PR electronics 7501 series Installation Manual

PR electronics A/S

Lerbakken 10

DK-8410 Rønde

Tel. +45 8637 2677

Fax +45 8637 3085

www.prelectronics.com

}

1

2

F

i

l

e

P

r

o

d

u

c

t

I

n

p

u

t

O

u

t

p

u

t

C

o

m

m

u

n

i

c

at

i

o

n

L

a

n

g

u

a

g

e

O

p

t

i

o

n

0

8

:

3

0

:

0

0

P

R

e

t

o

p

5

3

3

1

D

a

t

e

:

1

9

9

4

-

8

-

1

0

9

4

3

2

0

1

5

9

4

P

R

e

l

e

c

t

r

o

n

i

cs

A

n

a

l

o

g

i

n

p

u

t

A

n

a

l

o

g

o

u

t

p

u

t

S

e

r

i

al

n

o

:

I

n

p

u

t

t

y

p

e

:

O

u

t

p

u

t

t

y

p

e

:

4

-

2

0

m

A

U

p

s

ca

l

e

S

e

n

so

r

e

r

r

o

r

:

P

t

1

0

0

D

I

N

/

I

E

C

0

.

0

0

-

5

0

.

0

0

C

3

-

w

i

r

e

1

.

0

0

s

e

c

-

-

-

-

-

-

I

n

p

u

t

r

a

n

g

e

:

C

o

n

n

e

ct

i

o

n

:

C

o

l

d

j

u

n

c

t

i

o

n

c

o

m

p

:

R

e

s

p

o

n

s

e

t

i

m

e

:

T

ag

n

o

:

7501

+Vsupply

Input

Receiving

equipment

HART modem

250 Ω <

Rload<1100 Ω

}

1

2

7501

Safe area

+Vsupply

Input

Receiving

equipment

area

250 Ω <Rload<1100 Ω

DK UK FR DE

SN7501_102 (1540)

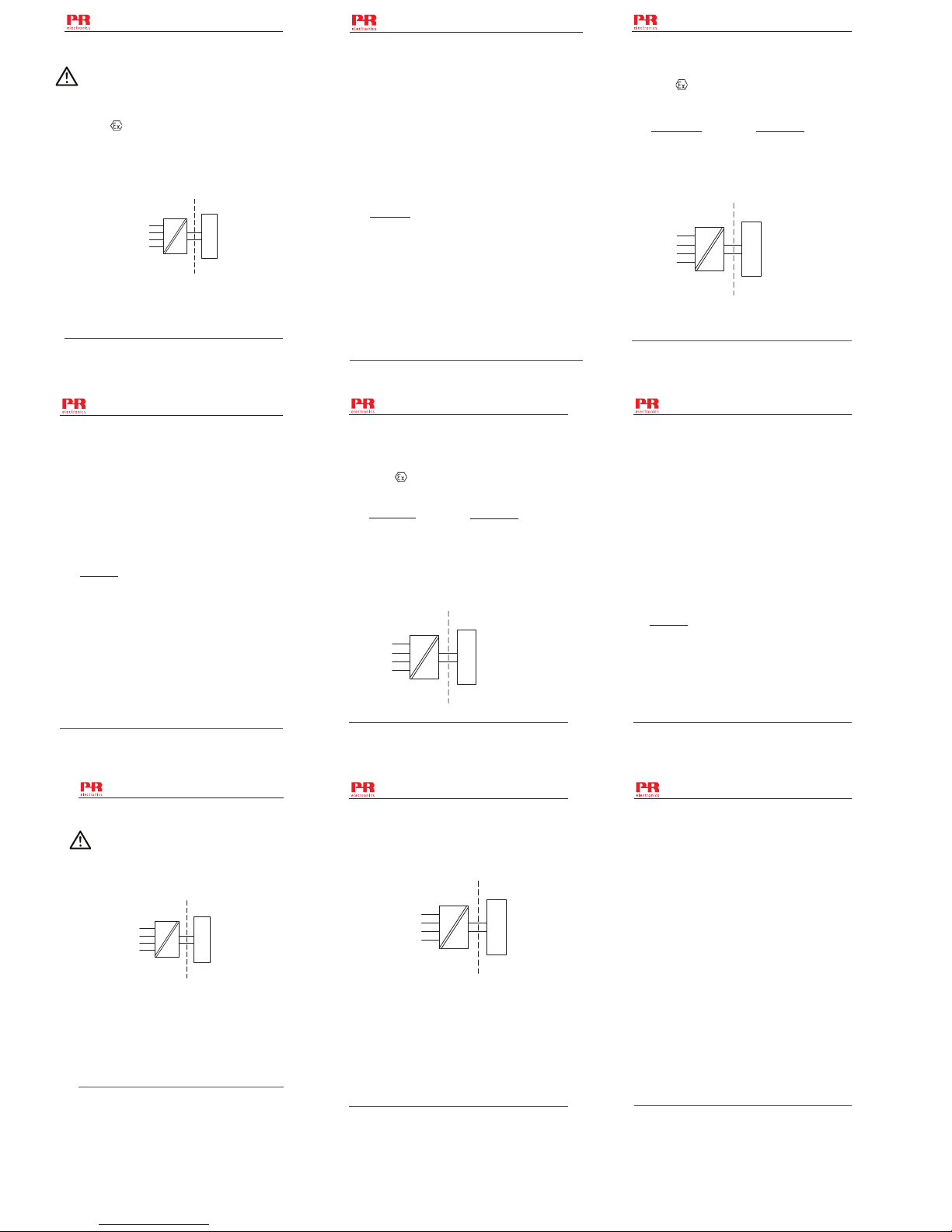

Mekaniske specifikationer Mechanical specifications Dimensions mécaniques

Abmessungen

DK UK

FR

DE

7501 - Installationsvejledning for teknikere.

7501 - Installation guide for technical personnel.

7501 - Guide d’installation pour le personnel qualifié.

7501 Installationsanleitung für Techniker.

UK

DK

FR

DE

ADVARSEL

Modulet må kun tilsluttes af kvalificerede teknikere, som er bekendte med

de tekniske udtryk, advarsler og instruktioner i installationsvejledningen,

og som vil følge disse.

Hvis der er tvivl om modulets rette håndtering, skal

der rettes henvendelse til den lokale forhandler eller

alternativt direkte til PR electronics A/S.

Installation og tilslutning af modulet skal følge landets gældende regler for installation af elektrisk

materiel.

Reparation af modulet må kun foretages af PR electronics A/S.

Transmitterdækslet må ikke ernes i eksplosionsfarligt område, når kredsløbet er strømførende.

Transmitterdækslet skal være helt lukket for at overholde kravene til eksplosionssikring.

Hvis transmitteren er installeret i områder med kraftige vibrationer, kan det være nødvendigt med ekstra

befæstning.

Ved installation i eksplosionsfarligt område skal den

tilhørende installationstegning følges nøje.

Vær opmærksom på ikke at frembringe mekaniske

gnister, når instrumentet og tilhørende enheder tilgås i eksplosionsfarligt område.

Elektriske specifikationer

Anvendelsestemperatur

med silikone O-ring.............. -40°C til +85°C

med FKM O-ring .................... -20°C til +85°

Reduceret LCD-ydeevne under -20°C og over

+70 °C

Opbevaringstemperatur ........ -40°C til +85°C

Kalibreringstemperatur ......... 20...28°C

Relativ luftfugtighed.............. 0...100% RF (kond.)

Kapslingsklasse ........................ IP54 / IP66 / IP68

type 4X

Mekaniske specifikationer

Diameter ...................................... Ø 110 mm

Mål, H x B x D ............................ 109x145x125,5 mm

Vægt, ca. ...................................... 1,3 kg

Ledningskvadrat ....................... 0,13...1,5 mm

2

/ AWG

26...16 flerkoret ledning

Klemskruetilspændings-

moment ........................................ 0,4 Nm

Vibration ...................................... IEC 60068-2-6 : 2007

2...25 Hz ................................... ±1,6 mm

25...100 Hz ............................. ±4 g

Fælles specifikationer:

Forsyningsspænding, DC

Ex: ia, egensikker ................. 10...30 VDC

(12...30 VDC med bag grundsbelysning)

Øvrige ....................................... 10...35 VDC

(12...35 VDC med bag grundsbelysning)

Isolationsspænd., test/oper. . 1,5 kVAC / 50 VAC

Langtidsstabilitet..................... 0,1% af span / år

Indgangsspecifikationer:

Indgang for RTD-typer:

Pt50, Pt100, Pt200, Pt500, Pt1000, Ni50, Ni100,

Ni120, Ni1000

Kabelmodstand pr.

leder (max.) ................................ 5 Ω

Følerstrøm ................................... Nom. 0,2 mA

Indgang for TC-typer:

B, E, J, K, L, N, R, S, T, U, W3, W5, Lr

mV-indgang:

Måleområde, spænding ......... -800...+800 mV

Min. span ..................................... 2,5 mV

Indgangsmodstand ................. 10 MΩ

Strømudgang:

Signalområde ............................. 4...20 mA

Min. signalområde .................... 16 mA

Belastningsmodstand ............ ≤ (Vforsyn. - 10) /

0,023 [Ω]

med baggrundsbelysning . ≤ (Vforsyn. - 12) /

0,023 [Ω]

Følerfejlsdetektering,

programmerbar ......................... 3,5...23 mA

NAMUR NE43 Upscale ........... 23 mA

NAMUR NE43 Downscale ..... 3,5 mA

HART-protolkolrevisioner...... HART 7 og HART 5

Direktiver:

EMC ................................................ 2004/108/EF

ATEX .............................................. 94/9/EF

EAC TR-CU 020/2011 ............ EN 61326-1

RoHS ............................................. 2011/65/EU

WARNING

Only technicians, who are familiar with

the technical terms, warnings, and

instructions in the manual and who are

able to follow these, should connect

the device.

Should there be any doubt as to the correct handling

of the device, please contact your local distributor or

PR electronics A/S.

Mounting and connection of the device should

comply with national legislation for mounting of

electric materials.

Repair of the device must be done by PR electronics

A/S only.

Do not remove the transmitter cover in explosive

atmospheres when the circuit is alive.

The transmitter cover must be fully engaged to meet

the explosion proof requirements.

If installed under high-vibration conditions, the

transmitter may require supplementary support.

For installation in hazardous area the corresponding

installation drawing must be followed in detail.

Take care not to generate mechanical sparking when

accessing the instrument and peripheral devices in a

hazardous location.

Electrical specifications

Operating tempeature

with silicone O-ring ............. -40°C to +85°C

with FKM O-ring .................... -20°C to +85°C

Reduced LCD performance below -20°C

and above +70°C

Storage temperature .............. -40°C to +85°C

Calibration temperature ........ 20...28°C

Relative humidity..................... 0...100% RH (cond.)

Protection degree .................... IP54 / IP66 / IP68

type 4X

Mechanical specifications:

Dimensions ................................ Ø 110 mm

Dimensions, H x W x D .......... 109x145x125.5 mm

Weight approx. .......................... 1.3 kg

Wire size ...................................... 0.13...1.5 mm

2

/ AWG

26...16 stranded wire

Screw terminal torque ........... 0.4 Nm

Vibration ...................................... IEC 60068-2-6 : 2007

2...25 Hz ................................... ±1.6 mm

25...100 Hz ............................. ±4 g

Common electrical specifications:

Supply voltage, DC:

Ex ia, intrinsically safe ....... 10...30 VDC

(12...30 VDC with

backlight)

Other ......................................... 10...35 VDC

(12...35 VDC with

backlight)

Isolation - test / working ...... 1.5 kVAC / 50 VAC

Long term stability .................. 0.1% of span / year

Input specifications:

RTD input types:

Pt50, Pt100, Pt200, Pt500, Pt1000, Ni50, Ni100,

Ni120, Ni1000

Cable resistance per

wire (max.) .................................. 5 Ω

Sensor current ........................... Nom. 0.2 mA

TC input types:

B, E, J, K, L, N, R, S, T, U, W3, W5, Lr

mV input:

Voltage input range ................ -800...+800 mV

Min. span ..................................... 2.5 mV

Input resistance........................ 10 MΩ

Output specifications:

Signal range ............................... 4...20 mA

Min. signal range ...................... 16 mA

Load resistance......................... ≤ (Vsupply - 10) /

0.023 [Ω]

with backlight ........................ ≤ (Vsupply - 12) /

0.023 [Ω]

Sensor error detection,

programmable ........................... 3.5...23 mA

NAMUR NE43 Upscale ........... 23 mA

NAMUR NE43 Downscale ..... 3.5 mA

HART protocol revisions ........ HART 7 and HART 5

Directives:

EMC 2004/108/EC .................. EN 61326-1

ATEX .............................................. 94/9/EC

EAC TR-CU 020/2011 ............ EN 61326-1

RoHS ............................................. 2011/65/EU

AVERTISSEMENT

Il est conseillé de réserver le

raccordement du module aux

techniciens qualifiés qui connaissent

les termes techniques, les

avertissements et les instructions

de ce guide et qui sont capables

d’appliquer ces dernières.

Si vous avez un doute quelconque quant à la

manipulation du module, veuillez contacter votre

distributeur local. Vous pouvez également vous

adresser à PR electronics SARL.

Le montage et le raccordement du module doivent

être conformes à la législation nationale en vigueur

pour le montage de matéri aux électriques.

Seule PR electronics SARL est autorisée à réparer le

module.

Ne retirez pas le couvercle du transmetteur en

atmosphère explosive lorsque l’appareil est sous

tension.

Le couvercle du transmetteur doit être serré à fond

pour être conforme aux exigences d’antidéflagrance.

Dans le cas où le transmetteur est exposé à des

fortes vibrations, il peut être nécessaire d’installer

un soutien supplémentaire.

Pour l’installation dans les atmosphères explosives,

le schéma d’installation correspondant doit être suivi

en détail.

Prenez soin de ne pas générer des étincelles

mécaniques lors de l’accès à l’appareil et instruments

périphériques dans une atmosphère explosive.

Spécifications

Plage d’utilisation

avec joint en silicone .......... -40°C à +85°C

avec joint en FKM................. -20°C à +85°C

Performance LCD réduit au dessous de -20°C et au

dessus de + 70°C

Température de stockage ..... -40°C à +85°C

Température de calibration .. 20...28°C

Humidité relative ..................... 0...100% HR (cond.)

Degré de protection ................ IP54 / IP66 / IP68

type 4X

Spécifications méchaniques :

Diamètre ...................................... Ø 110 mm

Dimensions, H x L x P ............ 109x145x125,5 mm

Poids, env. ................................... 1,3 kg

Taille des fils .............................. 0,13...1,5 mm

2

/ AWG

26...16 fil multibrins

Pression max. avant

déformation de la vis ............. 0,4 Nm

Vibration ...................................... IEC 60068-2-6 : 2007

2...25 Hz ................................... ±1.6 mm

25...100 Hz ............................. ±4 g

Spécifications communes :

Tension d’alimentation, cc :

Ex ia, intrinsèquement sûr 10...30 Vcc

(12...30 Vcc avec

rétro-éclairage)

Autres ....................................... 10...35 Vcc

(12...35 Vcc avec

rétro-éclairage)

Tension d’iso. test/opér. ........ 1,5 kVca / 50 Vca

Stabilité à long terme ............ 0,1% de l’EC / an

Spécifications d’entrée :

Entrée pour types RTD :

Pt50, Pt100, Pt200, Pt500, Pt1000, Ni50, Ni100,

Ni120, Ni1000

Résistance de ligne max.

par fil ............................................. 5 Ω

Courant de sonde ..................... nom. 0,2 mA

Entrée pour types TC :

B, E, J, K, L, N, R, S, T, U, W3, W5, Lr

Entrée mV :

Gamme de mesure, tension . -800...+800 mV

Plage de mesure min. ............. 2,5 mV

Résistance d’entrée ................ 10 MΩ

Sortie courant :

Gamme de signal...................... 4...20 mA

Plage de signal min. ................ 16 mA

Résistance de charge ............. ≤ (Valim. - 10) /

0,023 [Ω]

avec rétro-éclairage ............. ≤ (Valim. - 12) /

0,023 [Ω]

Détection de rupture de

sonde, programmable ............. 3,5...23 mA

NAMUR NE43

Haut d’échelle ........................ 23 mA

NAMUR NE43

Bas d’échelle .......................... 3,5 mA

Protocoles HART ...................... HART 7 et HART 5

Directives :

CEM ................................................ 2004/108/CE

ATEX .............................................. 94/9/CE

EAC TR-CU 020/2011 ............ EN 61326-1

RoHS ............................................. 2011/65/EU

145

127

65

126

114

64,50

40

D1

D2

D3

7

109,3

35

25

WARNUNG

Das Gerät darf nur von qualifizierten

Technikern angeschlossen werden,

die mit den technischen Ausdrücken,

Warnungen und Anweisungen in dieser

Installationsanleitung vertraut sind

und diese befolgen.

Sollten Zweifel bezüglich der richtigen Handhabung

des Gerätes bestehen, sollte man mit dem Händler

vor Ort Kontakt aufnehmen. Sie können aber auch

direkt mit PR electro nics GmbH Kontakt aufnehmen.

Die Installation und der Anschluss des Gerätes haben

in Über einstimmung mit den geltenden Regeln des

jeweiligen Landes bez. der Installation elektrischer

Apparaturen zu erfolgen

Reparaturen des Gerätes dürfen nur von PR electronics A/S vorgenommen werden.

In explosionsgefährdeten Atmosphären den

Deckel nicht abnehmen, wenn der Stromkreis unter

Spannung steht.

Der Gehäusedeckel muss vollständig geschlossen

sein, um die Ex-Schutz-Anforderungen zu erfüllen.

Bei der Installation in Bereichen mit starken

Schwingungen, kann das Gerät zusätzliche Unterstützung benötigen.

Bei der Installation in explosionsgefährdeten

Bereichen muss die entsprechende Installationszeichnung im Detail beachtet werden.

Vermeiden Sie bei der Arbeit am Gerät und dessen

Peripheriegeräte in explosionsgefährdeten Bereichen Funkenbildung durch mechanische Einwirkungen.

Elektrische Daten

Anwendungstemperatur

mit Silikon-O-Ring ................ -40°C bis +85°C

mit FKM-O-Ring..................... -20°C bis +85°C

Reduzierte LCD Leistung unter -20°C und

über +70°C

Lagertemperatur ...................... -40°C bis +85°C

Kalibrierungstemperatur ....... 20...28°C

Luftfeutigkeit ............................ 0...100% RF (kond.)

Schutzart ..................................... IP54 / IP66 / IP68

Typ 4X

Mechanische Spezifikationen

Durchmesser .............................. Ø 110 mm

Abmessungen, H x B x T ...... 109x145x125,5 mm

Gewicht, ca. ................................ 1,3 kg

Leitungsquerschnitt ............... 0,13..1,5 mm

2

/ AWG

26...16 Litzendraht

Klemmschrauben-

anzugsmoment ......................... 0,4 Nm

Schwingungen .......................... IEC 60068-2-6 : 2007

2...25 Hz ................................... ±1,6 mm

25...100 Hz ............................. ±4 g

Allgemeine Daten:

Versorgungsspannung, DC

Ex ia, eigensicher ................. 10...30 VDC

(12...30 VDC mit

Hintergrundbeleucht.)

Übrige ....................................... 10...35 VDC

(12...35 VDC mit

Hintergrundbeleucht.)

Isolationsspannung,

Test / Betrieb ............................. 1,5 kVAC / 50 VAC

Langzeitstabilität ..................... 0,1% d. Messsp. / Jahr

Elektrische Daten, Eingang:

Eingang für WTH-Typen:

Pt50, Pt100, Pt200, Pt500, Pt1000, Ni50, Ni100,

Ni120, Ni1000

Leitungswiderstand pro

Leiter (Max.) ............................... 5 Ω

Sensorstrom ............................... nom. 0,2 mA

Eingang für TE-Typen:

B, E, J, K, L, N, R, S, T, U, W3, W5, Lr

mV-Eingang:

Messbereich, Spannung ........ -800...+800 mV

Min. Messbereich (Spanne) .. 2,5 mV

Eingangswiderstand ............... 10 MΩ

Stromausgang:

Signalbereich ............................. 4...20 mA

Min. Signalbereich.................... 16 mA

Belastungswiderstand ........... ≤ (VVersorg. - 10) /

0,023 [Ω]

mit Hintergrundbeleucht. .. ≤ (VVersorg. - 12) /

0,023 [Ω]

Sensorfehlanzeige,

Programmierbar ........................ 3,5...23 mA

NAMUR NE43 aufsteuernd .. 23 mA

NAMUR NE43 zusteuernd .... 3,5 mA

Richtlinien:

EMV................................................ 2004/108/EG

ATEX .............................................. 94/9/EG

EAC TR-CU 020/2011 ............ EN 61326-1

RoHS ............................................. 2011/65/EU

Produktionsår fremgår af de to første cifre i serienummeret.

Year of manufacture can be taken from the first two digits in the serial number.

L’année de production est définie grace aux deux premiers chires du numéro de série.

Die ersten beiden Ziern der Serien nummer geben das Produktionsjahr an.

}

DK

UK

FR

DE

Typenr.

Type no.

No. de type.

Typennr.

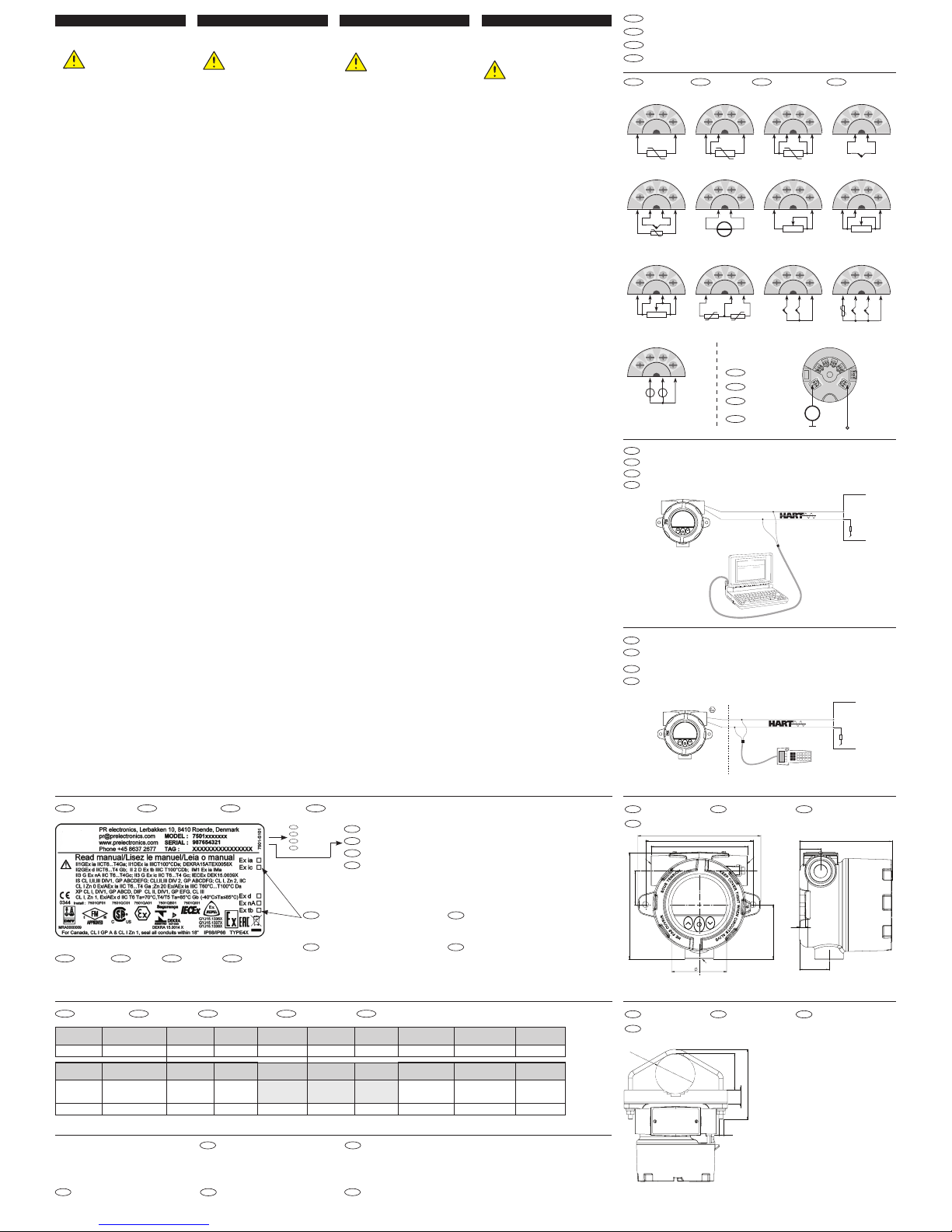

Konfiguration med HART modem og PReset PC konfigurationssoftware.

Configuration with a HART modem and the PReset software.

Programmation avec le modem HART et le logiciel PReset.

Programmierung mittels HART Modem und PReset PC Programmierungssoftware.

UK

DK

FR

DE

Konfiguration med HART kommunikator indeholdende 7501H5 eller 7501H7 DD driver.

Configuration with a HART compliant handheld communicator having the 7501H5 or 7501H7 DD driver

installed.

Programmation avec le communicateur HART chargé avec le pilote DD 7501H5 ou 7501H7 DD.

Programmierung mittels HART Datenaustauschgerät mit 7501H5 oder 7501H7 DD-Antrieb.

UK

DK

FR

DE

DK

Sideskilt / mærkning

UK

Side label / marking

FR

Etiquette / marquage

DE

Typenschild / Markierung

DK

Dokumentation, godkendelser og yderligere information

findes på internettet på www.prelectronics.dk

UK

Documentation, permits and other information can be

found on the internet at www.prelectronics.com

FR

La documentation et toute autre information peuvent

être trouvées sur l’Internet sur notre site:

www.prelectronics.fr

DE

Dokumentationen, Zulassungen und andere Informationen können auf unserer Internet-Seite unter

www.prelectronics.de gefunden und abgerufen werden.

BR

Documentações, licenças e outras informações podem ser

encontradas no site www.prelectronics.com

Product ATEX Area / Zone

Installation

drawing

IECEx Area / Zone

Installation

drawing

INMETRO Area / Zone

Installation

drawing

7501xxxxxx2 DEKRA 15ATEX0058 X 0, 1, 2, 20, 21, 22 7501QA01 DEK 15.0039 X 0, 1, 2, 20, 21, 22 7501QI01

DEKRA 15.0014 X

0, 1, 2, 20, 21, 22 7501QB01

Product CSA Zone / Div.

Installation

drawing

FM Zone / Div.

Installation

drawing

NEPSI GOST Ex EU RO marine

7501xxxxxx2

70024231

0, 1, 2 / Div. 1/ 2 7501QC01 3055380 0, 1, 2 / Div. 1/ 2 7501QF01

GYJ15.1336X

GYJ15.1337X

GYJ15.1338X

RU C DK.GB08.V.01316

MRA0000009

7501xxxxxx1

MRA0000009

DK

Godkendelser

UK

Approvals

FR

Approbations

DE

Zulassungen

BR

Aprovações

UK

When this product has been installed as

Ex ia, ic, d, nA or tb, use a punch marker in

the appropriate box to indicate the type of

installation on the top label.

FR

Lorsque ce produit a été installé comme Ex ia,

ic, d, nA ou tb W, utiliser un poinçon à marquer

dans la case appropriée pour indiquer le type

d’installation sur l’étiquette.

DE

Wenn dieses Produkt als Ex ia, ic, d, nA

oder tb installiert ist, nutzen Sie bitte die

entsprechenden Felder auf dem Top-Label, um

die Art der Installation zu kennzeichnen.

DK

Når modulet installeres som Ex ia, ic, d, nA eller

tb, skal der på topskiltet sættes en kørnerprik

til markering af den anvendte installationstype.

DK

Godkendelser

UK

Approvals

FR

ApprobationsDEZulassungen

UK

DK

FR

DE

+

-

12

+

-

1

+

-

2

+-+

-

12

+-+

-

2 1

3

4

6

5

+

-

3

4

6

5

3

4

6

5

+

-

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

-

+

12

m

A

Output:

Input:

Resistance, 2-wire

Resistance, 3-wire

RTD, 2-wire RTD, 3-wire RTD, 4-wire

TC, internal CJC

TC, external CJC mV

Resistance, 4-wire

TC, dierence

or average,

with external CJC

mV, dierence

or average

RTD, dierence

or average

TC, dierence

or average,

with internal CJC

DK

Indgangssignaler

UK

Input signals

FR

Signaux d’entrée

DE

Eingangssignale

DK

Udgangssignal

UK

Output signal

FR

Signal de sortie

DE

Ausgangssignal

M6

51

19

98

D = 1½" - 2"

Rørmontage - ovenfra Pipe-mounting – top view Montage tuyauterie -

vue de dessus

Rohrmontage - Draufsicht

DK UK

FR

DE

7501QA01

LERBAKKEN 10, 8410 RØNDE DENMARK. WWW.PRELECTRONICS.COM

Revision date:

2015-09-16

Version Revision

V2R0

Page:

2/6

Ex ia installation

General installation instructions

The sensor circuit is not infallibly galvanic isolated from the supply output circuit. However, the

galvanic isolation between the circuits is capable of withstanding a test voltage of 500Vac during 1

minute.

The enclosure must be connected to the potential matching line

If the transmitter is physically connected to a possible source of heating or cooling, e.g. by

mounting to a process pipe or a temperature sensor, the temperature at the point of connection

shall be within the ambient temperature range as given in the certificate or this manual.

Cable entries and blanking elements shall be used that are suitable for the application and correctly

installed.

For installalation in zone 0 / EPL Ga, the transmitter must be installed such, that even in the event

of rare incidents, ignition sources due to impact and friction, sparks are excluded.

Protection degree of IP 54 according to EN 60529 is achieved if certified cable glands or conduit

entry devices are used that are suitable for the application and correctly installed.

Protection degree of IP 68 according to EN 60529 is only achieved if certified cable glands or

conduit entry devices are used that are suitable for the application and correctly installed with

sealing washers or Loctite sealant added to the threads of the sensor, blanking elements and cable

glands.

For group III (dust), electrostatic charging of the paint layer shall be avoided

7501QA01

LERBAKKEN 10, 8410 RØNDE DENMARK. WWW.PRELECTRONICS.COM

Revision date:

2015-09-16

Version Revision

V2R0

Page:

3/6

Ex nA, ic installation:

Certificate

DEKRA15ATEX0058X

Marking II 3 G Ex nA IIC T6…T4 Gc

II 3 G Ex ic IIC T6...T4 Gc

II 3 D Ex ic IIIC T100°C Dc

Standards: EN 60079-0:2012, EN 60079-11:2012, EN60079-15:2010

Sensor

Terminal: 3,4,5,6

Ex ic

Uo: 9.6 VDC

Io: 28 mA

Po: 67 mW

Lo: 45 mH

Co: 28 μF

Supply

Terminal: 1,2

Ex ic

Ui: 35 VDC

Li: 0 μH

Ci: 2 nF

Supply

Terminal: 1,2

Ex nA

U : 35 VDC

1

2

6

5

4

3

+

-

Supply

7501

Hazardous area

Zone 2, 22

Non Hazardous Area

Type of protection Ex nA

O-ring Sealing : Silicone

T4: -40 ≤ Ta ≤ 85ºC T4 (7501A )

T4: -40 ≤ Ta ≤ 80ºC T4 (7501B )

T6: -40 ≤ Ta ≤ 60ºC T6

O-ring Sealing : FKM

T4: -20 ≤ Ta ≤ 85ºC (7501A )

T4: -20 ≤ Ta ≤ 80ºC (7501B )

T6: -20 ≤ Ta ≤ 60ºC

Type of protection Ex ic

T4: -40 ≤ Ta ≤ 85ºC T100ºC (7501A )

T4; -40 ≤ Ta ≤ 80ºC T100ºC (7501B )

T6: -40 ≤ Ta ≤ 60ºC T85 ºC

7501QA01

LERBAKKEN 10, 8410 RØNDE DENMARK. WWW.PRELECTRONICS.COM

Revision date:

2015-09-16

Version Revision

V2R0

Page:

1/6

7501 ATEX Installation

For safe installation of 7501 the following must be observed. The module shall only be installed by

qualified personnel who are familiar with the national and international laws, directives and

standards (EN60079-14) that apply to this area.

Year of manufacture can be taken from the first two digits in the serial number.

Ex ia installation:

ATEX Certificate

DEKRA15ATEX0058X

Marking

Standards: EN 60079-0: 2012, EN 60079-11: 2012, EN60079-26:2007

Non Hazardous Area

Hazardous area

Zone 0, 1, 2, 20, 21, 22, (Mines)

II 1 G Ex ia IIC T6...T4 Ga

II 1 D Ex ia IIIC T100°C Da

I M1 Ex ia I Ma ( 7501B )

Sensor

Terminal: 3,4,5,6

Uo: 9.6 VDC

Io: 28 mA

Po: 67 mW

Lo: 35 mH

Co: 3.5 μF

Supply

Terminal: 1,2

Ui: 30 VDC

Ii: 120 mA

Pi: 0.84 W

Li: 0 μH

Ci: 2 nF

T4: -40 ≤ Ta ≤ 85ºC T100 ºC ( 7501A)

T4: -40 ≤ Ta ≤ 80ºC T100 ºC ( 7501B)

T5: -40 ≤ Ta ≤ 60ºC T75 ºC

T6: -40 ≤ Ta ≤ 45ºC T60 ºC

1

2

6

5

4

3

+

-

Barrier

7501

7501QA01

LERBAKKEN 10, 8410 RØNDE DENMARK. WWW.PRELECTRONICS.COM

Revision date:

2015-09-16

Version Revision

V2R0

Page:

5/6

Ex d, tb installation:

ATEX Certificate

DEKRA15ATEX0058X

Marking

Standards: EN 60079-0:2012, EN 60079-1:2007, EN60079-31:2014

Non Hazardous Area

Hazardous area

Zone 1, 2, 21, 22

II 2 G Ex d IIC T6…T4 Gb

II 2 D Ex tb IIIC T100°C Db

Terminal: 3,4,5,6

Sensor: RTD or TC

Terminal: 1,2

Umax: 35 VDC

1

2

6

5

4

3

+

-

Supply

7501

Type of protection Ex d

T4,T5: -40 ≤ Ta ≤ 85ºC (7501A )

T4,T5: -40 ≤ Ta ≤ 80ºC (7501B )

T6: -40 ≤ Ta ≤ 70ºC

Type of protection Ex tb

O-ring Sealing : Silicone

-40 ≤ Ta ≤ 85ºC T100°C (7501A )

-40 ≤ Ta ≤ 80ºC T100°C (7501B )

-40 ≤ Ta ≤ 70ºC T85°C

O-ring Sealing : FKM

-20 ≤ Ta ≤ 85ºC T100°C (7501A )

-20 ≤ Ta ≤ 80ºC T100°C (7501B )

-20 ≤ Ta ≤ 70ºC T85°C

7501QA01

LERBAKKEN 10, 8410 RØNDE DENMARK. WWW.PRELECTRONICS.COM

Revision date:

2015-09-16

Version Revision

V2R0

Page:

4/6

Ex nA, ic installation:

For an ambient temperature exceeding 70 °C, heat resistant cables and cable glands suitable for at

least 90°C shall be used.

If the transmitter is physically connected to a possible source of heating or cooling, e.g. by

mounting to a process pipe or a temperature sensor, the temperature at the point of connection

shall be within the ambient temperature range as given in the certificate.

Cable entries and blanking elements shall be used that are suitable for the application and correctly

installed.

The enclosure must be connected to the potential matching line

Applied screw terminal torque is max 0.4 Nm on all terminals.

Protection degree of IP 54 according to EN 60529 is achieved if certified cable glands or conduit

entry devices are used that are suitable for the application and correctly installed.

Protection degree of IP 68 according to EN 60529 is only achieved if certified cable glands or

conduit entry devices are used that are suitable for the application and correctly installed with

sealing washers or Loctite sealant added to the threads of the sensor, blanking elements and cable

glands.

For group III (dust), electrostatic charging of the paint layer shall be avoided

7501QA01

LERBAKKEN 10, 8410 RØNDE DENMARK. WWW.PRELECTRONICS.COM

Revision date:

2015-09-16

Version Revision

V2R0

Page:

6/6

Ex d, tb installation:

Unused cable entries must be sealed by the blanking elements supplied with the 7501 or other Ex d

and/or Ex tb certified blanking elements suitable for the application. .

Only Ex d and/or Ex tb certified cable and cable glands shall be used that are suitable for the

application and correctly installed.

Protection degree of IP 54 according to EN 60529 is achieved if Ex d certified cable glands or

conduit entry devices are used that are suitable for the application and correctly installed.

Protection degree of IP 68 according to EN 60529 is only achieved if Ex d certified cable glands or

conduit entry devices are used that are suitable for the application and correctly installed with sealing

washers or Loctite sealant added to the threads of the sensor, blanking elements and cable glands.

The display cover must be screwed all the way in and the safety catch must be fastened before

putting into service. Do not open display cover until 30 minutes after disconnecting power to the

equipment allowing internal capacitors to discharge, or do not open display cover unless area is

known to be safe

For an ambient temperature exceeding 70 °C, heat resistant cables and cable glands suitable for at

least 90°C shall be used.

If the transmitter is physically connected to a possible source of heating or cooling, e.g. by mounting

to a process pipe or a temperature sensor, the temperature at the point of connection shall be within

the ambient temperature range as given in the certificate. The sensor shall be suitable for use as

entry device on an Ex d enclosure and shall not add volume to the 7501 enclosure. The thread of the

sensor must be in compliance with EN60079-1 / EN60079-31.

The enclosure must be connected to the potential matching line.

When the process temperature range exceeds the service temperature range it shall be verified by

on-site temperature measurements, taking the worst case conditions into account, that the service

temperature does not exceed the range of the module.

For group III (dust), electrostatic charging of the paint layer shall be avoided

No modification to the enclosure is allowed by the customer except as mentioned in the manual or

installation drawing.

7501QC01

LERBAKKEN 10, 8410 RØNDE DENMARK. WWW.PRELECTRONICS.COM

Revision date:

2015-09-22

Version Revision

V2R0

Page:

2/3

Explosion proof:

Explosion proof for Hazardous area

Class I, Division 1, Groups ABCD;

Class II, Division 1, Groups EFG;

Class III

Ex d IIC, Class I, Zone 1

T4,T5: -20/-40 ≤ Ta ≤ 85ºC T100°C

T6: -20/-40 ≤ Ta ≤ 70ºC T85°C

Non Hazardous Area

1

2

6

5

4

3

+

-

Supply

7501

Terminal: 1,2

Umax: 35 VDC

Terminal: 3,4,5,6

Sensor: RTD or TC

O-ring Sealing

Silicone rubber:-40°C ≤Ta ≤ +85°C

FKM rubber: -20°C ≤Ta ≤ +85°C

7501QC01

LERBAKKEN 10, 8410 RØNDE DENMARK. WWW.PRELECTRONICS.COM

Revision date:

2015-09-22

Version Revision

V2R0

Page:

1/3

7501 CSA Installation

For safe installation of 7501 the following must be observed. The module shall only be installed by

qualified personnel who are familiar with the national and international laws, directives and

standards that apply to this area.

Intrinsic Safe Installation:

Hazardous classified Location

Class I,Division1, Groups, ABCD;

Class II,Group EFG;

Class III, Division 1.

Class I, Zone 0, IIC

Ex/AEx ia IIC Ga

Warning:

Substitution of components may impair intrinsic safety.

The module must be installed according to the installation codes stipulated in the Canadian

Electrical Code (CEC) or for US the National Electrical Code (NEC).

Non classified Location

Terminal: 3,4,5,6

Uo: 9.6 VDC

Io: 28 mA

Po: 67 mW

Lo: 35 mH

Co: 3.5 μF

Terminal: 1,2

Ui: 30 VDC

Ii: 120 mA

Pi: 0.84 W

Li: 0 μH

Ci: 2 nF

UM < 250V

Voc or Uo < Vmax or Ui

Isc or Io < Imax or Ii

Po < Pi

Ca or Co > Ci + Ccable

La or Lo > Li + Lcable

The barrier must not

be connected to any

associated apparatus

which uses or

generates more than

250 VRMS

1

2

6

5

4

3

+

-

Barrier

7501

T4: -40 ≤ Ta ≤ 85ºC T100 ºC

T5: -40 ≤ Ta ≤ 60ºC T75 ºC

T6: -40 ≤ Ta ≤ 45ºC T60 ºC

7501QC01

LERBAKKEN 10, 8410 RØNDE DENMARK. WWW.PRELECTRONICS.COM

Revision date:

2015-09-22

Version Revision

V2R0

Page:

3/3

Explosion proof Installation.

Conduit and sensor connections must be in NPT modified threads.

Only third party certified sensors suitable for “Class I, Division 1 / Zone 1, Groups ABCD / IIC“ may

be connected to the Temperature Transmitter.

For Class I Group A installation and Class I Zone 1 installation, conduit seal is required within 18

inches of enclosure.

For an ambient temperature exceeding 70°C, heat resistant cables and cables suitable for at least

90°C shall be used.

The display cover must be screwed all the way in and the safety catch must be fastened before

putting the module into service.

Do not open / remove front cover unless area is known to be safe.

The remote temperature sensor must comply with the requirements for installation in hazardous

locations “Class I, Division 1 / Zone 1, Groups ABCD / IIC”

The remote temperature sensor must comply with the requirements for Ex d installation

Only certified cable and cable glands shall be used that are suitable for the application and

correctly installed.

For protection according to Type 4X / IP66 use Loctite 577 on threads of sensor and cable glands.

The enclosure must be connected to the potential matching line

Unused cable entries must be sealed by the blanking elements supplied with the 7501 or other Ex

certified blanking elements.

If the transmitter is physically connected to a possible source of heating or cooling, e.g. by

mounting to a process pipe or a temperature sensor, the temperature at the point of connection

shall be within the ambient temperature range as given in the certificate.

When the process temperature range exceeds the service temperature range it shall be verified by

on-site temperature measurements, taking the worst case conditions into account, that the service

temperature does not exceed the range of the module.

For Class II, III, electrostatic charging of the paint layer shall be avoided.

No modification to the enclosure is allowed by the customer except as mentioned in the manual or

installation drawing.

Loading...

Loading...