Precision boilers FPS-31-20, FPS-31-15, FPS-39-25, FPS-39-20, FPS-39-30 Installation And Operating Instruction

...

Installation and Operating Instruction

FIRED STEAM BOILER

Model FPS

With

Power Burners

FOR YOUR SAFETY

This product must be installed and serviced by a professional service technician or gas/oil

supplier, qualified in steam boiler installation. Improper installation and/or operation could

cause serious injury or death. Improper installation and/or operation will void the warranty. Do

not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

1

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or

property damage. Read the manual thoroughly. For assistance or additional information consult

a qualified installer, service agency or the gas/oil supplier.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call the fire department.

I M P O R T A N T

These instructions Are Intended as a Guide for the Installing Contractor and as a Reference for

the Operator, Owner and Serviceman

RETAIN THESE INSTRUCTIONS NEAR THE EQUIPMENT FOR READY REFERENCE

The instructions contained in this manual are intended as a guide only and do not supplant any

National, State or Local Codes.

This unit must be installed in accordance with those installation regulations in force in the local

area where the installation is to be made. Local regulations shall be carefully followed in all

cases. Authorities having jurisdiction shall be consulted before installation is made.

PRECISION has a commitment to product improvement and provides a continuing quest for the

highest standards of product performance. In pursuing this policy of continuous development

of products, the Manufacturer reserves the right to vary any details in this manual without

notice.

2

TABLE OF CONTENTS

I. GENERAL INFORMATION…………………………………………………………….……… 4

A. Introduction …………………………………………………………………………….…… 4

B. Warranty ………………………………………………………………………………….….. 4

C. Engineering Assistance ………………………………………………………………... 4

II. INSTALLATION …………………………………………………………………………………… 6

A. Uncrating……………………………………………………………………………………… 6

B. Placement………………………………………………………………………………….…. 6

C. Piping Connections………………………………………………………………………. 6

D. Electrical Connections………………………………………………………………….. 7

E. Fuel Connections………………………………………………………………………….. 7

GAS…………………………………………………………………………………………….…. 7

OIL…………………………………………………………………………………………….….. 9

F. Flue…………………………………………………………………………………………….…. 10

G. Combustion Air. …………………………………………………………………………... 11

III. START-UP ………………………………………………………………………………………….... 11

A. Pre-Startup Checks……………………………………………………………………….. 11

1. Piping Connections……………………………………………………………….…. 11

2. Pumps……………………………………………………………………………………... 11

3. Electrical …………………………………………………………………………………. 11

4. Combustion Air………………………………………………………………………... 12

5. Gas…………………………………………………………………………………………... 12

6. Oil…………………………………………………………………………………………….. 12

B. Filling the System…………………………………………………………………………... 12

C. Control Settings……………………………………………………………………………... 12

1. Controller………………………………………………………………………………... 12

2. High Limits……………………………………………………………………………….. 12

3. Low Water Cut-Off…………………………………………………………………… 12

D. Burner…………………………………………………………………………………………….. 12

1. Preparation for Startup – All fuels………………………………………….... 12

2. Startup……………………………………………………………………………………… 13

a. GAS BURNER………………………………………………………………………. 13

b. OIL BURNER……………………………………………………………………….. 13

IV. OPERATION AND MAINTENANCE………………………………………………………… 14

A. Operation……………………………………………………………………………………….. 14

B. Maintenance ………………………………………………………………………………….. 14

3

I. GENERAL INFORMATION

IMPORTANT WARNING

The Model FPS Boiler shall be installed according to the procedures detailed in this manual, or

the PRECISION warranty may be voided. The installation must conform to the requirements of

the local jurisdiction having authority, and to the latest edition of the National Fuel Gas Code,

ANSI Z223.1. Any modifications to the Boiler or its gas/oil controls may void the warranty. If

field conditions require modifications, consult the Factory.

A. INTRODUCTION

This manual supplies information on the application, installation and operation of Model

FPS – (Firetube) Steam Boiler. Review all application and installation procedures

completely before proceeding with the installation. Consult the PRECISION Factory, or

local Factory Representative, with any problems or questions regarding this equipment.

Experience has shown that improper installation causes most operating problems. The

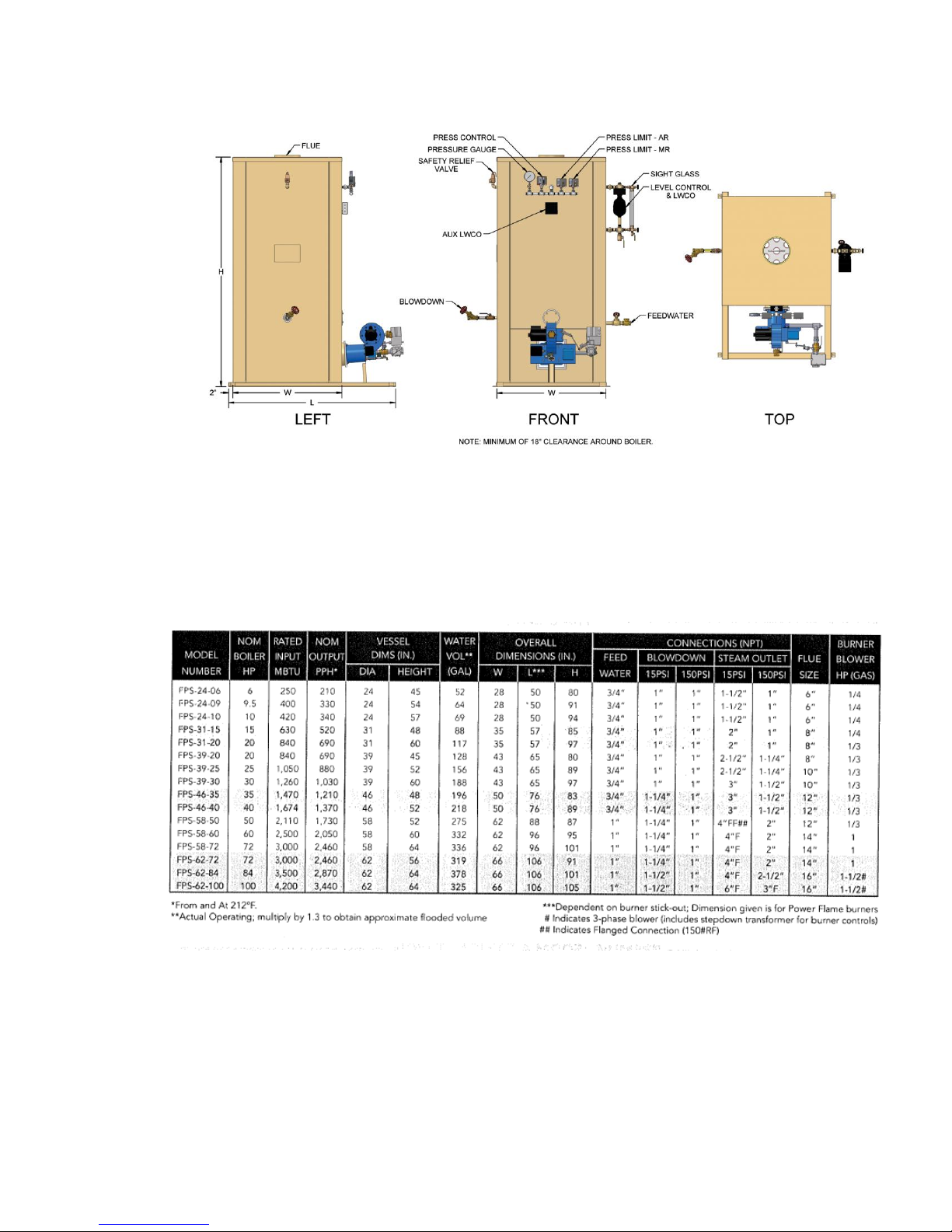

FPS models are offered in the basic configuration shown in Figure 1 and Table 1.

B. WARRANTY

PRECISION Fired Steam Boilers are covered by a limited warranty. A copy of the

warranty is included in the back of this manual. Make all warranty claims to an

authorized PRECISION Representative or directly to the Factory. Claims must include the

unit serial number, model number (per the name plate) and installation date. Shipping

and labor costs are not included in the warranty coverage.

Some accessory items may be shipped in separate packages. Verify receipt of all

packages listed on the packing slip. Inspect everything for damage immediately upon

delivery, and advise the carrier of any shortages or damage. File any such claims with

the carrier. The carrier, not the shipper, is responsible for shortages and damage to the

shipment, whether visible or concealed.

C. ENGINEERING ASSISTANCE

Consult the Representative or Factory regarding any questions or problems which may

come up involving the specification, installation or operation of PRECISION equipment.

An experienced engineering staff is ready to assist in assuring their proper application

and performance.

4

5

II. INSTALLATION

A. UNCRATING

1. Care must be given not to damage controls or to deform the unit’s casing during

remove of the crate.

2. When using pry bars or fork lifts, be certain to support the unit on the shipping

skids or the channel base.

3. Storage – Electrical equipment can be damaged if exposed to adverse weather.

The unit should be stored inside. The electrical panel and controls must be

covered with plastic throughout all construction to avoid accumulation of dust

and moisture on the controls and other components.

B. PLACEMENT

1. Provide a firm, level foundation for the unit. Standard fired units are not suitable

for placement on combustible flooring.

2. Leave a permanent space of 18 inches on the sides and rear, and 24 inches on

the front for burner maintenance.

3. Be sure to keep the burner and controls covered at all times while work is in

progress.

CAUTION: DO NOT USE THE UNIT’S HOUSING TOP FOR SCAFFOLDING!!

C. PIPING CONNECTIONS

NOTE: Refer to applicable dimensionable drawing (DD) appendixed to this manual.

1. Boiler piping connections and valves MUST comply with state and local codes, in

addition to compliance with ASME piping requirements.

2. Install the safety valves(s) on the connection(s) provided. Plumb the safety valve

outlet full size to the floor drain for low pressure boilers, or to a safe point of

discharge for high pressure boilers. When two or more valves are used, discharge

lines may be manifolded proved unions are included for disassembly and the

common discharge pipe size must be greater or equal in area to the total are of all

safety valve outlets combined. Check local codes for proper safety valve discharge

piping.

3. Connect the feedwater supply to the feedwater valve train as shown on the DD.

CAUTION: Do not oversize feedwater piping and valves on Steam Boilers, as this

may result in severe pressure fluctuations during feedwater cycles if the fill rate is

too rapid.

6

4. Pipe both the bottom blowdown, and surface blowoff (if provided) to a nearby

drain (low pressure Boilers) or to a blowdown receiver (Boilers greater than 15

psi). Check compliance with local codes. Be sure to provide a low point drain to

enable complete draining of the Boiler.

D. ELECTRICAL CONNECTIONS

CAUTION: The Boiler must be electronically grounded in accordance with the most

recent edition of the National Electrical Code, ANSI/NFPA 70. Do not rely on the gas or

water piping to ground the metal parts of the Boiler. The use of plastic pipe or

dielectric unions may isolate the Boiler electrically. Service and maintenance

personnel may be standing on wet floors and could be severely shocked by an

ungrounded Boiler.

1. Check the Boiler wiring diagram (WD) for correct voltage, frequency, phase and

amperage of the required branch circuit. The branch circuit must be protected by a

properly sized circuit breaker or fused safety switch.

2. Electrically ground the unit per NEC and local code requirements using AWG #10

Cu wire minimum.

3. All field installed electrical safety devices and controls (draft switches, relays,

timers, pressure reset devices, etc.) can be connected as shown in the wiring

diagram designated “Field Interlock Provision”.

E. FUEL CONNECTIONS

NOTE: Also refer to the burner literature supplied as an appendix to this manual

relative to the actual burner supplied with your unit.

-GAS

NOTE: Contact your local gas service company to assure that adequate gas service is

available and to review applicable installation codes for your area. The gas line

pressure should be in the range of 5-14 ins WC.

1. Size the main gas line in accordance with Table 2. The figures shown are for

straight lengths of pipe at 0.2 ins. WC pressure drop, which is considere4d normal

for low pressure systems. Note that fittings such as elbows and tees will add to the

pipe pressure drop.

2. Refer to Figure 2 for details of gas piping. Mount any items of the gas train shipped

loose as shown. Install the main gas cock with drop leg upstream of the regulator

and automatic valves. The pilot line should be piped into the upstream tapping on

the main gas train shut-off cock.

7

8

NOTE: For ease of servicing we recommend the use of a union immediately upstream of

the main gas pressure regulator or combination gas valve/pressure regulator.

3. Install vent lines from main gas regulator (if used) and (if applicable) diaphragm

gas valve. Vent line should be run to the outside of the building, terminating clear

of windows or fresh air intakes. Outside termination of vent should have a screen

to prevent insects from building nests in vent pipe. The vent should terminate in a

manner which will preclude the possibility of water, dirt or other matter from

entering the line.

4. Test gas lines for leaks using soap solution. Your local gas service company may

wish to carry out or witness this test.

CAUTION: Gas pressure above 14 ins. WC may damage the standard diaphragm

gas shut-off valve. Do not exceed this value when pressure testing lines unless you

cap off the line upstream of the main gas cock and pilot take-off.

-OIL

CAUTION: Most oil burners supplied on Model FPS and TPS units are designed for use

with light grade fuel oils – commercial standard grades #1 or #2.

1. Prior to installation, it is recommended that all national, local and other applicable

codes be reviewed to ensure total compliance.

NOTE: A two pipe (separate suction and return line) system must always be used.

The fuel pump is pre-set at the Factory for use only with a two pipe system. The

pump warranty will be voided if a one pipe system is used with this burner. Rigid

pipe connected directly to the pump may cause excessive vibration. It is

recommended that the connection to the pump be of copper tubing, complete

with vibration dampening loop, on both suction and return lines. Do not use

Teflon tape. The pump warranty will be voided if Teflon tape is used.

2. Size the oil supply and return lines in accordance with the guidelines provided in

the fuel pump instructions appendixed to this manual. It is very important to

properly size the oil suction line and oil filter to provide fuel flow to the burner

without exceeding 10” suction pressure (vacuum) at the oil pump suction port. Use

copper tubing with flare fitting or iron pipe on all installations. Use ½” OD oil lines

whenever possible. All units must utilize the proper size and type of suction line oil

filters.

9

3. Refer to Figure 3 for details of oil piping. All field piped components must be

mounted in the proper order as shown with the proper direction of oil flow.

CAUTION: Oil supply pressure to the burner oil pump must not exceed 3 psi per

NFAA Codes.

NOTE: Do not install manual valves in the return line between the pump and the

tank unless required by a specific code. If a manual valve is required, an automatic

relief valve must be installed across the manual valve to ensure that oil will bypass

directly back to the tank in the event the manual valve is inadvertently left in the

closed position.

4. Before starting up the system, all appropriate air and oil leak tests should be

performed. Make certain that the tank atmospheric vent line is unobstructed.

F. FLUE

CAUTION: Jurisdictional authority relating to venting/flue requirements vary widely. In

order to make certain of compliance, the controlling authorities should be consulted.

10

1. Use positive pressure breeching material. Breeching should be short, straight and

full size. Horizontal runs over 10’ or over (2) elbows should be avoided. Runs

should pitch upward at least 1” per foot.

2. A full size barometric damper should be installed in the breeching to regulate the

drafts. After startup, check the damper and breeching by holding a match near the

edge of the damper. A correct installation will pull the flame with the burner

running.

G. COMBUSTION AIR

1. Provide fresh air to support combustion and to supply adequate location

ventilation.

NOTE: All fuels require approximately 10 cubic feet of standard air (sea level at

60 degrees) per 1000 BTU’s firing rate, for theoretical perfect combustion. In

actual practice, a certain amount of excess air is required to ensure complete

combustion, but this can vary substantially with specific job conditions. Additional

air is lost from the boiler room through barometric dampers, draft diverters and

similar venting devices. It is generally accepted that ½ square inch of free air

opening (for each gas or oil burner in the room) per 1000 BTU/hr firing rate will be

adequate.

2. After startup, test to assure a positive boiler room pressure with the Boiler

operating at 100% input.

CAUTION: Under no circumstances should a boiler room be under negative

pressure. If combustion air is ducted to the burner, make sure the duct size is

adequate to assure proper burner operation.

III. START-UP

A. PRE-STARTUP CHECKS

1. Piping Connections

Are they complete and correct?

2. Pumps

Are the feed pumps functional?

Is the motor rotation correct?

3. Electrical

11

Is the branch circuit power supply as required per the burner name plate?

Is the unit properly grounded?

4. Combustion Air

Is adequate fresh combustion available?

Is the breeching/stack open and unobstructed?

5. Gas

Is the gas supply available?

6. Oil

Is there adequate amount of oil in the tank?

Is the oil the proper grade?

B. FILLING THE SYSTEM

1. The system and the Boiler should be thoroughly flushed before start up.

2. Operate water column and level control drain/blowdown valves to assure that

these are thoroughly flushed and operate properly.

3. Before firing the unit, be sure the unit is filled to the proper water level.

C. CONTROL SETTINGS

1. Controller

This is the pressure sensing device which controls the operation of the burner. Set

the controller for the desired steam pressure.

2. High Limits

Set the high limit auto reset control approximately 10% above the setting of the

controller. Manual reset limits should be set approximately 5% above the auto

reset limit, but should not be set higher than 95% of the safety valve set pressure.

3. Low Water Cut-Off

This limit is always Factory-set. If additional units are field installed, manual reset

LWCO’s should be positioned below the automatic reset limit.

D. BURNER

IMPORTANT: Read the burner O&M manual (Appendixed to this manual) thoroughly

before attempting to start the burner.

CAUTION: Failure to properly follow the detailed start up instructions given in the

burner O&M manual may result in an explosion which could cause property damage,

injury, or loss of life.

12

1. Preparation for Start Up – All Fuels

a. Run an inspection of the tightness of all electrical connections and retighten as

necessary. This tightness inspection is vital because vibration during shipment

can often loosen electrical connections.

b. Set the burner control panel switch to the “OFF” position.

c. Turn the operating control down to its lowest setting.

d. Check fuses and replace as necessary.

e. Depress the flame safeguard programming control reset button.

2. Start Up

- GAS BURNER

a. Manually open and close the main gas shut off cock, leak test cock and pilot

cock to determine that they operate freely. Open all three cocks. (Reset low

gas pressure switch if supplied).

b. Set the main power switch and burner panel control switch to the “ON”

position. Wait 30 seconds and turn up the operating control to the desired

setting.

c. The burner blower motor will start and after a suitable prepurge period (this

will vary with the type of flame safeguard control supplied- but will usually be a

minimum of 30 seconds to a maximum of 90 seconds) the burner pilot will

light, after which the main flamewill be established.

d. When burning gas on a Combination Gas/Oil unit that has a blower motor

driven oil pump, open all oil line valves. Oil must circulate through the oil

pump, even when burning gas.

- OIL BURNER

a. Open all valves in oil lines

b. If pilot gas ignition system is supplied – open and close the pilot gas cock to

determine that it is operating freely. Open the pilot gas cock.

c. Set the main power switch and burner panel control switch to the “ON”

position. Wait 30 seconds and turn up the operating control to the desired

setting.

d. The burner blower motor will start. Depending upon the type of flame

safeguard system supplied, the fuel ignition system may energize within 1 or 2

seconds after the blower motor starts or could be as long as 90 seconds.

13

NOTE: For more detailed burner start-up information, refer to the burner

literature supplied as an appendix to this manual relative to the actual burner

supplied with your unit.

IV. OPERATION AND MAINTENANCE

A. OPERATION

1. When the operating controller calls for pressure, the burner blower motor will

start and after a suitable prepurge period (30-90 seconds approximately) the

burner pilot will light. (The unit performs its own safety check and opens the main

valve only after the pilot is proven to be lit). The main flame is then established.

2. The operating controller will control to the desired steam pressure. The

differential adjustment should be set at the highest value which will still provide

acceptable steam pressure variation. Two pressure controllers are supplied on hilo fired units, and a proportional controller is supplied on modulating burners.

3. An automatic reset pressure limit is supplied as standard on all modulating units.

4. A manual reset high limit is provided as standard equipment on all units. The

burner will automatically shut down whenever an over pressure condition occurs.

5. A manual reset low water cutoff is also provided as standard equipment on all

units. The low water cutoff automatically shuts off the burner whenever the water

level drops below the Factory set level in the upper part of the tank.

NOTE: Warranty does not cover any damage caused by lack of required

maintenance or improper operating practices.

B. MAINTENANCE

1. At startup and at least every six months thereafter, the pilot and main burner

flame should be observed for proper performance. (Refer to burner literature

supplied with this manual for detailed information).

2. Inspect the venting system for obstruction, leakage, and corrosion at least once

per year.

3. Keep Boiler area clean and free from combustible material, gasoline and other

flammable vapors and liquids.

4. Be certain all combustion air and ventilation openings are unobstructed.

5. The gas and electric controls installed on these Boilers are engineered for both

dependable operation and long life, but the safety of this equipment completely

depends on their proper functioning. It is strongly recommended that the basic

14

items be checked yearly by a competent service person and replaced as necessary.

The basic controls are:

a. Operating Control

b. Pilot Safety System

c. Automatic Electric Gas/Oil Valve(s)

d. Limit Controls

6. Low water cutoffs should be inspected every six months, including cleaning probes

and flushing floats.

7. Firebox inspections can be made by removing the burner. If repairs are required,

the entire firebox can be withdrawn from beneath the pressure vessel by use of

the (3) jacking eyes attached to the vessel’s lower flange.

15

Loading...

Loading...