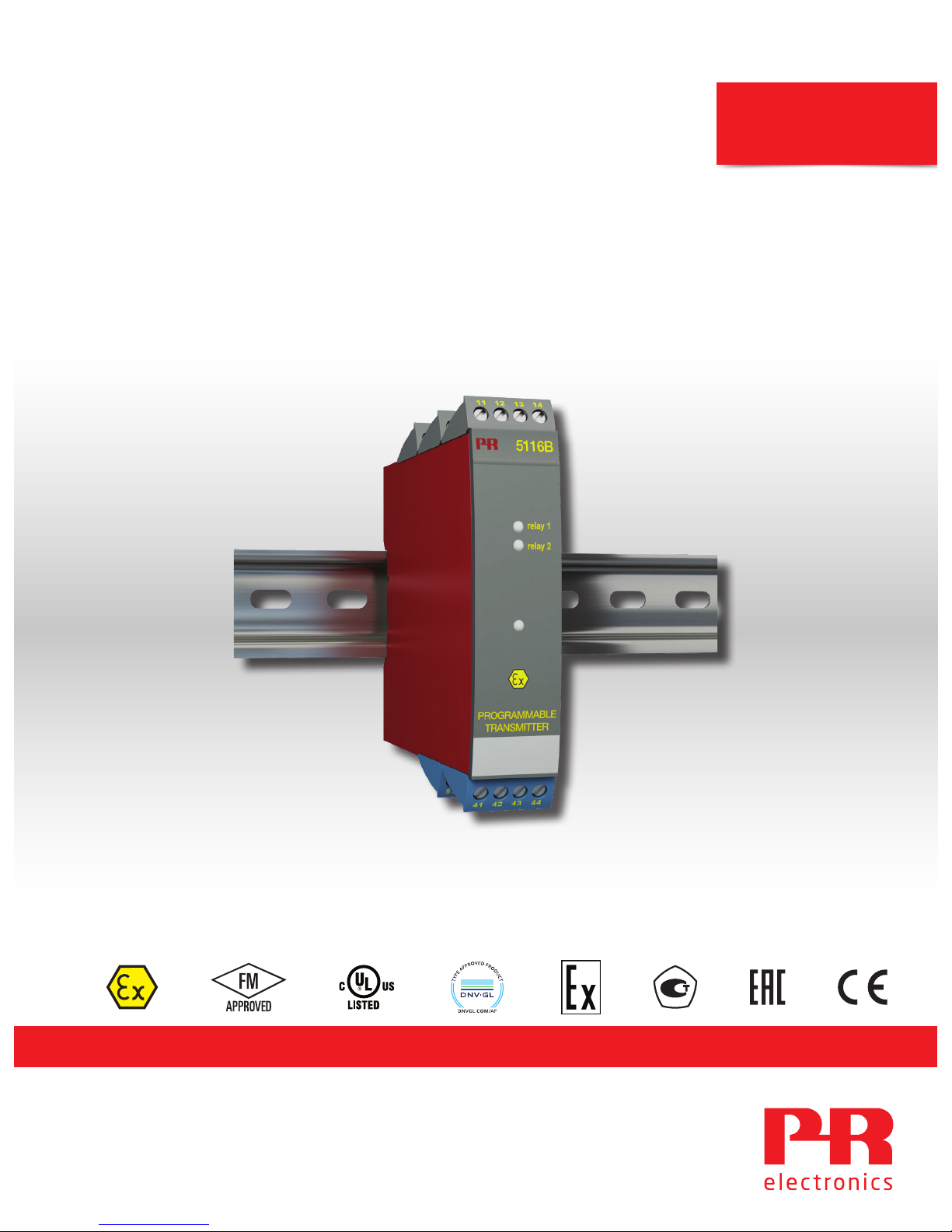

PR electronics 5116 Product Manual

PERFORMANCE

MADE

SMARTER

Product Manual

5116

Programmable transmitter

TEMPERATURE | I.S. INTERFACES | COMMUNICATION INTERFACES | MULTIFUNCTIONAL | ISOLATION | DISPLAY

No. 5116V104-UK

From serial no. 181570001

Communication

Display

I.S. Interface

Isolation

Multifunction

Temperature

6 Product Pillars

to meet your every need

With our innovative, patented technologies, we make signal conditioning smarter and simpler. Our portfolio is composed of six

product areas, where we offer a wide range of analog and digital devices covering over a thousand applications in industrial

and factory automation. All our products comply with or surpass the highest industry standards, ensuring reliability in even

the harshest of environments and have a 5-year warranty for greater peace of mind.

Individually outstanding, unrivalled in combination

Our range of temperature transmitters and sensors provides the highest level of signal integrity from the

measurement point to your control system. You can convert industrial process temperature signals to analog, bus or

digital communications using a highly reliable point-to-point solution with a fast response time, automatic selfcalibration, sensor error detection, low drift, and top EMC performance in any environment.

Our unique range of single devices covering multiple applications is easily deployable as your site standard. Having

one variant that applies to a broad range of applications can reduce your installation time and training, and greatly

simplify spare parts management at your facilities. Our devices are designed for long-term signal accuracy, low

power consumption, immunity to electrical noise and simple programming.

We provide inexpensive, easy-to-use, future-ready communication interfaces that can access your PR installed base

of products. The detachable 4501 Local Operator Interface (LOI) allows for local monitoring of process values,

device configuration, error detection and signal simulation. The next generation, our 4511 Remote Operator

Interface (ROI) does all that and more, adding remote digital communications via Modbus/RTU, while the analog

output signals are still available for redundancy.

With the 4511 you can further expand connectivity with a PR gateway, which connects via industrial Ethernet,

wirelessly through a Wi-Fi router or directly with the devices using our Por table Plant Supervisor (PPS) application.

The PPS app is available for iOS, Android and Windows.

Our display range is characterized by its flexibility and stability. The devices meet nearly every demand for display

readout of process signals, and have universal input and power supply capabilities. They provide a real-time

measurement of your process value no matter the industry, and are engineered to provide a user-friendly and

reliable relay of information, even in demanding environments.

We deliver the safest signals by validating our products against the toughest safety standards. Through our

commitment to innovation, we have made pioneering achievements in developing I.S. interfaces with SIL 2 Full

Assessment that are both efficient and cost-effective. Our comprehensive range of analog and digital intrinsically

safe isolation barriers offers multifunctional inputs and outputs, making PR an easy-to-implement site standard.

Our backplanes further simplify large installations and provide seamless integration to standard DCS systems.

Our compact, fast, high-quality 6 mm isolators are based on microprocessor technology to provide exceptional

performance and EMC-immunity for dedicated applications at a very low total cost of ownership. They can be

stacked both vertically and horizontally with no air gap separation between units required.

5116V104-UK 3

Programmable transmitter

5116

Table of contents

Warning ................................................................................................ 4

Symbol identification .................................................................................... 4

Safety instructions ...................................................................................... 5

Instructions for intrinsically safe installation of 5116B..................................................... 5

How to demount system 5000 ........................................................................... 6

Application ............................................................................................. 8

Technical characteristics ................................................................................. 8

Mounting / installation................................................................................... 8

Order ................................................................................................... 9

Electrical specifications.................................................................................. 9

Connections ............................................................................................ 14

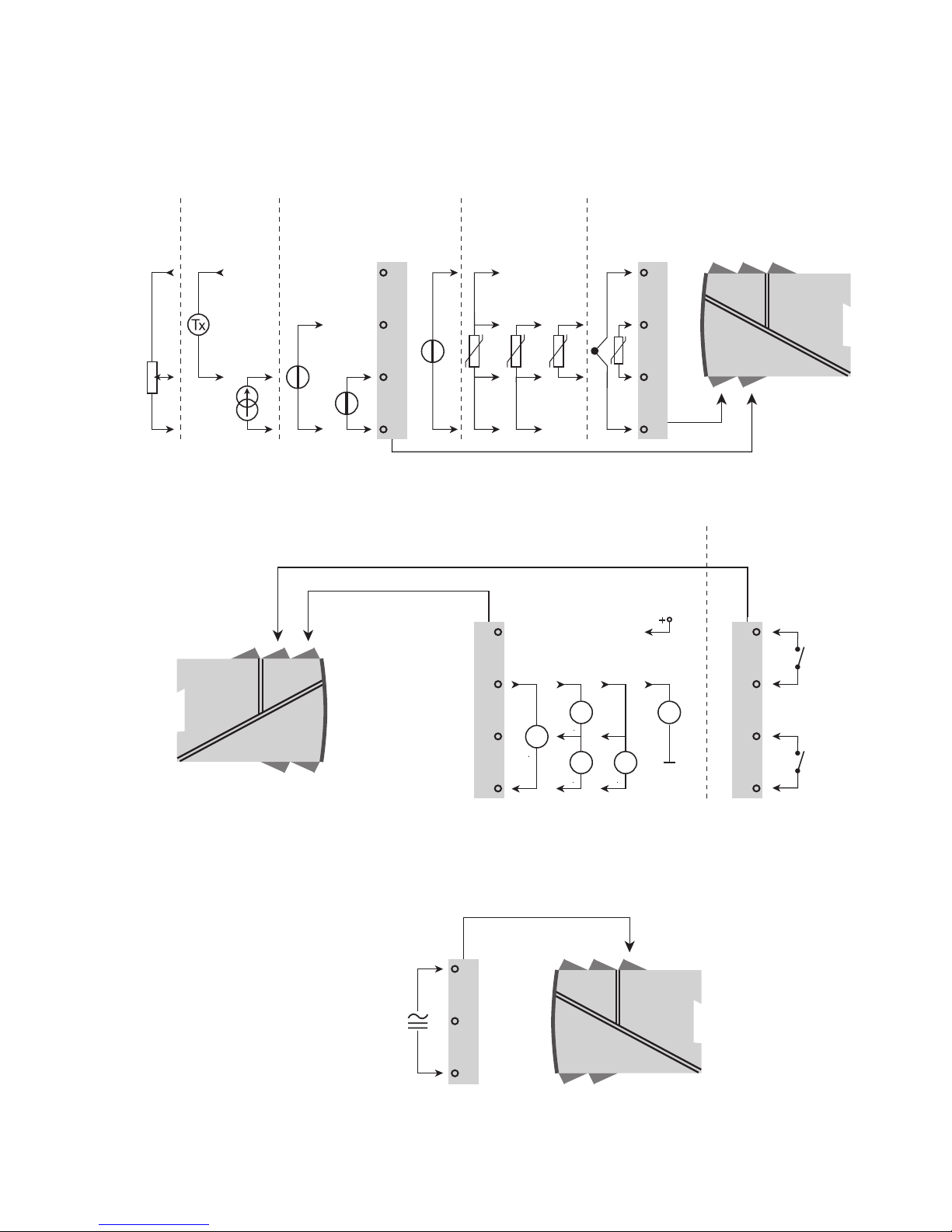

Block diagram........................................................................................... 16

Graphic depiction of relay actions Increasing / Decreasing .................................................. 17

Graphic depiction of relay action Window.................................................................. 17

5116 connection to Loop Link............................................................................ 18

Activation of the process calibration button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configuration of relay 1 & 2 in PReset .................................................................... 19

Process calibration 0% and 100% or only 0% .............................................................. 20

Error functions .......................................................................................... 20

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FM control drawing no. 5116QF01..................................................................... 22

4 5116V104-UK

Warning

This device is designed for connection to hazardous electric voltages.

Ignoring this warning can result in severe personal injury or mechanical damage.

To avoid the risk of electric shock and fire, the safety instructions of this manual must be observed and

the guidelines followed.

The specifications must not be exceeded, and the device must only be applied as described in the

following.

Prior to the commissioning of the device, this manual must be examined carefully.

Only qualified personnel (technicians) should install this device.

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

Warning

Until the device is fixed, do not connect hazardous voltages to the device.

The following operations should only be carried out on a disconnected device and under ESD-safe

conditions:

General mounting, wire connection and disconnection.

Troubleshooting the device.

Repair of the device and replacement of circuit breakers must be done by PR electronics A/S only.

Warning

To keep the safety distances, the relay contacts on the device must not be connected to both hazardous

and non-hazardous voltages at the same time.

SYSTEM 5000 must be mounted on a DIN rail according to DIN 46277.

The communication connector of SYSTEM 5000 is connected to the input terminals on which dangerous

voltages can occur, and it must only be connected to the programming unit Loop Link by way of the

enclosed cable.

Symbol identification

Triangle with an exclamation mark: Read the manual before installation and commissioning of the

device in order to avoid incidents that could lead to personal injury or mechanical damage. Warning /

demand. Potentially lethal situations.

The CE mark proves the compliance of the device with the essential requirements of the directives.

The double insulation symbol shows that the device is protected by double or reinforced insulation.

Ex devices have been approved acc. to the ATEX directive for use in connection with installations in

explosive areas.

HAZARD-

OUS

VOLTAGE

INSTAL-

LATION

GENERAL

5116V104-UK 5

Safety instructions

Definitions

Hazardous voltages have been defined as the ranges: 75 to 1500 Volt DC, and 50 to 1000 Volt AC.

Technicians are qualified persons educated or trained to mount, operate, and also trouble-shoot technically correct and in

accordance with safety regulations.

Operators, being familiar with the contents of this manual, adjust and operate the knobs or potentiometers during normal

operation.

Receipt and unpacking

Unpack the device without damaging it and check whether the device type corresponds to the one ordered. The packing

should always follow the device until this has been permanently mounted.

Environment

Avoid direct sun light, dust, high temperatures, mechanical vibrations and shock, and rain and heavy moisture. If necessary,

heating in excess of the stated limits for ambient temperatures should be avoided by way of ventilation.

All devices fall under Installation Category II, Pollution Degree 2, and Insulation Class II.

Mounting

Only technicians, who are familiar with the technical terms, warnings, and instructions in the manual and who are able to

follow these, should connect the device. Should there be any doubt as to the correct handling of the device, please contact

your local distributor or, alternatively,

PR electronics A/S

www.prelectronics.com

Mounting and connection of the device should comply with national legislation for mounting of electric materials, i.e. wire

cross section, protective fuse, and location. Descriptions of input / output and supply connections are shown in the block

diagram and side label.

The following apply to fixed hazardous voltages-connected devices:

The max. size of the protective fuse is 10 A and, together with a power switch, it should be easily accessible and close to

the device. The power switch should be marked with a label telling it will switch off the voltage to the device.

Year of manufacture can be taken from the first two digits in the serial number.

Instructions for intrinsically safe installation of 5116B

The intrinsically safe circuits are galvanically connected to the communications interface unit.

The communications interface may only be connected temporarily, under the condition that the connectors with terminal

numbers 41...44 and 51...54 are disconnected on the 5116B.

When a higher ingress protection than IP20 is required, this has to be achieved by an additional enclosure which is suitable for

the applicable environmental conditions.

When two or more units are placed next to each other it has to be assured that all the terminal numbers 41...44 and 51...54

are placed on the same side and are separated from the non-intrinsically safe circuits of the units which could be mounted

above or below it.

Each combination of circuits (to terminations 41...44 or to terminations 51...53 or to terminations 51...54) shall be connected

via separated cables or if the combinations are in one cable shall be type A or B in accordance with EN 60079-14 Clause

12.2.2.8.

UL installation requirements

Use 60/75°C copper conducters only.

For use only in pollution degree 2 or better.

Max. ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60°C

Max. wire size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AWG 26-14

UL file number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E231911

6 5116V104-UK

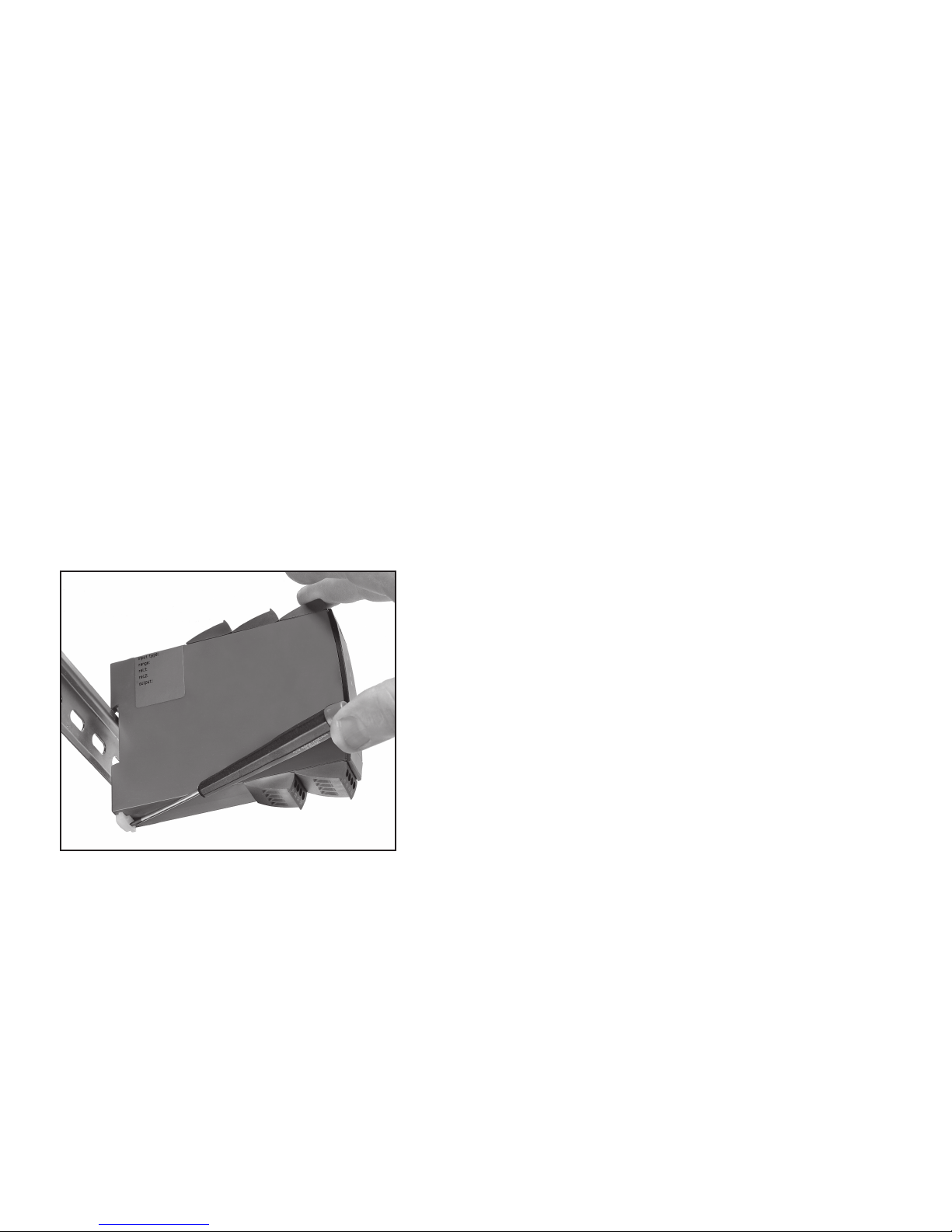

How to demount system 5000

First, remember to demount the connectors with hazardous voltages.

Picture 1:

By lifting the bottom lock, the device is detached from the DIN rail.

Calibration and adjustment

During calibration and adjustment, the measuring and connection of external voltages must be carried out according to the

specifications of this manual. The technician must use tools and instruments that are safe to use.

Normal operation

Operators are only allowed to adjust and operate devices that are safely fixed in panels, etc., thus avoiding the danger of

personal injury and damage. This means there is no electrical shock hazard, and the device is easily accessible.

Cleaning

When disconnected, the device may be cleaned with a cloth moistened with distilled water.

Liability

To the extent the instructions in this manual are not strictly observed, the custom er cannot advance a demand against PR

electronics A/S that would otherwise exist according to the concluded sales agreement.

33

32

31

14

13

12

11

24

23

22

21

mA

mA

V V

mA

44

43

42

41

54

53

52

51

4 3 2

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

5116V104-UK 7

Applications

Input signals:

Current Voltage

Potentiometer

RTD and lin. R TC

Connection, wires

V<=

2.5 V

2-wire

transmitter

V>

2.5 V

Bipolar

mV

Supply:

21.6...253 VAC

or

19.2...300 VDC

Output signals:

Relays

Analog, 0/4...20 mA and voltage

2-wire transmitter output

8 5116V104-UK

Programmable transmitter

5116

• Input for RTD, TC, mV, Ohm, potmeter, mA and V

• 2-wire supply > 16.5 V

• Bipolar voltage input

• Output for current, voltage and 2 relays

• Universal AC or DC supply

Application

• Linearised, electronic temperature measurement with RTD or TC sensor.

• Conversion of linear resistance variation to a standard analog current / voltage signal, i.e. from solenoids and butterfly

valves or linear movements with attached potentiometer.

• Power supply and signal isolator for 2-wire transmitters.

• Process control with 2 potential-free relay contacts which can be configured for advanced functions.

• Galvanic separation of analog signals and measurement of floating signals.

Technical characteristics

• Within a few seconds the user can program PR5116 to suit the specific application.

• By way of the front push-button the input can be calibrated to the exact span of the process. Zero drift on the process

signal can be adjusted by a single press of the front buttton.

• Continuous check of vital stored data for safety reasons.

• 3-port 3.75 kVAC galvanic isolation.

Mounting / installation

• Mounted vertically or horizontally on a DIN rail. As the devices can be mounted without any distance between

neighbouring units, up to 42 devices can be mounted per metre.

Loading...

Loading...