PR electronics 7501 Product Manual

PERFORMANCE

MADE

SMARTER

Product Manual

7501

Field mounted HART

temperature transmitter

TEMPERATURE | I.S. INTERFACES | COMMUNICATION INTERFACES | MULTIFUNCTIONAL | ISOLATION | DISPLAY

No. 7501V107-UK

Serial no.: 170807001-170816075

6 Product Pillars

to meet your every need

With our innovative, patented technologies, we make signal conditioning smarter and simpler. Our portfolio is composed of six

product areas, where we offer a wide range of analog and digital devices covering over a thousand applications in industrial

and factory automation. All our products comply with or surpass the highest industry standards, ensuring reliability in even

the harshest of environments and have a 5-year warranty for greater peace of mind.

Individually outstanding, unrivalled in combination

Our range of temperature transmitters and sensors provides the highest level of signal integrity from the

measurement point to your control system. You can convert industrial process temperature signals to analog, bus or

digital communications using a highly reliable point-to-point solution with a fast response time, automatic selfcalibration, sensor error detection, low drift, and top EMC performance in any environment.

Our unique range of single devices covering multiple applications is easily deployable as your site standard. Having

one variant that applies to a broad range of applications can reduce your installation time and training, and greatly

simplify spare parts management at your facilities. Our devices are designed for long-term signal accuracy, low

power consumption, immunity to electrical noise and simple programming.

We provide inexpensive, easy-to-use, future-ready communication interfaces that can access your PR installed base

of products. The detachable 4501 Local Operator Interface (LOI) allows for local monitoring of process values,

device configuration, error detection and signal simulation. The next generation, our 4511 Remote Operator

Interface (ROI) does all that and more, adding remote digital communications via Modbus/RTU, while the analog

output signals are still available for redundancy.

With the 4511 you can further expand connectivity with a PR gateway, which connects via industrial Ethernet,

wirelessly through a Wi-Fi router or directly with the devices using our Portable Plant Supervisor (PPS) application.

The PPS app is available for iOS, Android and Windows.

Our display range is characterized by its flexibility and stability. The devices meet nearly every demand for display

readout of process signals, and have universal input and power supply capabilities. They provide a real-time

measurement of your process value no matter the industry, and are engineered to provide a user-friendly and

reliable relay of information, even in demanding environments.

We deliver the safest signals by validating our products against the toughest safety standards. Through our

commitment to innovation, we have made pioneering achievements in developing I.S. interfaces with SIL 2 Full

Assessment that are both efficient and cost-effective. Our comprehensive range of analog and digital intrinsically

safe isolation barriers offers multifunctional inputs and outputs, making PR an easy-to-implement site standard.

Our backplanes further simplify large installations and provide seamless integration to standard DCS systems.

Our compact, fast, high-quality 6 mm isolators are based on microprocessor technology to provide exceptional

performance and EMC-immunity for dedicated applications at a very low total cost of ownership. They can be

stacked both vertically and horizontally with no air gap separation between units required.

7501V107-UK 3

Field mounted HART

temperature transmitter

7501

Table of contents

Warning ................................................................................................ 4

Applications ............................................................................................ 5

Order................................................................................................... 6

Accessories ............................................................................................. 6

Technical data .......................................................................................... 6

Block diagram .......................................................................................... 9

Marking................................................................................................. 9

Mechanical specifications ................................................................................ 10

Mounting ............................................................................................... 12

Protection degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Assembly and disassembly .............................................................................. 15

Connections ............................................................................................ 20

Optical buttons.......................................................................................... 21

Operating the optical buttons ............................................................................ 21

Display ................................................................................................. 21

Device and sensor status indication ...................................................................... 24

Display menu ........................................................................................... 25

Display .............................................................................................. 28

Tags................................................................................................. 28

Calibration ........................................................................................... 29

Simulation ........................................................................................... 30

Sensor .............................................................................................. 31

HART................................................................................................ 31

Write-protect ........................................................................................ 32

Language............................................................................................ 32

HART Revision ....................................................................................... 32

Help text overview ...................................................................................... 33

Programming ........................................................................................... 37

Changing the HART protocol version ...................................................................... 38

Retrofit................................................................................................. 40

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

ATEX Installation Drawing ............................................................................ 42

IECEx Installation Drawing ............................................................................ 48

FM Installation Drawing............................................................................... 54

CSA Installation Drawing.............................................................................. 59

Desenho de instalaçao INMETRO ...................................................................... 62

Document history ....................................................................................... 68

4 7501V107-UK

Warning

Only technicians, who are familiar with the technical terms, warnings, and instructions in the manual and

who are able to follow these, should connect the device.

Should there be any doubt as to the correct handling of the device, please contact your local distributor

or PR electronics A/S.

Mounting and connection of the device should comply with national legislation for mounting of electric

materials.

Repair of the device must be done by PR electronics A/S only.

Do not remove the transmitter cover in explosive atmospheres when the circuit is live.

The transmitter cover must be fully engaged to meet the explosion proof requirements.

If installed under high-vibration conditions, the transmitter may require supplementary support.

For installation in hazardous area the corresponding installation drawing must be followed in detail.

Take care not to generate mechanical sparking when accessing the instrument and peripheral devices in

a hazardous location.

+

-

+

-

+

-

+-

+-

21

2

21

1

1

2

+

-

7501V107-UK 5

Field mounted HART temperature transmitter

7501

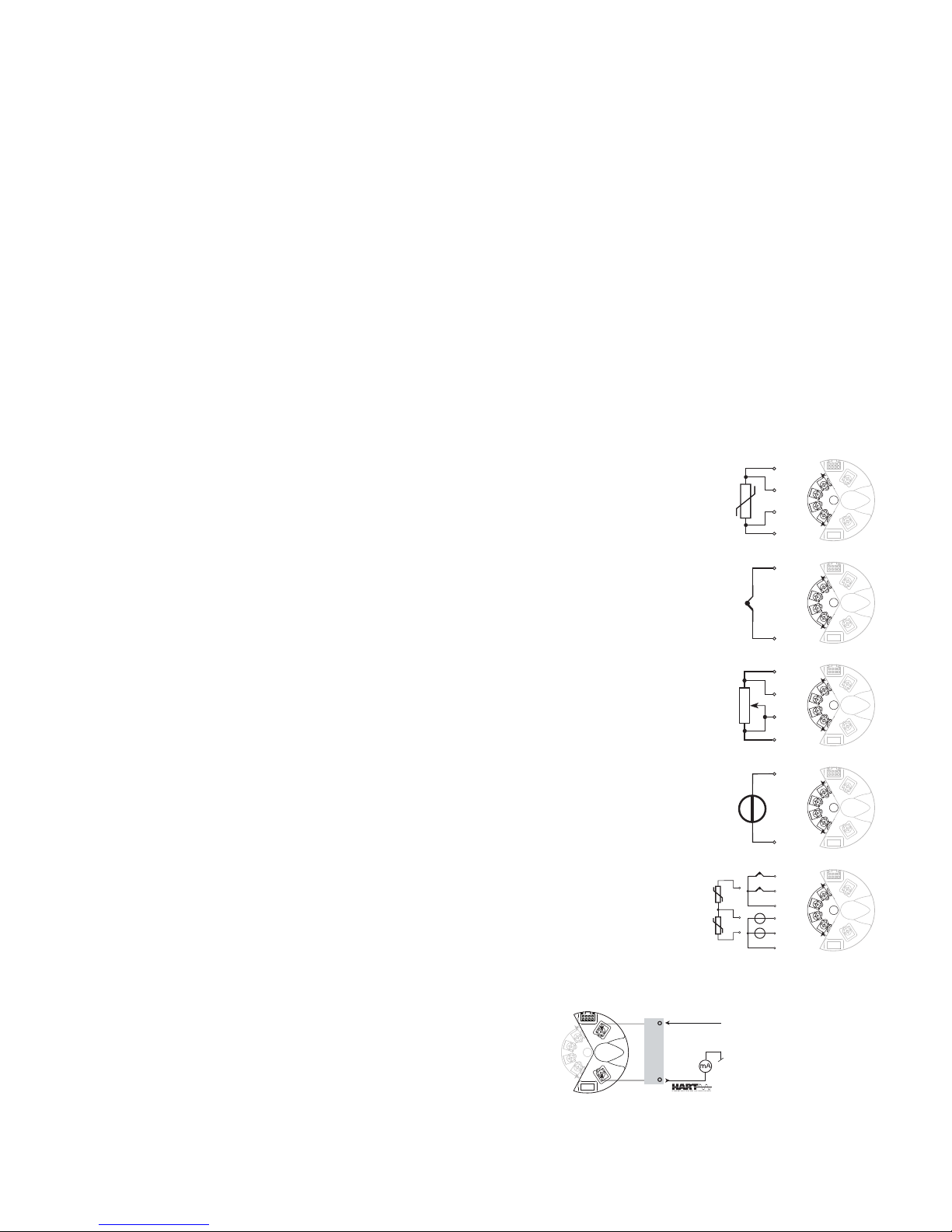

• RTD, TC, Ohm, and bipolar mV input and analog output

• High definition local operator interface (LOI) with 3 optical buttons

• Selectable red or white backlight

• Ex d explosion proof / flameproof in aluminum or 316 stainless steel version

• HART 7 functionality with HART 5 compatibility

High defintion display

• 0, 90, 180, & 270 degree position adjustments.

• Monitoring, programming and diagnostics view.

• Extensive diagnostics with flashing red or white backlight

• Supports 7 languages.

Local operator interface (LOI)

• 3 optical buttons; up, down and enter.

• Dynamically adaptive to wear or accumulation of dirt.

• Immune to interference from ambient light sources.

• Useable with or without gloves.

Configuration

• From the LOI through the PR guided menu.

• PReset and HART modem.

• HHC, DCS or AMS via HART.

Mounting / installation

• For installation in zone 0, 1, 2 and zone 20, 21, 22,and in

Class 1, Division 1 and 2 applications.

• Hardware assessed for use in SIL 2 applications.

• Mounting on 1.5”–2” pipe bracket or on wall / bulkhead.

Application

• Linearized temperature measurement with TC and RTD

sensors e.g. Pt100 and Ni100.

• HART communication and 4...20 mA analog PV output for

individual, difference or average temperature

measurement of up to two RTD or TC input sensors.

• Conversion of linear resistance to a standard analog

current signal, e.g from valves or Ohmic level sensors.

• Amplification of bipolar mV signals to standard 4...20 mA

current signals.

• Up to 63 transmitters (HART 7) can be connected in a

multidrop communication setup.

Technical characteristics

• NAMUR NE43 and NE89.

• HART protocol revision can be changed by user

configuration to either HART 5 or HART 7 protocol.

Applications

Input signals:

TC to 4...20 mA

Ex ia: 10...30 VDC

(12...30 VDC with backlight)

Other: 10...35 VDC

(12...35 VDC with backlight)

4...20 mA

Resistance to 4...20 mA

mV to 4...20 mA

Difference or average

RTD, TC or mV

2-wire output and HART:

RTD to 4...20 mA

6 7501V107-UK

Accessories

8550 = 7501 M20 plug text alu encl. silicone O-ring

8550-F = 7501 M20 plug text alu encl. FKM O-ring

8550-S = 7501 M20 plug text stainless steel encl. silicone O-ring

8550-SF = 7501 M20 plug text stainless steel encl. FKM O-ring

8551 = 7501 NPT plug alu encl.

8551-S = 7501 NPT plug text stainless steel encl.

8552 = Pipe-mounting bracket P5-B-N (1½”-2”)

1117 = 5-point calibration certificate

Technical data

Environmental conditions:

Operating tempeature

with silicone O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40°C to +85°C

with FKM O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -20°C to +85°C

Reduced LCD performance below -20°C and above +70°C

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40°C to +85°C

Calibration temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20...28°C

Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0...100% RH (condensing)

Protection degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP54 / IP66 / IP68 / type 4X

Mechanical specifications:

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø 110 mm

Dimensions, H x W x D, aluminum / stainless steel. . . . . . . . . . . . . . . . 109.3 x 145 x 126 mm / 107.4 x 145 x 124

Weight approx., aluminum / stainless steel . . . . . . . . . . . . . . . . . . . . 1.3 / 2.8 kg

Wire size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.13...1.5 mm

2

/ AWG 26...16 stranded wire

Screw terminal torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.4 Nm

Vibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IEC 60068-2-6

2...25 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±1.6 mm

25...100 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±4 g

Display:

Display resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 x 64 pixels

Number of digits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Response time, button to display . . . . . . . . . . . . . . . . . . . . . . . . . . < 150 ms

Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Selectable ON / OFF

Backlight color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Selectable white or red

Error indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Selectable white or red (flashing)

Common electrical specifications:

Supply voltage, DC:

Ex ia, intrinsically safe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10...30 VDC

(12...30 VDC with backlight)

Other. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10...35 VDC

(12...35 VDC with backlight)

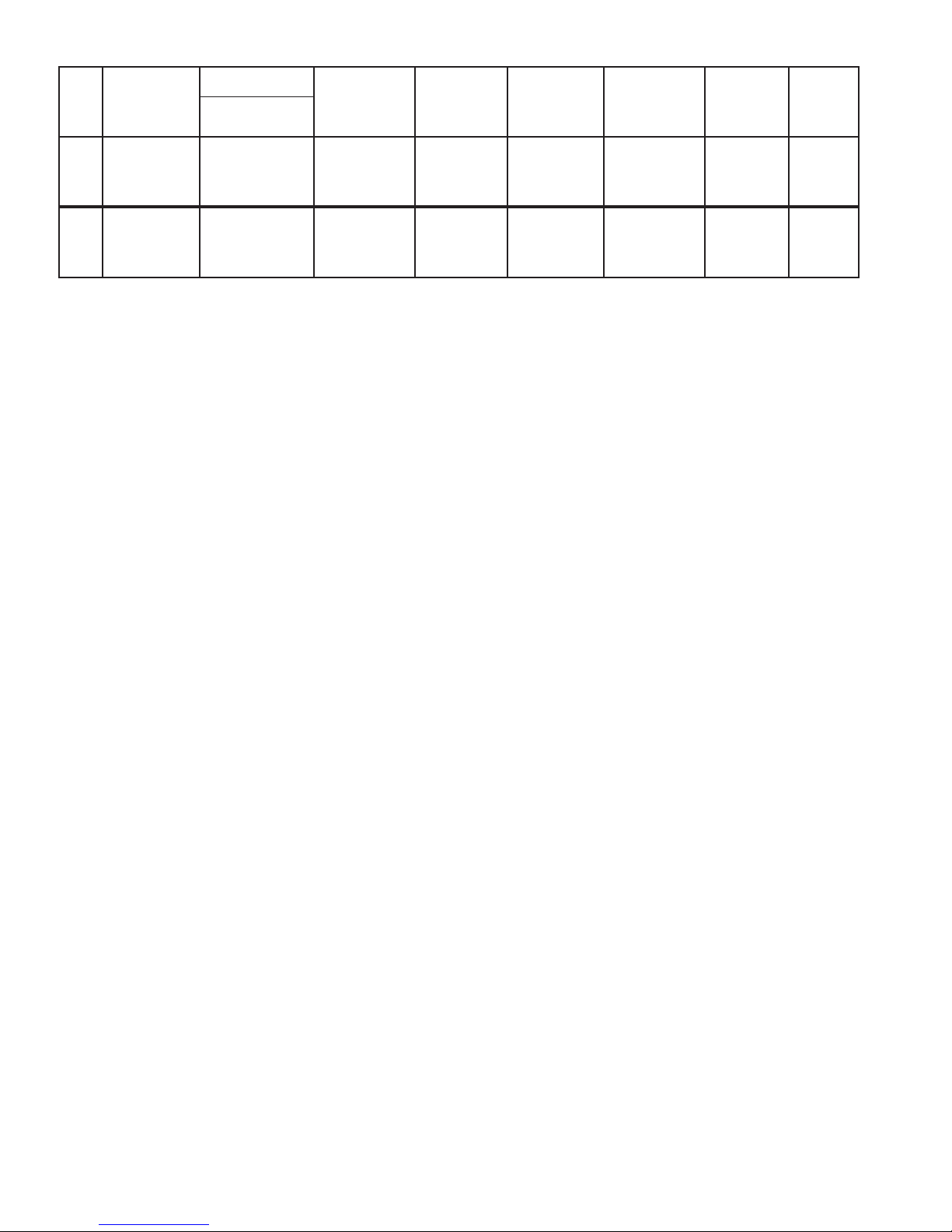

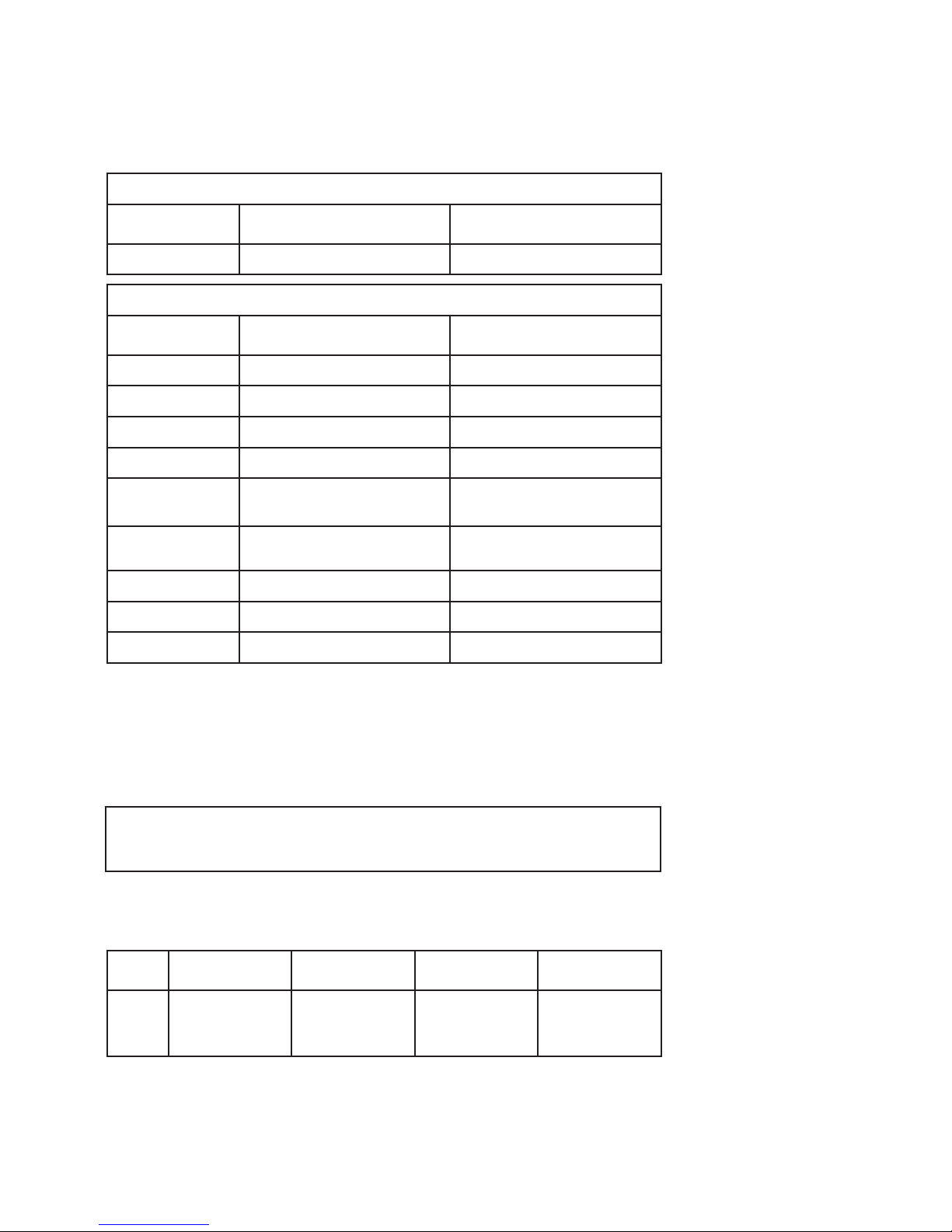

Order

Example : 7501A3B1A12

Type Housing

Local operator

interface

O-ring

Conduit

thread

(D1, D2 & D3)

Paint

type

Transmitter Approvals

Cover color

Optical

buttons

Display

7501 Low copper

aluminum (AL)

: A No

No

Yes

No

Yes

Yes

: 1

: 2

: 3

-40 to +85°C

silicone rubber

-20 to +85°C

FKM rubber

: A

: B

M20x1.5 6H

½ NPT mod.

: 1

: 2

Epoxy

Epoxy + polyurethane

: A

: B

Yes

No

(comes with

a connection kit)

: 1

: 2

General

purpose

Hazardous

area

: 1

: 2

Red

Grey

: -

: GY

7501 316 Stainless

steel (RF)

: B No

Yes

Yes

Yes

: 2

: 3

-40 to +85°C

silicone rubber

-20 to +85°C

FKM rubber

: A

: B

M20x1.5 6H

½ NPT mod.

: 1

: 2

None : N Yes

No

(comes with

a connection kit)

: 1

: 2

General

purpose

Hazardous

area

: 1

: 2

Steel : -

7501V107-UK 7

Isolation - test / working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 kVAC / 50 VAC

Signal / noise ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . > 60 dB

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HART

Start-up time (transmitter to display). . . . . . . . . . . . . . . . . . . . . . . . Max. 5 s

Response time (programmable) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1...60 s

Long term stability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1% of span / year

Accuracy, the greater of general and basic values:

TC B

1

accuracy specification range . . . . . . . . . . . . . . . . . . . . . . . . . > 400°C

TC B

2

accuracy specification range . . . . . . . . . . . . . . . . . . . . . . . . . > 160°C < 400°C

TC B3 accuracy specification range . . . . . . . . . . . . . . . . . . . . . . . . . > 85°C < 160°C

TC B

4

accuracy specification range . . . . . . . . . . . . . . . . . . . . . . . . . < 85°C

TC cold junction compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . < ±1.0°C

Max. oset on input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50% of selec. max. value

Input specifications:

RTD input types:

Pt50, Pt100, Pt200, Pt500, Pt1000, Ni50, Ni100, Ni120, Ni1000

Cable resistance per wire (max.). . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Ω

(up to 50 Ω per wire is possible with reduced measurement accuracy)

Sensor current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nom. 0.2 mA

RTD

type

Min.

value

Max.

value

Min.

span

Standard

Pt100

Ni100

Lin. R

-200°C

-60°C

0 Ω

+850°C

+250°C

7000 Ω

10°C

10°C

25 Ω

IEC 60751

DIN 43760

-----

EMC - immunity influence. . . . . . . . . . . . . . . . . . . . . . . . . < ±0.1% of span

Extended EMC immunity:

NAMUR NE 21, A criterion, burst . . . . . . . . . . . . . . . . . . . . < ±1% of span

General values

Input type Absolute accuracy Temperature coecient

All ≤ ±0.05% of span ≤ ±0.005% of span / °C

Basic values

Input type Basic accuracy Temperature coecient

Pt50 - Pt1000 ≤ ±0.1°C ≤ ±0.005°C/°C

Ni50 - Ni1000 ≤ ±0.2°C ≤ ±0.005°C/°C

Lin. R ≤ ±0.1 Ω ≤ ±5 mΩ / °C

Volt ≤ ±10 μV ≤ ±0.5 µV / °C

TC type:

E, J, K, L, N, T, U

≤ ±0.5°C

≤ ±0.025°C / °C

TC type:

B

1

, Lr, R, S, W3, W5

≤ ±1°C

≤ ±0.1°C / °C

TC type:B

2

≤ ±3°C ≤ ±0.3°C / °C

TC type:B

3

≤ ±8°C ≤ ±0.8°C / °C

TC type:B

4

not specified not specified

8 7501V107-UK

TC input types:

Cold junction compensation (CJC):

Constant, internal or external via a Pt100 or Ni100 sensor

mV input:

Voltage input range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -800...+800 mV

Min. span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 mV

Input resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 MΩ

Output specifications:

Signal range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4...20 mA

Min. signal range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 mA

Updating time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440 ms

Load resistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ (Vsupply - 10) / 0.023 [Ω]

with backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ (Vsupply - 12) / 0.023 [Ω]

Sensor error detection, programmable . . . . . . . . . . . . . . . . . . . . . . . 3.5...23 mA

(shorted sensor error detection is ignored at TC and mV input)

NAMUR NE43 Upscale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 mA

NAMUR NE43 Downscale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 mA

HART protocol revisions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HART 7 and HART 5

Marine approval:

EU RO Mutual Recognition Type Approval . . . . . . . . . . . . . . . . . . . . . MRA0000009

Ex approvals:

ATEX 2014/34/EU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DEKRA 15 ATEX 0058 X

IECEx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IECEx DEK 15.0039 X

cFMus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FM16US0009X / FM16CA0010X

cCSAus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70024231

INMETRO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DEKRA 15.0014 X

NEPSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GYJ15.1336X, GYJ15.1337X and

GYJ15.1338X

EAC Ex TR-CU 012/2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RU C-DK.GB08.V.01316

Observed authority requirements:

EMC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2014/30/EU

RoHS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2011/65/EU

EAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR-CU 020/2011

Functional Safety:

Hardware assessed for use in SIL 2 applications

FMEDA report - www.prelectronics.com

Type

Min.

temperature

Max.

temperature

Min.

span

Standard

B

E

J

K

L

Lr

N

R

S

T

U

W3

W5

0°C

-100°C

-100°C

-180°C

-200°C

-200°C

-180°C

-50°C

-50°C

-200°C

-200°C

0°C

0°C

+1820°C

+1000°C

+1200°C

+1372°C

+900°C

+800°C

+1300°C

+1760°C

+1760°C

+400°C

+600°C

+2300°C

+2300°C

100°C

50°C

50°C

50°C

50°C

50°C

50°C

100°C

100°C

50°C

50°C

100°C

100°C

IEC584

IEC584

IEC584

IEC584

DIN 43710

GOST 3044-84

IEC584

IEC584

IEC584

IEC584

DIN 43710

ASTM E988-90

ASTM E988-90

7501V107-UK 9

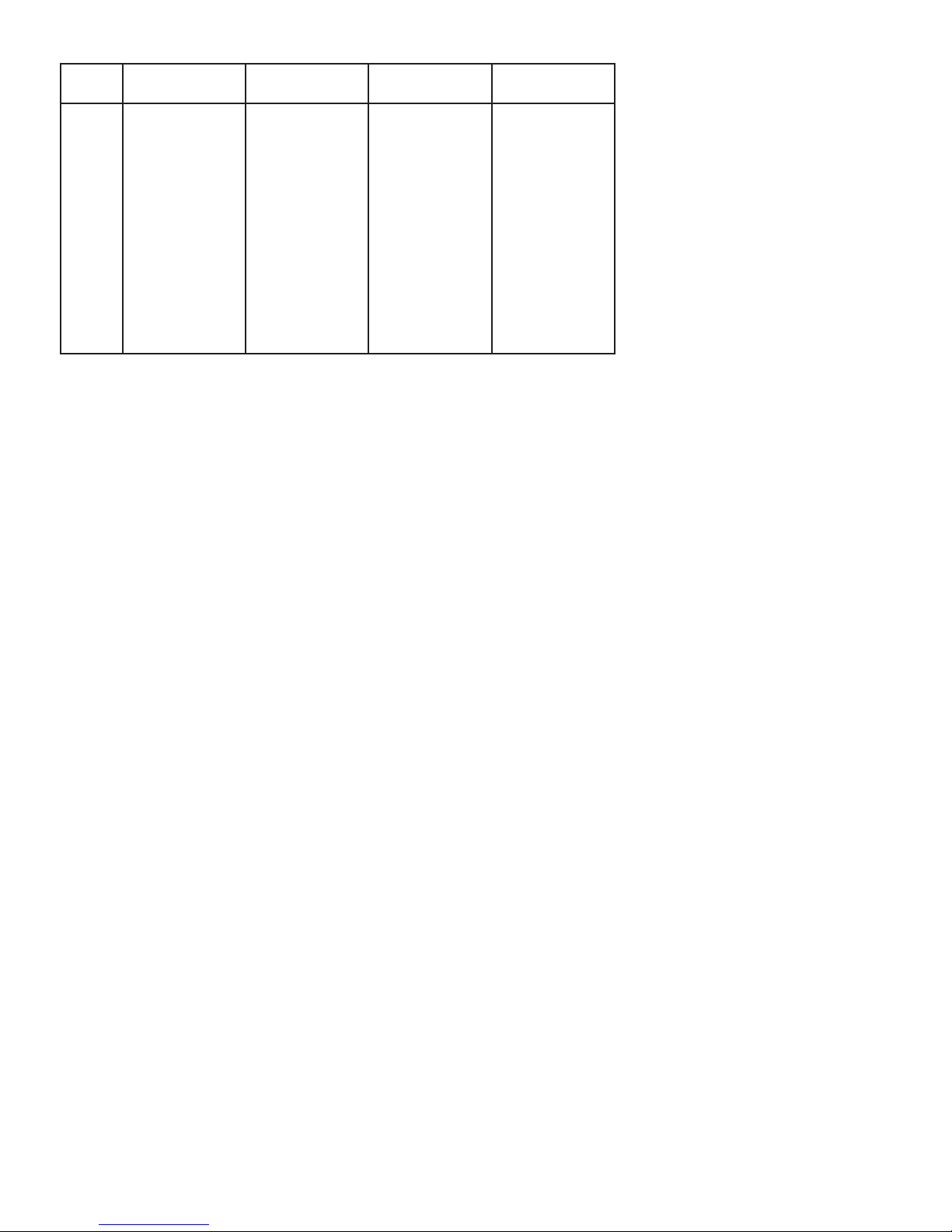

Block diagram

Marking

Caution

The ambient temperature range depends on T rating, type of protection and sealing materials, see the installation drawing.

T1

T2

T3

T4

T5

T6

7501

HART

HART

Application

Sensor

UP DOWN ENTER

HART

slave

HART

“master”

HART

modem

Filter

HART

modem

Supply

Display

5337

HART

transmitter

4...20 mA

+ HART

4...20 mA

+ HART

8 V / 4...20 mA

When this product has been installed as Ex

ia, ic, d, nA or tb, use a punch marker in the

appropriate box to indicate the type of

installation on the top label.

145

127

65

AL: 126

RF: 124

114

64,50

40

D1

D2

D3

145

127

114

64,50

40

D1

D2

D3

AL: 126

RF: 124

10 7501V107-UK

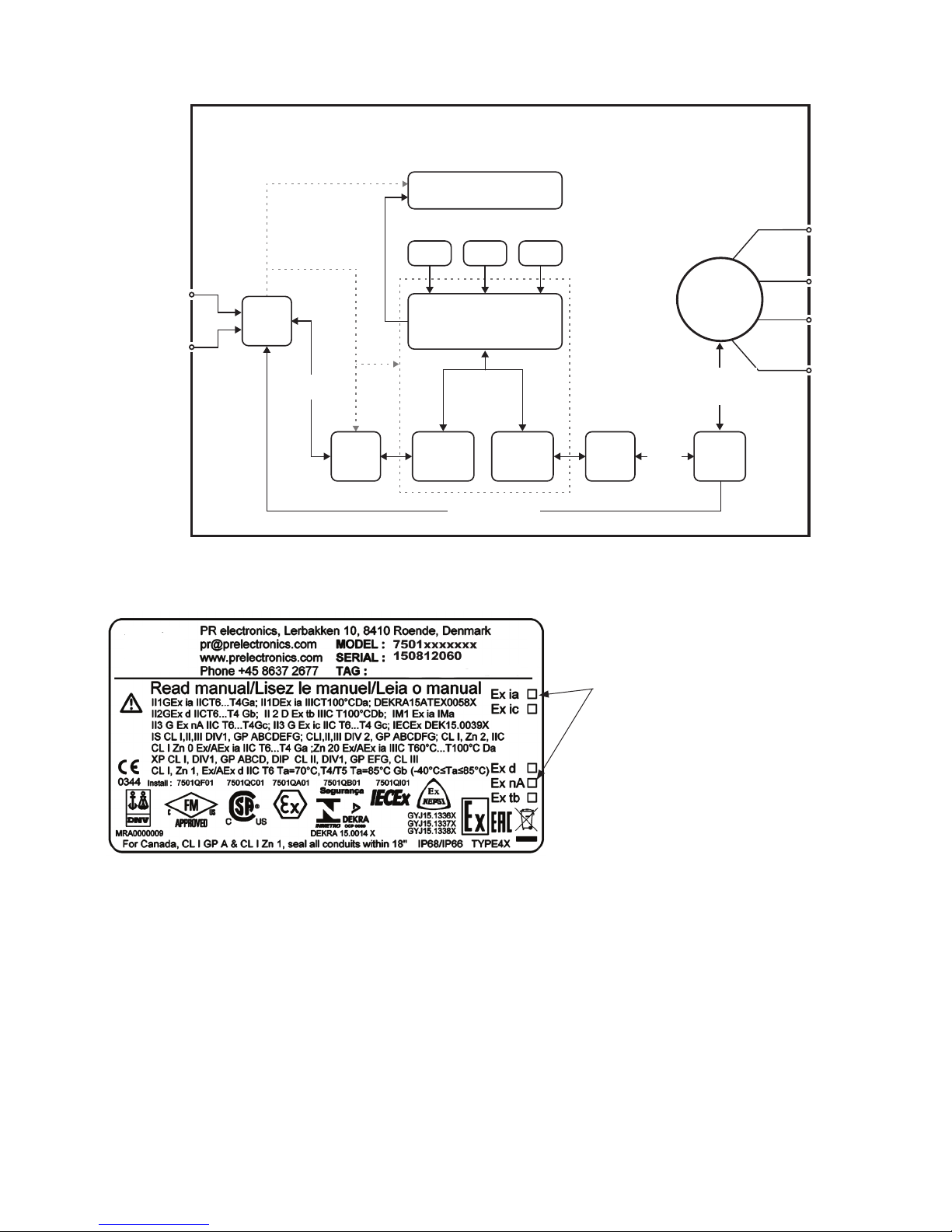

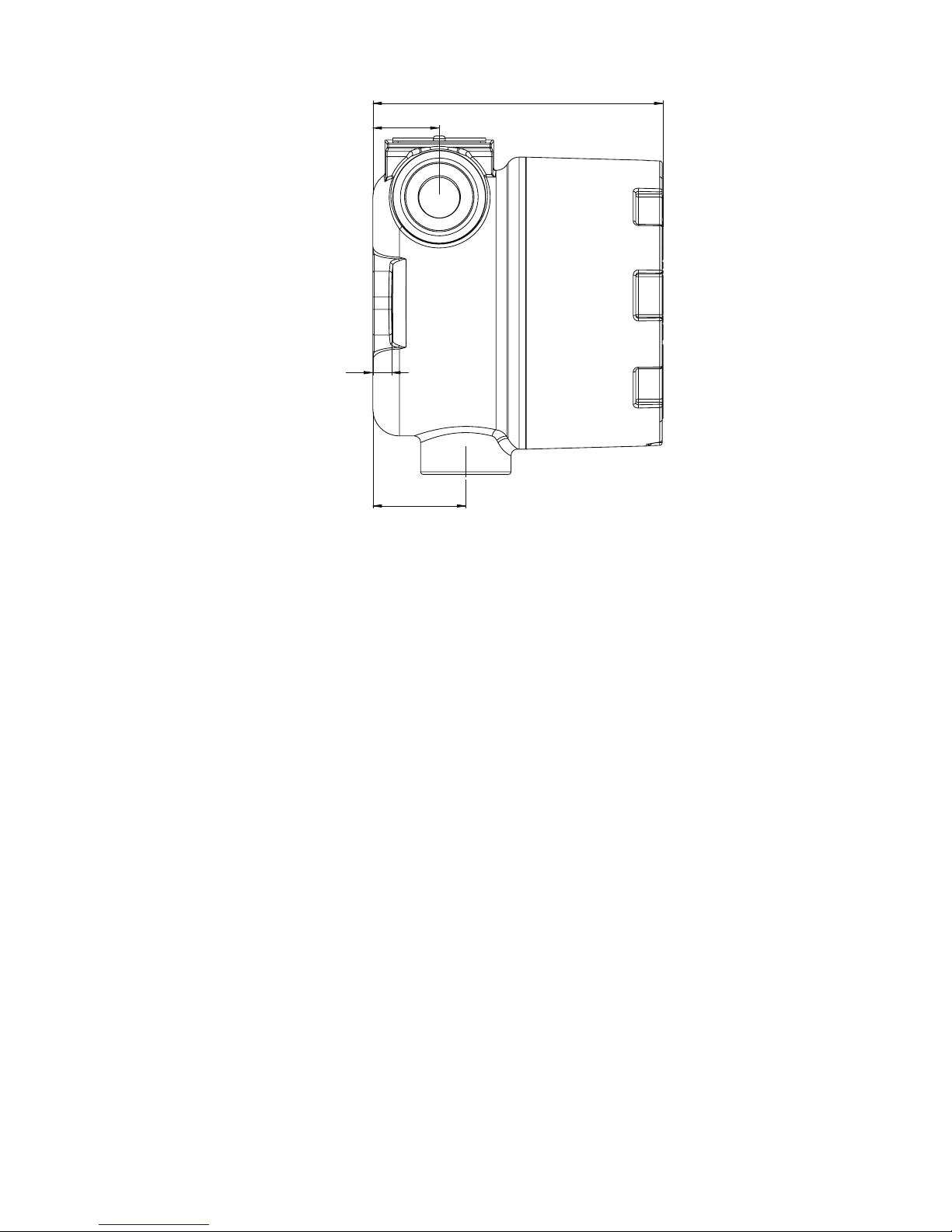

Mechanical specifications

It is important to be careful when screwing the cover on or off. The thread surface must be free of any

grains, pellets or other impurities as these can cause the cover to seize or damage the threads.

! Never use force to screw on the cover.

Should it be necessary to open the connection head cover after operation in maximum temperature,

please be aware that the cover may be blocked (does not give when attempting to open it by hand). In

this case, keep the cover under tension with your hand and hit the cover gently with a rubber hammer.

All dimensions below in mm. AL = aluminum version and RF = stainless steel version.

Front view – with buttons and display

Front view – no buttons or display

AL: 7

RF: 6

AL: 109.3

RF: 107.4

AL: 35

RF: 34

AL: 25 / RF: 24

7501V107-UK 11

Side view

2 x Ø 7

127

12 7501V107-UK

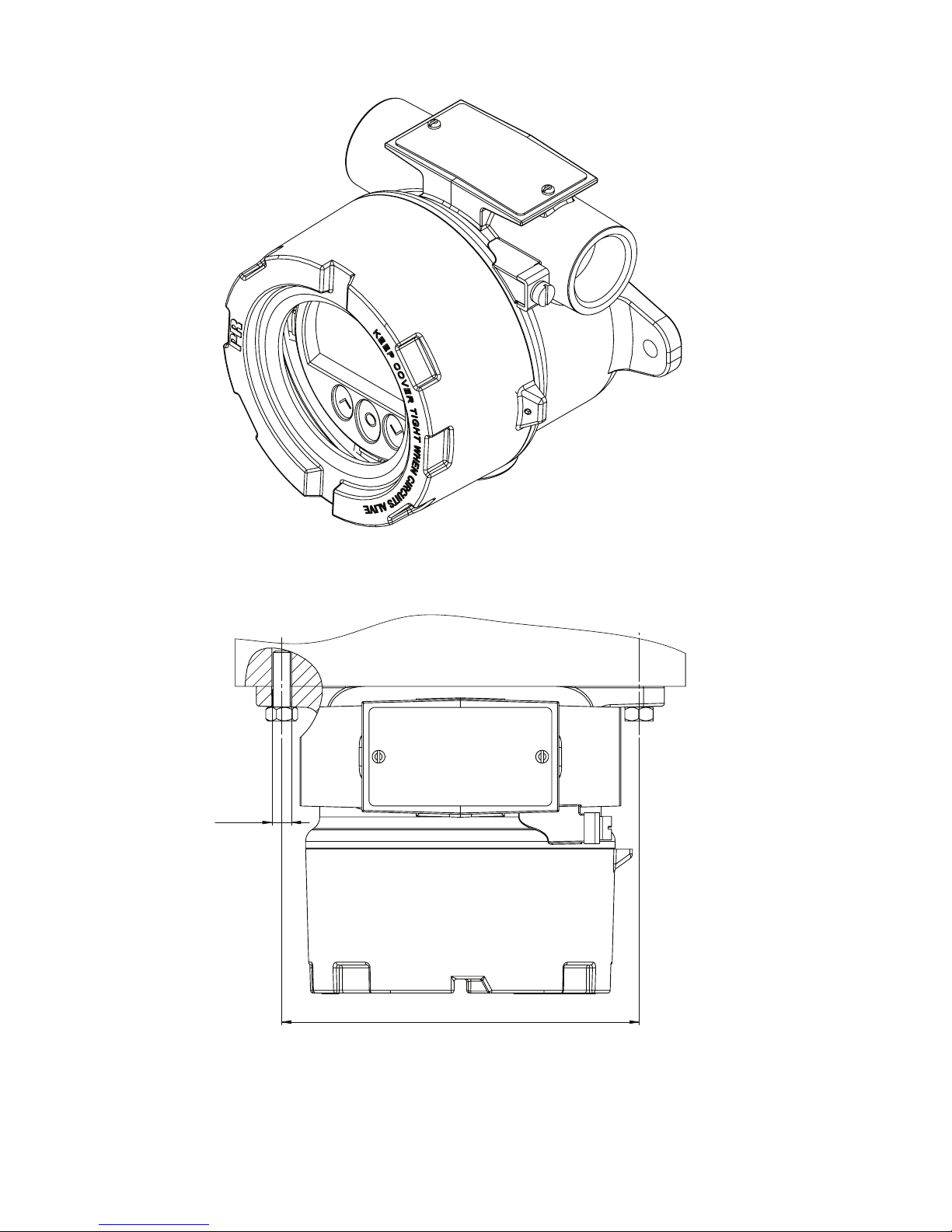

Mounting

Wall-mounting – side view

Wall-mounting – top view

M6

51

19

98

D = 1½" - 2"

7501V107-UK 13

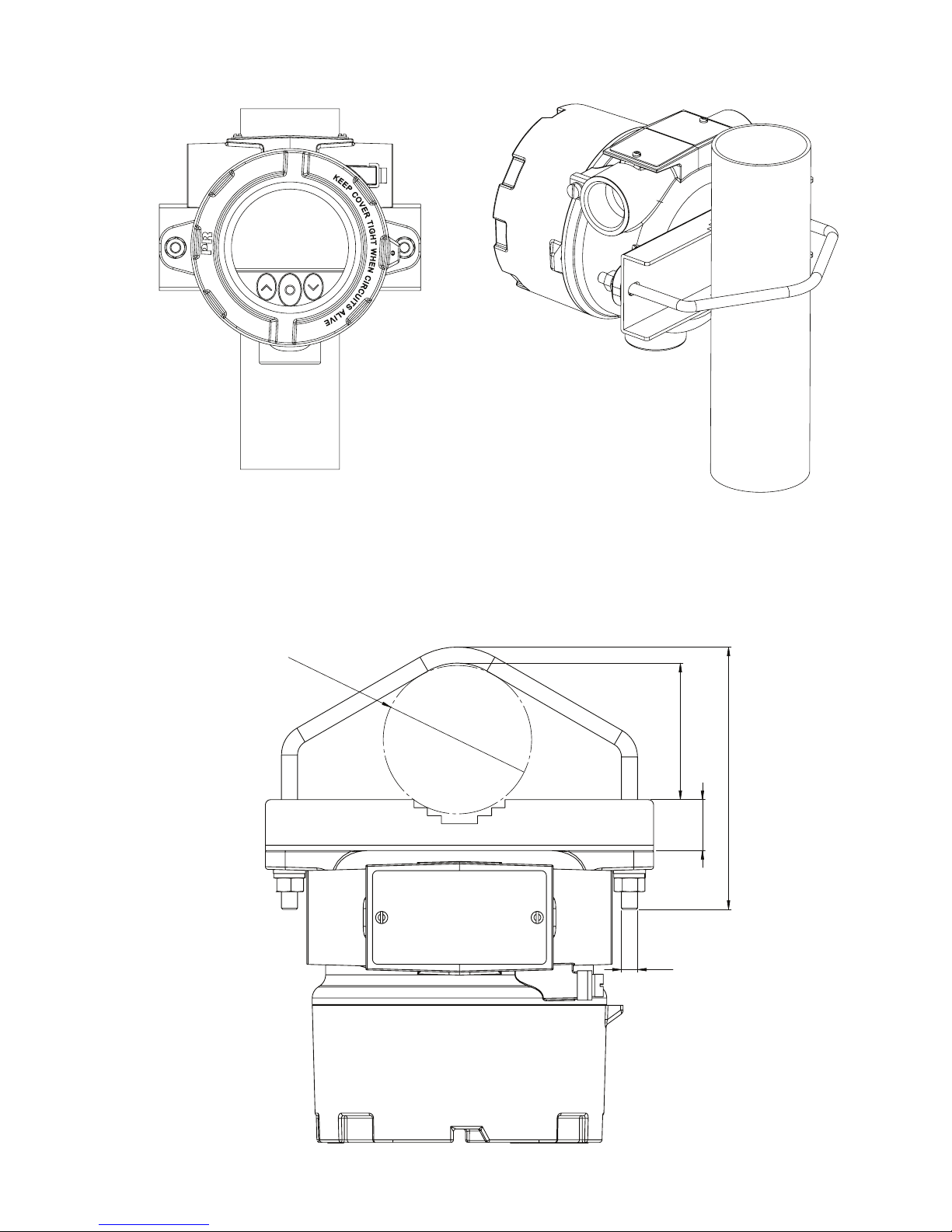

Pipe-mounting – front and back view

Pipe-mounting – top view

14 7501V107-UK

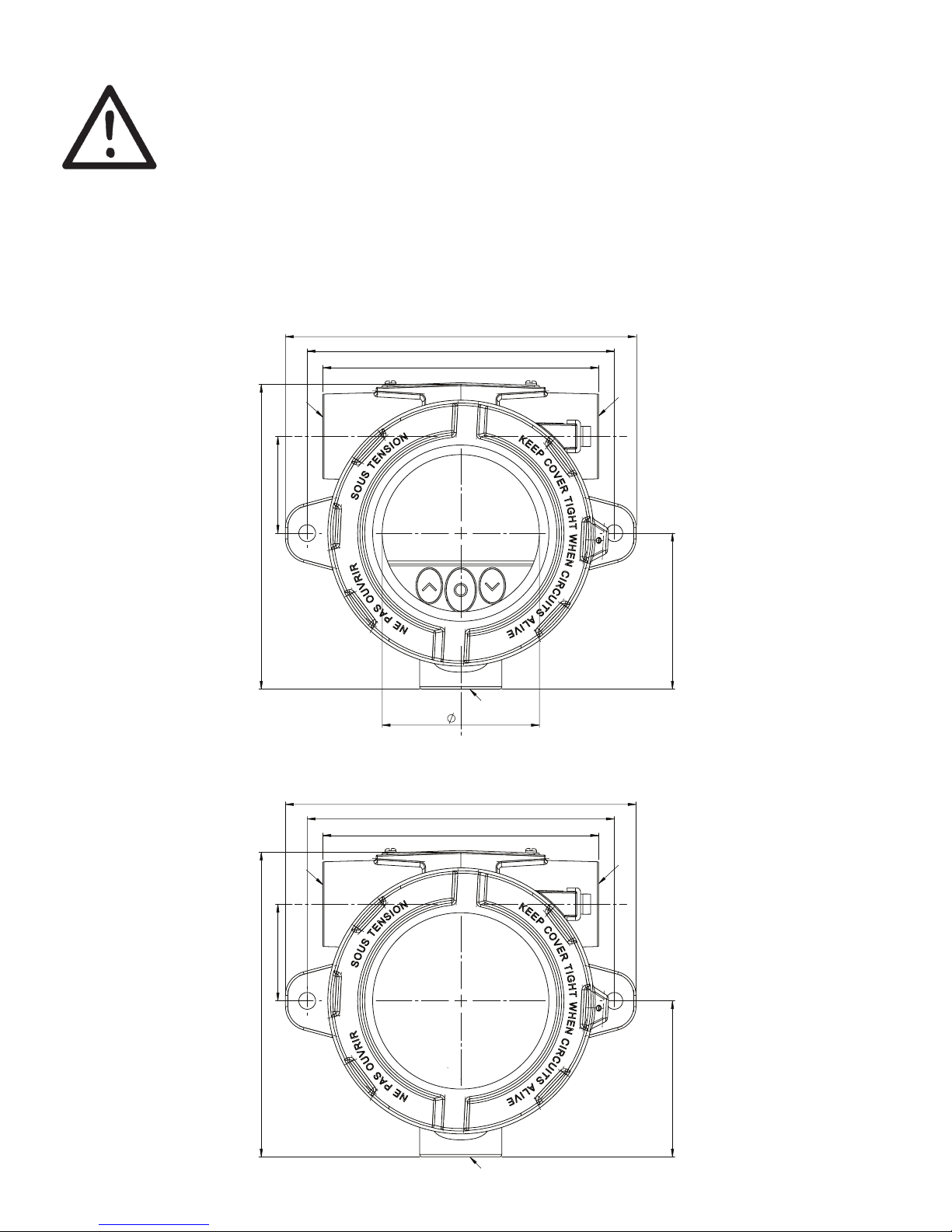

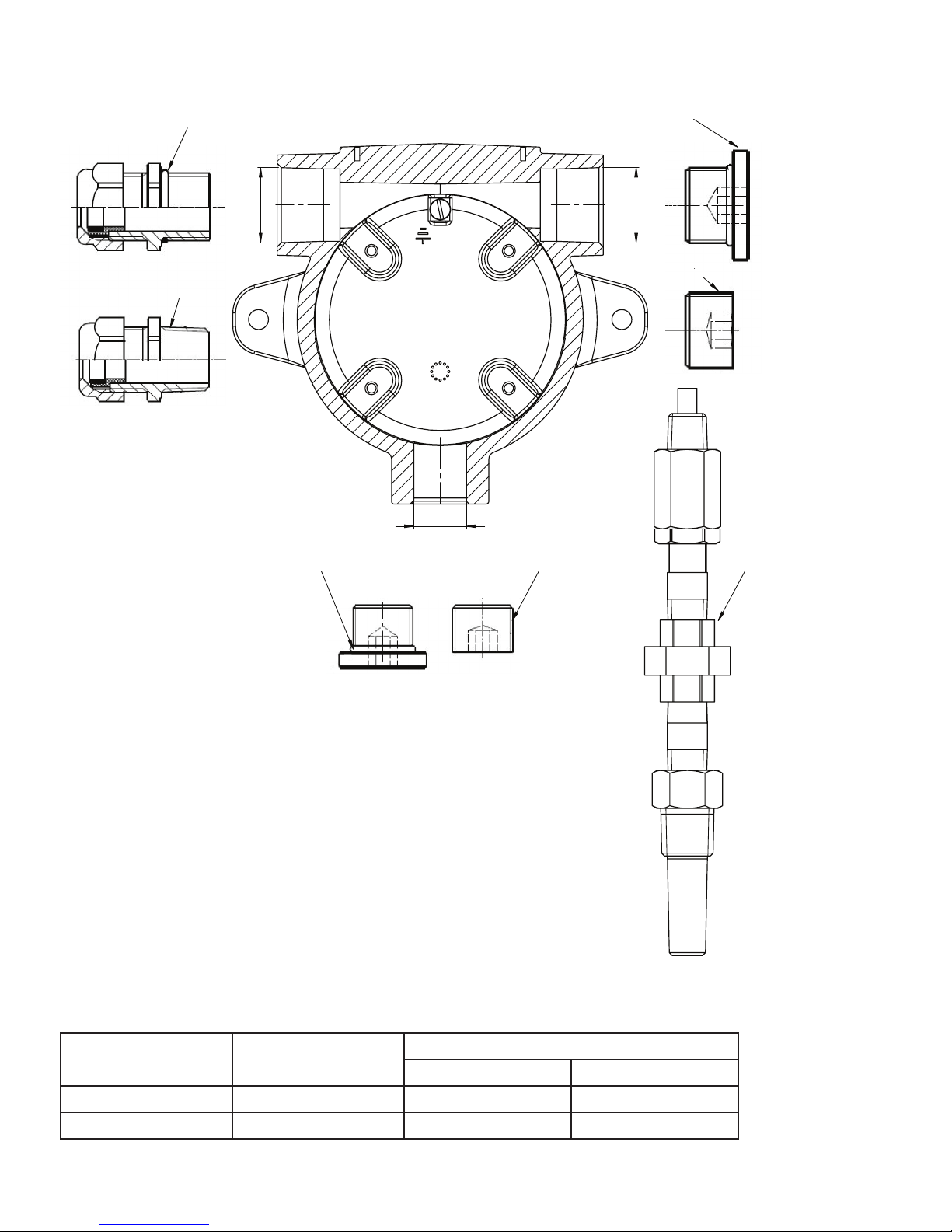

Protection degree

Blind plug M20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP54

With O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP66 - IP68

Blind plug ½” NPT MOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP54

With locktite 577 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP66 - IP68

Protection degree is defined by the connection with the lowest IP rating.

It is optional to connect a sensor to any of the three conduit openings.

Blind plugs are Ex approved only when used together with 7501.

Earth terminal and protection terminal

Placement Typ e

Cable cross section [mm

2

]

Stranded wire Solid wire

Inside Protection terminal 1.5 2.5

Outside Earth terminal 4.0 6.0

D1

D2

D3

Sealing washer

Threaded sealant

Sealing washer

Threaded sealant

Threaded sealant

SensorSealing washer

Blanking elements

Cable glands

20 x 1.5

½ NPTmod

½ NPTmod

20 x 1.5

A-F = 2mm

1 2

3 3

7501V107-UK 15

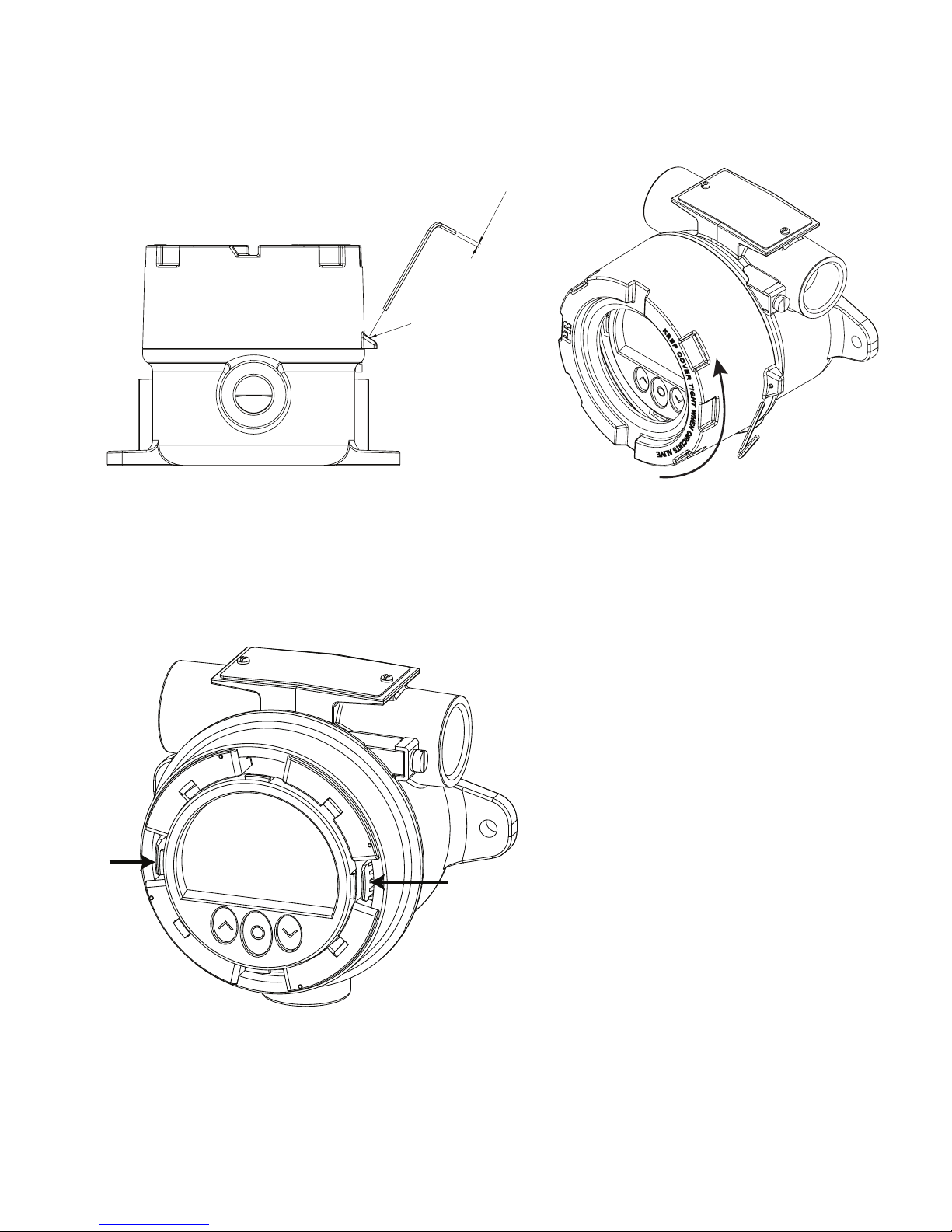

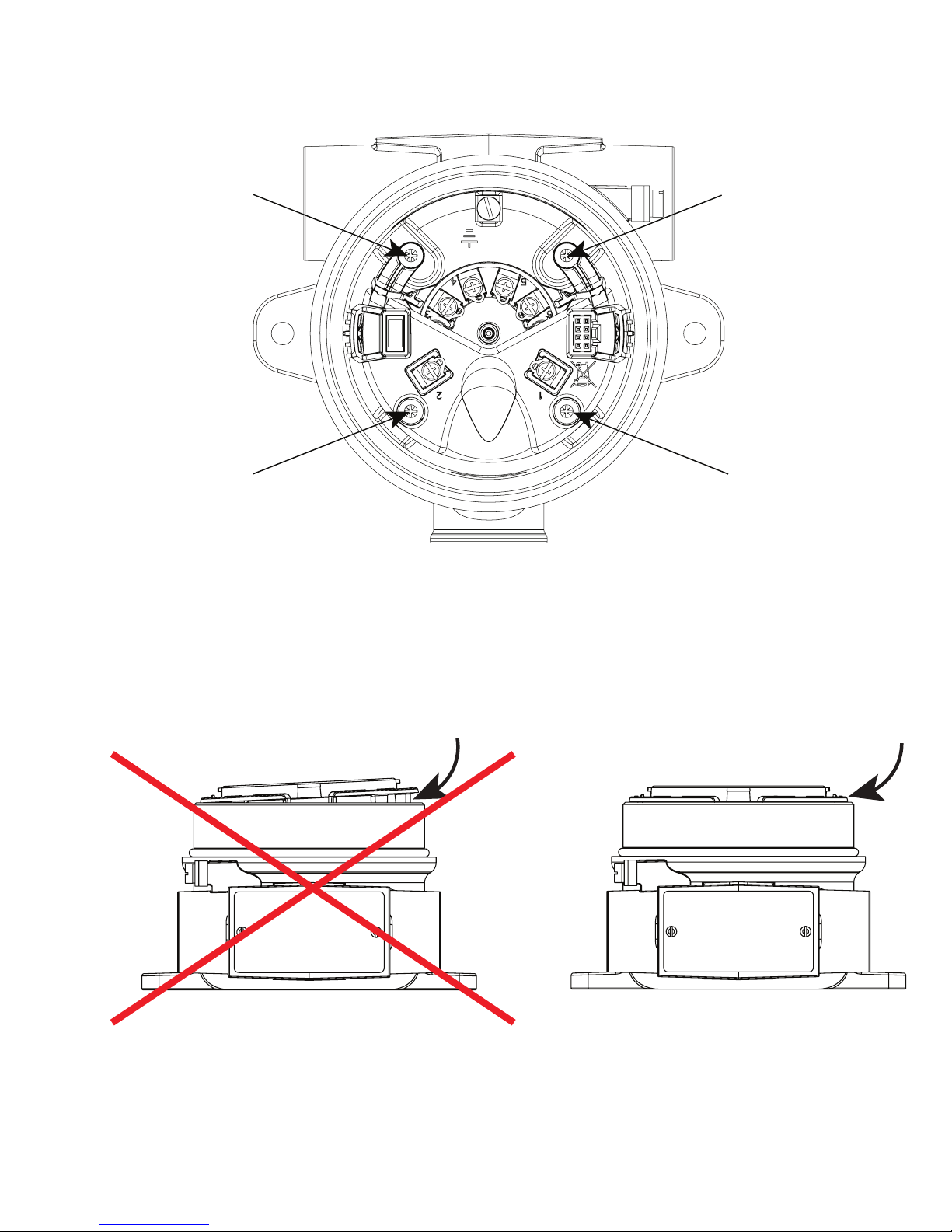

Assembly and disassembly

To connect sensor wires to the 7501 or change the orientation of the display, the housing must be disassembled and the

internal device must be extracted.

!! Disconnect power to the device before disassembly.

1. Release the locking screw, using a hex spanner with a cross-flat of 2 [mm]. This screw is situated on the housing top.

2. Unscrew the housing lid by turning it counterclockwise.

Point 3 and 4 only apply to devices with buttons and display.

3. Press and hold the two clamps located on the left and right side of the display unit.

Locking screw

a a

b b

16 7501V107-UK

4. While holding the clamps, pull the display unit outwards to remove it.

5. The display can now be turned in steps of 90 degrees for best viewing angle.

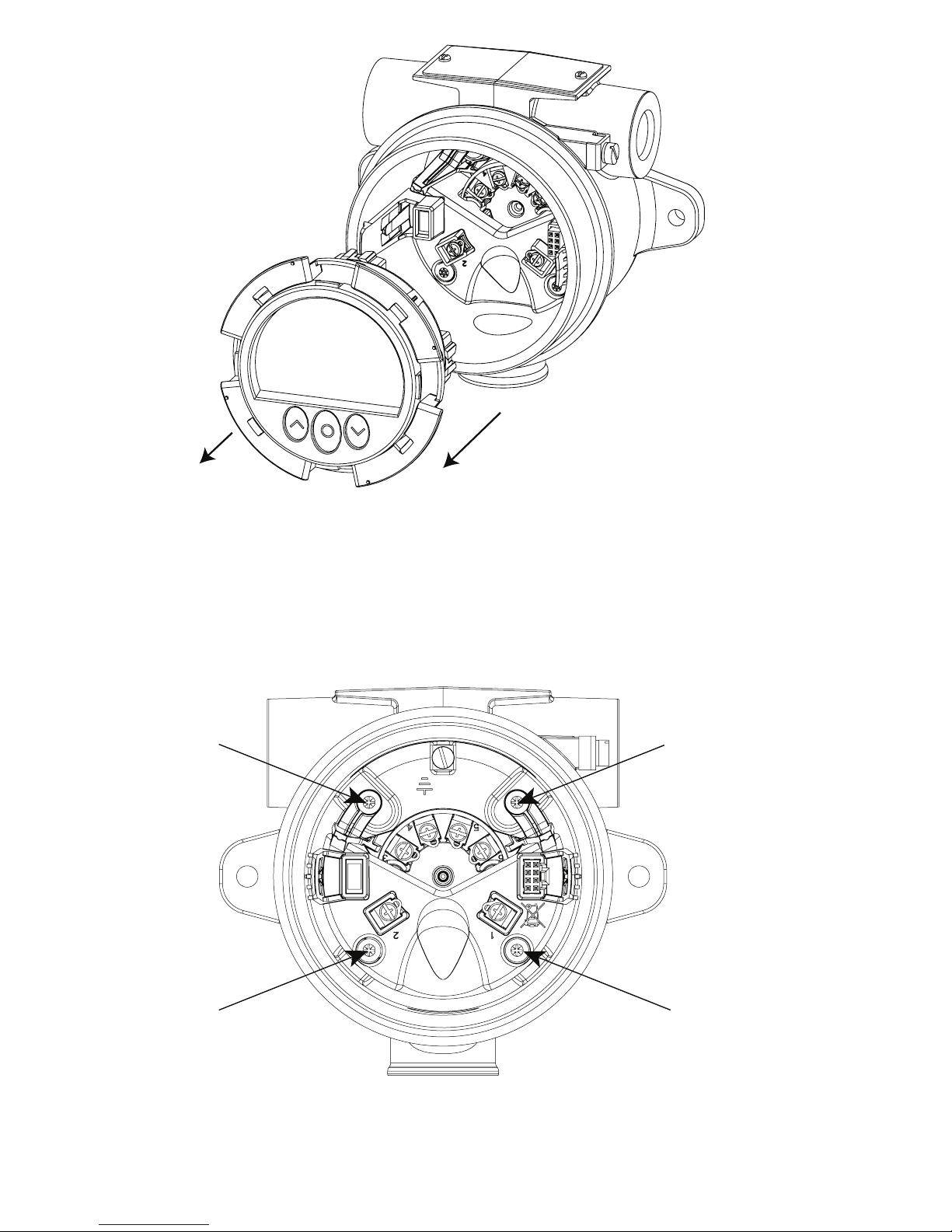

6. For easy connection of sensor wires, we recommend extracting the transmitter from the housing (see the section

Connections for information on connecting sensors to the internal 5337).

7. Unscrew the two screws (a) fastening the connector bracket to the housing, using a Posidriv form Z screwdriver.

8. Unscrew the two screws (b) fastening the fixation bracket to the housing, and pull out the entire assembly.

7501V107-UK 17

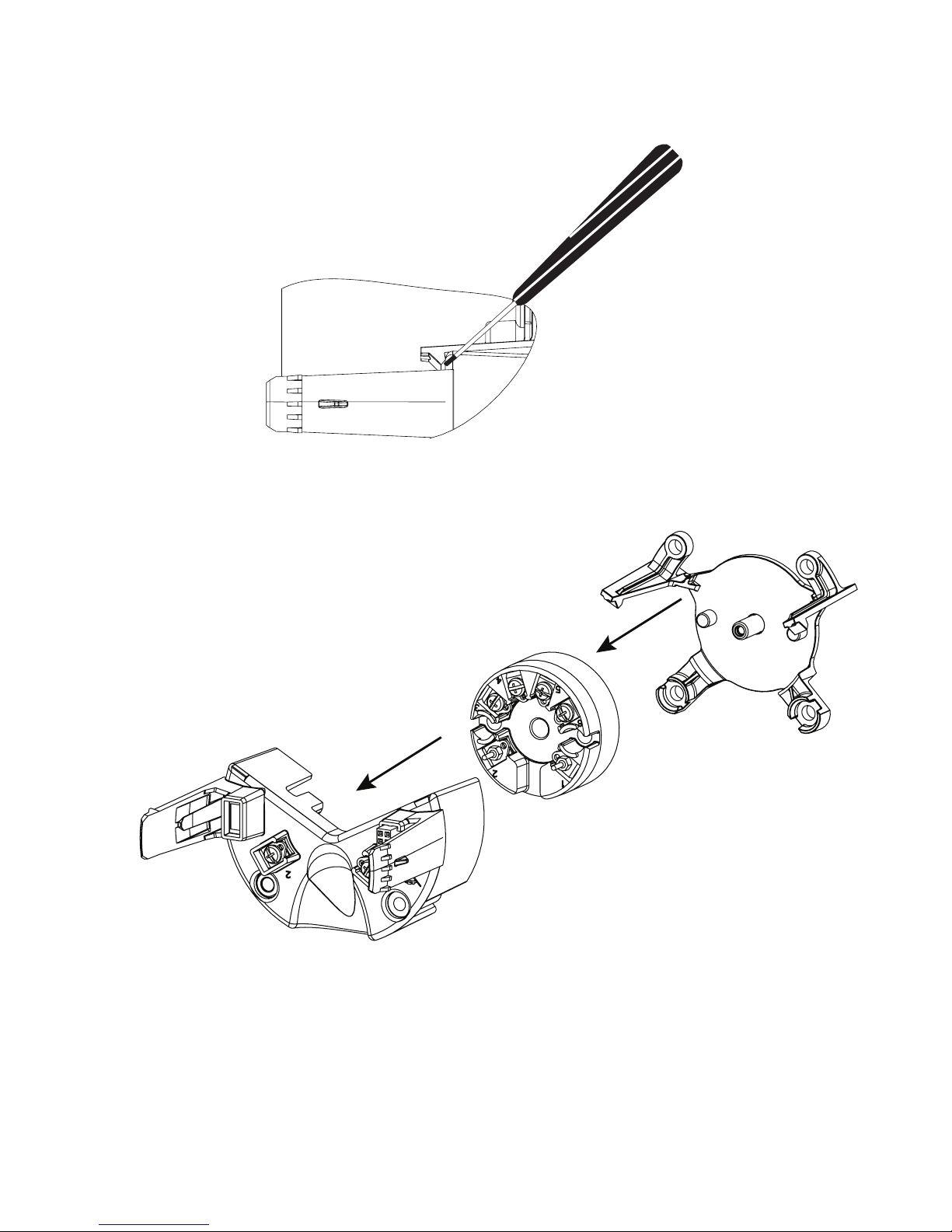

9. Use a screwdriver (or your fingers) to lever the taps (one on each side) on the fixation bracket to release it from the

transmitter connector bracket.

NB! Do not use excessive force.

10. Separate the connector bracket, transmitter and fixation bracket.

RF

Al

18 7501V107-UK

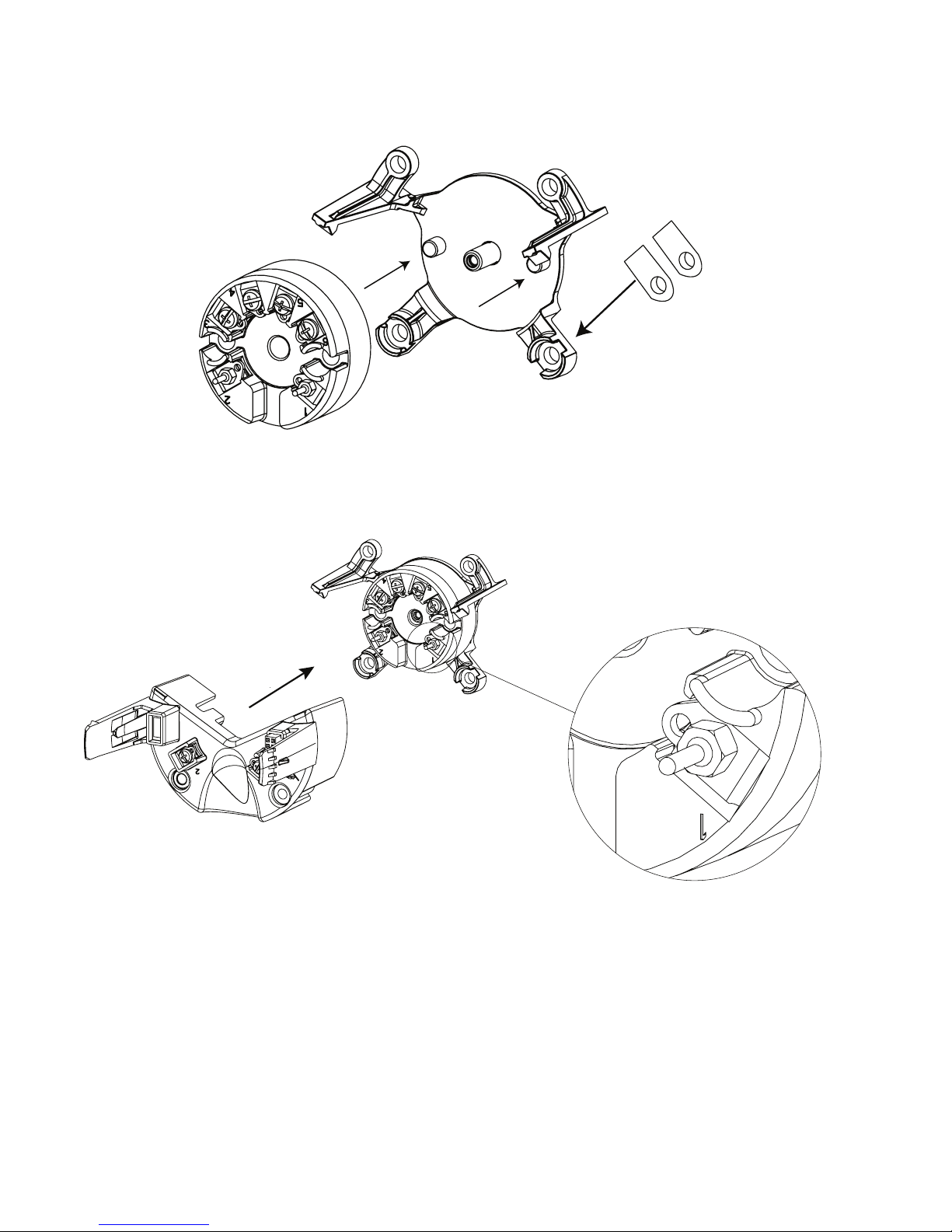

Assembly

1. Place the transmitter in the fixation bracket using the guidance taps on the bracket. Make sure terminals 1 and 2 are

facing downwards.

NB. The fixation bracket is not interchangeable between the aluminum and stainless steel housing. Check the bottom

right-hand corner for identifier (Al for aluminum and RF for stainless steel).

2. Slide the connector bracket onto the transmitter using the dovetails as guides. Make sure the golden connector pins on

terminal 1 and 2 on the transmitter slide into place in the corresponding terminals on the connector bracket.

Press the bracket into place until you hear a distinct click.

a a

b b

7501V107-UK 19

3. Slide the assembly back into the housing and refasten the 4 screws (a + b), using the 28 mm screws for the connector

bracket (a) and the 10 mm screws for the fixation bracket (b).

4. Finally, click the display unit back into place and screw the cover back on.

Correct mounting of display unit

20 7501V107-UK

Connections

+

-

12

+

-

1

+

-

2

+-+

-

12

+

-

+

-

2 1

3

4

6

5

+

-

3

4

6

5

3

4

6

5

+

-

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

3

4

6

5

-

+

12

m

A

Output:

Input:

Resistance, 2-wire

Resistance, 3-wire

RTD, 2-wire RTD, 3-wire RTD, 4-wire

TC, internal CJC

TC, external CJC mV

Resistance, 4-wire

TC, dierence

or average,

with external CJC

mV, dierence

or average

RTD, dierence

or average

TC, dierence

or average,

with internal CJC

7501V107-UK 21

Optical buttons

The user interface features 3 optical buttons: , 2 and . The buttons can be operated both with or without gloves1.

The buttons are immune to interference from ambient light sources and other panel meters (e.g. other 7501 devices mounted

in close proximity).

Additionally, the optical buttons are adaptive, meaning that they will adapt to wear and e.g. dirt left on the surface.

The buttons work both with and without a front cover mounted.

If a rapid increase in optical reflection occurs, e.g. from mounting the cover or from dust/dirt on the glass, the buttons may

activate. If a key-press is detected for a period of more than 70 seconds, it is assumed to be a failure key-press and the

adaptive functionality will re-initialize in order to restore correct keypad functionality. This re-initialization can also be done

by repowering the device.

Operating the optical buttons

The optical buttons are used for operating and programming the 7501. They offer multi-functionality depending on whether

you press or long-press them. With the exception of the calibration and simulation menus (see the section Display menu), the

display will return to the monitor view if no key-press is registered within one minute.

In monitor view: switch to next process variable.

Elsewhere: increase the value of the selected parameter (except if device is write-protected).

2 In monitor view: switch to previous process variable.

Elsewhere: decrease the value of the selected parameter (except if device is write-protected).

Accept chosen value and proceed to next parameter

Hold Progressively increase (scroll) the numerical value (except if device is write-protected)

Hold 2 Progressively decrease (scroll) the numerical value (except if device is write-protected)

Hold Ignore the chosen value and return to previous parameter

Hold + 2 Unlock the monitor view and enter configuration menu

2

Key presses are reflected in the symbols bar with the following symbols:

Up button is pressed

Down button is pressed

Enter button is pressed

Display

The 96 x 64 pixel display can be rotated in 90-degree increments for easy vertical or horizontal viewing. The adjustable

backlight enables you to view process values in all lighting conditions without an external light source, and it can be

configured to flash if an error occurs. Both the optional backlight and the flashing error backlight can be selected as red or

white, or turned off completely.

Display views

The appearance of the display will change to reflect the state of the 7501. This allows for easy and intuitive operation, status

indication and guides you in configuring the device.

1 Dark colored gloves can cause reduced sensitivity.

2 If error color (see the section Display menu) is set to red or white and the display backlight is flashing, the first key press cancels the flashing

backlight.

Loading...

Loading...