OPERATOR’S MANUAL

PRECISION MANUFACTURING, INC.

424 N. Harding Avenue

Sedalia, MO 65301

Phone (660) 827 6131

Fax (660) 827-7366

www.precisionmfg.com

MANUAL #GR120307

TABLE OF CONTENTS

INTRODUCTION................................................................................... 3

REGISTRATION…………………………………………………………….. 3

WARRANTY.......................................................................................... 3

SAFETY AND SIGNAL WORDS................... .................................... ... 4

EQUIPMENT SAFETY GUIDELI NES................... ................................ 5

SAFETY SIGN LOCATIONS....................... ................... ...................... 6

SAFETY DECAL CARE....... .. .................... ................ ... ........................ 7

BEFORE OPERATION......................................................................... 8

DURING OPERATION..... ... .................................... ................... ........... 9-10

FOLLOWING OPERATION... .................... ........................................... 10

HIGHWAY AND TRANSPORT OPERATION. .............. ... .................... . 11

PERFORMING MAINTENANCE........................................................... 12-13

PARTS LIST……………........................................................................ 14-15

BOLT TORQUE……………………….................................................... 16

111 & 115 SERIES ADD-A-GRAPPLE INSTALLATION/OPERATING

INSTRUCTIONS …………………………………………………… ……….. 17

222 & 225 SERIES ADD-A-GRAPPLE INSTALLATION/OPERATING

INSTRUCTIONS …………………………………………………… ………. 18

333 GRAPPLE RAKE INSTALLATION/OPERATING

INSTRUCTIONS…………………………………………………………….. 19

344, 433, & 444 GRAPPLE RAKE INSTALLATION/OPERATING

INSTRUCTIONS …………………… ………………………………………. 20

2

INTRODUCTION

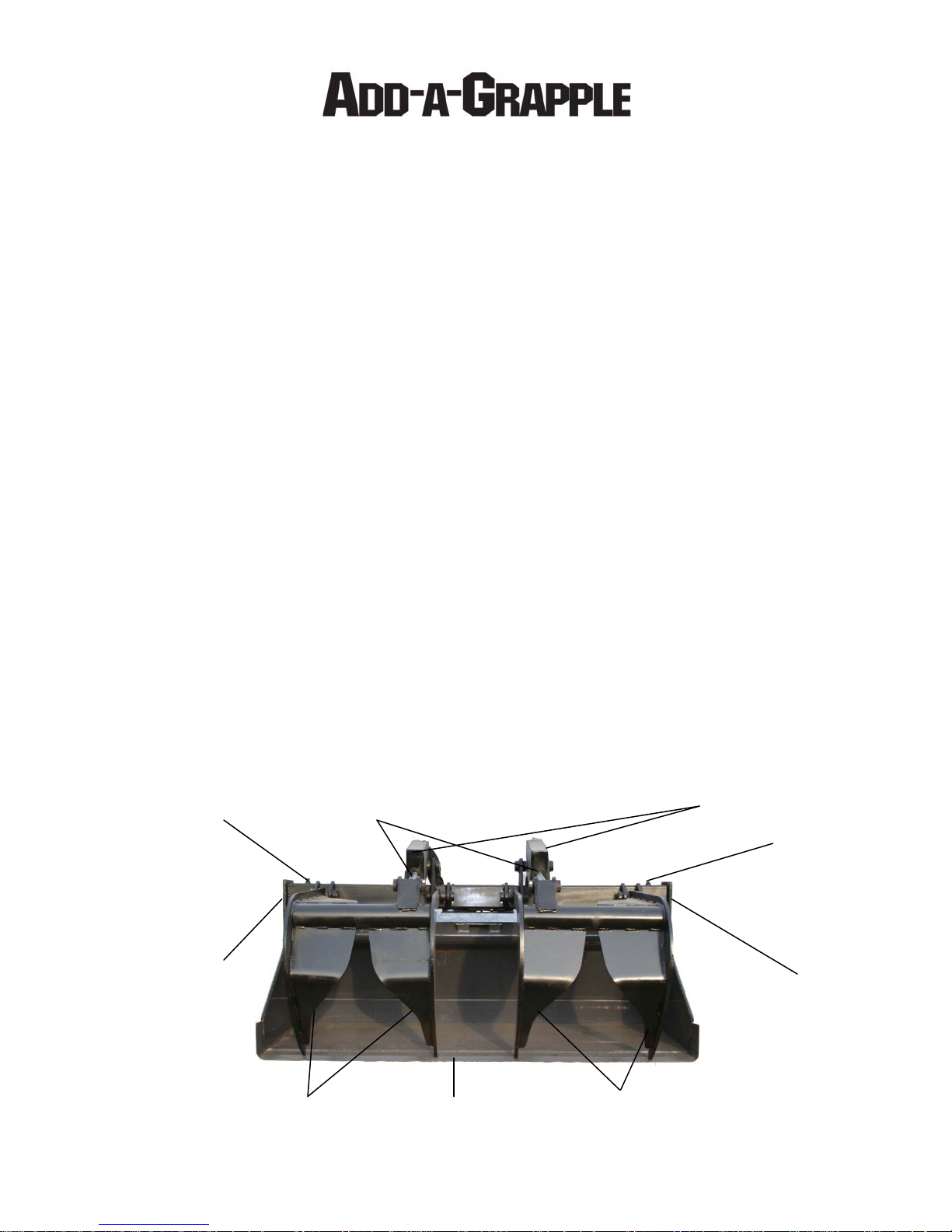

Thank you for purchasing your new Add-A-Grapple/Grapple Rake by Precision

Manufacturing. The Add-A-Grapple is designed to be mounted on an existing bucket . The

Add-A-Grapple and Grapple Rake are designed to pick up limbs, brush and other hard to

handle loose material. No other use is intended.

REGISTRATION

Registration card must be competed and mailed prior to use of equipment. We respect your

privacy. Your personal information will not be shared without permission.

If your registration card is lost or mis plac e d, pl eas e contact Precision Manu fact uri ng for a

replacement.

WARRANTY

Precision Manufacturing warrants all new products manufactured and/or marketed by

Precision Manufacturing to be free from defects in material and workmanship under normal

usage and service for one year from the date of first use by the buyer, or for one year from the

date of the purchase as indicated on the receipt/invoice, whichever occurs first. Repairs or

replacements covered under this warranty shall be warranted for the remaining portion of the

original warranty period or ninety (90) days, whichever is longer. This warranty shall apply

provided the products are returned to Precision Manufacturing’s designated facility freight

prepaid.

This Warranty excludes all products or component parts that, in the opinion of Precision

Manufacturing, have been subjected to negligent use, misuse, alteration, or accident, or that

have been repaired with component parts other than those manufactured or used by Precision

Manufacturing.

Precision Manufacturing does not warrant component parts supplied by manufacturers who

provide separate warranties for their merchandise. It is the obligation of the buyer to contact

these suppliers directly for warranty claims, service, and replacement of defective materials

and component parts.

Precision Manufacturing reserves the right to make design changes, improve design, or

change specifications at any time without any contingent obligation to owners of products

previously sold by Precision Manufacturing.

This Warranty shall not be interpreted to render Precision Manufacturing liable for injuries or

damages of any kind, direct, consequential, or contingent, to persons or property. Precision

Manufacturing shall not be liable for any recovery greater than the cost of repair of defects in

workmanship.

Precision Manufacturing shall not be held responsible by buyers for failure to perform any of

the obligations of this Warranty if such failures are the result of circumstances of Force

Majeure, such as, but not limited to floods, earthquakes, transportation strikes, labor disputes

with outside suppliers, or any other conditions beyond the control of Precision Manufacturing.

Warranty service is available by contacting your dealer or distributor.

This Warranty gives you specific legal rights and you may have other rights.

3

SAFETY

TAKE NOTE! THIS SAFETY ALERT SYMBOL FO UND THROUGHOUT THIS MANUAL IS

USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR PERSONAL

SAF ETY AND THE SAF ETY OF OTHERS. FAILURE TO FOLLOW THESE INST RUCTIONS

CAN RESULT IN INJURY OR DEATH.

THIS SYMBOL MEANS

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING and CAUTION with the safety

messages. The appropriate signal word for each has been selected using the following

guidelines:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in

death or serious injury. This signal word is to be limited to the most extreme situations

typically for machine components, which, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result

in death or serious injury, and includes hazards that are exposed when guards are

removed. It may also be used to alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, i f not avoided may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

If you have questions not answered in this manual or require additional copies or the manual is

damaged, please contact your dealer or Precision Manufacturing, Inc., 424 North Harding Ave.

Sedalia, MO 65301. Phone (660) 827-6131, Fax (660) 827-7366.

4

SAFETY – YOU CAN LIVE WITH IT

EQUIPMENT SAFETY GUIDELINES

Safety of the operator is one of the main concerns in designing a new piece of equipment.

Designers and manufacturers build in as many safety features as possible. However, every

year many accidents occur which could have been avoided by a few seconds of thought and a

more careful approach to handling equipment. You, the operator, can avoid personal injury.

Study the following precautions and insist those working with you, or for you, follow them.

In order to provide a better view, certain photographs or illustrations in this manual may show

an assembly with a safety shield removed. However, equipment should never be operated in

this condition. Keep all shields in place. If shield removal becomes necessary for repairs,

replace the shield prior to use.

Replace any CAUTION, WARNING, DANGER or instruction safety decal that is not readable

or is missing. Location of such decals is indicated in this manual.

Do not attempt to operate this equipment under the influence of drugs or alcohol.

Review the safety instructions with all users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The

operator should be a responsible adult familiar with machinery and trained in this equipment’s

operations. Do not allow persons to operate or assemble this unit until they have read this

manual and have developed a thorough understanding of the safety precautions and of how it

works.

To prevent injury or death, use a tractor or skid-steer equipped with a Roll Over Protective

System (ROPS)/ (FOPS). Do not paint over, remove or deface any safety signs or warning

decals on your equipment. Observe all safety signs and practice the instructions on them.

Never exceed the limits of a piece of machinery. If its ability to do a job, or to do so safely, is in

questions, DON’T TRY IT.

5

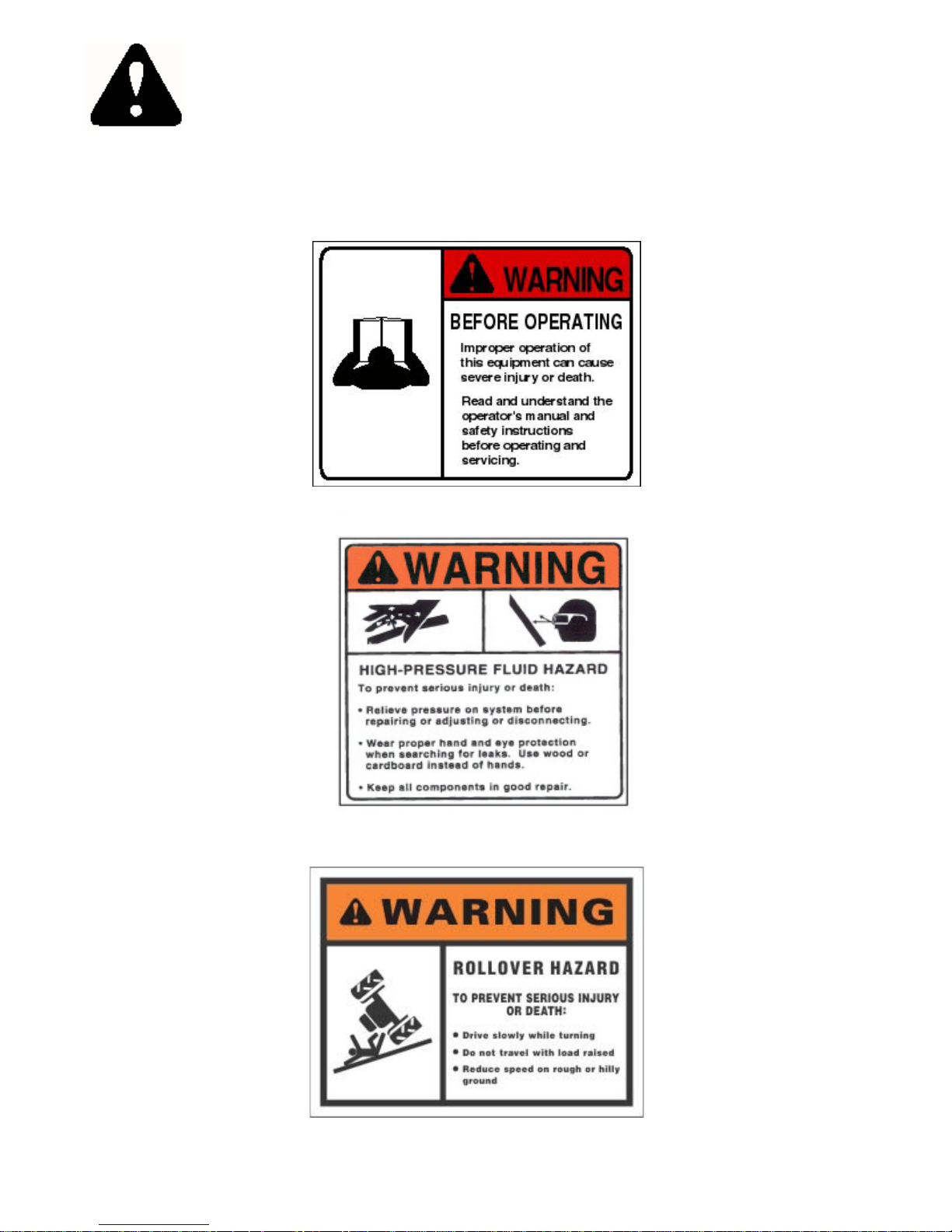

SAFETY SIGN LOCATIONS

The types of Safety Signs on the equipment are shown in the illustration below. Good safety

requires that you familiarize yourself with the various Safety Signs, the type of warning and the

area, or particular function related to that area, that requires your SAFETY AWARENESS.

6

SAF ETY DECAL CARE

. Keep safety decals and signs clean and legible at all times.

. Replace safety decals and signs that are missing or have become illegible.

. Replaced parts that displayed a safety sign should also display the current

sign.

. Safety decals or signs are available from your Distributor or Dealer Parts

Department or the factory.

How to install Safety Decals

. Be sure that the installation area is clean and dry.

. Decide on the exact position before you remove the backing paper.

. Remove the smallest portion of the split backing paper.

. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

. Small air pockets can be pierced with a pin and smoothed out using the piece

of decal backing paper.

REMEMBER: Your best assurance against accidents is a careful and

responsible operator. If there is any portion of this manual or function you do not

understand, contact the local authorized dealer or the manufacture r .

7

BEFORE OPERATION

. Carefully study and understand this manual before operating attachment.

. Do not wear loose-fitting clothing, which may catch in moving parts.

. Always wear protective clothing and substantial shoes.

. It is recommended that suitable protective hearing and (eye protection)

sight protectors are worn.

. Keep bolts tightened to specified torque.

. Assure that all tires ar e inflated evenly.

. Give the unit a visual inspection for any loose bolts, worn parts or cracked

welds, and make the necessary repairs. Follow the maintenance safety

instructions included in this manual.

. Be sure that there are no tools lying on or in the equipment.

. Do not use the unit until you are sure that the area is clear, especially

children and animal s .

. Because it is possible that this equipment may be used in dry areas or

in the presence of combustibles, special precautions should be taken to

prevent fires and fir e-fighting equipment should be readily available.

. Don’t hurry the learning process or take the unit for granted. Ease into it

and become familiar with your new equipment.

. Practice operation of your equipment and its attachments. Completely

familiarize yourself with your new equipment.

. Use a tractor equipped with a Roll Over Protective System (ROPS) or (FOPS).

. The manufacturer does not recommend usage of tractor with ROPS removed.

. Move tractor wheels/tracks to the widest recommended settings to increase stability.

8

DURING OPERATION

. Beware of bystanders, particularly children! Always look around to make sure

that it is safe to start the engine or move the unit. This is particularly important with

higher noise levels and quiet cabs, as you may not hear people shouting.

. NO PASSENGERS ALLOWED – Do not carry passengers anywhere on, or

in the tractor or equipment except as required for operation.

. Keep hands and clothing clear of moving parts.

. Do not clean, lubricate or adjust your equipment while it is moving.

. When halting operation, even periodically, set the tractor brakes, shut off

the engine and remove the ignition key.

- DO NOT operate near the edge of drop-offs or banks.

- DO NOT operate on steep slopes as overturn may result.

- Operate up and down (not across) intermediate slopes. Avoid sudden

Starts and stops.

. Pick the most level possible route when transporting across fields. KEEP

UNIT IN LOWERED POSITION WHEN TRANSPORTING. Avoid the edges

of ditches or gullies and steep hillsides.

. Be extra careful when working on inclines.

. Periodically clear the equipment of brush, twigs or other materials to prevent

Build up of dry combustible materials.

. Maneuver the equipment at safe speeds.

. AVOID OVERHEAD WIRES OR OTHER OBSTACLES. CONTACT WIT H

OVERHEAD LINES COULD CAUSE SERIOUS INJURY OR DEATH.

. Avoid loose fill, rocks and holes; they can be dangerous for equipment operation or

movement

. Allow for unit length when making turns.

. DO NOT WALK OR WORK UNDER RAISED COMPONENTS OR ATTACHMENTS

UNLESS SECURELY POSTIONED AND BLOCKED.

. Keep all bystanders, pets and livestock clear of the work area.

. Operate the tractor from the operator’s seat only.

9

DURING OPERATION CONT.

. Never stand alongside of unit with engine running or attempt to start engine and/or operate

machine while standing alongside of unit.

. Never leave running equipment unattended.

. As a precaution, always recheck the equipment after each day’s operation. Correct all

problems. Follow the maintenance safety procedures.

. Avoid operating the equipment on excessively steep hills and especially on hills that ar e

steeper than 15 degrees. Avoid crossing slopes if possible and do not make sharp uphill

steering corrections or a rollover could result. If your tractor starts to tip over on a slope,

turn the front wheels quickly downhill to regain stability and control.

The best way to climb most hills is to drive straight up while maintaining a steady ground

speed and constant engine RPM. The best way to descend most hills is straight down

while using steady pressure on the brakes without locking them up. Locking the brakes in

a steep downhill situation can result in loss of traction, steering and control. When you

must cross a slope on soft terrain, keep the front wheels turned slightly uphill and maintain

a constant speed and a strai g ht line o f trav el .

Driving too fast, being inattentive and turning too sharply on slippery surfaces can result in

rollovers and accidents almost quicker than any other ground condition we know of. Snow

cover, wet surfaces, loose gravel and frozen ground can all contribute to this dangerous

condition. In these conditions maintain a sharp focus on what you are doing and the terrain

you are on. Do not make sharp turns and avoid the need for hard braking if at all possible.

If you start to skid or slid in a turn, turn the front wheels in the direction of the skid to regain

control.

FOLLOWING OPERATION

. Following operation, or when detaching, stop the tractor, set the brakes. Disengage the

PTO and all power drives, shut off the engine and remove the ignition keys.

. Store the unit in an area away from human activity.

. Do not store equipment where it will be exposed to livestock for long periods of time.

Damage and livestock injury could result.

. Do not permit children to play on or around the stored unit.

. Make sure all parked machines are on a hard level surface.

10

HIGHWAY AND TRANSPORT OPERATION

. Adopt safe driving practices.

- Keep the brake pedals latched together at all times. NEVER USE INDEPENDENT

BRAKING AS LOSS OF CONTROL AND/O R UPSET OF UNIT CAN RESULT.

- Always drive at a safe speed relative to local conditions and ensure that your speed is

low enough for an emergenc y stop to be safe and secure. Keep speed to a minimum.

- Reduce speed prior to turns to avoid the risk of overturning.

- Avoid sudden uphill turns on steep slopes.

- Always keep the tractor in gear to provide engine braking when going

down hill. Do no t coast.

- Do not drink and driv e.

. Comply with state and local laws governing highway safety and movement

of farm machinery on public roads.

. Use approved accessory lighting flags and necessary warning devices to

protect operators of other vehicles on the highway during the daylight and

nighttime trans port .

. The use of flashing amber lights is acceptable in most localities. However,

some localities prohibit their use. Local laws should be checked for all

highway lighting and marking requirements.

. When driving the tractor and equipment on the road or highway under 40

kph (20 mph) at night or during the day, use flashing amber warning lights

and a slow moving vehicle (SMV) identification emblem.

. Plan your route to avoid heavy traffic.

. Be a safe and courteous driver. Always yield to oncoming traffic in all

situations, including narrow bridges, intersections, etc.

. Be observant of bridge loading ratings. Do not cross bridges rated lower

than the gross weight at which you are operating.

. Watch for obstructions overhead and to the side while transporting.

. Always operate equipment in a position to provide maximum visibility at

all times. Make allowances for increased length and weight of the equipment

when making turns, stopping the unit, etc.

11

PERFORMING MAINTENANCE

. Good maintenance is your responsibility. Poor maintenance is an invitation

for trouble.

. Make sure there is plenty of ventilation. Never operate the engine of the

tractor in a closed building. The exhaust fumes can cause asphyxiation.

. Before working on this machine, stop the tractor, set the brakes, lower

loader bucket, grapple, or clipper, disengage the PTO and all power drives, shut

off engine and remove the ignition keys.

. Be certain all-moving parts on attachments have come to a complete stop before attempting

to perform maintenance.

. Always use a safety support and block the wheels. Never use a jack to

support the machin e.

. Use extreme caution when making adjustments.

. Follow the torque chart in this manual when tightening bolts and nuts.

. Never use your hands to locate a hydraulic leak on attachments. Use a small

piece of cardboard or wood. Hydraulic fluid escaping under pressure can

penetrate the skin.

. Before disconnecting hydraulic lines, shut off hydraulic supply and relieve

all hydraulic pressure.

. Openings in the skin and minor cuts are susceptible to infection from hydraulic

fluid. If injured by escaping hydraulic fluid, see a doctor at once.

Gangrene can result. Without immediate medical treatment, serious

infection and reactions can occur.

12

PERFORMING MAINTENANCE CONT.

. Replace all shields and guards after servicing and before moving.

. After servicing, be sure all tools, parts and service equipment are removed.

. Do not allow grease or oil to build up on eq ui pment .

. Never replace hex bolts with a grade of less than provided on the original equipment.

. Refer to bolt torque chart for head identification marking.

. Where replacement parts are necessary for periodic maintenance and

servicing, genuine factory replacement parts must be used to restore your

equipment to original specifications. The manufacturer will not claim

responsibility for use of unapprov ed par ts and/ or accessories and other

damages as a result of their use.

. If equipment has been altered in any way from original design, the

manufacturer does not accept any liability for injury or warranty.

. A fire extinguisher and first aid kit should be kept readily accessible while

performing maintenance on this equipment.

13

111100 SINGLE ADD-A-GRAPPLE

ITEM

QTY

PART NO.

DESCRIPTION

1 1 111-2

CENTER FRAME WELDMENT

2 1 111-3

RIGHT FRAME WELDMENT

3 1 111-4

LEFT FRAME WELDMENT

4 1 111-1

GRAPPLE TINE WELDMENT

5 1 P100X2900-HB31

PIVOT SHAFT

6 1 HCYL-2X6-TDL

2”X6” HYDRAULIC CYLINDER

7 2 MP126

LYNCH PIN

112200 DOUBLE ADD-A-GRAPPLE

ITEM

QTY

PART NO.

DESCRIPTION

2 1 111-3

RIGHT FRAME WELDMENT

3 1 111-4

LEFT FRAME WELDMENT

4 2 111-1

GRAPPLE TINE WELDMENT

5 2 P100X2900-HB31

PIVOT SHAFT

6 2 HCYL-2X6-TDL

2”X6” HYDRAULIC CYLINDER

7 4 MP126

LYNCH PIN

222440 & 222550 DOUBLE ADD-A-GRAPPLE

ITEM

QTY

PART NO.

DESCRIPTION

1 1 222-1

CENTER FRAME WELDMENT

2 2 222-2

FRAME MOUNT WELDMENT

3 1 222-3

GRAPPLE TINE WELDMENT - RIGHT

4 1 222-4

GRAPPLE TINE WELDMENT - LEFT

5 2 HCYL-2X8-WCT

2”X8” HYDRAULIC CYLINDER

333S60”/ 72” SINGLE GRAPPLE RAKE

ITEM

QTY

PART NO.

DESCRIPTION

1 1 333-1 5FT/ 333-1 6FT

RAKE WELDMENT

3 1 P100X3175-HB31

PIVOT SHAFT

4 2 MP126

LYNCH PIN

5 1 HCYL-2X6-TDL

2”X6” HYDRAULIC CYLINDER

333D60”/ 72” DOUBLE GRAPPLE RAKE

ITEM

QTY

PART NO.

DESCRIPTION

1 1 333-1 5FT/ 333-1 6FT

RAKE WELDMENT

2

2

333-2

GRAPPLE TINE WELDMENT

3 1 P100X6075-HB31

PIVOT SHAFT

4 2 MP126

LYNCH PIN

5 2 HCYL-2X6-TDL

2”X6” HYDRAULIC CYLINDER

PARTS LIST

1 1 111-2 CENTER FRAME WELDMENT

2 1 333-2 GRAPPLE TINE WELDMENT

14

344S72” SINGLE GRAPPLE RAKE

ITEM

QTY

PART NO.

DESCRIPTION

1 1 344-3-6FT

RAKE WELDMENT- 72”

2 1 344-8S

SINGLE GRAPPLE WELDMENT

3 2 HCYL-2X8-WCT

2”X8” HYDRAULIC CYLINDER

344D72” DOUBLE GRAPPLE RAKE

ITEM

QTY

PART NO.

DESCRIPTION

1 1 344-3-6FT

RAKE WELDMENT- 72”

2 1 344-8D

DOUBLE GRAPPLE WELDMENT

3 2 HCYL-2X8-WCT

2”X8” HYDRAULIC CYLINDER

433S58”/ 72”/ 85” SINGLE GRAPPLE RAKE

ITEM

QTY

PART NO.

DESCRIPTION

1 1 433-3-5FT/ 6FT/ 7FT

RAKE WELDMENT

2 1 433-8S

SINGLE GRAPPLE WELDMENT

3 2 HCYL-2.5X8-WCT

2.5”X8” HYDRAULIC CYLINDER

433D58”/ 72”/ 85” DOUBLE GRAPPLE RAKE

ITEM

QTY

PART NO.

DESCRIPTION

1 1 433-3-5FT/ 6FT/ 7FT

RAKE WELDMENT

3 2 HCYL-2.5X8-WCT

2.5”X8” HYDRAULIC CYLINDER

444S72”/ 85” SINGLE GRAPPLE RAKE

ITEM

QTY

PART NO.

DESCRIPTION

1 1 444-3-6FT/ 7FT

RAKE WELDMENT

2 1 444-8S

SINGLE GRAPPLE WELDMENT

3 2 HCYL-2.5X8-WCT

2.5”X8” HYDRAULIC CYLINDER

444D72”/ 85” DOUBLE GRAPPLE R AKE

ITEM

QTY

PART NO.

DESCRIPTION

1 1 444-3-6FT/ 7FT

RAKE WELDMENT

2 1 444-8D

DOUBLE GRAPPLE WELDMENT

3 2 HCYL-2.5X8-WCT

2.5”X8” HYDRAULIC CYLINDER

2 1 433-8D DOUBLE GRAPPLE WELDMENT

15

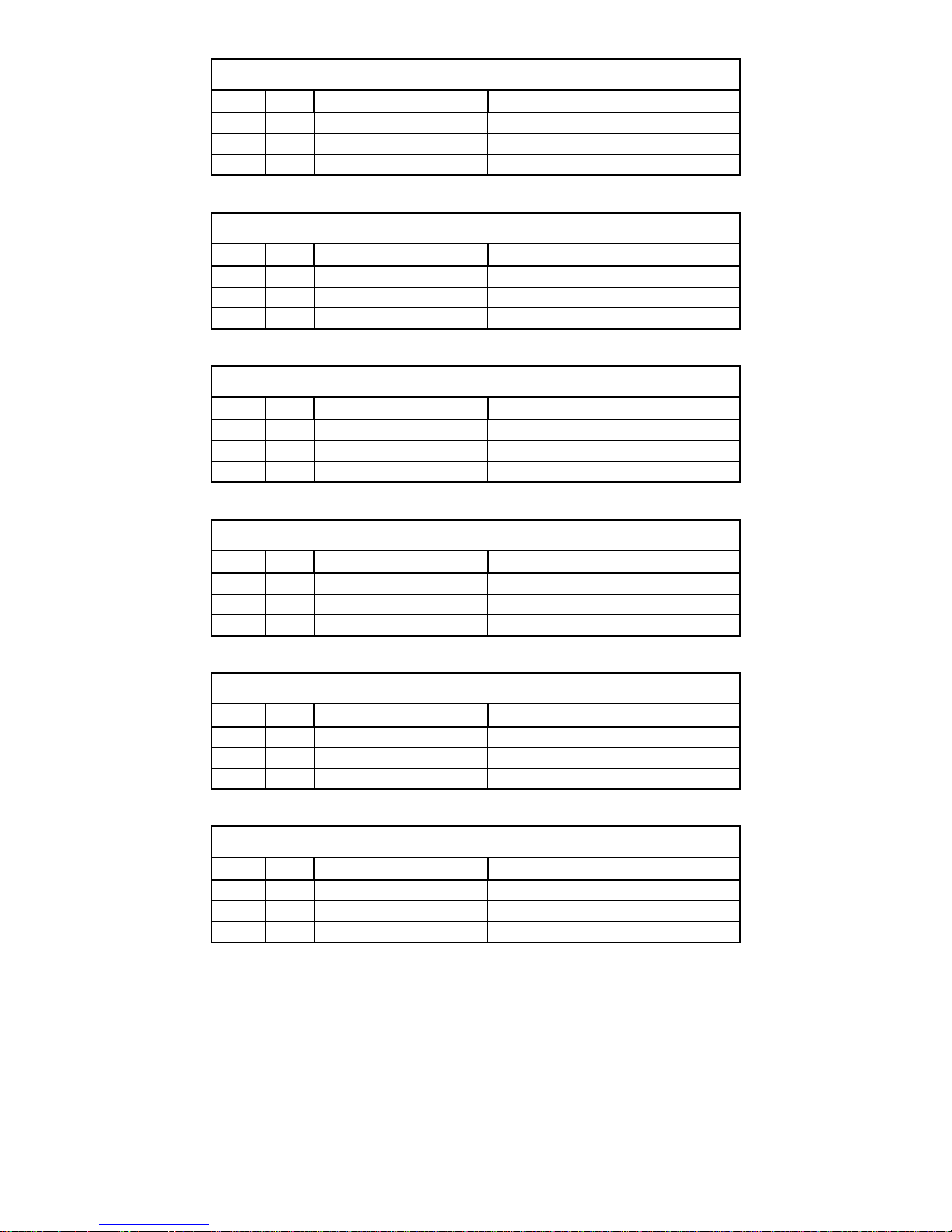

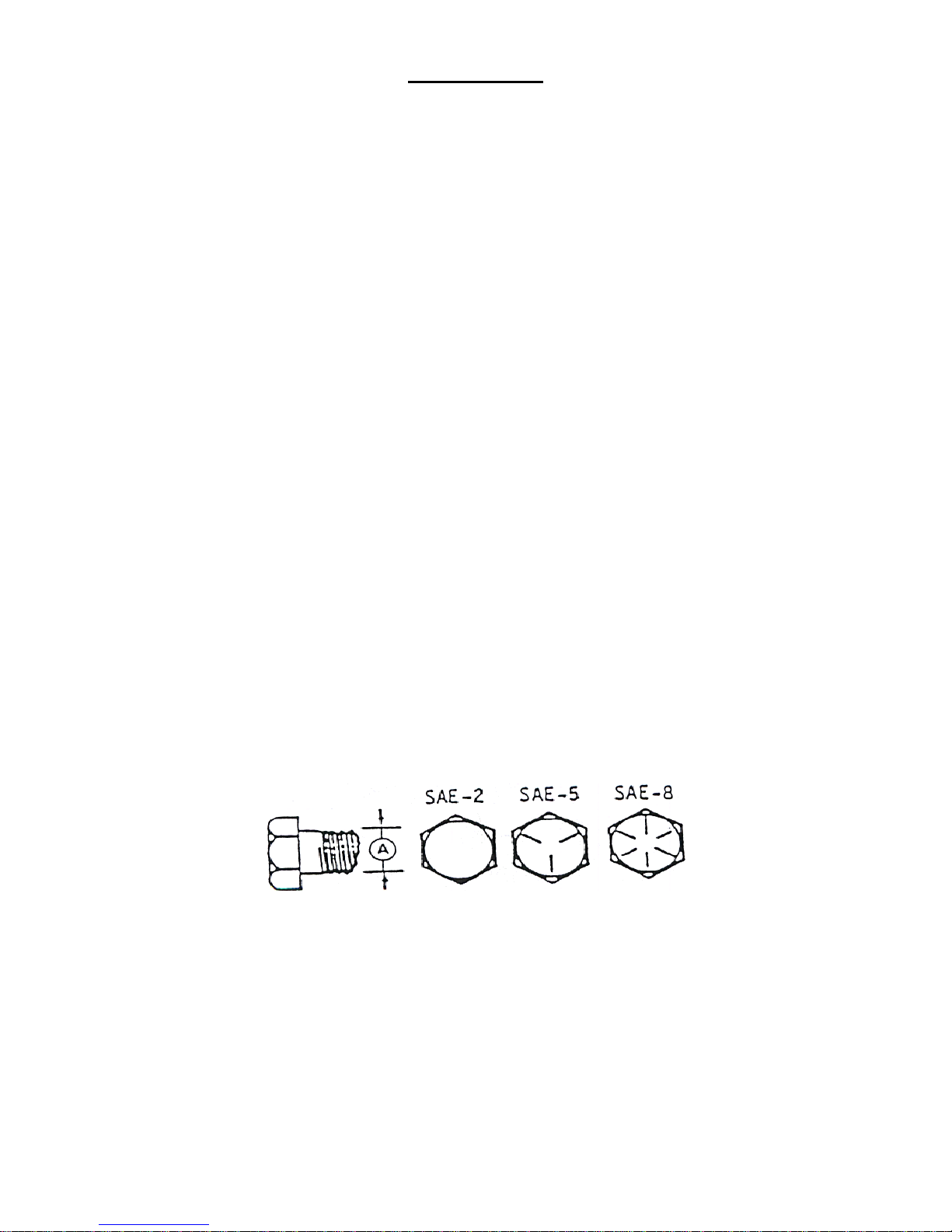

BOLT TORQUE

CHECKING BOLT TORQUE

The table shown below gives correct torque values for various bolts and cap screws. Tighten

all bolts to the torques specified in chart unless otherwise noted. Check tightness of bolts

periodically, using bolt torque chart as a guide. Replace with the same strength bolt.

TORQUE SPECIFICATIONS

Bolt Diameter Bolt Torque –

SAE 5 SAE 8

“A” lb.-ft. Nm lb.-ft. NM

3/8” 33 (45) 45 (63)

½” 80 (110) 115 (155)

5/8” 150 (204) 220 (299)

¾” 290 (390) 400 (540)

1 ¼” 1,105 (1503) 1,975 (2686)

Torque figures indicated above are valid for non-g r eased or non-oiled threads and heads

unless otherwise specified. Therefore, do not grease or oil bolts or cap screws unless

otherwise specified in this manual. When using locking elements, increase torque values by

5%.

* Torque value for bolts and cap screws are identified by their head markings.

16

INSTALLATION INSTRUCTIONS (111 & 112 Series)

Adjustable

2” x 6”

Tines

Adjustable

Locking Bolts

Locking Bolts

Cutting Edge

The Add-A-Grapple mount is designed to accept either a single or a double set of grapples. Grapple(s) is easily

removed when not in use. Grapple expands to fit buckets 60” to 79” wide. Grapple tines open up to approx. 33”.

Step 1 – Fully extend the 2” x 6” cylinder(s) so grapple(s) will be in the closed position.

Step 2 – Loosen the locking bolts on the side brackets. Position the mount above bucket so tines set

approximately 1” inside cutting edge of the bucket.

Step 3 – Position side brackets for drilling 4 holes on each side. Make sure all four holes will be free from

obstruction inside the bucket and will have room for tightening the nuts.

Step 4 – Clamp the adjustable side brackets to outside of bucket. Tighten the two locking bolts on each side

bracket.

Step 5 – Drill 4, ½” holes for each side bracket.

Step 6 – Tighten all bolts and nuts

Step 7 – You are now ready to plumb the 2” x 6” cylinder(s) to your hydraulic outlets. If you have double

cylinders, the hydraulic hoses should be “T”ed together with only one set of hydraulic hoses to control both

cylinders (an optional hose kit with cylinder guards (P/N K33990) is available for double grapples only). The

cylinder ports are 3/8” pipe thread. Make sure hose lengths are long enough to allow full raising, lowering and

tilting of bucket.

NOTE: If additional hydraulic outlets need to be added, please refer to accessories Part # MP010 – Selector

Valve Kit.

Cylinder

Mount

Side Brackets

Side Brackets

17

NOTE: Hoses Must Be Purchased Separately

Adjustable

Locking Bolts

2 X 8

Tines

Cylinder

Adjustable

Bucket Cutting Edge

Tines

(222 Contractor Series and 225 Commercial Series)

INSTALLATION INSTRUCTIONS

The Add-A-Grapple (222) weighs approximately 387 lbs. The 225 weighs approximately 413 lbs. Be

sure you have assistance and proper equipment to help in lifting and aligning of the grapple. The 222

grapple adjusts to fit buckets 68” to 90” in width. The 225 grapple adjusts to fit buckets 80” to 100” in

width. Be sure top mount clears operation of pin handles that lock the bucket to the loader brackets.

Step 1 –

Fully extend the 2” x 8” cylinder so grapple will be in the closed position. The center of pin to

pin is 24” when fully extended.

Step 2 – Loosen the locking bolts for the side brackets and move them out just wider than the bucket.

Step 3 - Position the mount above bucket so tines set approximately 1” to 2” inside cutting edge of the

bucket.

Step 3 – Clamp the adjustable side brackets to outside of bucket. Tighten the two locking bolts on each

side bracket. Be sure surface on side of bucket is flat under the entire area of the side bracket. A steel

plate (not provided) of equal thickness to any uneven surface under the side bracket may need to be

used.

Step 4 – Position side brackets for drilling 4 to 6 holes on each side of bucket. Make sure at least four

holes will be free from obstruction inside the bucket and still have room for tightening the nuts inside the

bucket. Additional holes may be drilled in side brackets to secure bracket to side of bucket.

Step 5 – Drill 4, 5/8” holes (six holes if additional bolts are used) for each side bracket.

Step 6 – Tighten all bolts and nuts. Four 5/8” grade 8 bolts and nuts are provided. Torque to 220 lb-ft.

NOTE: If additional hydraulic outlets need to be added, please refer to accessories Xtra Valve Kits.

222 ADD-A-GRAPPLE

Cylinders

Guards

Locking Bolts

Side Brackets

Side Brackets

18

INSTALLATION INSTRUCTIONS

(333 Series)

Loader brackets are not included with the 333 series grapple rake. Attach brackets that fit your

loader according to your loader brand and model specifications provided by your loader

manufacturer. Bracket s can be or dered separately.

One set of remote hydraulic outlets is required to operate the grapple cylinder. One 2” x 6”

(two cylinders on double) hydraulic cylinder operates the grapple tines to grab and hold the

material. The cylinder(s) has 3/8” pipe thread outlets. A 3/8” diameter hydraulic hose is

acceptable. A hose kit (K33990) is available for the double grapple.

Route the hoses (not supplied) from the hydraulic cylinder to the remote hydraulic outlets

located on the equipment. Make sure hoses will not be snagged or pinched by loader or

equipment parts.

The Grapple Rake is designed to handle fallen trees and limbs, loose stumps, loose rocks and

other hard to handle material. Equipment is not designed to pull attached roots, trees, buried

rocks or concrete.

NOTE: The Grapple Rake is only recommended for equipment with Rollover Protection

Structure (ROPS).

19

(444, 433 and 344 Series)

Loader brackets are not included with the 444, 433 and 344 series gr appl e rake. Att ach

brackets that fit your loader according to your loader brand and model specifications provided

by your loader manufacturer. Brackets can be ordered separately.

Hoses are included. Couplers to fit your equipment must be ordered separately.

One set of remote hydraulic outlets is required to operate the grapple cylinders. Two 2.5” x 8”

(2” x 8” on 344) hydraulic welded cylinders operate the grapple to grab and hold the material.

The cylinders have ½” “O” Ring outlets. A 3/8” diameter hydraulic hose is acceptable.

The Grapple Rake is designed to handle fallen trees and limbs, loose stumps, loose rocks and

other hard to handle material. Equipment is not designed to pull attached roots, trees, buried

rocks or concrete.

NOTE: The Grapple Rake is only recommended for equipment with Rollover Protection

Structure (ROPS).

20

Loading...

Loading...