AFV-P Series

Programmable AC & DC Power Supply

User Manual

AC Power Corp. (Preen)

V 1.05.01EN

The information in this document is subject to change without notice.

© AC Power Corp. (Preen). All rights reserved

Contents

Legal Notices

The information in this product manual is subject to change without notice.

AC Power Corp. makes no warranty of any kind with regard to this user manual, including, but not limited to, the implied warranties of merchantability and fitness for

a particular purpose. AC Power Corp. shall not be held liable for errors contained

herein or direct, indirect, special, incidental or consequential damages in connection

with the furnishing, performance, or use of this material.

Copyright Notices. Copyright 2017 AC Power Corp. (Preen), all rights reserved. Reproduction, adaptation, or translation of this document without prior written permission is prohibited, except as allowed under the copyright laws.

Contents

Warranty

Preen’s AFV-P series is warranted against defects in material and workmanship for a

period of two year after date of shipment. Preen agrees to repair or replace any assembly or component found to be defective, under normal use during this period.

Preen’s obligation under this warranty is limited solely to repairing any such product

which in sole Preen’s opinion proves to be defective within the scope of the warranty when returned to the factory or to an authorized service center. Transportation to

the factory or service center is to be prepaid by the purchaser. Shipment should not

be made without prior authorization by Preen.

This warranty does not apply to any products repaired or altered by persons not authorized by Preen, or not in accordance with instructions furnished by Preen. If the

product is defective as a result of misuse, improper repair, or abnormal conditions or

operations, repairs will be billed at cost.

Preen assumes no responsibility for its product being used in a hazardous or dangerous manner either alone or in conjunction with other equipment. High voltage

used in some products may be dangerous if misused. Special disclaimers apply to

these products. Preen assumes no liability for secondary charges or consequential

damages and in any event, Preen’s liability for breach of warranty under any contract or otherwise, shall not exceed the purchase price of the specific product

shipped and against which a claim is made.

Any recommendations made by Preen for use of its products are based upon tests

believed to be reliable, but Preen makes no warranty of the results to be obtained.

This warranty is in lieu of all other warranties, expressed or implied, and no representative or person is authorized to represent or assume for Preen any liability in

connection with the sale of our products other than set forth herein.

AC Power Corp. (Preen)

USA

192 Technology Dr., Suite S, Irvine, CA 92618

TEL +1 949-988-7799

Taipei

3F No. 200 Gangqian Road, Neihu Dist., Taipei 114, Taiwan

TEL +886 2-2627-1899 FAX +886 2-2627-1879

Contents

WARNING

LETHAL VOLTAGES. The product can supply 440V peak at its output. DEATH on

contact may result if either the output terminals or the output circuits connected

to the output are touched when the product output is on.

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation, service, and repair of this product. Failure to comply with these precautions

or specific WARNINGS given elsewhere in this manual will violate safety standards of

design, manufacture, and intended use of the product.

Preen assumes no liability for the customer‘s failure to comply with these requirements.

BEFORE APPLYING POWER

Verify that the product is set to match with the power line input.

PROTECTIVE GROUNDING

Make sure to connect the product to the protective ground to prevent an electric

shock before turning on the power.

NECESSITY OF PROTECTIVE GROUNDING

Never cut off the internal or external protective grounding wire, or disconnect the

wiring of protective grounding terminal. Doing so will cause a potential shock hazard

that may bring injury to a person.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the product in the presence of flammable gases or fumes.

DO NOT REMOVE THE COVER OF THE PRODUCT

Personnel who operate the product must not remove the cover of the product.

Component replacement and internal adjustment can be done only by qualified service personnel.

Contents

Table of Contents

1 GENERAL INFORMATION ............................................................................................... 1

1.1 Introduction .................................................................................................... 1

1.2 Key Features .................................................................................................... 2

1.3 Specifications .................................................................................................. 3

1.4 Exterior ........................................................................................................... 5

1.5 Name of Parts ................................................................................................. 6

2 INSTALLATION .................................................................................................................. 9

2.1 Inspection ....................................................................................................... 9

2.2 User Preparation ............................................................................................. 9

2.3 Input Connection ............................................................................................. 9

2.4 Output Connection ......................................................................................... 10

2.5 Remote Sense Connection .............................................................................. 11

2.6 Power-on Procedures ..................................................................................... 12

2.7 Product Handle Installation ............................................................................ 13

2.8 Interface Card Installation .............................................................................. 13

2.8.1 RS232/RS485 9-Pin D-Type Connector ....................................................................... 14

2.8.2 PLC Remote In & Out Connector ................................................................................ 14

3 LOCAL OPERATION ....................................................................................................... 16

3.1 General .......................................................................................................... 16

3.2 Operation via the Touch Screen and the Rotary Knob ............................................. 16

3.3 MAIN Page ..................................................................................................... 18

3.3.1 Output Voltage Range ................................................................................................. 19

3.4 MENU Page .................................................................................................... 20

3.5 SETTINGS Page ............................................................................................... 21

3.5.1 TESTING Subpage (ADVANCED Mode) ........................................................................ 21

3.5.2 TESTING Subpage (BASIC Mode) ................................................................................ 31

3.5.3 SYSTEM Subpage ......................................................................................................... 37

3.6 COMMUNICATION Page .................................................................................. 43

3.6.1 ETHERNET Subpage .................................................................................................... 43

Contents

3.6.2 GENERAL Subpage ...................................................................................................... 44

3.6.3 GENERAL Subpage with GPIB interface (optional) ..................................................... 45

3.7 RESULTS Page ................................................................................................. 46

3.8 WAVE Page ..................................................................................................... 47

3.9 METER Page ................................................................................................... 49

3.10 INFORMATION Page...................................................................................... 51

3.11 Protection .................................................................................................... 52

4 CALIBRATION ................................................................................................................. 54

4.1 HI-Range Voltage 310V ................................................................................... 56

4.2 LO-Range Voltage 155V .................................................................................. 57

4.3 HI-Range Voltage 60V ..................................................................................... 58

4.4 LO-Range Voltage 60V .................................................................................... 59

4.5 HI-Range RMS Current .................................................................................... 62

4.6 LO-Range RMS Current ................................................................................... 63

4.7 Peak Current .................................................................................................. 64

4.8 Output Socket Current (Specialize for AFV-P-5000) .......................................... 66

5 PROGRAMMABLE FEATURES .................................................................................... 68

5.1 General .......................................................................................................... 68

5.2 STEP Feature .................................................................................................. 72

5.3 RAMP Feature ................................................................................................ 82

5.4 TRANSIENT Feature ........................................................................................ 84

6 THEORY OF OPERATION ............................................................................................. 87

7 REMOTE OPERATION ................................................................................................... 88

7.1 General .......................................................................................................... 88

7.2 Remote Control Software: General Mode ....................................................... 90

7.3 Remote Control Software: Program Mode ...................................................... 93

7.4 Remote Control Software: Additional Features ............................................... 95

AFV-P Series User Manual

NOTICE

If the Power Factor (PF) corresponding to the AC output is less than 0.65, 100%

output current can be achieved under 0%-100% output voltage, which can be ap-

plied to any product model and any output voltage range of the product.

1 General Information

1.1 Introduction

Preen’s AFV-P series is a programmable AC power supply with DC output and precision measurements. This compact power supply comes in four power levels, 600VA,

1250VA, 2500VA and 5000VA, which provides stable output voltage and output frequency with low distortion. The PWM design of power stage allows for full

volt-ampere into loads. The front panel has both touch screen and rotary knob for

setting the product output, which provide an easy operation and measurement

reading display. Remote control for the product can be accomplished selectively via

RS232, RS485, Ethernet, USB or GPIB.

The following figures show the V/I curve according to the AC & DC output of the

product, which can be applied to any product model and any output voltage range of

the product.

Figure 1.1 V/I curve for the AC output of the product

1

AFV-P Series User Manual

Figure 1.2 V/I curve for the DC output of the product

1.2 Key Features

A. Configuration

1. Local operation via the touch screen and the rotary knob on the front panel.

2. Remote control via RS232, RS485, Ethernet, USB or GPIB.

3. Protection for OVP, LVP, OCP, OPP, OTP, RCP, Fan Fail and AMP Fail.

4. Temperature-controlled fan speed.

B. Input / Output

1. Selective output voltage range with full scale 310V/Auto.

2. Universal input voltage range 98~132VAC/196~264VAC.

3. Wide output voltage from 0 to 310VAC & output frequency from 15 to 1000Hz.

4. Measurement readings of V, I, P, VA , VAR, f, Ipk, CF and PF.

5. Output of Synchronized signal.

2

AFV-P Series User Manual

Model

AFV-P-600

AFV-P-1250

AFV-P-2500

AFV-P-5000

AC Input

Phase

Single

Input Voltage Range

98-132Vac/196-264Vac

196-264Vac/175-235Vac

Input Frequency

47~63Hz

Max. Current

10A

20A

20A

40A

AC Output

Power (VA)

600VA

1250VA

2500VA

5000VA

Power (W)

500W

1000W

2000W

4000W

Phase

1ϕ /2 Wire + G

Voltage Range

0-155V

rms

/0-310V

rms

Voltage Resolution

0.1V

rms

Frequency

40-500Hz (opt. 15-1000Hz)

Frequency

Resolution

0.1Hz, at 15-100Hz; 1Hz, at 100-1000Hz

Max. Current (RMS)

5A/2.5A

10A/5A

20A/10A

40A/20A

Max. Current (Peak)

22.5A/11.3A

45A/22.5A

90A/45A

180A/90A

Total Harmonic

Distortion (THD)

0.3%, at 40-100Hz; 0.5%, at 101-500Hz; 0.8%, at 501-1000Hz

(Resistive Load)

Line Regulation

0.1V

Load Regulation

0.07% F.S (Resistive Load)

Response Time

300s

Crest Factor

3

Inrush Current

4.5 peak current/RMS current

DC Output

Power

300W

600W

1250W

2500W

Voltage Range

0-210V/0-420V

Max. Current

2.5A/1.25A

5A/2.5A

10A/5A

20A/10A

Ripple & Noise (RMS)

0.15%

0.24%

Measurement

Voltage Range

0-420V

Voltage Accuracy

(0.2% of Reading + 5 Counts)

Voltage Resolution

0.1V

1.3 Specifications

Technical specifications of product are listed below. All specifications have been

tested according to Preen’s standard test procedures.

3

AFV-P Series User Manual

Frequency Range

15-1000Hz

Frequency Accuracy

0.1Hz at 40-500Hz;

0.2Hz at 501-1000Hz

Frequency Resolution

0.1Hz

Current Range

Hi: 1-12A/

Lo: 0.005-1.2A

Hi: 2-24A/

Lo: 0.005-2.4A

Hi: 0.05-48A

Current Accuracy

(1% of Reading + 5 Counts), at 40-500Hz;

(1% of Reading + 10 Counts), at 501-1000Hz

Current Resolution

Hi: 0.01A/Lo: 0.001A

Hi: 0.01A

Peak Current Range

0-45A

0-90A

0-180A

Peak Current Accuracy

(1% of Reading + 5 Counts), at 40-500Hz;

(1% of Reading + 10 Counts), at 501-1000Hz

Peak Current Resolution

0.1A

Power Range

Hi: 100-1200W/

Lo: 0-120W

Hi: 200-2400W/

Lo: 0-240W

Hi: 0-4800W

Power Accuracy

(2% of Reading + 10 Counts), at 40-500Hz;

(2% of Reading + 15 Counts), at 501-1000Hz

Power Resolution

Hi: 1W/Lo: 0.1W

Hi: 1W

General

Efficiency

77% at Max. Power

80% at Max. Power

Protection

OVP, LVP, OCP, OPP, OTP, RCP, Fan Fail and AMP Fail

Remote Interface

Standard: RS232/RS485/Ethernet/USB/PLC Remote In & Out;

Option: GPIB/Analog Control

Over Current Foldback

Constant Current (CC) Mode

Synchronized Signal

ON Mode (5V DC Signal) or EVENT Mode (5V DC Pulse Signal)

Memories

50 Memory Sets & 1200 Steps (24 Steps/Memory Set)

Operating Temperature

0-40C

Dimensions

(H×W×D) (mm3)

89×442×450

89×442×600

222.5×442×600

Weight

Approx. 16kg

Approx. 20kg

Approx. 31.3kg

Approx. 70kg

All specifications are subject to change without notice

Table 1.1 Technical specifications

4

AFV-P Series User Manual

1.4 Exterior

Product exterior of the AFV-P series are given as follows,

(a) Front-side view of the AFV-P series.

(b) Right-side view of the AFV-P series.

Figure 1.3 Product exterior of the AFV-P series

Figure 1.4 Product exterior of the AFV-P series in axis-side view

5

AFV-P Series User Manual

Item

Name

Description

1

Power Switch

Press this switch to turn on/ turn off the product.

2

Touch Screen

Input programming data or options by manipulating the

touch screen to the desired one.

3

Rotary Knob

Input programming data or options by turning the rotary

knob to the desired one.

4

Output & Reset Button

Press this button to enable/disable the product output.

1.5 Name of Parts

A. Front Panel

Figure 1.5 Front panel

B. Rear Panel

Figure 1.6 Rear panel (for the product model of AFV-P-600)

6

AFV-P Series User Manual

Figure 1.7 Rear panel (for the product models of AFV-P-1250)

Figure 1.8 Rear panel (for the product models of AFV-P-2500)

Figure 1.9 Rear panel (for the product model of AFV-P-5000)

7

AFV-P Series User Manual

Item

Name

Description

5

AC Output Socket

This socket is used to output AC power to the load.

6

Output Terminals

These terminals can output AC & DC power to the load.

7

Remote Sense Connector

This connector senses directly at the terminals of the load to

compensate any voltage drop on the connecting cable.

NOTICE: Make sure to connect the terminal “SL” of the remote

sense connector to the terminal “L” of the load, and connect

the terminal “SN” of the remote sense connector to the ter-

minal “N” of the load. Notice that reverse polarity is not al-

lowed. 8 USB Interface

This interface is used for remote control via the USB cable.

9

RS232/RS485 Interface

This interface is used for remote control via the RS232/RS485

cable

10

Ethernet Interface

This interface is used for remote control via the Ethernet ca-

ble.

11

Input Voltage Selector

Verify this selector is switching to the position (either 115V or

230V) matching the input voltage.

NOTICE: This selector is specialized for the product models of

AFV-P-600 and AFV-P-1250.

12

PLC Remote In & Out

These interfaces are used for remote control via the PLC pro-

gramming cable.

13

USB Interface

The interface is used for firmware update via the USB cable.

14

Synchronized Signal I/O

This I/O is used to output synchronized signal via the BNC ca-

ble.

15

Input Terminals

(AC Inlet)

These terminals are used to connect the product with the

power line input.

NOTICE: These terminals are replaced by the AC inlet for the

product model of AFV-P-600.

8

AFV-P Series User Manual

WARNING

Protective Grounding. To protect users, the wire connected to terminal “G” (that

is GND) must be connected to the earth ground. Under no circumstances shall

this product operated without an adequate protective grounding connection.

2 Installation

2.1 Inspection

After unpacking the product, please inspect any damage that may have occurred

during the shipment. Save all packing materials in case the product has to be returned one day.

If any damage is found, please file a claim with the carrier immediately. Do not return

the product to the factory without obtaining the prior Return Merchandise Authorization (RMA) acceptance from Preen.

2.2 User Preparation

In the beginning, the product must be connected to an appropriate power line input.

Then, since fans intelligently cool it, it must be installed in sufficient space for circulation of air. It should be used in an area where the ambient temperature does not ex-

ceed 40C.

2.3 Input Connection

The input terminals are located on the rear panel of the product (see Figure 2.1). The

input power cord must be rated at least for 85C. The input power cord must have

rated current which is greater than or equal to the maximum input rated current of

the product.

See Figure 2.1 and do the following procedures step by step:

1. Remove the safety cover from the rare panel of the product.

2. Screw the power cord to the input terminals of the product as follows,

2.1 green or yellow wire to the terminal “G” of the input terminals;

2.2 white or blue wire to the terminal “N” of the input terminals; and

2.3 black or brown wire to the terminal “L” of the input terminals.

3. Slip the safety cover over the input terminals, and secure the cover with two

screws.

9

AFV-P Series User Manual

NOTICE

When output voltage contains DC composition, Terminal “L” of the output ter-

minals indicates the “+” terminal; terminal “N” of the output terminals indi-

cates the “-” terminal.

Installation of the power cord to the product must be done by a professional and in

accordance with local electrical codes.

Figure 2.1 Input terminals

2.4 Output Connection

The output terminals are located on the rear panel of the product (see Figure 2.2).

The terminals “N” and “L” of the output terminals are connected to the load. To

match the safety requirements, the safety cover for the output terminals must be

fastened. The wires to the load must be sufficiently large gauges, so they will not

overheat while carrying the output current.

Figure 2.2 Output terminals

Figure 2.3 Output terminals to the load

10

AFV-P Series User Manual

2.5 Remote Sense Connection

The product supports remote sense function, which monitors the voltage at the load

instead of the output terminal of the product. It ensures the delivery of accurate

voltage as programmed at the load by automatically compensating the output voltage drop over the connecting cable.

Remove the iron chip from the terminals “SN” and “SL” of the remote sense connector,

and connect the terminals of the remote sense connector to the corresponding terminal of the load. Because the sensing leads carry only a few millamperes, the sensing leads are much lighter than the load leads. The sensing leads are part of the

feedback path of the product, so they must be kept at a low resistance in order to

maintain the best performance. The sensing leads must be connected to the load

carefully, so that they will not be open-circuited. If the sensing leads are left unconnected or become open-circuited during operation, the product will disable the output. The sensing leads must be a twisted pair to minimize the pickup of external

noise. The sensing leads need to be connected to the load as close as possible.

Figure 2.4 Remote sense connector

11

AFV-P Series User Manual

WARNING

Before turning on the product, all protective grounding terminals, extension

cords, and devices connected to the product must be connected to a protective

ground. Any interruption of the protective ground will cause a potential shock

hazard that could result in personal injury.

2.6 Power-on Procedures

Apply power and press the power switch to turn on the product, then the touch

screen located on the front panel will light up and display the POWER-ON page

shown as below,

Figure 2.5 POWER-ON page

After displaying the POWER-ON page, the MAIN page is continuously shown on the

touch screen as follows, and then users can input programming data or options by

either manipulating the touch screen or turning the rotary knob.

Figure 2.6 MAIN page

12

AFV-P Series User Manual

2.7 Product Handle Installation

To install the handles to the right-side and the left-side of the product, please refer to

the Figure 2.7 to fix the handles to the product with eight screws.

Figure 2.7 Product handle

2.8 Interface Card Installation

To install the interface card or replace the standard interface card with optional interface card, please refer to the Figure 2.8 to install or replace the interface card with

two screws.

Figure 2.8 Interface Card

13

AFV-P Series User Manual

Figure 2.9 RS232/RS485 9-Pin D-Type

female connector

Pin NO.

Definition

1

No Connection

2

RS232 TX

3

RS232 RX

4

No Connection

5

GND

6

No Connection

7

RS485 D+

8

RS485 D-

9

No Connection

Figure 2.10 PLC remote input male

connector

Pin NO.

Definition

1

No Connection

2

RS232 TX

3

RS232 RX

4

No Connection

5

GND

6

No Connection

7

RS485 D+

8

RS485 D-

9

No Connection

2.8.1 RS232/RS485 9-Pin D-Type Connector

To remotely control the product output via the interface RS232 or RS485, please

connect a computer with the product via the RS232/RS485 9-pin D-type connector

according to the following instructions.

The definition for the pins of the RS232/RS485 9-pin D-type female connector is given as follows:

2.8.2 PLC Remote In & Out Connector

To remotely control the product output via the PLC remote interface, please connect

a computer with the product via the PLC remote In & Out connector according to the

following instructions.

The definition for the pins of the PLC remote input male connector is given as follows,

14

AFV-P Series User Manual

Figure 2.11 PLC remote output

female connector

Pin NO.

Definition

1

Pass

2

Pass

3

Fail 4 Fail

5

Processing

6

Processing

7

No Connection

8

No Connection

9

No Connection

The definition for the pins of the PLC remote output female connector is given as

follows:

15

AFV-P Series User Manual

3 Local Operation

3.1 General

The product can support local operation or remote operation. The remote operation

enabled via complete communication interfaces, such as RS232, RS485, Ethernet,

USB or GPIB will be described in Chapter 8. In this section, the local operation enabled via the touch screen and the rotary knob on the front panel will be described.

The product is configured for local operation when it is turned on.

3.2 Operation via the Touch Screen and the Rotary Knob

The product provides the user-friendly programming interface using the touch screen

and rotary knob on the front panel for users. Each display of the touch screen on the

product represents an operational page.

Before describing each operational page, the followings show how to use touch

screen and rotary knob to input programming data or options. When the power-on

procedures are finished (refer to Subsection 2.6), the touch screen will display the

MAIN page subsequently.

A. Touch Screen

Press the item shown on the touch screen directly, so as to choose the desired item

(see Figure 3.1). Use the virtual numeric and decimal keys to set value, and then

press the icon on the touch screen to confirm. After setting value, users can

revise value by pressing the icon , or press the icon to return to the

previous page.

Figure 3.1 Press the desired item on the touch screen

16

AFV-P Series User Manual

Figure 3.2 Virtual numeric and decimal keys

B. Rotary Knob

Turn the rotary knob on the front panel to move the cursor shown on the touch

screen, and press the rotary knob to choose the desired item. After choosing the desired item, continue to turn the rotary knob to set value, and then press the rotary

knob to confirm.

Figure 3.3 Move the cursor on the touch screen by turning the rotary knob

17

AFV-P Series User Manual

3.3 MAIN Page

When users turn on the product, the touch screen shows the MAIN page after the

power-on procedures. The MAIN page shows the output settings and the measurement readings of the product output. Users can set output value by using the touch

screen or the rotary knob (refer to Subsection 3.2), and then press the output & reset

button on the front panel to enable the output of the product. Please see the following figures:

Figure 3.4 MAIN page when the product output is off

Figure 3.5 MAIN page when the product output is on

The description for the items and the icons on the MAIN page are given as follows:

1) : Press to set the output voltage.

2) : Press to set the maximum rated current.

3) : Press to set the output frequency.

4) : Press to set the maximum rated power.

5) : Press to enter into the MENU page.

18

AFV-P Series User Manual

NOTICE

When the product output is off, the upper-right side of the MAIN page will be the

icon ; when the product output is on, the upper-right side of the MAIN

page will be the icon .

6) : Press to enter into the METER page.

7) : Press to enter into the PROGRAMMABLE page.

8) / : Press to set the output voltage range, with two options of HIGH

and AUTO.

9) / : Shown the status of the output or the error code.

10) : Press to lock/unlock the operation of the touch screen, and only

allow pages to switch between the MAIN page and the METER page when

the operation of the touch screen is locked.

11) : Press to enter into the WAVE page.

3.3.1 Output Voltage Range

The product supplies full output voltage range with two options of HIGH and AUTO.

Users can press the icon / to set output voltage range at the MAIN page.

HIGH indicates that the maximum output voltage will be 310V; AUTO indicates that

the maximum output voltage switches automatically between 155V and 310V as re-

quired.

19

AFV-P Series User Manual

Figure 3.6 Set the output voltage range from HIGH to AUTO

3.4 MENU Page

If the MAIN page is shown on the touch screen, users can press the icon to

enter into the MENU page. Please see the following figures,

Figure 3.7 MENU page 1 Figure 3.8 MENU page 2

The description for the icons at the MENU page is given as follows:

1) : Press to enter into the SETTINGS page.

2) : Press to enter into the PROGRAMMABLE page.

3) : Press to enter into the COMMUNICATION page.

4) : Press to enter into the RESULTS page.

5) : Press to enter into the WAVE page.

20

AFV-P Series User Manual

6) : Press to enter into the METER page.

7) : Press to enter into the INFORMATION page.

8) : Press to return to the MAIN page.

9) : Press to return to the previous page.

10) : Press to move to the previous page of the MENU page.

11) : Press to move to the next page of the MENU page.

3.5 SETTINGS Page

If the MENU page is shown on the touch screen, users can press the icon to

enter into the SETTINGS page, and the SETTINGS page includes two subpages: the

TESTING subpage and the SYSTEM subpage.

3.5.1 TESTING Subpage (ADVANCED Mode)

After pressing the icon to enter into the SETTINGS page, the TESTING sub-

page at the ADVANCED mode will be shown on the touch screen in advance, and the

ADVANCED mode is the default operational mode. Please see the following figures:

Figure 3.9 TESTING subpages 1 & 2 (ADVANCED mode)

21

AFV-P Series User Manual

Figure 3.10 TESTING subpage 3 & 4 (ADVANCED mode)

The description for the items and the icons at the TESTING subpage (ADVANCED

mode) are given as follows:

1) : Press to set the operational mode, with two options

of ADVANCE and BASIC.

2) : Press to set the output mode, with two options of

AC and DC.

3) : Press to enable/disable the over current foldback,

with two options of OFF and ON.

4) : Press to set the start angle, with options from 0 to

359.

5) : Press to set the end angle, with options from 0 to

359.

6) : Press to set the power-on status, with three options

of OFF, ON and LAST.

7) : Press to set the voltmeter point, with two options of

INT and EXT.

8) : Press to enable/disable the fail stop feature, with

two options of OFF and ON.

22

AFV-P Series User Manual

NOTICE

The present operational mode can be seen on the lower-left side of the touch

screen (that is, the icon / ). Users can set the operational

mode from the default ADVANCED mode to the BASIC mode by pressing the icon

twice at the TESTING subpage 1 on the touch screen. The

detailed description of the BASIC mode will be given in Section 3.5.2.

9) : Press to enable/disable the consecutive step feature,

with two options of ON and OFF.

10) : Press to enable/disable the synchronized signal,

with three options of EVENT, OFF and ON.

11) : Press to move to the previous page of the TESTING subpage.

12) : Press to move to the next page of the TESTING subpage.

23

AFV-P Series User Manual

3.5.1.1 Output Mode (AC or DC)

At the TESTING subpage 1 (ADVANCED mode), users are allowed to set the output

mode with two options of AC and DC, so as to fit their application. Then, the MAIN

page will change correspondingly according to the output mode.

Figure 3.11 MAIN page when the output mode is AC

Figure 3.12 MAIN page when the output mode is DC

The procedures of setting the output mode from AC to DC are given as below:

1. Press the item twice to set the output mode from AC

to DC.

2. Press the icon to confirm.

24

AFV-P Series User Manual

Figure 3.13 Set the output mode from AC to DC (ADVANCED mode)

3.5.1.2 Over Current Foldback

At the TESTING subpage 1 (ADVANCED mode), users are allowed to enable the over

current foldback. When the output current exceeds the maximum rated current, and

the over current foldback is enabled, the product can automatically control the output voltage to maintain the output current at the maximum rated current.

The procedures of enabling the over current foldback are given as below:

1. Press the item twice to switch the icon status from

OFF to ON.

2. Press the icon to confirm and enable the over current foldback.

Figure 3.14 Enable the over current foldback (ADVANCED mode)

3.5.1.3 Output Phase Angle

At the TESTING subpage 2 (ADVANCED mode), users are allowed to set the output

phase angel with options from 0 to 359 by using the touch screen and the rotary

knob (refer to Subsection 3.2). In other words, the product can control the output

phase angle (that is, the start angle and the end angle) of the output waveform.

Firstly, the procedures of setting the start angle from 0 to 90 by using the virtual

25

AFV-P Series User Manual

numeric keys are given as below:

1. Press the item to use the virtual numeric keys to set

the value of 90.

2. Press the icon to confirm.

Figure 3.15 Set the start angle from 0 to 90 (ADVANCED mode)

Secondly, the procedures of setting the end angle from 0 to 270 by using the virtual

numeric keys are given as below:

1. Press the item to use the virtual numeric keys to set

the value of 270.

2. Press the icon to confirm.

Figure 3.16 Set the end angle from 0 to 270 (ADVANCED mode)

26

AFV-P Series User Manual

3.5.1.4 Power-on Status

At the TESTING subpage 2 (ADVANCED mode), users are allowed to set the power-on

status with three options of OFF, ON and LAST. OFF indicates that the output is off

after turning on the product; ON indicates that the output is on after turning on the

product; LAST indicates that if the output remains on while turning off the product

previously, the output is on after turning on the product currently, otherwise, the

output is off after turning on the product currently.

The procedures of setting the power-on status are given as below:

1. Press the item repeatedly to switch the icon status

from OFF to either ON or LAST.

2. Press the icon to confirm.

Figure 3.17 Three options of the power-on status (ADVANCED mode)

3.5.1.5 Synchronized Signal

At the TESTING subpage 4 (ADVANCED mode), users are allowed to enable the synchronized signal. There are three options of the synchronized signal: EVENT, OFF, and

ON, and the default option is EVENT. EVENT indicates that the product outputs a 5V

DC pulse signal when the product output changes; OFF indicates that the synchronized signal is disabled; ON indicates that the product continuously outputs a 5V DC

signal when the product output is on, and stop the 5V DC signal when the product

output is off.

27

AFV-P Series User Manual

Figure 3.18 Three options of the synchronized signal (ADVANCED mode)

3.5.1.6 Voltage Sense

There are two options for users to set the voltmeter point: INT and EXT, and the default option is INT. INT indicates that the voltmeter point is located at the terminals

“N” and “L” of the output terminals of the product; EXT indicates that the voltmeter

point is located at the terminals “SN” and “SL” of the output terminals.

The procedures of setting the voltmeter point from INT to EXT are given as below:

1. Press the item twice to switch the icon status from

INT to EXT.

2. Press the icon to confirm.

Figure 3.19 Set the voltmeter point from INT to EXT (ADVANCED mode)

28

AFV-P Series User Manual

NOTICE

When the voltmeter point is set to be EXT, but the terminals “SL” and “SN” are not

connected to the load, the Low Voltage Protection (LVP) will be triggered after the

output is on.

Figure 3.20 The MAIN page when LVP is triggered

3.5.1.7 Other Settings

At the TESTING subpage 3 (ADVANCED mode), users are allowed to enable the fail

stop feature and the consecutive step feature.

A. Fail Stop Feature

There are two options of the fail stop feature: OFF and ON, and the default option is

OFF. OFF indicates that the product will continue the output when the measurement

readings exceed the rated values; ON indicates that the product will stop the output

when the measurement readings exceed the rated values.

The procedures of enabling the fail stop are given as below:

1. Press the item twice to switch the icon status from

OFF to ON.

2. Press the icon to confirm and enable the fail stop feature.

Figure 3.21 Enable the fail stop feature (ADVANCED mode)

29

AFV-P Series User Manual

B. Consecutive Step Feature

There are two options of the consecutive step feature: ON and OFF, and the default

option is ON. ON indicates that each Step and Memory Set will be continuously performed without any HINT page when the PROGRAMMABLE feature is performed;

OFF indicates that the HINT page will be displayed between each Step of the Memory

Set for users to confirm when the PROGRAMMABLE feature is performed.

The procedures of disabling the consecutive step are given as below:

1. Press the item twice to switch the icon status from

ON to OFF.

2. Press the icon to confirm and disable the consecutive step feature.

Figure 3.22 Disable the consecutive step feature (ADVANCED mode)

Figure 3.23 HINT page

30

AFV-P Series User Manual

3.5.2 TESTING Subpage (BASIC Mode)

If the operational mode is set to be the BASIC mode, the TESTING subpage at the

BASIC mode will be shown on the touch screen after entering into the SETTINGS page.

The manner of setting the operational mode can be referred to Section 3.5.1. Please

see the following figures,

Figure 3.24 TESTING subpages 1 & 2 (BASIC mode)

Figure 3.25 TESTING subpages 3 & 4 (BASIC mode)

The description for the items and the icons at the TESTING subpage (BASIC mode) are

given as follows,

1) : Press to set the operational mode, with two options

of ADVANCE and BASIC.

2) : Press to set the output mode, with two options of

AC and DC.

3) : Press to enable/disable the over current foldback,

with two options of OFF and ON.

4) : Press to set the start angle, with options from 0 to

359.

31

AFV-P Series User Manual

5) : Press to set the end angle, with options from 0 to 359.

6) : Press to set the power-on status, with three options of OFF,

ON and LAST.

7) : Press to set the voltmeter point, with two options of INT and

EXT.

8) : Press to set the maximum rated voltage, with options from

0V to 310V.

9) : Press to set the minimum rated voltage, with options from

0V to 310V.

10) : Press to enable/disable the synchronized signal, with three

options of EVENT, OFF and ON.

11) : Press to set the maximum rated frequency, with options

from 40Hz to 500Hz (opt. from 15Hz to 1000Hz).

12) : Press to set the minimum rated frequency, with options

from 40Hz to 500Hz (opt. from 15Hz to 1000Hz).

13) : Press to move to the previous page of the TESTING subpage.

14) : Press to move to the next page of the TESTING subpage.

3.5.2.1 Output Mode (AC or DC)

There are two output mode of the product: AC and DC. Users can set the output

mode at the TESTING subpage 1 (BASIC mode) to fit the product application. Then,

the MAIN page will change correspondingly according to the output mode (see Figure 3.26).

The procedures of setting the output mode from AC to DC are given as below:

1. Press the item twice to set the output mode from AC

to DC.

32

AFV-P Series User Manual

2. Press the icon to confirm.

Figure 3.26 Set the output mode from AC to DC (BASIC mode)

3.5.2.2 Over Current Foldback

At the TESTING subpage 1 (BASIC mode), users are allowed to enable the over current foldback. When the output current exceeds the maximum rated current, and the

over current foldback is enabled, the product can automatically control the output

voltage to maintain the output current at the maximum rated current.

The procedures of enabling the over current foldback are given as below:

1. Press the item twice to switch the icon status from

OFF to ON.

2. Press the icon to confirm and enable the over current foldback.

Figure 3.27 Enable the over current foldback (BASIC mode)

3.5.2.3 Output Phase Angle

At the TESTING subpage 2 (BASIC mode), users are allowed to set the output phase

angel with options from 0 to 359 by using the touch screen and the rotary knob

(refer to Subsection 3.2). The product can control the output phase angle (that is, the

33

AFV-P Series User Manual

start angle and the end angle) of the output waveform.

Firstly, the procedures of setting the start angle from 0 to 90 by using the virtual

numeric keys are given as below:

1. Press the item to use the virtual numeric keys to set

the value of 90.

2. Press the icon to confirm.

Figure 3.28 Set the start angle from 0 to 90 (BASIC mode)

Secondly, the procedures of setting the end angle from 0 to 270 by using the virtual

numeric keys are given as below:

1. Press the item to use the virtual numeric keys to set

the value of 270.

2. Press the icon to confirm.

Figure 3.29 Set the end angle from 0 to 270 (BASIC mode)

34

AFV-P Series User Manual

3.5.2.4 Power-on Status

At the TESTING subpage 2 (BASIC mode), users are allowed to set the power-on status with three options of OFF, ON and LAST. OFF indicates that the output is off after

turning on the product; ON indicates that the output is on after turning on the product; LAST indicates that if the output remains on while turning off the product previously, the output is on after turning on the product currently, otherwise, the output

is off after turning on the product currently.

The procedures of setting the power-on status are given as below:

1. Press the item repeatedly to switch the icon status

from OFF to either ON or LAST.

2. Press the icon to confirm.

Figure 3.30 Three options of the power-on status (BASIC mode)

3.5.2.5 Rated Voltage

At the TESTING subpage 3 (BASIC mode), users are allowed to set the rated voltage

with options from 0V to 310V by using the touch screen and the rotary knob (refer to

Subsection 3.2). When users set value of the output voltage exceeding the rated

voltage (that is, the maximum rated voltage and the minimum rated voltage), the

product can automatically control the setting value of the output voltage to maintain

the output voltage at the rated voltage.

3.5.2.6 Rated Frequency

At the TESTING subpage 4 (BASIC mode), users are allowed to set the rated frequency with options from 40Hz to 500Hz (opt. from 15Hz to 1000Hz) by using the touch

screen and the rotary knob (refer to Subsection 3.2). When users set value of the

output frequency exceeding the rated frequency (that is, the maximum rated fre-

35

AFV-P Series User Manual

quency and the minimum rated frequency), the product can automatically control

the setting value of the output frequency to maintain the output frequency at the

rated frequency.

3.5.2.7 Synchronized Signal

At the TESTING subpage 4 (BASIC mode), users are allowed to enable the synchronized signal with three options of EVENT, OFF and ON, and the default option is

EVENT. EVENT indicates that the product outputs a 5V DC pulse signal when the

product output changes; OFF indicates that the synchronized signal is disabled; ON

indicates that the product continuously outputs a 5V DC signal when the product

output is on, and stop the 5V DC signal when the product output is off.

Figure 3.31 Three options of the synchronized signal (BASIC mode)

3.5.2.8 Voltage Sense

At the TESTING subpage 3 (BASIC mode), users are allowed to set the voltmeter point

with two options of INT and EXT, and the default option is INT. INT indicates that the

voltmeter point is located at the terminals “N” and “L” of the output terminals of the

product; EXT indicates that the voltmeter point is located at the terminals “SN” and

“SL” of the output terminals.

The procedures of setting the voltmeter point from INT to EXT are given as below:

1. Press the item twice to switch the icon status from

INT to EXT.

2. Press the icon to confirm.

36

AFV-P Series User Manual

NOTICE

When the voltmeter point is set to be EXT, but the terminals “SL” and “SN” are not

connected to the load, the Low Voltage Protection (LVP) will be triggered after the

output is on.

Figure 3.32 Set the voltmeter point from INT to EXT (BASIC mode)

3.5.3 SYSTEM Subpage

After pressing the icon to enter into the SETTINGS page, the TESTING sub-

page will be shown on the touch screen, and users can press the icon

on the upper-right side of the touch screen to enter into the SYSTEM subpage. Please

see the following figures,

Figure 3.33 SYSTEM subpages 1 & 2

37

AFV-P Series User Manual

Figure 3.34 SYSTEM subpage 3

The description for the items and the icons at the SYSTEM subpage are given as fol-

lows,

1) : Press to set the operational language, with four op-

tions of ENGLISH, 繁體中文 and 简体中文.

2) : Press to set the alarm volume, with options from 0

to 9.

3) : Press to set the backlight level of the touch screen,

with options from 0 to 9.

4) : Press to set the RESULTS feature, with three options

of LAST, ALL and P/F.

5) : Press to unlock/lock the PROGRAMMABLE feature,

with two options of OFF and ON.

6) : Press to reset the product to the default settings.

7) : Press to enter into the CALIBRATION page (refer to

Section 4).

8) : Press to move to the previous page of the SYSTEM subpage.

9) : Press to move to the next page of the SYSTEM subpage.

38

AFV-P Series User Manual

3.5.3.1 Operational Language

At the SYSTEM subpage 1, users are allowed to set the operational language with

four options of ENGLISH, 繁體中文 and 简体中文, and the default operational

language is ENGLISH. ENGLISH indicates English; 繁體中文 indicates Traditional

Chinese; 简体中文 indicates Simplified Chinese..

The procedures of setting the operational language are given as below:

1. Press the item repeatedly to switch the icon status to

the desired language.

2. Press the icon to confirm.

Figure 3.35 Four options of the operational language

3.5.3.2 Alarm Volume

At the SYSTEM subpage 1, users are allowed to set the alarm volume with options

from 0 to 9 by using the touch screen and the rotary knob (refer to Subsection 3.2),

and the default alarm volume is 5. The bigger the number is, the higher the alarm

volume is.

The procedures of setting the alarm volume from 5 to 9 by using the touch screen

are given as below:

1. Press the item to use the virtual numeric keys to set

the value of 9.

2. Press the icon to confirm.

39

AFV-P Series User Manual

Figure 3.36 Set the alarm volume from 5 to 9

3.5.3.3 Backlight Level

At the SYSTEM subpage 1, users are allowed to set the backlight level of the touch

screen with options from 0 to 9 by using the touch screen and the rotary knob (refer

to Subsection 3.2), and the default backlight level is 9. The bigger the number is, the

brighter the touch screen is.

The procedures of setting the backlight level from 9 to 5 by using the touch screen

are given as below:

1. Press the item to use the virtual numeric keys to set

the value of 5.

2. Press the icon to confirm.

Figure 3.37 Set the backlight level from 9 to 5

3.5.3.4 RESULTS Feature

At the SYSTEM subpage 2, users are allowed to set the RESULTS feature with three

options of LAST, ALL and P/F, and the default option is LAST. LAST indicates that the

product will only display the result of the last Step Loop at the RESULTS page after

performing the PROGRAMMABLE feature; ALL indicates that the product will display

each Step Loop at the RESULTS page after performing the PROGRAMMABLE feature;

40

AFV-P Series User Manual

P/F indicates that the product will display whether each Step Loop is pass the output

test or not at the RESULTS page after performing the PROGRAMMABLE feature (refer

to Subsection 3.5.5).

Figure 3.38 Three options of the RESULTS feature.

3.5.3.5 Other Settings

A. Unlock/Lock the PROGRAMMABLE Feature

At the SYSTEM subpage 2, users are allowed to unlock/lock the PROGRAMMABLE

feature of the product with two options of OFF and ON, and the default option is OFF.

The procedures of locking the PROGRAMMABLE feature are given as below:

1. Press the item twice to switch the icon status from

OFF to ON.

2. Press the icon to confirm and lock the PROGRAMMABLE feature.

Figure 3.39 Lock the PROGRAMMABLE feature.

B. Reset to the Default Settings

At the SYSTEM subpage 2, users are allowed to reset the product to the default settings. The procedures of resetting the product to the default setting are given as be-

41

AFV-P Series User Manual

low:

1. Press the item twice to switch the icon status to YES.

2. Press the icon to confirm and reset the product.

Figure 3.40 Reset the product to the default settings

42

AFV-P Series User Manual

3.6 COMMUNICATION Page

If the MENU page is shown on the touch screen, users can press the icon to

enter into the COMMUNICATION page, and the COMMUNICATION page includes two

subpages: the ETHERNET subpage and the GENERAL subpage.

3.6.1 ETHERNET Subpage

After pressing the icon to enter into the COMMUNICATION page, the

ETHERNET subpage will be shown on the touch screen in advance. Please see the

following figures,

Figure 3.41 ETHERNET subpages 1 & 2

The description for the items and the icons at the ETHERNET subpage are given as

follows,

1) : Press to set the IP mode with two options of AUTO

mode and MANUAL mode.

2) : Press to set the IP address under the MANUAL

mode.

3) : Press to set the subnet mask under the MANUAL

mode.

4) : Press to set the default gateway under the MANUAL

mode.

43

AFV-P Series User Manual

5) : Press to set the MAC address under the MANUAL

mode.

6) : Press to set the Ethernet port under the MANUAL

mode.

7) : Press to move to the previous page of the ETHERNET subpage.

8) : Press to move to the next page of the ETHERNET subpage.

3.6.2 GENERAL Subpage

After pressing the icon to enter into the COMMUNICATION page, the

ETHERNET subpage will be shown on the touch screen in advance, and users can

press the icon on the upper-right side of the touch screen to enter into

the GENERAL subpage. Please see the following figures,

Figure 3.42 GENERAL subpages 1 & 2

The description for the items and the icons at the GENERAL subpage are given as fol-

lows,

1) : Press to enable/disable the PLC remote feature.

2) : Press to set the command format, with two options

of MODBUS and SCPI.

3) : Press to set the Modbus ID, with options from 1 to

44

AFV-P Series User Manual

255.

4) : Press to set the Baud rate, with five options of

9600bps, 19200bps, 38400bps, 57600bps and 115200bps.

5) : Press to move to the previous page of the GENERAL subpage.

6) : Press to move to the next page of the GENERAL subpage.

3.6.3 GENERAL Subpage with GPIB interface (optional)

After replacing the standard interface card with the optional GPIB interface card (refer to Subsection 2.8), the GENERAL subpage with the GPIB interface will be shown

on the touch screen. Please see the following figure,

Figure 3.43 GENERAL subpage with the GPIB interface

The description for the items at the GENERAL subpage with GPIB interface are given

as follows,

1) : Press to enable/disable the PLC remote feature.

2) : Press to set the GPIB address.

45

AFV-P Series User Manual

3.7 RESULTS Page

If the MENU page is shown on the touch screen, users can press the icon to

enter into the RESULTS page. Please see the following figures,

Figure 3.44 RESULTS page

The description for the icons at the RESULTS page are given as follows,

1) : Press to see the settings of the desired Step of the Memory Set.

2) : Show the label number of the current Memory Set.

3) : Show the label number of the current Step.

4) : Show whether the desired Step of the Memory Set

is pass the output test or not.

5) : Press to select the previous Step of the Memory Set.

6) : Press to select the next Step of the Memory Set.

46

AFV-P Series User Manual

3.8 WAVE Page

If the MENU page is shown on the touch screen, users can press the icon to

enter into the WAVE page. Please see the following figures,

Figure 3.45 WAVE page when the product output is off

Figure 3.46 WAVE page when the product output is on

Additionally, when the product output is on, users can also press the icon lo-

cated the upper-right side of the MAIN page to enter into the WAVE page.

Figure 3.47 MAIN page when the product output is on

47

AFV-P Series User Manual

The description for the icons at the WAVE page are given as follows,

1) : Press to set the displaying scale of the output voltage, with two

options of 40V and 200V per division.

2) : Press to set the display scale of the time, with six options of

1ms, 2ms, 4ms, 10ms, 100s, 200s and 400s per division.

3) : Press to set the display scale of the output current, with two

options of 2A and 20A per division for the product models of AFV-P-600 and

AFV-P-1250; 4A and 40A per division for the product model of AFV-P-2500;

8A and 80A per division for the product model of AFV-P-5000.

4) : Press to set the waveform displayed at the WAVE

page, with options of merely displaying the output voltage, merely displaying

the output current and displaying both of the above. The waveform of the

output voltage is shown in green; the waveform of the output current is

shown in orange.

48

AFV-P Series User Manual

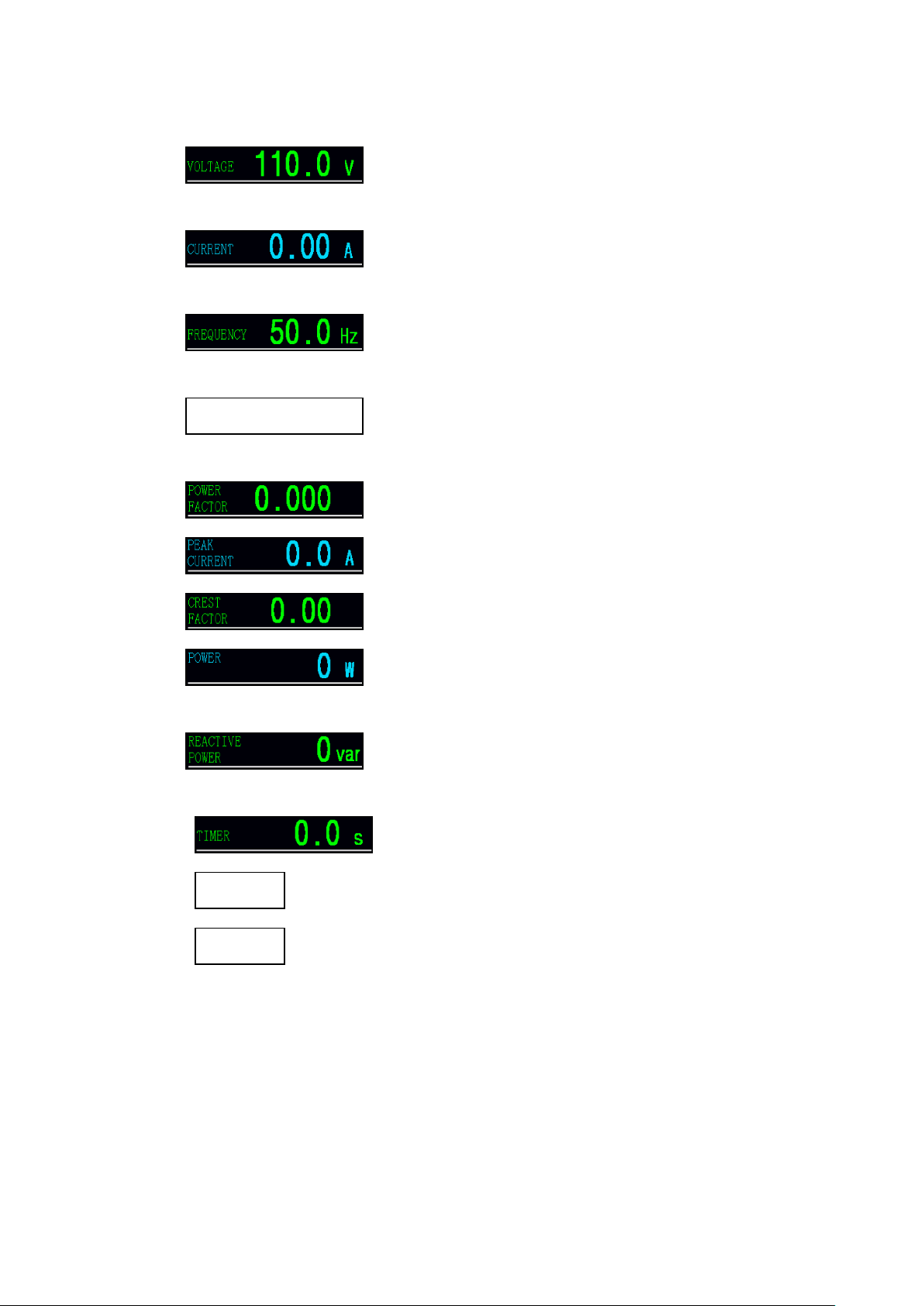

3.9 METER Page

If the MENU page is shown on the touch screen, users can press the icon to

enter into the METER page. Please see the following figures,

Figure 3.48 METER page when the product output is on

Figure 3.49 METER page when the PROGRAMMABLE feature is performed

Additionally, when the MAIN page is shown on the touch screen, users can also press

the icon at the MAIN page to enter into the METER page.

Figure 3.50 MAIN page

49

AFV-P Series User Manual

The description for the items and the icons at the METER page are given as follows,

1) : Show the measurement reading of the output volt-

age.

2) : Show the measurement reading of the output cur-

rent.

3) : Show the measurement reading of the output fre-

quency.

4) : Show the measurement reading of the apparent

power.

5) : Show the measurement reading of the power factor.

6) : Show the measurement reading of the peak current.

7) : Show the measurement reading of the crest factor.

8) : Show the measurement reading of the output pow-

er.

9) : Show the measurement reading of the reactive

power.

10) : Show the elapsed time of the product output.

11) : Show the label number of the current Memory Set.

12) : Show the label number of the current Step.

50

AFV-P Series User Manual

3.10 INFORMATION Page

If the MENU page is shown on the touch screen, users can press the icon to

enter into the INFORMATION page. Please see the following figures:

Figure 3.51 INFORMATION page

The description for the items at the INFORMATION page are given as follows:

1) : Show the producer of the product.

2) : Show the product model.

3) : Show the serial number of the product.

4) : Show the firmware version of the product

5) : Show the firmware version of the Ethernet card.

6) : Show the HMI firmware version of the product.

7) : Press to move to the previous page of the INFORMATION page.

8) : Press to move to the next page of the INFORMATION page.

51

AFV-P Series User Manual

Error Code

Protection

Condition

Possible Cause

Possible Solution

OVP

Over Voltage

Protection

1. Load oscillation.

2. Problem of the voltage

feedbacking from the load

to the inverter circuitries.

3. Fault of the inverter con-

trol circuitries.

1. Remove the load to in-

spect the output voltage.

2. Seek the technical assis-

tance.

LVP

Low Voltage

Protection

1. Load oscillation.

2. Incorrect wiring of the

terminals SL and SN when

setting voltmeter point to

EXT.

3. Fault of the inverter con-

trol circuitries.

1. Remove the load to in-

spect the output voltage.

2. Inspect the wiring of the

terminals SL and SN.

3. Seek the technical assis-

tance.

OCP

Over Current

Protection

When the output current

exceeds the maximum rated

current.

1. Decrease the output

voltage to fit the maximum

rated current

2. Remove the load to in-

spect the output current

OPP

Over Power

Protection

When the output power

exceed the maximum rated

power.

1. Decrease the output

voltage to fit the maximum

rated power.

2. Remove the load to in-

spect the output power.

OTP

Over Temperature

1. Poor ventilation.

1. Provide adequate space

3.11 Protection

The product provides complete protection for OVP, LVP, OCP, OPP, OTP, RCP, Fan Fail

and AMP Fail. When the protection is triggered, the product will immediately stop

the product output, and show the error code corresponding to the protection condition on the touch screen.

Please notice that if any protection is triggered, users shall eliminate the cause of the

protection condition according to the Table 3-11-1 before resuming the product

output. After eliminating the cause of the protection condition, users can press the

output & reset button on the front panel to unlock the protection, so as to resume

the product output.

Error code, possible causes and solution corresponding to the protection condition

are listed as below:

52

AFV-P Series User Manual

Protection

2. High environmental tem-

perature.

for product ventilation

2. Use the vacuum cleaner

to clean the air inlet

3. Install the product on the

place with environmental

temperature not exceeding

40C.

RCP

Reverse Current

Protection

Problems of the current

feedbacking from the load

to the inverter circuitries.

Remove the load to inspect

the output voltage.

Fan Fail

Fan Failure

Fault of the fan.

Seek the technical assis-

tance.

AMP Fail

Inverter Failure

1. Load oscillation

2. Problems of the voltage

feedbacking to the inverter

circuitries

3. Fault of the inverter cir-

cuitries.

1. Remove the load to in-

spect the output voltage.

2. Seek the technical assis-

tance.

Table 3.1 Troubleshooting Table

53

AFV-P Series User Manual

4 Calibration

The product provides a simple way to calibrate the product output and measurement

accuracy without opening cover. Users can perform the calibration according to the

procedures given as follows step by step. A voltage meter, a current meter and suita-

ble load are needed while performing the calibration procedures. Connections for

the instruments mentioned above please refer to Figure 4.1.

Figure 4.1 Instrument connection for calibration

At the SYSTEM subpage 3 of the SETTINGS page, users can press the item

, and then use the virtual numeric keys to set the value of

8888, so as to enter into the CALIBRATION page. Please see the following figures,

Figure 4.2 Enter into the CALIBRATION page from the SYSTEM subpage 3

54

AFV-P Series User Manual

Figure 4.3 CALIBRATION pages 1 & 2

Figure 4.4 CALIBRATION page 3

The description for the items at the CALIBRATION page are given as follows,

1) : Press to enter into the page which calibrates the

HI-Range voltage 310V.

2) : Press to enter into the page which calibrates the

LO-Range voltage 155V.

3) : Press to enter into the page which calibrates the

HI-Range voltage 60V.

4) : Press to enter into the page which calibrates the

LO-Range voltage 60V.

5) : Press to enter into the page which calibrates the

HI-Range RMS current.

6) : Press to enter into the page which calibrates the

55

AFV-P Series User Manual

NOTICE

Before calibrating the HI-Range voltage 310V, the load shall be temporally re-

moved from the product to avoid a potential electric shock.

LO-Range RMS current.

7) : Press to enter into the page which calibrates the

peak current.

8) : Press to enter into the page which calibrate the

output socket current (specialize for the product model of AFV-P-5000).

9) : Press to move to the previous page of the CALIBRATION page.

10) : Press to move to the next page of the CALIBRATION page.

4.1 HI-Range Voltage 310V

At the CALIBRATION page 1, users are allowed to enter into the page which calibrates

the HI-Range voltage 310V. The procedures of calibrating the HI-Range voltage 310V

are given as below:

1. Press the item repeatedly to enter into the page

which calibrates the HI-Range voltage 310V (refer to Figure 4.5).

2. Connect the product with the voltage meter (refer to Figure 4.1).

3. Press the output & reset button on the front panel to enable the calibration of

the HI-Range voltage 310V (refer to Figure 4.6), and then the product will start to

output the voltage which is closed to 310V.

4. Use the rotary knob to adjust the product output until the measurement read-

ing of the output voltage shown on the touch screen is closed to the measure-

ment reading shown on the voltage meter.

5. Press the rotary knob to confirm and finish the calibration.

56

AFV-P Series User Manual

Figure 4.5 Enter into the page which calibrates the HI-Range voltage 310V

Figure 4.6 Enable the calibration of the HI-Range voltage 310V

4.2 LO-Range Voltage 155V

At the CALIBRATION page 1, users are allowed to enter into the page which calibrates

the LO-Range voltage 155V. The procedures of calibrating the LO-Range voltage 155V

are given as below:

1. Press the item repeatedly to enter into the page

which calibrates the LO-Range voltage 155V (refer to Figure 4.7).

2. Connect the product with the voltage meter (refer to Figure 4.1).

3. Press the output & reset button on the front panel to enable the calibration of

the LO-Range voltage 155V (refer to Figure 4.8), and then the product will start to

output the voltage which is closed to 155V.

4. Use the rotary knob to adjust the product output until the measurement read-

ing of the output voltage shown on the touch screen is closed to the measure-

ment reading shown on the voltage meter.

5. Press the rotary knob to confirm and finish the calibration.

57

AFV-P Series User Manual

NOTICE

Before calibrating the LO-Range voltage 155V, the load shall be temporally re-

moved from the product to avoid a potential electric shock.

Figure 4.7 Enter into the page which calibrates the LO-Range voltage 155V

Figure 4.8 Enable the calibration of the LO-Range voltage 155V

4.3 HI-Range Voltage 60V

At the CALIBRATION page 1, users are allowed to enter into the page which calibrates

the HI-Range voltage 60V. The procedures of calibrating the HI-Range voltage 60V are

given as below:

1. Press the item repeatedly to enter into the page

which calibrates the HI-Range voltage 60V (refer to Figure 4.9).

2. Connect the product with the voltage meter (refer to Figure 4.1)

3. Press the output & reset button on the front panel to enable the calibration of

the HI-Range voltage 60V (refer to Figure 4.10), and then the product will start to

output the voltage which is closed to 60V.

4. Use the rotary knob to adjust the product output until the measurement read-

ing of the output voltage shown on the touch screen is closed to the measure-

58

AFV-P Series User Manual

NOTICE

Before calibrating the HI-Range voltage 60V, the load shall be temporally re-

moved from the product to avoid a potential electric shock.

ment reading shown on the voltage meter.

5. Press the rotary knob to confirm and finish the calibration.

Figure 4.9 Enter into the page which calibrates the HI-Range voltage 60V

Figure 4.10 Enable the calibration of the HI-Range voltage 60V

4.4 LO-Range Voltage 60V

At the CALIBRATION page 2, users are allowed to enter into the page which calibrates

the LO-Range voltage 60V. The procedures of calibrating the LO-Range voltage 60V

are given as below:

1. Press the item repeatedly to enter into the page

which calibrates the LO-Range voltage 60V (refer to Figure 4.11).

2. Connect the product with the voltage meter (refer to Figure 4.1)

3. Press the output & reset button on the front panel to enable the calibration of

the LO-Range voltage 60V (refer to Figure 4.12), and then the product will start to

output the voltage which is closed to 60V.

59

AFV-P Series User Manual

4. Use the rotary knob to adjust the product output until the measurement read-

ing of the output voltage shown on the touch screen is closed to the measure-

ment reading shown on the voltage meter.

5. Press the rotary knob to confirm and finish the calibration.

60

AFV-P Series User Manual

NOTICE

Before calibrating the LO-Range voltage 60V, the load shall be temporally re-

moved from the product to avoid a potential electric shock.

Figure 4.11 Enter into the page which calibrates the LO-Range voltage 60V

Figure 4.12 Enable the calibration of the LO-Range voltage 60V

61

AFV-P Series User Manual

NOTICE

The definition of the suitable load for calibrating the HI-Range RMS current are

given as follows, and the suitable load shall be resistive load.

Model

Resistive Value

Rated Power

AFV-P-600

20Ω

500W

AFV-P-1250

10Ω

1000W

AFV-P-2500

5Ω

2000W

AFV-P-5000

2.5Ω

4000W

4.5 HI-Range RMS Current

At the CALIBRATION page 2, users are allowed to enter into the page which calibrates

the HI-Range RMS current. The procedures of calibrating the HI-Range RMS current

are given as below:

1. Press the item repeatedly to enter into the page

which calibrates the HI-Range RMS current (refer to Figure 4.13).

2. Connect the product with the current meter and suitable load (refer to Figure

4.1).

3. Press the output & reset button on the front panel to enable the calibration of

the HI-Range RMS current (refer to Figure 4.14), and then the product will start to

output the voltage which is closed to 100V.

4. Use the rotary knob to adjust the product output until the measurement read-

ing of the output current shown on the touch screen is closed to the measure-

ment reading shown on the current meter.

5. Press the rotary knob to confirm and finish the calibration.

Figure 4.13 Enter into the page which calibrates the HI-Range RMS current

62

AFV-P Series User Manual

NOTICE

The definition of the suitable load for calibrating the LO-Range RMS current are

given as follows, and the suitable load shall be resistive load.

Model

Resistive Value

Rated Power

AFV-P-600

200Ω

50W

AFV-P-1250

100Ω

100W

AFV-P-2500

50Ω

200W

AFV-P-5000

25Ω

4000

Figure 4.14 Enable the calibration of the HI-Range RMS current

4.6 LO-Range RMS Current

At the CALIBRATION page 2, users are allowed to enter into the page which calibrates

the LO-Range RMS current. The procedures of calibrating the LO-Range RMS current

are given as below:

1. Press the item repeatedly to enter into the page

which calibrates the LO-Range RMS current (refer to Figure 4.15).

2. Connect the product with the current meter and suitable load (refer to Figure

4.1).

3. Press the output & reset button on the front panel to enable the calibration of

the LO-Range RMS current (refer to Figure 4.16), and then the product will start to

output the voltage which is closed to 100V.

4. Use the rotary knob to adjust the product output until the measurement read-

ing of the output current shown on the touch screen is closed to the measure-

ment reading shown on the current meter.

5. Press the rotary knob to confirm and finish the calibration.

63

AFV-P Series User Manual

Figure 4.15 Enter into the page which calibrates the LO-Range RMS current

Figure 4.16 Enable the calibration of the LO-Range RMS current

4.7 Peak Current

At the CALIBRATION page 3, users are allowed to enter into the page which calibrates

the peak current. The procedures of calibrating the peak current are given as below:

1. Press the item repeatedly to enter into the page

which calibrates the peak current (refer to Figure 4.17).

2. Connect the product with the current meter and suitable load (refer to Figure

4.1).

3. Press the output & reset button on the front panel to enable the calibration of

the peak current (refer to Figure 4.18), and then the product will start to output

the voltage which is closed to 100V.

4. Use the rotary knob to adjust the product output until the measurement read-

ing of the peak current shown on the touch screen is closed to the measurement

reading shown on the current meter.

5. Press the rotary knob to confirm and finish the calibration.

64

AFV-P Series User Manual

NOTICE

The definition of the suitable load for calibrating the peak current are given as

follows, and the suitable load shall be resistive load.

Model

Resistive Value

Rated Power

AFV-P-600

20Ω

500W

AFV-P-1250

10Ω

1000W

AFV-P-2500

5Ω

2000W

AFV-P-5000

2.5Ω

4000W

Figure 4.17 Enter into the page which calibrates the peak current

Figure 4.18 Enable the calibration of the peak current

65

AFV-P Series User Manual

4.8 Output Socket Current (Specialize for AFV-P-5000)

At the CALIBRATION page 3, users are allowed to enter into the page which calibrates

the output socket current. Since the maximum output current corresponding to the

product model of AFV-P-5000 is 40A, which exceeds the maximum rated current of

the AC output socket (that is, 20A), the calibration of the output socket current is

necessary to protect the AC output socket from over current damage.

The procedures of calibrating the output socket current are given as below:

1. Press the item repeatedly to enter into the page

which calibrates the output socket current (refer to Figure 4.19).

2. Connect the product with the current meter and the load with 5Ω and the rat-

ed power exceeding 2000W (refer to Figure 4.1).

3. Press the output & reset button on the front panel to enable the calibration of

the output socket current (refer to Figure 4.20), and then the product will start to

output the voltage which is closed to 100V.

4. Use the rotary knob to adjust the product output until the measurement read-

ing of the output current shown on the touch screen is closed to the measure-

ment reading shown on the current meter.

5. Press the rotary knob to confirm and finish the calibration.

Figure 4.19 Enter into the page which calibrates the output socket current

66

AFV-P Series User Manual

Figure 4.20 Enable the calibration of the output socket current

67

AFV-P Series User Manual

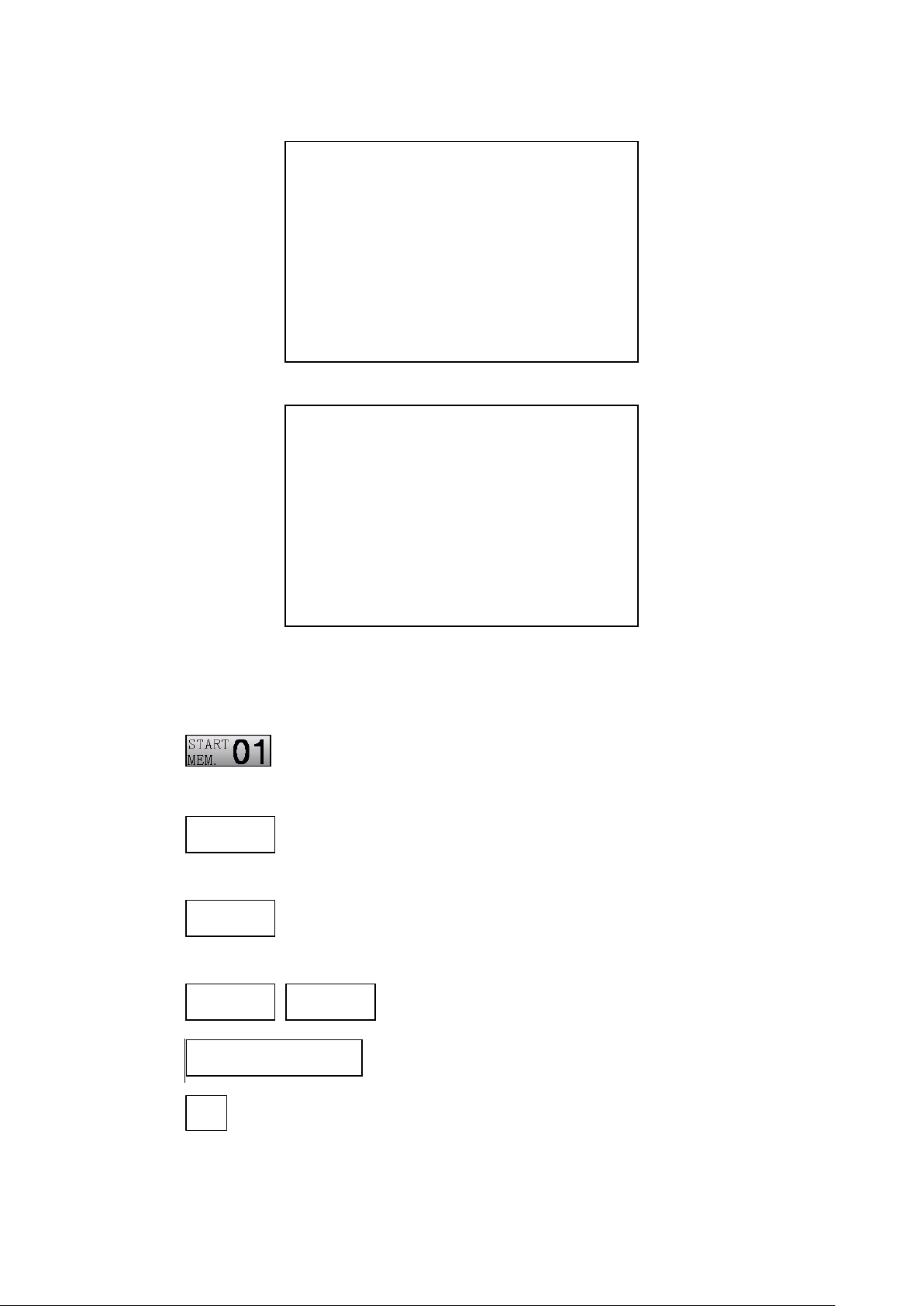

5 PROGRAMMABLE Features

5.1 General

The product can not only provide the steady output voltage and output frequency,

but also provide several powerful functions to simulate all kinds of power line conditions and disturbance. Users can make the output change according to the setting

value step by step via the STEP feature (refer to Subsection 5.2), or make the output

change according to the setting slew rate via the RAMP feature (refer to Subsection

5.3), even make the output change according to the setting value for a specific period

of time via the TRANSIENT feature (refer to Subsection 5.4).

A. PROGRAMMABLE Page

Two options of entering into the PROGRAMMABLE page are given as below,

1. At the MAIN page, users can press the icon to enter into the PRO-

GRAMMABLE page.

2. At the MENU page 1, users can press the icon to enter into the PRO-

GRAMMABLE page.

Figure 5.1 MAIN page Figure 5.2 MENU page 1

68

AFV-P Series User Manual

Figure 5.3 PROGRAMMABLE page when the Memory Loop is off