PWS, 8M COVER PAGE

Please read this Owners’ Guide

completely before installing or

operating your

Precision Water Distiller.

Specifications are subject to

change without notice.

Precision

Water Distillers

Owners’ Guide

Model: 8-M Model: 8-MST

Part No. 500000 Part No. 500001

Series: 0015 Series: 0014

Manufactured By:

Precision Design & Manufacturing Inc.

9024-100 Street

Westlock, AB, Canada

T7P 2L4

http://www.precisioncanada.com

e-mail: info@precisioncanada.com

Phone: (780) 349 4933

FAX: (780) 349 4957

Part No. 097126A

Series: 0015

Printed in Canada

This page left intentionally blank.

2

Table of Contents

TABLE OF CONTENTS .............................................................................................................................. 3

INTRODUCTION ........................................................................................................................................ 4

RECORDS ..................................................................................................................................................... 5

PRECISION WATER SYSTEMS WATER DISTILLER WARRANTY ................................................ 6

IMPORTANT SAFETY PRECAUTIONS .................................................................................................. 7

PRECISION WATER SYSTEMS WATER DISTILLER OWNERS' SUMMARY ............................... 8

WATER DISTILLER AND OPTIONAL STORAGE TANK FEATURES ............................................ 9

10 FACTORS THAT WILL AFFECT YOU WATER DISTILLER PRODUCTION ......................... 10

UNDERSTANDING HOW PURE WATER IS PRODUCED ................................................................. 12

FINDING A GOOD INSTALLATION LOCATION ............................................................................... 13

UNPACKING YOUR WATER DISTILLER ........................................................................................... 13

WATER DISTILLER INSTALLATION TOOLS ................................................................................... 15

WATER DISTILLER LEG INSTALLATION ........................................................................................ 16

OPTIONAL STORAGE TANK ASSEMBLY .......................................................................................... 16

OPTIONAL STORAGE TANK TO DISTILLER HEAD ASSEMBLY ................................................ 18

IMPURITIES DRAIN TUBE INSTALLATION...................................................................................... 19

BOILING TANK LID INSTALLATION ................................................................................................. 20

OPTIONAL STORAGE TANK LID REMOVAL AND INSTALLATION .......................................... 20

OPERATION ............................................................................................................................................... 21

CONTROLS - POWER, FAN, AND OVERHEAT RESET ..................................................................................... 21

BEFORE INITIAL WATER DISTILLER OPERATION ......................................................................................... 23

NORMAL OPERATION .................................................................................................................................. 23

MAINTENANCE AND CLEANING ........................................................................................................ 25

REGULAR INSPECTION AND CLEANING OF BOILING TANK .......................................................................... 25

CLEANING THE BOILING TANK USING CLEANER DESCALER ....................................................................... 26

REPLACING CHARCOAL IN POST CHARCOAL FILTER CANISTER (USED WITH 8-M) ..................................... 27

REPLACING CHARCOAL IN CHARCOAL FILTER CANISTER (USED WITH 8-MST) ......................................... 28

STERILIZATION............................................................................................................................................ 29

Liquid Sterilization of Optional Storage Tank ........................................................................................ 29

Steam Sterilization of Water Distiller Head ............................................................................................ 30

Steam Sterilization of Water Distiller Head, Filter Canister and Optional Storage Tank ...................... 32

Maintenance Schedule Table .................................................................................................................. 33

Owner Maintenance Record Table.......................................................................................................... 33

TROUBLESHOOTING .............................................................................................................................. 34

ADDITIONAL OPTIONS .......................................................................................................................... 36

SPECIFICATIONS AND TECHNICAL INFORMATION .................................................................... 37

WIRING LIST AND SCHEMATICS .................................................................................................................. 38

INDEX .......................................................................................................................................................... 40

WARRANTY REGISTRATION CARD ................................................................................................... 41

3

Introduction

Congratulations on the purchase of the most advanced water distiller

in the industry! When installed and maintained properly, your

Precision Water Systems water distiller will provide years of safe,

trouble free service. It is important to observe and follow the safety

and maintenance instructions carefully. If you have any questions or

concerns regarding installation or operation of your water distiller,

please contact your dealer.

All 120 VAC Precision Water Systems Water Distillers are certified to

cCSAus Classes 2831-02 and 2831-82 under the Canadian and

American Electrical Code.

All Water distillers are factory tested with a high voltage ‘Dielectric

Strength Test’ and ground fault test prior to shipping.

Precision Water Systems Water Distillers have been tested by

EnviroTest Laboratories which found the water distillation units to be

very effective water treatment systems capable of removing both

harmful pathogens and toxic chemicals from water. In their study all

pathogens were eliminated and none were found in the distilled

water. The water distillation system also effectively removed all of

the soluble inorganic chemicals tested. Removal efficiencies of 99%

or greater were achieved for almost every chemical tested.

All Precision Water Systems Water Distillers are operated and tested

at the factory and have produced distilled water to make sure all

components are functioning properly. All water distillers are wiped

clean before shipping, but there may be a water ring inside the boiling

tank. There may also be an off-colour line at the seams of the

storage and boiler tank. This is caused by the TIG welding process

used during manufacturing. This is normal and is not a sign of a

problem. Follow all the Before Initial Water Distiller Operation

procedures and you will have pure water in no time.

Your Precision Water Systems Water Distiller must be installed

according to any Local, State or Provincial Regulations.

4

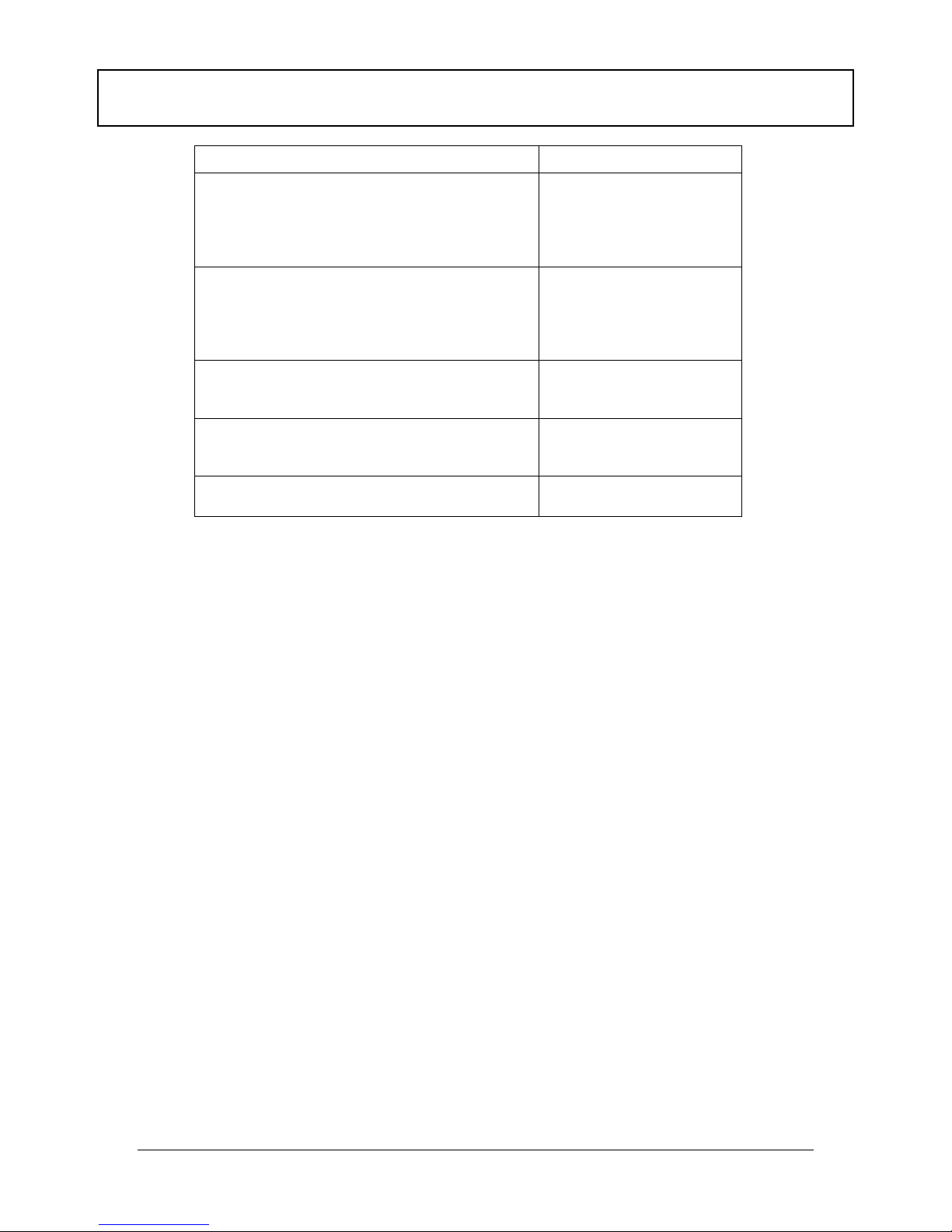

Records

SERIAL PLATE LOCATION DIAGRAM - 8GPD

SERIAL PLATE LOCATION DIAGRAM - MST

Please record all of the important information below to assist you and the service

center in case there is any service work required in the future. All of the

information is required to properly identify your water distiller and optional

storage tank and will make servicing much easier. The information is located on

the serial plate on the side of the water distiller head and optional storage tank.

The Serial Plate Location Diagram below shows sample serial plates.

Distiller Head Optional Storage Tank

Serial Plate Location Diagram

Distiller Head:

Model: PWS 8-M

Series: eg: 0001

Serial Number: eg: 0123012

Optional Storage Tank:

Model: PWS 8-MST

Series: eg: 0001

Serial Number: eg: 0123012

Date of Purchase: ___________________________________________________

5

Precision Water Systems Water

Distiller Warranty

- The warranty for your Precision Water

Systems Water Distiller covers defects in

materials for two (2) years on all parts and

labour to the original purchaser.

- Stainless Steel parts are covered by a 15 year

pro rated warranty. This covers all stainless

steel parts such as the boiling and optional

storage tank. With this warranty it is the

responsibility of the distiller owner to properly

maintain the distiller. If there is any misuse

or abuse the warranty will be void.

- Precision Water Systems does not warrant any

transportation charges incurred to complete

the repair. The distiller owner is responsible

for all shipping charges to and from the

service center.

- Warranty is void if the distiller is found to

have been consumer damaged or misused,

caused by acts of God, unauthorized

alteration, repair or vandalism.

6

Important Safety Precautions

When using electrical appliances, basic safety precautions should always be

followed including the following:

1. Read all instructions.

2. Do not touch hot surfaces. Use handles or knobs.

3. To protect against electrical shock do not immerse cords or plugs in

water or other liquid.

4. Close supervision is necessary when any appliance is used near

children.

5. Do not allow children to operate this appliance.

6. Unplug from outlet when not is use and before cleaning. Allow to cool

before putting on or taking off parts.

7. Do not operate any appliance with a damaged cord or plug or after the

appliance malfunctions or has been damaged in any manner. Return

appliance to the nearest service facility for examination, repair or

adjustment.

8. The use of accessory attachments not recommended by the

appliance manufacturer may cause injuries.

9. Do not use outdoors.

10. Do not let cord hang over edge of table counter, or touch hot surfaces.

11. Do not place on or near a hot gas or electric burner, or in a heated

oven.

12. Extreme caution must be used when moving an appliance containing

hot water.

13. Always attach plug to appliance first, then plug cord into the wall

outlet. To disconnect, turn any controls to “off”, then remove plug

from wall outlet.

14. This appliance is intended for household use.

15. Save these instructions.

Additional Safety Recommendations

1. Always unplug appliance before servicing.

2. Do not use extension cords with appliance.

3. Ensure there is adequate air space around the appliance to allow the heat

from the appliance to be removed and supply adequate fresh air for

cooling.

7

Precision Water Systems Water Distiller

Owners’ Summary

The following is a summary of the information contained in this

Owners’ Guide and required to install and operate your Water

Distiller

1) Find a good location for installing your Water Distiller –

See Finding a Good Installation Location.

2) Unpack the water distiller and parts - See Unpacking

Your Water Distiller.

3) Assemble the Water Distiller – See

Water Distiller Leg Installation

Optional Storage Tank Assembly

Impurities Drain Tube Installation

Boiling Tank Lid Installation

4) Steam sterilize boiling tank – See Steam Sterilization

of Water Distiller Head in the Maintenance and

Cleaning section.

5) Load Charcoal Filter Canister – See Replacing

Charcoal in Post Charcoal Filter Canister (Used

with 8-M without Optional Storage Tank) in the

Maintenance and Cleaning section.

6) Follow procedure in Normal Operation section.

7) Enjoy pure, distilled water!

8

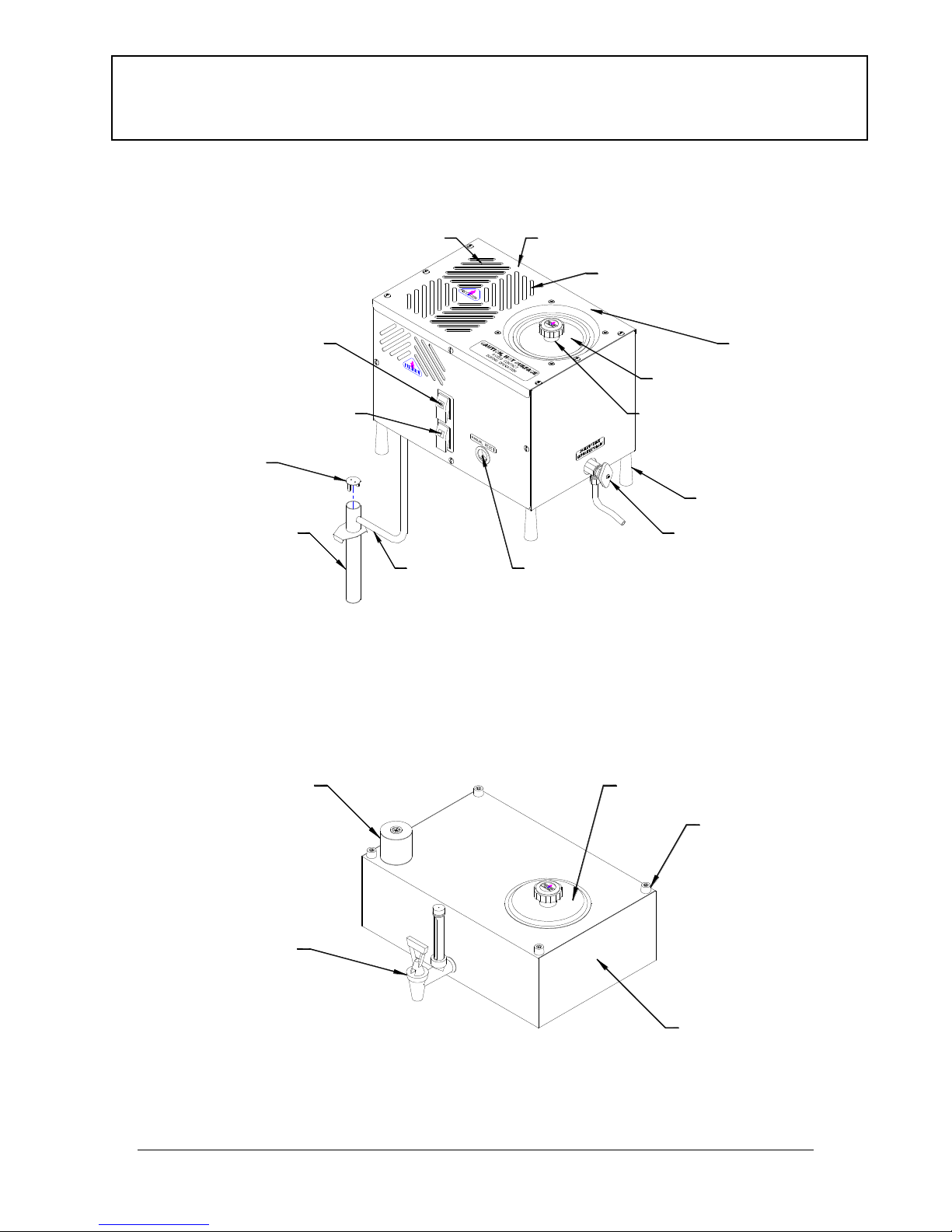

Water Distiller and Optional Storage Tank

Features

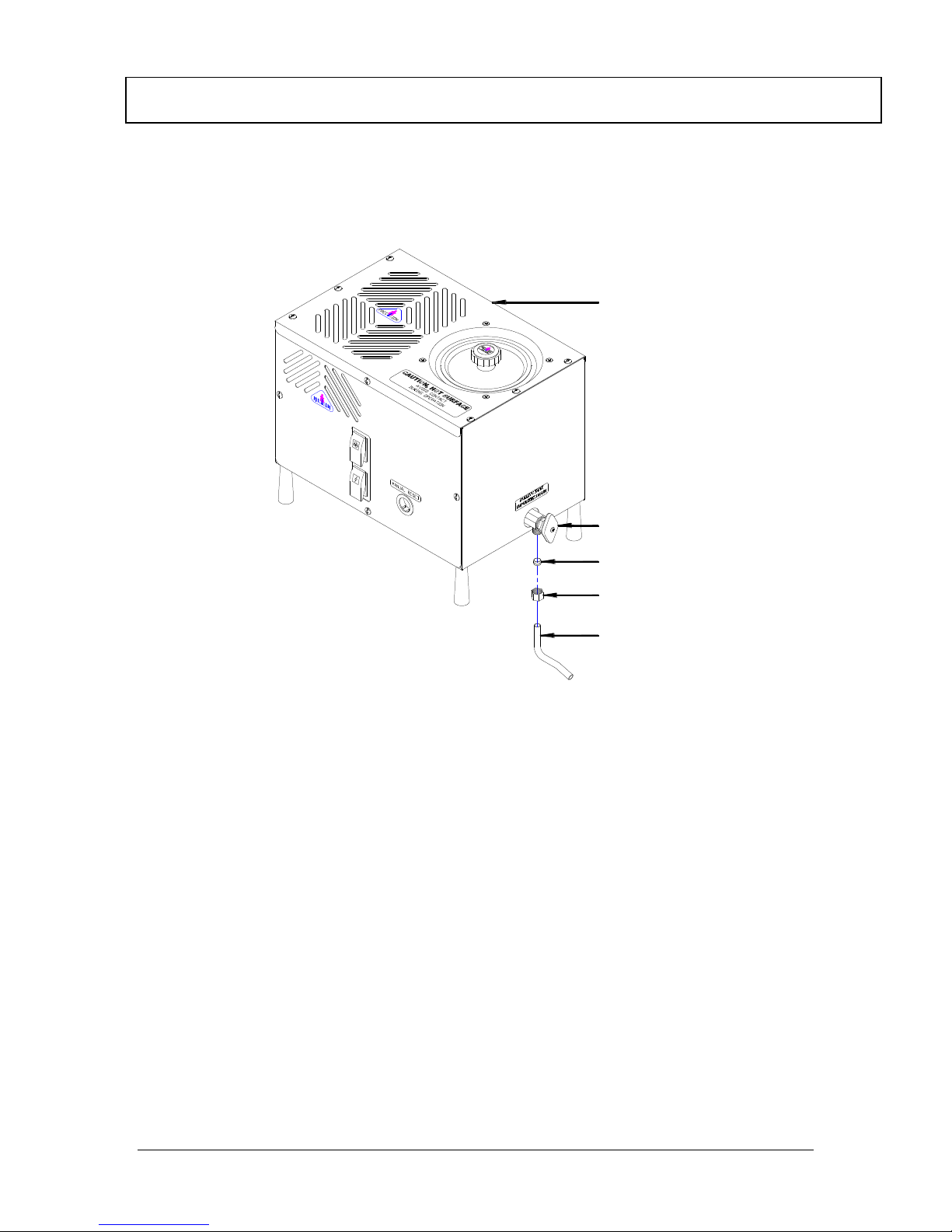

DISTILLER FEATURES DIAGRAM, PWS 8M

CONDENSING COIL SHIPPING STRAP

(REMOVE BEFORE USE)

FAN SWITCH

POWER SWITCH

OVERHEAT RESET SWITCH

BOILING TANK LID

GAS RELEASE VENT (HIDDEN)

CONDENSING COIL (INSIDE)

BOILING TANK

(INSIDE)

LEG

DRAIN VALVE

POST CHARCOAL

FILTER

FILTER CAP

FEED TUBE

LID KNOB

MANUAL STANDARD TANK FEATURES

SIGHT GAUGE AND

DRAIN VALVE

STORAGE TANK

CHARCOAL FILTER

CANISTER BODY

LEG

STORAGE TANK LID

8-M Distiller Features

8-MST Optional Storage Tank Features

9

10 Factors That Will Affect Your Water Distiller

Production

1. Water Volume Measurement

a) How are you measuring your water? The most accurate is by weight.

1 litre of pure water = 1 kg = 1000 g = 2.2046 lbs

b) Water distillers are rated in US gallons, NOT Imperial Gallons.

1 US Gallon = 3.785 litres = 3.785 kg = 8.344 lbs = 0.833 Imp. Gallons

c) Most distilled water holding tanks do not completely drain from the tap.

Ensure this volume of water is included in your calculation by completely

draining the tank or starting your production check with this volume pre filled.

2. Line Voltage

The line voltage at the outlet where the distiller is connected should be checked

with a voltmeter. Line voltage is often much less than expected, especially in

rural areas. Line voltage will also usually drop off dramatically when the daily

commercial load hits the grid from approximately 8 am to 5 pm (often when the

distiller owner is not home and unable to check the line voltage). Line voltage

lower than the distiller rated voltage (on the serial plate) will drastically lower the

water production.

3. Fill Water Temperature

The water used to fill the machine may affect the water production. Cooler fill

water will take more time/energy to heat to the boiling point than hot water.

4. Ambient Air Temperature

Water distillers with cooling fans must have sufficient ventilation so that the

boiled steam can be cooled and condensed into distilled water. Restriction of air

flow (such as a closed cupboard) will result in a hot ambient air build up which

will not allow all of the steam to condense into distilled water and some water

production may escape as steam into the atmosphere through the charcoal filter

or volatile gas release vent. This steam loss can also occur in hot summer

periods or very warm climates.

10

5. Heating Element and Boiler Cleanliness

As the water distiller removes impurities some of the impurities may cling to the

boiler tank and the heating element. Any of this scale may build up around the

heating element and actually insulate it, which will drastically decrease the

thermal efficiency of the heating element and require more time/energy to boil

water, which will decrease the water production.

6. Altitude

The water distiller is rated at the altitude of the manufacturer, which is

approximately 675 m (2214 ft) above sea level. Locations lower than this (closer

to sea level) will have reduced water production due to the higher boiling point of

water at higher atmospheric pressures at lower altitudes.

7. Operating Time, Warm-up Period & Suitable Storage

When checking the water distiller production, the start time should be when the

first few drops of water have entered the charcoal filter canister. Do not start

timing when the distiller turns on as it takes a few minutes for the heating

element, boiler tank and water to heat up. The distiller production rating does

NOT account for this time, but rather the continuous production after the distiller

is up to temperature. Ensure when checking production that you have suitable

water storage for holding the amount of water that will be produced.

8. Manual Fill Boiling Tank Fill Level

When checking the water distillation production on manual fill water distillers the

amount of water initially poured into the boiling tank will affect the production.

Water should be filled to the water level pin so that once the water is hot the

maximum amount of water can be distilled without having to heat up and refill.

Under-filling the boiler will decrease the amount of water distilled. Again, the

warm-up time should not be included in the production rate

9. Boiling Tank Heating Element

Once all other factors have been eliminated or checked, have an authorized

service center check that the proper heating element has been installed in your

distiller. Always replace heating elements with the manufacturers supplied

heating elements. Other elements are available from hardware stores, home

repair centers etc. and look like the same element but they are almost always not

the same. Even if the voltage and wattage are the same, they usually have

different wattage densities and most likely different element sheath materials,

which will result in premature heater burnout in continuous water distillation of

raw water. These heating elements will also likely affect you water distillation

capacity.

10. Combination of the above Factors.

Often a reduced water distiller’s production is a combination of many or all of the

above factors. To ensure maximum production from your water distiller, keep

your water distiller clean and operate it in a well-ventilated area and use room

temperature feed water where possible.

11

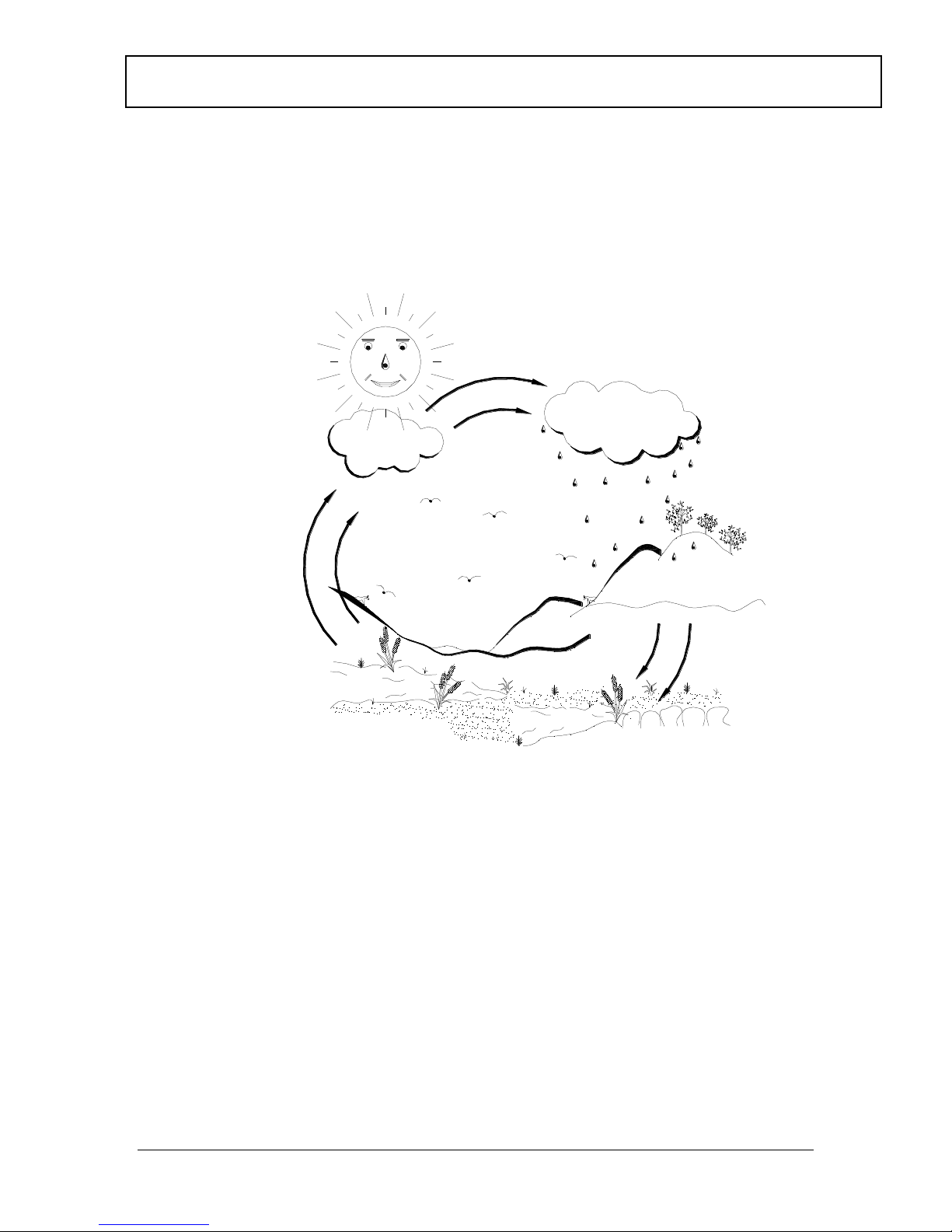

CONDENSATION

EVAPORATION

SMOG, DUST, ETC.

ROCK DEEP PERCOLATION

GROUND WATER

SURFACE WATER

HYDROLOGICAL CYCLE DIAGRAM

PRECIPITATION

Understanding How Pure Water is Produced

Your water distiller operates the same as Nature’s hydrological cycle. See

the Hydrological Cycle Diagram below. Nature uses the heat of the sun to

vaporize surface water and draw it into the atmosphere leaving the impurities

behind. As the vapour cools it condenses and returns back to the earth as rain

or snow. When rain or snow falls it passes through smog, dust and many other

types of contaminants. These contaminants can be picked up by the falling rain

or snow. Additional contamination of water can occur when it moves through the

ground.

Hydrological Cycle Diagram

Water Distillers complete their own hydrological cycle. The advantage of

a water distiller over Nature is that the water is produced in a closed environment

free of pollution and contaminants.

Your water distiller uses the boiling tank to heat the feed water to create

steam. The steam rises from the boiling tank leaving almost all of the impurities

behind. The steam enters the condensing coil and is cooled by the fan. As the

steam cools it condenses into pure distilled water and is stored in a water bottle

or optional stainless steel storage tank. The charcoal filter (between the

condensing coil and storage container) and the volatile gas vent remove any

contaminants that boil at lower temperatures than the boiling point of water. The

impurities from the process remain in the boiling tank and are drained to a

suitable drain.

12

(B) 1x(A) 1x

UNPACKING DISTILLER BOX DIAGRAM

Unpacking Your Water Distiller

Finding a Good Installation Location

Before installing your water distiller it is important to find a good location.

Following the points listed below will provide the best location for your water

distiller:

1. The water distiller must be plugged directly into a dedicated 120VAC, 15

Amp wall outlet.

2. The water distiller requires sufficient airflow around it to operate. The air

is used to cool the water distiller condensing coil. Locate the water

distiller in an area that will provide enough room for good air flow. Do not

place the water distiller in an enclosed area like a closet.

3. Locate the water distiller where a pail, suitable container or drain can be

used for the impurities drain.

4. When unpacking the water distiller and options note the sizes and

consider this when picking an installation location.

5. Locate the water distiller away from a bedroom or other area where the

noise of the water distiller may be undesirable.

6. Locate the water distiller in an area that is clean and free of dust so the

cooling coils remain clean when the fan is drawing fresh air.

Your Water distiller has been shipped in one box. The Water Distiller Box

Components Diagram shown as follows displays all of the parts that will be in

the water distiller box.

Check

List

(A) 1 – Water Distiller Head

(B) 1 -- Parts Bag

(Water Distiller Parts Bag Components Diagrams shown as follows)

Water Distiller Box Components Diagram

Water Distiller Box Check List

13

(C) 1x(B) 1x

(G) 1x (H) 4x(F) 1x

(A) 1x (D) 1x

(E) 4x

Water Distiller Parts Bag Components Diagram

Water Distiller Parts Bag Check List

Check

List Part No.

(A) 500409 1 – Post Filter

(B) 080115 1 – Sample Descaler/Cleaner

(C) 080116 1 – Sample Coconut Charcoal

(D) 500212 1 – Tube, Manual Drain, Stainless Steel

(E) 054009 4 – Black Plastic Legs

(F) 500184 1 – Boiling Tank Lid

(G) 052000 1 – 2’ Clear Sterilization Drip Tube

(H) 018004 4 – ½” x 5/16” SS Washers

1. Remove all loose pieces from the water distiller box and save all

packaging until all the parts are identified and located.

2. Check inside boiler tank and optional storage tank for any parts that may

be shipped in that area. If any parts are missing or if you have been given

the wrong part, DO NOT return the water distiller unit. Contact your dealer

for the required parts. They will be pleased to assist you.

3. Remove all protective plastic from water distiller head, boiling tank lid and

optional storage tank and lid.

14

TOOLS REQUIRED:

For Water Distiller Installation

(A) 5/8” Open End Wrench

(B) Adjustable Wrench

Water Distiller Installation Tools

(A) (B)

OR

COIL SUPPORT TIE

WATER DISTILLER HEAD

SHIPPING TIE REMOVAL DIAGRAM

4. Refer to Shipping Tie Removal Diagram above. Cut/Remove the coil

support tie located on the top of the water distiller head. Be careful not to

scratch the water distiller when removing. This tie supports the cooling

coil during shipping only.

Shipping Tie Removal Diagram

15

Water Distiller Leg Installation

Optional Storage Tank Assembly

DISTILLER LEGS INSTALL DIAGRAM

BULKHEAD

WASHER

LEG

POWER CORD

SIGHT GAUGE INSTALL DIAGRAM

3/8" JAM NUTSTORAGE TANK

SIGHT GAUGE

VALVE HANDLE

DRAIN VALVE THREADED FAUCET END

GASKET

1. Refer to the Water Distiller Leg Installation Diagram shown

below. Place a ½ x 5/16” stainless steel washer on the threads of

each leg and screw the legs into the bottom of the distiller head.

Water Distiller Leg Installation Diagram

Sight Tube Assembly

1. Remove the sight gauge from the parts bag and packaging.

Sight Gauge Installation Diagram

16

2. Refer to the Sight Gauge Installation Diagram above. Remove

NOTE: The sight glass is fragile, do not push on the gauge (push on

bottom near threaded area).

SIGHT GAUGE INSTALLATION DIAGRAM

the plastic hex jam nut from the threaded body of the valve (leaving

water gasket on threads).

3. Remove the storage tank lid by holding down on the lid and turning

the black knob counter clockwise approximately five turns. Slide

the lid to one side and turn the knob and lid while tilting. This

should allow the Tee Bar bracket under the lid to come out of the

tank opening. Slide the lid out.

4. Push the gasket tightly up against the valve.

5. Insert the threaded valve end with gasket attached through the hole

on the front of the storage tank.

6. While holding the sight gauge with valve in the storage tank hole

with one hand, insert your other hand with the plastic hex jam nut

through the storage tank lid opening.

7. Place the hex nut onto the threaded end of the valve.

8. Hand tighten the hex nut clockwise onto the valve.

Tightening Sight Gauge Nut Diagram

9. Refer to the Tightening Sight Gauge Nut Diagram above. To

fully tighten the nut, turn the valve counter-clockwise1/4 of a turn to

the start position and ensure that the jam nut is still hand tight.

Holding the jam nut, turn the valve clockwise until upright at the

finish position.

10.Make sure the storage tank is free from any dust or material and

replace the storage tank lid.

11.Check for leaks when storage tank begins filling.

17

Optional Storage Tank to Distiller Head

Assembly

CHARCOAL FILTER

CANISTER BODY

DRAIN VALVE

VALVE HANDLE

THREADED FAUCET END

STORAGE TANK TO DISTILLER HEAD ASSEMBLY DIAGRAM

STORAGE TANK

SIGHT GAUGE

GASKET

LEG

STORAGE

TANK LID

DISTILLER HEAD

3/8"

JAM NUT

1. If you have purchased the optional storage tank, place the Charcoal

Canister in the top of Storage Tank.

2. Place lid on storage tank.

3. Refer to the Distiller Head to Optional Storage Tank Assembly

Diagram below. Place Distiller head on top of the optional storage tank

by placing the legs of the distiller head onto the leg stubs on the optional

storage tank.

Distiller Head to Optional Storage Tank Assembly Diagram

18

Impurities Drain Tube Installation

DISTILLER HEAD

MANUAL DRAIN VALVE INSTALL DIAGRAM

COMPRESSION SLEEVE

COMPRESSION NUT

MANUAL DRAIN TUBE

DRAIN VALVE

TO SEWER OR

IN A CONTAINER

1. Refer to the Impurities Drain Tube Installation Diagram shown below.

Remove the compression nut and compression sleeve from the Drain

Valve.

Impurities Drain Tube Installation Diagram

2. Take the stainless steel manual drain tube from the parts bag. Slip the

compression nut and compression sleeve over the manual drain tube.

3. While holding the compression nut and sleeve on the drain tube, push the

manual drain tube into the drain valve. Push the compression sleeve into

the valve with the nut and thread the nut onto the valve.

4. Position the drain tube away from the distiller and tighten the nut with a

5/8” open end wrench or adjustable wrench. When draining the boiling

tank of the water distiller, the manual drain tube should be drained into a

suitable container or sewer.

19

Boiling Tank Lid Installation

Optional Storage Tank Lid Removal and

Installation

BOILER LID INSTALL DIAGRAM

1. Remove any protective plastic coating (white, blue or clear plastic) from

the lid.

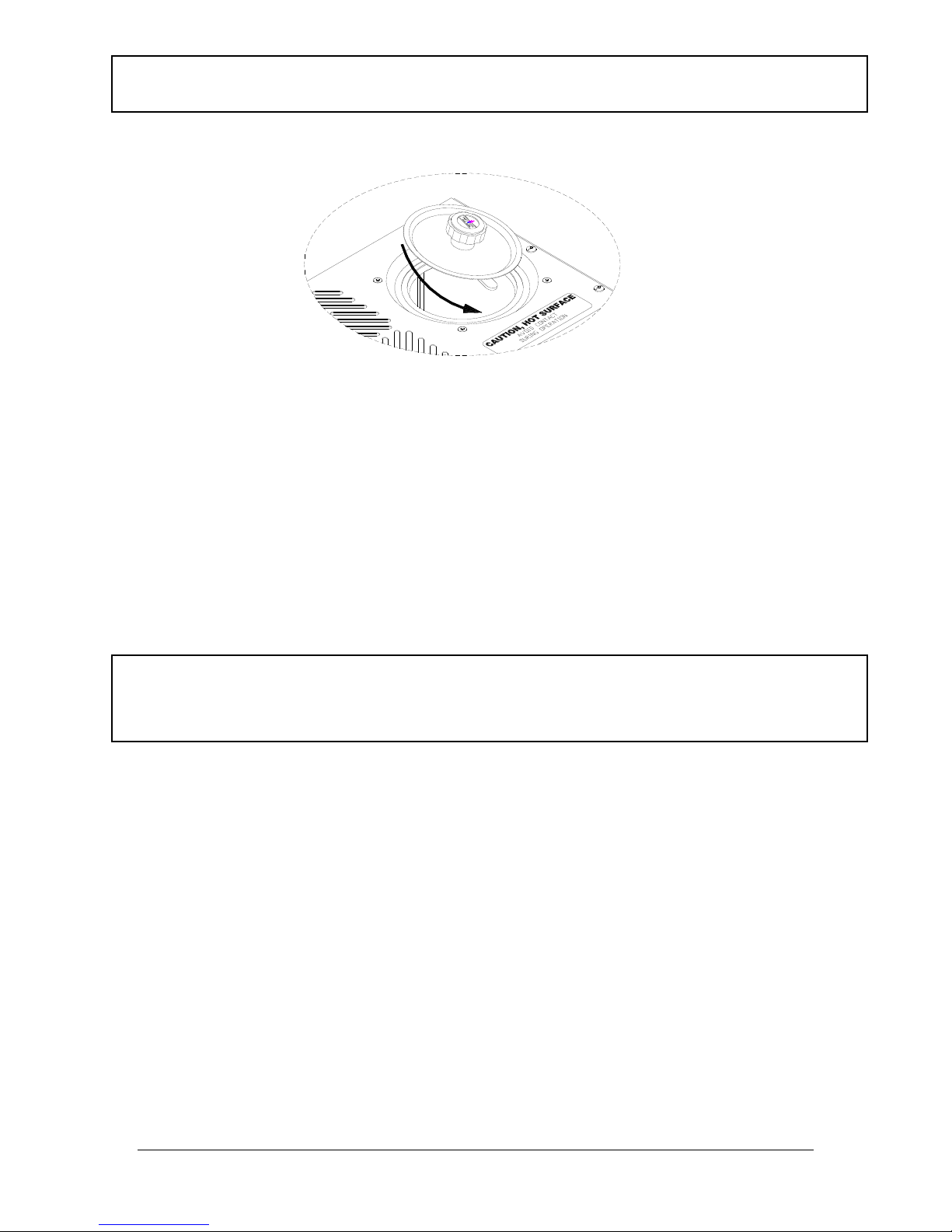

2. Refer to the Boiling Tank Lid Operation Diagram above. Take the

boiling tank lid in your hand. Hold the Tee Bar bracket and turn the Lid

Knob counter-clockwise so that there is ½” of space between the Tee Bar

bracket and the lid.

3. Tip the lid so that the Tee Bar bracket slips under the rim of the boiling

tank opening on one side, and then slide the lid so the Tee Bar bracket

slips under the other side of the rim. Center the lid.

4. Turn clockwise to tighten the lid onto the boiling tank. The water level pin

inside the boiling tank will prevent the lid from turning while tightening.

Practise removing and replacing the lid a few times as the lid will need to

be removed each time the water distiller is filled or cleaned.

1. To remove the optional storage tank lid, turn the Lid Knob counter-

clockwise while lifting. Lifting while turning holds the Tee Bar bracket

under the lid and allows you to loosen the lid. Continue turning and lifting

until there is ½” of space between the Tee Bar bracket and the lid.

2. Tip the lid so that the Tee Bar bracket slips out from under the rim of the

optional storage tank opening on one side, and then slide the lid so the

Tee Bar bracket slips out from under the other side of the rim.

3. To Replace the optional storage tank lid, tip the lid so that the Tee Bar

bracket slips under the rim of the boiling tank opening on one side, and

then slide the lid so the Tee Bar bracket slips under the other side of the

rim. Center the lid.

4. While lifting up on the optional storage tank lid knob, turn clockwise to

tighten the lid onto the optional storage tank. When upward pressure is

no longer needed to prevent the lid from turning the lid is tight.

Boiling Tank Lid Operation Diagram

20

Operation

NOTE: Read all parts of the Owners Guide before operating the

water distiller. Follow the Before Initial Water Distiller Operation

steps and be sure to complete a Steam Sterilization of the Water

Distiller Head, Filter Canister and Optional Storage Tank (if

purchased) before distilling water for household use for the first

time or after a period of storage or non-use.

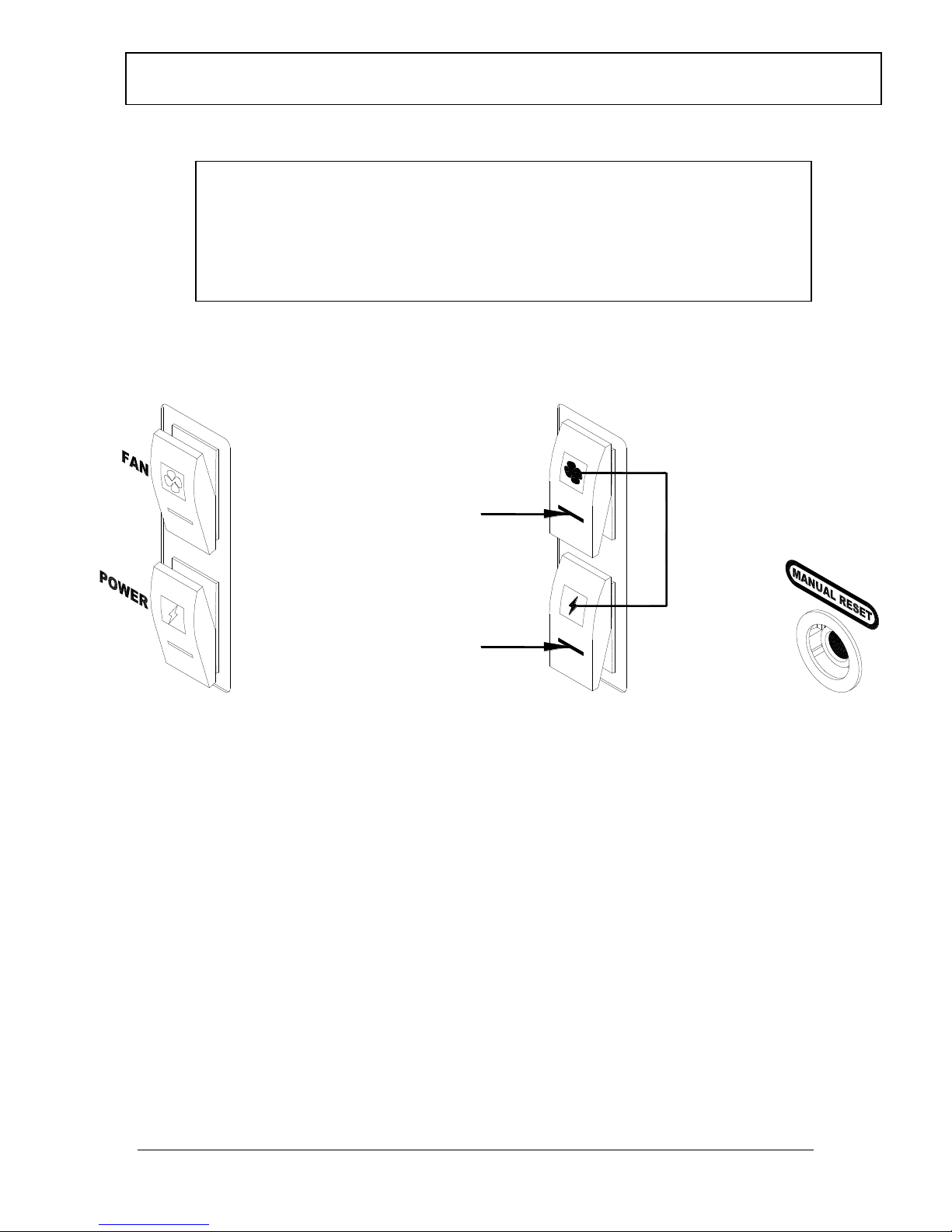

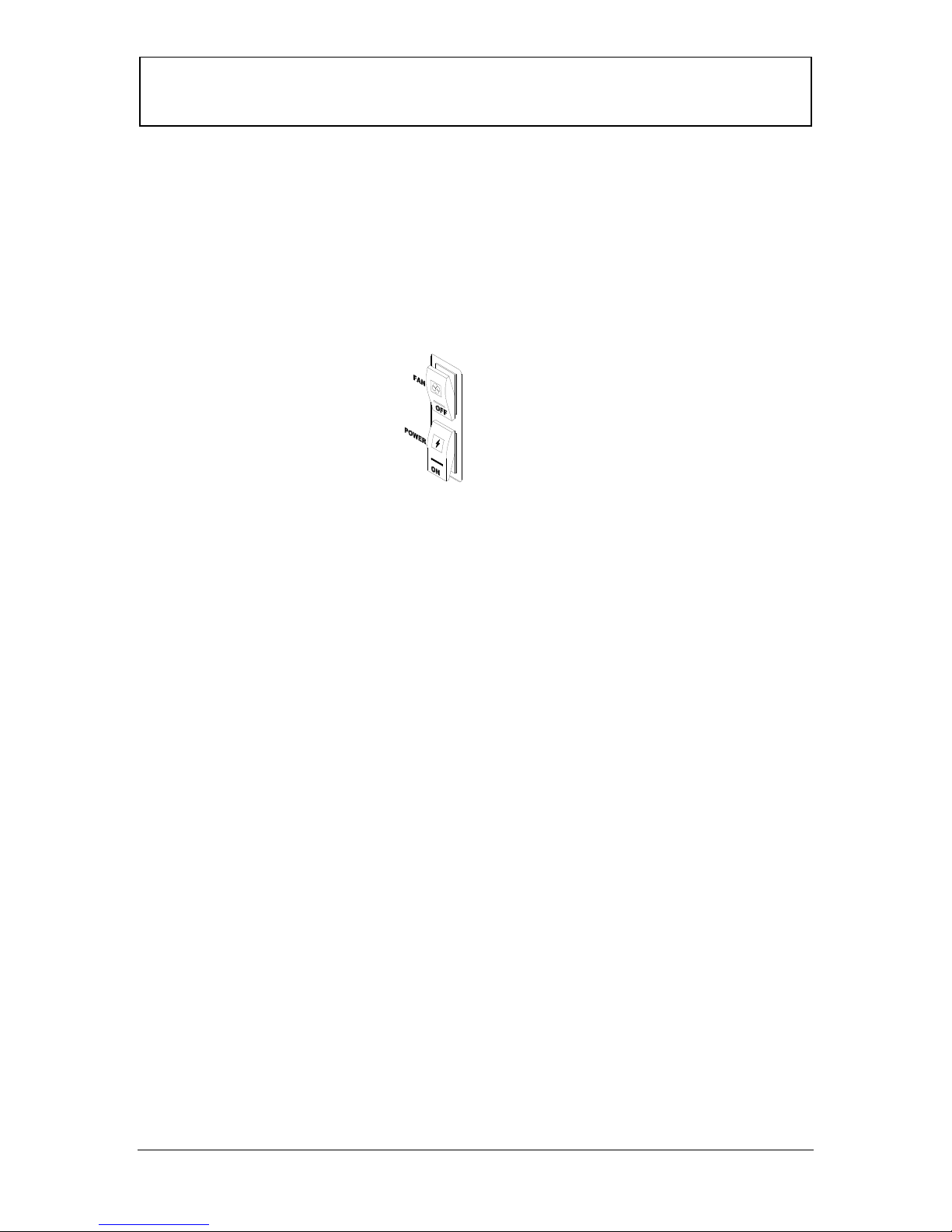

OPERATION SWITCHES DIAGRAM

COOLING FAN

INDICATOR LIGHT

HEATING ELEMENT

INDICATOR LIGHT

POWER ON INDICATOR LIGHTS

ONOFF

Controls

(A) (B) (C)

Operation Switches Diagram

Refer to the Operation Switches Diagram above. There are two grey

power switches (A&B) and one overheat manual reset switch (C) on the front of

the water distiller head that allow you to control all functions of the water distiller

21

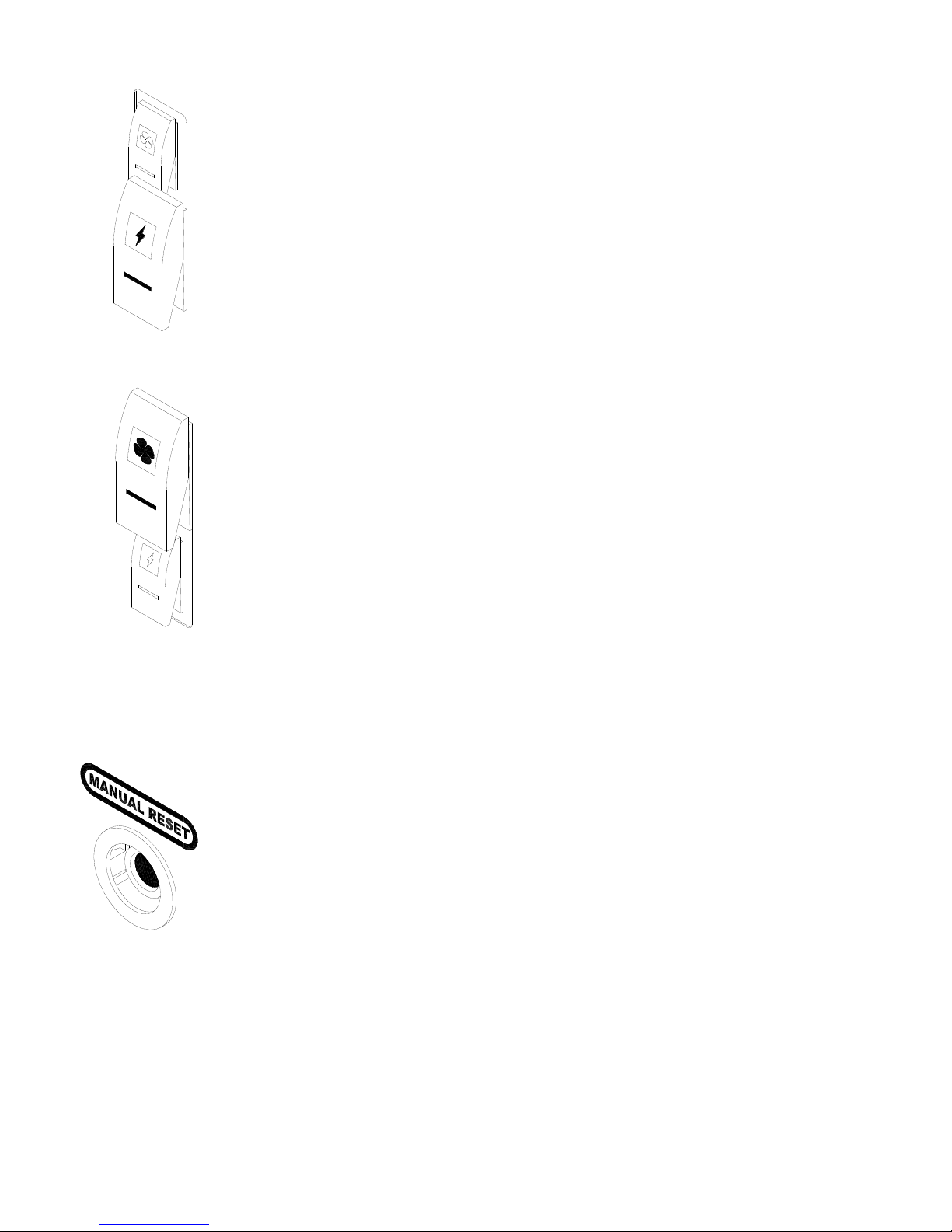

Power – ON/OFF

- Red indicator light.

- Normally ON when water distiller is operating.

Controls power to the entire water distiller.

- Top square indicator light is illuminated whenever the

switch is on. It will remain illuminated even when the

water distiller is not operating.

- Bottom rectangular indicator light is illuminated only

when the heating element in the boiler is on.

- Turn power switch to OFF to stop Water distiller

operation.

- Recessed into front of the water distiller head front

cover.

- The reset button will shut the unit off if the water

distiller has overheated, it may be reset once the water

distiller has cooled off. If the problem persists this

may also indicate a problem and should be looked at

by a service center.

- The reset button is a safety feature and is designed to

shut the water distiller down should it overheat.

- Push your finger through the hole in the front cover

labelled ‘Manual Reset’ to reset. A snap will be heard

when the switch is reset and distilling can resume.

- Amber indicator light.

- Normally ON when water distiller is operating.

Controls power to the cooling coil fan.

- Top square indicator light is illuminated whenever the

power switch is on. It will remain illuminated even

when the water distiller is not operating.

- Bottom rectangular indicator light is illuminated only

when the fan is on. Fan should be running if the water

distiller is distilling water.

- Turn Fan Switch to OFF only when performing a

steam sterilization of the water distiller.

FAN SWITCH DIAGRAM

(ON POSITION)

FAN

POWER SWITCH DIAGRAM

POWER

(ON POSITION)

Fan – ON/OFF

Overheat Reset Switch – Manual Reset

22

Before Initial Water Distiller Operation

Normal Operation

NOTE: Do not overfill the boiling tank, this will cause the raw water to enter

the cooling coil and into your container or optional storage tank.

BOILING TANK WATER LEVEL PIN DIAGRAM

BOILER FLOAT

WATER GAUGE

PIN

INSIDE BOILER

HEATING

ELEMENT

WATER LEVEL

IMPURITIES DRAIN

OUTLET

Perform steam sterilization on the water distiller head, filter canister and

optional storage tank as described in the Maintenance and Cleaning section.

operly

1. Remove the lid from the Boiling Tank and ensure the drain is closed by

turning the drain faucet fully clockwise.

2. See the Boiling Tank Water Level Fill Pin Diagram below. Fill the

boiling tank with water until the water reaches the bottom of the water

gauge pin.

Boiling Tank Water Level Fill Pin Diagram

3. Replace the lid back onto the boiling tank and tighten. The lid must be

snug, but do not over tighten.

4. Turn the Power and Fan switches to the ON position.

5. Your water will now distil into the optional storage tank or a container of

your choice. The distiller will shut down automatically when the water

level is just above the heating element in the boiling tank.

23

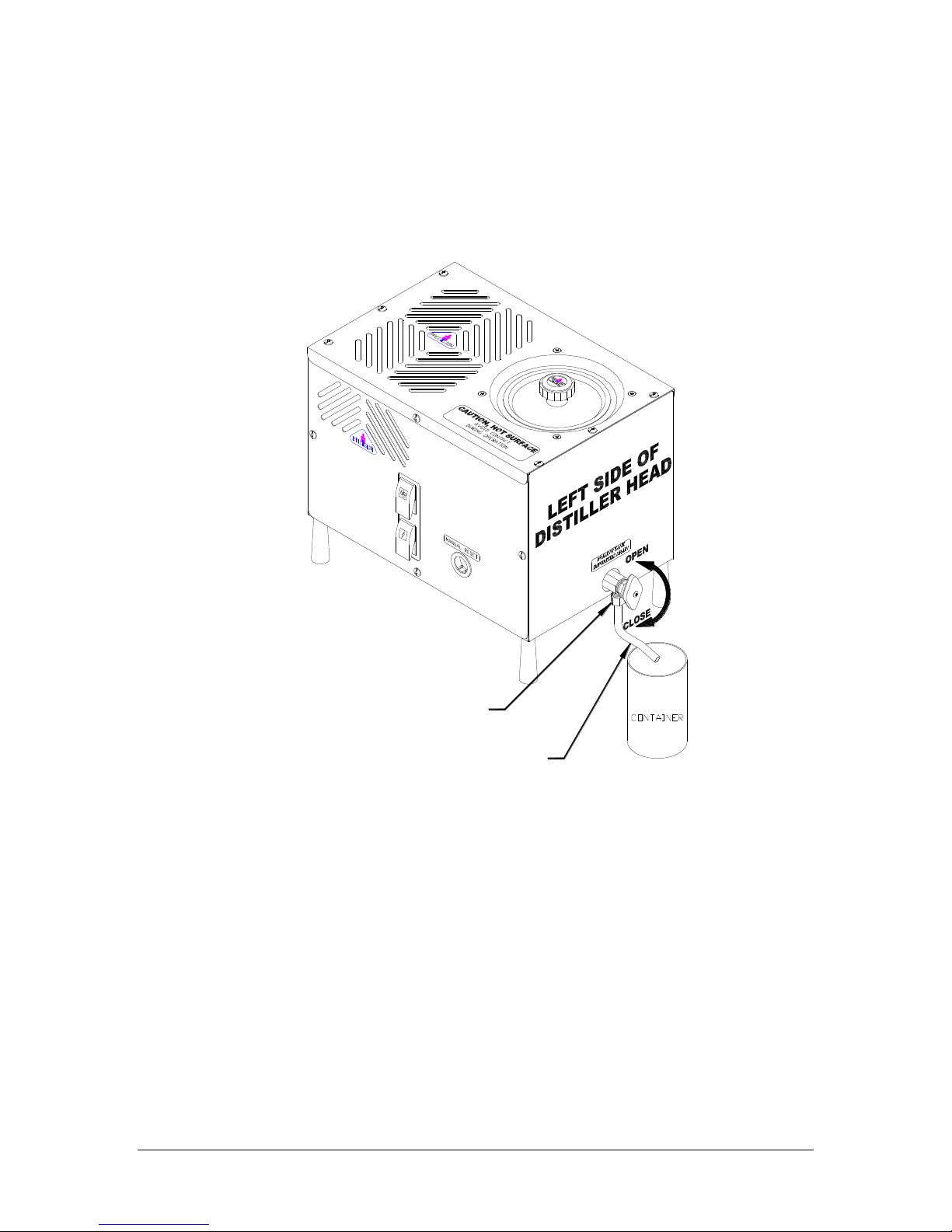

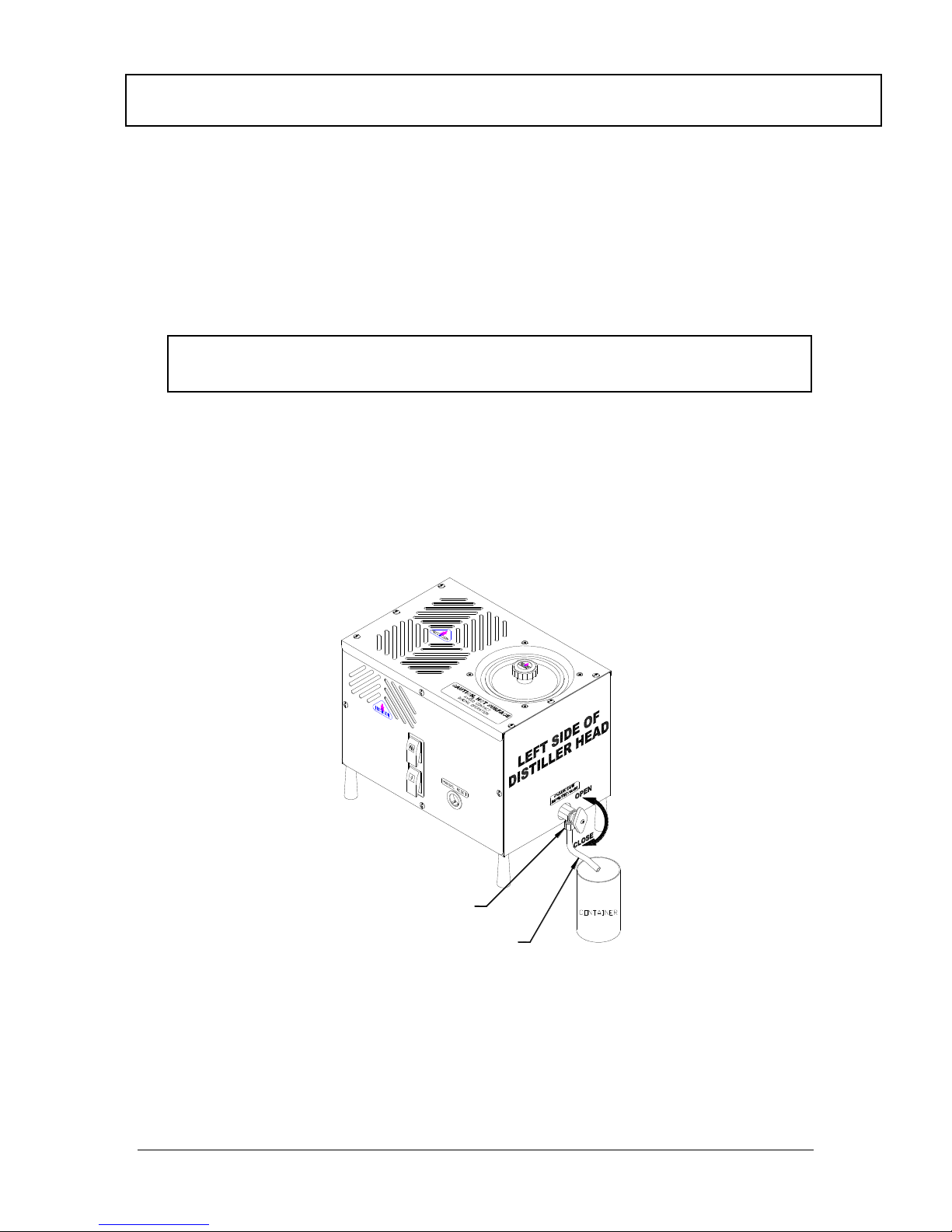

MANUAL DRAIN FAUCET

BOILING TANK DRAIN VALVE DIAGRAM

STAINLESS STEEL DRAIN TUBE

6. When the distiller has stopped, you may refill the boiling tank with water.

Caution – The distiller will be very hot for several hours after

shutting down.

7. To prevent a build up of scale and contaminants in the boiling tank, it is

recommended that the impurities from the boiling tank be drained after at

least every second distillation process. Routinely draining the impurities

will prolong the life of the water distiller and reduce cleaning.

Manual Drain Faucet Location Diagram

8. Refer to the Manual Drain Faucet Location Diagram above. The water

distiller boiling tank can be drained by turning and opening the manual

drain faucet and draining into a suitable floor drain or container.

24

Maintenance and Cleaning

NOTE: Regular Cleaning is much easier than trying to clean after a

prolonged period of time!

MANUAL DRAIN FAUCET

BOILING TANK DRAIN VALVE DIAGRAM

STAINLESS STEEL DRAIN TUBE

Introduction

The purpose of purchasing a water distiller is so you will not have to drink

the unknown impurities in your drinking water. A water distiller effectively

removes the impurities and chemicals from your water and returns the taste of

pure water so that it is pleasing and healthy to drink for the entire family.

It is important to also keep the water distiller clean so that it can perform

properly and efficiently. Regular cleaning and maintenance will allow the water

distiller to continually provide pure water for a very long time.

Regular Inspection and Cleaning of the Boiling Tank

1. To prevent a build up of scale and contaminants in the boiling tank, it is

recommended that the impurities from the boiling tank be drained after at

least every second distillation process. There may be an off colour line at

the seams of the boiler tank, this is caused by the TIG welding process

used during manufacturing. This is normal and is not a sign of any

concern.

Manual Drain Faucet Location Diagram

2. Refer to the Manual Drain Faucet Location Diagram above. The water

distiller boiling tank can be drained by opening the manual drain faucet

and draining into a suitable floor drain or container.

3. It is important to develop a regular maintenance routine.

25

4. Check for scale build up on the walls of the boiler tank and the heating

CAUTION: Descaler is a corrosive and poisonous substance. Read

safety precautions on the package. As the initial water is added to the

descaler in the boiling tank it will produce a bubbling foam substance. Do

not overfill the boiling tank. Always leave boiling tank lid off when ever the

boiling tank is being descaled to reduce fumes travelling through the

cooling coil. Dispose of the first gallon of distilled water as a precaution.

BOILING TANK WATER LEVEL PIN DIAGRAM

BOILER FLOAT

WATER GAUGE

PIN

INSIDE BOILER

HEATING

ELEMENT

WATER LEVEL

IMPURITIES DRAIN

OUTLET

element. The heating element is the most critical. If there is 1/8” of build

up or more on the heating element, then it is time to clean the boiling tank

using the cleaner descaler. This process is described in the next section.

5. After checking the boiling tank every two weeks for about three months,

you will be able to set up your own schedule as to how often the boiling

tank needs to be cleaned with the cleaner descaler. Distilled water

quantity use and raw water quality will determine your schedule.

Cleaning the Boiling Tank using the Cleaner Descaler

1. Turn all switches off and allow the water distiller to cool down.

2. Remove any loose scale from inside the boiling tank by hand through the

boiler lid. If you are using the optional storage tank, remove the filter

canister and place the sterilization tube onto the coil tube to by pass the

optional storage tank. See Steam Sterilization of Water Distiller Head

in this Maintenance and Cleaning section for more details.

3. Add 3 tablespoons of descaler cleaner to the boiling tank.

4. Fill the boiling tank half full with hot tap water.

5. Mix the cleaning solution well to dissolve the descaler in the water.

6. Fill up the remaining portion of the boiling tank with hot tap water to the

bottom of the water gauge pin. See Boiling Tank Water Gauge Pin

Diagram below.

Boiling Tank Water Gauge Pin Diagram

26

NOTE: Replace charcoal in filter every 2 months or every 500 gallons of

distilled water.

FILTER INSTALL DIAGRAM

FILTER CAP

FEED TUBE

WATER BOTTLE

POST CHARCOAL

FILTER

BULKHEAD, 3/8"JG

(INSIDE DISTILLER)

TUBE, SS, 3/8" X 1-1/2"

7. Let the solution stand overnight. Leave the boiling tank lid off during

cleaning to prevent descaler fumes from entering the cooling coil.

8. The next morning or when the mineral content is soft, drain the boiling

tank using the drain faucet. Remove any remaining loose scale by hand.

9. Repeat cleaning if necessary.

10.Once all the scale has been removed, rinse the boiling tank several times

with warm tap water.

11.Complete steam sterilization process on the boiling tank. See Steam

Sterilization in this Maintenance and Cleaning Section. Reinstall the

filter canister.

12.The boiling tank is now clean and ready to produce pure water again.

Replacing Charcoal in Post Charcoal Filter Canister (Used with

8-M without Optional Storage Tank)

1. Turn all switches off and allow the water distiller to cool down.

Post Charcoal Filter Charcoal Replacement Diagram

2. Refer to the Post Charcoal Filter Charcoal Replacement Diagram

above. Remove the feed tube from the filter by pulling it out of the filter.

3. Over a sink or suitable garbage can, remove the lid of the filter completely

and empty charcoal from canister and rinse.

4. Fill canister 2/3 full with new charcoal and rinse over a sink or pail with

approximately 2 cups of distilled water until water runs clear.

5. Press the filter cap back on to the post filter canister.

6. Insert the feed tube approximately ½” back into the hole on the side of the

filter canister.

7. Place the filter on the side of any storage container or bottle.

27

Replacing Charcoal in Charcoal Filter Canister (Used with 8-MST

NOTE: Replace charcoal in filter every 2 months or every 500 gallons of

distilled water.

FILTER INSTALL DIAGRAM

BULKHEAD, 3/8"JG

(INSIDE DISTILLER)

TUBE, SS, 3/8" X 1-1/2"

FILTER CAP

CHARCOAL FILTER

CANISTER BODY

Optional Storage Tank)

1. Turn all switches off and allow the water distiller to cool down.

Filter Canister Charcoal Replacement Diagram

2. Refer to the Filter Canister Charcoal Replacement Diagram above.

Remove the complete charcoal filter canister by lifting the front corner of

the water distiller head.

3. Over a sink or suitable garbage can, remove the lid of the filter completely

and empty charcoal from canister and rinse.

4. Fill canister 2/3 full with new charcoal and rinse over a sink or pail with

approximately 2 cups of distilled water until water runs clear.

5. Press the filter cap back on to the filter canister.

6. Lift the corner of water distiller head and slide the filter into the storage

tank and lower the water distiller head so the 3/8” tube enters the top of

the filter.

28

NOTE: This is performed whenever it is suspected that the water distiller

head or optional storage tank are contaminated.

NOTE: Liquid Sterilization Solutions can be made from Household bleach.

The bleach should be diluted to 100-200 PPM. Products such as Javex,

have 6% Sodium Hypochlorite and should be diluted by placing 3

teaspoons per gallon of water. Always use Chlorine bleach that does not

contain any other ingredients. Alternatively, Hydrogen Peroxide solutions

may be used by placing 3 teaspoons per gallon of water.

Sterilization

Introduction:

Steam Sterilization should be performed on the water distiller boiler and the

optional storage tank before the water distiller is used for the first time or after a

period of storage or non-use. After initial sterilization, the boiler should be steam

sterilized after any maintenance is performed and/or cleaning including the

descaling process. The optional storage tank requires cleaning and steam

sterilization after any maintenance, or if there are any problems with the quality of

the distilled water.

If there is a water quality concern and the system may be contaminated, it is

important to first remove the source of contamination and remove all

contaminated debris and then complete a Liquid Sterilization before a Steam

Sterilization.

Liquid Sterilization of Optional Storage tank

1. It important to first remove the source of contamination and remove all

contaminated debris before liquid sterilization.

2. Drain the water distiller.

3. Add 1/2 gallon of Liquid Sterilizing solution to the water distiller optional

storage tank. If desired, spray some of the solution throughout the inside

of the optional storage tank. Drain a small amount of the sterilizing

solution out of the drain faucet to sterilize the faucet.

4. Wait 20 minutes and drain the sterilizing solution.

5. Rinse the entire inside of the optional storage tank with at least 2 gallons

of distilled water.

6. Repeat the flushing of the optional storage tank with distilled water 2-3

times; continue until no chlorine smell is coming from the faucet.

7. Complete a Steam Sterilization of the boiling and optional storage tanks.

29

Steam Sterilization of Water Distiller Head

BULKHEAD,3/8"

(INSIDE DISTILLER)

STERILIZATION TUBE

3/8OD X 1-1/2"

SS TUBE

BULKHEAD,3/8"JG

1. Make sure the water distiller is cool before starting.

Steam Sterilization Diagram

2. Refer to the Steam Sterilization Diagram above. If you are using the

optional storage tank, lift the front corner of the water distiller head and

remove the charcoal filter.

3. Install the sterilization tube. Place the sterilization tube on the 3/8”

stainless steel filter inlet tube on the bottom of the water distiller head.

4. Place the other end of the steam sterilization tube into a container as it will

drip water and steam.

5. Fill the boiling tank with water to the bottom of the water gauge pin.

30

Steam Sterilization Operation Switches Diagram

STEAM STERILIZATION OPERATION SWITCHES DIAGRAM

6. Refer to Steam Sterilization Operation Switches Diagram above. Turn

only the power switch ON. Leave the fan switch OFF. As the water

distiller continues to heat up, it will sterilize the water distiller with steam

by allowing pure steam to travel out of the cooling coil. Water and steam

will drip from the sterilization tube. Caution: The Water Distiller is

extremely hot during sterilization.

7. Leave the water distiller on for 1 hour.

8. After the sterilization cycle is complete, turn the fan switch ON and allow

any water in the cooling coil to drain. Leave the water distiller running

with the fan on for about 15 minutes.

9. The water distiller will be very hot so turn all switches OFF (power and

fan) and let the water distiller cool down for approximately 1 hour.

10. Remove the sterilization drip tube by pulling the plastic tube off the

stainless steel charcoal filter inlet tube (keep the sterilization tube for

future sterilizations).

11. Replace the charcoal in the post charcoal filter canister. See Replacing

Charcoal in Post Charcoal Filter Canister (Used with 8-M without

Optional Storage Tank) in this Maintenance and Cleaning Section.

12. The water distiller head is sterilized and ready for operation.

31

Steam Sterilization of Water Distiller Head, Filter Canister and

Optional Storage Tank

STEAM STERILIZATION OPERATION SWITCHES DIAGRAM

1. Make sure the water distiller is cool before starting.

2. Refer to the Steam Sterilization Diagram in the previous section-Steam

Sterilization of Water Distiller Head. Lift the front corner of the water

distiller head.

3. Remove the charcoal filter canister. Remove all charcoal and rinse until

clean. Replace empty filter canister between water distiller head and

optional storage tank

4. Place a container under the front optional storage tank sight gauge valve

and leave the valve in the open position.

Steam Sterilization Operation Switches Diagram

5. Refer to Steam Sterilization Operation Switches Diagram above. Turn

only the power switch ON. Leave the fan switch OFF. As the water

distiller continues to heat up, it will sterilize the water distiller head, filter

canister and optional storage tank with steam by allowing pure steam to

travel out of the cooling coil. Water and steam will drip from the optional

storage tank valve. Caution: The Water Distiller is extremely hot

during sterilization.

6. Leave the water distiller on for 1 hour.

7. After sterilization cycle is complete. Turn the fan switch ON and allow any

water in the cooling coil to drain. Leave the water distiller running with the

fan on for about 15 minutes.

8. The water distiller will be very hot so turn all switches OFF (power and

fan) and let the water distiller cool down for approximately 1 hour.

9. After cooling down, the water distiller may need to be tipped or rocked

forward and back to remove all the water from the optional storage tank.

10.Close the optional storage tank sight gauge valve.

11.Replace the charcoal in the charcoal filter canister. See

Replacing Charcoal in Charcoal Filter Canister (Used with 8-MST

Optional Storage Tank) in this Maintenance and Cleaning Section.

12.The water distiller head, filter canister and optional storage tank are

sterilized and ready for operation.

32

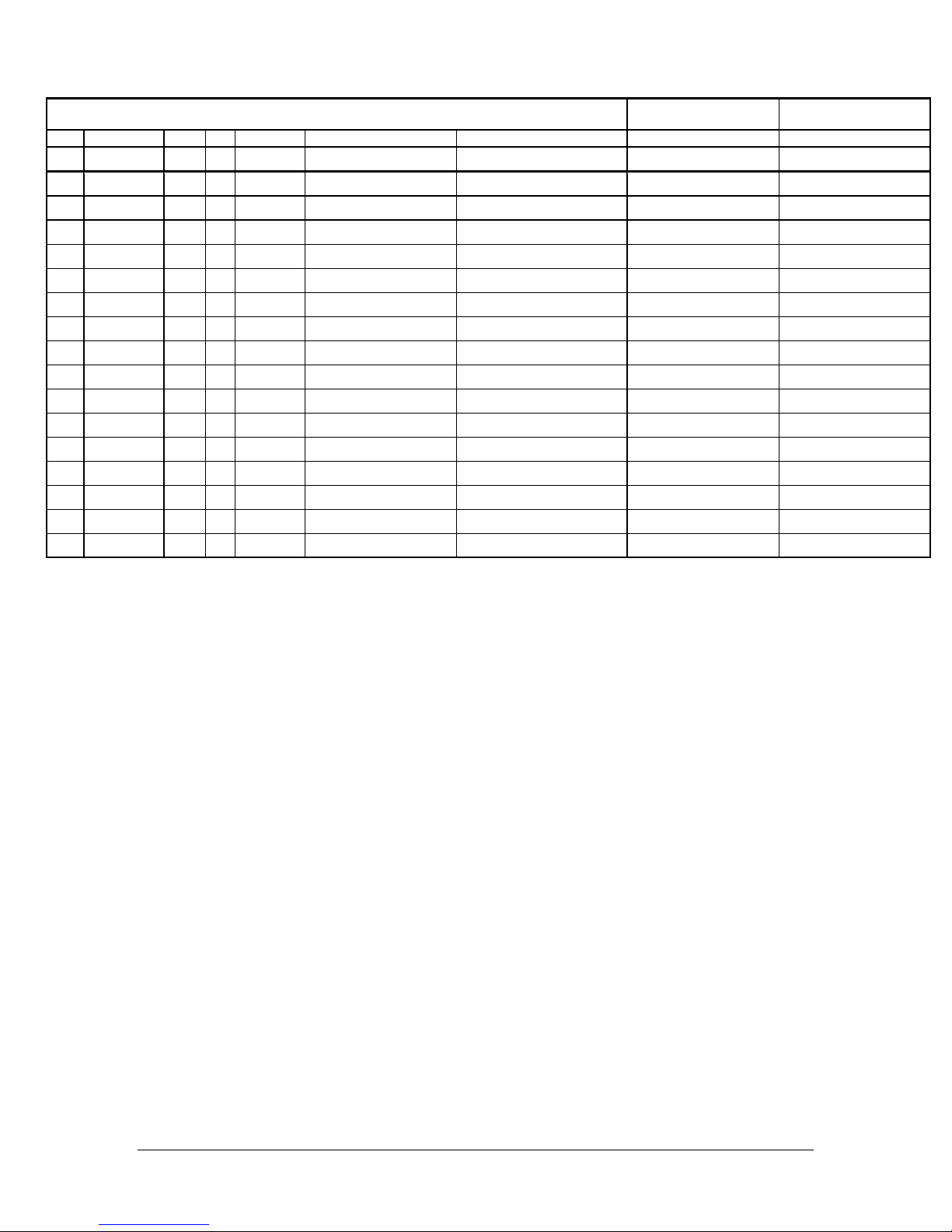

Initially

Weekly

Monthly

Semi-

Annually

Annually

As

Needed

1) Check Scale Build

Up.

X

X

2) Change Charcoal in

Charcoal Filter

Canister.

X X

X

3) Clean Boiling Tank

using Cleaner

Descaler.

X

X

4) Steam Sterilization

of Boiling Tank after

cleaning.

X

5) Steam Sterilization

of Boiler and Optional

Storage Tank.

X

X

Change Charcoal

in Charcoal Filter

Canister

Clean Boiling

Tank using

Cleaner Descaler

Steam

Sterilization of

Boiling Tank

Steam

Sterilization of

Boiling and

Optional Storage

Tank

Date

Jan 21/03

Completed By

BDR

Date

Completed By

Date

Completed By

Date

Completed By

Date

Completed By

Maintenance Schedule Table

Owner Maintenance Record Table

33

A) Water distiller does not

operate.

1. Water distiller is not plugged in securely to the

wall outlet or the circuit breaker is off.

2. Power switch on the water distiller is turned off.

3. Reset button has shut the unit off. The reset

button will shut the unit off if the water distiller

has overheated, it may be reset once the water

distiller has cooled off. This may also indicate a

problem and should be looked at by a service

center. The reset button is a safety feature and

is designed to shut the water distiller down

should it overheat. Push your finger through the

hole in the front cover labelled ‘Manual Reset’ to

reset. It will snap once reset.

4. Reset button is faulty and needs to be replaced.

Call Service Center.

B) Water is coming out from

the top of the charcoal filter.

1. Charcoal is old and compacted. Replace

coconut charcoal. See Maintenance sectionReplacing Charcoal in Charcoal Filter Canister.

2. Charcoal filter is more than 2/3 full. There must

be an air gap between the charcoal and the top

of the filter. Remove Charcoal filter and make

sure charcoal filter is only 2/3 full.

C) Steam or water is

escaping from the top of the

cooling coil.

1. The cooling coil is equipped with a gas release

vent, a very small hole in the top of the coil. This

is to release certain volatile gases. Steam may

escape from this hole. This is normal.

2. If little or no water is being produced the cooling

coil may have become disconnected from the

boiling tank. Call Service Center.

Troubleshooting

Caution! Always Disconnect Water Distiller Electrical plug and Let the

Water Distiller cool down completely before completing any

Troubleshooting.

PROBLEM CAUSE

34

PROBLEM CAUSE

D) Charcoal Filter is very hot

and steam is escaping from

the filter.

1. The fan switch is turned off. Check Switch.

2. Fan motor is not running properly, may be

defective, or the fan motor switch may be

defective. Call Service Center.

3. Cooling coil fins are plugged with dust, dirt, or

grease. Remove and clean or take to a service

center for maintenance.

4. The location of the water distiller does not

provide enough airflow for good cooling. Move

the water distiller to an area with more air

movement.

E) Water distiller may start

to boil, then shuts off. It

may restart after cooling

down. Very small amount of

water is produced.

1. Faulty Reset button. After letting water distiller

cool down and trying to reset several times, call

Service Center.

F) Water distiller runs

properly but little or no

water is produced.

1. Improper Heating Element is installed or Heating

Element is faulty. Call Service Center.

2. Boiler tank lid is loose. Check by moving Boiler

Tank Lid Knob.

3. Reset button may be defective or weak. See A)

3 above.

G) Strange taste in Distilled

Water.

1. Boiling tank and/or optional storage tank may

require cleaning. See maintenance section on

cleaning water distiller.

2. Boiling tank was over filled.

3. Charcoal filter requires new Coconut Charcoal.

H) Fan does not operate

automatically.

1. Fan switch is in OFF position. Check Switch.

2. Fan motor may be defective. Call Service

Center.

I) Distiller does not seem to

produce as much water as

specified.

See Section in Guide: 10 Factors That Will Affect

Your Water Distiller Production.

Contact any Precision Water Systems Service Center to correct

any problems with your water distiller that are not covered in

this guide.

To locate a Service Center in your area contact the manufacturer at:

Precision Design & Manufacturing Inc.

Westlock, Alberta, Canada

T7P 2H7

http://www.precisionwaterdistillers.com

Email: info@precisioncanada.com

Phone: (780) 349 4933 FAX: (780) 349 4957

35

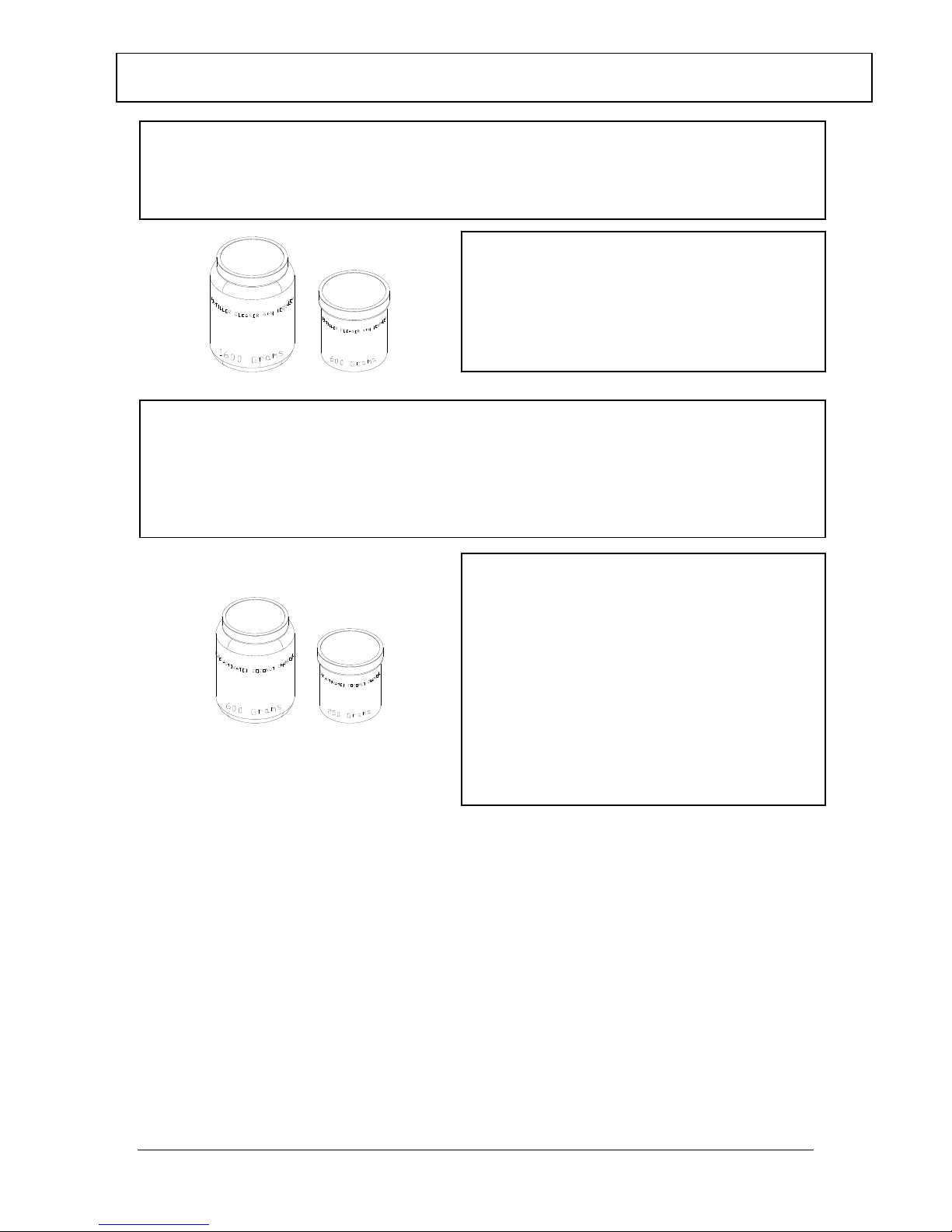

Additional Options

Water Distiller Cleaner and Descaler

600 g #500102

1600 g #500103

Used for regular maintenance to clean

the scale out of the boiling tank.

Dissolves water minerals in water

distillers, coffeepots, dishwashers or

most metal products where water scale

is a problem.

Pure Activated Coconut Charcoal for

Refillable Charcoal Filter Canisters

250 g #500106

600 g #500107

Contains 100% pure crushed coconut

shells that have been steam activated at

extremely high temperatures creating a

porous grade of activated charcoal. This

coconut charcoal can be used along with

any type of home or commercial water

distiller. Coconut charcoal is used to

trap any gases or obnoxious odors that

may escape the distillation process. Do

not use any other charcoal such as

aquarium type.

36

Model

8-M

Electrical Specifications

Voltage

Amperage

Power

Frequency

120VAC

9.2 Amps

1100 Watts

60 Hertz

Water distiller Physical Size

Height-w/ lid

-w/o lid

Width-w/ drain valve

Depth-

13-1/2”(34.3 cm)

13” (33.0 cm)

18” (45.7 cm)

10-5/8”(27.0 cm)

Water distiller Weight

Dry: Water distiller Only

25 lbs. (11 kg)

Water distiller Production Capacity

Approx. Prod. Capacity

Approx. Daily Prod. Capacity

0.3 US gal/h (1.2 L/h)*

8 US gal (30.0 L)/24 hrs.

Optional Storage Tank Capacity

Storage Capacity to Lid lip

3.7 US gal (13.9 L)

Specifications and Technical Information

*Note: Performance based on optimum conditions including water

temperature, ambient temperature, line voltage, boiling tank

cleanliness, boiler fill level, etc

37

Wiring List (8GPD Manual) Part # 500246-

SERIES 15

No. Part# Color Ga Length From Conn. ToConn. From Location To Location

1 500287 GRN 16 3" #10RING#14-#16 POWER CORD GROUND POWER CORD

2 500287 BLK 16 14" F250 #14-#16 POWER CORD POWER SWITCH #2 POWER CORD

3 500287 WHT 16 16" #10RING#14-#16 POWER CORD RESET SWITCH #2 POWER CORD

4 500395 BLK 18 8" F250#18-#22&PIGG#18-#22 FAN MOTOR (ORG/BLU) FAN SWITCH #2 FAN MOTOR

5 500395 BLK 18 12" 2 (#10RING#18-#22) FAN MOTOR (YLW/WHT) RESET SWITCH #4 FAN MOTOR

6 095103 BLK 16 9" F250 #14-#16 #10 RING #14-#16 MICROSWITCH "NC" HEATING ELEMENT B

7 095024 YLW 16 6" #10RING#14-#16 #10 RING #14-#16 RESET SWITCH #3 HEATING ELEMENT A

8 095025 WHT 16 12" F250 #14-#16 #10 RING #14-#16 FAN SWITCH #3 HEATING ELEMENT B

9 095104 RED 16 7" F250 #14-#16 #10 RING #14-#16 MICROSWITCH "COM" RESET SWITCH #1

10 095027 ORG 16 9" F250 #14-#16 #10 RING #14-#16 POWER SWITCH #3 RESET SWITCH #4

11 095028 GRN 16 9" F250 #14-#16 #10 RING #14-#16 POWER SWITCH #8 RESET SWITCH #1

12 095029 BRN 16 9" F250 #14-#16 #10 RING #14-#16 FAN SWITCH #6 RESET SWITCH #4

13 095010 WHT 16 3" PIGG #14-#16 F250#14-#16 FAN SWITCH #2 FAN SWITCH #7

14 095010 WHT 16 3" PIGG #14-#16 F250#14-#16 POWER SWITCH #3 POWER SWITCH #6

15 095031 BRN 16 13" F250 #14-#16 #10 RING #14-#16 POWER SWITCH #7 HEATING ELEMENT B

16 095032 BLU 16 10" #10RING#14-#16 F250 #14-#16 RESET SWITCH #3 FAN SWITCH #8

38

WIRING DIAGRAM, 8GPD MANUAL

39

Index

Boiling Tank Lid, 22

Capacities

distilled production, 41

storage tank, 41

Charcoal

changing, 30, 31

Charcoal Filter

Installing Canister, 31

Charcoal Filter Canister

replacing charcoal, 31

Cleaning

boiling tank using the cleaner descaler, 28

regular inspection/cleaning of the boiling tank, 27

Descaler

instructions, 28

Electrical

location, 14

requirements, 14

Hydrological Cycle, 13

Inspection-boiling tank, 27

Installation

drain tube, 21

water distiller tools, 17

Lid

boiling tank, 22

storage tank, 22

Location-suitable distiller, 14

Maintenance and Cleaning, 27

record table, 37

schedule, 37

Operation, 23

fan switch, 24

normal, 25

overheat reset switch, 24

power switch, 24

Options

charcoal-replacement order, 40

cleaner and descaler-replacement order, 40

Post Charcoal Filter

replacing charcoal, 30

Record of purchase, 5

Safety Precautions, 7

Service Centre Locator, 39

Shipping Tie Removal, 17

Startup- Summary, 8

Sterilization, 32

liquid- optional storage tank, 32

steam- water distiller head, 33

steam- water distiller head, filter canister and

optional storage tank, 35

Terminology, 9

Troubleshooting, 38

Warranty, 6

Weights, 41

40

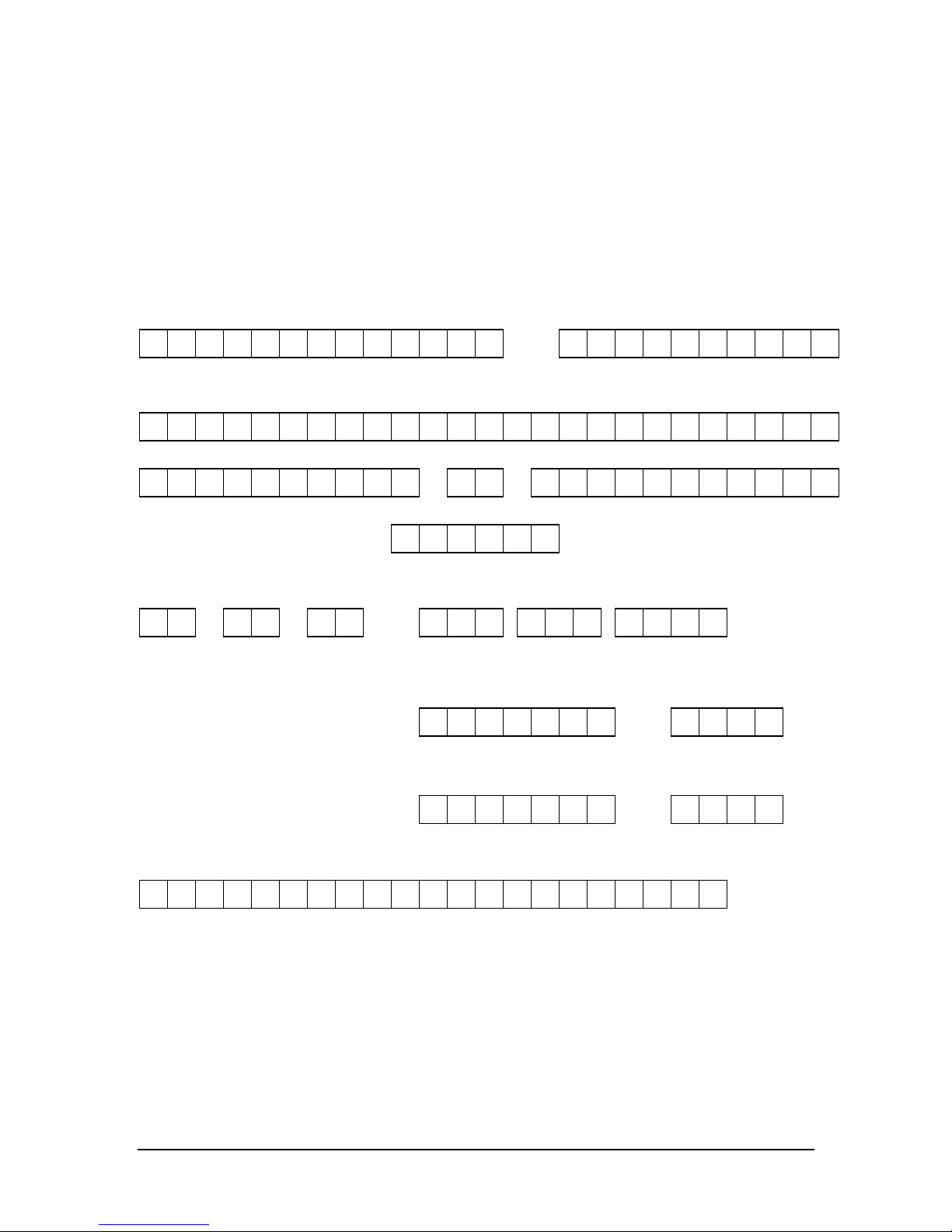

Precision Water Systems Water Distiller

Warranty Registration

IMPORTANT! Precision Water Systems IMPORTANT!

Please complete the information below and return it within the next ten days so we may register your purchase.

Last Name First Name

Address: (Mailing)

Date of Purchase:

Month Day Year Phone Number:

Model Number Serial Number Series:

8-M

(Water Distiller)

Model Number Serial Number Series:

8-MST

(Optional Storage Tank)

Purchased From:

Thank you for purchasing this fine Precision Water Systems Water Distiller.

City Province/State Country

Zip Code/Postal Code

Please fill in information completely and mail directly to:

Precision Design & Manufacturing Inc.

10331 – 105th Street

Westlock, Alberta, Canada

T7P 2H7

Or Fax To: 780-349-4957

41

Loading...

Loading...