DIGITAL PANEL METERS

Universal Temperature Meters

Model PD750, PD751, PD752

Instruction Manual

• J, K, T, E, R, and S Thermocouples

• 100 Ω Platinum RTD

• 10 Ω Copper RTD

• 120 Ω Nickel RTD

• Displays °F or °C

• Factory Calibrated for All Inputs

• Type T T/C and RTDs Displayed to 0.1°

• NEMA 4X, IP65 Front Panel

• 115 VAC, 230 VAC, or 24 VDC Power Options

• 2 or 4 Relays + 4-20 mA Output Option

PRECISION DIGITAL CORPORATION

19 Strathmore Road • Natick MA 01760 USA

Tel (800) 610-5239

• Fax (508) 655-8990

¨

www.predig.com

UL Listed (PD750 AC Powered Units Only)

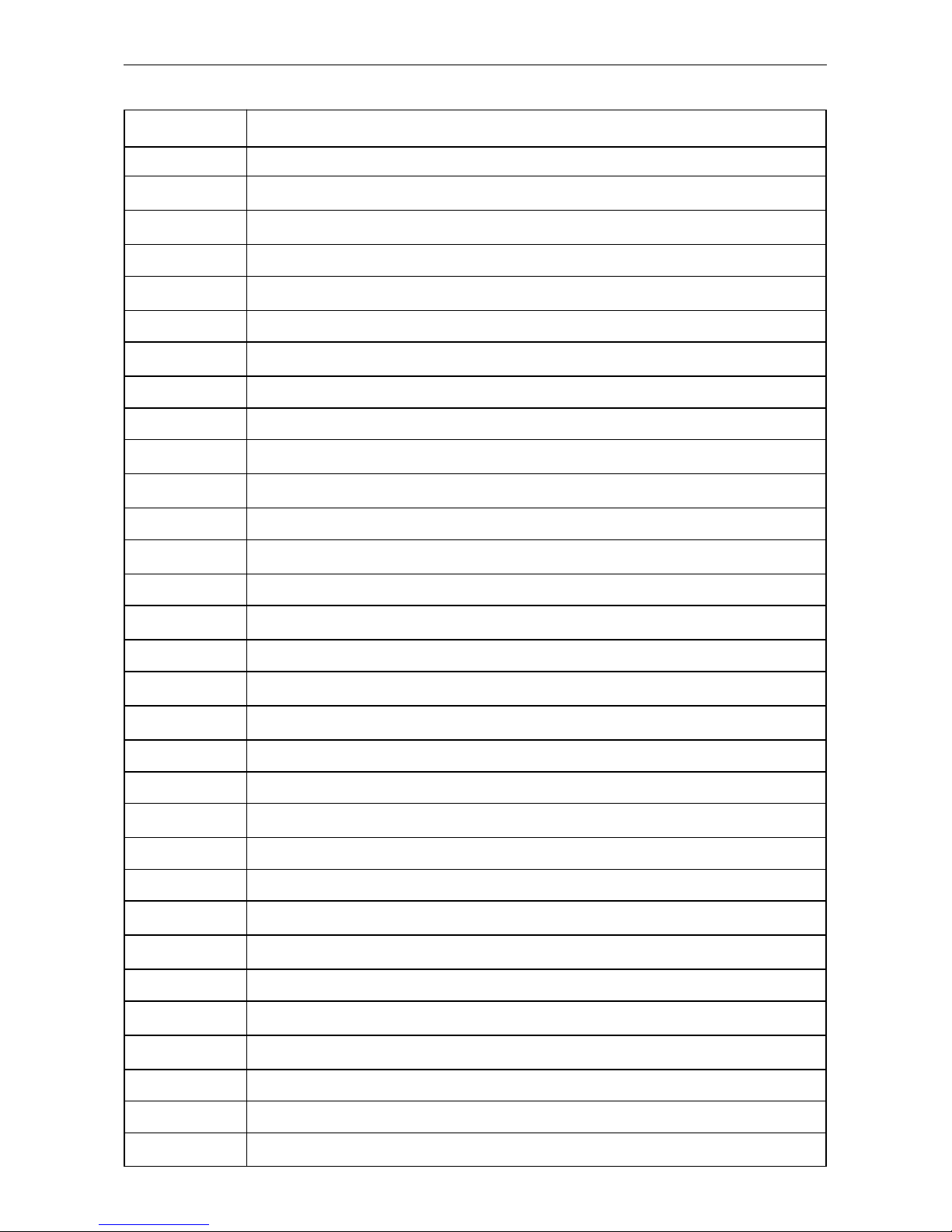

TABLE OF CONTENTS

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

POWER and SIGNAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

CALIBRATION FLOW CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CALIBRATION ([ALIb) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

INPUT TYPE (TYPE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

SCALE (For[) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4 ALARM POINTS (Alars) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

FAIL-SAFE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

RELAYS (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

SWITCHING INDUCTIVE LOADS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

ISOLATED 4-20 mA OUTPUT OPTION (OvtPvt) . . . . . . . . . . . . . . . . . . . . . . . . .18

LOCKOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

MOUNTING DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

OPTION CARD INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

OTHER PRECISION DIGITAL PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

DEFINITIONS

TYPE, INPUT TYPE: To program unit for input type,(i.e. T/C or RTD).

For[, Fahrenheit or Celsius: To program unit for Fahrenheit or Celsius display.

[ALIb, CALIBRATION: To re-calibrate unit using a calibrated signal source.

Alars, ALARM and RELAY POINTS: Sets alarm and relay set and reset points.

0vtPvt, 4-20 mA OUTPUT OPTION: Programs optional 4-20 mA output values.

Error, ERROR: Calibration not successful.

0PEN, OPEN T/C: Open thermocouple circuit indicated by flashing display.

WARNING

Hazardous voltages exist within enclosure.

Installation and service should be performed only by trained service personnel.

AVERTISSEMENT

Les pièces à l'intérieur du boîtier portent des tensions dangereuses. Seules

des personnes qualifiées et bien entrainées devraient entreprondre l'ótalonnage et

la maintenance.

Notice

The information contained in this document is subject to change without notice.

2

!

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

!

www.predig.com

ORDERING INFORMATION

Type J, K, T, E, R, S, and 100 Ω Platinum RTD :

10 Ω Copper

120 Ω Nickel

3

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

115 VAC 230 VAC 24 VDC Options Installed Option

Model Model Model Card*

PD750-3-N PD750-4-N PD750-2-N No Options

PD750-3-14 PD750-4-14 PD750-2-14 2 Relays PD174

PD750-3-15 PD750-4-15 PD750-2-15 4-20mA Out PD175

PD750-3-16 PD750-4-16 PD750-2-16 2 Relays + PD176

4-20 mA Out

PD750-3-17 PD750-4-17 PD750-2-17 4 Relays PD177

PD750-3-18 PD750-4-18 PD750-2-18 4 Relays + PD178

4-20 mA Out

Ordering example: PD750-3-14, temperature meter powered from

115 VAC (-3) with 2 relays (-14).

115 VAC 230 VAC 24 VDC Options Installed Option

Model Model Model Card*

PD751-3-N PD751-4-N PD751-2-N No Options

PD751-3-14 PD751-4-14 PD751-2-14 2 Relays PD174

PD751-3-15 PD751-4-15 PD751-2-15 4-20mA Out PD175

PD751-3-16 PD751-4-16 PD751-2-16 2 Relays + PD176

4-20 mA Out

PD751-3-17 PD751-4-17 PD751-2-17 4 Relays PD177

PD751-3-18 PD751-4-18 PD751-2-18 4 Relays + PD178

4-20 mA Out

115 VAC 230 VAC 24 VDC Options Installed Option

Model Model Model Card*

PD752-3-N PD752-4-N PD752-2-N No Options

PD752-3-14 PD752-4-14 PD752-2-14 2 Relays PD174

PD752-3-15 PD752-4-15 PD752-2-15 4-20mA Out PD175

PD752-3-16 PD752-4-16 PD752-2-16 2 Relays + PD176

4-20 mA Out

PD752-3-17 PD752-4-17 PD752-2-17 4 Relays PD177

PD752-3-18 PD752-4-18 PD752-2-18 4 Relays + PD178

4-20 mA Out

www.predig.com

SPECIFICATIONS

Basic Meter

INPUTS: PD750: Field selectable: type J, K, T, E, R, or S Thermocouples with 1°

resolution; type T to 0.1° 100 Ω platinum RTD (.00385 or .00392 curve)

to 1° or 0.1° resolution.

PD751: 10 Ω copper RTD

PD752: 120 Ω nickel RTD

DISPLAY: Bright, large, 0.56” (14.2mm) high efficiency red, 41/2 digits. F or C may

be switched on to indicate Fahrenheit or Celsius.

COLD JUNCTION REFERENCE: Automatic, fixed, no user calibration needed.

SENSOR BREAK DETECTION: Open sensor circuit indicated by display flashing

0pen. All relays and alarm status LEDs go to alarm state.

HOLD READING: Connect switch to ACK/HLD and COM terminals, also connect

jumper pins on rear.

ACCURACY: See Thermocouple and RTD chart, page 11.

LOCKOUT: Jumper JP2 at rear of instrument restricts modification of calibration

values.

INPUT IMPEDANCE: Greater than 100 KΩ.

POWER: AC power: 115 VAC ±10%, 50/60 Hz, 10 VA.

230 VAC ±10%, 50/60 Hz, 10 VA.

DC power: 22-28 VDC, 6 watts max.

ISOLATION: AC power: 1500 VAC; DC power: 500 VDC.

NORMAL MODE REJECTION: 64 dB at 50/60 Hz

ENVIRONMENTAL: Operational ambient temperature range: 0 to +60°C. Storage

temperature range: -40 to +85°C. Relative humidity: 0 to 90% non-condensing.

ENCLOSURE: 1/8 DIN, high impact plastic, UL 94V-0.

FRONT PANEL: NEMA 4X, IP65, panel gasket provided.

WEIGHT: 19.7 oz (559 g) (including options)

CONNECTIONS: Removable screw terminal block, accepts #22 to #12 AWG.

ALARM POINTS: 4, any combination of high or low alarms.

ALARM STATUS INDICATION: Front panel LED

ALARM DEADBAND: 0-100% of full scale, user selectable.

UL FILE NUMBER: E160849; 508 Industrial Control Equipment

(PD750 AC Powered Unit only)

4

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

www.predig.com

OPTIONS

Relays

RATING: 2 or 4 SPDT (form C); rated 2 Amp @ 30 VDC or 2 Amp @ 250 VAC

resistive load; 1/14 HP @ 125 / 250 VAC for inductive loads.

RESET: User select.

1. Automatically when the input passes the reset point.

2. Automatically + manually (via user supplied switch or front panel ACK button).

Manual reset resets all manually resetable relays.

FAIL-SAFE OPERATION: The relay coils are energized in the non-alarm condition.

In the case of a power failure, the relays will go to the alarm state. Fail-safe operation by removing jumper J2 located on the Options Board.

AUTO INITIALIZATION: When power is applied to the meter, the relays will always

reflect the state of the input to the meter.

DEADBAND: 0-100%, User selectable.

Isolated 4-20 mA Transmitter Output

CALIBRATION RANGE: The transmitter output can be calibrated so that a 4 mA

output is produced for any number displayed on the meter. The 20 mA output may

correspond to any number displayed on the meter above or below the 4 mA output

display.

OOUUTTPPUUTT LLOOOOPP RREESSIISSTTAANNCCEE:

:

Power supply: minimum maximum

24 VDC 10 Ω 600 Ω

35 VDC (external) 600 Ω 1000 Ω

ACCURACY: ± 0.1% F.S., ± .004 mA.

ISOLATION: 500 VDC or peak AC, input-to-output or input/output-to-power line.

EXTERNAL LOOP POWER SUPPLY: 35 V max.

WARRANTY:

2 years parts & labor

EXTENDED WARRANTY:

1 or 2 years, refer to the Price List for details.

5

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

www.predig.com

SETUP

Programming and installing the meter involves six basic

steps.

Step 1 Remove jumper JP2 if installed, to disable the lockout feature.

Step 2 Configure the input signal jumper JP1 according to the input

type, thermocouple or RTD, see charts below.

Step 3 Connect the input signal according to the chart below.

Step 4 Connect power.

Step 5 Program the input type, choice 0-10, see page 11.

Step 6 Program the scale type, Fahrenheit or Celsius, see page 12.

POWER and SIGNAL CONNECTIONS

For DC powered units see diagrams on page 7

Four-Wire RTD Connections

RTD

AC

L

D

T

ALU

NHO

G/K

I

K

C

SCO

A

L

LLP+P- CAE+Ð

O

C

K

X

MC

/

H

L

D

IN

LLP+P- CAE+Ð

O

C

K

X

MC

/

H

L

D

IN

JP2

JP1

No Connection

Three-Wire RTD Connections

RTD

AC

JP2

JP1

Two-Wire RTD Connections

RTD

AC

LLP+P- CAE+Ð

O

C

K

X

MC

/

H

L

D

IN

LLP+P- CAE+Ð

O

C

K

X

MC

/

H

L

D

IN

JP2

JP1

Thermocouple Connections

AC

T/C

JP2

JP1

L

D

T

ALU

NHO

G/K

I

K

C

SCO

A

L

L

D

T

ALU

NHO

G

/

K

I

K

C

S

C

O

A

L

L

D

T

ALU

NHO

G

/

K

I

K

C

S

C

O

A

L

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

6

24 V Transmitter

power: P+, P-

POWER and SIGNAL CONNECTIONS for

DC POWERED UNITS

WIRING INSTRUCTIONS

1. All field connections to be made with either solid or stranded insulated wire.

Strip length =

1

/4" (7 mm). Tighten screw terminals to 4.5 lb-in (0.5 Nm).

Do not pre-treat wire with solder.

2. Terminals connected to line voltage (e.g. L, RELAY 1-4): Use AWG # 12-18 copper wire,

600 volt, 60°C or 60/75°C. Connect only one wire to each terminal.

3. Terminals not connected to line voltage (e.g. IN, EXC, ACK, COM, P+, P-, V+, V-, +, -):

Use AWG #12-22 wire. If using AWG #20 or smaller wire, up to two wires may be connected

to each terminal. If using AWG #18 or larger wire, only one wire may be connected to each

terminal.

7

Two-Wire RTD Connections

RTD

JP2

JP1

Thermocouple Connections

22-28 VDC

22-28 VDC

T/C

JP2

JP1

Four-Wire RTD Connections

RTD

L

D

T

A

L

U

NHO

G/K

I

K

C

S

C

O

A

L

L

D

T

A

L

U

NHO

G/K

I

K

C

S

C

O

A

L

JP2

JP1

No Connection

22-28 VDC

Three-Wire RTD Connections

RTD

JP2

JP1

22-28 VDC

L

D

T

A

L

U

NHO

G/K

I

K

C

S

C

O

A

L

L

D

T

A

L

U

NHO

G/K

I

K

C

S

C

O

A

L

C

AV+V-

E+Ð

O

C

K

X

MC

IN

C

AV+V-

E+Ð

O

C

K

X

MC

IN

C

AV+V-

E+Ð

O

C

K

X

MC

IN

C

AV+V-

E+Ð

O

C

K

X

MC

IN

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

www.predig.com

PROGRAMMING

The meter’s Single Button Scaling feature allows it to be programmed using only the

ENTER button. The general procedure is to press the ENTER button to accept a

flashing display or to wait for the display to scroll and press ENTER when the

desired display appears.

For instance when the ENTER button is pressed, the meter scrolls through the standard programming routine titles: [ALIb , TYPE, For[, Alars. It will also scroll the

optional programming routine title: OvtPvt if the meter contains the isolated 4-20

mA Output Option. To enter a programming routine, press ENTER when the meter

displays the desired programming routine title.

The following flow chart overviews the meter programming routines.

There are 5 basic programming instructions

1. If the flashing display is OK, press ENTER before it stops flashing to accept it.

2. If the flashing display is not OK, (or if ENTER was not pressed in time to

accept it), wait for first digit to flash.

3. If a flashing digit is OK press ENTER before it starts to scroll to accept it.

4. If a flashing digit is not OK, (or if ENTER was not pressed in time to accept it),

wait for the digit to scroll, and press ENTER when OK.

5. Digits will scroll until ENTER is pressed. When a digit is accepted by pressing

ENTER, the next digit flashes.

For best results, allow the meter to warm up for at least

30 minutes before calibrating.

2 point

Calibration

Program

Alarms

Set

Decimal

Point

Program

Noise

Filter

Calibrate

4-20 mA

Output

Press

ENTER

Press

ENTER

Press

ENTER

Press

ENTER

Press

ENTER

Press ENTER

Display scrolls programming routines.

Press ENTER to select desired routine.

8

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

www.predig.com

CALIBRATION FLOW CHART

The following flow chart illustrates a 2 point calibration using Single Button Scaling.

The same general procedure is used for alarm set and reset point programming and

4-20 mA output programming.

9

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

Calibration

Complete!

Press ENTER

Press ENTER when

appears

flashes

Apply

input 1 signal

(e.g. 2 V)

Press ENTER

flashes

apply input 2

(e.g. 20 V)

Is

entire flashing

display OK?

Press ENTER

Wait for

digit to flash

Has

input 2 been

calibrated

yet?

Is

the flashing

digit OK?

Press ENTER

Press

ENTER when OK

Wait for digit

to scroll

Is

entire display

flashing?

YES

YES

YES

YES

NO

NO

NO

NO

www.predig.com

CALIBRATION (

(ALIb)

The PD750 is pre-calibrated for 6 types of thermocouples and 2 types of 100 Ω RTD

sensors. The PD751 is pre-calibrated for 10 Ω copper RTD sensors and the PD752

is pre-calibrated for 120 Ω nickel RTD sensors.

These input ranges may be re-calibrated and should be checked every 12 months.

Calibration is performed from the front panel using the ENTER button. It does not

require any tools or disassembly of the meter. The only equipment needed is a thermocouple calibrator or a 5 decade resistance box with an accuracy of about 0.1%

and a minimum resistance of 0.01 Ω for RTDs.

Go to INPUT TYPE on page 11 if calibration is not necessary.

Input 1 Calibration

1. Press ENTER, when [ALIb appears press ENTER again.

2. Meter flashes iNPT1. Apply input 1 (low signal) using a calibrator, THEN press

ENTER.

3. All digits flash for 3 seconds.

If this is the desired display for input 1, press ENTER before

entire display stops flashing, (meter will then flash InPt 2). Go

to step 9 below.

If this is not the desired display, (or if ENTER was not pressed

in time to accept the display) wait for the first digit to flash.

First digit flashes for 3 seconds before it scrolls.

4. When digit is OK, press ENTER, next digit will flash for 3 seconds before it scrolls.

5. When flashing digit is OK, press ENTER, next digit will flash for 3 seconds before

it scrolls.

6. Repeat step 4 for each remaining digits.

7. When last digit is OK, press ENTER.

8. Entire display will flash for 3 seconds. Press ENTER within the 3 seconds if OK to

complete input 1 calibration. If not OK, wait for first digit to flash and go to step 3

above.

9. Meter flashes iNPT 2. Apply input 2 (high signal) using a calibrator, THEN press

ENTER.

10. GO TO STEP 3 ABOVE.

CCaalliibbrraattiioonn EErrrroor

r

An Error message during calibration indicates that the calibration process was not

successful. The meter should be recalibrated.

An Error message will appear if input 1 and input 2 signals are within 4 millivolts.

An Error message will appear if input 1 signal is inadvertently also applied for

input 2 calibration, or ENTER is pressed before applying input 2.

10

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

INPUT TYPE (

TYPE

)

The meter must be programmed for the input type it is to accept. Selecting the

wrong input type will cause an incorrect temperature to be displayed.

Selecting Input Type

1. Press ENTER. When TYPE appears, press ENTER again.

2. The meter displays TYPE and starts to scroll through make it choice. Press

ENTER when desired digit appears, (see chart below). Meter will then reset back to

indication mode.

PD750 Input Ranges

PD751 Input Ranges

PD752 Input Ranges

11

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

Type Number Type of Input Range Accuracy

0 Type J T/C -328° to 1382°F ±2°F

-200° to 750°C ±1°C

1 Type K T/C -328° to 2498°F ±2°F

-200° to 1330°C ±1°C

2 Type T T/C -330° to 760°F ±2°F

-200° to 404°C ±1°C

3 Type T T/C -330.0° to 760.0°F ±2°F

(0.1°) -200.0° to 404.0°C ±1°C

4 Type E T/C -328° to 1832°F ±2°F

-200° to 1000°C ±1°C

5 Type R T/C 32° to 3213°F ±5°F

0° to 1767°C ±3°C

6 Type S T/C 40° to 3214°F ±6°F

4° to 1768°C ±3°C

7 100 Ω RTD -328.0° to 1382.0°F ±0.7°F

(0.00385, 0.1°) -200.0° to 750.0°C ±0.4°C

8 100 Ω RTD -328.0° to 1382.0°F ±0.7°F

(0.00392, 0.1°) -200.0° to 750.0°C ±0.4°C

9 100 Ω RTD -328° to 1382°F ±1°F

(0.00385, 1°) -200° to 750°C ±1°C

10 100 Ω RTD -328° to 1382°F ±1°F

(0.00392, 1°) -200° to 750°C ±1°C

Type Number Type of Input/ Resolution Range Accuracy

0 10 Ω Cu -328.0° to 500.0°F ±0.2°F

0.1 degree -200.0° to 260.0°C ±0.1°C

1 10 Ω Cu -328° to 500°F ±0.2°F

1 degree -200° to 260°C ±0.1°C

Type Number Type of Input/ Resolution Range Accuracy

2 120 Ω Ni -112.0° to 608.0°F ±0.2°F

0.1 degree -80.0° to 320.0°C ±0.1°C

3 120 Ω Ni -112° to 608°F ±0.2°F

1 degree -80° to 320°C ±0.1°C

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

RECOMMENDED CALIBRATION POINTS

SCALE (For[

)

F or C may be switched on to indicate Fahrenheit or Celsius.

Selecting Fahrenheit or Celsius

1. Press ENTER, when For[appears press ENTER again.

2. The meter will display F or [ alternately. Press ENTER when desired character is

flashing. Meter will then return to indication mode and display the temperature in

either Fahrenheit or Celsius.

12

www.predig.com

Type Type of Input Input 1 Input 2 Check

Number (Low) (High) (Middle)

0 Type J T/C 32°F 1182°F 600°F

1 Type K T/C 32°F 1183°F 960°F

2 Type T T/C 32°F 693°F 360°F

3 Type T T/C 32.0°F 693.0°F 360.0°F

4 Type E T/C 32°F 1652°F 840°F

5 Type R T/C 100°F 3000°F 1500°F

6 Type S T/C 100°F 3000°F 1500°F

7 100Ω RTD 32.0°F 1148.0°F 590.0°F

(0.00385, 0.1°) 100Ω 320.12Ω 215.61Ω

8 100Ω RTD 32.0°F 1127.0°F 580.0°F

(0.00392, 0.1°) 100Ω 320.89Ω 215.87Ω

9 100Ω RTD 32°F 1148°F 590°F

(0.00385, 1°) 100Ω 320.12Ω 215.61Ω

10 100Ω RTD 32°F 1127°F 580°F

(0.00392, 1°) 100Ω 320.89Ω 215.87Ω

13

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

4 ALARM POINTS (

Alars

)

The meter is equipped with 4 alarm points as a standard feature. Each alarm may

be programmed for either a high or low alarm and for 0-100% deadband. Front

panel LEDs indicate alarm status.

Options for 2 and 4 relays are available.

To program a high alarm, program the set point above the reset point. To program a

low alarm, program the set point below the reset point.

To program the alarm deadband, set the reset point above or below the set point by

an amount equal to the desired deadband value.

Example: Alarm 2 is a high alarm that trips at 1500° and has a deadband of 100°

Alarm 2 set point is set at 1500° and its reset point at 1400°

Alarm Set and Reset Point Programming (

Alars

)

Alarm set and reset point programming is performed in the Alars routine.

1. To enter the Alars routine, press ENTER and when Alars appears, press

ENTER again. This starts a scan of the 4 alarm set and reset points.

The scan sequence begins with a flashing display of alarm #1 set point. The “1”

LED and “S” LED are illuminated to indicate the meter is flashing alarm #1 set point

value.

2. All digits flash for 3 seconds.

If this is the desired display for this alarm point, press ENTER. Pressing

ENTER completes this alarm point programming. Proceed to step 8 for

next alarm point programming.

If this is not the desired display, wait for the first digit to flash. It will flash

for 3 seconds before it starts to scroll.

3. If the first flashing digit is OK, press ENTER before it starts to scroll to accept it,

the next digit flashes- go to step 6. If not OK, wait for first digit to scroll.

4. When the first digit is OK, press ENTER and the next digit flashes for 3 seconds

before it starts to scroll.

www.predig.com

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

5. If the flashing digit is OK, press ENTER before it scrolls. If not OK, wait for digit to

scroll.

6. When digit is OK, press ENTER. Program remaining digits in same fashion.

7. When the last digit is OK, press ENTER. The entire display flashes for 3 seconds.

Press ENTER if OK to complete alarm point programming and proceed to step 8. If

not OK, wait, first digit flashes. Repeat steps 3-7.

8. When an alarm set or reset point has been programmed the scan moves to the

next alarm set or reset point. To program the remaining alarm set and reset points,

repeat steps 2-8.

Determine which alarm set or reset point is being programmed by noting which

LEDs are illuminated. For instance, if the “3” LED and the “R” LED are illuminated,

the meter is displaying alarm #3 reset point. When alarm programming is complete

the meter will display the process input signal and the front panel LEDs will indicate

alarm status.

Programming Confirmation

To verify that the alarm set and reset points have been programmed as desired,

press ENTER, and press ENTER again when Alars appears. Before the display

stops flashing #1 set point value, press ENTER again to advance the display to #1

reset point. Continue skipping through the remaining alarm set and reset points. To

alter an alarm point value, wait for the first digit to flash and follow steps 3-8 above.

Alarm Operation

When the meter detects an alarm, a front panel LED illuminates to indicate which

alarm point has been tripped. This LED will stay illuminated until the meter display

passes through the reset point.

Alarm Acknowledgment

The ACK button on the front panel resets the optional relays only and has no effect

on the alarm status LEDs.

14

www.predig.com

15

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

FAIL-SAFE OPERATION:

The relay coils are energized in the non-alarm condition. In the case of a power failure, the relays will go to the alarm state. The fail-safe operation can be disabled by

removing jumper J2 located at the front of the relay option card.

OPTION CARD PIN-OUTS

Notes:

1. Alarm acknowledgement terminals (ACK and COM) are located on the meter main board.

2. In the alarm condition, the NC contact is connected to common in the fail-safe mode.

Relays

Ribbon Cable

Front

J2

Screw Terminals (Rear of PCB)

Relay #1 Common

Relay #1 NC

Relay #1 NO

Relay #2 Common

Relay #2 NC

Relay #2 NO

Relay #3 Common

Relay #3 NC

Relay #3 NO

Relay #4 Common

Relay #4 NC

Relay #4 NO

Function:

Transmitter +

Transmitter -

Pin:

1

2

3

4

5

6

1

2

1

2

3

4

5

6

PD175

PD178

PD177

PD176

PD174

J1

J2

J3

www.predig.com

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

RELAYS (Optional)

The meter is available with 2 and 4 relays. The SPDT relays can be programmed

for automatic or automatic + manual reset. The relays can also be programmed for

0-100% deadband.

Set and Reset Point Programming

Refer to page 13 to program the alarm (relay) set and reset points.

Automatic and Manual Reset Programming

There are two ways to reset the relays:

1. Automatically when the signal passes through the reset point.

2. Automatically + manually via the front panel ACK button, or a user supplied

switch across terminals at the rear of the instrument. That is, a relay may be manually reset prior to the signal passing through the reset point, or, if it is not, it will automatically reset when the signal passes through the reset point.

A manual reset will reset all relays that are programmed for automatic + manual

reset.

An array of jumpers located behind the front panel on the Display Board is used to

program each relay for either automatic or automatic + manual reset. Refer to page

21 for front panel removal instructions. The top jumper is used for relay 1, the next

for relay 2, etc. A relay will automatically reset if no jumper is installed. A relay will

automatically reset, plus can be manually reset, if a jumper is installed over its

respective pins.

Jumpers to program relays for either automatic or automatic + manual reset.

Example: Relay 1 is programmed for automatic reset only.

Relays 2, 3, and 4 are programmed for automatic + manual reset.

16

1

2

3

4

www.predig.com

17

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

SWITCHING INDUCTIVE LOADS

The meter has the ability to suppress electrical noise generated by switching inductive loads. However, installing suppressors improves this performance even more

and prolongs the life of the meter’s relay contacts.

This suppression can be obtained with RC networks assembled by the user or purchased as a complete assembly. Refer to the following circuits for RC network

assembly and installation:

AC and DC LOADS

Choose R and C as follows

R: 0.5 to 1 Ω for each volt across the contacts

C: 0.5 to 1 µF for each 1 A through closed contacts

Notes

1. Use capacitors rated for 240 VAC.

2. Snubbers may affect load release time of solenoid loads, check to confirm proper operation.

3. Install the RC network right at the meter’s relay screw terminals. An RC network may also be

installed across the load.

LOW VOLTAGE DC LOADS

Use a diode with a reverse breakdown voltage two to three times the circuit voltage

and forward current at least as large as the load current.

RC NETWORKS

Suppressors are available and should be applied to each relay that switches an

inductive load. Part number PDX6901.

1

2

3

L

O

A

D

1

2

3

L

O

A

D

www.predig.com

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

ISOLATED 4-20 mA OUTPUT OPTION (

OvtPvt

)

The meter can be equipped with an isolated 4-20 mA output signal option that can

be programmed to produce a 4-20 mA output for virtually any input.

Connections

The following drawings illustrate the 4-20 mA output signal being powered from the

meter’s internal 24 V power supply (AC powered units only) and by an external

power supply.

4-20 mA output signal being powered by meter’s internal 24 V power supply.

AC powered units only

4-20 mA output signal being powered from an external 24 V power supply.

If the output loop is powered by an external supply, the loop power supply

must be turned on before the meter is turned on. Otherwise, the output loop signal

may be incorrect.

Calibration

The isolated 4-20 mA output signal is calibrated using the front panel ENTER button

and uses the same Single Button Scaling technique that is used to calibrate the signal input and the alarm set and reset points. A multimeter may be connected to the

output terminals to verify calibration, but it is not required as part of the calibration

process.

+

+

+

-

-

-

Signal

I

nput

Meter, Recorder

Controller, etc.

-

+

EACPP L L

+

+

+

+

-

-

-

-

Loop

Power Supply

Meter, Recorder

Controller, etc.

Signal

Input

-

+

EACPP L L

!

18

www.predig.com

19

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

4 mA Output Calibration

1. Press ENTER, when OvtPvt appears press ENTER again.

2. All digits flash for 3 seconds, a green LED labeled “4” illuminates indicating the

flashing display is the value at which the meter will produce a 4 mA output.

If this is the desired display at which the meter will produce a 4 mA out

put, press ENTER before entire display stops flashing. The meter indicates that the 4 mA Output Calibration is now complete by illuminating

the green “20” LED. Go to 20 mA Output Calibration below.

If this is not the desired display, (or if ENTER was not pressed in time to

accept the display) wait for the first digit to flash.

3. First digit flashes for 3 seconds before it scrolls.

4. When first digit is OK, press ENTER, next digit will flash for 3 seconds before it

scrolls.

5. When flashing digit is OK, press ENTER, next digit will flash for 3 seconds before

it scrolls.

6. Repeat step 5 for each remaining digits.

7. When last digit is OK, press ENTER.

8. Entire display will flash for 3 seconds. Press ENTER within the 3 seconds if OK to

complete 4 mA Output Calibration. If NOT OK, wait for first digit to flash and go to

step 5 above.

20 mA Output Calibration

Note: The 20 mA output calibrates in the same fashion as 4 mA output so the 4 mA

Calibration Instructions will be referenced for most of the 20 mA Calibration

Instructions.

1. When ENTER is pressed to complete the calibration for 4 mA output, the green

LED labeled “20” illuminates indicating the flashing display is the value at which the

meter will produce a 20 mA output.

2. Repeat steps 2-8 in 4 mA Output Calibration above.

3. Upon acceptance of the display corresponding to the 20 mA output, the meter

exits the outPut routine and returns to indication mode.

www.predig.com

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

Programming Confirmation

The values that have been programmed to produce the 4 and 20 mA outputs can be

quickly checked to make sure they are the desired values. To do this, enter the

OvtPvt routine by pressing ENTER and then pressing ENTER again when

OvtPvt appears.

The green “4” LED illuminates indicating the meter is displaying the value at which it

will produce a 4 mA output. Confirm that this is the desired value. Press ENTER

(within 3 seconds) before the entire display stops flashing and the green “20” LED

illuminates indicating the meter is displaying the value at which it will produce a 20

mA output. Confirm that this is the desired value. Press ENTER (within 3 seconds)

before the entire display stops flashing and the meter returns to indication mode.

LOCKOUT

Install jumper JP2 at rear of instrument to restrict modification of calibration values.

When ENTER is pressed with lockout jumper in place, only Alars and OvtPvt

routines are displayed. These routines may be entered to view their settings, but the

settings may not be altered.

20

www.predig.com

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

OPTIONS CARD REMOVAL & INSTALLATION

Meter options are installed at the factory. To disable relays’ fail-safe operation, it is

necessary to remove the Boards from the case. Refer to the following instructions

and illustrations.

Disconnect power prior to performing

the following operations.

The meter's snap-off cover is held in place by 6 latches that snap into notches on

the snap-off cover. To remove the snap-off cover from the meter, grasp it firmly on

its top and bottom edges and pull it forward. The latch plate remains around the

meter's case.

To remove the circuit boards from the case:

1. Unscrew the retaining screws holding the circuit boards to the case.

2. Remove the screw terminal connectors at the rear of the meter.

3. Push the boards through the case by applying pressure to the circuit boards at

the rear of the meter. Apply pressure evenly to both boards.

4. Do not apply pressure to the vertical display board.

Front Cover Removal

5. Configure fail-safe jumper on Options Board as required. Remove J2 jumper to

disable fail-safe operation.

6. To avoid electric shock, re-install the circuit boards in the case prior to applying

power.

Latch

Snap-off Cover

Latch Plate

Notch

Retaining Screws and Washers

All programming and calibrating can be performed

with the circuit boards installed in the case.

21

22

To re-install the meter in its case:

1. Fold the Options Board over the Main Board, grasp both boards so the Main

Board is on the bottom and the two Boards are separated by about an inch.

2. Insert the two boards together into the case. Be sure both the top and bottom

boards engage the rails, which hold them in place.

3. Do not press on the Display Board when seating the assembly in the case.

4. Install washers and retaining screws in 4 corners of meter and install front cover.

Option Card Installation

MOUNTING DIMENSIONS

Mounting Dimensions

Notes:

1. Panel cutout required: 1.772" X 3.622" (45 mm x 92 mm) 1/8 DIN

2. Panel thickness: 0.125" - 0.250" (3.17 mm - 6.34 mm)

3. Clearance: allow 6 inches (152 mm) behind the panel

22

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

Input Configuration

Jumpers

Display PCB

Ribbon Cable

Transformer

Relays

J2

Front

Screw Terminals (Rear of PCB)

Panel Thickness Ð

.125"-.250" (3.17mm-6.34mm)

6" (152mm) Clearance

SIDE VIEWFRONT VIEW

4.25" (108mm)

4.30" (109mm) Installed

4.83" (123mm) Req'd for Inst.

2.30"

(59mm)

.575"

(14.6mm)

Other Precision Digital Products

23

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

MODEL DESCRIPTION

PD118 MINIMUX®8 Point Scanner

PD141AFO VIGILANTE®four Point Annunciator with First-Out

PD202-253 Digital Pressure Gauges

PD602 Dart Low-Cost 1/8 DIN Process Meter

PD644 Javelin D High-Voltage DC Panel Meter

PD650 2.3" LED NEMA 4X Large Display Process Meter

PD655 1.0" LED NEMA 4X Large Display Process Meter

PD656 0.8" LED Exp-Proof Large Display Process Meter

PD660 Low-Cost NEMA 4X Loop Powered Meter

PD661 Low-Cost Exp-Proof Loop Powered Meter (FM & CSA)

PD673 4

1

/2

Digit Loop Powered 1/8 DIN Meter

PD675 4

1

/2

Digit Loop Powered NEMA 4X Meter (FM & CSA)

PD677 4

1

/2

Digit Loop Powered Exp-Proof Meter

PD685 3

1

/2

Digit Loop Powered NEMA 4X Meter (GeneralPurpose)

PD686 3

1

/2

Digit Loop Powered NEMA 4X Meter (FM & CSA)

PD687 3

1

/2

Digit Loop Powered Exp-Proof Meter (FM & CSA)

PD690 1/8 DIN Analog Input Process Meter (UL Listed)

PD691 1/8 DIN Strain Gauge & mV Input Meter (UL Listed)

PD692 1/8 DIN Analog Input Flow Rate/Totalizer (UL Listed)

PD693 1/8 DIN Pulse Input Flow Rate/Totalizer (UL Listed)

PD696 1/8 DIN Loop Powered Flow Rate/Totalizer

PD697 NEMA 4X Loop Powered Flow Rate/Totalizer

PD698 Exp-Proof Loop Powered Flow Rate/Totalizer (FM & CSA)

PD740 Javelin T TC & RTD Temperature Meter (Low-Cost)

PD751-752 10 Ω Cu & 120 Ω Ni RTD Temperature Meters (UL Listed)

PD755 1.0" LED NEMA 4X Large Display Temperature Meter

PD756 0.8" LED Exp-Proof Large Display Temperature Meter

PD757 2.3" LED NEMA 4X Large Display Temperature Meter

PD765 Trident Process & Temperature Meter (UL Listed)

PD865 Snooper Modbus Serial Input Meter

PD940-981 ConsoliDator®Multi-Channel Controllers

Model PD750, PD751, PD752 Universal Temperature Meters Instruction Manual

LIM750 Rev E

How to Contact Precision Digital

• For Technical Support please

call: (800) 610-5239 or (508) 655-7300

fax: (508) 655-8990

e-mail: support@predig.com

• For Sales Support or to place an order please

call: (800) 343-1001 or (508) 655-7300

fax: (508) 655-8990

e-mail: sales@predig.com

• For Extended Warranty, Setup & Calibration

Services please visit

www.predig.com

• For an online version of this instruction manual

please visit

www.predig.com

PRECISION DIGITAL CORPORATION

19 Strathmore Road • Natick MA 01760 USA

Tel (800) 610-5239

• Fax (508) 655-8990

11/05

Loading...

Loading...