Page 1

Super-Flow® 24

FOREMOST IN AIR FILTRATION

General

Flanders Super-Flow®24 is a V-bed HEPA filter

(99.99% at 0.30 micrometer) specifically designed

for high airflow applications requiring HEPA efficiency

at an ultra low-pressure drop. The Super-Flow

can be incorporated into systems with air velocities

of 600 fpm and a pressure drop of 1.0-inch w.g.

®

24

Product Design

The Super-Flow®24 filters are manufactured with wet

laid microfine fiberglass media. The media is formed

into a minipleat utilizing a hot melt separator and

arranged in a V-bed configuration. There are twelve

individual minipleat packs sealed on all four sides

to the frame with two-component polyurethane.

The frame is constructed of 20 ga. galvaneal, aluminum or stainless steel and consists of vertical

support struts of the same material. Vertical supports are attached to the frame body without the

use of mechanical fasteners. The vertical supports

act as the sealing surface of the mini pleat packs.

High Velocity

Low Airflow Resistance HEPA Filter

Bulletin PB1410-1106

Product Options

The Super-Flow®24 are available in aluminum,

galvaneal or stainless steel frames and with gasket

seal or gel seal design. The Super-Flow®24 filters

are UL 900 Class 2 listed.

• Gasket Seal

The filter gasket is 1/4" x 3/4" black neoprene

attached to the frame with an adhesive and the

gasket joints are dovetailed to ensure no

penetration of particulate due to the gasket. The

filter is designed for installation into Flanders front

load B-1 holding frame, C-3 Gasket Seal Housing

and Surelock-B Side Access Housing.

• Gel Seal

The filter gasket is Flanders Blu Jel

channel around the perimeter of the frame. The

gel seal design provides the highest degree of

sealing integrity between the filter and holding

device. The filter is designed for installation into

Flanders front load A-4 holding frame or C-4 Gel

Seal Housings.

®

filled into a

Important Features

The product offers the following advantages over conventional HEPA filters.

• Longer Life

Gasket seal

of media compared to 240 sq. ft. for traditional

HEPA filters. The greater media area provides a

longer time period between filter replacements.

• Improved Efficiency

The significant quantity of media translates into

an extremely low media velocity. Therefore a

minimum overall efficiency of 99.99% at 0.30 μm

is easily assured. Traditional HEPA filters have an

overall efficiency of 99.97% at 0.30 μm.

• Lower Operating Cost

The typical HEPA filter pressure drop can range

from 1.4-inch w.g. to 1.8-inch w.g. at the rated

flow. The pressure drop of the

1.0-inch w.g. at the rated flow.

Super-Flow®24 filters have 400 sq. ft.

Super-Flow®24 is

Flanders Filters~ Foremost in Air Filtration

Toll Free: 1-800-637-2803

Page 2

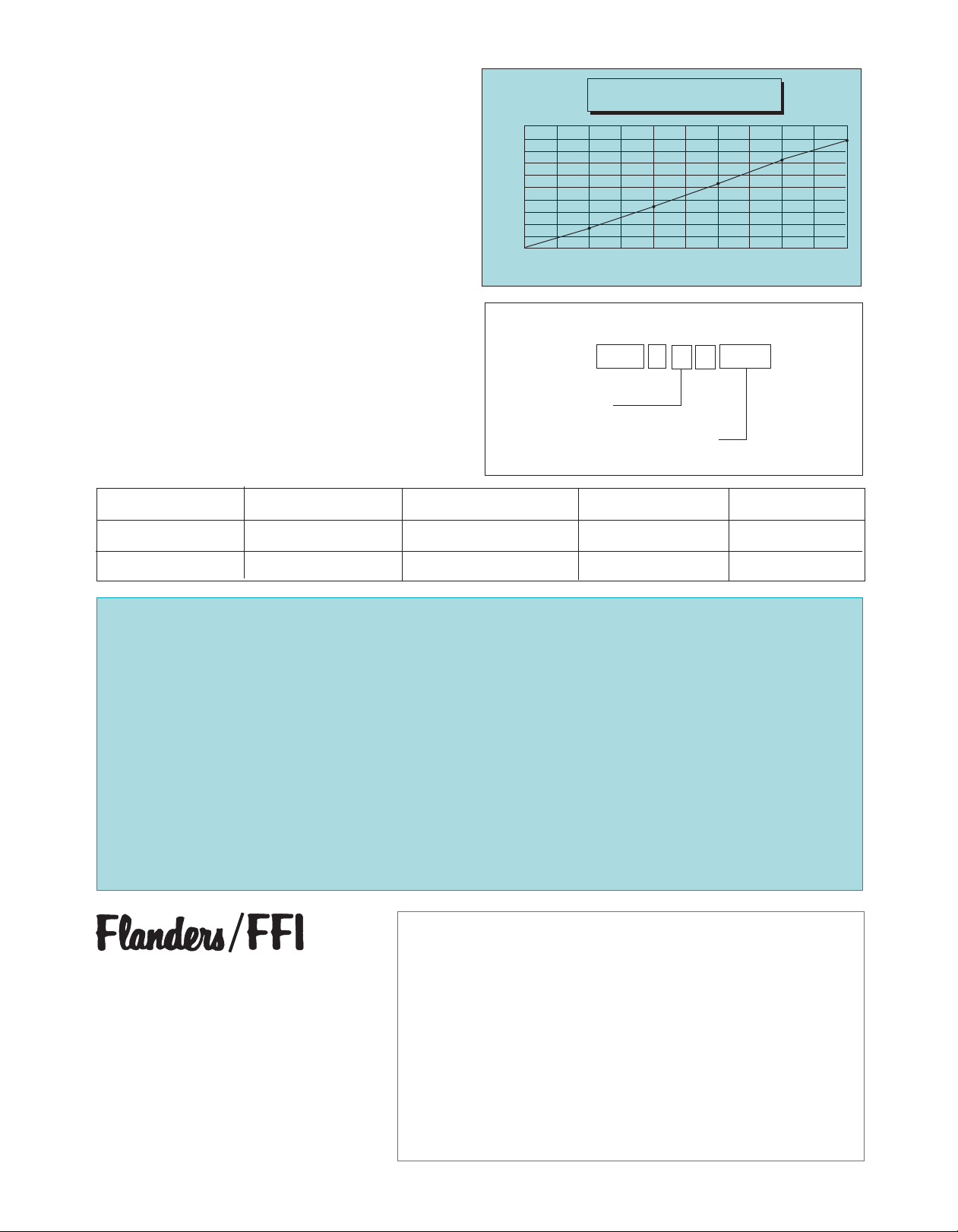

Performance Data Notes:

The Super-Flow

ultra low-pressure drop for HVAC systems supplying

air to critical areas.

Figure 1 illustrates the

as a function of airflow rate for gasket seal and gel seal

designs.

®

24 filters offer HEPA efficiency at an

Super-Flow®24 pressure drop

Installation Considerations

All products have a rated overall efficiency of 99.99% at

0.30 μm and a maximum pressure drop of 1.0-inch w.g.

at the rated flow. Specify the following:

Material Types: 8 = Galvaneal

5 = Aluminum

3 = Stainless Steel

Super-Flow® 24 99.99% on 0.3 um

Pressure Drop vs Air Volume

1.00

0.90

0.80

0.70

0.60

0.50

Drop (in w.g.)

0.40

0.30

0.20

0.10

0.00

Pressure

0 500 1000 1500 2000 2400

Air Volume (cfm)

Sample Model Number

SF24 - 8 - (*) (*)

Gasket Types: G = Neoprene

F = Blu Jel

®

Gasket Locations: 1 = Upstream

Material Type

Gasket Type & Location

2 = Downstream

Model Number Nominal Size Actual Size Media Area RatedFlow

SF24(*)-(*) 24" x 24" x 12 24" x 24" x 11-1/2" 400 sq. ft. 2400

SF24(*)-(*) 12" x 24" x 12 12" x 24" x 11-1/2" 195 sq. ft. 1320

Guide Specifications

1.0 General

1.1 HEPA filters shall be Flanders Super-Flow

24 as manufactured by Flanders.

1.2 Filter sizes, efficiencies and capacities shall

be as specified on the drawings.

2.0 Construction

2.1 Filters shall be constructed with twelve 1"

pleated media packs arranged in a V-bank

configuration. The media packs shall be

formed by pleating wet laid micro-fiberglass

media with continuous beads of a cured,

nonvolatile adhesive.

®

2.2 The filter frame shall be 20 ga. galvaneal steel,

stainless steel and aluminum shall consist of eight

C-channel supports attached without the use of

mechanical fasteners. The media packs shall be

sealed around the entire periphery to the frame with

two-component polyurethane.

3.0 Performance

3.1 The minimum filter efficiency shall be 99.99% at

0.30 μm when tested with polydisperse DOP aerosol

at the rated airflow.

3.2 The maximum pressure drop shall be 1.0" w.g. at

the rated airflow.

Flanders Filters, Inc.

531 Flanders Filters Road

Washington, NC 27889

Phone: 252-946-8081

Fax: 252-946-3425

Toll Free: (800)637-2803

Website: www.flanderscorp.com

®

Represented By

Flanders Filters ~ Foremost in Air Filtration

Toll Free: 1-800-637-2803

Loading...

Loading...