Page 1

9 2 0 3

S o l e n o i d /

a l a r m d r i v e r

N o. 9 20 3V 10 1- IN

P ro d u c t v e r s i o n : 9 2 0 3 - 0 0 1

DK

UK

FR

DE

ES

RU

PENDING

S I G N A L S T H E B E S T

PENDING

Page 2

DK

PR electronics A/S tilbyder et bredt program af analoge og digitale

signalbehandlingsmoduler til industriel automation. Programmet

består af Isolatorer, Displays, Ex-barrierer, Temperaturtransmittere,

Universaltransmittere mfl. Vi har modulerne, du kan stole på i selv

barske miljøer med elektrisk støj, vibrationer og temperaturudsving, og alle produkter opfylder de strengeste internationale standarder. Vores motto »Signals the Best« er indbegrebet af denne

filosofi – og din garanti for kvalitet.

UK

PR electronics A/S offers a wide range of analogue and digital

signal conditioning modules for industrial automation. The product

range includes Isolators, Displays, Ex Interfaces, Temperature

Transmitters, and Universal Modules. You can trust our products

in the most extreme environments with electrical noise, vibrations

and temperature fluctuations, and all products comply with the

most exacting international standards. »Signals the Best« is the

epitome of our philosophy – and your guarantee for quality.

FR

PR electronics A/S offre une large gamme de produits pour le

traite ment des signaux analogiques et numériques dans tous

les domaines industriels. La gamme de produits s’étend des

transmetteurs de température aux afficheurs, des isolateurs aux

interfaces SI, jusqu’aux modules universels. Vous pouvez compter

sur nos produits même dans les conditions d’utilisation sévères,

p.ex. bruit électrique, vibrations et fluctuations de température.

Tous nos produits sont conformes aux normes internationales les

plus strictes. Notre devise »SIGNALS the BEST« c’est notre ligne

de conduite - et pour vous l’assurance de la meilleure qualité.

DE

PR electronics A/S verfügt über ein breites Produktprogramm

an analogen und digitalen Signalverarbeitungsmodule für die industrielle Automatisierung. Dieses Programm umfasst Displays,

Temperaturtransmitter, Ex- und galvanische Signaltrenner, und

Universalgeräte. Sie können unsere Geräte auch unter extremen

Einsatzbedingungen wie elektrisches Rauschen, Erschütterungen

und Temperaturschwingungen vertrauen, und alle Produkte von

PR electronics werden in Überein stimmung mit den strengsten

internationalen Normen produziert. »Signals the Best« ist Ihre

Garantie für Qualität!

1108

Page 3

SOLENOID / ALARM DRIVER

9203

CONTENTS

Warning .............................................................................. 2

Symbol identification .......................................................... 2

Safety instructions .............................................................. 2

How to demount system 9000 ........................................... 4

EC declaration of conformity ............................................. 5

Advanced features ............................................................. 6

Application ......................................................................... 6

Technical characteristics .................................................... 6

Applications ........................................................................ 7

PR 4501 Display / programming front ............................... 8

Order: 9203B ...................................................................... 9

Visualisation in 4501 of hardware / software error ............ 13

Connections ....................................................................... 14

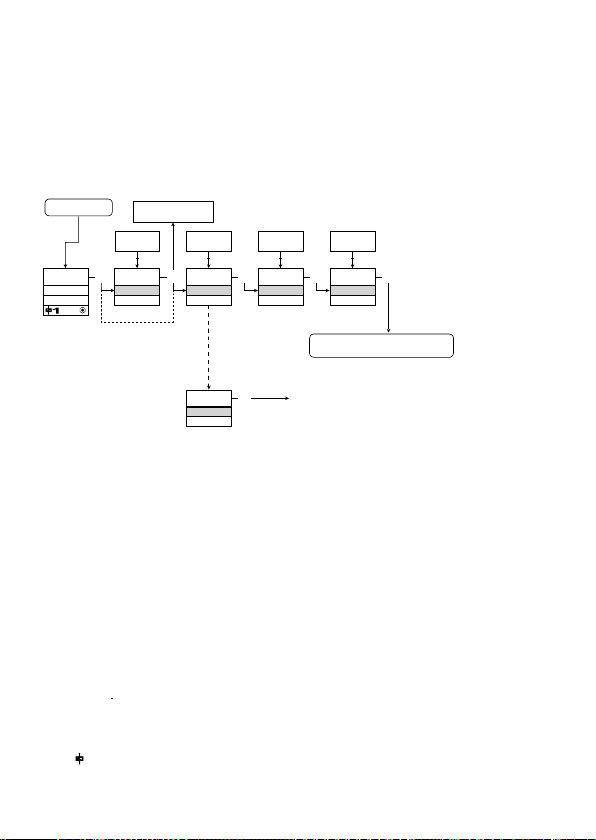

Block diagram .................................................................... 15

Signal error indications without display front ..................... 16

Configuration / operating the function keys ...................... 16

Routing diagram ................................................................. 18

Routing diagram, Advanced settings (ADV.SET) ................ 19

Scrolling help texts in display line 3 ................................... 20

Appendix ............................................................................ 21

IECEx Installation Drawing .............................................. 22

ATEX Installation Drawing ............................................... 24

FM Installation Drawing ................................................... 26

Safety Manual .................................................................. 28

9203 - Product Version 9203-001 1

Page 4

The following operations should only be carried out on a

CONTENTS

WARNING

disconnected device and under ESD-safe conditions:

General mounting, connection and disconnection of wires.

Troubleshooting the device.

Repair of the device and replacement of circuit breakers

must be done by PR electronics A/S only.

Do not open the front plate of the device as this will cause

damage to the connector for the display / programming front

PR 4501. This device contains no DIP-switches or jumpers.

SYMBOL IDENTIFICATION

WARNING

Triangle with an exclamation mark: Read the manual before installation

and commissioning of the device in order to avoid incidents that could

lead to personal injury or mechanical damage.

The CE mark proves the compliance of the device with the essential

requirements of the directives.

The double insulation symbol shows that the device is protected by

double or reinforced insulation.

Ex devices have been approved according to the ATEX directive for

use in connection with installations in explosive areas. See installation

drawings in appendix.

SAFETY INSTRUCTIONS

DEFINITIONS

Hazardous voltages have been defined as the ranges: 75...1500 Volt DC, and

50...1000 Volt AC.

Technicians are qualified persons educated or trained to mount, operate, and

also troubleshoot technically correct and in accordance with safety regulations.

Operators, being familiar with the contents of this manual, adjust and operate

the knobs or potentiometers during normal operation.

2 9203 - Product Version 9203-001

Page 5

RECEIPT AND UNPACKING

CONTENTS

Unpack the device without damaging it and check whether the device type

corresponds to the one ordered. The packing should always follow the device

until this has been permanently mounted.

ENVIRONMENT

Avoid direct sunlight, dust, high temperatures, mechanical vibrations and shock,

as well as rain and heavy moisture. If necessary, heating in excess of the stated

limits for ambient temperatures should be avoided by way of ventilation.

The device must be installed in pollution degree 2 or better.

The device is designed to be safe at least under an altitude up to 2 000 m.

MOUNTING

Only technicians who are familiar with the technical terms, warnings, and

in struc tions in the manual and who are able to follow these should connect the

device.

Should there be any doubt as to the correct handling of the device, please

contact your local distributor or, alternatively,

PR electronics A/S

www.prelectronics.com

The use of stranded wires is not permitted for mains wiring except when wires

are fitted with cable ends.

Descriptions of input / output and supply connections are shown in the block

diagram and on the side label.

The device is provided with field wiring terminals and shall be supplied from a

Power Supply having double / reinforced insulation. A power switch shall be

easily accessible and close to the device. The power switch shall be marked as

the disconnecting unit for the device.

For installation on Power Rail 9400 the power is supplied by Power Control Unit

9410.

Year of manufacture can be taken from the first two digits in the serial number.

CALIBRATION AND ADJUSTMENT

During calibration and adjustment, the measuring and connection of external

voltages must be carried out according to the specifications of this manual. The

technician must use tools and instruments that are safe to use.

9203 - Product Version 9203-001 3

Page 6

NORMAL OPERATION

CONTENTS

Operators are only allowed to adjust and operate devices that are safely fixed

in panels, etc., thus avoiding the danger of personal injury and damage. This

means there is no electrical shock hazard, and the device is easily accessible.

CLEANING

When disconnected, the device may be cleaned with a cloth moistened with

distilled water.

LIABILITY

To the extent that the instructions in this manual are not strictly observed, the

customer cannot advance a demand against PR electronics A/S that would

otherwise exist according to the concluded sales agreement.

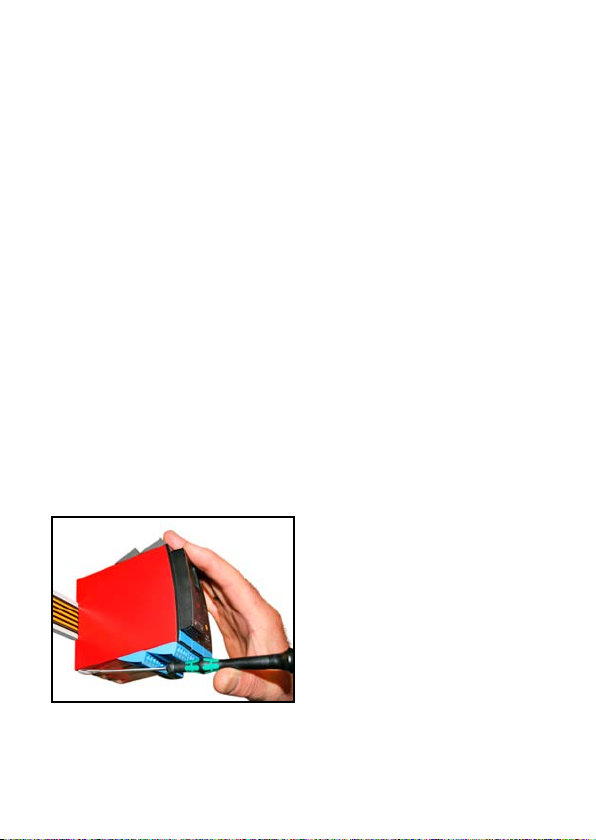

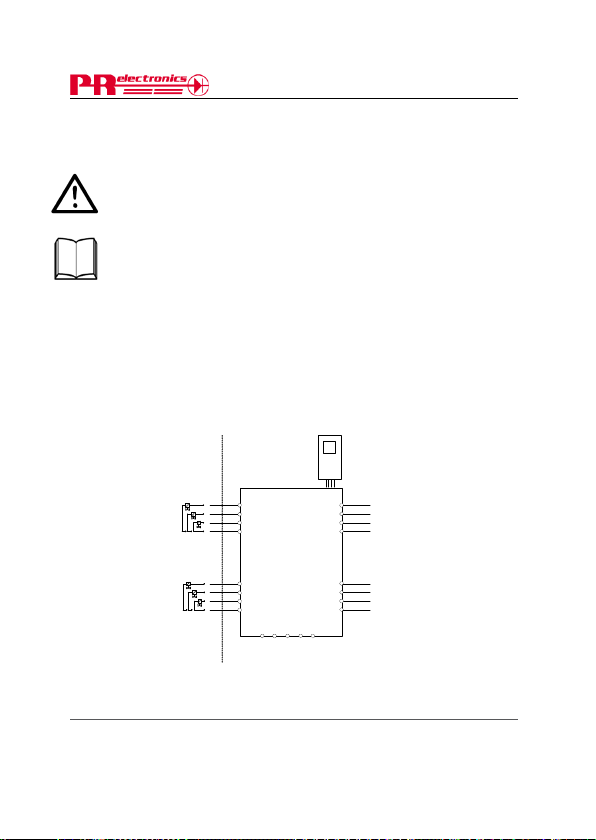

HOW TO DEMOUNT SYSTEM 9000

Picture 1:

By lifting the bottom lock, the device

is detached from the DIN rail.

4 9203 - Product Version 9203-001

Page 7

EC DECLARATION OF CONFORMITY

CONTENTS

As manufacturer

PR electronics A/S

Lerbakken 10

DK-8410 Rønde

hereby declares that the following product:

Type: 9203

Name: Solenoid / alarm driver

is in conformity with the following directives and standards:

The EMC Directive 2004/108/EC and later amendments

EN 61326-1 : 2006

For specification of the acceptable EMC performance level, refer to the

electrical specifications for the device.

The Low Voltage Directive 2006/95/EC and later amendments

EN 61010-1 : 2001

The ATEX Directive 94/9/EC and later amendments

EN 61241-0 : 2006, EN 61241-11 : 2006, EN 60079-0 : 2006,

EN 60079-11 : 2007, EN 60079-15 : 2005, EN 60079-26 : 2007

ATEX certificate: KEMA 07ATEX0147 X

Notified body

KEMA Quality B.V. (0344)

Utrechtseweg 310, 6812 AR Arnhem

P.O. Box 5185, 6802 ED Arnhem

The Netherlands

Rønde, 13 January 2010 Kim Rasmussen

Manufacturer’s signature

9203 - Product Version 9203-001 5

Page 8

SOLENOID / ALARM DRIVER

CONTENTS

9203

• Universal Ex driver for solenoids, acoustic alarms and LEDs

• Extended self-diagnostics

• 1 or 2 channels

• Can be supplied separately or installed on power rail, PR 9400

• SIL 2-certified via Full Assessment

Advanced features

• Universal Ex driver for the control of solenoids etc. with various Ex data by

way of three built-in Ex barriers.

• Two hardware versions make it possible to choose either Low (35 mA) or High

(60 mA) current output.

• Configuration and monitoring by way of detachable display front (PR 4501).

• Selection of direct or inverted function for each channel via PR 4501 and the

possibility of reducing the output current to the hazardous area to suit the

application.

• Optional monitoring of the output current to the hazardous area by way of PR

4501.

• Optional redundant supply via power rail and/or separate supply.

Application

• The device can be mounted in the safe area and in zone 2 / div. 2 and

transmit signals to zone 0, 1, 2, 20, 21 and 22.

• Ex driver for the control of ON / OFF solenoids, acou stic alarms and LEDs

mounted in the hazardous area.

• The 9203 is controlled by an NPN/PNP signal or a switch signal.

• Monitoring of internal error events via the individual status relay and/or a

collective electronic signal via the power rail.

• The 9203 has been designed, developed and certified for use in SIL 2

applications according to the requirements of IEC 61508.

Technical characteristics

• 1 green and 2 yellow/red front LEDs indicate operation status and malfunction.

• 2.6 kVAC galvanic isolation between input, output and supply.

6 9203 - Product Version 9203-001

Page 9

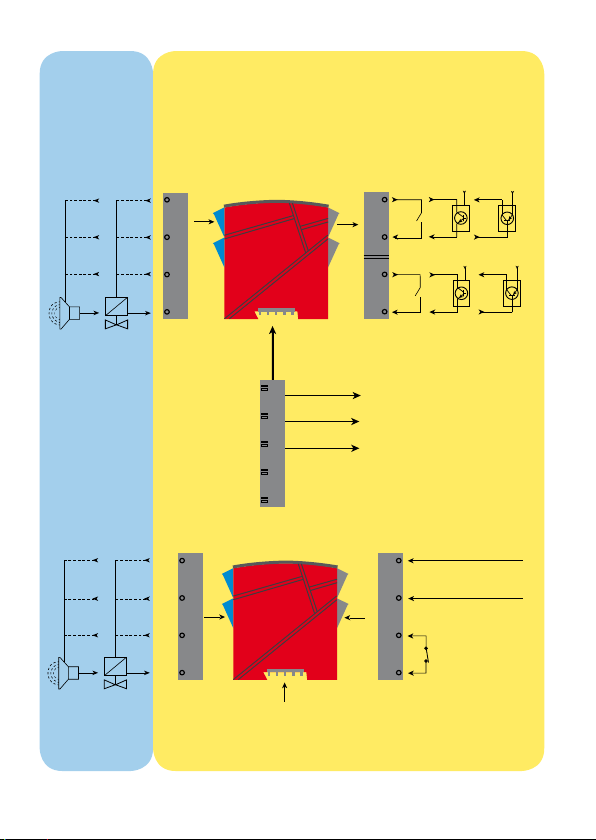

APPLICATIONS

CONTENTS

Output

signals:

Channel 1

SolenoidAlarm

Channel 2

SolenoidAlarm

Zone 0, 1, 2,

20, 21, 22 /

Cl. I/II/III, div. 1

gr. A-G

44

43

42

41

14

13

12

11

Power rail

Status relay signal

Rail, +24 VDC

Rail, Gnd.

No connection

No connection

Power connection:

54

53

52

51

Supply via

power rail

Zone 2 / Cl. 1, div. 2, gr. A-D or safe area

Input signals:

Gnd. -

31

Supply +19.2...3 1.2 VDC

32

Device status

33

N.C.

34

Device status

Channel 2

V

+

V

+

Channel 1

V

+

V

+

9203 - Product Version 9203-001 7

Page 10

PR 4501 DISPLAY / PROGRAMMING FRONT

CONTENTS

Functionality

The simple and easily understandable menu structure

and the explanatory help texts guide you effortless ly and

automatically through the configuration steps, thus making

the product very easy to use. Functions and configuration

options are described in the section ”Configuration /

operating the function keys”.

Application

• Communications interface for modification of operational parameters in 9203.

• When mounted in the process, the display shows process values and device

status.

Technical characteristics

• LCD display with 4 lines; Line 1 (H=5.57 mm) shows status for each channel

(OK or error). Line 2 (H=3.33 mm) shows output for channel 1 (ON / OFF),

line 3 (H=3.33 mm) shows output for channel 2 (ON / OFF), and line 4 shows

whether the device is SIL-locked. Static dot = SIL-locked and flashing dot =

not SIL-locked. Line 4 also indicates if the output is active.

• In order to protect the configuration against unauthorised changes, access to

the menus can be blocked by a password.

Mounting / installation

• Click 4501 onto the front of 9203.

8 9203 - Product Version 9203-001

Page 11

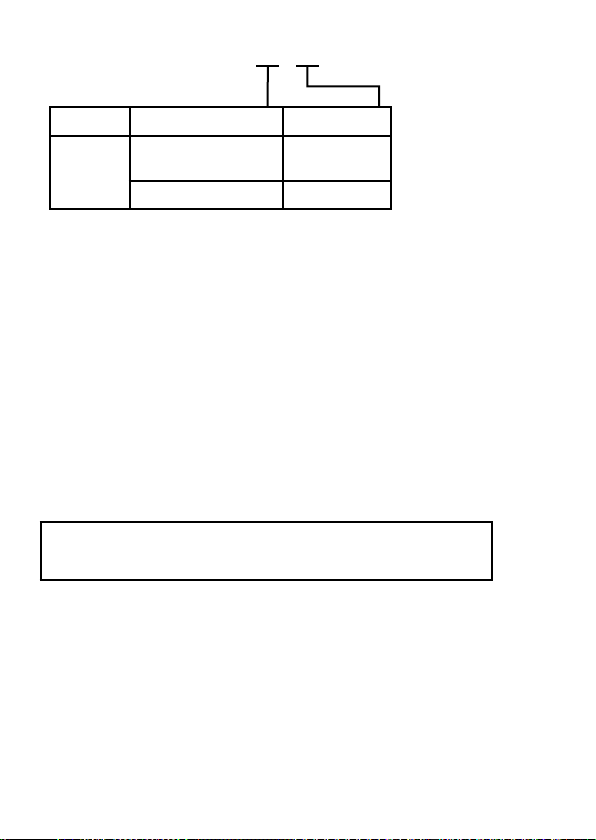

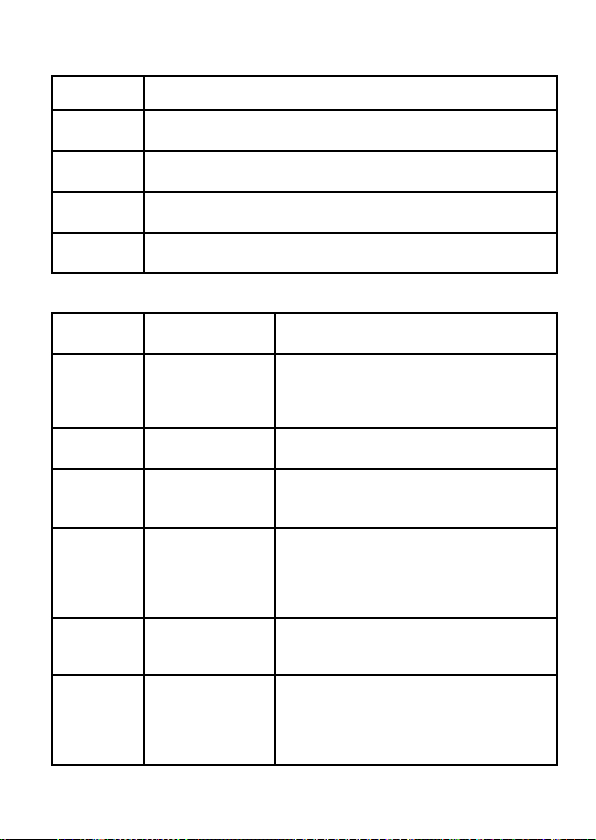

Order: 9203B

CONTENTS

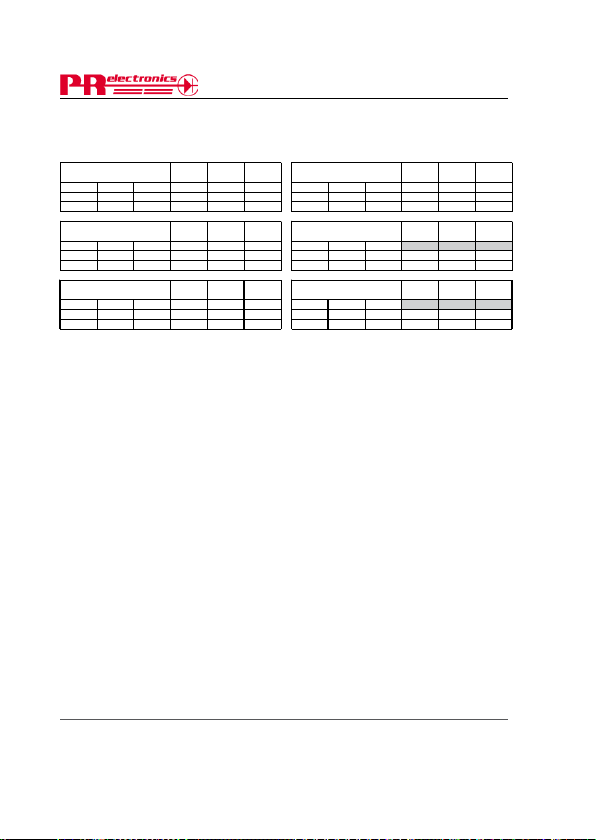

Type Ex barrier [Ex ia] Channels

9203B

Low current . . . : 1 Single . . . : A

Double . . : B

High current . . . : 2 Single . . . : A

4501 = Display / programming front

9400 = Power rail

Electrical specifications

Specifications range .................................... -20...+60°C

Storage temperature ................................... -20...+85°C

Common specifications:

Supply voltage............................................. 19.2...31.2 VDC

Max. consumption....................................... ≤ 3.5 W (2 channels)

Fuse ............................................................. 1.25 A SB / 250 VAC

Isolation voltage, test / operation:

Input / output / supply ......................... 2.6 kVAC / 250 VAC

Output 1 to output 2 ............................ 1.5 kVAC / 150 VAC reinforced

Status relay to supply .......................... 1.5 kVAC / 150 VAC reinforced

Communications interface .......................... Programming front 4501

EMC immunity influence ..................................... < ±0.5% of span

Extended EMC immunity:

NAMUR NE 21, A criterion, burst ....................... < ±1% of span

Calibration temperature............................... 20...28°C

Wire size (min....max.) ................................. 0.13...2.08 mm

stranded wire

Screw terminal torque ................................. 0.5 Nm

Relative humidity ......................................... < 95% RH (non-cond.)

Dimensions, without display front (HxWxD) . 109 x 23.5 x 104 mm

Dimensions, with display front (HxWxD) ..... 109 x 23.5 x 116 mm

Protection degree ........................................ IP20

Weight ......................................................... 170 g / 185 g with 4501

2

/ AWG 26...14

9203 - Product Version 9203-001 9

Page 12

NPN and mechanical switch:

CONTENTS

Trig level LOW ............................................. ≤ 2.0 VDC

Trig level HIGH ............................................ ≥ 4.0 VDC

Max. external voltage .................................. 28 VDC

Input impedance ......................................... 3.50 kΩ

PNP:

Trig level LOW ............................................. ≤ 8.0 VDC

Trig level HIGH ............................................ ≥ 10.0 VDC

Max. external voltage .................................. 28 VDC

Input impedance ......................................... 3.50 kΩ

Special PNP trig input:

If the input signal comes from a device where the output is connected as an

open collector with pull up resistor, a diode must be connected in series with

the input signal. See connections drawing at page 34 for further details.

Outputs:

Output ripple ............................................... < 40 mV RMS

Ex / I.S. data:

9203B1A / 9203B1B

Terminal

41-42 / 51-52

Uo 28 V 28 V 28 V

Io 93 mA 100 mA 110 mA

Po 0.65 W 0.70 W 0.77 W

Vout.

no load

Vout.

with load

Iout. max 35 mA 35 mA 35 mA

Co 80 nF 640 nF 2.1 µF 80 nF 640 nF 2.1 µF 80 nF 640 nF 2.1 µF

Lo 4.2 mH 16.8 mH 32.6 mH 3.5 mH 14.2 mH 27.6 mH 2.9 mH 11.8 mH 22.8 mH

Lo/Ro

Min. 24 V Min. 24 V Min. 24 V

Min. 12.5 V Min. 13.5 V Min. 14.5 V

IIC IIB IIA IIC IIB IIA IIC IIB IIA

54

218

µH/Ω

436

µH/Ω

µH/Ω

Terminal

41-43 / 51-53

50

µH/Ω

201

µH/Ω

402

µH/Ω

Terminal

41-44 / 51-54

46

µH/Ω

184

µH/Ω

369

µH/Ω

10 9203 - Product Version 9203-001

Page 13

9203B2A

CONTENTS

Terminal

41-42

Uo 28 V 28 V 28 V

Io 115 mA 125 mA 135 mA

Po 0.81 W 0.88 W 0.95 W

Vout.

no load

Vout.

with load

Iout. max 50 mA 60 mA 50 mA 60 mA 50 mA 60 mA

Co 80 nF 640 nF 2.1 µF 640 nF 2.1 µF 640 nF 2.1 µF

Lo 2.69 mH 10.8 mH 20.8 mH 9.1 mH 17.6 mH 7.8 mH 15.1 mH

Lo/Ro

Min. 24 V Min. 24 V Min. 24 V

Min. 11.5 V Min. 9 V Min. 12.5 V Min. 10 V Min. 13.5 V Min. 11 V

IIC IIB IIA IIC IIB IIA IIC IIB IIA

44

176

µH/Ω

353

µH/Ω

µH/Ω

Terminal

41-43

163

µH/Ω

327

µH/Ω

Terminal

41-44

150

µH/Ω

Relay output:

Status relay in safe area:

Max. voltage......................................... 125 VAC / 110 VDC

Max. current ......................................... 0.5 A AC / 0.3 A DC

Max. power .......................................... 62.5 VA / 32 W

301

µH/Ω

9203 - Product Version 9203-001 11

Page 14

Marine approval:

CONTENTS

Det Norske Veritas, Ships & Offshore ......... Pending

GOST R approval:

VNIIFTRI, Cert No. ....................................... Pending

SIL certification:

exida, Cert No. ............................................ XXXXXXX

Observed authority requirements: Standard:

EMC 2004/108/EC ...................................... EN 61326-1

LVD 2006/95/EC .......................................... EN 61010-1

ATEX 94/9/EC .............................................. EN 60079-0, -11, -15 , -26

and EN 61241-0, -11

IECEx ........................................................... IEC 60079-0, -11, -15 and -26

IEC 61241-0 and -11

c FM us ....................................................... FM 3600, 3611, 3810

CSA E60079-0, -15

CSA 22.2 -25, -142, -213

ANSI/ISA-12.00.01 / 12.12.02

UL, Standard for Safety .............................. UL 61010-1

SIL .............................................................IEC 61508

12 9203 - Product Version 9203-001

Page 15

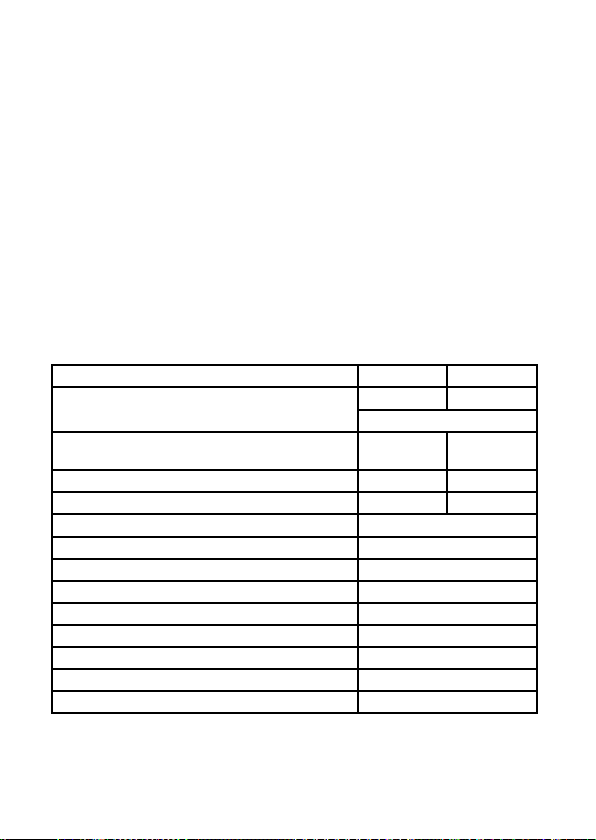

Visualisation in 4501 of hardware / software error

CONTENTS

Communications test 4501 / 9203 NO.CO Connection error

EEprom error - check configuration FL.ER

Hardware error DE.ER

Hardware error FC.ER

EEprom error - check configuration CO.ER

Hardware error CA.ER Factory calibration error

Hardware error HW.ER

Hardware error OC.ER

Hardware error MS.ER

Hardware error MI.ER

Hardware error MC.ER

! All error indications in the display flash once per second. The help text explains the error.

Errors affecting both channels are shown as error on channel 1 - and the line showing channel 2 is

blank.

Hardware error can be reset in two ways. Either step through the menus (if the other channel is to

stay in operation) or power cycle the device.

Error search Readout Cause

Readout at hardware error:

Configuration error or crc

mismatch, recovery confi-

guration is loaded

Invalid recovery configura-

tion in device

Invalid code checksum

in 4501

Invalid configuration

(CRC or data)

HW setup -

configuration mismatch

Main output controller

communication error

Main internal supply

out of bounds

Main initialisation

selftest failed

Main flash or ram

selftest failed

9203 - Product Version 9203-001 13

Page 16

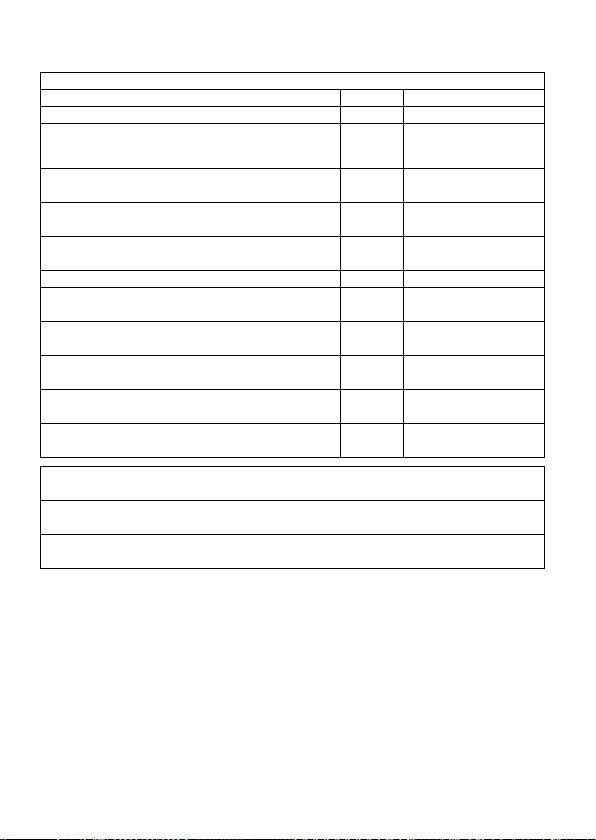

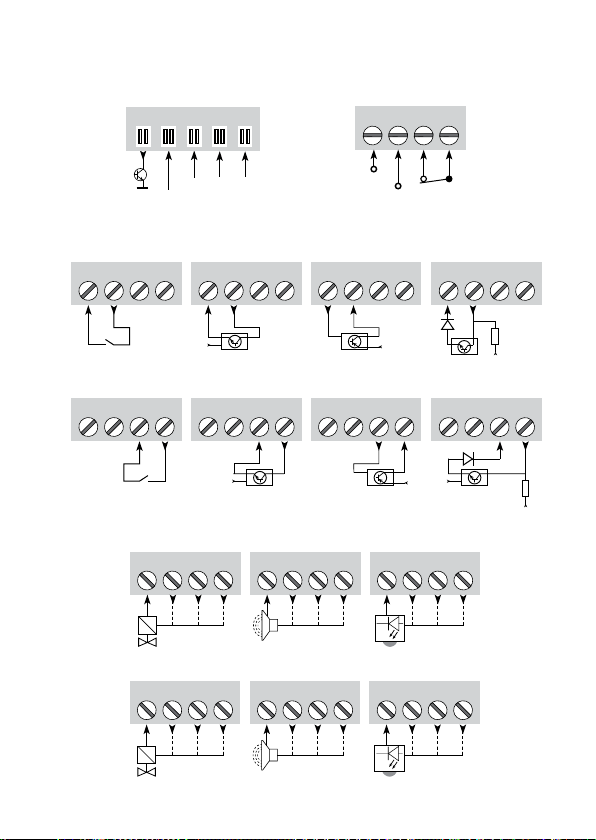

CONNECTIONS

CONTENTS

Error

NC = No connection

Switch PNP, switchNPN, switch

11 12 13 14

Channel 1

11 12 13 14

Channel 2

Solenoid, ON / OFF

Channel 1Channel 2

Solenoid, ON / OFF Acoustic alarm LED

Power rail

connections

91 92 93 94 95

+24 V

NCNCGnd.

11 12 13 14

V

+

Inputs:

Supply and

status relay

31 32 33 34

Gnd.

+24 V

11 12 13 14

V

+

N.C.

Special PNP

11 12 13 14

D

Special PNP

11 12 13 14

V

+

11 12 13 14

11 12 13 14

V

+

V

+

Outputs:

Acoustic alarm LED

51 52 53 54 51 52 53 54 51 52 53 54

41 42 43 4441 42 43 44 41 42 43 44

trig input

V

trig inputSwitch PNP, switchNPN, switch

D

R

+

R

V

+

14 9203 - Product Version 9203-001

Page 17

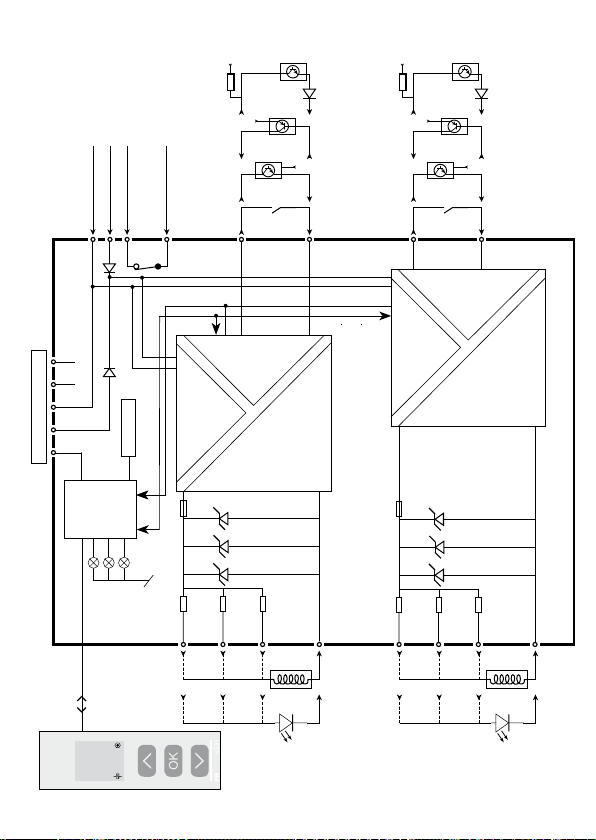

Gnd. -

CONTENTS

Supply +24 VDC

31

323433

NC*NC*

+24V

92 93 94 95

Power rail connections

91

Status relay N.C.

FLASH

BLOCK DIAGRAM

V

+

R

+

V

Status relay N.C.

Input +

12

trig input

Special PNP

PNP

NPN

Switch

D

+

V

Input, gnd.

11

Channel 1

V

+

R

Input +

14

trig input

D

Special PNP

+

V

PNP

NPN

Switch

+

V

Input, gnd.

* NC = No connection

13

Channel 2

92039203

CPU

Device status, Green

ON

Yellow/Red

Yellow/Red

Ch. 1 status,

Ch. 2 status,

1

OFF

Fuse

R Ex3

44

Output +

R Ex2

434142

R Ex1

Output, gnd.

Fuse

R Ex3

54

Output +

R Ex2

535152

R Ex1

9203 - Product Version 9203-001 15

Output, gnd.

Page 18

Signal error indications without display front

CONTENTS

LED and error signal indications

State Green LED

Device OK Flashing Energised OFF

No supply OFF OFF OFF De-energised ON

Device defective OFF Red Red De-energised ON

Ch. 1, output ON Flashing Yellow Energised OFF

Ch. 1, output OFF Flashing OFF Energised OFF

Ch. 2, output ON Flashing Yellow Energised OFF

Ch. 2, output OFF Flashing OFF Energised OFF

Ch 1:

Yellow / Red

Ch 2:

Yellow / Red

Status relay,

N.C.

Power rail

signal status

CONFIGURATION /

OPERATING THE FUNCTION KEYS

Documentation for routing diagram.

In general

When configuring the 9203, you will be guided through all parameters and you

can choose the settings which fit the application. For each menu there is a

scrolling help text which is automatically shown in line 3 on the display.

Configuration is carried out by use of the 3 function keys:

1 will increase the numerical value or choose the next parameter

2will decrease the numerical value or choose the previous parameter

3will accept the chosen value and proceed to the next menu

When configuration is completed, the display will return to the default state 1.0.

Pressing and holding 3 will return to the previous menu or return to the default

state (1.0) without saving the changed values or parameters.

If no key is activated for 1 minute, the display will return to the default state

(1.0) without saving the changed values or parameters.

16 9203 - Product Version 9203-001

Page 19

Further explanations

CONTENTS

Password protection: Programming access can be blocked by assigning a

password. The password is saved in the device in order to ensure a high

degree of protection against unauthorised modifications to the configuration.

Default password 2008 allows access to all configuration menus.

Signal and device error information via display front 4501

The display front can be configured to show output status, output current or

tag no. for both channels. In case of hardware error, a help text explaining the

error will be displayed.

Advanced functions

The unit gives access to a number of advanced functions which can be reached

by answering “Yes” to the point “adv.set”.

Display setup: Here you can adjust the brightness contrast and the backlight.

Setup of TAG numbers with 5 alphanumerics. Selection of functional readout

in line 2 and 3 of the display - choose between readout of output status,

output current or tag no. When selecting ”ALT” the readout toggles between

the display options.

Password: Here you can choose a password between 0000 and 9999 in order

to protect the device against unauthorised modifications to the configuration.

The device is delivered default without password.

Language: In the menu ”LANG” you can choose between 7 different language

versions of help texts that will appear in the menu. You can choose between

UK, DE, FR, IT, ES, SE and DK.

Safety Integrity Level (SIL): See Safety Manual for details.

9203 - Product Version 9203-001 17

Page 20

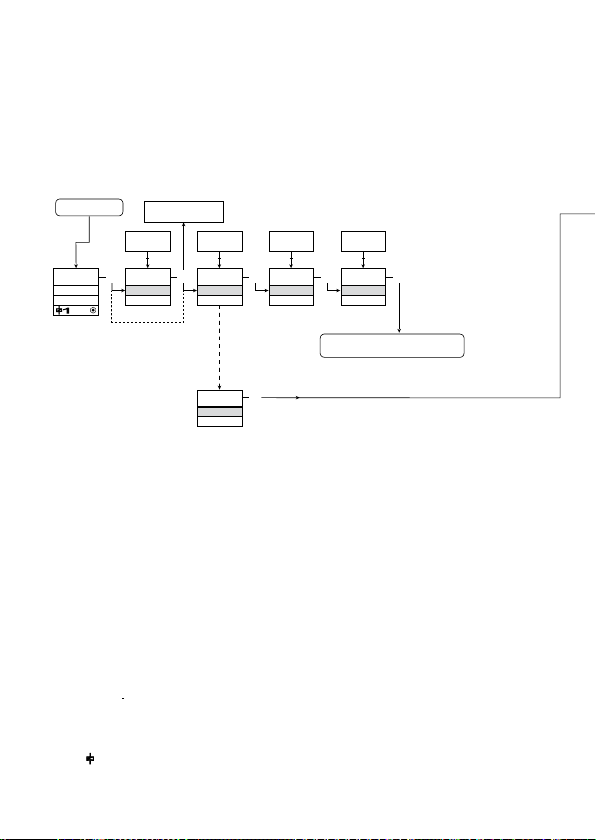

ROUTING DIAGRAM

CONTENTS

If no key is activated for 1 minute, the display will return to the default state 1.0

without saving configuration changes.

1 Increase value / choose next parameter

2 Decrease value / choose previous parameter

3 Accept the chosen value and proceed to the next menu

Hold 3 Back to previous menu / return to menu 1.0 without saving

3

Directly to [EN.SIL]

if SIL-lock is enabled

0000

9999

1 2

0000

PASSW.

Txt 1

1.1

3

NO

YES

1 2

NO

ADV.SET

Txt 2

YES

ADV.SET

Txt 2

DIR

INV

1 2

3

DIR

CH1.FUN

Txt 7

3

Power up

ON

OFF

1.0

1.0 = Default state

Line 1 shows status for channel 1

and channel 2.

Line 2 shows output status for

channel 1, output current or tag no.

Line 3 shows output status for

channel 2, output current or tag no.

Line 4 indicates whether the device

is SIL-locked.

1.1 = Only if password-protected.

1.2 = If password has been set.

Line 1 symbols:

= OK. Flashing = error.

Line 2 and 3 symbols:

ON = channel 1 ON

OFF = channel 2 OFF.

Line 4 symbols:

Static dot = SIL-locked.

Flashing dot = Not SIL-locked.

= output is active.

DIR

INV

1 2

3

DIR

CH2.FUN

Txt 7

3

To default state 1.0

Red text signifies safety

parameters in a SIL configuration.

See safety manual for details

18 9203 - Product Version 9203-001

Page 21

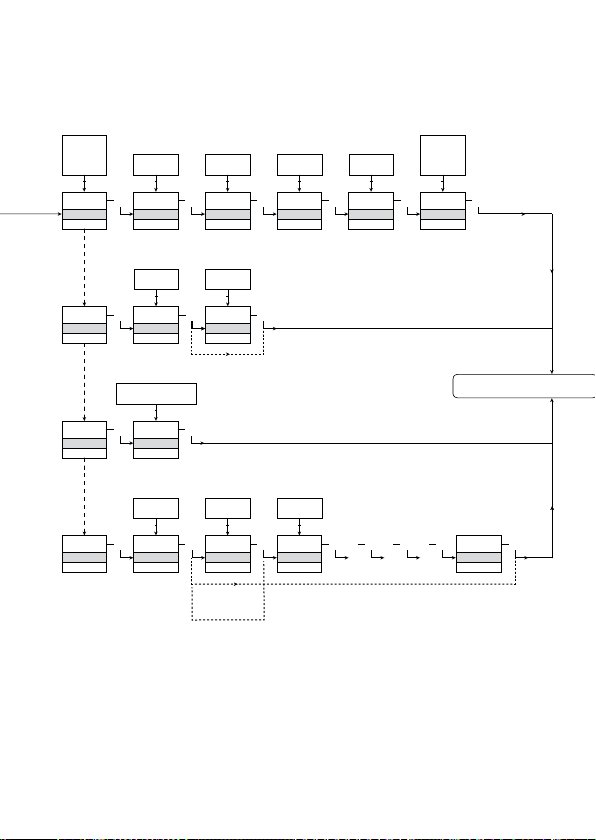

ROUTING DIAGRAM,

CONTENTS

ADVANCED SETTINGS (ADV.SET)

DISP,

PASS,

LANG,

SIL

1 2

DISP

SETUP

Txt 6

PASS

SETUP

Txt 06

LANG

SETUP

Txt 06

SIL

SETUP

Txt 06

9

0

1 2

3

3

CONTRA

Txt 9

YES

NO

1 2

3 3

YES

EN.PASS

Txt 15

DE, DK, ES, FR,

IT, SE, UK

1 2

3

UK

LANGUA

Txt 17

YES

NO

1 2

3

YES

EN.SIL

Txt 14

3

3

3

3

0000

NEW.PAS

NO

2008

NEW.PAS

NO

1.2

9

0

1 2

9

LIGHT

Txt 10

9999

0000

1 2

Txt 16

0000

9999

1 2

Txt 16

3

3

3

9

A

1 2

3

TAG1

VALVE 5

Txt 11

LOCK

OPEN

1 2

LOCK

CONFIG

Txt 13

TAG2

VALVE 6

Verify SIL configuration

3 3 3 3

. . . . . . . . . . . . . .

9

A

1 2

Txt 11

ALT

LOAD

TAG

D.OUT

1 2

3

3

LOAD

DISP

Txt 12

3

To default state 1.0

3

SIL.OK

9203 - Product Version 9203-001 19

Page 22

SCROLLING HELP TEXTS IN DISPLAY LINE 3

CONTENTS

[01]

Set correct password

[02]

Enter advanced setup?

[06]

Enter language setup

Enter password setup

Enter display setup

Enter SIL setup

[07]

Select direct channel function

Select inverted channel function

[09]

Adjust LCD contrast

[10]

Adjust LCD backlight

[11]

Write a 5-character channel tag

[12]

Show output state in display

Show output load in display

Show tag in display

Alternate information shown in display

[13]

Configuration SIL status (Open / Locked)

[14]

Enable SIL configuration lock

[15]

Enable password protection?

[16]

Set new password

[17]

Select language

[20]

No communication - check connections

[21]

EEprom error - check configuration

[22]

Hardware error

20 9203 - Product Version 9203-001

Page 23

APPENDIX

CONTENTS

IECEX INSTALLATION DRAWING

ATEX INSTALLATION DRAWING

FM INSTALLATION DRAWING

SAFETY MANUAL

9203 - Product Version 9203-001 21

Page 24

CONTENTS

9203QI01

IEC60079-26:2006, IEC61241-0:2004, IEC61241-11:2005

9203

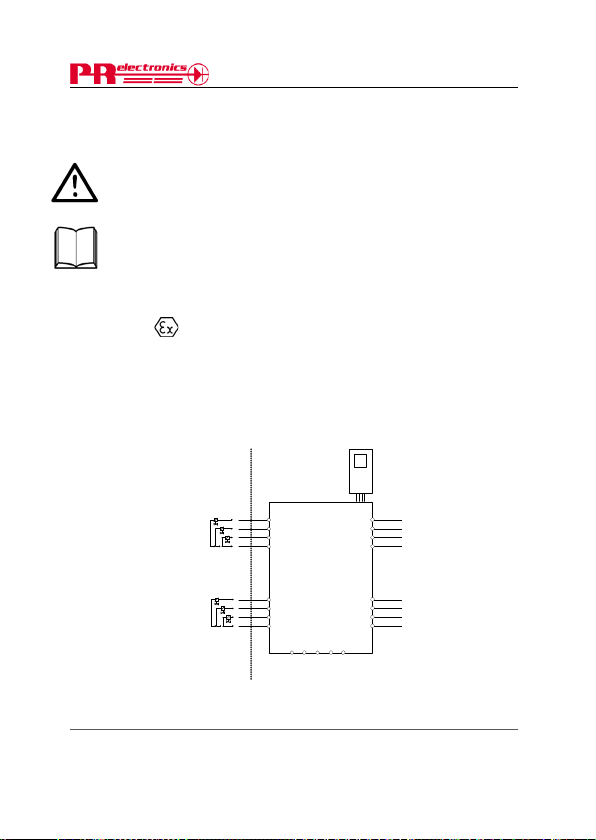

For safe installation of 9203B the following must be observed. The module shall only be installed by

qualified personnel who are familiar with the national and international laws, directives and

standards that apply to this area.

Year of manufacture can be taken from the first two digits in the serial number.

4501

For Installation in Zone 2 / Division 2 the following must be observed.

The 4501 programming module is to be used solely with PR electronics modules. It is important

that the module is undamaged and has not been altered or modified in any way. Only 4501

modules free of dust and moisture shall be installed.

Certificate IECEx KEM 09.0001X

Marking

Standards IEC60079-15:2005, IEC60079-11:2006, IEC60079-0:2007

Hazardous area Non Hazardous area

Zone 0, 1, 2, 20, 21, 22 or Zone 2

IECEx Installation drawing

Ex nA nC IIC T4 Gc

[Ex ia Ga] IIC/IIB/IIA

[Ex ia Da] IIIC

-20 ≤ Ta ≤ 60ºC

44

43

42

41

54

53

52

51

91 92 93 94 95

Power

Rail

4501

9203

34

33

32

31

14

13

12

11

Supply / Input

(terminal 11,12,13,14)

(terminal 31,32,33,34)

(terminal 91,92,93,94,95)

Um: 253 V, max. 400 Hz

Revision date:

2009-12-10

Version Revision

V3 R0

22 9203 - Product Version 9203-001

Prepared by:

PB

Page:

1/2

Page 25

CONTENTS

9203QI01

Modul 9203B1A & 9203B1B

Terminal 41-42 / 51-52

Modul 9203B1A & 9203B1B

Modul 9203B1A & 9203B1B

Installation notes.

Uo 28 V IIC 80 nF 4.2 mH 54 μH/Ω Uo 28 V IIC 80 nF 2.69 mH 44 μH/Ω

Io 93 mA IIB 640 nF 16.8 mH 218 μH/Ω Io 115 mA IIB 640 nF 10.8 mH 176 μH/Ω

Po 0.65 W IIA 2.1 μF 32.6 mH 436 μH/Ω Po 0.81 W IIA 2.1 μF 20.8 mH 353 μH/Ω

Terminal 41-43 / 51-53

Uo 28 V IIC 80 nF 3.5 mH 50 μH/Ω Uo 28 V IIC

Io 100 mA IIB 640 nF 14.2 mH 201 μH/Ω Io 125 mA IIB 640 nF 9.1 mH 162 μH/Ω

Po 0.70 W IIA 2.1 μF 27.6 mH 402 μH/Ω Po 0.88 W IIA 2.1 μF 17.6 mH 325 μH/Ω

Terminal 41-44 / 51-54

Uo 28 V IIC 80 nF 2.9 mH 46 μH/Ω Uo 28 V IIC

Io 110 mA IIB 640 nF 11.8 mH 184 μH/Ω Io 135 mA IIB 640 nF 7.8 mH 150 μH/Ω

Po 0.77 W IIA 2.1 μF 22.8 mH 369 μH/Ω Po 0.95 W IIA 2.1 μF 15.1 mH 301 μH/Ω

Terminal (31,32) Terminal (11,12 and 13,14)

Supply: Input:

Voltage 19.2 – 31.2 VDC Voltage max. 28 VDC

Power max. 3.5 W Trig: NPN Low < 2 V, High > 4 V

Trig: PNP Low < 8 V, High > 10 V

Terminal (33,34)

Status Relay: Non Hazardous location Zone 2 installation

Voltage max. 125 VAC / 110 VDC 32 VAC / 32 VDC

Power max. 62.5 VA / 32 W 16 VA / 32 W

Current max. 0.5 AAC / 0.3 ADC 0.5 AAC / 1 ADC

For installation in Zone 2, the module must be installed in an outer enclosure having an IP protection

of at least IP54 according to type of protection Ex-n or Ex-e.

For installation on Power Rail in Zone 2, only Power Rail type 9400 supplied by Power Control Unit

type 9410 is allowed.

In type of protection “intrinsic safety iD” the parameters for intrinsic safety for gas group IIB are

applicable.

If the sensor circuits (Terminals 41...44, 51…54) have been installed in a type of protection other than

“intrinsic safety”, the module shall not be re-installed in type of protection ”intrinsic safety”.

Do not separate connectors when energized and an explosive gas mixture is present.

Do not mount or remove modules from the Power Rail when an explosive gas mixture is present.

The maximum internal Power dissipation for adjacent modules is assumed to be max. 2 W each.

Revision date:

2009-12-10

Co Lo Lo/Ro

Co Lo Lo/Ro

Co Lo Lo/Ro

Version Revision

V3 R0

Modul 9203B2A

Terminal 41-42

Modul 9203B2A

Terminal 41-43

Modul 9203B2A

Terminal 41-44

Prepared by:

Co Lo Lo/Ro

Co Lo Lo/Ro

Co Lo Lo/Ro

PB

Page:

2/2

9203 - Product Version 9203-001 23

Page 26

CONTENTS

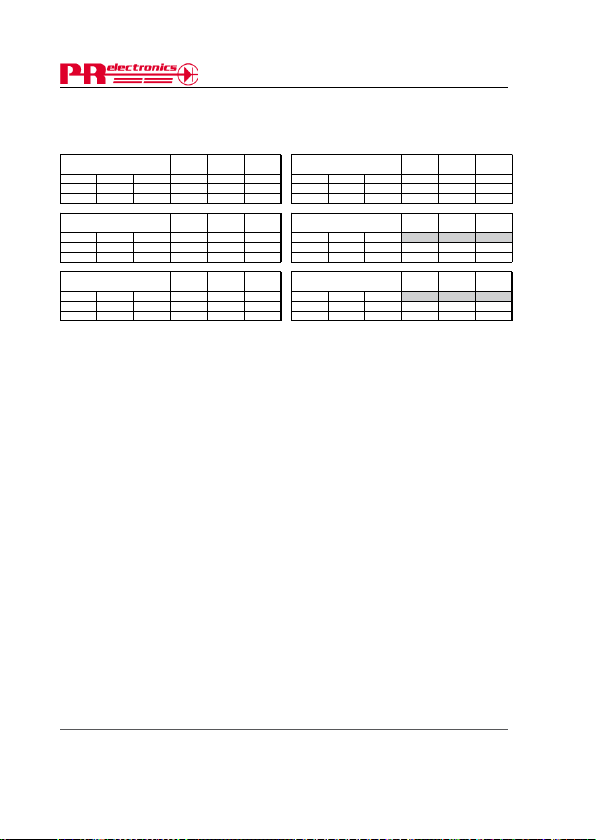

Standards EN 60079-0 : 2006, EN 60079-11 : 2007, EN 60079-15 : 2005

EN 60079-26 : 2007, EN 61241-0 : 2006, EN 61241-11 : 2006

9203

For safe installation of 9203B the following must be observed. The module shall only be installed by

qualified personnel who are familiar with the national and international laws, directives and

standards that apply to this area.

Year of manufacture can be taken from the first two digits in the serial number.

4501

For Installation in Zone 2 / Division 2 the following must be observed.

The 4501 programming module is to be used solely with PRelectronics modules. It is important

that the module is undamaged and has not been altered or modified in any way. Only 4501

modules free of dust and moisture shall be installed.

ATEX Certificate KEMA 07ATEX 0147 X

Marking

Revision date:

2009-12-10

ATEX Installation drawing

II 3 G Ex nA nC IIC/IIB/IIA T4

II (1) G [Ex ia] IIC/IIB/IIA

II (1) D [Ex iaD]

-20 ≤ Ta ≤ 60ºC

44

43

42

41

54

53

52

51

Version Revision

V3 R0

Non Hazardous Area

or Z

Hazardous area

Zone 0,1,2, 20, 21, 22

one 2

91 92 93 94 95

Power

Rail

4501

34

33

32

31

14

13

12

11

9203

Supply / Input

(terminal 11,12,13,14)

(terminal 31,32,33,34)

(terminal 91,92,93,94,95)

Um: 253 V, max. 400 Hz

Prepared by:

PB

9203QA01

Page:

1/2

24 9203 - Product Version 9203-001

Page 27

CONTENTS

9203QA01

Modul 9203B1A & 9203B1B

Terminal 41-42 / 51-52

Modul 9203B1A & 9203B1B

Modul 9203B1A & 9203B1B

Uo 28 V IIC 80 nF 4.2 mH 54 μH/Ω Uo 28 V IIC 80 nF 2.69 mH 44 μH/Ω

Io 93 mA IIB 640 nF 16.8 mH 218 μH/Ω Io 115 mA IIB 640 nF 10.8 mH 176 μH/Ω

Po 0.65 W IIA 2.1 μF 32.6 mH 436 μH/Ω Po 0.81 W IIA 2.1 μF 20.8 mH 353 μH/Ω

Terminal 41-43 / 51-53

Uo 28 V IIC 80 nF 3.5 mH 50 μH/Ω Uo 28 V IIC

Io 100 mA IIB 640 nF 14.2 mH 201 μH/Ω Io 125 mA IIB 640 nF 9.1 mH 162 μH/Ω

Po 0.70 W IIA 2.1 μF 27.6 mH 402 μH/Ω Po 0.88 W IIA 2.1 μF 17.6 mH 325 μH/Ω

Terminal 41-44 / 51-54

Uo 28 V IIC 80 nF 2.9 mH 46 μH/Ω Uo 28 V IIC

Io 110 mA IIB 640 nF 11.8 mH 184 μH/Ω Io 135 mA IIB 640 nF 7.8 mH 150 μH/Ω

Po 0.77 W IIA 2.1 μF 22.8 mH 369 μH/Ω Po 0.95 W IIA 2.1 μF 15.1 mH 301 μH/Ω

Co Lo Lo/Ro

Co Lo Lo/Ro

Co Lo Lo/Ro

Modul 9203B2A

Terminal 41-42

Modul 9203B2A

Terminal 41-43

Modul 9203B2A

Terminal 41-44

Co Lo Lo/Ro

Co Lo Lo/Ro

Co Lo Lo/Ro

Terminal (31,32) Terminal (11,12 and 13,14)

Supply: Input:

Voltage 19.2 – 31.2 VDC Voltage max 28 VDC

Power max. 3.5 W Trig: NPN Low < 2 V, High > 4 V

Trig: PNP Low < 8 V, High > 10 V

Terminal (33,34)

Status Relay: Non Hazardous location Zone 2 installation

Voltage max. 125 VAC / 110 VDC 32 VAC / 32 VDC

Power max. 62.5 VA / 32 W 16 VA / 32 W

Current max. 0.5 AAC / 0.3 ADC 0.5 AAC / 1 ADC

Installation notes.

For installation in Zone 2, the module must be installed in an outer enclosure having an IP protection

of at least IP54, according to type of protection Ex-n or Ex-e.

For installation on Power Rail in Zone 2, only Power Rail type 9400 supplied by Power Control Unit

type 9410 is allowed.

In type of protection “intrinsic safety iD” the parameters for intrinsic safety for gas group IIB are

applicable.

After the sensor circuits (Terminals 41...44, 51...54) have been installed in a type of protection other

than “intrinsic safety”, the module shall not be re-installed in type of protection ”intrinsic safety”.

Do not separate connectors when energized and an explosive gas mixture is present.

Do not mount or remove modules from the Power Rail when an explosive gas mixture is present.

The maximum internal Power dissipation for adjacent modules is assumed to be max. 2 W each.

Revision date:

2009-12-10

Version Revision

V3 R0

Prepared by:

PB

Page:

2/2

9203 - Product Version 9203-001 25

Page 28

FM Installation Drawing

CONTENTS

LERBAKKEN 10, 8410 RØNDE DENMARK

9203

For safe installation of 9203B the following must be observed. The module shall only be

installed by qualified personnel who are familiar with the national and international laws,

directives and standards that apply to this area.

Year of manufacture can be taken from the first two digits in the serial number.

4501

For Installation in Zone 2 / Division 2 the following must be observed.

The 4501 programming module is to be used solely with PR electronics modules. It is

important that the module is undamaged and has not been altered or modified in any way.

Only 4501 modules free of dust and moisture shall be installed.

c-FM-us Certificate 3035277

Hazardous area

Class I/II/III, Division 1, Group A,B,C,D,E,F,G

or Class I, Zone 0/1 Group IIC, [AEx ia] IIC or

or Class I, Zone 0/1 Group IIC, [Ex ia] IIC

Simple Apparatus or

Intrinsically safe apparatus

with entity parameters:

Vmax (Ui) ≥ Vt (Uo)

Imax (Ii) ≥ It (Io)

Pi ≥ Pt(Po)

cable + Ci

Ca(Co) ≥ C

cable + Li

La(Lo) ≥ L

Revision date:

2009-12-10

FM Installation drawing

Non Hazardous Area or

Class I, Division 2, Group A,B,C,D T4

Version Revision

V3 R0

or Class I, Zone 2 Group IIC T4

-20 ≤ Ta ≤ 60ºC

44

43

42

41

54

53

52

51

91 92 93 94 95

Power

4501

34

33

32

31

14

13

12

11

9203

Rail

Supply / Input

(terminal 11,12,13,14)

(terminal 31,32,33,34)

(terminal 91,92,93,94,95)

: 253 V, max. 400 Hz

U

m

Prepared by:

PB

9203QF01

Page:

1/2

26 9203 - Product Version 9203-001

Page 29

CONTENTS

9203QF01

LERBAKKEN 10, 8410 RØNDE DENMARK

Modul 9203B1A & 9203B1B

Terminal 41-42 / 51-52

Uo/Voc 28 V

Io/Isc 93 mA

Po 0.65 W

Modul 9203B1A & 9203B1B

Terminal 41-43 / 51-53

Uo/Voc 28 V

Io/Isc 100 mA

Po 0.70 W

Modul 9203B1A & 9203B1B

Terminal 41-44 / 51-54

Uo/Voc 28 V

Io/Isc 110 mA

Po 0.77 W

Co/Ca Lo/La

80 nF 4.2 mH 54 μH/Ω Uo/Voc 28 V

IIC or A,B

IIB or C,E,F

640 nF 16.8 mH 218 μH/Ω Io/Isc 115 mA

2.1 μF 32.6 mH 436 μH/Ω P o 0.81 W

IIA or D,G

Co/Ca Lo/La

IIC or A,B

80 nF 3.5 mH 50 μH/Ω Uo/Voc 28 V

640 nF 14.2 mH 201 μH/Ω Io/Isc 125 mA

IIB or C,E,F

2.1 μF 27.6 mH 402 μH/Ω P o 0.88 W

IIA or D,G

Co/Ca Lo/La

80 nF 2.9 mH 46 μH/Ω Uo/Voc 28 V

IIC or A,B

640 nF 11.8 mH 184 μH/Ω Io/Isc 135 mA

IIB or C,E,F

IIA or D,G

2.1 μF 22.8 mH 369 μH/Ω P o 0.95 W

Terminal (31,32) Terminal (11,12 and 13,14)

Supply: Input:

Voltage 19.2 – 31.2 VDC Voltage max. 28 VDC

Power max. 3.5 W Trig: NPN Low < 2 V, High > 4 V

Trig: PNP Low < 8 V, High > 10 V

Terminal (33,34)

Status Relay: Non Hazardous location: Division 2 or Zone 2 installation:

Voltage max. 125 VAC / 110 VDC 32 VAC / 32 VDC

Power max. 62.5 VA / 32 W 16 VA / 32 W

Current max. 0.5 AAC / 0.3 ADC 0.5 AAC / 1 ADC

Installation notes:

The installation and wiring shall be in accordance with the Canadian Electrical Code for Canada and

National Electrical Code NFPA 70, Article 500 or 505 for installation in USA.

The module must be supplied from a Power Supply having double or reinforced insulation.

The use of stranded wires is not permitted for mains wiring except when wires are fitted with cable

ends.

For installation on the 9400 Power Rail the power must be supplied from Power Control Module Unit

9410.

The module must be installed in pollution degree 2 or better.

The module must be installed in an enclosure suitable for the environment for which it is used.

For installation in Zone 2 or Division 2, the module must be installed in a suitable outer enclosure

according to the regulations in the CEC for Canada or NEC for USA.

The module is galvanically isolated and does not require grounding.

Use 60 / 75 ºC copper conductors with wire size AWG: (26-14).

The maximum internal Power dissipation for adjacent modules is assumed to be max. 2 W each.

Warning: Substitution of components may impair intrinsic safety and / or suitability for Div. 2 / Zone 2.

Warning: To prevent ignition of explosive atmospheres, disconnect power before servicing and do not

separate connectors when energized and an explosive gas mixture is present.

Warning: Do not mount or remove modules from the Power Rail when an explosive gas mixture is

present.

Lo/Ro or

La/Ra

Lo/Ro or

La/Ra

Lo/Ro or

La/Ra

Modul 9203B2A

Terminal 41-42

Modul 9203B2A

Terminal 41-43

Modul 9203B2A

Terminal 41-44

IIC or A,B

IIB or C,E,F

IIA or D,G

IIC or A,B

IIB or C,E,F

IIA or D,G

IIC or A,B

IIB or C,E,F

IIA or D,G

Co/Ca Lo/La

80 nF 2.69 mH 44 μH/Ω

640 nF 10.8 mH 176 μH/Ω

2.1 μF 20.8 mH 353 μH/Ω

Co/Ca Lo/La

640 nF 9.1 mH 162 μH/Ω

2.1 μF 17.6 mH 325 μH/Ω

Co/Ca Lo/La

640 nF 7.8 mH 150 μH/Ω

2.1 μF 15.1 mH 301 μH/Ω

Lo/Ro or

La/Ra

Lo/Ro or

La/Ra

Lo/Ro or

La/Ra

Revision date:

2009-12-10

Version Revision

V3 R0

Prepared by:

PB

Page:

2/2

9203 - Product Version 9203-001 27

Page 30

SAFETY MANUAL

SOLENOID / ALARM DRIVER

9203

This safety manual is valid for the following product versions:

9203-001

Version No. V3R0

Page 31

9203 Solenoid / Alarm Driver Safety Manual

0. CONTENTS

1. Observed standards ................................................................................ 2

2. Acronyms and abbreviations ................................................................... 2

3. Purpose of the product ........................................................................... 3

4. Assumptions and restrictions for use of the product.............................. 3

4.1 Basic safety specifications ............................................................. 3

4.2 Associated equipment .................................................................... 3

4.2.1 Safety output ....................................................................... 3

4.2.2 Safety input ......................................................................... 3

4.3 Failure rates .................................................................................... 3

4.4 Safe parameterisation ..................................................................... 4

4.5 Installation in hazardous areas ....................................................... 4

5. Functional specification of the safety functions...................................... 4

6. Functional specification of the non-safety functions .............................. 4

7. Safety parameters ................................................................................... 4

8. Hardware and software configuration ..................................................... 5

9. Failure category ....................................................................................... 5

10. Periodic proof test procedure ................................................................. 5

11. Procedures to repair or replace the product ........................................... 5

12. Maintenance ............................................................................................ 5

13. Documentation for routing diagram ........................................................ 6

13.1 In general ........................................................................................ 6

13.2 Further explanations ....................................................................... 6

13.2.1 Password protection ........................................................... 6

13.4 Advanced functions ........................................................................ 6

13.4.1 Display setup ...................................................................... 7

13.4.2 Password ............................................................................ 7

13.4.3 Language ............................................................................ 7

13.4.4 Power rail ............................................................................ 7

13.4.5 Safety integrity level ............................................................ 7

14 Safe parameterisation - user responsibility ............................................. 8

14.1 Safety-related configuration parameters ........................................ 8

14.2 Verification procedure ..................................................................... 8

14.2.1 If no password is set ........................................................... 8

14.2.2 If password is set ................................................................ 9

14.3 Functional test ................................................................................ 9

15. Fault reaction and restart condition ........................................................ 9

16 User interface .......................................................................................... 10

16.1 Scrolling help texts in display line 3 ............................................... 10

16.3 Routing diagram - Advanced settings (ADV.SET)........................... 12

17 Connections diagram .............................................................................. 13

Version No. V3R0 1

Page 32

Safety Manual 9203 Solenoid / Alarm Driver

1. Observed standards

Standard Description

IEC 61508

IEC 61508-

2:2000

IEC 61508-

3:1998

IEC 61326-

3-1:2008

Functional Safety of electrical / electronic / programmable

electronic safety-related systems

Part 2: Requirements for electrical / electronic / programmable

electronic safety-related systems

Part 3: Software requirements

Immunity requirements for safety-related systems

2. Acronyms and abbreviations

Acronym /

Abbreviation

Element

PFD

PFH

SFF

SIF

SIL

Designation Description

Term defined by IEC 61508 as “part of a

subsystem comprising a single component

or any group of components that performs

one or more element safety functions”

Probability of

Failure on Demand

Probability of dan-

gerous Failure per

Hour

Safe Failure

Fraction

Safety Integrity

Function

Safety Integrity

Level

This is the likelihood of dangerous safety

function failures occurring on demand.

The term “Probability” is misleading, as IEC

61508 defines a Rate.

Safe Failure Fraction summarises the

fraction of failures which lead to a safe

state and the fraction of failures which will

be detected by diagnostic measures and

lead to a defined safety action.

Function that provides fault detection (to

ensure the necessary safety integrity for the

safety functions)

The international standard IEC 61508

specifies four discrete safety integrity levels

(SIL 1 to SIL 4). Each level corresponds to

a specific probability range regarding the

failure of a safety function.

2 Version No. V3R0

Page 33

9203 Solenoid / Alarm Driver Safety Manual

3. Purpose of the product

Universal Ex driver for the control of solenoids etc. with various Ex data by

way of three built-in Ex barriers.

The device can be mounted in the safe area and in zone 2 / div. 2 and

transmit signals to zone 0, 1, 2, 20, 21 and 22.

Ex driver for the control of ON / OFF solenoids, acou stic alarms and LEDs

mounted in the hazardous area.

The 9203 is controlled by an NPN/PNP signal or a switch signal.

Monitoring of internal error events via the individual status relay and/or a

collective electronic signal via the power rail.

The 9203 has been designed, developed and certified for use in SIL 2

applications according to the requirements of IEC 61508.

4. Assumptions and restrictions for use of the product

4.1 Basic safety specifications

Operational temperature range ..... -20...+60°C

Storage temperature range ........... -20...+85°C

Power supply type, min. ................ Double or reinforced

Supply voltage ............................... 19.2...31.2 VDC

Mounting area ................................ Zone 2 / Division 2 or safe area

Mounting environment ................... Pollution degree 2 or better

4.2 Associated equipment

4.2.1 Safety output

The safety output shall be connected to the equipment with a

minimum load of 10 KΩ

4.2.2 Safety input

The safety input signal frequency shall not be higher than 20 Hz,

and the pulse length shall not be shorter than 25 ms.

4.3 Failure rates

The basic failure rates from the Siemens standard SN 29500 are used

as the failure rate database.

Failure rates are constant, wear-out mechanisms are not included.

External power supply failure rates are not included.

Version No. V3R0 3

Page 34

Safety Manual 9203 Solenoid / Alarm Driver

4.4 Safe parameterisation

The user is responsible for verifying the correctness of the configuration

parameters. (See section 14 Safe parameterisation - user responsibility).

Manual override may not be used for safety applications.

4.5 Installation in hazardous areas

The IECex Installation drawing, ATEX Installation drawing and FM

Installation drawing shall be followed if the products are installed in

hazardous areas.

5. Functional specification of the safety functions

Ex driver for the control of ON / OFF solenoids, acou stic alarms and LEDs

mounted in the hazardous area.

6. Functional specification of the non-safety functions

The status relay (terminal 33 and 34), error signal on power rail (terminal 91)

and LED outputs are not suitable for use in any Safety Instrumented Function.

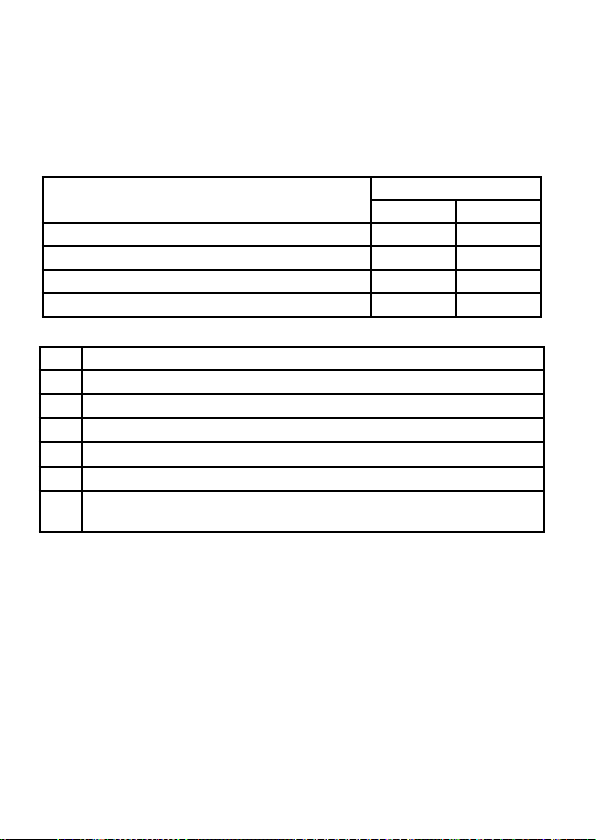

7. Safety parameters

B1A, B1B B2A

Probability of dangerous Failure per Hour (PFH) 4.30E-08 4.60E-08

Probability of failure on demand (PFD) -

1 year proof test interval

Proof test interval (10% of loop PFD) 5 years

Safe Failure Fraction 91% 91%

Demand response time

Demand mode High

Demand rate 1000 s

Mean Time To Repair (MTTR) 24 hours

Diagnostic test interval 10 seconds

Hardware Fault Tolerance (HFT) 0

Component Type B

SIL capability SIL 2

Description of the “Safe State” De-energised

Note1: The 9203 contains no lifetime limiting components, therefore the PFH

figures are valid for up to 12 years, according to IEC 61508.

1

Note

2.73E-04 2.92E-04

4 years

ms

<10

4 Version No. V3R0

Page 35

9203 Solenoid / Alarm Driver Safety Manual

8. Hardware and software configuration

All configurations of software and hardware versions are fixed from factory,

and cannot be changed by end-user or reseller.

This manual only covers products labelled with the product version (or range

of versions) specified on the front page.

9. Failure category

Failure category

Fail Safe Detected 0.00E+00 0.00E+00

Fail Safe Undetected 4.77E-07 4.80E-07

Fail Dangerous Detected 0.00E+00 0.00E+00

Fail Dangerous Undetected 4.30E-08 4.60E-08

Failure rates (1/h)

B1A, B1B B2A

10. Periodic proof test procedure

Step Action

1 Bypass the safety PLC or take other appropriate action to avoid a false trip

Connect a simulator identical to the input setup

2

Perform an ON / OFF signal for each channel

3

Observe whether the output channel acts as expected

4

Restore the input terminals to full operation

5

Remove the bypass from the safety PLC or otherwise restore normal

6

operation

This test will detect approximately 95% of possible “du” (dangerous undetected)

failures in the device. The proof test is equivalent to the functional test.

11. Procedures to repair or replace the product

Any failures that are detected and that compromise functional safety should

be reported to the sales department at PR electronics A/S.

Repair of the device and replacement of circuit breakers must be done by

PR electronics A/S only.

12. Maintenance

No maintenance required.

Version No. V3R0 5

Page 36

Safety Manual 9203 Solenoid / Alarm Driver

13. Documentation for routing diagram

The routing diagram is shown in section 16.2.

13.1 In general

When configuring the 9203, you will be guided through all parameters

and you can choose the settings which fit the application. For each

menu there is a scrolling help text which is automatically shown in line

3 on the display.

Configuration is carried out by use of the 3 function keys:

1 will increase the numerical value or choose the next parameter

2will decrease the numerical value or choose the previous parameter

3will accept the chosen value and proceed to the next menu

When configuration is completed, the display will return to the default

state 1.0.

Pressing and holding

default state (1.0) without saving the changed values or parameters.

If no key is activated for 1 minute, the display will return to the default

state (1.0) without saving the changed values or parameters.

13.2 Further explanations

13.2.1 Password protection

Access to the configuration can be blocked by assigning

a password. The password is saved in the device in order

to ensure a high degree of protection against unauthorised

modifications to the configuration. Default password 2008

allows access to all configuration menus.

Password protection is mandatory in SIL applications.

13.4 Advanced functions

The unit gives access to a number of advanced functions which can be

reached by answering “Yes” to the point “adv.set”.

3 will return to the previous menu or return to the

6 Version No. V3R0

Page 37

9203 Solenoid / Alarm Driver Safety Manual

13.4.1 Display setup

Here you can adjust the brightness contrast and the backlight.

Setup of tag numbers with 5 alphanumerics. Selection of

functional readout in line 2 and 3 of the display - choose between

readout of digital output or tag no. When selecting ”ALT” the

readout toggles between digital output and tag no.

13.4.2 Password

Here you can choose a password between 0000 and 9999 in

order to protect the device against unauthorised modifications

to the configuration. The device is delivered default without

password.

13.4.3 Language

In the menu ”LANG” you can choose between 7 different

language versions of help texts that will appear in the menu. You

can choose between UK, DE, FR, IT, ES, SE and DK.

13.4.4 Power rail

In the menu ”RAIL” you can choose if errors in the device are

transmitted to the central surveillance in the PR 9410 power

control unit.

13.4.5 Safety integrity level

See Safe parameterisation - user responsibility

Version No. V3R0 7

Page 38

Safety Manual 9203 Solenoid / Alarm Driver

14 Safe parameterisation - user responsibility

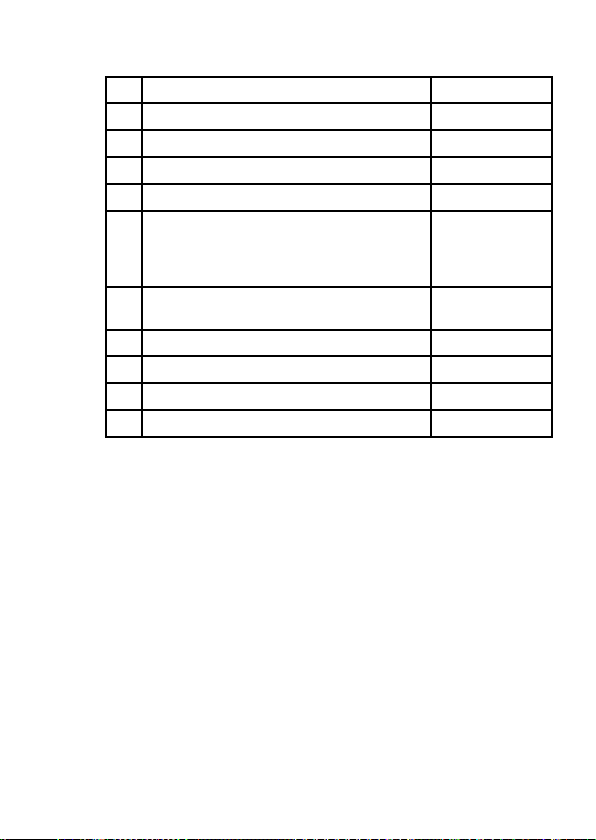

14.1 Safety-related configuration parameters

Parameters Value Description

CH1.FUN DIR / INV Direct / inverted channel function

CH2.FUN. DIR / INV Direct / inverted channel function

PASSW 0 - 9999 New password

The above safety-related configuration parameters are marked in red

text in the routing diagrams and must be verified by the user in a SILconfiguration.

14.2 Verification procedure

The verification is done using the display / programming front PR 4501

by following the procedure described below.

14.2.1 If no password is set

Action Display shows

1 Press OK ADV.SET

2 Set (ADV.SET) to Yes and press OK DISP SETUP

3 Step down to (SIL SETUP) and press OK EN.SIL

4 Set (EN SIL) to YES and press OK NEW.PASS

5 Set password to a number between 0 and

9999 and press OK

(At this time the device starts operating in

SIL mode with the entered configuration

parameters!)

6 Press OK to confirme verification of the

OPEN-LOCK in the display

7 Verify Channel 1 function and press OK CH2:FUN

8 Verify Channel 2 function and press OK PASSW

9 Verify password and press OK SIL.OK

10 Verify SIL and press OK

* Open is shown briefly in the display.

VerifyOPEN

”briefly”

LOCK*

CH1.FUN

8 Version No. V3R0

Page 39

9203 Solenoid / Alarm Driver Safety Manual

14.2.2 If password is set

Action Display shows

1 Press OK PASSW

2 Enter password and press OK ADV.SET

3 Set (ADV.SET) to Yes and press OK DISP SETUP

4 Step down to (SIL SETUP) and press OK EN.SIL

5 Set (EN SIL) to YES and press OK

(At this time the device starts operating in

SIL mode with the entered configuration

parameters!)

6 Press OK to confirme verification of the

OPEN-LOCK in the display

7 Verify Channel 1 function and press OK CH2:FUN

8 Verify Channel 2 function and press OK PASSW

9 Verify password and press OK SIL.OK

10 Verify SIL and press OK

VerifyOPEN

”briefly”

LOCK*

CH1.FUN

* Open is shown briefly in the display

14.3 Functional test

The user is responsible for making a functional test after verification of

safety parameters. The procedure for periodic proof test described in

section 10 shall be used.

15. Fault reaction and restart condition

When the 9203 detects a fault the output will go to Safe State, in which the

safety output will go to ”de-energised”.

For device faults there are 2 ways of bringing the device out of Safe State.

1. Power cycle the device.

2. Bring the device out of SIL mode (choose “NO” in the menu point ”EN.

SIL”), and set it back to SIL mode again (choose “YES” in the menu point

“EN.SIL” and verify the configuration).

Version No. V3R0 9

Page 40

Safety Manual 9203 Solenoid / Alarm Driver

16 User interface

16.1 Scrolling help texts in display line 3

[[01]

Set correct password

[02]

Enter advanced setup?

[06]

Enter language setup

Enter password setup

Enter display setup

Enter SIL setup

[07]

Select direct channel function

Select inverted channel function

[09]

Adjust LCD contrast

[10]

Adjust LCD backlight

[11]

Write a 5-character channel tag

[12]

Show output state in display

Show output load in display

Show tag in display

Alternate information shown in display

[13]

Configuration SIL status (Open / Locked)

[14]

Enable SIL configuration lock

[15]

Enable password protection?

[16]

Set new password

[17]

Select language

[20]

No communication - check connections

[21]

EEprom error - check configuration

[22]

Hardware error

10 Version No. V3R0

Page 41

9203 Solenoid / Alarm Driver Safety Manual

ROUTING DIAGRAM

If no key is activated for 1 minute, the display will return to the default

state 1.0 without saving configuration changes.

1 Increase value / choose next parameter

2 Decrease value / choose previous parameter

3 Accept the chosen value and proceed to the next menu

Hold 3 Back to previous menu / return to menu 1.0 without saving

3

Directly to [EN.SIL]

if SIL-lock is enabled

0000

9999

1 2

0000

PASSW.

Txt 1

1.1

3

NO

YES

1 2

NO

ADV.SET

Txt 2

YES

ADV.SET

Txt 2

DIR

INV

1 2

3

DIR

CH1.FUN

Txt 7

Continued on the page

3

Routing diagram ADV.SET

Power up

ON

OFF

1.0

1.0 = Default state

Linie 1 shows status for channel 1

and channel 2.

Linie 2 shows output status for

channel 1, output current or tag no.

Linie 3 shows output status for

channel 2, output current or tag no.

Line 4 indicates whether the module

is SIL-locked.

1.1 = Only if password-protected.

1.2 If password has been set.

Line 1 symbols:

= OK. Flashing = error.

Line 2 and 3 symbols:

ON = channel 1 ON

OFF channel 2 OFF.

Line 4 symbols:

Static dot = SIL-locked.

Flashing dot = Not SIL-locked.

= output is active.

DIR

INV

1 2

3

DIR

CH2.FUN

Txt 7

3

To default state 1.0

Version No. V3R0 11

Page 42

Safety Manual 9203 Solenoid / Alarm Driver

16.3 Routing diagram - Advanced settings (ADV.SET)

DISP,

PASS,

LANG,

SIL

1 2

DISP

SETUP

Txt 6

PASS

SETUP

Txt 06

LANG

SETUP

Txt 06

SIL

SETUP

Txt 06

9

0

1 2

3

3

CONTRA

Txt 9

YES

NO

1 2

3 3

YES

EN.PASS

Txt 15

DE, DK, ES, FR,

IT, SE, UK

1 2

3

UK

LANGUA

Txt 17

YES

NO

1 2

3

YES

EN.SIL

Txt 14

3

3

3

3

0000

NEW.PAS

NO

2008

NEW.PAS

NO

1.2

9

0

1 2

9

LIGHT

Txt 10

9999

0000

1 2

Txt 16

0000

9999

1 2

Txt 16

3

3

3

9

A

1 2

TAG1

VALVE 5

Txt 11

LOCK

OPEN

1 2

LOCK

CONFIG

Txt 13

9

A

1 2

3

TAG2

VALVE 6

Txt 11

3

3

Verify SIL configuration

3 3 3 3 3

. . . . . . . . . . . . . .

ALT

LOAD

TAG

D.OUT

1 2

3

LOAD

DISP

Txt 12

To default state 1.0

SIL.OK

12 Version No. V3R0

Page 43

9203 Solenoid / Alarm Driver Safety Manual

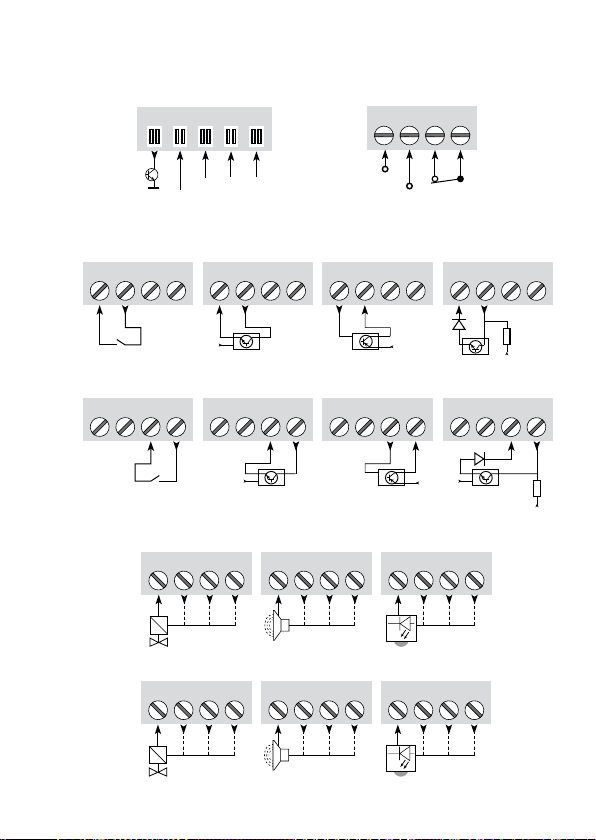

17 Connections diagram

Power rail

connections

91 92 93 94 95

Supply and

status relay

31 32 33 34

Error

NC = No connection

Switch PNP, switchNPN, switch

11 12 13 14

Channel 1

11 12 13 14

Channel 2

Solenoid, ON / OFF

Channel 1Channel 2

Solenoid, ON / OFF Acoustic alarm LED

+24 V

NCNCGnd.

Inputs:

11 12 13 14

V

+

Gnd.

11 12 13 14

+24 V

V

+

N.C.

Special PNP

11 12 13 14

D

Special PNP

11 12 13 14

V

+

11 12 13 14

11 12 13 14

V

+

V

+

Outputs:

Acoustic alarm LED

51 52 53 54 51 52 53 54 51 52 53 54

41 42 43 4441 42 43 44 41 42 43 44

trig input

V

trig inputSwitch PNP, switchNPN, switch

D

R

+

R

V

+

Version No. V3R0 13

Page 44

Displays

Programmable displays with a wide

selection of inputs and outputs for display of temperature,

volume and weight, etc. Feature linearisation, scaling,

and difference measurement functions for programming

via PReset software.

Ex interfaces

signals as well as HART

Interfaces for analogue and digital

®

signals between sensors / I/P

converters / frequency signals and control systems in Ex

zone 0, 1 & 2 and for some modules in zone 20, 21 & 22.

Isolation

digital signals as well as HART

Galvanic isolators for analogue and

®

signals. A wide product

range with both loop-powered and universal isolators

featuring linearisation, inversion, and scaling of output

signals.

Temperature

A wide selection of transmitters for DIN

form B mounting and DIN rail modules with analogue

and digital bus communication ranging from applicationspecific to universal transmitters.

Universal

PC or front programmable modules with

universal options for input, output and supply. This range

offers a number of advanced features such as process

calibration, linearisation and auto-diagnosis.

Page 45

www.prelectronics.fr

sales@prelectronics.fr

www.prelectronics.de

sales@prelectronics.de

www.prelectronics.es

sales@prelectronics.es

www.prelectronics.it

sales@prelectronics.it

www.prelectronics.se

sales@prelectronics.se

www.prelectronics.co.uk

sales@prelectronics.co.uk

www.prelectronics.com

sales@prelectronics.com

Head office

Denmark www.prelectronics.com

PR electronics A/S sales@prelectronics.dk

Lerbakken 10 tel. +45 86 37 26 77

DK-8410 Rønde fax +45 86 37 30 85

Loading...

Loading...