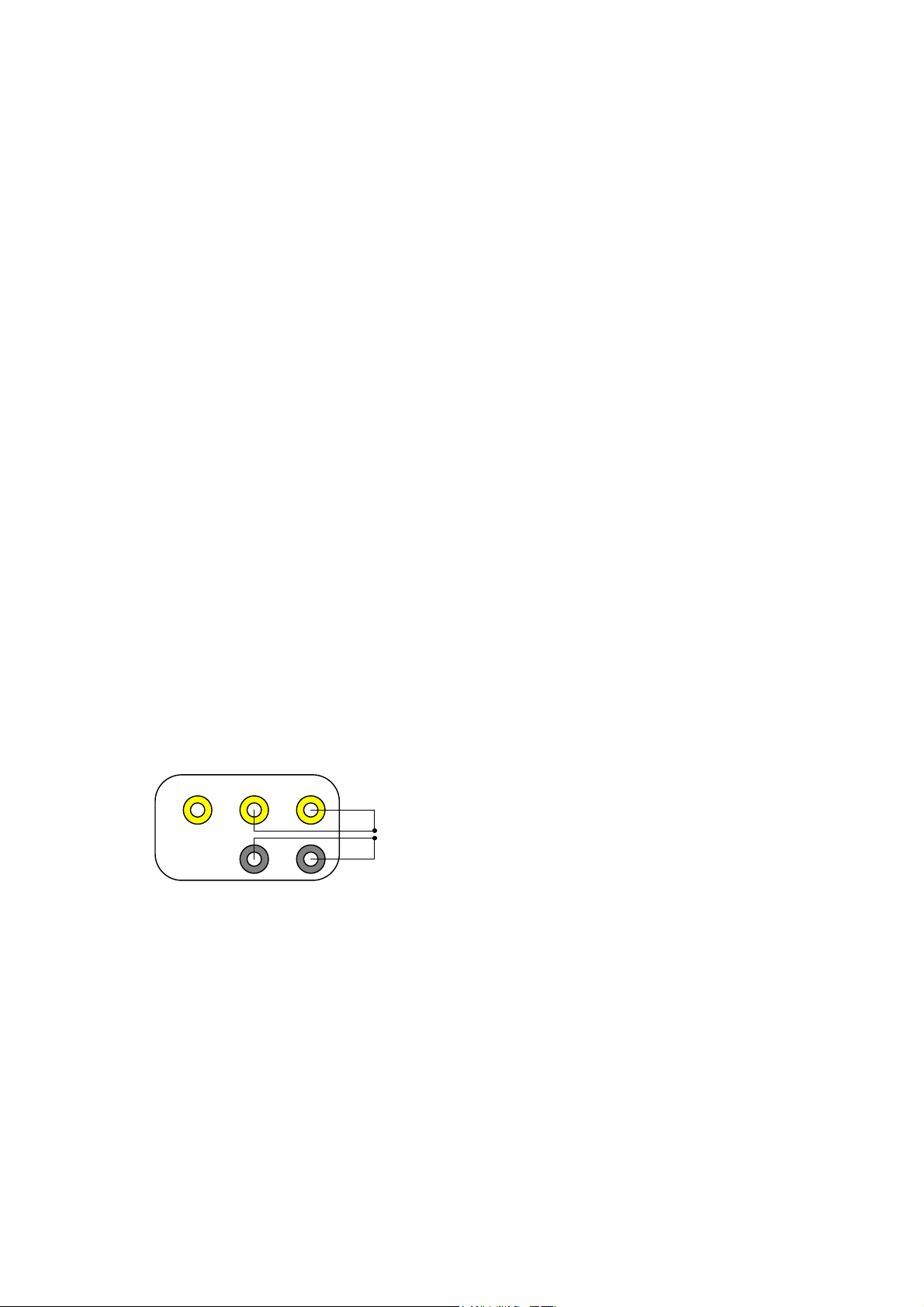

Ω

V

Hi Hi

Amps

Ω

4 W Sense

LoLo Hi

Figure: Rear Panel Input Connectors

Connection of measurement leads should be carried out according to the table on the

next page.

In order to switch to the rear panel input connectors, please read the upcoming section, “Operations with rear panel inputs and Scanner.”

2-6

_____________________________________________________________________________________________________________________________________

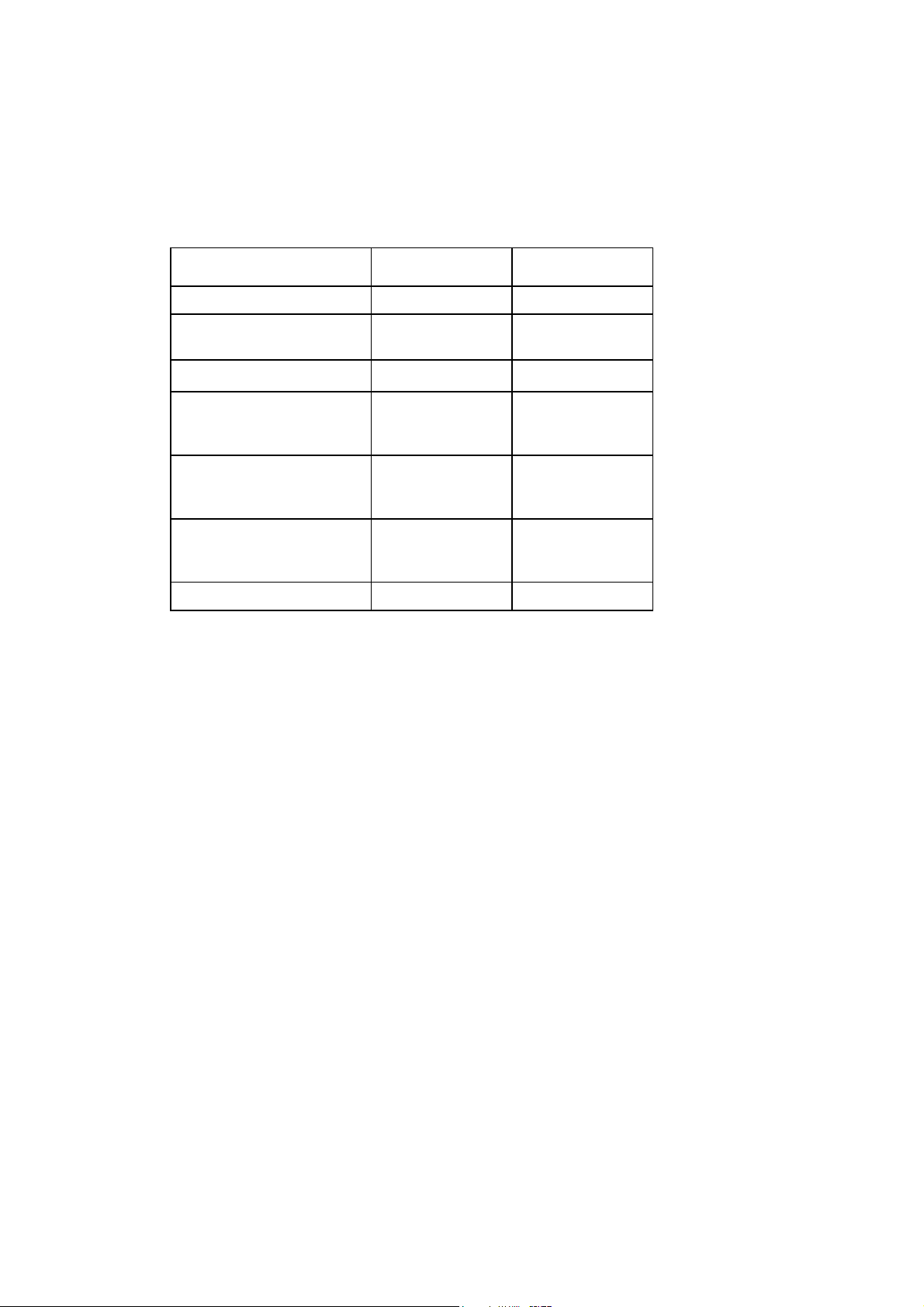

The following table gives information about the connection of measurement cables:

Measurement Hi Connector Lo Connector

DC and AC Voltage V-Hi Connector V-Lo Connector

2 Getting Started

DC and AC Current Amps-Hi Connec-

tor

2-wire Resistance V-Hi Connector V-Lo Connector

4-wire Resistance

Source

Sense

Temperature with RTDs

Source

Sense

Frequency / Period

Voltage

Current

Continuity Test V-Hi Connector V-Lo Connector

V-

Hi Connector

Sense-Hi Conn.

V-

Hi Connector

Sense-Hi Conn.

V-Hi Connector

Amps-Hi Conn.

V-Lo Connector

V-

Lo Connector

Sense-Lo Conn.

V-

Lo Connector

Sense-Lo Conn.

V-Lo Connector

V-Lo Connector

Table: Connection of Measurement Cables

In dealing with the Scanner option, please refer to chapter "Technical Specifications"

for information on measurement cable connections. There you will find a full description of the 50-line Sub-D connectors on the rear panel of the unit.

2-7

Rack Mounting

_____________________________________________________________________________________________________________________________________

Operation with rear panel inputs and Scanner

If the 5017 is to be operated from the rear panel inputs or the built-in scanner, please

proceed as follows:

)

1. Please remove all measurement cables from the connectors and

unplug the unit.

2. Turn the unit upside down, so that it is lying on its top shell.

3. Remove the four screws from the unit case's bottom shell.

4. Remove the unit case's bottom shell.

5. Tightly grasp and remove and then swap the two front-rear cable-set connectors that are visible on the left, as seen from the front panel of the unit. Only

the rear cable-set connector is connected to the preamplifier input circuitry.

The front cable-set connector is essentially a place-holder for the input that is

not being used.

6. While re-sealing the case, make sure that no wires are caught anywhere.

After turning the unit on (of course, you should first re-seal the unit’s cover) the

channel indicator field in the display will show the indication “REAR,” or a channel

number (if the Scanner is installed).

The software automatically checks for any rear-panel connections when the unit is

turned on and tests if the cable set connector has been moved from front panel input

to rear-panel input.

2.11 Rack Mounting

A rack adapter with two height units is offered for the 5017. The unit has a width of

one-half 19-inch, so it can be combined with another half-19-inch unit. More information about rack mounting can be found in the Chapter “Accessories.”

When installing the unit into a 19-inch rack, you should take into account, that the

ventilation openings in the back are not covered up. In addition, it should be possible

to cut power to the unit in an emergency, through the use of an EMERGENCY OFF

switch somewhere nearby.

Note: When the unit is installed in a 19-inch rack, and is to be operated through

the rear panel inputs or the Scanner, please make sure that the front-rear

cable-set connector in the unit has been connected to rear-panel input, prior

to installing the unit into the rack (see the previous section on

“Connection of Measurement Leads”).

2-8

_____________________________________________________________________________________________________________________________________

2 Getting Started

2.12 Miscellaneous

Conforming to the Norm EN 61010

The Digital Multimeter 5017 is produced according to EN 61010. This means the

highest possible level of safety for the user, in relation to “dangerous body currents,”

“high temperatures,” and “mechanical endangerment".

This has the consequence, that this unit cannot be switched from front-panel to rearpanel input with a switch, as is found with multimeters of other brands.

The minimum of 5.5mm clearance and creepage distance at a nominal voltage of

1000Vdc is not implemented by standard slide switches. When 1000V are applied to

the front input connectors, and a switch to the rear input connectors is effected by

slider switch, a dangerous transfer of high voltage from the front inputs to the rear

inputs can occur.

In our opinion, the manual re-positioning of the Front-Rear cable-set connector is not

the most elegant, but certainly the safest solution at the moment. This does not mean,

however, that PREMA will not come up with a completely new solution in the future.

Scanner with Model 5017SC

For the model 5017SC with integrated scanner it is important to take the DC and AC

voltage limits of the Scanner into account, depending on which option is installed.

The input voltage at the rear panel is limited to 125 Vpk with the standard scanner

option.

The limit of 1000Vpk continues to be valid for the front input connectors only.

Current measurement and the 1000V range can only be selected while using the front

input connectors .

2-9

Miscellaneous

_____________________________________________________________________________________________________________________________________

2-10

_____________________________________________________________________________________________________________________________________

3 Quick Start

3 Quick Start

3.1 Default Settings

When the unit is turned on for the first time, the following settings are defaulted to:

Measurement Function Vdc

•

Measurement Range 300V

•

Measurement Time 1s

•

Front Input Connectors Active

•

Automatic Filter On (AVG 10)

•

Pt100 sensor for temperature measurement

•

• all other functions switched off

The power-on setting can be stored in the menu "Configure, Settings, Save" .

You can set the instrument to the factory settings with the menu "Configure, Settings,

Load Fact, Set".

3.2 Scanner (5017SC)

You can find the inputs of the scanner on the rear panel of the instrument. When delivered the front input connectors are active.

The connections to the scanner can be done with two 50-pole sub-D connectors or

two adaptercards 3110 (see chapters "Accessories" and "Technical Specifications").

3-1

Measuring Voltage

_____________________________________________________________________________________________________________________________________

3.3 Measuring Voltage

Measurement Functions

DC Voltage

AC Voltage

AC Voltage with DC Component

VDC

VAC

VAC

key

key

key and

COUPL

key

Measurement Ranges

Vdc 300mV, 3V, 30V, 300V, 1000V

Vac 200mV, 2V, 20V, 200V, 700V

Resolution and Measurement Times

Vdc 20 / 40 / 100 ms 5½ digits

200 / 400 ms / 1s 6½ digits

2 / 4 / 10 / 20 / 40 / 100 s 7½ digits

Vac 100 ms 5½ digits

0.2 / 0.4 / 1 / 2 / 4 / 10 / 20 / 40 / 100s 6½ digits

max. Resolution in the smallest range Vdc: 10nV Vac: 100nV

Frequency Range Vac: 20 Hz to 1 MHz

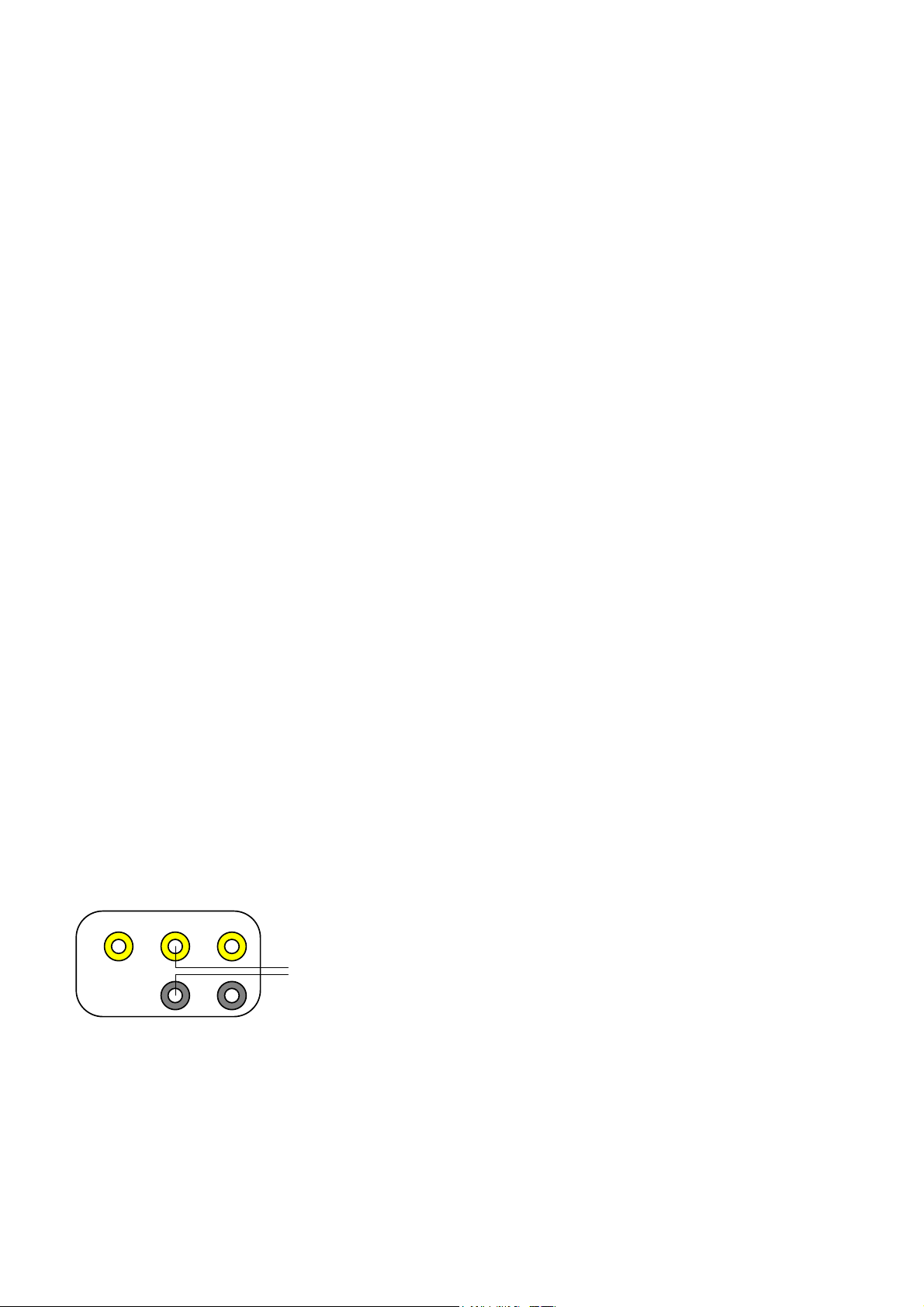

Amps

HI HI

V

Ω

LO

Ω4

Sense

+

DC or AC Voltage

__

Figure: Connection of measurement leads in Voltage Measurement

The rear plugs are connected correspondingly.

For model 5017SC with scanner the measurement leads are connected to Hi and Lo of

the respective channel.

3-2

_____________________________________________________________________________________________________________________________________

3 Quick Start

3.4 Measuring Current

Measurement Functions

DC Current

AC Current

AC Current with DC Component

IDC

IAC

IAC

key

key

key and

COUPL

key

Measurement Ranges

Idc 200 µA, 2 mA, 20 mA, 200 mA, 2 A

Iac 200 µA, 2 mA, 20 mA, 200 mA, 2 A

Resolution and Measurement Times

Idc 20 / 40 / 100 ms 5½ digits

0.2s to 100s 6½ digits

Iac 100 / 200 ms 5½ digits

400 ms / 1 / 2 / 4 / 10 / 20 / 40 / 100 s 6½ digits

Frequency Range Iac: 20 Hz to 5kHz

max. Resolution in the smallest range Idc: 100pA Iac: 100pA

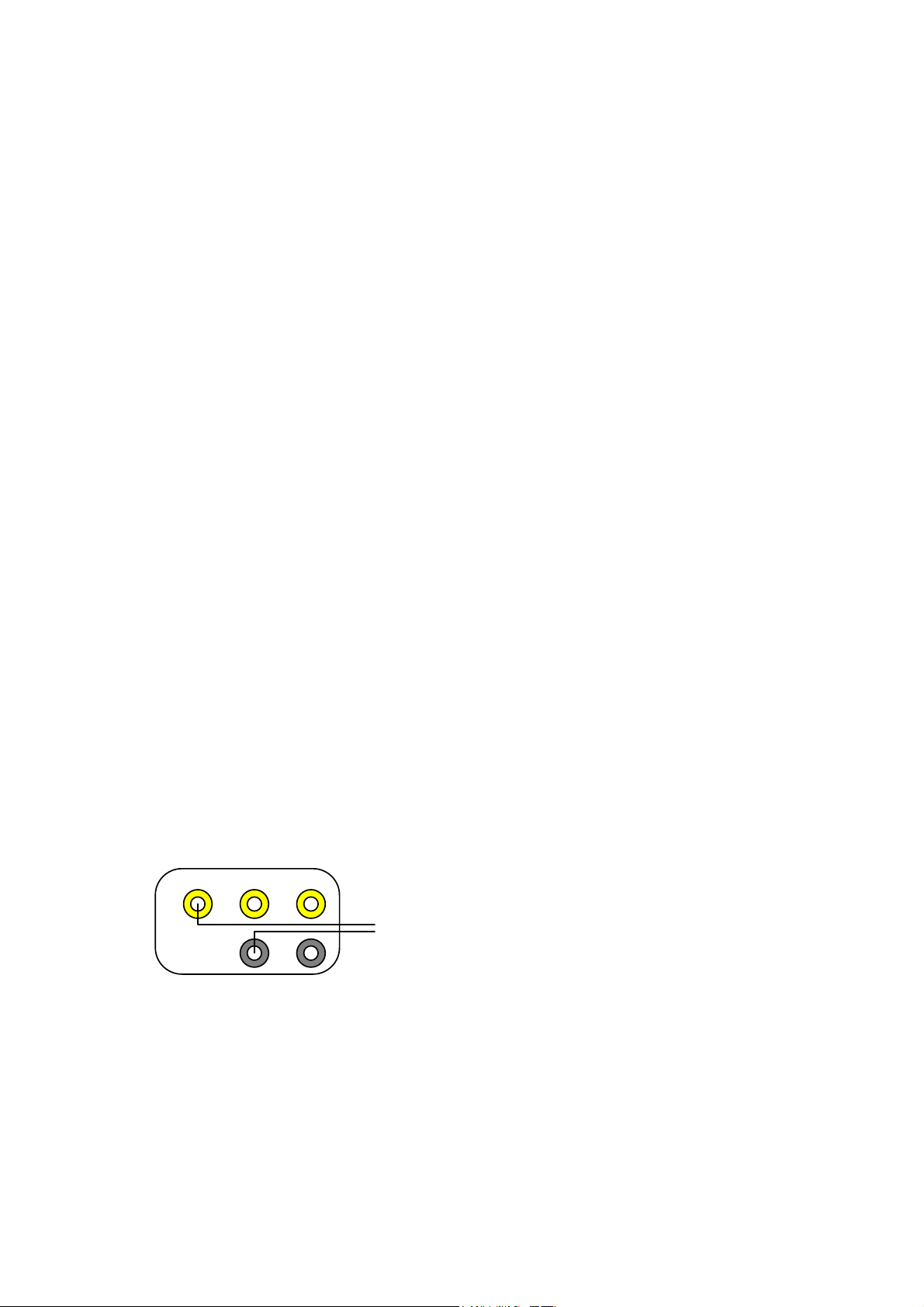

V

Amps

HI HI

Ω

LO

Ω4

Sense

+

_

DC or AC

Current

Figure: Connection of measurement leads in Current Measurement

The rear plugs are connected correspondingly.

For model 5017SC with scanner current measurement is possible only through the

front plugs.

3-3

Measuring Resistance

_____________________________________________________________________________________________________________________________________

3.5 Measuring Resistance

Measurement Functions

2-Wire Resistance Measurement Ω2

4-Wire Resistance Measurement Ω4

W

W

key

key

Measurement Ranges

300 Ω, 3 kΩ, 30 kΩ, 300 kΩ, 3 MΩ, 30 MΩ

Measurement Times

20 / 40 / 100 ms 5½ digits

200 / 400 ms / 1s 6½ digits

2 / 4 / 10 / 20 / 40 / 100 s 7½ digits

max. Resolution in the smallest range 7½ digits, 10µ

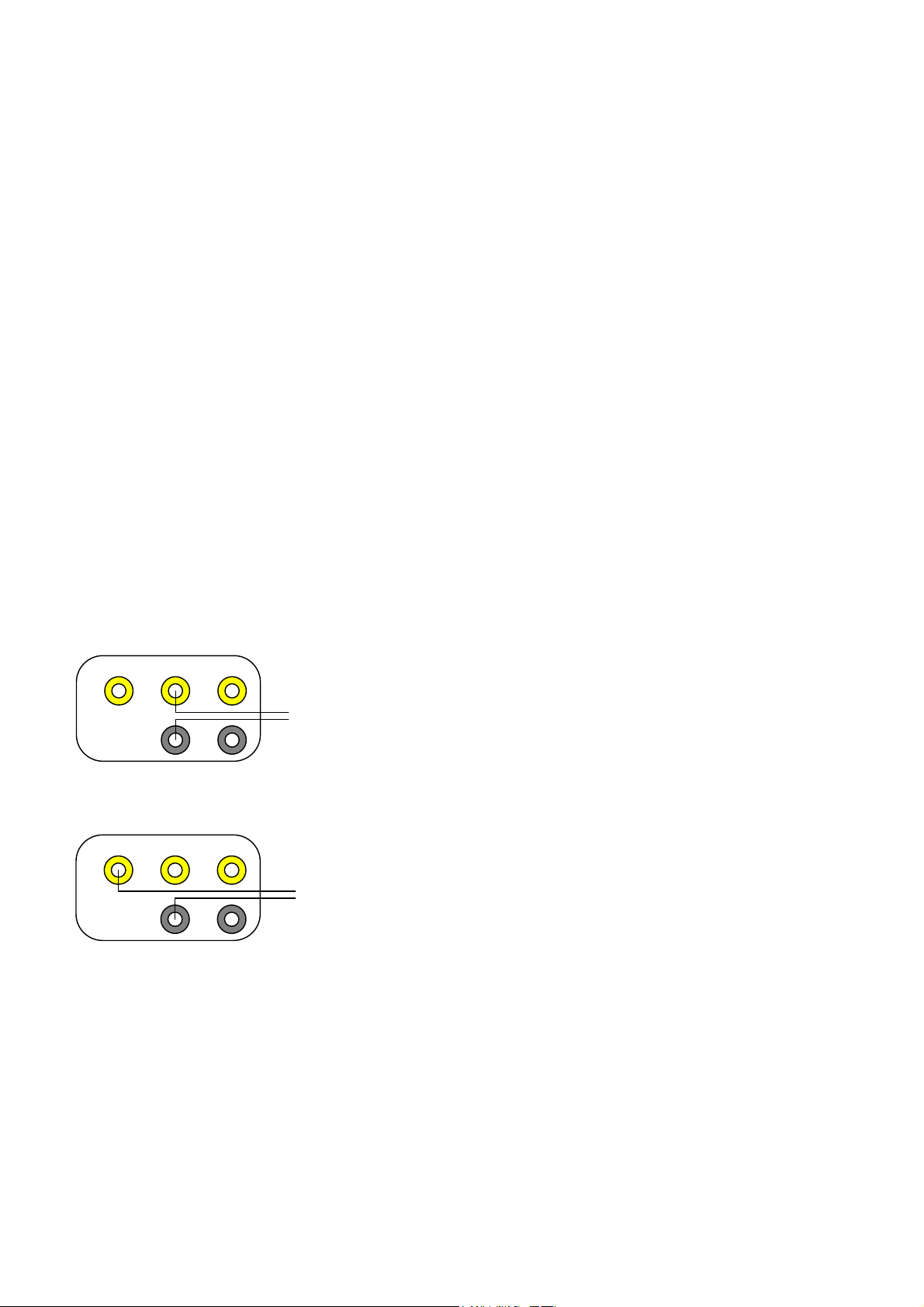

Ω

LO

Ω4

Sense

Resistance

2-wire

Amps V

HI HI

Ω

Figure: Connection of leads in resistance measurement (2-wire)

Amps V

HI HI

Ω

LO

Ω4

Sense

Resistance

4-wire

Figure: Connection of leads in resistance measurement (4-wire)

The rear plugs are connected correspondingly.

For model 5017SC with scanner the measurement leads are connected to Hi and Lo

(2-wire) or Hi, Lo (Source) and SHi, SLo (Sense) of the respective channel.

3-4

_____________________________________________________________________________________________________________________________________

3 Quick Start

3.6 Measuring Temperature

Sensors

RTDs: Pt10, Pt25, Pt100, Pt500, Pt1000

Sensor Configuration

in the menu "Device, Temp Sensor"

Resolution and Measurement Times

0.01 K / 0.01°C / 0.01°F 100 / 200 / 400 ms

0.001 K / 0.001°C / 0.001°F 1 s to 100 s

Select °C / °F / K press

Amps V

HI HI

ΩΩ4

Sense

RTD

Sensors

LO

TEMP

Figure: Connection of measurement leads for RTD Sensors

key again

The rear plugs are connected correspondingly.

For model 5017SC with scanner the measurement leads are connected to Hi, Lo

(Source) and SHi, SLo (Sense) of the respective channel.

3-5

Frequency and Period Measurement

_____________________________________________________________________________________________________________________________________

3.7 Frequency and Period Measurement

Measurement Functions

Frequency for Vac

Period for Vac

Frequency for Iac

Period for Iac

VAC

VAC

IAC

IAC

key and

key and

key and

key and

FREQ

PERIOD

key

FREQ

PERIOD

key

key

key

Select first the function Vac or Iac and adapt the right measurement range. Then select the frequency function.

Time Base 10ms / 100ms / 1s / 10s

Resolution

Frequency 1 Hz, max. 7½ digits, max. frequency 1MHz

Period Vac: 40µs to 5s / Iac: 100µs to 5s

Amps V

HI HI

ΩΩ4

LO

Sense

+

Frequency and Period

Measurement

__

with Voltage

Figure: Connection of Leads in Freq. Meas. of a Voltage

Amps V

HI HI

ΩΩ4

LO

Sense

+_Frequency and Period

Measurement

with Current

Figure: Connection of Meas. Leads in Freq. Meas. of a Current

The rear plugs are connected correspondingly.

For model 5017SC with scanner the measurement leads are connected to Hi and Lo

(Voltage) of the respective channel.

Frequency measurement of a current is only possible through the front plugs.

3-6

_____________________________________________________________________________________________________________________________________

3 Quick Start

3.8 Continuity Test

The continuity test can be selected with the

CONT KEY

.

Continuity Test Activate loudspeaker at 50Ω

Display: open or close

3.9 Selecting Measurement Ranges

The measurement range can be changed with the

AUTO KEY

key is used to automatically pre-select a measurement range (2nd +

Ø key and the × key. The 2

MenuOut key). The “AUTO” indication then appears in the status display.

If the measurement range is set manually, and a measurement signal is too large for

that range, “Overflow” will be indicated on the display.

If automatic ranging is on, a higher measurement range is automatically selected

when a display of about 190 000 *) digits is reached. A lower measurement range is

selected when a reading of lower than about 10 000 *) is reached.

Automatic range switching occurs within <5ms.

ND

-

Note: The measurement range and the integration time are stored for every

measurement function.

*) for 5-½ digit display

3-7

Setting the Integration Time / Resolution

_____________________________________________________________________________________________________________________________________

3.10 Setting the Integration Time / Resolution

The integration time (and consequently the resolution) can be changed with the

and the cursor keys. The ×

KEY

increases the integration time, the Ø

KEY

KEY

creases the integration time.

Integration Time Resolution

20ms, 40ms, 100ms 5½ Digits

200ms, 400ms, 1s 6½ Digits

2s to 100s 7½ Digits *)

*) for Vdc and

Ω

Table: Integration Times and Resolutions

Note: Range and Integration Time are stored for the respective measurement

function.

TIME

de-

3-8

_____________________________________________________________________________________________________________________________________

3.11 Display

The display can be changed and configured in the menu "Device, Display",

format.

Display with Settings

3 Quick Start

MATH FILT REM

REAR

9 ÞÞßß

TRIG STORE ADR

Figure: Display with Settings

Selecting with Menu "Device, Display, Settings".

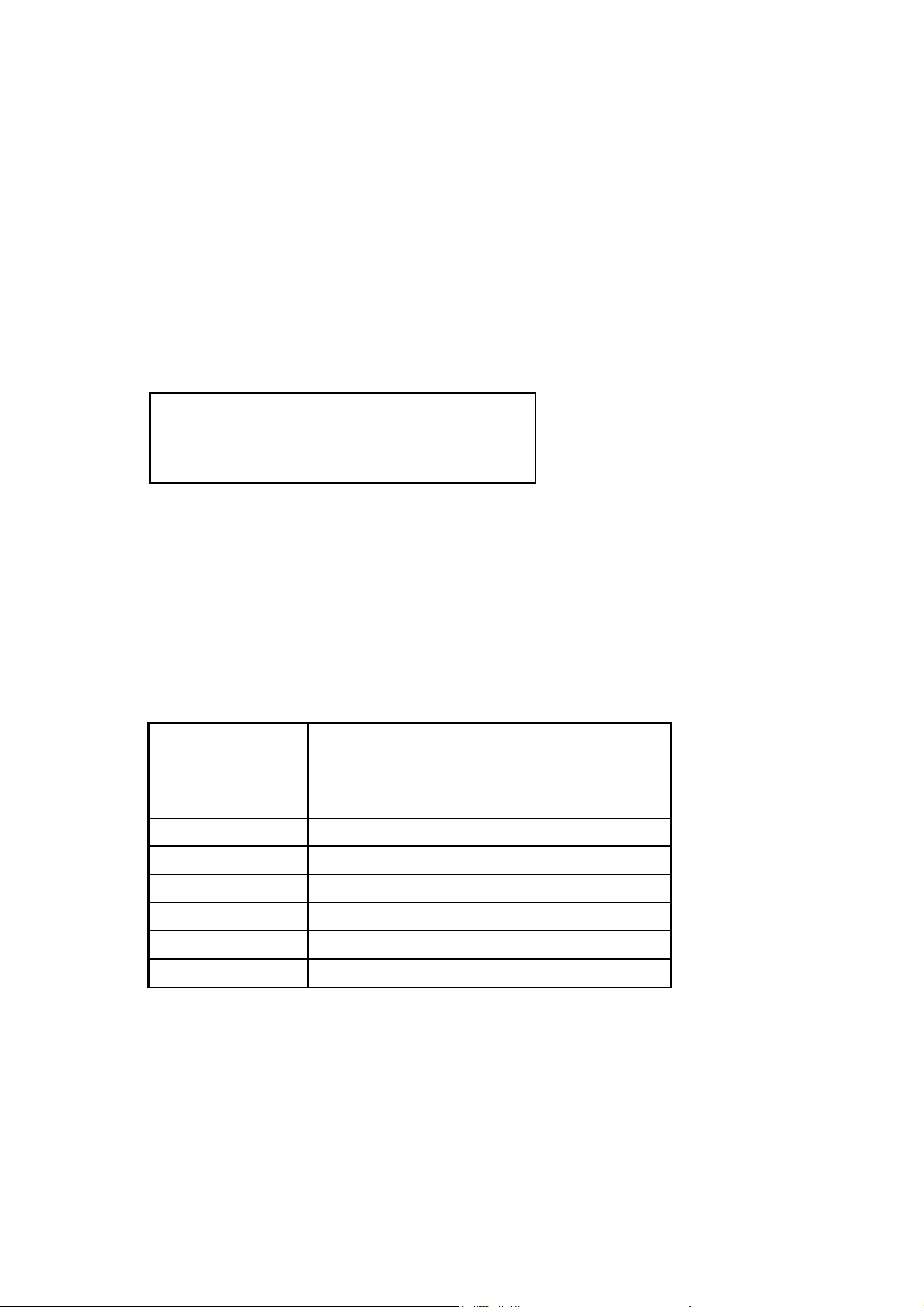

Meaning of the Settings

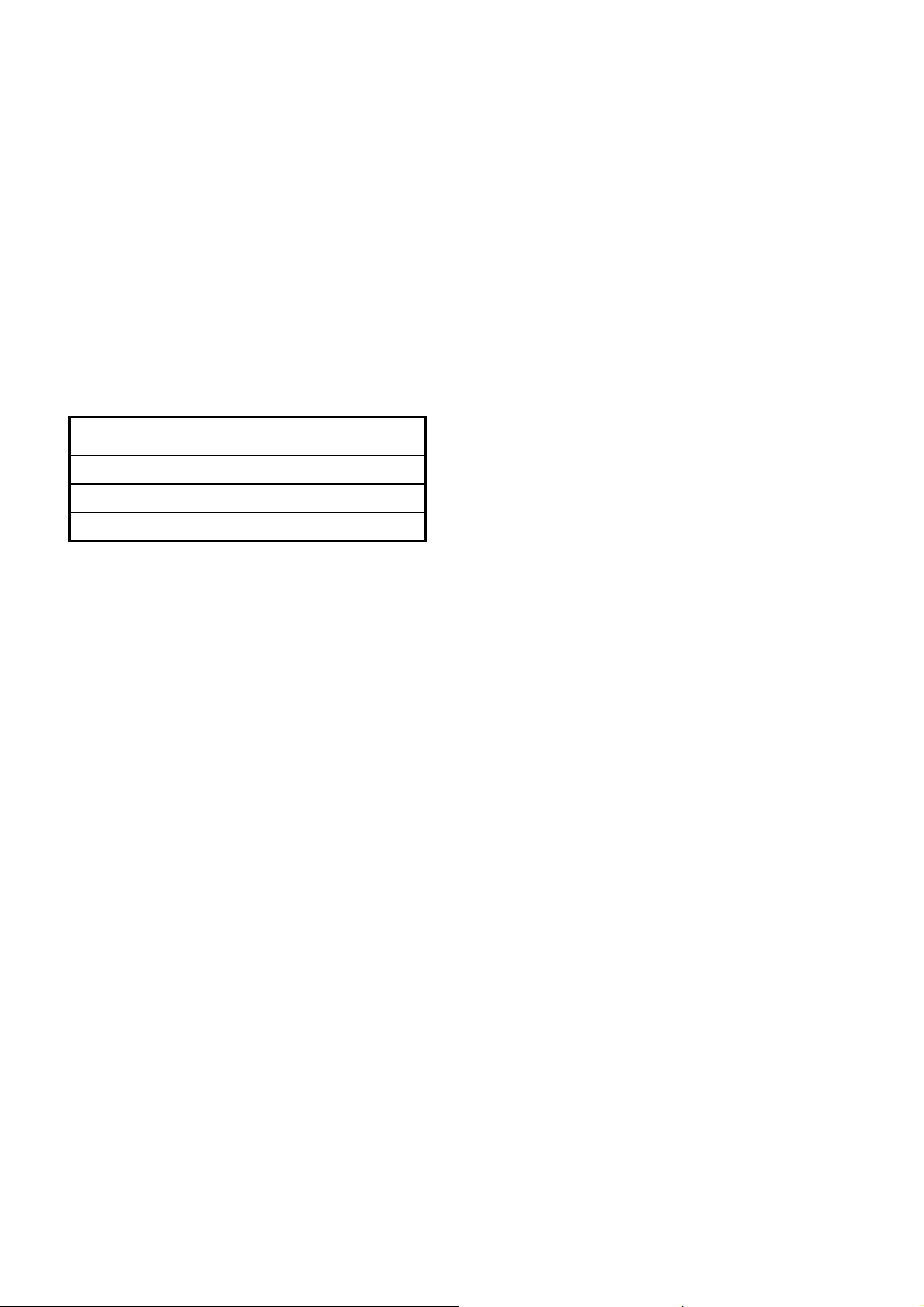

Settings Bedeutung

REAR Rear inputs are active

MATH Mathematic program is active

FILT Filter is switched on

AUTO

REM Device is in remote mode

AUTO Auto Ranging is switched on

TRIG Device is in trigger mode

STORE not used

ADR Device is in talker / listener mode

Table: Meaning of the Settings

3-9

Loading...

Loading...