Page 1

Owners Manual TD 1250

CONTENTS

(click on a topic to view)

CONGRATULATIONS ENDPANEL LAYOUT

FEATURES / SPECIFICATIONS ENDPANEL LAYOUT (cont.)

INSTALLATION TROUBLESHOOTING

WIRING TROUBLESHOOTING

POWER / GROUND TROUBLESHOOTING (cont.)

CONNECTIONS TROUBLESHOOTING (cont.)

CONNECTIONS (cont.) SYSTEM DIAGRAM 1 / 2

INPUTS / CONNECTIONS BLOCK DIAGRAM

INPUTS WARRANTY

(cont.)

Page 2

Thank you for choosing TUBE DRIVER. Tube Drivers musicality and absolute sonic

transparency allow accurate reproduction of recorded music enabling you to hear as well as

feel the music the way the artist intended. These handcrafted amplifiers feature full differential

“front ends” based upon a true instrumentation amplifier topology. Tube Drivers utilize only

the highest quality Svetlana tubes in our unique configurations. All of the internal amplifier

stages have been designed to have ultra-wide bandwidth together with a high degree of

linearity. The tubes used in these amplifiers provide both voltage gain and current gain where

they are connected in Cascode and Cathode Follower configurations. D.C. servos are used

to control any D.C. offset. These servos are critically positioned in the circuit so that not only

is D.C. offset eliminated but also any subtle differences between tubes are internally

compensated. These tube stages are then connected to a high current BiPolar output stage

that uses the same audiophile quality Sanken output devices featured in the PrecisionPower

2500F1.The output stages receive their power from a highly regulated D.C. power supply

which enhances their performance significantly. Very little negative feedback is used. Low

feedback designs have greatly improved sound quality having an extremely warm and open

sound with enhanced musicality consistent with only the highest quality home tube amplifiers.

Service

Do not attempt to service TUBE DRIVER products yourself.

Performing exploratory surgery on your audio equipment yourself

will void the warranty . Many parts of your TUBE DRIVER gear

are custom built to our specifications. Our factory parts are not

made available to anyone else nor are they for sale. Our goal

is to make sure that your TUBE DRIVER product will always

sound as good as the day it was purchased. Contact your

authorized TUBE DRIVER dealer about obtaining any warranty

service through TUBE DRIVER.(See Warranty insde back cover)

Model

Serial Number

Purchase Date

Caution!

The extended use of a high powered audio system may

result in hearing loss or damage. While TUBE DRIVER

systems are capable of

incredible accuracy, they are also designed for you to

enjoy at more reasonable levels all of the sonic subtleties

created by musicians. Please observe all local sound

ordinances.

"Concert Level"

volumes with

BA CK TO CONTENTS

Page 3

Fully regulated adaptive MosFET power supply

Balanced Mini-Din Input

High Voltage Input Capability with Input Attenuation Switch

Gold Plated RCA Input connectors

Three Year Warranty when installed by an Authorized

Completely Designed and Handcrafted in the USA

TD

dealer

Specifications

Power Bandwidth: 5 Hz -50 KHz

Total Harmonic Distortion: 0.2% or less (A-weighted)

Input Topology: Balanced Differential

Input Sensitivity: 500mV - 12 volts RMS

Input Impedance: 10K Ohms

Output Impedance: 2 - 16 Ohms

Continuous Output Power

TD1250

250 WRMS x 1 @ 4 Ohms

500 WRMS x 1 @ 2 Ohms

Dimensions

TD1250

Length = 17”

Height = 3.2”

Width = 9.25”

1

BA CK TO CONTENTS

Page 4

Tools/Parts Needed for Installation

Small flat blade screwdriver

Phillips screwdriver (#2 or medium sized)

Wire cutters

Wire strippers

4 – #6 round head screws, and 1 – #8 sheet metal screw

(or nut, bolt, and star washer)

2 – Ring connectors (large enough to accommodate your method of grounding)

In-line fuse or circuit breaker — see fuse requirements below

Power and groundwire — see Power Wire Calculator on the next page

Speaker wire — 16 gauge or larger

Grommets (sized to work with the power wire you plan to use in your installa-

tion)

Tube of silicone sealant

(not supplied)

Fuse Requirements

Recommended Fuse Rating for TD1250 i s 10 0 Amps

You will need to install an in-line fuse or circuit breaker in the power wire

within 18” of the battery. This fuse or circuit breaker protects your vehicle

from fire in case the power wire shorts to the vehicle bod y. If you are only using

one amplifier, use the recommended fuse rating. If you are using more than one

amplifier, add up the fuse ratings for all amplifiers, and use this sum for your main

fuse or circuit breaker. Use a power distribution block or fuse near your amplifiers

with the appropriate fuse for each individual power wire.

The information below is a basic formula you can use to determine approximate

current draw. A 50% amplifier ef ficiency rating is used as an average. This formula

is only a guideline. Using wire of a larger gauge can only improve the current transfer

of your system. Do not use smaller gauge wire.

Total 4-Ohm rated RMS output x 2 = Total Input Wattage

Total Input Wattage/Supply Voltage = Current Draw (in Amps)

Example:

Your TD1250 has 1 channels at 250 watts RMS into 4-Ohms

(250 x 2 =500). You would use the formula below:

250W x 2 = 500W/12.5V = 40 Amps Total Current Draw

2

BA CK TO CONTENTS

Page 5

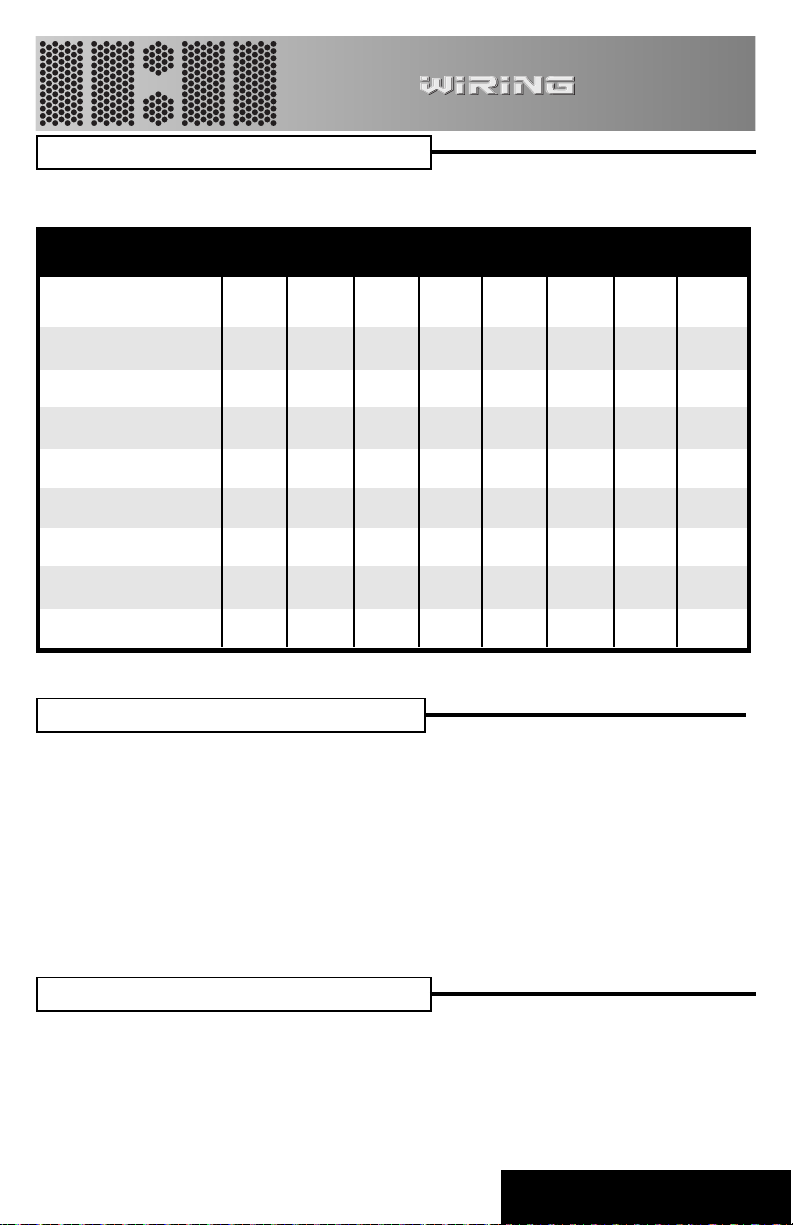

Power Wire Calculator

Recommended MINIMUM Gauge

Total Current Dra w Length of Wire to Run (in Feet)

(in Amps) < 3 4 - 7 7 - 10 10 - 13 13-16 16-19 19-22 22-28

0 - 20 14 12 12 10 10 8 8 8

20 - 35 12 10 8 8 6 6 8 4

35 - 50 10 8 8 6 6 4 4 4

50 - 65 8 8 6 4 4 4 4 2

65 - 85 6 6 4 4 2 2 2 0

85 - 105 6 6 4 2 2 2 2 0

105 - 125 4 4 4 2 2 0 0 0

125 - 150 2 2 2 2 0 0 0 0

Warning!

Amplifiers Generate Heat!

Y ou can mount the TUBE DRIVER in any position, even upside-down. However,

you must maintain proper airflow. Do not install your TUBE DRIVER under

carpets or enclose it behind airtight panels. In trunk-mounted applications, be sure

to provide venting for air circulation. Let the amplifier breathe. Without adequate

air circulation, your Tube Driver will turn itself down to protect itself.

Mounting

Y ou need to mount your TUB E D RIVER securely in your vehicle to prevent damage.

You may mount the system right-side up, on its side, or upside-down, provided

there is adequate ventilation.

3

BA CK TO CONTENTS

Page 6

Warning!

To prevent a short to ground, disconnect the negative (-) terminal of the system’s

battery before you begin. If the power cable shorts to ground, current will continue

to flow until the short is opened, the main fuse blows, the battery explodes, or the

wire melts.

Reconnect the terminal only after you make all connections.

Grounding

Your TUBEDRIVER is designed to operate from a car’s positive 12 volt, negative

ground electrical system. The ground wire should be the same gauge as the power

wire indicated in the chart.

The main power cable should run from the amplifier location, through or under the

vehicle, to the battery . Y ou must use a grommet wherever the cable passes through

a steel panel to prevent an eventual short to ground.

The ground connection is the most important part of any installation. If the

connections are poor and/or the resistance is high, the resulting drops in voltage

will rob you of amplifier power and may allow noise to enter your system. Your new

Tube Driver features a fully regulated power supply. It will make full power even if

the voltage changes. It will draw more current at lower voltages to make that power.

Lower voltage and high cable resistance means more total current draw. Using a

digital multimeter (DMM), try to get cable resistance as low as possible. If resistance

is too high, use a larger gauge wire. T ry to ground your system to a single point in

the vehicle. In larger systems, use distribution blocks and run both power and ground

cables directly to the system battery.

Remote Turn-on

IMPORT ANT! Your new Tube Driver is equipped with our unique tube warm-up

circuit. When your system is turned on, The LED labeled “WARM UP” will

illuminate and full power is applied to the tube heaters for appr ox. 35 seconds.

The internal fan will then turn on and two seconds later the amp outputs will

be switched on. The system will then play as normal.

You must connect a wire to the remote (REM) terminal (located in the speaker

terminal plug) of your amplifier to power on your TUBEDRIVER. The source unit

normally provides a remote amp turn-on or power antenna lead that provides this

+12 volts when you turn on the unit.

• Run a wire from the chosen turn-on lead to the REM connection

of your TUBEDRIVER (See Endpanel Lay out: Page 10)

• Tighten the connection

4

BA CK TO CONTENTS

Page 7

Speaker Connections

Follow these simple instructions and refer to the diagram below to

make your speaker connections:

• Using at least 16 gauge wire, run wire from the speakers to the

amplifier(s) using the same precautions that you followed for

running the power, ground, and remote wires

• Cut off excess wire

• Use wire strippers to strip 1/4 inch of insulation at the end of

the wires

• Attach the speaker wires to the amplifier’s

it in

POWERLOCK

connector and plug

Power

5

lock

Connector

BA CK TO CONTENTS

Page 8

Bridging

All multi-channel TUBE DRIVERS are capable of being bridged into a 4-

Ohm mono output without switches or bridging modules.

Your new Model 1250 is a mono (single channel) amplifier. It cannot

be bridged. The two pairs of speaker terminals are in parallel, so

connecting two 4 ohm woofers (one on each pair of terminals) would

result in a 2 ohm load to the amplifier.

Note: A total impedance of less than 2-ohms may trig ger the protection

circuitry causing reduced output and may eventually damage your

amplifier.

Connections

(Two four ohm subwoofers connected in parallel = two ohm load on the amplifier.)

6

BA CK TO CONTENTS

Page 9

Input Jacks

The TUBE DRIVER includes both RCA and Mini-Din (balanced) inputs. The

supplied RCA connections allow you to use TU B E DRIVER with other brands

of audio gear.

noise reduction over standard RCA input types. Our fully balanced Mini-DIN

connection system features high signal voltage capability and the highest

possible sound quality. A single cab le for 2 channels also simplifies installation.

Cables from the source unit, non-powered equalizer, or crossover go here.

Both left and right inputs should be used for maximum amplifier output.

Our Differential RCA inputs provide a dramatic improvement in

Balanced Inputs

Standard Coaxial RCA Cables

Standard coaxial RCA cables utilize two connections: a center wire (signal

positive) attached to the center pin of the RCA connector along with a braided

outer conductor (signal negative) connected to the outer ring of the RCA

connector. This design almost always allows radiated noise to enter the system,

since the signal is not well protected.

Balanced Mini-DIN Cable

Balanced Mini-Din connections use six pins and one grounding ring. Pins 1 and

2 are open connections, normally they would carry your remote turn on voltage.

Pins 3/4 and 5/6 are a pair of twisted conductors for the music signal. The twisting

of the inner wires rejects or eliminates radiated noise by more than 30 dB. The

inner pair of wires are then protected by an outer shield connected to Pin 1. This

means the music signals can be kept as far away as possible from the power

and chassis ground paths of other circuitry, allowing the transmission of pure

music between points while protecting it from noise generating equipment and

wiring present in the vehicle. The diagram below shows the pin configuration

for the Mini-Din connections.

56

3

7

4

BA CK TO CONTENTS

Page 10

Input Gain Control

There is an Input Gain Control located on the end panel under the RCA

input jacks. This is not a volume control! This control matches the output

signal voltage of the source unit to the amplifier inputs.

By turning the control clockwise (to the right), the inputs of the amplifier

become more sensitive and will allow a weak signal of approximately 1/2

volt to drive the amplifier to full power. At the same time, while an amplifier

with its level control at maximum is able to drive a weak signal, it also picks

up and amplifies any noises lurking in the background, such as a brake light

pop,

alternator

Increasing the signal voltage to the amplifier by using a high output source

unit (or a TUBE DRIVER LD-3) makes the music much louder. By turning

the level control counterclockwise (to the left), the amp inputs will be less

sensitive. The amp will reproduce music at full power while making any

noise floor insignificant. Y our TUBEDRIVER accepts signal levels of up to

12 volts RMS.

whine,

or ignition

tick.

Setting Input Gain

1. Set the Input Gain Control to just above the lowest setting.

2. Turn the master volume on the source unit or pre-amp to almost full

volume.

3. With music playing, slowly increase each Input Gain Control until you

hear distortion. Turn down the Gain Control until the distortion stops.

8

BA CK TO CONTENTS

Page 11

Power Side

1. POWER

A red light indicates that the amplifiier is turned on (After warm-up sequence).

2. WARM UP

A red light indicated that the tubes are warming up. (Refer to Pg. 4; Remote Turn-on)

3. POWER / GROUND

After you have securely connected your power and ground wires, plug in the

connector here.

1

2

3

9

BA CK TO CONTENTS

Page 12

Input/Control Side

1. SPEAKER OUTPUTS / REMOTE (Turn-on)

After connecting remote and speaker wires plug in the connector here.

2. GAIN

Use this control to match the output level of the head unit to the outputs of the amplifier.

3. INPUTS

Plug in the RCA outputs from your head unit here.

4. BALANCED / RCA

This switch is used to select between the unbalanced RCA inputs or the

balanced MINI-DIN inputs.

1

4326

5

5. BALANCED INPUT

Plug in the mini-din output from the LDX-33 crossover, LD-3 Line Driver, or other

balanced source here.

6. -12dB

For use with high level inputs (4V up to 12V). Push this switch in to attenuate the

input by 12dB

7. COOLING VENTS

7

10

BA CK TO CONTENTS

Page 13

No Sound

Is the WARM UP LED

YES

The warm up cycle can take up to

40 sec., Is there sound after that?

NO

Is there

signal on the

RCA’s?

YES

You’re done

YES

Contact your

dealer

Do you have 12V at the amplifier’s

connections?

YES

Does the amp

remote (REM)

have 12V?

YES

Check main

system fuse.

Did that work?

NO

Check all

connections.

Repair as

needed

NO

Trace back the amp

remote to your source

unit. Repair as needed

YES NO

You’re done

Contact your

dealer

Amplifier Turning D o w n at Normal Volume

Turn the system off, wait approx. 5 min., then turn

the system back on. Listen for awhile. Did it work?

NO

NO

Check speaker wires for shorts or other

damage and correct as needed.

Did that fix the problem?

YES

You’re done

Check voltage supply to

ensure sufficient voltage.

Did that work?

NO

YES NO

You’re done

Contact your

YES

If sound is heard, the Amp

may have thermally turned

down. Check for proper air

flow and correct as needed.

You’re done.

dealer

11

BA CK TO CONTENTS

Page 14

No Sound in One Channel

Check the pre-amp (RCA/Mini-Din) cables for open connections and make

corrections. Did you find open connections?

NO

YES

Reverse the left and right inputs.

SOUND IS NOW IN...

Opposite Channel

Problem is further up the signal

path. Reconnect RCA’s to amp

as normal. Reverse RCA inputs

at crossover.

SOUND IS NOW IN...

Opposite Channel

Reverse RCA outouts of head unit

SOUND IS NOW IN...

Opposite Channel

Problem is in the head unit

Problem is in the speaker or

speaker wire of the silent channel.

Check speaker leads for pinched,

shorted, or open connections.

Problem is in the crossover.

Contact your dealer.

Problem is in the RCA cables.

You’re done

Same Channel

Same Channel

Same Channel

Amplifier Turning Down at High Volume

Check speaker cables for shorts. Check for

excessively low speaker impedance. Fixed?

NO

Check voltage supply to ensure

sufficient voltage is being delivered.

Is amp getting enough air to cool off?

Did that solve the problem?

NO

If using passive crossovers, are the

connections correct?

NO

Voltage at amp may be dropping

below minimum limits.

Power output of amp may exceed

power handling of parts. Upgrade as

needed.

12

YES

You’re done

YES

You’re done

YES

BA CK TO CONTENTS

Page 15

Noises While the Engine is On

Alternator whine:

This noise changes in frequency with engine RPM. Check for:

.

Excessive input level

.

High resistance in cabling or corroded and/or loose connections

.

Polarity of the input cables

If the problem persists, check the

Ticks/buzz:

This noise should go faster and slower with engine RPM, but not really change in

frequency. This is due to the ignition or the fuel pump.

.

T ry moving the input cab les to av oid contact with the fuel pump or wiring

If the problem persists, check the

Accessory pop:

This popping noise occurs as the result of turn signals, brake lights, etc. You can

try:

.

Mo ving the cables to avoid contact with the wires for the accessories

.

Relocating various ground connections

whines and pops checklist

whines and pops checklist

below.

below.

Whines and pops:

If you have a combination of noises, or if one or more of the problems listed above

persists despite efforts to stop the problem, the noise may be caused by one or

more of the following problems:

.

Excessively high input level setting on the amplifier

.

Poor or open shielding, extra long cables or corroded input cables

.

Bad connections

.

Bad (or high resistance) system ground

.

Reversed polarity on audio signal cables

.

Poor quality source unit

13

BA CK TO CONTENTS

Page 16

Noises While the Engine is On or Off

System hiss:

System hiss is a white noise that occurs even when the engine is off. It is

usually due to excessively high gain settings. If the hiss is still audible

when you disconnect the input cables from the amplifier, check the input

level on the amplifier. If the hiss disappears when you remove the input

cable, it may be a poor quality source unit, components between the

amplifier and the source unit, or poor level settings.

Distortion:

Distortion is garbled sounding music. Use the following chart to help you

find the source of distortion.

Is there audible distortion at all of

the amplifier outputs?

NO

Check each side of the amplifier

independently to see if the

distortion is only on one channel.

Is that the case?

Try reducing the input level

controls.

YES NO

Swap the output connection left

to right. Did the problem switch

sides?

Swap the input side left/right. Did

the distortion switch sides?

Check for distortion in the signal

path prior to the amplifier.

Check and/or replace the speaker

that is distorting.

YES

Check the source unit and

components between the source

unit and amplifier

Contact your dealer.

YES

YESNO

NO

14

BA CK TO CONTENTS

Page 17

15

BA CK TO CONTENTS

Page 18

+

-

AMP

GAIN

DIF.

INPUT ATTENUATION

Switch

BALANCED/RCA

AMP

INVERTED

SUM

DIF.

Switch

BALANCED/RCA

RCA

Left Input

Left

Right

Input

MINI-DIN

16

RCA

Right Input

BA CK TO CONTENTS

Page 19

Three-Year Limited U.S.A. Warranty

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state. TUBE DRIVER warrants its products to be free from defects in materials and

workmanship under normal use and service for a period of three (3) years from the date of

original purchase when the unit is installed by an Authorized Dealer. Non-Authorized Dealer

installed products carry a one (1) year parts and ninety (90) days labor limited warranty. The

extent and conditions of Limited Warranty are as follows:

1. Authorized Dealer Installed Products: TUBE DRIVER will either repair or replace at no charge,

to the original purchaser, any unit which upon examination discloses to be defective and under

warranty, provided the defect occurs within three (3) years from the date of original purchase

when the unit is installed by an Authorized Dealer and the product is returned immediately to

TUBE DRIVER. This warranty is not transferable.

2. Non-Authorized Dealer Installed Products: TUBE DRIVER will either repair or replace at no

charge, to the original purchaser, any unit which upon examination discloses to be defective and

under warranty, provided the defect occurs within ninety (90) days from the date of purchase and

the product is returned immediately to TUBE DRIVER. Warranty claims beyond ninety (90) days

for Non-Authorized Dealer Installed Products will be for parts only and will extend for one (1)

year from the date of purchase. This warranty is not transferable.

3. The date of purchase and proof of Authorized Dealer Installation of a TUBE DRIVER product

must be established by an original sales receipt which must accompany the article being returned

for warranty work.

4. This warranty shall NOT apply to any TUBE DRIVER product found to have the original factory

serial number removed or defaced. All products received (by TUBE DRIVER) for in warranty or

out of warranty repair, with their original serial numbers removed or defaced, will NOT be repaired

and will be returned to sender, freight collect. Refer to original packaging for the serial number of

your component speakers.

5. The provisions of this warranty shall not apply to any TUBE DRIVER product used for a purpose

for which it is not designed, which has been repaired or altered in any way, or which has been

connected, installed, or adjusted other than in accordance with the instructions furnished in TUBE

DRIVER’S owner’s manual. Nor shall this warranty apply to any part which has been subject to

misuse, neglect, or accident.

6. TUBE DRIVER does not authorize any other persons to assume any other liability in connection

with its products. THIS WARRANTY IS THE ONLY EXPRESS WARRANTY MADE BY

TUBEDRIVER APPLICABLE TO ITS PRODUCTS. ANY IMPLIED WARRANTY OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE APPLICABLE TO

TUBEDRIVER PRODUCTS IS LIMITED IN DURATION TO THE DURATION OF THIS LIMITED

WARRANTY. TUBEDRIVER SHALL NOT BE LIABLE FOR THE INCIDENTAL,

CONSEQUENTIAL, OR COMMERCIAL DAMAGES RESUL TING FROM THE BREACH OF THIS

WRITTEN WARRANTY. Some states or provinces do not allow the exclusion or limitation of

incidental or consequential damages or limitations on how long an implied warranty lasts; so the

above limitations or exclusions may not apply to you.

7. Y our product will be serviced on an in-warranty basis within the warranty period for the correction

of warranted defects. If improper operation of your TUBE DRIVER product should occur, contact

your Authorized Dealer for assistance with the return and factory repair of your TUBEDRIVER

product. If an Authorized Dealer is not available, return the unit including your name, telephone

number, return address, a copy of your sales receipt, and a description of the problem to:

TUBE DRIVER, Inc.

Service Department

4829 S. 38th Street

Phoenix, AZ 85040-2964

TO RETURN TUBEDRIVER PRODUCTS OUT OF W ARRANTY: Return the unit, postage prepaid,

in the original protective carton. Please include a description of the problem and, if desired, a

request for an estimate of repair costs. Unless a request for an estimate is included, the unit will

be repaired as necessary. Please contact TUBE DRIVER Customer Service at 1-888-627-6937

for questions concerning out of warranty repair charges. Repaired unit will be returned with an

itemized statement, C.O.D.

BA CK TO CONTENTS

Loading...

Loading...