Page 1

CW-410

Page 2

Page 3

CW-410 Assembly Guide

Important Safety Guidelines

for Owners

Follow these guidelines to maintain proper working

condition of the equipment:

Important: Do not modify the equipment or any of

its parts, or permanently remove any part from the

equipment. Do not use accessory attachments that

are not recommended by Precor, as such attachments

might cause injuries.

• Qualified technicians must perform all regular

maintenance.

• Make sure that trainers, facility personnel, and

maintenance technicians understand how to use

the equipment, know important safety guidelines,

and can recognize potential problems such as a

worn cable or cracked weld.

• Strength training requires a significant focus by the

facility and its staff to maintain the quality of the

fitness environment. If possible, the facility should

provide direct supervision of the fitness equipment

at all times by people knowledgeable about the

safe operation of the equipment and trained to

recognize potential problems.

• If any staff member witnesses unsafe use of

the equipment, he or she should address the

user directly, demonstrate the proper technique,

and review the Important Safety Information for

Users. Precor recommends posting a copy of the

Important Safety Information for Users near the

equipment in a prominent location.

• Make sure the equipment is stable and placed on

a solid, level surface. The equipment is designed to

be freestanding; however, equipment can be bolted

to the floor for extra stability. Consult a qualified

general contractor for proper fastening methods.

• Make sure that the equipment is installed with

enough free space for safe operation. With most

equipment, the general rule is to allow about a

4-foot (1.2-meter) circle of space from the user’s

center. For Functional Training equipment, make

sure that the operating space is large enough to

allow the cables to be fully extended in all possible

directions.

• Check the equipment thoroughly based on the

recommended inspection schedules outlined in

this manual, including daily, weekly, monthly and

annual checks.

• Place an “out-of-order” sign on the equipment

during maintenance of the equipment or the

surrounding area. Users should never be

allowed to operate the equipment until it has

been inspected and works properly. If a piece of

equipment needs service, keep it out of use until

repaired.

• Whenever a weight can drop and hit a user,

such as with an Olympic bench, Precor highly

recommends that a helper or spotter be used.

• Do not place the equipment outdoors or on wet

surfaces.

Obtaining Service

For information about product operation

or service, refer to the Precor web site

at www.precor.com where you can also

find customer support numbers or a list of

Precor authorized service centers.

If you call or e-mail Customer Support, have

the serial number available.

You can find the serial number printed on

a label affixed to the equipment. For future

reference, write the serial number in the

space provided below.

Serial number:

_______________________

Important Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS

page 3

Page 4

CW-410 Assembly Guide

Important Safety Information

for Users

Before beginning any fitness program, you should

obtain a complete physical examination from your

physician.

French equivalent of the preceding paragraph, for the

Canadian market: Il est conseillé de subir un examen

médical complet avant d’entreprendre tout programme

d’exercise. Si vous avez des étourdissements ou des

faiblesses, arrêtez les exercices immédiatement.

When using exercise equipment, you should always

take basic precautions, including the following:

• If you do not understand how to operate a piece of

equipment, ask someone from the facility such as

a trainer to demonstrate how to use it and explain

any safety instructions.

• Do not allow children on or near the equipment.

Do not leave children unsupervised around the

equipment.

• Use the equipment only for its intended purpose.

Do not use accessory attachments that are not

recommended by the manufacturer, as such

attachments may cause injuries.

• Wear proper exercise clothing and shoes for your

workout—no loose clothing.

• Do not overexert yourself or work to

exhaustion. Use reasonable judgment when

working with weights. Avoid using excessive

weight, which may cause injury.

• If you feel pain or abnormal symptoms, stop

exercising immediately and consult your physician.

• Keep head, limbs, fingers, and hair clear of all

moving parts while the equipment is in use. Keep

hands clear of racking pegs.

• Never drop or insert objects into any opening in the

equipment.

• Always check the equipment before using it. If

you spot a potential problem, contact someone in

the facility immediately. Do not use the equipment

until the facility has verified that the equipment is

working properly. Do not attempt to fix a broken or

jammed machine.

• Do not use the equipment outdoors or on wet

surfaces.

• Do not drop or slam the weight stack while

exercising.

• Do not use the equipment if an

“out of order” sign has been placed

on it.

• Read all posted instructions, including all safety

instructions and warnings.

Important Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS

page 4

Page 5

CW-410 Assembly Guide

Table of Contents

Important Safety Guidelines for Owners ................................................................ 3

Obtaining Service ...................................................................................................................................... 3

Important Safety Information for Users ................................................................... 4

Preparations ............................................................................................................... 6

1

2

Unpacking the Equipment ......................................................................................................................... 6

Required Tools ......................................................................................................................................... 6

Installation Requirements .......................................................................................................................... 6

Hardware Kit ............................................................................................................................................. 7

Assembly Instructions .............................................................................................. 9

Open the Box ........................................................................................................................................... 9

Assemble the Unit ..................................................................................................................................... 10

Assemble the Pads ................................................................................................................................... 13

Clean the Pads and Assembly .................................................................................................................. 13

Table of Contents

Product Specifications ..............................................................................................16

page 5

Page 6

CW-410 Assembly Guide

1

The CW-410 parts are inspected before shipment.

Each unit contains several pieces that require

assembly. You will need to obtain adult assistance

during the assembly process.

Preparations

Required Tools

Tools that you need to obtain before assembling the

unit include:

❏ Wire cutter or utility knife

❏ ¾-inch open-end wrench

❏ Rubber mallet

Installation Requirements

Follow these installation requirements when

assembling the unit:

Unpacking the Equipment

When you open a box, carefully unpack the pieces and

lay them on the floor near the location where you plan

to use them.

CAUTION: Be careful when you remove the

packaging material with a utility knife. Do not cut

the upholstery or scratch the paint.

If any items are missing, contact the dealer from whom

you purchased the unit. For more information, refer to

Obtaining Service.

• Review the Important Safety Guidelines for

Owners.

• Assemble the unit where it will be used.

Provide ample space around the unit.

• Install components in the sequence shown.

• Insert all fasteners in the same direction.

For aesthetic purposes, insert all the fasteners

in the same direction unless specified (in text or

illustrations) to do otherwise.

• Leave room for adjustments. Tighten the

fasteners to keep the unit stable, but leave room

for adjustments. Do not fully tighten fasteners until

instructed to do so.

Preparations

page 6

Page 7

CW-410 Assembly Guide

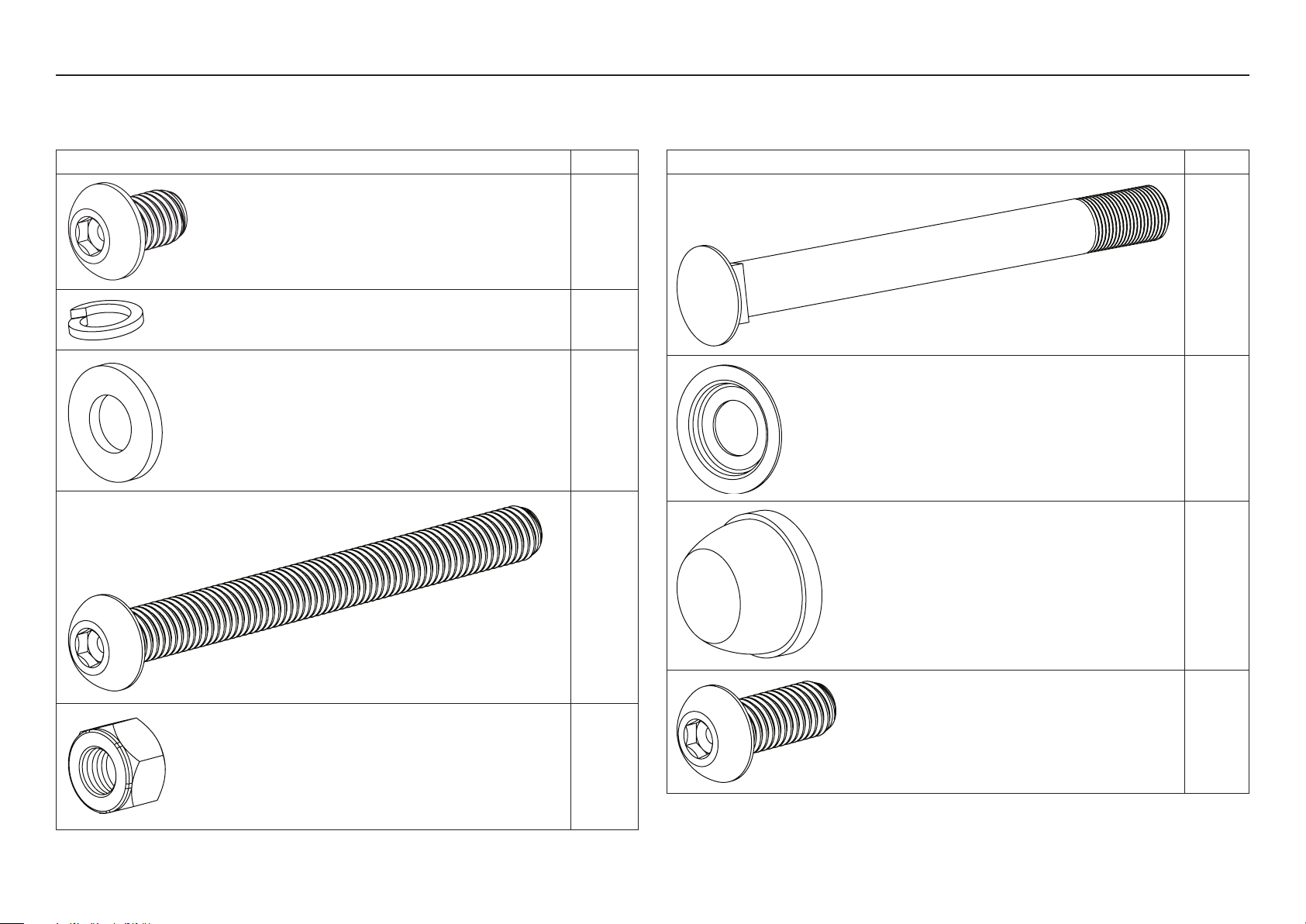

Hardware Kit

Fastener Qty

½ x ¾-inch Buttonhead screw (A) 6

½-inch Split washer (B) 9

½-inch Washer (C) 23

Fastener Qty

½ x 5-inch Carriage bolt (F) 6

½-inch Hat washer (G) 10

Plastic cap (H) 10

½ x 5¼-inch Buttonhead screw (D) 4

½-inch Locknut (E) 10

Preparations, continued

½ x1¼-inch Buttonhead screw (J) 3

page 7

Page 8

CW-410 Assembly Guide

Hardware Kit, continued

Fastener Qty

Spacer (K) 3

Shoulder bolt (L) 1

Bumper (M) 4

Fastener Qty

⁵⁄₁₆-inch Split washer (P) 8

⁵⁄₁₆-inch Washer (R) 8

5

⁄16 x 1¼-inch Buttonhead screw (S) 4

5

⁄16 x 3-inch Buttonhead screw (N) 4

Preparations, continued

page 8

Page 9

CW-410 Assembly Guide

Assembly

2

Assembly of the CW-410 takes about 45 minutes to

complete. If this is the first time you have assembled

this type of equipment, plan on allowing more time.

Be careful to open boxes and assemble components in

the sequence presented in this manual.

Note: With so many assembled parts, proper alignment

and adjustment is critical. While tightening the

fasteners, be sure to leave room for adjustments. Do

not fully tighten fasteners until instructed to do so.

Instructions

Open the Box

Use wire cutters to open the box and remove the

packing materials.

The illustration shows how the CW-410 will look when

you have completed its assembly. The callouts identify

specific pieces.

Upright Frame

Weight Bar

Plate

Weight Plate

Holder

Back Pad

Seat Pad

Foot Rest

Assembly Instructions

Base Assembly

Cross Brace

Assembly

page 9

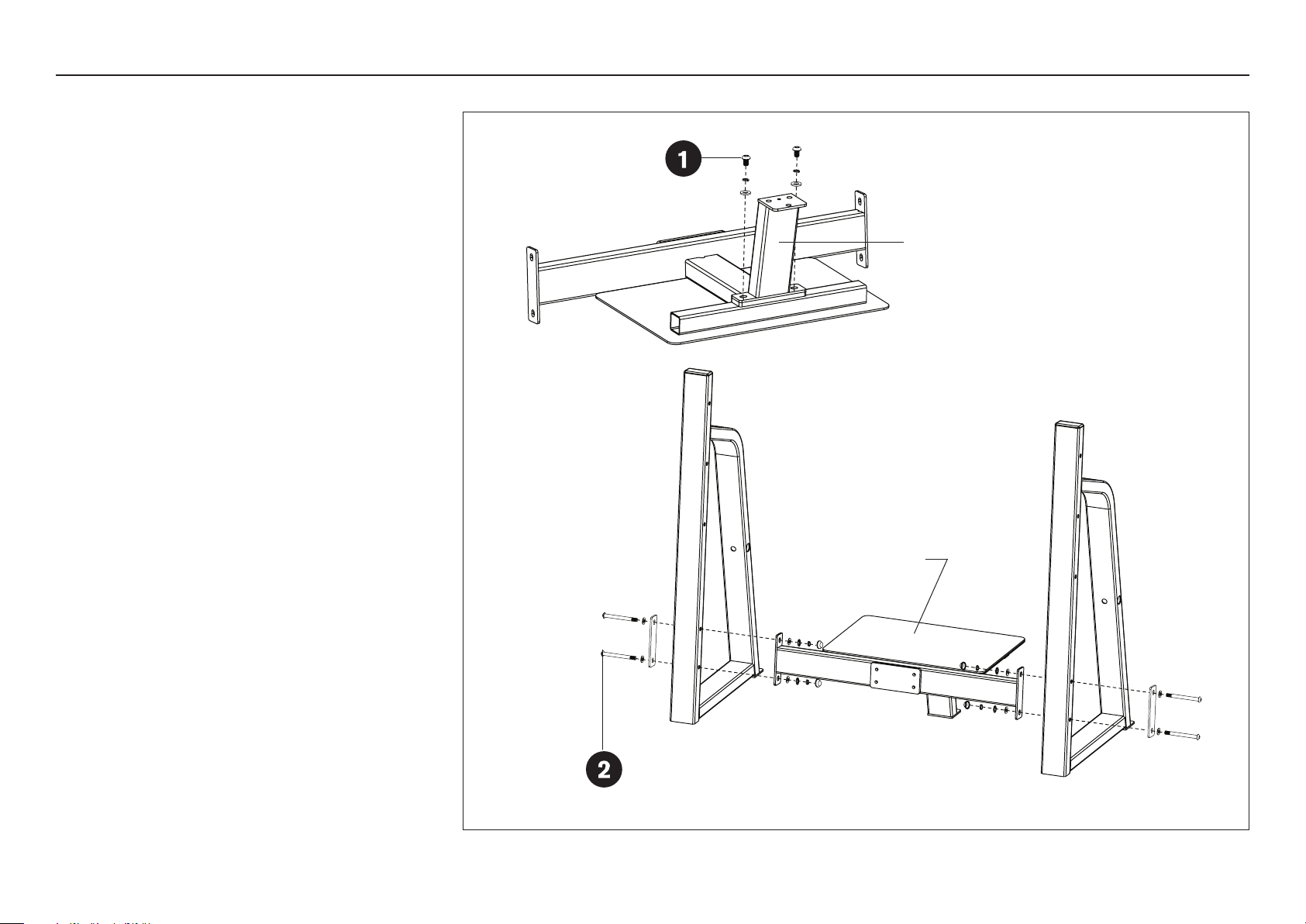

Page 10

CW-410 Assembly Guide

Assemble the Unit

1. Turn the Cross Brace Assembly over and Attach

the Cross Brace Stabilizer to the Cross Brace

Assembly using

two ¾-inch buttonhead screws (A)

two ½-inch split washers (B)

two ½-inch washers (C)

Wrench tighten.

2. Attach the Cross Brace Assembly to the Upright

Frames with two Backing Plates using

four 5¼-inch buttonhead screws (D)

eight ½-inch washers (C)

four ½-inch locknuts (E)

Loosely tighten the fasteners so the Upright

Frames are stable, but adjustments can be made

when installing the Base Assembly.

2 - ¾” buttonhead screws

2 - split washers

2 - washers

Cross Brace

Stabilizer

Assemble the Unit

Cross Brace

Assembly

4 - 5¼” buttonhead screws

8 - washers

4 - locknuts

4 - hat washers

4 - plastic caps

page 10

Page 11

CW-410 Assembly Guide

3. Attach the Base Assembly to the Cross Brace

Assembly using

four ¾-inch buttonhead screws (A)

four ½-inch split washers (B)

Wrench tighten.

4. Make sure the unit is stable and the Base

Assembly rests firmly on the floor. Return to the

Upright Frames and wrench tighten the fasteners

using a ¾-inch open-end wrench.

Important: In the following two steps, insert the

bolts so that their heads face outward on both

sides. If the heads of the bolts face inward, their

threaded ends can protrude far enough to damage

the finish on barbell weight plates.

5. Attach the left-hand Weight Bar Plate to the outside

of the left-hand Front Upright using

three 5-inch carriage bolts (F)

three ¹₂-inch washers (C)

three ½-inch hat washers (G)

three ½-inch locknuts (E)

Wrench tighten and snap a Plastic Cap (H) over

each locknut.

6. Repeat step 5 to attach the right-hand Weight Bar

Plate to the outside of the right-hand Front Upright.

7. Slide the Foot Rest through the Base Assembly

and secure it using

one 1¼-inch buttonhead screw (J)

one ½-inch split washer (B)

one ½-inch washer (C)

one spacer (K)

Wrench tighten.

Note: For ease of assembly, place a split washer,

a flat washer, and a spacer onto the screw before

inserting it.

3 - 5” carriage bolts

3 - washers

3 - hat washers

3 - locknuts

3 - plastic caps

1 - 1¼” buttonhead screw

1 - split washer

1 - washer

1 - spacer

3 - 5” carriage bolts

3 - washers

3 - hat washers

3 - locknuts

3 - plastic caps

4 - ¾” buttonhead screws

4 - split washers

Assemble the Unit, continued

page 11

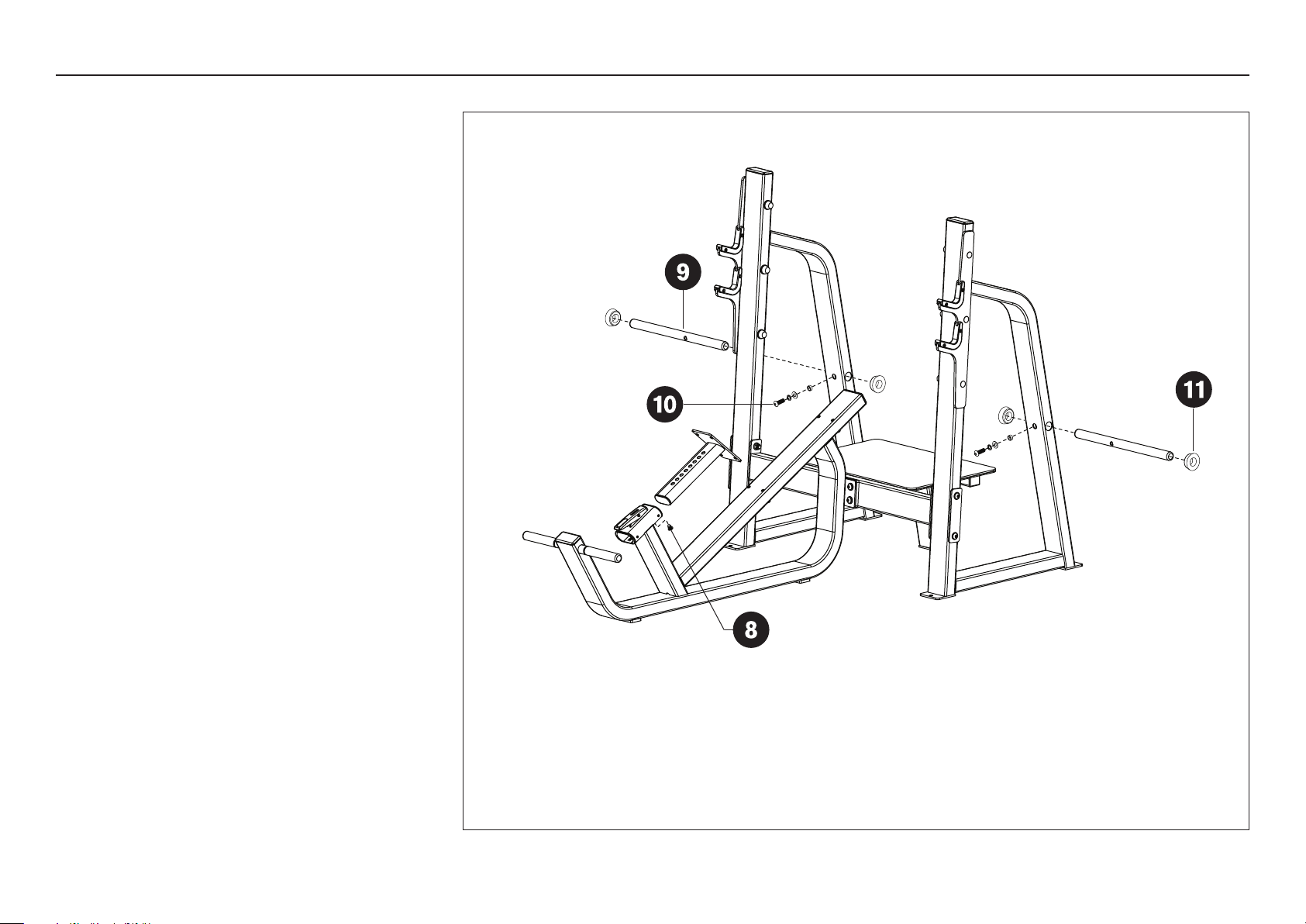

Page 12

CW-410 Assembly Guide

8. Press the handle on the Base Assembly and slide

the Seat Adjustment into the Base Assembly.

Release the handle while the pin is aligned with

one of the holes in the Seat Adjustment. Secure

the Seat Adjustment using

one shoulder bolt (L)

Wrench tighten.

9. Insert the Weight Plate Holders into the Upright

Frames as shown in the illustration. Turn the

Weight Plate Holders so the mounting holes align

with the holes in the Upright Frame.

10. Secure the Weight Plate Holders using

two 1¼-inch buttonhead screws (J)

two ½-inch split washers (B)

two ½-inch washers (C)

two spacers (K)

Wrench tighten.

Note: For ease of assembly, place a split washer,

a flat washer, and a spacer onto each screw before

inserting the screw.

11. Slide a Bumper (M) onto each end of the Weight

Plate Holders, and press firmly against the Upright

Frames.

Note: Make sure the small side of each bumper

faces the Upright Frame.

2 - 1¼” buttonhead screws

2 - split washers

2 - washers

2 - spacers

Assemble the Unit, continued

1 - shoulder bolt

page 12

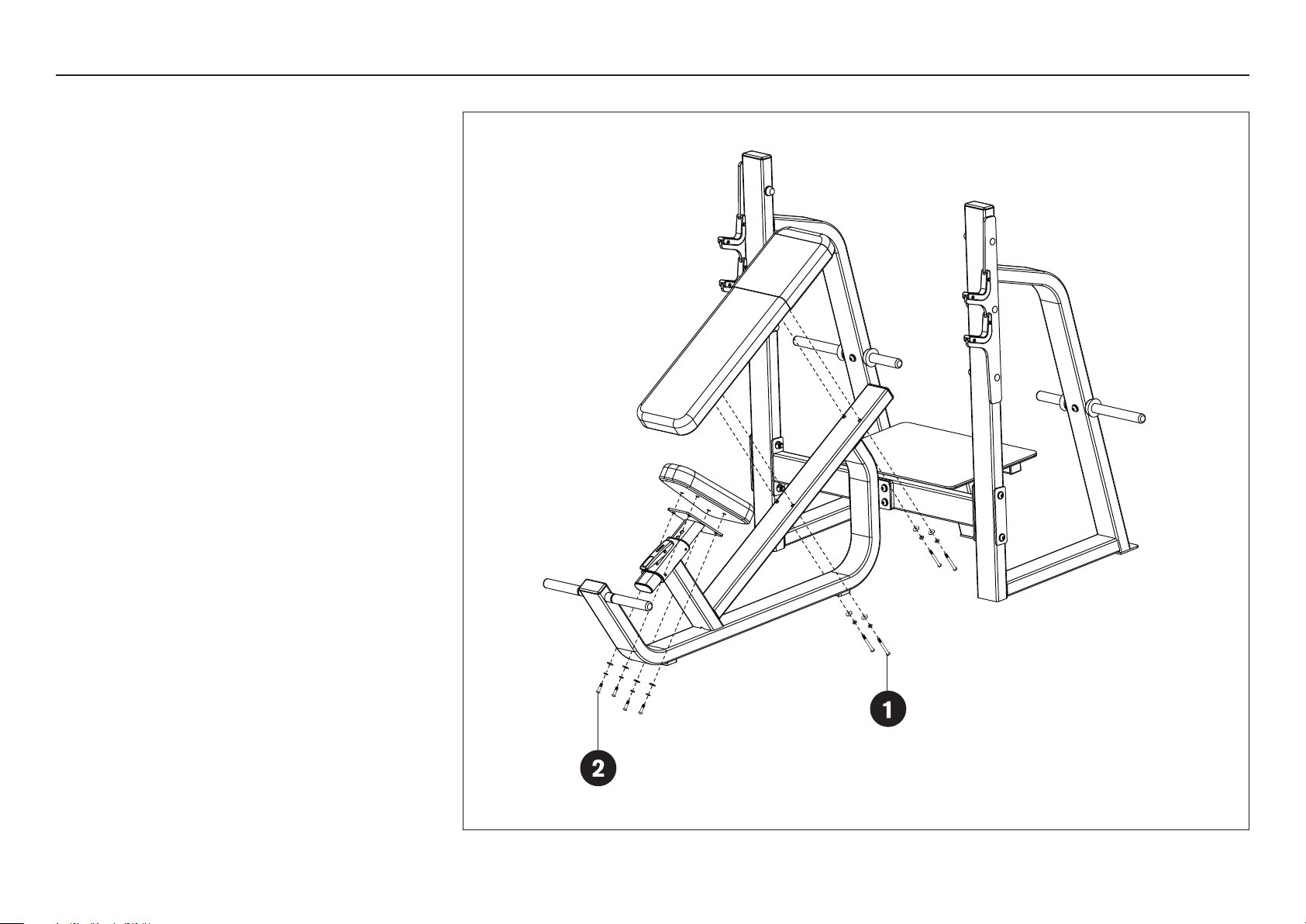

Page 13

CW-410 Assembly Guide

Assemble the Pads

1. Attach the Back Pad to the Base Assembly using

four 3-inch buttonhead screws (N)

four 5⁄16-inch split washers (P)

four 5⁄16-inch washers (R)

Wrench tighten.

2. Attach the Seat Pad to the Seat Adjustment using

four 1¼-inch button head screws (S)

four 5⁄16-inch split washers (P)

four 5⁄16-inch washers (R)

Wrench tighten.

This completes the assembly of the CW-410.

Clean the Pads and Assembly

To clean the pads, moisten a clean, soft cloth in a

mild solution of soap and water and wipe all the parts

thoroughly. Dry the pads with a clean, dry cloth.

Use the same procedure to clean the main structure.

Frequently vacuum the floor underneath the CW-410 to

prevent the accumulation of dust and dirt.

Assemble the Pads

4 - 3” buttonhead screws

4 - split washers

4 - washers

4 - 1¼” buttonhead screws

4 - split washers

4 - washers

page 13

Page 14

CW-410 Assembly Guide

Notes:

page 14

Page 15

CW-410 Assembly Guide

Notes:

page 15

Page 16

CW-410 Specifications

Length: 79 inches (201 cm)

Height: 55 inches (140 cm)

Width: 70 inches (178 cm)

Shipping weight: 280 lb (127 kg)

Precor Incorporated

20031 142nd Avenue NE

P.O. Box 7202

Woodinville, WA USA 98072-4002

1-800-347-4404

Precor, Icarian, and Move Beyond are registered trademarks of Precor Incorporated.

Copyright 2014 Precor Incorporated.

Specifications subject to change without notice.

www.precor.com

NOTICE:

Precor is widely recognized for its innovative, award winning designs of exercise equipment. Precor aggressively seeks U.S. and

foreign patents for both the mechanical construction and the visual aspects of its product design. Any party contemplating the use of

Precor’s product designs is hereby forewarned that Precor considers the unauthorized appropriation of its proprietary rights to be a

very serious matter. Precor will vigorously pursue all unauthorized appropriation of its proprietary rights.

CW-410 Assembly Guide CW34514-104 rev D

30 November 2014

Page 17

General Safety &

Maintenance Manual

Precor Icarian Line

Commercial Strength Equipment

Page 18

Page 19

Important Safety Guidelines for Owners

Follow these guidelines to maintain proper working condition of the

equipment:

Important: Do not modify the equipment or any of its parts, or

permanently remove any part from the equipment. Do not use

accessory attachments that are not recommended by Precor, as

such attachments might cause injuries.

• Qualified technicians must perform all regular maintenance.

• Check that all fasteners are securely tightened. Cables should be

secured at both end connections and properly threaded. Weight

stacks should be secure and functioning properly. Handle

attachments should be properly connected.

• Make sure that trainers, facility personnel, and maintenance

technicians understand how to use the equipment, know

important safety guidelines, and can recognize potential

problems such as a worn cable, loose hardware, or cracked

weld.

• Strength training requires a significant focus by the facility and its

staff to maintain the quality of the fitness environment. If possible,

the facility should provide direct supervision of the fitness

equipment at all times by people knowledgeable about the safe

operation of the equipment and trained to recognize potential

problems.

IMPORTANT SAFETY GUIDELINES

General Safety and Maintenance Manual: Important Safety Guidelines for Owners 1

Page 20

• If any staff member witnesses unsafe use of the equipment, he or

she should address the user directly, demonstrate the proper

technique, and review the Important Safety Information for

Users. Precor recommends posting a copy of the Important

Safety Information for Users near the equipment in a prominent

location.

• Locate the equipment at least 40 inches (1 meter) away from

walls or furniture on either side of the equipment, and 40 inches

(1 meter) away from objects behind the equipment. For

Functional Training equipment, make sure that the operating

space is large enough to allow the cables to be fully extended in

all possible directions.

IMPORTANT SAFETY GUIDELINES

• Make sure the equipment is stable and placed on a solid, level

surface. The equipment is designed to be freestanding; however,

it can be bolted to the floor for extra stability. Precor highly

recommends that the equipment be bolted to the floor to reduce

the risk of toppling the equipment due to improper use. Since

floor construction varies, please consult a professional building

engineer for proper fastening.

• Check the equipment thoroughly based on the recommended

inspection schedules outlined in this manual, including daily,

weekly, monthly and annual checks. Ensure all bolt connections

are tight and that the threaded cables are properly and tightly

secured at both ends.

• Place an “out-of-order” sign on the equipment during

maintenance of the equipment or the surrounding area. Users

should never be allowed to operate the equipment until it has

been inspected and works properly. If a piece of equipment

needs service, keep it out of use until it is repaired.

General Safety and Maintenance Manual: Important Safety Guidelines for Owners 2

Page 21

• When working with the weight stacks, do not attempt to free any

jammed assemblies without assistance as this may cause injury.

With the help of another person, carefully return the weight stack

to the proper position with the top plate resting on the first

weight.

• Do not allow the equipment to be used if the top plate or weight

stack is pinned in a raised position. With the help of another

person, carefully return the machine to the proper position with

the top plate resting on the first weight. Inspect the cable to

ensure that it is seated in all of the pulleys.

• Whenever a weight can drop and hit a user, such as with an

Olympic bench, Precor highly recommends that a helper or

spotter be used to ensure a safe workout with the equipment.

• Do not place the equipment outdoors or on wet surfaces.

IMPORTANT SAFETY GUIDELINES

Safety Approval

Certain Precor commercial strength equipment is Class S/C

certified according to EN957 –1/2 standards. See an authorized

Precor dealer for a complete and current listing of certified

machines.

General Safety and Maintenance Manual: Important Safety Guidelines for Owners 3

Page 22

Important Safety Information for Users

Before beginning any fitness program, you should obtain a complete

physical examination from your physician.

French equivalent of the preceding paragraph, for the Canadian

market: Il est conseillé de subir un examen médical complet avant

d’entreprendre tout programme d’exercise. Si vous avez des

étourdissements ou des faiblesses, arrêtez les exercices

immédiatement.

When using exercise equipment, you should always take basic

precautions, including the following:

• If you do not understand how to operate a piece of equipment, ask

someone from the facility such as a trainer to demonstrate how to

use it and explain any safety instructions.

• Do not allow children on or near the equipment. Do not leave

children unsupervised around the equipment.

• Use the equipment only for its intended purpose. Do not use

accessory attachments that are not recommended by the

manufacturer, as such attachments may cause injuries.

• Wear proper exercise clothing and shoes for your workout—no loose

clothing.

• Do not overexert yourself or work to exhaustion. Use reasonable

judgment when working with weights. Avoid using excessive

weight, which may cause injury.

• If you feel pain, faintness, dizziness, or abnormal symptoms, stop

exercising immediately and consult your physician.

• Never drop or insert objects into any opening in the equipment.

• Check that all fasteners are securely tightened. Cables should be

secured at both end connections and properly threaded. Weight

stacks should be secure and functioning properly. Handle

attachments should be properly connected. Pay particular attention

to the condition of cables and cable ends. If you notice a loose

cable end or any fraying of the cable or cable jacket, do not use the

product and contact someone in the facility immediately.

• Always check the equipment before using it. If you spot a potential

problem, contact someone in the facility immediately. Do not use the

equipment until the facility has verified that the equipment is working

properly. Do not attempt to fix broken or jammed equipment.

• Do not use the equipment outdoors.

• Do not drop or slam the weight stack while exercising.

• Be sure the selector pin is completely inserted. Use only the pin

provided by the manufacturer. If unsure, contact someone in the

facility.

• Never pin the weights in an elevated position. Do not use the

equipment if the top plate or weight stack is pinned in a raised

position. Notify facility’s personnel to repair the equipment and

ensure that it is working properly.

• Do not use the equipment if an “out of order” sign has been placed

on it.

• Read all posted instructions, including all safety instructions and

warnings.

• Keep head, limbs, fingers, and hair clear of all moving parts while the

equipment is in use. Keep hands clear of racking pegs.

General Safety and Maintenance Manual: Important Safety Guidelines for Owners 4

Page 23

Table of Contents

Important Safety Guidelines for Owners ...........................1

Safety Approval ............................................................................... 3

Important Safety Information for Users ...................................... 4

Before You Begin .....................................................................7

Recommended Tools ..................................................................... 7

Obtaining Service ........................................................................... 8

Daily Inspection ........................................................................9

Clean Upholstery ............................................................................ 9

Inspect Pads for Wear ................................................................10

Clean and Inspect Frames .........................................................10

Inspect All Fasteners ...................................................................11

Inspect Cables and End Connections .....................................11

Check Warning Labels and Instruction Placards .................13

Weekly Inspection ................................................................. 15

Condition and Deep Clean Upholstery ...................................15

Clean and Lubricate Cable Rod Ends .....................................16

Clean and Lubricate Guide Rods .............................................16

Inspect Cables, Connections, and Tension ...........................17

Inspect Cable Handle Attachments .........................................18

Inspect Pulleys ..............................................................................18

Inspect Weight Stack and Selector Pin ..................................18

Inspect and Lubricate Bearings and Bushings .....................19

Check Seat Adjustment and Test Pop Pins ...........................20

General Safety and Maintenance Manual: Table of Contents 5

Page 24

Monthly Inspection ................................................................21

Inspect Frames and Movement Arms ......................................21

Lubricate Pop Pins .......................................................................22

Check and Lubricate Ratcheting Seat Lever .........................23

Inspect All Fasteners ...................................................................24

Annual Maintenance ..............................................................25

Weight Stack Annual Maintenance ..........................................25

Inspect and Lubricate Pop Pins ................................................26

Recommended Maintenance Checklist ............................27

General Safety and Maintenance Manual:: Table of Contents 6

Page 25

Before You Begin

Precor recommends implementing a thorough maintenance program

that incorporates regular safety inspections by qualified maintenance

technicians as outlined in this manual.

This manual explains how to maintain the Precor Icarian line of

commercial strength equipment. It provides information about items

that need to be inspected and maintained on a daily, weekly, monthly,

and annual basis. You should perform those tasks that are appropriate

for the equipment you are maintaining, and skip those tasks that do

not apply. To help you, a checklist is located at the back of this manual

that you can follow during your maintenance checks to ensure that

nothing appropriate is missed and that your inspection process is

documented.

This manual covers the general maintenance procedures that you can

perform in the fitness facility. However, if the equipment requires

service beyond the maintenance procedures covered in this manual,

refer to Obtaining Service.

Important: Always purchase replacement parts and hardware from

Precor. These parts are tested and manufactured specifically for the

Precor Icarian line of commercial strength equipment. If you use parts

not approved by the manufacturer, you could void the Precor Limited

Warranty. Use of parts not approved by Precor may cause injury.

Recommended Tools

We recommend that you put together a toolbox with the following

tools. This list covers the tools you may need when you inspect and

maintain the equipment.

• Complete combination box wrench set from ¹⁵⁄₁₆ to ¹₂-inch

• Complete socket set from ¹⁵⁄₁₆ to ¹₂-inch

• Hex nut driver: ¹₄-inch

• 12-inch adjustable wrench

• Complete hex key set from ³⁄₈ to ⁵⁄₆₄-inch

• Rubber mallet

• Straight shank punch: ¹₄-inch

Precor recommends that maintenance technicians thoroughly read

and understand the safety guidelines and maintenance procedures

covered in this manual.

Note: If the equipment requires assembly, a separate assembly guide

is provided. For information on how to use a piece of equipment, refer

to the instructional label found on the equipment.

General Safety and Maintenance Manual: Before You Begin 7

Page 26

Obtaining Service

You should not attempt to service the strength equipment, except for

the maintenance tasks described in this manual. If any items are

missing, contact your dealer. If you need more information regrading

customer support numbers or a list of Precor authorized service

centers, visit the Precor website at www.precor.com.

If you have any questions regarding a piece of equipment, locate its

serial number and contact Precor Customer support. Precor uses the

serial number to establish the model and year of the product. You can

generally find the serial number underneath the seat support.

For future reference, write the serial numbers, model numbers, and

dates of purchase for your Precor strength training equipment in the

space provided. You may want to list all equipment information below

for easy reference.

Model #: _______ Serial #: _______________________

Date purchased: _________________________

Model #: _______ Serial #: _______________________

Date purchased: _________________________

Model #: _______ Serial #: _______________________

Date purchased: _________________________

Model #: _______ Serial #: _______________________

Date purchased: _________________________

Model #: _______ Serial #: _______________________

Date purchased: _________________________

Model #: _______ Serial #: _______________________

Date purchased: _________________________

General Safety and Maintenance Manual: Before You Begin 8

Model #: _______ Serial #: _______________________

Date purchased: _________________________

Model #: _______ Serial #: _______________________

Date purchased: _________________________

Model #: _______ Serial #: _______________________

Date purchased: _________________________

Page 27

Daily Inspection

You will need to perform the following tasks each day to maintain the

equipment and keep it operating smoothly:

• Clean any upholstery on the equipment.

• Inspect pads for wear.

• Clean and inspect equipment frames.

• Inspect cables and end connections for wear.

• Check warning and instructional labels for readability.

• Check that all fasteners are properly secured.

Clean Upholstery

To remove surface dirt and perspiration, clean upholstery daily with a

mild soap and water solution in a spray bottle. Spray upholstered

surfaces lightly and wipe dry with a clean cloth.

Important: To clean the upholstery, do not use cleaning products that

have any of these ingredients: solvents, alcohol, ammonia, or

petroleum. Use a mild detergent-based cleaner instead.

General Safety and Maintenance Manual: Daily Inspection 9

Page 28

Inspect Pads for Wear

Clean and Inspect Frames

Inspect pads for cracks in the upholstery, broken and loose stitching,

loose staples, and loose mounting bolts. Replace pads as needed

(refer to Obtaining Service to purchase new pads.)

Important: Do not reupholster pads or use pads not approved by

Precor.

To remove grease and dirt, clean frames daily with a mild soap and

water solution in a spray bottle. Wipe the equipment down with a

damp cloth and dry completely. Be sure to wipe down both painted

parts and chrome or plated parts.

To restore and maintain luster of chrome parts, use a commercial

chrome cleaner.

As you clean, inspect the frames for cracks, rust, or other damage.

Make sure welds are solid and fasteners are properly secured.

General Safety and Maintenance Manual: Daily Inspection 10

Page 29

Inspect All Fasteners

Inspect Cables and End Connections

Fasteners can loosen with normal use. Inspect all nuts, bolts, screws

and other fasteners to make sure they are tight and installed correctly.

Be sure to check fasteners at bolted joints to make sure the

connections are secure. If a fastener is loose but in good condition,

retighten it. If you are concerned about the integrity of the fastener,

remove it, clean the threads and inspect it for any damage such as

cracks, bad threads, corrosion, or rust. Reinstall the fastener if it

appears to be in good condition. Otherwise, remove the equipment

from service until a new fastener can be installed properly. You can

order new fasteners from Customer Support. For additional

information refer to Obtaining Service.

Important: Fastener quality and specifications vary considerably.

Replace only with the Precor approved fastener specifically

engineered for the precise application. Failure to do so will void the

Precor Limited Warranty.

CAUTION: Carefully inspect the cables, pulleys, fasteners, and

related hardware regularly. Replace any cable at the first sign of

wear using only Precor-supplied replacement parts. With regular

use, a cable can become worn and might fail. Sudden failure of

a worn cable can cause severe injury to a user. Refer to

Obtaining Service to purchase replacement parts.

Inspect the cables and end connections each day, and replace if

damaged. Check for kinks, frayed wires, or deterioration of the cable

coating. Look for signs of wear particularly at crimped ends of the

cable and near pulleys. (Refer to Figure 1.)

Important: Cables must be replaced immediately if they are

damaged to avoid possible injury to users.

General Safety and Maintenance Manual: Daily Inspection 11

Page 30

Some obvious signs of cable damage are as follows:

Exposed inner wire

Zig-zag/wavy

Kinked

Necked-down

Ballooned

Cable bolt must be inserted a

minimum of 7 threads into the

selector stem.

Locking jam nut

1. Exposed inner wire, stretching or cuts in the coating, or broken

coating in the area that passes over a pulley

2. A zigzag or wavy pattern

3. Kinks, which may indicate internal damage

4. A necked-down cover

5. A ‘ballooned” cover

In addition to inspecting the cables and end connections for damage,

check the following:

• Ensure that each cable is properly adjusted and tightened at the top

of the weight stack.

• Check cable pulleys, end connections, and end fittings. Make sure

all connections are tight, adjusting cable tension as necessary.

• Make sure that the cable bolt is threaded at lease seven turns into

the selector stem or a minimum of ¹₂-inch (13 mm). The distance

shown should be ³₄-inch (19 mm) or less. Tighten the locking jam

nut to 600 in-lb (68 N-m). Refer to Figure 2.

Figure 1: Signs of cable damage

General Safety and Maintenance Manual: Daily Inspection 12

Figure 2: Proper cable bolt insertion

Page 31

Check Warning Labels and Instruction

Improper use of this machine will result in injury.

Before using, consult a qualified instructor.

Inspect cables and connections and do not use

if any component is worn or damaged.

CAUTION

PULLDOWN 304

Select appropriate lifting weight.

Adjust thigh pad to rest securely

on top of legs.

Grip bar with hands evenly spaced.

Pull bar down to upper chest

with a slow, controlled movement,

pulling handles behind neck is

not recommended, as injuries

could result.

Slowly return to the start position.

Placards

Inspect warning and instructional labels daily tom make sure that all

the information can be clearly read. If any portion is not visible or part

of the label is not adhered properly, replace that label immediately

(refer to Obtaining Service for purchase information).

Clean labels and placards as needed with a mild soap and water

solution in a spray bottle, and dry thoroughly with a soft cloth.

The following figure shows an example of a user instructional label.

Figure 3 shows a typical user instruction placard.

Figure 3: Sample user instruction placard

General Safety and Maintenance Manual: Daily Inspection 13

Page 32

Precor products come equipped with a number of standard warning

KEEP HANDS AND FEET CLEAR WHILE MACHINE IS IN USE

The weight stack cable bolt must be

inserted a minimum of seven full turns

into the selector stem, and the jam nut

tightened down firmly against the

selector stem top.

labels. The following figures show sample warning labels you may see

on the equipment depending on the model and product line:

Figure 4: This warning label may appear on weight stacks with a pulley

mounted at the top

Figure 5: This warning label may appear on or near weight stacks where

a cable bolt is threaded into the selector stem

Figure 6: A version of this warning label appears on the equipment frame

General Safety and Maintenance Manual: Daily Inspection 14

Page 33

Weekly Inspection

This section covers the tasks you should do each week to maintain the

equipment. Perform the following tasks as appropriate for the unit you

are maintaining:

• Condition and deep clean upholstery.

• Clean and lubricate cable rod ends.

• Clean and lubricate guide rods.

• Inspect cables, connections, and tension.

• Inspect cable handle attachments.

• Inspect pulleys.

• Inspect each weight stack and selector pin.

• Inspect and lubricate bearings and bushings.

• Check seat adjustment and test pop pins.

Condition and Deep Clean Upholstery

Condition and deep clean the upholstery weekly with a lanolin-based

hand cleaner or upholstery cleaner.

Important: To clean the upholstery, do not use cleaning products that

have any of these ingredients: solvents, alcohol, ammonia, or

petroleum. Use a mild detergent-based cleaner instead.

General Safety and Maintenance Manual: Weekly Inspection 15

Page 34

Clean and Lubricate Cable Rod Ends

Lubricate here

Clean and Lubricate Guide Rods

Inspect the exposed areas of the guide rods for cleanliness. Using a

dry cloth, wipe any buildup of dirt of grease from the rods. Check

cable rod ends to ensure the shoulder bolt is secure. If cable rod ends

are noisy, you can lubricate them with a silicone spray lubricant, such

as Super Lube®. Spray the lubricant onto the joint where the spherical

portion is enclosed in the outer housing (refer to Figure 7). Wipe off

any excess lubricant with a cloth.

Figure 7: Lubricate cable rod ends with silicone spray lubricant

Important: Do not use petroleum-based lubricants such as WD-40®,

Vaseline®, or motor oil.

Inspect the exposed areas of the guide rods for cleanliness. Using a

dry cloth, wipe any buildup of dirt or grease from the rods.

Lubricate the exposed areas of the guide rods by applying a light coat

of a silicone spray lubricant. Spray the silicone lubricant on a cloth and

then wipe the guide rods with the cloth. Be careful with any lubricant

spray; it can stain carpet and clothing.

CAUTION: Do not attempt to lubricate the guide rods when the

equipment is in use. Attempting to lubricate between the weight

plates without completely disassembling the stack will result in

serious injury.

Important: Do not use petroleum-based lubricants or motor oil.

These lubricants tend to cause a rapid buildup of dirt and hair on the

weight plates, which can cause the plates to stick together.

Note: The CW802 Smith Machine has counter-balance guide rods

behind the maintenance shields, which should be cleaned and

lubricated weekly.

General Safety and Maintenance Manual: Weekly Inspection 16

Page 35

Inspect Cables, Connections, and

Tension

Each week, give the cables and connections a thorough inspection

and check cable tensions. The following lists the specific things you

need to inspect:

• Check the cable termination at the weight stack. Make sure that the

cable bolt is threaded at least a minimum of seven turns into the

selector stem or a minimum of ¹₂-inch (13 mm), so that there is no

more than ³₄-inches (19 mm) between the top of the jam nut and

base of the bolt head. Check and adjust accordingly. Also make

sure that the locking jam nut is tight against the selector stem.

• Check the cable, especially near all pulleys, wheels, and cams.

• Check the cable as it terminates at the cam, which is stationary on

most equipment. Inspect the bolt passing through the cam end

fitting to be sure the two jam nuts are tightened against each other.

Also, check the entire cable routing to verify that there is no

interference with any structure.

• Inspect the ball end of the cable where the cable connection rests

in the clevis housing.

• Ensure that each cable is properly adjusted and tightened at the top

of the weight stack.

• Check cable pulleys, end connections, and end fittings. Make sure

all connections are tight, adjusting cable tension as necessary.

General Safety and Maintenance Manual: Weekly Inspection 17

Page 36

Inspect Cable Handle Attachments

Check these

areas closely.

Spring clip gate

properly closed

Spring clip gate not

properly closed

Inspect Pulleys

Check the cable-to-handle attachment area very closely. Refer to

Figure 8. Look for frayed cable ends, broken thimbles, bent cables,

worn spring clips, worn handles, and any other unusual wear.

Figure 8: Check connections to handles carefully

Also, check the spring clip gate and make sure it closes properly and

engages securely. Refer to Figure 9. Check the spring clip, links, and

cable to ensure integrity; replace any spring clip link that does not

function properly or shows wear.

Precor uses precision ball bearing idler pulleys to smoothly guide

the cable.

Inspect each pulley for damage, including hairline cracks, chips, or

missing sections. Worn surfaces in the pulleys can cause severe

damage to the cables and must be replaced at the first sign of wear or

damage.

Be certain that the wheels turn freely as the equipment is used.

Inspect each pulley for excessive side-to-side play, which indicates

worn bearings or loose mounting bolts. If excessive play is discovered,

remove the pulley to inspect the bearings, and replace the entire

pulley if necessary.

Inspect Weight Stack and Selector Pin

Weight stacks are made of precision machine plates that are

designed as a single mechanism to stack precisely. Use only Precorsupplied add-on weights and weight selector pins.

On a weekly basis, inspect weight stacks and selector pins. Wipe

each plate with a damp cloth as needed. Inspect all plates for sharp

burs or damage. Wipe dirt and dust off the guide rods.

Make sure the equipment uses only the original Precor selector pin. In

addition, make sure the selector pin can be fully inserted and retained

in each weight plate.

Figure 9: Check spring clip gate to ensure proper closure

General Safety and Maintenance Manual: Weekly Inspection 18

Page 37

Inspect and Lubricate Bearings and

Bushings

Precor uses high quality bearings designed for strength applications

and long service life. Each week, do the following to maintain the

bearings and bushings on the equipment:

• Bronze bushings: Precor recommends using a small amount of

silicone spray lubricant to lubricate the bushings. Spray directly

onto the guide rod and then rotate the guide rod through its

complete range of motion several times. Inspect bushings for

excessive wear and damage. Be careful when using the spray

lubricant; it can stain carpet and clothing. Wipe off any excess

lubricant with a cloth.

• Nylon bushings: Lubricate the nylon bushings on the guide rods by

applying a light coat of silicone spray lubricant. Spray the silicone

lubricant on a clot, then wipe the cloth along the full length of the

guide rod.

• Sealed Bearing Pivot Points: These locations are protected from

the outside environment and require no lubrication. While cleaning

the equipment, wipe down the guide rods and external bearing

surfaces with a cloth to prevent the build up of dust and

perspiration.

• Linear Bearings: Case hardened guide rods are used in areas that

use linear bearings (refer to Figure 10). Inspect each end of the rod

to ensure they are fastened correctly and all bolts are tight.

Wipe down rods using a light application of a silicon spray lubricant

to remove dust, hair, and dirt. Polish the guide rod using fine grade

steel wool if surface rust or oxidation is present.

Important: Do not use petroleum-based lubricants or motor oil.

These lubricants tend to cause a rapid buildup of dirt and hair on

the weight plates, which can cause the plates to stick together.

If you lubricate the rods regularly, then the bearings will function as

designed. Otherwise, the rods may corrode, which can cause the

bearing to become clogged and jammed, leading to the bearing

actually gouging the rod. Be sure to remove surface rust and

oxidation from the hardened rails immediately.

Figure 10: Shows a typical location of a linear bearing in its housing

General Safety and Maintenance Manual: Weekly Inspection 19

Page 38

Check Seat Adjustment and

Test Pop Pins

Precor strength equipment has two types of adjustments:

• 2x4-inch or 2x2-inch telescoping sleeve adjustment for most seat

assemblies

• ¹₂-inch slotted plate adjustments used on most free-weight bench

adjustments

Inspect all adjustments for proper fit and function. Inspect plastic

sliders for excessive wear or damage.

Adjustments use either a high-tensile pop pin plunger assembly or a

ratcheting lever assembly. Inspect and tighten all pop pin caps.

General Safety and Maintenance Manual: Weekly Inspection 20

Page 39

Monthly Inspection

This section covers the tasks you should perform each month to

maintain the equipment. Perform the following tasks as appropriate for

the unit you are maintaining:

• Inspect frames and movement arms.

• Lubricate pop pins.

• Check and lubricate ratcheting seat lever

• Inspect all fasteners.

Inspect Frames and Movement Arms

Inspect frames and movement arms monthly for proper function and

integrity. Check for cracks, chipped paint, or rust. Touch up dings and

chips in the paint as needed. Replace any component at first signs of

wear.

Note: You can order touch-up paint from Precor by calling Customer

Support. Refer to Obtaining Service.

Inspect frames for cracks particularly at the joints. If any cracks are

found, immediately take the equipment out of service, and repair it

using a qualified maintenance technician. Refer to Important Safety

Guidelines for Owners and Obtaining Service).

General Safety and Maintenance Manual: Monthly Inspection 21

Page 40

To remove surface rust from the frame, rub lightly with a fine wet/dry

sand paper or fine steel wool. Finish with Precor’s touch-up paint if

needed. Maintain paint luster with an application of a mild automotive

wax product.

To maintain the powder coated and chrome parts, use a mild

detergent-based cleaner for light dirt and grime removal. For removing

heavier dirt and grease and for polishing, use a good automotive

polish. For scuffs and marks that are not removed by the above

methods, use a fine-grit cleanser. Do not use solvents, lacquer thinner,

acetone, or finger nail polish remover. For high wear areas, ABS

shields have been provided. Replacement shields are available from

Precor Customer Support. For additional information refer to

Obtaining Service.

Lubricate Pop Pins

Pull out the pop pin as far as it goes and apply a small amount of

silicone spray lubricant. Wipe off any excess lubricant with a cloth.

(Refer to Figure 11.)

CAUTION: Pulling out the pop pin may cause the unit to adjust

position suddenly. To avoid injury, keep your hands and head

away from moving parts.

Test the pop pin for proper function and engagement in each

adjustment hole.

Figure 11: Lubricate the pop pin by pulling it out

General Safety and Maintenance Manual: Monthly Inspection 22

Page 41

Check and Lubricate Ratcheting

Seat Lever

Precor designed the ratcheting seat so users can easily move the seat

to a comfortable position. After lowering the seat by pressing on the

lever to disengage, a user can sit on the seat and pull it up to the

desired position. As the seat moves, the ratcheting lever snaps in and

out of each hole, making an audible noise.

The ratcheting seat requires little maintenance. However, because

seat safety is important to the safety of a workout, you should check

the ratcheting seat lever each month to see if it sticks when used. You

also want to ensure that the pin fully engages in each adjustment hole.

To test if the seat lever needs lubrication, slightly elevate the seat while

pressing and releasing the lever. The lever should snap back out

easily. If the lever sticks, lubricate the pivot pin in the lever with silicone

spray lubricant. Wipe off any excess lubricant with a cloth. (Refer to

Figure 12.)

Lubricate on each side with a

silicone spray lubricant.

Figure 12: If needed, lubricate the pivot pin on the ratcheting seat lever

If desired, you can detach the seat by removing the retaining pin,

allowing you to remove the chrome for cleaning. Removing the seat

also allows clear access to the ratcheting lever to test its pivoting

action.

General Safety and Maintenance Manual: Monthly Inspection 23

Page 42

Inspect All Fasteners

Precor products are assembled with Grade 5 fasteners or better. With

normal use, these fasteners can loosen. Inspect all nuts, bolts, hex key

bolts, screws, and other fasteners to ensure they are tight and

installed correctly.

Be sure to check fasteners at bolted joints to ensure connection is

secure. If the fastener is loose, but in good condition, retighten it. If

you are concerned about the integrity of the fastener, remove it, clean

the threads, and inspect it for any damage such as cracks, bad

threads, corrosion, or rust. Reinstall the fastener if it appears to be in

good condition. Otherwise, remove the equipment from service until a

new fastener can be installed properly. You can order new fasteners

from Customer Support. Refer to Obtaining Service.

General Safety and Maintenance Manual: Monthly Inspection 24

Page 43

Annual Maintenance

Perform these tasks on an annual basis, as appropriate for your

equipment:

Weight Stack Annual Maintenance

Once a year, Precor recommends disassembling the weight stack to

clean and inspect it thoroughly.

• Carefully remove the cable and guide rods from the weight stack.

Completely disassemble the weight stack in a well-ventilated area,

away from the exercise floor.

• Inspect weight plates and clean them thoroughly. Cracked or

broken plates should be replaced immediately (refer to Obtaining

Service to purchase replacements). Clean each plate individually

and inspect guide bushings.

• Inspect the bushings of the top weight plate and each individual

weight plate and replace a plate if it is excessively worn or broken.

• Clean the selector stem and inspect it for wear and damage.

• Reassemble the weight stack.

• Wipe down the weight stack enclosures (shrouds) with a damp

cloth as needed. Inspect all fasteners to ensure the shroud is

securely mounted.

Important: Precor recommends that you replace worn and damaged

cables during routine maintenance. It is recommended that all cables

be replaced annually.

General Safety and Maintenance Manual: Annual Maintenance 25

Page 44

Inspect and Lubricate Pop Pins

Pop pin plunger

assembly shown with

telescoping sleeve type

adjustment

Hex head cap

Remove the pop pin assembly by loosening the hex head cap.

CAUTION: Pulling out the pop pin may cause the unit to adjust

position suddenly. To avoid injury, keep your hands and head

away from moving parts.

Inspect the plunger and spring for excessive wear and damage, and

replace as required.

Apply a small amount of silicone spray lubricant to the spring and

plunger, and then reinstall the entire assembly. Tighten hex head cap.

Wipe off any excess lubricant with a cloth.

Figure 13: Inspect pop pins (pop pin shown in exploded view for clarity)

General Safety and Maintenance Manual: Annual Maintenance 26

Page 45

Recommended Maintenance Checklist

Please retain for your records.

Maintenance Record the Month of ______________________

Brand Name ______________________

Model Name & Number ______________________

Serial Number ______________________

In Service Date ______________________

Initial box when completed: write N/A if not applicable to the equipment.

Daily Check 1 2 3 4 5 6 7 8 9 10111213141516171819202122232425262728293031

Clean upholstery

Clean & inspect frames

Inspect pads for wear

Inspect cables & end connections

Check labels and placards

Week ly Check

Condition & clean upholstery

Clean & lubricate cable rod ends

Clean & lubricate guide rods

Inspect cables/connections/tension

Inspect cable handle attachments

Inspect pulleys

Inspect each weight stack & Pin

Inspect & lube bearings & bushings

Check seat adjust. and pop pins or

Inspect frames & movement arms

Inspect & lubricate pop pins or

Check & lubricate ratcheting seat

Weigh t st ack main tenance Date: Initials:

Inspect & lubricate pop pins or

ratcheting lever

Monthly Check 28

ratcheting lever

Inspect all fasteners

Annual Check

ratcheting lever

Maintenance Tips

Upholstery Wipe clean using a mild soap and water solution or other appropriate cleaner for vinyl.

Cable Replace any cable that shows signs of wear or damage.

Frames Wipe clean using a mild soap and water solution.

Guide rods Lubricate guide rods with silicone spray lubricant.

Date Initials:

7 14 21 28

Important: It is recommended that cables be changed annually. Only factory provided selector key, lanyard, handle attachment, and handle should be used on selectorized weight

General Safety and Maintenance Manual: Recommended Maintenance Checklist 27

stacks. Use of any parts other than those provided by the manufacturer will invalidate the product warranty and may cause injury to users.

Page 46

Notes:

General Safety and Maintenance Manual: Recommended Maintenance Checklist 28

Page 47

Page 48

Precor Incorporated

20031 142nd Ave NE

P.O. Box 72 0 2

Woodinville, WA USA 98072-4002

Precor, Icarian, Jade, and Move Beyond are registered trademarks of Precor Incorporated.

Super Lube is a registered trademark of Synco Chemical Corporation.

WD-40 is a registered trademark of CD-40 Company.

Vaseline is a registered trademark of Unilever.

Copyright 2014 Precor Incorporated.

Specifications subject to change without notice.

www.precor.com

NOTICE:

Precor is widely recognized for its innovative, award winning designs of exercise equipment. Precor

aggressively seeks U.S. and foreign patents for both the mechanical construction and the visual aspects of its

product design. Any party contemplating the use of Precor product designs is hereby forewarned that Precor

considers the unauthorized appropriation of its proprietary rights to be a very serious matter. Precor will

vigorously pursue all unauthorized appropriation of its proprietary rights.

General Safety & Maintenance Manual CW39162-111 rev A, en

31 October 2014

Loading...

Loading...