Preen ADG-P-40-750, ADG-P-100-300, ADG-P-60-500, ADG-P-200-150, ADG-P-240-125 User Manual

...

ADG-P Series

Programmable DC Power Supply

User Manual

AC Power Corp. (Preen)

V 1.02.00EN

The information in this document is subject to change without notice.

©AC Power Corp. (Preen). All rights reserved

Contents

Legal Notices

The information in this product manual is subject to change without notice.

AC Power Corp. makes no warranty of any kind with regard to this user manual, including, but not limited to, the implied warranties of merchantability and fitness for

a particular purpose. AC Power Corp. shall not be held liable for errors contained

herein or direct, indirect, special, incidental or consequential damages in connection

with the furnishing, performance, or use of this material.

Copyright Notices. Copyright 2017 AC Power Corp. (Preen), all rights reserved. Reproduction, adaptation, or translation of this document without prior written permission is prohibited, except as allowed under the copyright laws.

Contents

Warranty

Preen’s ADG-P series is warranted against defects in material and workmanship for a

period of two year after date of shipment. Preen agrees to repair or replace any assembly or component found to be defective, under normal use during this period.

Preen’s obligation under this warranty is limited solely to repairing any such product

which in sole Preen’s opinion proves to be defective within the scope of the warranty when returned to the factory or to an authorized service center. Transportation to

the factory or service center is to be prepaid by the purchaser. Shipment should not

be made without prior authorization by Preen.

This warranty does not apply to any products repaired or altered by persons not authorized by Preen, or not in accordance with instructions furnished by Preen. If the

product is defective as a result of misuse, improper repair, or abnormal conditions or

operations, repairs will be billed at cost.

Preen assumes no responsibility for its product being used in a hazardous or dangerous manner either alone or in conjunction with other equipment. High voltage

used in some products may be dangerous if misused. Special disclaimers apply to

these products. Preen assumes no liability for secondary charges or consequential

damages and in any event, Preen’s liability for breach of warranty under any contract or otherwise, shall not exceed the purchase price of the specific product

shipped and against which a claim is made.

Any recommendations made by Preen for use of its products are based upon tests

believed to be reliable, but Preen makes no warranty of the results to be obtained.

This warranty is in lieu of all other warranties, expressed or implied, and no representative or person is authorized to represent or assume for Preen any liability in

connection with the sale of our products other than set forth herein.

AC Power Corp. (Preen)

USA

192 Technology Dr., Suite S, Irvine, CA 92618

TEL +1 949-988-7799

Taipei

3F No. 200 Gangqian Road, Neihu Dist., Taipei 114, Taiwan

TEL +886 2-2627-1899 FAX +886 2-2627-1879

Contents

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation, service, and repair of this product. Failure to comply with these precautions

or specific WARNINGS given elsewhere in this manual will violate safety standards of

design, manufacture, and intended use of the product.

Preen assumes no liability for the customer‘s failure to comply with these requirements.

BEFORE APPLYING POWER

Verify that the product is set to match with the power line input.

PROTECTIVE GROUNDING

Make sure to connect the product to the protective ground to prevent an electric

shock before turning on the power.

NECESSITY OF PROTECTIVE GROUNDING

Never cut off the internal or external protective grounding wire, or disconnect the

wiring of protective grounding terminal. Doing so will cause a potential shock hazard

that may bring injury to a person.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the product in the presence of flammable gases or fumes.

DO NOT REMOVE THE COVER OF THE PRODUCT

Personnel who operate the product must not remove the cover of the product.

Component replacement and internal adjustment can be done only by qualified service personnel.

WARNING

LETHAL VOLTAGES. DEATH on contact may result if either the output terminals or

the output circuits connected to the output are touched when the product output

is on.

Contents

Table of Contents

1 GENERAL INFORMATION ............................................................................................... 1

1.1 Introduction .................................................................................................... 1

1.2 Specifications .................................................................................................. 1

1.3 Exterior ........................................................................................................... 6

2 INSTALLATION .................................................................................................................. 9

2.1 Inspection ....................................................................................................... 9

2.2 User Preparation ............................................................................................. 9

2.3 Remove the Front Door from the Product Enclosure ....................................... 10

2.4 Input Connection ............................................................................................ 10

2.5 Output Connection ......................................................................................... 11

3 LOCAL OPERATION ....................................................................................................... 13

3.1 Power-on Procedures ..................................................................................... 13

3.2 General Page .................................................................................................. 14

3.2.1 Output Measurement ................................................................................................. 15

3.2.2 Output Settings ........................................................................................................... 15

3.2.3 Run & Stop .................................................................................................................. 15

3.2.4 Constant Voltage Mode .............................................................................................. 15

3.2.5 Constant Current Mode .............................................................................................. 16

3.3 Function Page ................................................................................................. 17

3.3.1 Step Setting ................................................................................................................. 17

3.3.2 Step Performing .......................................................................................................... 18

3.3.3 Gradual Setting ........................................................................................................... 19

3.3.4 Gradual Performing .................................................................................................... 20

3.4 Protection ...................................................................................................... 21

3.4.1 Protection: Vin UVP .................................................................................................... 21

3.4.2 Protection: Vin OVP .................................................................................................... 21

3.4.3 Protection: OVP .......................................................................................................... 22

3.4.4 Protection: OCP .......................................................................................................... 22

4 REPAIR AND MAINTENANCE ..................................................................................... 23

Contents

4.1 Emergency Troubleshooting ........................................................................... 23

4.2 Dust Check ..................................................................................................... 23

4.3 Product Maintenance ..................................................................................... 23

4.3.1 Daily Maintenance ...................................................................................................... 23

4.3.2 Monthly Maintenance ................................................................................................ 25

5 REMOTE CONTROL ....................................................................................................... 26

5.1 Remote Read .................................................................................................. 26

5.2 Remote Write ................................................................................................. 27

5.3 Transmission Example .................................................................................... 28

5.4 MODBUS Address Table .................................................................................. 31

ADG-P Series User Manual

1

1 General Information

1.1 Introduction

Preen’s ADG-P series is a programmable DC power supply with high power density

and high output power, and it offers great response time, high accuracy and many

output voltage and current combinations. Designed for the increasing demand of

high power DC power supplies, ADG-P series is ideal for testing EV-type motor/compressor, server power supply, fuse, circuit breaker, contactor and PV inverter,

or ADG-P series can be used as a facility power or EMC chamber power.

With output power up to 100kW per unit, ADG-P series can offer output voltage up

to 1600V or output current up to 2000A. Users can select standard interface RS-485

or optional interfaces RS-232 and GPIB. With built-in STEP and GRADUAL features,

ADG-P series allows easy setup on test sequence. According to CV/CC settings and

load conditions, ADG-P series can operate as a current or voltage source. Its remote

sense feature can effectively reduce voltage drop caused by cable length and provides more flexibility on installation.

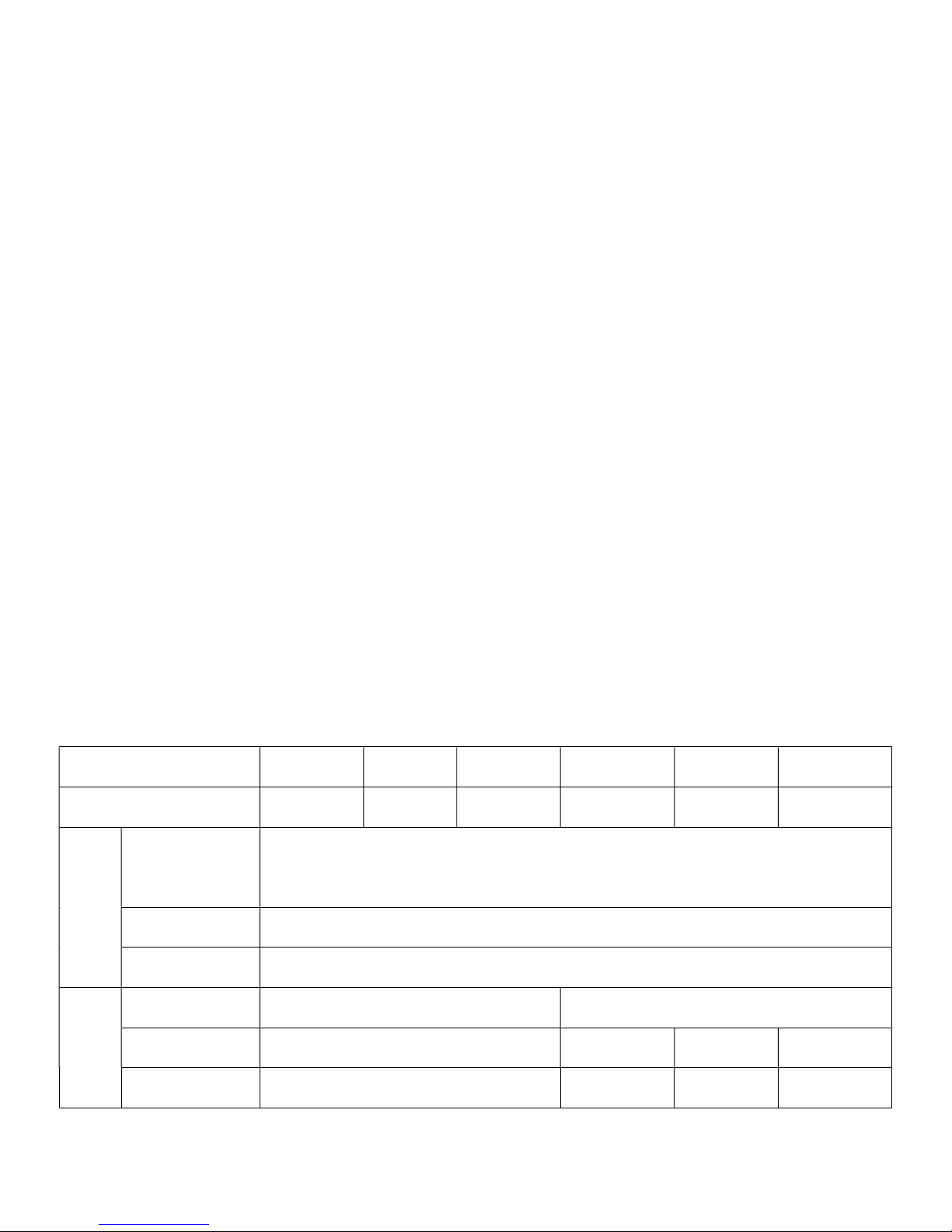

1.2 Specifications

Technical specifications of product are listed below. All specifications have been

tested according to Preen’s standard test procedures.

30kW ADG-P-40-750 ADG-P-60-500 ADG-P-100-300 ADG-P-200-150 ADG-P-240-125 ADG-P-320-94

50kW ADG-P-40-1250 ADG-P-60-834 ADG-P-100-500 ADG-P-200-250 ADG-P-240-208 ADG-P-320-156

AC

Input

Voltage

3Φ3W + G

380 VAC/400VAC/415VAC/440VAC/480VAC ± 10%

Frequency 47-63Hz

Power Factor

≧90% at maximum power

DC

Output

Line Regulation

≦0.3% ≦0.1%

Load Regulation

≦0.3% ≦0.065% ≦0.104% ≦0.14%

Voltage Ripple (RMS)

≦0.5% ≦0.26% ≦0.19% ≦0.16%

ADG-P Series User Manual

2

Voltage Noise (Peak)

≦3.7% ≦2% ≦0.88%

Voltage Slew Rate*1

≦65ms ≦60ms ≦85ms

Transient Response*2

≦4-12ms

Measurement

Voltage Accuracy 0.5% F.S.

Voltage Resolution 0.1V

Current Accuracy 0.5% F.S.

Current Resolution 0.1A

Protection

Type Vin OVP, Vin UVP, OVP, OCP and OTP

OVP Range 5% - 115% from front panel

OVP Accuracy 1% F.S.

OCP Range 5% - 115% from front panel

OCP Accuracy 1% F.S.

General

Efficiency

≧87% ≧90%

Remote Sense Limits

3% maximum voltage drop from product output to load

(for product models with output voltage lower than 1000VDC)

Operational Temperature

0°C-40°C

Storage Temperature -20°C-70°C

Isolation Input to product cover: 2000VAC

Dimension (H×W×D) 41.5×23.6×31.5 inch3/1050×600×800 mm3

Weight*3

30kW: approx. 496lbs/225kg

50kW: approx. 511lbs/232kg

30kW: approx. 412lbs/187kg

50kW: approx. 423lbs/192kg

ADG-P Series User Manual

3

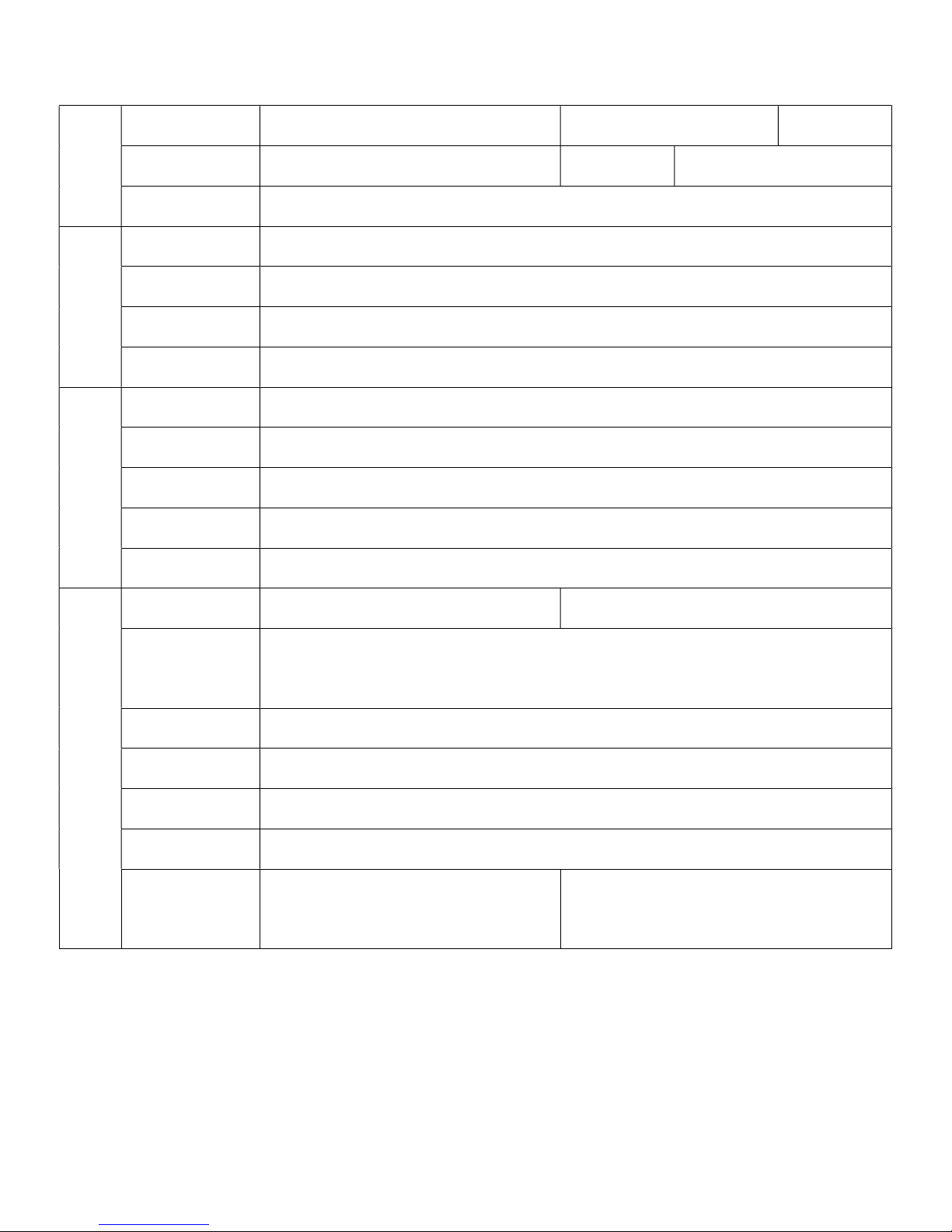

30kW ADG-P-400-75 ADG-P-500-60 ADG-P-640-47 ADG-P-800-38 ADG-P-1000-30 ADG-P-1600-18

50kW ADG-P-400-125 ADG-P-500-100 ADG-P-640-78 ADG-P-800-63 ADG-P-1000-50 ADG-P-1600-31

AC

Input

Voltage

3Φ3W + G

380 VAC/400VAC/415VAC/440VAC/480VAC ± 10%

Frequency 47-63Hz

Power Factor

≧90% at maximum power

DC

Output

Line Regulation

≦0.1%

Load Regulation

≦0.032% ≦0.14% ≦0.132% ≦0.034% ≦0.02% ≦0.05%

Voltage Ripple (RMS)

≦0.13% ≦0.109% ≦0.07% ≦0.05% ≦0.08%

Voltage Noise (Peak)

≦0.88% ≦1.34% ≦0.77% ≦0.29% ≦0.27% ≦0.4%

Voltage Slew Rate*1

≦115ms ≦280ms

Transient Response*2

≦4-12ms

Measurement

Voltage Accuracy 0.5% F.S.

Voltage Resolution 0.1V

Current Accuracy 0.5% F.S.

Current Resolution 0.1A

Protection

Type Vin OVP, Vin UVP, OVP, OCP and OTP

OVP Range 5% - 115% from front panel

OVP Accuracy 1% F.S.

OCP Range 5% - 115% from front panel

OCP Accuracy 1% F.S.

General

Efficiency

≧90%

Remote Sense Limits

3% maximum voltage drop from product output to load

(for product models with output voltage lower than 1000VDC)

Operational Temperature

0°C-40°C

ADG-P Series User Manual

4

Storage Temperature -20°C-70°C

Isolation Input to product cover: 2000VAC

Dimension (H×W×D) 41.5×23.6×31.5 inch3/1050×600×800 mm3

Weight*3

30kW: approx. 412lbs/187kg

50kW: approx. 423lbs/192kg

75kW ADG-P-40-1875 ADG-P-60-1250 ADG-P-100-750 ADG-P-320-234 ADG-P-640-117 ADG-P-1000-75

100kW ADG-P-40-2500 ADG-P-60-1666 ADG-P-100-1000 ADG-P-320-313 ADG-P-640-156 ADG-P-1000-100

AC

Input

Voltage

3Φ3W + G

380 VAC/400VAC/415VAC/440VAC/480VAC ± 10%

Frequency 47-63Hz

Power Factor

≧90% at maximum power

DC

Output

Line Regulation

≦0.1%

Load Regulation

≦0.1% ≦0.15% ≦0.15% ≦0.08% ≦0.08% ≦0.1%

Voltage Ripple (RMS)

≦1.3% ≦1.5% ≦0.1% ≦0.2%

Voltage Noise (Peak)

≦7% ≦5% ≦0.65% ≦0.35% ≦0.8%

Voltage Slew Rate*1

≦120ms ≦90ms ≦120ms ≦130ms

Transient Response*2

≦10-20ms

Measurement

Voltage Accuracy 0.5% F.S.

Voltage Resolution 0.1V

Current Accuracy 0.5% F.S.

Current Resolution 0.1A

Protection

Type Vin OVP, Vin UVP, OVP, OCP and OTP

OVP Range 5% - 115% from front panel

OVP Accuracy 1% F.S.

ADG-P Series User Manual

5

OCP Range 5% - 115% from front panel

OCP Accuracy 1% F.S.

General

Efficiency

≧90%

Remote Sense Limits

3% maximum voltage drop from product output to load

(for product models with output voltage lower than 1000VDC)

Operational Temperature

0°C-40°C

Storage Temperature -20°C-70°C

Isolation Input to product cover: 2000VAC

Dimension (H×W×D) 59.8×23.6×31.5 inch3/1520×600×800 mm3

Weight*3

≦300kg

*1 For output voltage change from 5% to 90% at maximum power after output softstart.

*2 Recover to ±0.1% of regulated output with a 50% to 100% or 100% to 50% step load change.

*3 Weight might be different due to optional features or different input voltage. Please contact us for details.

All specifications are subject to change without notice.

Above specification is for output voltage over 1%.

Table 1.1 Technical specifications

ADG-P Series User Manual

6

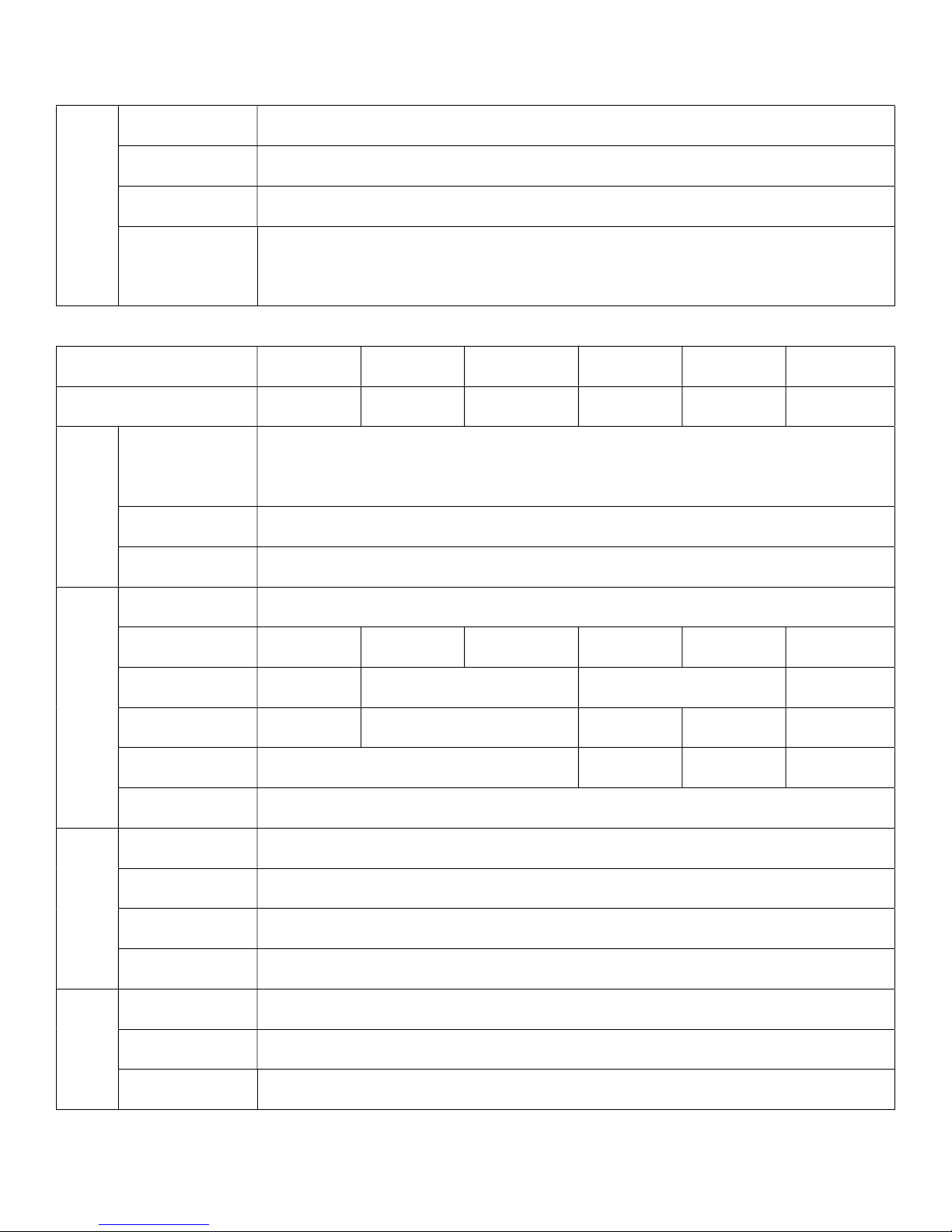

1.3 Exterior

Product exterior of the ADG-P series with power level 30kW, 50kW, 75kW and 100kW

are given as follows,

(a) Front-side view of the ADG-P series (30kW&50kW)

(b) Right-side view of the ADG-P series (30kW&50kW)

Figure 1.1 Product exterior of the ADG-P series (30kW&50kW)

ADG-P Series User Manual

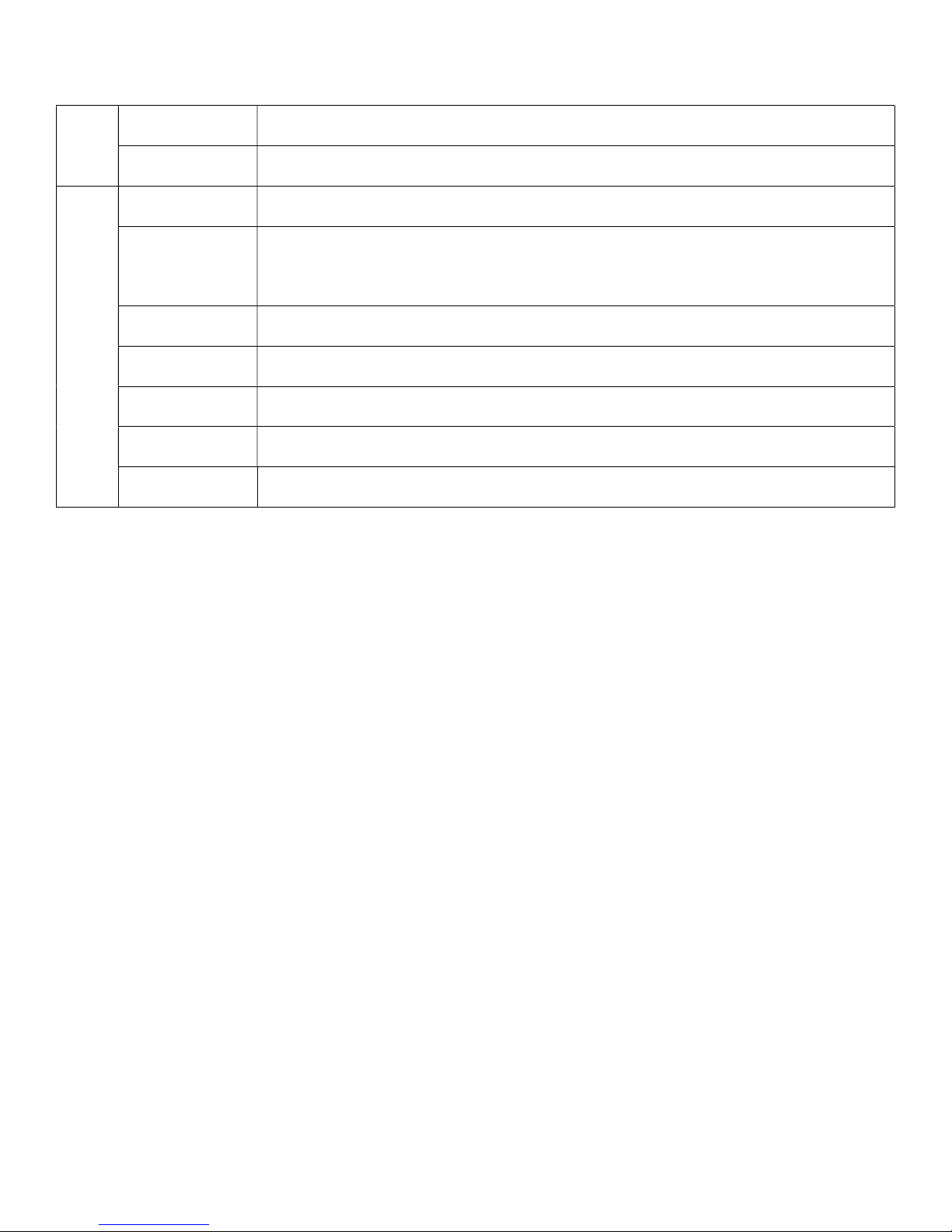

7

Figure 1.2 Product exterior of the ADG-P series in axis-side view (30kW&50kW)

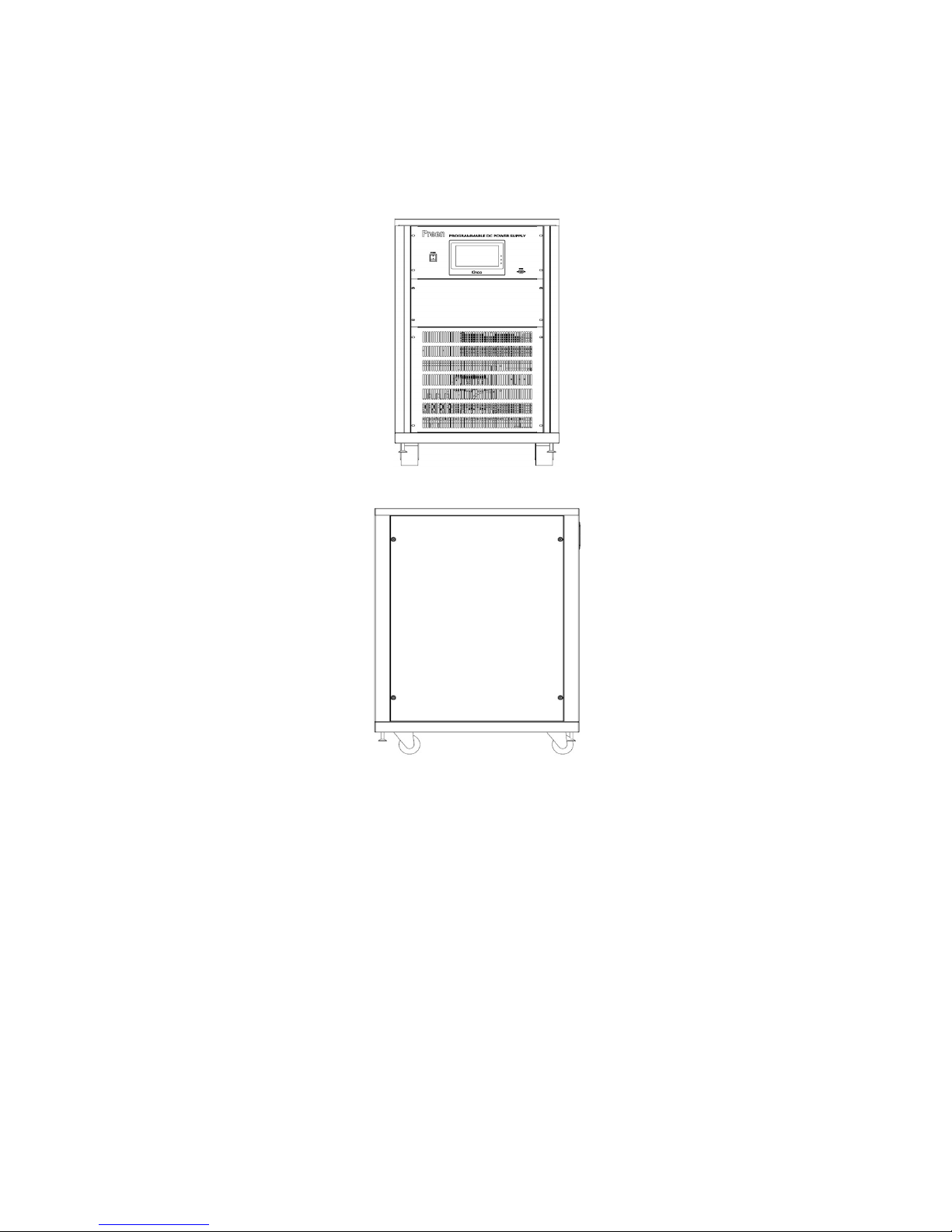

(a) Front-side view of the ADG-P series (75kW&100kW)

ADG-P Series User Manual

8

(b) Right-side view of the ADG-P series (75kW&100kW)

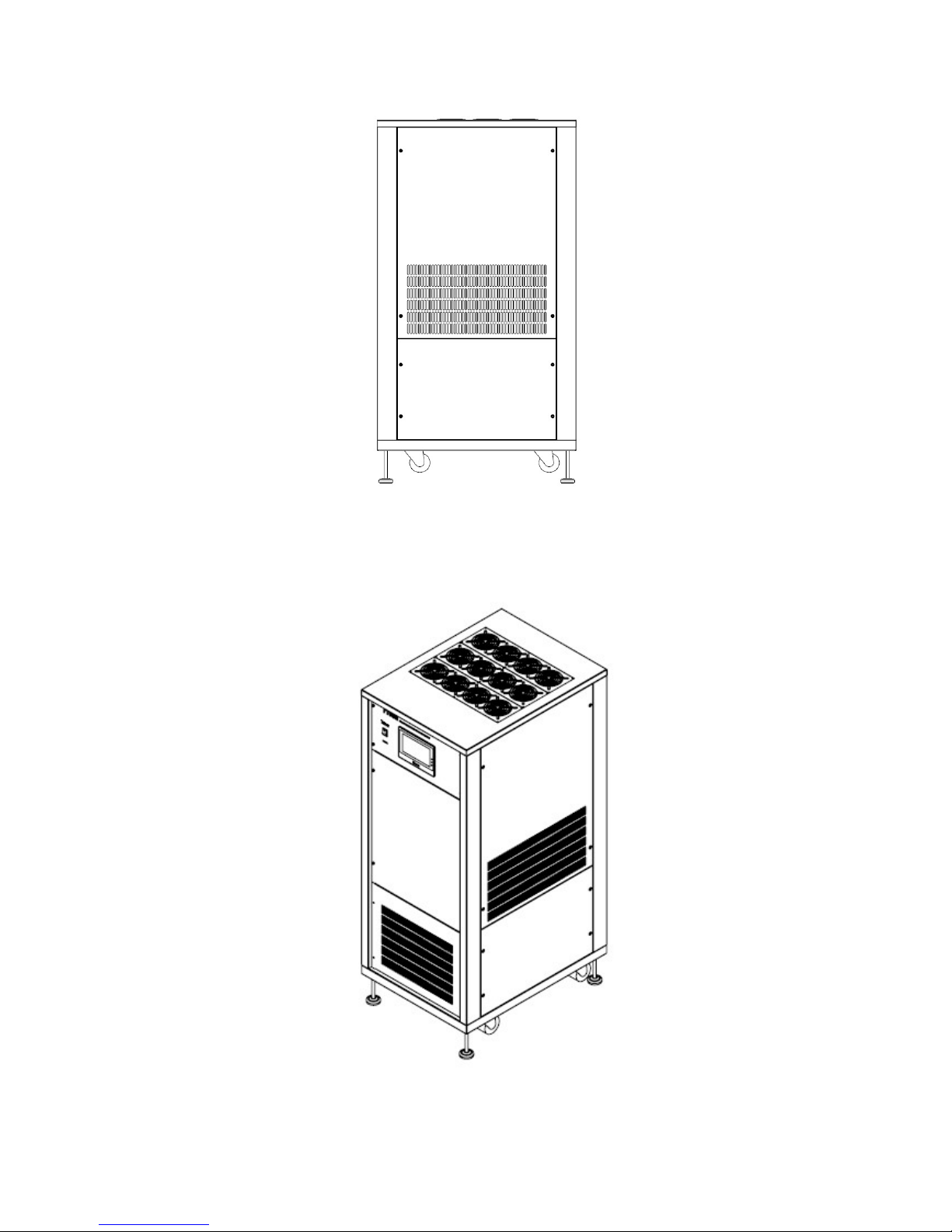

Figure 1.3 Product exterior of the ADG-P series (75kW&100kW)

Figure 1.4 Product exterior of the ADG-P series in axis-side view (75kW&100kW)

ADG-P Series User Manual

9

2 Installation

2.1 Inspection

Each ADG-P series DC power supply has been carefully tested by Preen before shipping, but some damage might occur on the product during shipping, so please inspect the product carefully before installation. If there is any damage, please contact

the shipping company or directly contact Preen, and provide photos according to the

damage. A technical staff will contact users immediately.

2.2 User Preparation

ADG-P series should be installed in indoor and in dry environment with little dust.

Location for installing ADG-P series must be stable and secure due to its heavy

weight, and users should notice that ADG-P series is better to be placed on the

ground.

The front space for the product should be space with at least 105 cm length in order

to fully remove the front door. For easy maintenance and well ventilated, the back

space for the product should be space with at least 80 cm length, and its top space

should be space with at least 60 cm length.

Make sure that the ambient temperature around the product should be lower than

40˚C.

ADG-P Series User Manual

10

2.3 Remove the Front Door from the Product Enclosure

For input/output connection, please remove the front door from the product enclosure since the front door is fixed to the product via screws, and there are terminals

of AC input and DC output inside the front door.

Figure 2.1 Remove the front door from the product enclosure

2.4 Input Connection

The AC input terminals are located inside the front door of the product (see Figure

2.2). AC wires must be rated at least for 85C. The AC wires must have rated current

which complies with Spec. limit of the product.

To perform input connection for the product, please see Figure 2.2 and do the following procedures step by step:

1. Use a multi-meter to confirm that power line input complies with the Spec.

limit of the product.

2. Stop the power line input, and use the multi-meter to confirm that input voltage (L-L) from the power line input should be 0.

3. Connect the AC input terminals of L1, L2 and L3 with the power line input of L1,

L2 and L3 via AC wires sequentially.

ADG-P Series User Manual

11

4. Confirm that the AC wires between the power line input and the AC input terminals are secured.

Installation of the AC wires to the product must be done by a professional and according to local electrical codes.

Figure 2.2 AC Input terminals

2.5 Output Connection

To perform output connection for the product, please see Figure 2.3 and do the following procedures step by step:

1. Stop the product output, and use the multi-meter to confirm that output voltage should be 0.

2. Connect the DC output terminals “+” and “-” with positive and negative terminals from the load via metal wires sequentially.

3. Confirm that metal wires between the DC output terminals and the load are

secured.

AC Input Terminals

ADG-P Series User Manual

12

Figure 2.3 DC output terminals

DC Output Terminals

ADG-P Series User Manual

13

3 Local Operation

3.1 Power-on Procedures

WARNING

Before turning on the product, all protective grounding terminals, extension

cords, and devices connected to the product must be connected to a protective

ground. Any interruption of the protective ground will cause a potential shock

hazard that could result in personal injury.

After applying power and turning on the product, the touch screen located on the

front panel will light up and display the start-up page shown as below, and then it

will enter into General page in few seconds.

Figure 3.1 Start-up page

ADG-P Series User Manual

14

3.2 General Page

The description for the items and the icons at the General page are given according

to the figure below. Users can press the display area, and then the digital scope will

be shown at the General page to provide product output waveform.

Figure 3.2 General page

Figure 3.3 Digital scope at the General page

NOTICE

Before pressing the icon “RUN” at the General page to start the product output,

make sure that output terminals are correctly connected to the load.

ADG-P Series User Manual

15

3.2.1 Output Measurement

At the General page, the item “Voltage” indicates measurement of the present DC

output voltage; the item “Current” indicates measurement of the present DC output

current; the item “Power” indicates measurement of the DC output power.

3.2.2 Output Settings

At the General page, the item “V-set” indicates the DC output voltage set; the item

“I-set” indicates the DC output current set; the item “Setting” indicates function of

time setting; the icon “Reset” indicates function of product reset after protection.

3.2.3 Run & Stop

The product will start the DC output after pressing the icon “Run” at the General

page. Similarly, the product will stop the DC output after pressing the icon “Stop” at

the General page.

3.2.4 Constant Voltage Mode

When the output current from the load is lower than or equal to the DC output current set, the product will perform at the constant voltage mode. Once the product

performs at the constant voltage mode, the sign will be shown next to the

item “Voltage” at the General page.

Figure 3.4 General page when the product performs at the constant Voltage mode

ADG-P Series User Manual

16

3.2.5 Constant Current Mode

When the output current from the load is higher than the DC output current set, the

product will perform at the constant current mode. Once the product performs at

the constant current mode, the sign will be shown next to the item “Current” at the General page.

Figure 3.5 General page when the product performs at the constant Voltage mode

NOTICE

When ADG-P series performs at the constant current mode, the DC output voltage

will be automatically adjusted to match load conditions.

ADG-P Series User Manual

17

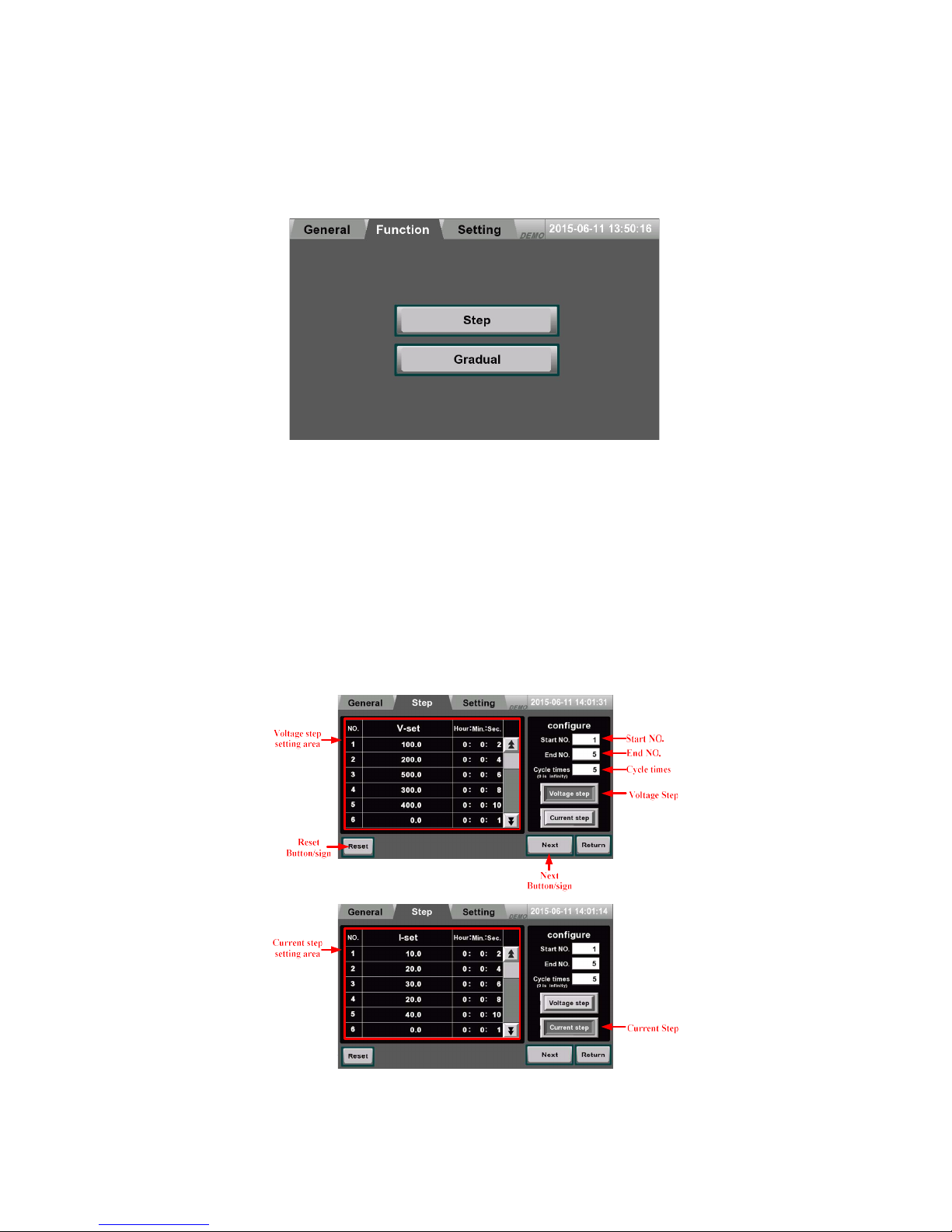

3.3 Function Page

Press the icon “Function” to enter into the function page.

Figure 3.6 Function page

3.3.1 Step Setting

Press the icon “Step” to enter into the step page, and the step page is shown below.

After entering into the step page, press the icon “Voltage step” or “Current step” to

operate at voltage/current step mode. Then, set output voltage/current and dwell

time for each set (up to 24 sets) in the step setting area, and set start number, end

number and cycle times for performing the step feature (repeatedly performing the

step feature when setting the cycle times as 0). After finishing the setting above,

press the icon “Next” to enter into the next page.

Figure 3.7 Step setting

ADG-P Series User Manual

18

3.3.2 Step Performing

Press the icon “Run” to perform the step feature, and output status is shown on the

output display area. Similarly, the output display area can show the output status by

waveform display or digit display. “Run status” includes performing number, output

voltage, elapsed time and total cycle times. Press the icon “Lock” to lock the function

of other icons. Press the icon “Stop” to stop the step feature. Once an abnormal condition occurs, press the icon “Reset” to eliminate the abnormal condition, and press

the icon “Return” to return to the step page.

Figure 3.8 Step performing

ADG-P Series User Manual

19

3.3.3 Gradual Setting

Press the icon “Gradual” to enter into the gradual page, and the gradual page is

shown below. After entering into the gradual page, press the icon “Voltage grad” or

“Current grad” to operate at voltage/current gradual mode. Then, set start output

voltage/current, end output voltage/current and dwell time for each set (up to 12

sets) in the gradual setting area, and set start number, end number and cycle times

for performing the step feature (repeatedly performing the gradual feature when

setting the cycle times as 0). After finishing the setting above, press the icon “Next”

to enter into the next page.

Figure 3.9 Gradual setting

ADG-P Series User Manual

20

3.3.4 Gradual Performing

Press the icon “Run” to perform the gradual feature, and output status is shown on

the output display area. Similarly, the output display area can show the output status

by waveform display or digit display. “Run status” includes performing number, output voltage, elapsed time and total cycle times. Press the icon “Lock” to lock the

function of other icons. Press the icon “Stop” to stop the gradual feature. Once an

abnormal condition occurs, press the icon “Reset” to eliminate the abnormal condition, and press the icon “Return” to return to the gradual page.

Run status

Lock

Button/sign

Return

Button/sign

Output

Button/sign

Close

Button/sign

Reset

Button/sign

Output

display

area

Figure 3.10 Gradual performing

ADG-P Series User Manual

21

3.4 Protection

3.4.1 Protection: Vin UVP

When the input voltage for the product is lower than a default value, Vin UVP will be

triggered and the product will immediately stop the output. Then, the sign “Vin UV”

will be shown below the item “Voltage” at the General page. To reset the product

from Vin UVP, please press the icon “Reset”.

3.4.2 Protection: Vin OVP

When the input voltage for the product is higher than a default value, Vin OVP will be

triggered and the product will immediately stop the output. Then, the sign “Vin OV”

will be shown below the item “Voltage” at the General page. To reset the product

from Vin OVP, please press the icon “Reset”.

ADG-P Series User Manual

22

3.4.3 Protection: OVP

When the output voltage of the product is higher than a default value, OVP will be

triggered and the product will immediately stop the output. Then, the sign “OV” will

be shown below the item “Voltage” at the General page. To reset the product from

OVP, please press the icon “Reset”.

3.4.4 Protection: OCP

When the output current of the product is higher than the DC output current set,

OCP will be triggered and the product will immediately stop the output. Then, the

sign “OC” will be shown below the item “Current” at the General page. To reset the

product from OCP, please press the icon “Reset”.

ADG-P Series User Manual

23

4 Repair and Maintenance

4.1 Emergency Troubleshooting

If ADG-P series has any abnormal conditions or triggers any product protection, users

must immediately stop the product output and turn off the product.

4.2 Dust Check

ADG-P series must be installed in dry and clean room, and please clean the dust for

the product every six months once.

4.3 Product Maintenance

Extreme temperature, high humidity, heavy dust, chemical pollution and physical vibration all could impose negative impacts on the life and reliability of the product.

However, the natural aging of all the electrical and mechanical components would

further cause it to be more vulnerable to all kinds of faults. Therefore, daily and

monthly maintenance are necessary, and they are important to the reliability of the

product in the long run.

NOTICE

Only authorized and trained technical staffs are allowed to carry out the maintenance on the product.

4.3.1 Daily Maintenance

First, this product must operate in the environment stated in this user manual. Daily

inspection on the environment and this product should be carried out regularly. It is

recommended to record product data of operational environment, operational condition, output settings and etc. For product maintenance and its reference, it is also

recommended to build detailed “product usage log file”.

ADG-P Series User Manual

24

Abnormal conditions on the product can be detected by the daily inspection and

maintenance. Once an abnormal condition is detected, users should identify its root

cause, and eliminate the abnormal condition accordingly. If users are unable to identify the root cause or eliminate the abnormal condition, please call our customer service for technical support immediately. The earlier the abnormal condition can be

removed, the longer the life of the product. Please check the daily maintenance list

given below,

Object

Details

Criteria

Items Period

Methods

Environment

1. Temperature and humidity

2. Dust, moisture and water

leakage

3. Abnormal chemical vapor

Anytime

1. Thermometer and hygrometer

2. Visual inspection

3. Visual inspection and smell

1.1. Ambient temperature must

be lower than 40˚C or full load

output should be de-rated

1.2 Humidity should be complied

with the Spec. limit

2. Little dust is allowed; no con-

densing; no water drop on the

product

3. No abnormal smell; no abnor-

mal color in the air

Product

1. Abnormal physical vibration

2. Heat dissipation

3. Acoustic noise

Anytime

1. Visual inspection

2. Thermometer

3. Sense of hearing

1. No abnormal physical vibration

2.1. Fan speed and air flow

should be complied with product

operation

2.2 Temperature on the surface of

the product enclosure must be

lower than 30˚C

3. No abnormal acoustic noise

In/Out

Conditions

1. Input voltage

2. Output Voltage

3. Output Current

4. Temperature inside the prod-

uct

Anytime

1. Voltmeter

2. Voltmeter

3. Ammeter

4. Thermometer

1. Within the Spec. limit

2. Within the Spec. limit

3. Within the Spec. limit

4. Inside temperature must be

lower than 40˚C

Table 4.1 Daily Maintenance List

ADG-P Series User Manual

25

4.3.2 Monthly Maintenance

For monthly maintenance, screen filter for the air inlet should be detached and clean

for well ventilated. According to the usage of this product and the environment

where it operates, monthly maintenance can be carried out every 3-6 months once.

NOTICE

Remover the front door of the product enclosure to detach and re-install the

screen filter. There is a cover in front of the screen filter, and this cover should be

removed before detaching the screen filter.

ADG-P Series User Manual

26

5 Remote Control

Preen provides specialized control software for ADG series programmable

high power DC power supply, and this control software eases remote op-

eration for users to quickly set product output. Additionally, Preen pro-

vides MODBUS protocol for users, and users can use such protocol to

program product control according to their practical requirements.

5.1 Remote Read

Read packet format

ID Function Code 03H Length Start Address CRC16

1 Byte

1 Byte 1 Byte

2 Bytes 2 Bytes

Read feedback packet format (correct)

ID Function Code 03H Status Code Length Data (High to Low) CRC16

1 Byte

1 Byte 1 Byte 1 Byte

N Bytes 2 Bytes

Read feedback packet format (error)

ID Function Code 03H Status Code Length CRC16

1 Byte

1 Byte 1 Byte 1 Byte 2 Bytes

ADG-P Series User Manual

27

5.2 Remote Write

Write packet format

ID Function Code 10H Length Start Address Data (High to Low) CRC16

1 Byte

1 Byte 1 Byte

2 Bytes N Byte 2 Bytes

Write feedback packet format (correct)

ID Function Code 10H Status Code Length CRC16

1 Byte

1 Byte 1 Byte 1 Byte 2 Bytes

Write feedback packet format (error)

ID Function Code 10H Status Code Length CRC16

1 Byte

1 Byte 1 Byte 1 Byte 2 Bytes

The following descriptions are for the packet format mentioned above:

1. ID: Product MODBUS ID, which has default setting 01H.

2. Function Code: MODBUS identification code, which is used for re-

mote read or remote write.

3. Status Code: Status code will be 00H while transmitting correctly;

otherwise, status code will be error code while transmitting incorrect-

ly.

ADG-P Series User Manual

28

Status Code

Description

00H Correct

02H CRC error

03H Data length error

04H Function code error

05H Address error

06H Output voltage exceeding the rated value

07H Output current exceeding the rated value

08H Product output writing prohibited

5.3 Transmission Example

Remotely read the product (correct)

Remotely read the setting value Vout_set. Start address will be 0000H, and

data length will be 4 bytes.

ID Function Code 03H Length Start Address CRC16

01H

03H 04H 00 00H 58 45H

Feedbacks status code 00H from the product to indicate correct

reading

The setting value will be 42C80000H(Format of IEEE754), which indicates

ADG-P Series User Manual

29

100V.

ID Function Code 03H Status Code Length Data (High to Low) CRC16

01H

03H 00H 04H 42 C8 00 00H D6 81H

Remotely read the product (error)

Remotely read the setting value Vout_set. Start address will be 0000H,

data length will be 4 bytes, and CRC16 is incorrect.

ID Function Code 03H Length Start Address CRC16

01H

03H 04H 00 00H 58 40H

Feedbacks status code 02H from the product to indicate incorrect

reading

It is known that 02H indicates CRC error by looking up the table.

ID Function Code 03H Status Code Length CRC16

01H

03H 02H 00H F0 B8H

Remotely write into the product (correct)

Remotely write the setting value Vout_set 100V. Start address will be

0000H, and data length will be 4 bytes. 100V can be transformed into

42C80000H.

ID Function Code 10H Length Start Address Data (High to Low) CRC16

ADG-P Series User Manual

30

01H

10H 04H 00 00H 42 C8 00 00H D6 2AH

Feedbacks status code 00H from the product to indicate correct writ-

ing

ID Function Code 10H Status Code Length CRC16

01H

10H 00H 00H 00 DH

Remotely write into the product (error)

Remotely write the setting value Vout_set 800V. Start address will be

0000H, and data length will be 4 bytes. 800V can be transformed into

44480000H.

ID Function Code 10H Length Start Address Data (High to Low) CRC16

01H

10H 04H 00 00H 44 48 00 00H D7 4AH

Feedbacks status code 06H from the product to indicate incorrect

writing.

It is known that 06H indicate incorrect setting value Vout_set by looking

up the table.

ID Function Code 10H Status Code Length CRC16

01H

10H 06H 00H 03 BDH

ADG-P Series User Manual

31

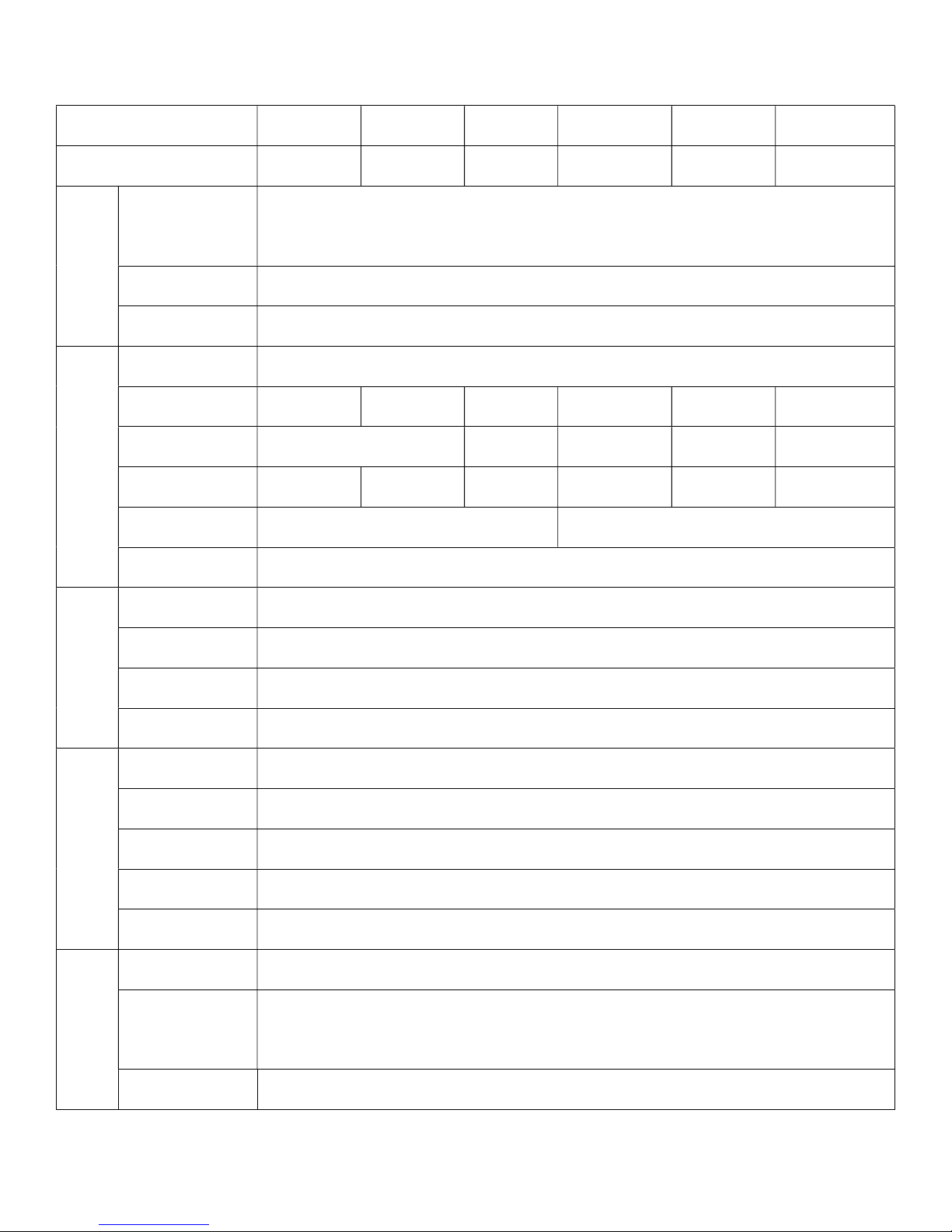

5.4 MODBUS Address Table

Parameter Name Start Address Function Length

Format

Output Voltage Setting 0000H 03H/10H 4 bytes IEEE754

Output Voltage Setting 0004H 03H/10H 4 bytes IEEE754

Product Output 0008H 03H/10H 1 byte

00H: Stop

01H: Output

Remote Control 0009H 03H/10H 1 byte

00H: Local Operation

01H: Remote Operation

Error Reset 000BH 10H 1 byte

01H: Reset the product after

eliminating the an error con-

dition

Input Voltage 04C0H 03H 4 bytes IEEE754

Output Voltage 04C4H 03H 4 bytes IEEE754

Output Current 04C8H 03H 4 bytes IEEE754

Product Status 04CCH 03H 1 byte

Each bit indicates different

status flag.

Bit 0: Reserved

Bit 1: CV Mode

Bit 2: CC Mode

ADG-P Series User Manual

32

Bit 3: Vin OVP

Bit 4: Vin UVP

Bit 5: OVP

Bit 6: UVP

Bit 7: OTP

Loading...

Loading...