Page 1

Haptic

Feedback

+44 (0) 1932 252 482

www.precisionmicrodrives.com

enquiries@precisionmicrodrives.com

Evaluation Kit

Quick Start Guide

Page 2

1 Introduction

Welcome to the Haptic Feedback Evaluation Kit!

This Quick Start Guide will show you how to get up and running, whilst demonstrating the

dierent modes of operation. There are also some useful references towards the end.

Learn more

Please read the full User Manual for complete information on technical details and advice

for accessing the advanced features of the Haptic Feedback Evaluation Kit.

Additional Resources

Online at precisionmicrodrives.com/haptic-kit you can nd a range of additional resources

available, including:

l Downloadable PDF of this document

l Downloadable PDF of the full User Manual

l A4 printable posters for reference (Eect Table, True Haptics Menu Map, etc.)

l Tutorials on the advanced features

l Arduino code for dierent Modes of Operation and example applications

l Further resources as they are developed!

Further Development

Once you have experienced haptics with this kit, you may want to apply it to your own

projects. We have an extensive range of vibration actuators that can be found on our

website at precisionmicrodrives.com/vibration-motors and are available to purchase in

our online shop. However, if you are unable to nd what you are looking for or you need

some support, our engineers are always happy to answer any questions. Please contact

us using any of the methods shown below.

Contact Precision Microdrives

For questions about the Haptic Feedback Evaluation Kit, ordering and quotes, or technical

queries please do not hesitate to get in touch:

+44 (0) 1932 252 482

www.precisionmicrodrives.com

enquiries@precisionmicrodrives.com

2

Page 3

2 System Overview

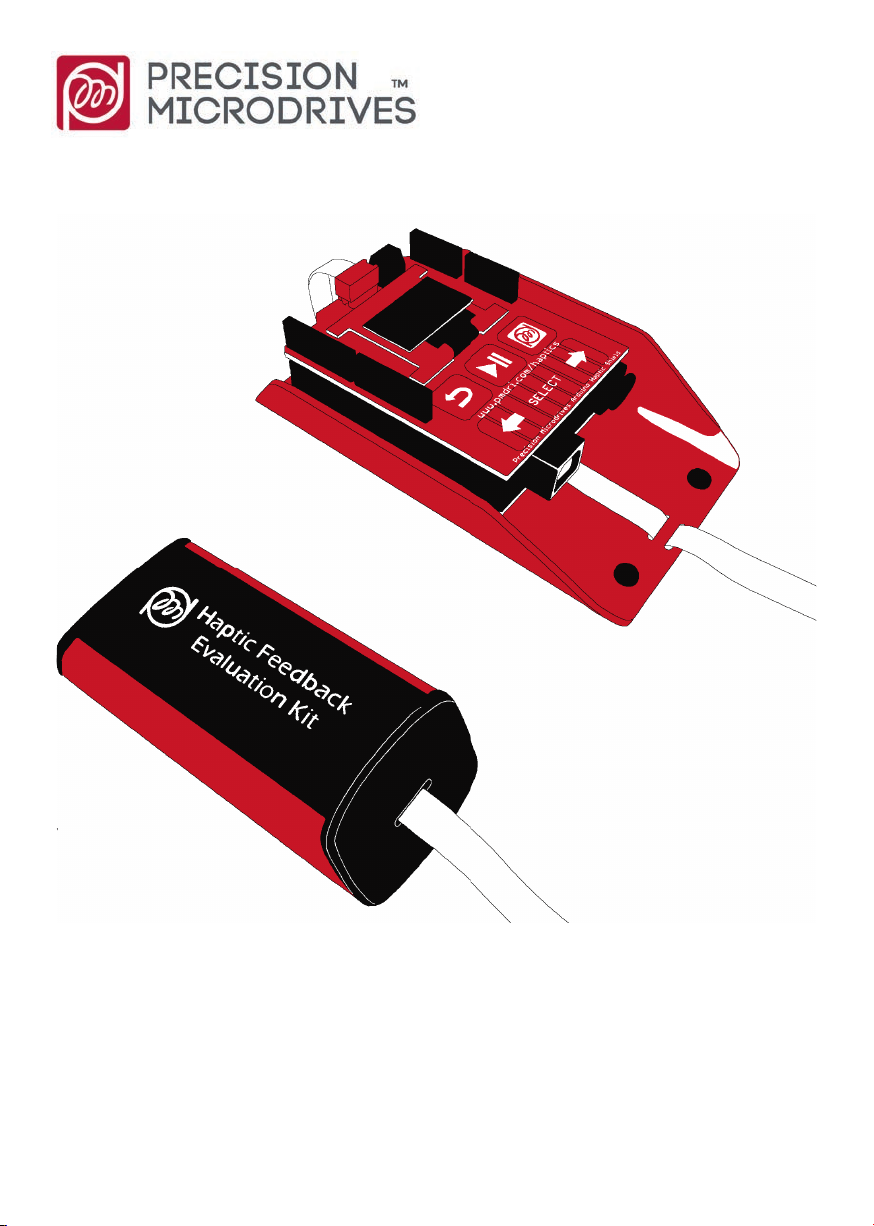

The Haptic Feedback Evaluation Kit is comprised of two main hand-held units, the Haptic

Controller and the Haptic Grip:

Haptic Feedback Evaluation Kit

Haptic Controller

Haptic Shield

Haptic Grip

Arduino UNO R3

Haptic Controller

Together, the Haptic Shield and the Arduino UNO R3 make up the Haptic Controller and act

as the ‘brains’ of the system.

Arduino is an open source development platform for electronics, as a term it is colloquially

use to describe the parent company, the product range, or a speci c board. The UNO

R3 is based on the Atmel ATmega328 microcontroller, its stackable headers enable the

functionality to be extended by connecting customised boards, called ‘shields’, which

mate with the Arduino.

The Precision Microdrives Haptic Shield is specially designed for haptic feedback, with

capacitive touch buttons for input and a Texas Instruments DRV2605L haptic driver and

MOSFET for vibration output.

Haptic Grip

The Haptic Grip houses 4 di erent vibration actuators to enable users to experience

a range of haptic feedback and vibration alerting, including 3 ERMs (304-103, 306-109,

308-102) and the C10-100 LRA.

This makes it easy to compare haptic e ects against each other and feel the e ects

independently of the Haptic Controller. It is designed to have a form factor that can

represent a variety of end applications, such as hand held instruments or joystick

interfaces.

A PDF reference is available at precisionmicrodrives.com/haptic-kit which lists key

parameters of each motor included, with space for notes about other actuators you may

use.

3

Page 4

3 Setup & Installation

The Haptic Feedback Evaluation Kit arrives completely assembled with all hardware

provided in the box. To start, simply connect the kit to one of the power sources outlined

below.

Power

The Arduino allows you to supply power via the USB port or DC connector. You can use

either option. However, please note that old versions of the Haptic Shield must be powered

via USB only. If this Quick Start Guide was supplied with your kit, you have the new version

and may proceed with your preferred choice. If you are reading this online, you should

double check your version of the Haptic Shield by visiting precisionmicrodrives.com/

haptic-kit.

If using a USB port on a computer or laptop to power the unit you may be subject to

current limiting on the USB port. You will need to install the Arduino drivers to correct

this. When the actuators are vibrating the current draw can peak over 100mA. By installing

the drivers the Arduino is able to negotiate up to 500 mA. Not installing the drivers risks

limiting the current to the motors, thereby reducing the performance and in some cases

not allowing the kit to start-up.

(In some computers, particularly laptops, several USB ports can use the same internal

power supply. If possible, remove other USB devices that may be connected to the same

line as the kit.)

Drivers and Software

Installing the drivers and sof tware for the Arduino Uno R3 is simple, but they are updated

periodically. Therefore it is best to get the latest version and instructions from the Arduino

website (note URLs are case-sensitive):

l Navigate to arduino.cc/en/Main/Software or search ‘Arduino software’

l Install the Arduino software, includes drivers and IDE (1.8.7 at time of release)

l Refer to the Getting Started page for more help arduino.cc/en/Guide/HomePage

Existing Arduino Users and Kit Owners

If you already have the Arduino IDE installed, we recommend ensuring you upgrade

to the latest version. If you wish to continue using an older version, please visit

precisionmicrodrives.com/haptic-kit for legacy support.

For owners of the Rev1 kit, please ensure you replace the libraries with the Rev2 versions.

For full upgrade instructions, please visit precisionmicrodrives.com/haptic-kit.

4

Page 5

4 Intro Mode

The Intro Mode rmware is loaded onto the Haptic Controller prior to shipping. After

successfully completing the installation process and providing power, the kit will

automatically start and the Precision Microdrives logo will appear on the OLED main

screen.

Intro Mode serves as an introduction to haptic feedback and vibration alerting. This makes

it perfect for those who are unfamiliar with haptics, or for demonstrating to colleagues the

value of the features. Even if you are experienced with haptic feedback, you may wish to

explore the tutorials to discover some of the additional features of the DRV2605L.

There are four tutorials in the Intro Mode,

use the Left and Right buttons to move

between them.

Play Button

PMD But tonBack Button

Right ButtonLeft Button

Select Button

Press the Select button to start:

l Quick-Start Demo

l Haptic Feedback Tutorial

l Vibration Alerting Tutorial

l DRV2605 Overview

Develop Understanding

Each tutorial has several slides for you to read about the concepts demonstrated. They

are easy to follow and you can go back by pressing the Left button, or exit with the Back

button.

Feel Eects

At specic points in each tutorial you will be prompted to press the Play button. Dierent

eects are played on the Haptic Grip or the Haptic Controller, you can repeat them by

pressing the Play button a second time.

Apply

Not only will the tutorials walk you through the concepts of vibration alerting and haptic

feedback, some also include example applications. Start thinking about how you would

use haptics to improve your product, then try out the Engineering Mode.

5

Page 6

5 Engineering Mode

The Engineering Mode uses dierent rmware that needs to be loaded into the Arduino,

to perform this you will need to have installed the Arduino Environment (see Section 3)

and have downloaded the code from precisionmicrodrives.com/haptic-kit. It gives access

to a greater range of eects and functionality.

It is also recommended you read the Section 5 of the User Manual to get the most out of

the Engineering Mode. The User Manual is available online at precisionmicrodrives.com/

haptic-kit.

Upload the Code

To enter the engineering mode, you need to compile and upload the code

through the Arduino Environment. Downloaded and extract the code to your

chosen folder, open the EngineeringMode.ino le (.ino les are called ‘sketches’).

Supporting les called ‘libraries’ are included in the zip, ensure the Sketchbook

Location (File -> preferences) points to the folder above the libraries folder. If

everything is correct you can click the 'upload’ button. More detailed instructions

available in the User Manual or at precisionmicrodrives.com/haptic-kit.

Using True Haptics

Here you can experience haptic feedback through the DRV2605 which includes 123

dierent haptic eects and 6 libraries. Navigate clicks, bumps, pulses, and many more

options.

Press the Play button to play the chosen eect and press the PMD button to cycle

actuators. The True Haptics Menu Map and Eect ID Table (Sections 9 and 10) will help you

nd eects quickly.

Using Vibration Alerting

Vibration alerts can be played through the on-board MOSFET and PWM. Build your own

vibration alerting waveform by setting each variable in the Vibration Alerting section,

including vibration power, vibration waveform, on time, and o time. Please note that

LRAs require an AC signal, so cannot be played by the on-board MOSFET.

Keep Developing

Try using the DRV2605 librar y and example code to start prototyping your own system.

The Arduino can be used to accept inputs, the library lets you easily interface with the

DRV2605, and you can connect to an external actuator using the terminals on the Haptic

Shield.

6

Page 7

6 Development Mode

Having approached haptics with the Intro Mode and gained a more in depth idea of what

our motors can do through using the Engineering mode, you may be thinking about how

you can develop this into your own project.

The Development Mode has been created to allows designers to implement haptics using

our Haptic feedback kit. You can download the rmware from precisionmicrodrives.com/

haptic-kit.

Modifying and uploading the code

All the software needed to run in our Haptic Kit is available on our website and users

can deal in the Software without restriction, including without limitation, the rights to use,

copy or modify it.

The Development Mode program is used to start writing your own code. It handles

the initialisation of the pins, I

the DRV2605 Arduino Library Reference useful, but those unfamiliar with Arduino

programming may nd the tutorials and examples more benecial.

To upload the code in the kit, follow the same instructions as in the Engineering

Mode. This will give you complete access to the open source code. The motors

are driven using the driver DRV2605 from Texas Instrument. The Development

Mode will allow you to program the driver and choose the setting that best

suits your application and the PMD motor you are using. You can refer to

Texas Instruments (TI) to understand the features of the driver and map of addresses.

You can connect an external actuator to the kit using the green screw terminal

and program your own patterns, eects and recurrences. It is also worth noting that the

OLED display is disabled in the Development Mode as it is designed to be very simple. This

means that nothing will appear on it and the pins that were required to drive it are now

available. The Pin Mapping in section 8 will help you identify which pins are free.

2

C bus, and the serial port. Advanced users will nd

Tutorials and Examples

You will nd on our website dierent tutorials and examples to follow with the

Development Mode. Here is a few options for the users to continue investigating and

developing new haptics applications.

1: How to connect an external motor to the Haptic Feedback Evaluation Kit

precisionmicrodrives.com/content/connecting-external-actuator-vibration-motor-to-the-

m20-200-haptics-kit/

2: Driving multiple LRA's

precisionmicrodrives.com/content/new-haptic-feedback-evaluation-kit-tutorial-driving-

multiple-lras/

3: Using the Audio-to-Vibe function

precisionmicrodrives.com/content/tutorial-using-haptic-feedback-with-music-or-audio-

signals/

7

Page 8

7 DRV2605 Library

The DRV2605 and DRV2605L from Texas Instruments are functionally similar, the

DRV2605L is available in a 10VSSOP package and is used in the Haptic Feedback Evaluation

Kit. However, you should be able to use the library with either chip. If you have any issues

in Development Mode, please contact us.

8

Page 9

8 Pin Mapping

Key of pin requirements

OLED 3V3, 5V, GND, 5, 8 , 10, 11, 13

Haptic Grip 5V, GND, A0, A1, 3, 4

DRV2605 3V3, 5V, GND, A4, A5, 5, 7, 9

Capacitive Touch 3V3, 5V. GND, A4, A5, 2

MOSFET 5V, GND, 4, 9

Touch driver - IRQ

Grip select

Source select

SPI (CS) OLED 3

Shield LRA Selec t

DRV2605 - EN 6

SPI (DC ) OLED 5

PWM (IN/TRIG, MOSFET

SPI (RES) OLED 4

SPI (DAT) OLED 9

I2C SCL

I2C SDA

Shield ERM Select

Grip Connect 6 (S2)

Grip Connect 3 (S1)

SPI (CLK ) OLED 8

12C Addresses

USING 7 BITS ADDRESSING

Capacitive Touch Driver MPR121 0x5D

Haptic Driver DRV2605L 0x5A

9

Page 10

9 True Haptics Menu Map

Look ing to nd a specic eect in the True Haptics menu? You can use the reference below

in conjunction with the Eect Table to nd the menu location of each eect available on

the DRV2605L.

Clicks

Ramps

Single

Double

Triple

Buzzes

Strong

Medium

Tick

Transition

Strong

Medium

Tick

Triple

Other

Buzzes

1, 2, 3, 17, 18, 19, 20

21, 22, 20

4, 5, 6, 24, 25, 26

58, 59, 60, 61, 62 ,63

10, 11, 27, 28, 29,

30, 37, 38, 39, 40

31, 32, 33, 41, 42, 43

34, 35, 36, 44, 45, 46

12

13, 14, 47, 48, 49,

50, 51, 118

Short

Up

Medium

Long

Short

86, 110, 87, 111, 92,

116, 93, 117

84, 108, 85, 109, 90,

114, 91, 115

82, 106, 83, 107, 88,

112, 89, 113

74, 98, 75, 99, 80,

104, 81, 105

Down

Medium

Long

72, 96, 73, 97, 78,

102, 79, 103

70, 94, 71, 95, 76,

100, 77, 101

Alerts

Alerts

Alerts

5, 16

Library

Bumps

Pulses

10

Hums

Bumps

Pulses

Hums

7, 8, 9

52, 53, 54, 55, 56, 57

64, 65, 66, 67, 68,

69, 119, 120, 121,

122, 123

Library

Library

Audio2Haptics

Audio-

2Haptics

Audio-

2Haptics

Shield Haptics

Shield

Haptics

Shield

Haptics

1, 2, 3, 4, 5

ERM, LRA

Page 11

10 Eect Table

ID Waveform Menu

1Strong Click 100% 63Clicks > Single > Strong Transition Click 6 10%

2

Strong Click 60%64Clicks > Single > Strong Transition Hum 1 100%

3

Strong Click 30%65Clicks > Single > Strong Transition Hum 2 80%

4

Sharp Click 100% 66Clicks > Single > Tick Transition Hum 3 60%

5

Sharp Click 60%67Clicks > Single > Tick Transition Hum 4 40%

Sharp Click 30%68Clicks > Single > Tick Transition Hum 5 20%

6

7

Soft Bump 100% 69Other > Bumps Transition Hum 6 10%

8

Soft Bump 60%

9

Soft Bump 30%71Other > Bumps

10

Double Click 100% 72Clicks > Double > Strong

11

Double Click 60%73Clicks > Double > Strong

12

Triple Click 100% 74Clicks > Triple

13

Soft Fuzz 60%75Other > Buzzes

14

Strong Buzz 100% 76Other > Buzzes

15

750ms Alert77Other > Alerts

16

1000ms Alert78Other > Alerts

17

Strong Click 1 100% 79Clicks > Single > Strong

18

Strong Click 2 80%80Clicks > Single > Strong

19

Strong Click 3 60%81Clicks > Single > Strong

20

Strong Click 4 30%82Clicks > Single > Strong

21

Medium Click 1 100% 83Clicks > Single > Medium

22

Medium Click 2 80%84Clicks > Single > Medium

23

Medium Click 3 60%85Clicks > Single > Medium

24

Sharp Tick 1 100% 86Clicks > Single > Tick

25

Sharp Tick 2 80%

26

Sharp Tick 3 60%88Clicks > Single > Tick

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

Buzz 1 100% 109Other > Buzzes

48

Buzz 2 80% 110Other > Buzzes

49

Buzz 3 60% 111Other > Buzzes

50

Buzz 4 40% 112Other > Buzzes

51

Buzz 5 20% 113Other > Buzzes

52

Pulsing St

53

54

55

56

57

58

59

60

61

62

rong 1 100% 114Other > Pulses

Pulsing Strong 2 80% 115Other > Pulses

Pulsing Medium 1 100% 116Other > Pulses

Pulsing Medium 2 60% 117Other > Pulses

Pulsing Sharp 1 100% 118Other > Pulses

Pulsing Sharp 2 60% 119Other > Pulses Smooth Hum 50%

Transition Click 1 100% 120Clicks > Single > TransitionSmooth Hum 40%

Transition Click 2 80% 121Clicks > Single > TransitionSmooth Hum 30%

Transition Click 3 60% 122Clicks > Single > TransitionSmooth Hum 20%

Transition Click 4 40% 123Clicks > Single > TransitionSmooth Hum 10%

Transition Click 5 20%

Clicks > Single > Transition

ID Waveform Menu

Clicks > Single > Transition

Other > Hums

Other > Hums

Other > Hums

Other > Hums

Other > Hums

70Other > Bumps

Transition Ramp Down Medium Smooth 1 100-0% Ramps > Down > Medium

Transition Ramp Down Medium Smooth 2 100-0% Ramps > Down > Medium

Transition Ramp Down Medium Sharp 2 100-0% Ramps > Down > Medium

87Clicks > Single > Tick

89Short Double Click Strong 1 100% Clicks > Double > Strong

90Short Double Click Strong 2 80%Clicks > Double > Strong

91Short Double Click Strong 3 60%Clicks > Double > Strong

92Short Double Click Strong 4 30%Clicks > Double > Strong

93Short Double Click Medium 100% Clicks > Double > Medium

94Short Double Click Medium 2 80%Clicks > Double > Medium

Transition Ramp Down Long Smooth 1 50-0%

95Short Double Click Medium 3 60%Clicks > Double > Medium

96Short Double Sharp Tick 1 100% Clicks > Double > Tick

97Short Double Sharp Tick 2 80%Clicks > Double > Tick

Transition Ramp Down Medium Smooth 2 50-0%Ramps > Down > Medium

98Short Double Sharp Tick 3 60%Clicks > Double > Tick

99Long Double Sharp Click Strong 1 100% Clicks > Double > Strong

100Long Double Sharp Click Strong 2 80%Clicks > Double > Strong

101Long Double Sharp Click Strong 3 60%Clicks > Double > Strong

102Long Double Sharp Click Strong 4 30%Clicks > Double > Strong

Transition Ramp Down Medium Sharp 1 50-0%Ramps > Down > Medium

103Long Double Sharp Click Medium 1 Clicks > Double > Medium

Transition Ramp Down Medium Sharp 2 50-0%Ramps > Down > Medium

104Long Double Sharp Click Medium 2 80%Clicks > Double > Medium

105Long Double Sharp Click Medium 3 60%Clicks > Double > Medium

106Long Double Sharp Tick 1 100% Clicks > Double > Tick

107Long Double Sharp Tick 2 80%Clicks > Double > Tick

108Long Double Sharp Tick 3 60%Clicks > Double > Tick

Long Buzz for Programmatic Topping 100% Other > Buzzes

Other > Hums

Ramps > Down > LongTransition Ramp Down Long Smooth 1 100-0%

Ramps > Down > LongTransition Ramp Down Long Smooth 2 100-0%

Ramps > Down > StrongTransition Ramp Down Short Smooth 1 100-0%

Ramps > Down > StrongTransition Ramp Down Short Smooth 2 100-0%

Ramps > Down > LongTransition Ramp Down Long Sharp 1 100-0%

Ramps > Down > LongTransition Ramp Down Long Sharp 2 100-0%

Ramps > Down > MediumTransition Ramp Down Medium Sharp 1 100-0%

Ramps > Down > StrongTransition Ramp Down Short Sharp 1 100-0%

Ramps > Down > StrongTransition Ramp Down Short Sharp 2 100-0%

Ramps > Up > LongTransition Ramp Up Long Smooth 1 0-100%

Ramps > Up > LongTransition Ramp Up Long Smooth 2 0-100%

Ramps > Up > MediumTransition Ramp Up Medium Smooth 1 0-100%

Ramps > Up > MediumTransition Ramp Up Medium Smooth 2 0-100%

Ramps > Up > ShortTransition Ramp Up Short Smooth 1 0-100%

Ramps > Up > ShortTransition Ramp UP Short Smooth 2 0-100%

Ramps > Up > LongTransition Ramp Up Long Sharp 1 0-100%

Ramps > Up > LongTransition Ramp Up Long Sharp 2 0-100%

Ramps > Up > MediumTransition Ramp Up Medium Sharp 1 0-100%

Ramps > Up > MediumTransition Ramp Up Medium Sharp 2 0-100%

Ramps > Up > ShortTransition Ramp Up Short Sharp 1 0-100%

Ramps > Up > ShortTransition Ramp Up Short Sharp 2 0-100%

Ramps > Down > Long

Ramps > Down > LongTransition Ramp Down Long Smooth 2 50-0%

Ramps > Down > MediumTransition Ramp Down Medium Smooth 1 50-0%

Ramps > Down > StrongTransition Ramp Down Short Smooth 1 50-0%

Ramps > Down > StrongTransition Ramp Down Short Smooth 2 50-0%

Ramps > Down > LongTransition Ramp Down Long Sharp 1 50-0%

Ramps > Down > LongTransition Ramp Down Long Sharp 2 50-0%

Ramps > Down > StrongTransition Ramp Down Short Sharp 1 50-0%

Ramps > Down > StrongTransition Ramp Down Short Sharp 2 50-0%

Ramps > Up > LongTransition Ramp Up Long Smooth 1 0-50%

Ramps > Up > LongTransition Ramp Up Long Smooth 2 0-50%

Ramps > Up > MediumTransition Ramp Up Medium Smooth 1 0-50%

Ramps > Up > MediumTransition Ramp Up Medium Smooth 2 0-50%

Ramps > Up > ShortTransition Ramp Up Short Smooth 1 0-50%

Ramps > Up > ShortTransition Ramp Up Short Smooth 2 0-50%

Ramps > Up > LongTransition Ramp Up Long Sharp 1 0-50%

Ramps > Up > LongTransition Ramp Up Long Sharp 2 0-50%

Ramps > Up > MediumTransition Ramp Up Medium Sharp 1 0-50%

Ramps > Up > MediumTransition Ramp Up Medium Sharp 2 0-50%

Ramps > Up > ShortTransition Ramp Up Short Sharp 1 0-50%

Ramps > Up > ShortTransition Ramp Up Short Sharp 2 0-50%

Other > Hums

Other > Hums

Other > Hums

Other > Hums

Other > Hums

11

Page 12

Looking for the perfect design?

We can help.

Precision Microdrives is an ISO 9001:2015

trusted designer and manufacturer of

miniature, cost-eective, and well engineered

motors and mechanisms. We are specialists in,

l Trusted precision motor design

l Flexible motor & mechanism

manufacturing

l Dependable quality control & after-sales

support

l Industry leading motor testing and

validation

Our UK based motor design engineers, will support you through the complex process

of specif ying, developing, validating, and mass manufacturing, a custom motor or

mechanism. The result? A part perfect for your application.

Delivered, 'On-Time & To Spec'.

SPEAK TO OUR DESIGN ENGINEERS TODAY

Design for application case studies

ENCAPSULATED

VIBRATION MOTOR FOR A

CPR TRAINING DUMMY

l Low volume,

high value

manufacturing

l Custom CNC

machined enclosure

l Optimised haptic

performance

l Custom PCB

including EMI lters

PRECISION SPEED AND

TORQUE CONTROLLED

SERVO WITH INTEGRATED

TUNABLE PID LOOP FOR

SINGLE-USE SCIENTIFIC

INSTRUMENT

l Medium volume,

high value assembly

l Adapted control

software including digital

IO (to customer’s

specication)

Email: enquiries@precisionmicrodrives.com

Call: +44 (0) 1932 252 4 82

CUSTOMISED PRECISION

GEAR MOTOR WITH

ROBUST OPTICAL

ENCODER

l

High volume production

l Application specic

output shaft

l Rear motor shaft with

noise resistant optical

encoder

l Tailored motor

performance curves

Loading...

Loading...