Prefect Control PRE9200, PRE9220, PRE9250, PRE9280 Installation Instructions Manual

Prefect Instructions

1

Prefect Control Ltd Unit 2, Church Field Business Park, Church Field Road, Sudbury, Suffolk, CO10 2YF

Tel: 01787 320 604 Fax: 0845 450 3020 Email: mail@prefectcontrols.com Website: www.prefectcontrols.com

Due to our policy of continuous improvement, we reserve the right to change specifications without notice

V1.1

IN-146

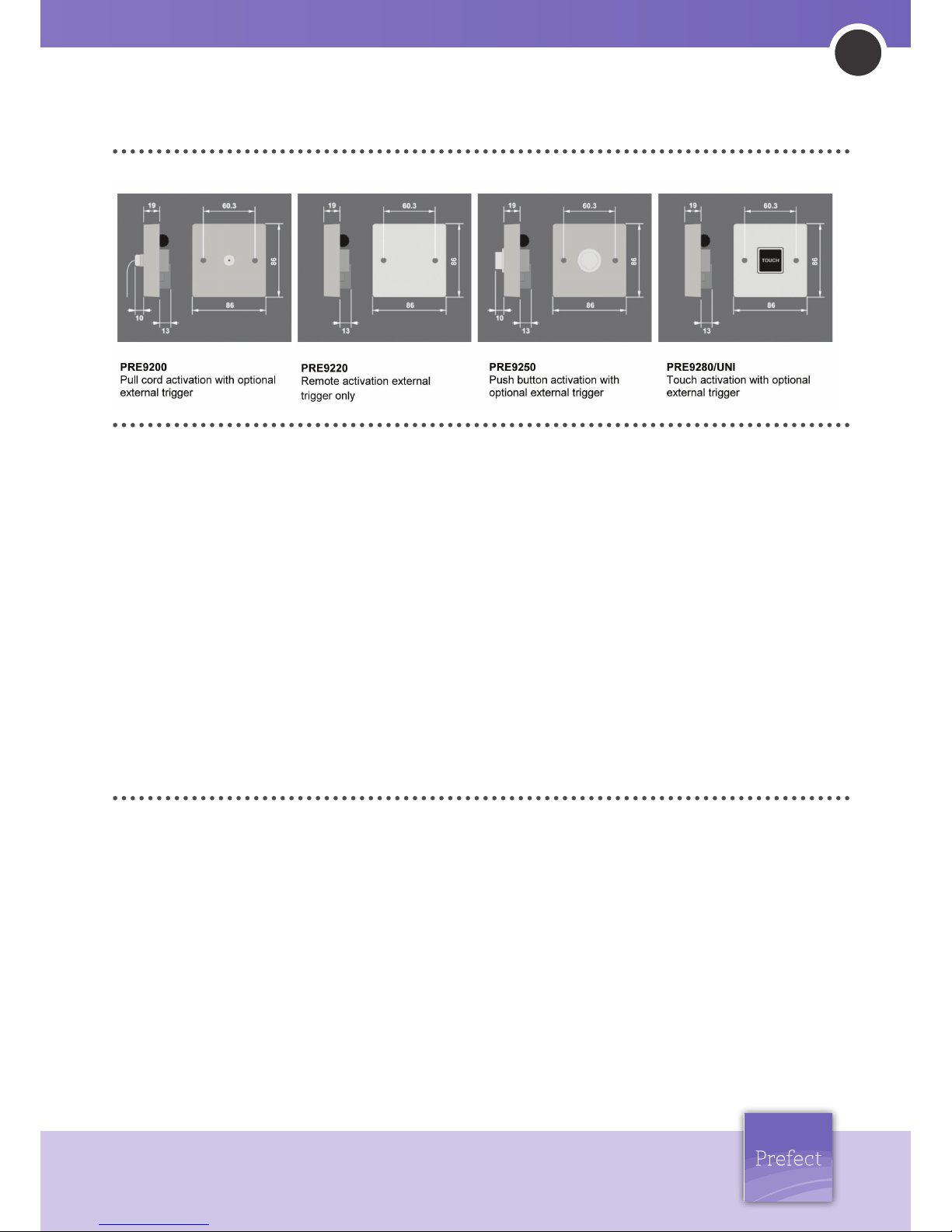

PRE9200, 9220, 9250, 9280UNI Run Back Timers

The PRE9200 series of time delay switches are designed to

provide timed control of lighting, heating or ventilation loads.

Using push button, touch (light press required), pull cord or

remote activation, the user can switch on a load for a preset

time period and have the load turn off automatically after the

time period has elapsed.

Multiple timing ranges come as standard to allow the time out

period to be set accurately. Time setting is achieved using

switches and a thumbwheel at the rear of the unit.

Several modes of operation are selectable using the switches:

• ON/OFF mode: Activating the timer will turn on the load and

start the timing. Activating the timer again during a timer run

will immediately turn off the load and stop the time run.when

a 230v trigger voltage is applied to the TRIG terminal the timer

will start. Disconnecting then reconnecting the trigger voltage

will then stop the timer.

• Resetting mode: activating the timer will turn on the load

and start the time run. Activating the timer again during an

exsisting time run will re-start the time run period from scratch.

When using an external trigger in this mode, the timer will not

start until the trigger is removed making it ideal for pump or

fan overrun applications.

• Non-resetting: Activating the timer will turn on the load and

start the time run. Triggering the timer again during a time

run will have no effect. Applying a 230v trigger to the TRIG

terminal will start the time run. whether the voltage remains or

is disconected the time run will complete.

Operation:

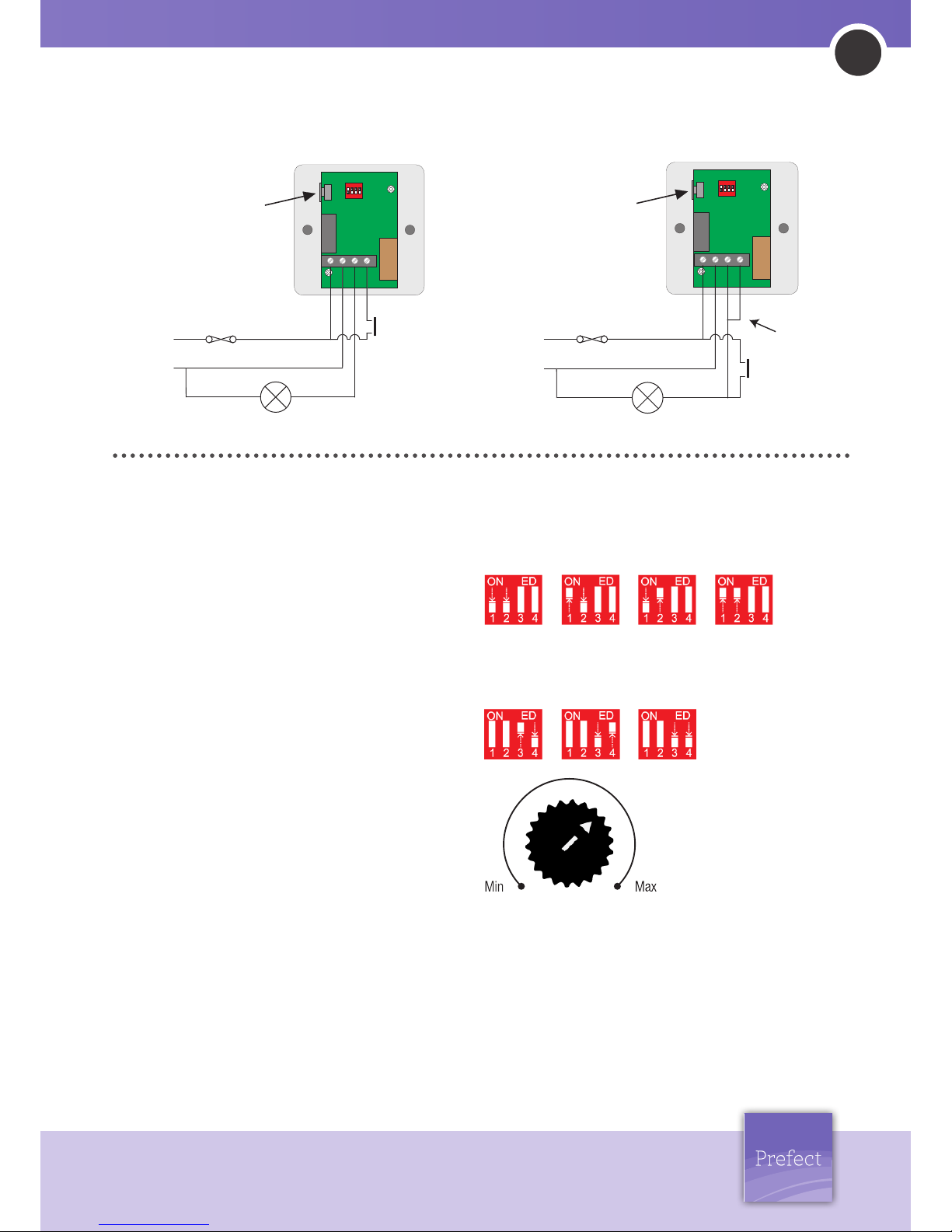

Wire the PRE9200 timers as in diagram 1. Connection to the

TRIG terminal is optional on all units except the PRE9220 remote

timer. Applying a live to the trigger terminal will start the timer

running. A momentary switch can be used, for example, in

corridor lighting applications. A permanent input can be used,

for example, in pump overrun applications.

To switch from more than one position simply wire two or more

units in parallel to achieve two way and intermediate switching,

or use the trigger terminal with a slave switch.

For lighting applications that call for the replacement of a three

wire switching system follow diagram 2. When installing touch

switches do not fix to a vibrating or uneven surface.

Installation Instructions:

Prefect Instructions

2

Prefect Control Ltd Unit 2, Church Field Business Park, Church Field Road, Sudbury, Suffolk, CO10 2YF

Tel: 01787 320 604 Fax: 0845 450 3020 Email: mail@prefectcontrols.com Website: www.prefectcontrols.com

Due to our policy of continuous improvement, we reserve the right to change specifications without notice

V1.1

IN-146

Installation Instructions Continued...

WARNING. This device works at mains potential. Be sure to take

care when working with electricity. Ensure all work complies

with relevant regulations in force at time of installation.

1. Perform safe ilsoation procedure of the appropriate cicuits

2. Connect the timer to the conductors

Live supply to the L terminal

Neutral to the N terminal

Load to the LIVE OUT terminal

Where required connect the external trigger to the TRIG

terminal.

3. Set the timing range according to the diagram opposite. For

example; if a timmming range of 100 minutes is required set

the switches to; 1 to 2 hours.

4. Set the thumb wheel to the precise time setting. the

thumbwheel adjusts between the time settings set by the

switches. Following the example above the wheel would need

to be set to a 2 o’clock position.

5. Double check all connections are correct & firmly fitted.

6. Ensuring the cabaling is not in a position to become damaged

fit the unit to the box

7. When safe to do so, switch the mains supply back on at the

distribution board.

Installation & Settings:

Diagram 1 Diagram 2

LOAD: 16 Amp resistive load 10 Amp incandescent lighting 6 Amp

fluorescent lighting 3 Amp compact fluorescent lighting 3 Amp

low energy lighting. 3 Amp low voltage lighting (switch primary of

transformer) Fluorescent lighting (max 6 fittings recommended). For

fluorescent lighting total power factor correction capacitance must

not exceed 40μF. 3 Amp fans and ventilation equipment . Switch

SON lighting loads via a contactor

SUPPLY VOLTAGE: 220-240 Volts AC 50 Hz

TIMING PERIOD: Adjustable 1 second to 2 hours in ranges

FIXING METHOD: Surface fixing 25mm deep plastic surface mount

moulded box. Flush fixing 25mm steel wall box or 32mm deep

cavity wall box.NOTE: When using a metal box ensure the top and

bottom lugs are removed from the box.

TERMINAL CAPACITY: 4.0mm2

MATERIAL: Flame retardant ABS

TYPE: Class 2

TEMPERATURE: -10°C to 35°C CONFORMITY EMC-89/336/EEC

TIMING

ADJUSTMENT

LIVE IN

NEUTRAL

LOAD

CIRCUIT PROTECTION

(IF REQUIRED)

SLAVE TRIGGER

LINK

43

ON

TIME

21

L

N

LIVE

OUT

TRIG

TIMING

ADJUSTMENT

LIVE IN

NEUTRAL

LOAD

CIRCUIT PROTECTION

(IF REQUIRED)

SLAVE TRIGGER

43

ON

TIME

21

L

N

LIVE

OUT

TRIG

1hour2hours

1sec5mins

15mins1hour

5mins15mins

Resetting

mode

non-resetting

mode

on/off

mode

The timming wheel selects

the run time. Clockwise turn

increases time, anti-clockwise

decreases time.

Loading...

Loading...