Page 1

Rigid-Air

General

Rigid-Air extended media surface rigid filters are

designed for use in most commercial or industrial

HVAC systems where medium to high efficiency

filtration is required.

They feature your selection of media backed with

expanded metal and pleated. The pleats are held

in place by rigid pleat separators, available in either

plastic or metal styles on 12"depth filters. 6" depth

filters feature rugged fiberboard separators. RigidAir is available in two media types: lofted fiberglass

and micro-fine synthetic with average efficiency

ranges of 50-55%, 60-65%, 80-85% and 90-95%

per ASHRAE Standard 52.1 and MERV 10-14 per

ASHRAE Standard 52.2.

These filters are especially suitable for variable air

volume systems. Operating face velocity ranges

are from 0 to 375 fpm for 6" deep filters, and from

0 to 675 fpm for 12" deep filters. Two frame styles

are available: a single header model and a box type

without header. Rigid-Air filters are UL 900 Class 2

listed. Optional Class 1 listed are available with

metal inserts and fiberglass media.

Spun G

lass or Synthetic Media Rigid Filter

Bulletin PB1001-1106

The headered version should be selected for use

with the hardware listed. If the filter is to be installed

so that it protrudes upstream of the holding frame,

the box style filter is required.

Physical Data

Frame: 24 ga. corrosion-resistant steel

doubleturned flange makes a stronger frame.

Media: Lofted fiberglass or micro-fine synthetic.

Media Supports: Expanded metal grid with metal

or plastic pleat separator.

Face Grid: Horizontal and diagonal metal supports.

Header: 13/16" wide 26 ga. corrosion-resistant

steel.

Operating Limits: 180° F 100% RH%.

Actual Header or Box Filter Face Size: Nominal

size less 5/8" (e.g., a nominal 24" x 24" filter is

actually 23 3/8" x 23 3/8").

Actual Depth: 5-7/8" or 11-1/2".

Installation Considerations

Rigid-Air filters may be installed in Astr Holding

Frames, K-Trac Filter Framing Modules, Sureseal

Side Access Housings or in similar existing

hardware.

Important Features

• Ecologically advanced filtration medium made

entirely from recycled materials.

• Rugged corrosion-resistant steel casing minimizes

damage during shipping and handling.

• Lofted fiberglass micro-fine or synthetic media is

held in position by upstream and downstream

plastic or metal pleat supports.

• Units are available with or without header.

• Filters are completely rigid.

• MERV 10-14

Flanders PrecisionAire ~ Foremost in Air Filtration

Toll Free:1-800-637-2803

1

Page 2

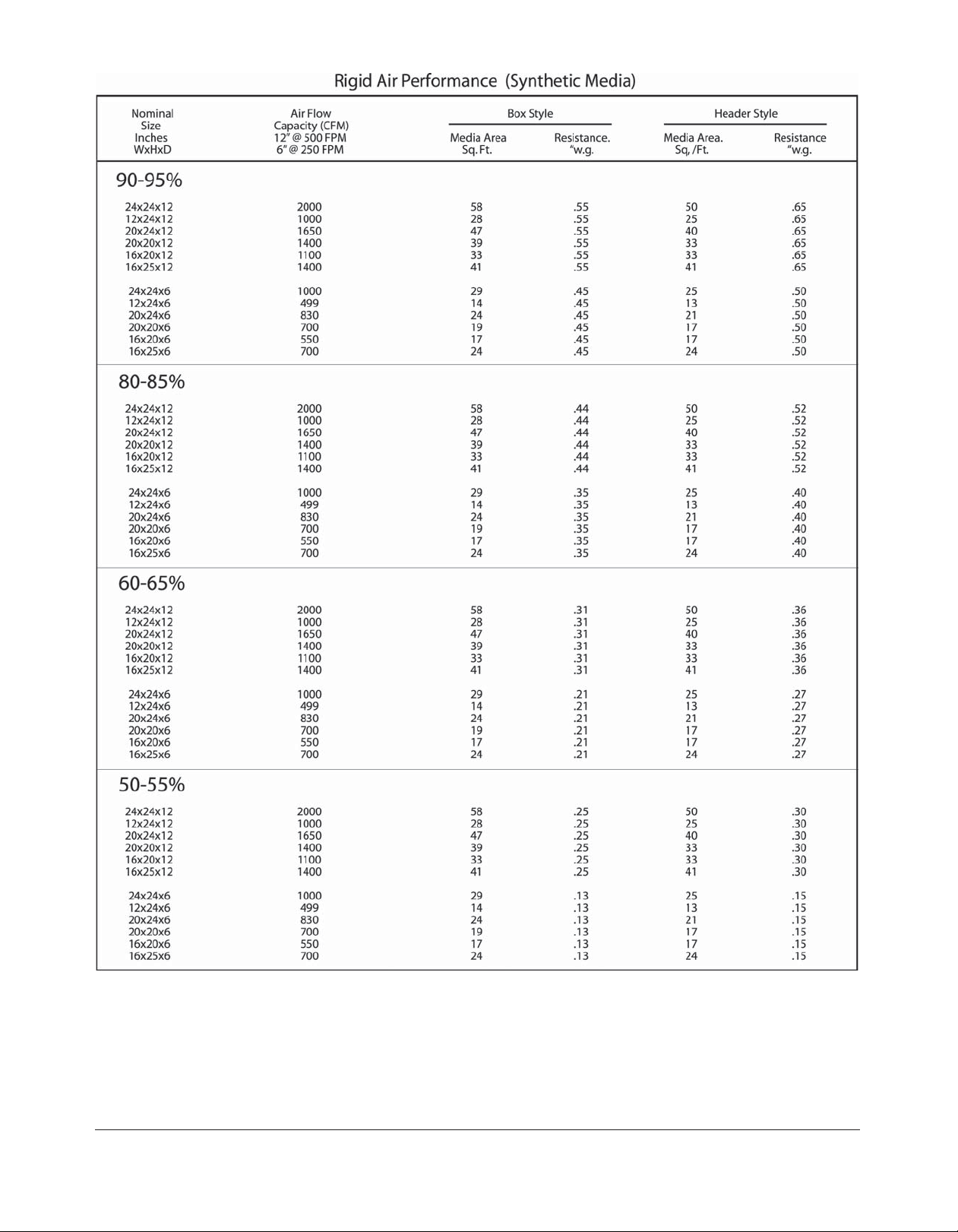

Notes:

1. PD represents clean pressure drop in inches w.g. Recommended final pressure drop for all models is 1.5" w.g.

2. Efficiency is average and is based on ASHRAE Standard 52.1 and 52.2 test methods.

3. Performance tolerances conform to Section 7.4 of ARI Standard 850.

4. Actual filter face size is 5/8" under on height and width. Actual filter depth is 5-7/8" or 11-1/2"

5. Pressure drop values shown are for synthetic media. Glass media approximately 20% greater.

6. Perfmormance values shown in this publication may be averages or estimates intended to generally represent product

styles. Contact factory for latest actual test data on specific Flanders Precisionaire models.

Flanders PrecisionAire ~ Foremost in Air Filtration

2

Toll Free:1-800-637-2803

Page 3

Double Turned flange

for a stronger frame.

Corrosion Resistant Steel Frame

• 5-7/8" or 11-1/2"

depths

Choice of media

Lofted fiberglass or

micro-fine synthetic

Diagonal support

prevent racking.

• Available with or

without header

• Class 1 available

with glass media

and metal fingers.

Robust Media Support

Expanded metal pleat

backng and choice of metal

or plastic pleat supports.

Rigid-Air Box Type Filter

With Metal Pleat Separators

Flanders PrecisionAire ~ Foremost in Air Filtration

Toll Free:1-800-637-2803

Rigid-Air Filter with Header and

Plastic Pleat Separators

3

Page 4

Application Guidelines

Hospital Applications

Rigid-Air filters may be used wherever job

requirements and available space will

accommodate 6" or 12" deep filters. Rigid-Air filters

should be selected using 24" x 24" and 24" x 12"

face sizes. This allows for 12" increments in height

and width of the filter bank and insures that

replacement cartridges will be readily available.

Rigid-Air filters should be installed with pleats vertical

wherever possible. It is permissible to install 24" x

12" face size cartridges with pleats horizontal if

necessary to meet the size requirements of the filter

bank.

VAV Systems

Filter banks should be sized so that the maximum

rated flow at design conditions falls within the

published recommended velocities. Rigid-Air filters

may be applied at any capacity between zero flow

and cataloged capacities.

Guide Specifications

1.0 General

1.1 Medium and high efficiency self-supporting filters

shall be Rigid-Air lofted fiberglass or micro-fine

synthetic media rigid filters as manufactured by

Flanders Precisionaire.

1.2 Filter sizes, efficiencies and capacities shall be

as scheduled on the drawings.

2.0 Filter Construction

2.1 Filters shall be constructed of lofted micro-fine

fiberglass or micro-fine synthetic media

laminated to a non-woven backing, bonded to

an expanded metal wire grid and pleated to form

the filter pack.

2.2 The filter pack shall be strengthened on the air

entering and air exiting sides with horizontal and

diagonal metal support members.

2.3 The enclosing frame shall be assembled in a

rigid manner and shall incorporate a header on

the air entering side if required by the application.

Rigid-Air filters may be used on the downstream

side of the supply fan in hospitals if they are far

enough from the fan so that the high fan discharge

velocity will not affect them. Rigid-Air rigid filters can

withstand adverse air flow conditions better than

bag filters and are the preferred selection for these

applications.

Gasketed Headers

Rigid-Air headered filters installed in Flanders KTrac Filter Framing Modules or Sureseal Side

Access Housings require gaskets on opposite

header sides to prevent air bypass.

To specify headered version Rigid-Air filters with

gasketed headers, add suffix “SA” (side access),

“GU” (upstream), “GD” (downstream) and “GS”

(sides) to the model number.

2.4 The filter pack shall be sealed into a 24 ga.

corrosion-resistant steel casing with metal or

plastic pleat separators on the upstream and

downstream sides to maintain pleat

configuration.

3.0 Performance

3.1 Initial and final resistances shall not exceed the

scheduled values.

3.2 Media area must equal or exceed that of the

specified filter.

3.3 The average efficiency shall be as determined

by the ASHRAE Standard 52.1 test methods.

3.4 The Filter shall meet MERV 10-14 as determined

by ASHRAE Standard 52.2 test standards.

3.5 The manufacturer shall guarantee performance

as stated in its literature within tolerances as

outlined is Section 7.4 of ARI Standard 850.

3.6 Filters to be UL 900 Class 2 or 1 listed.

Representative

Flanders ~ PrecisionAire

Foremost in Air Filtration

:

Toll Free

4

1-800-637-2803

Flanders PrecisionAire ~ Foremost in Air Filtration

Toll Free:1-800-637-2803

Loading...

Loading...