Page 1

PRECISION HARDWARE

APEX 2000 SERIES

Page 2

TABLE OF CONTENTS

GENERAL INFORMATION

WIDE STILE EXIT DEVICES & TRIMS Page

Rim Devices ..................................................................4, 5

Surface Vertical Rod Devices ........................................6, 7

Mortise Devices ............................................................8, 9

Wood Door Concealed Vertical Rod Devices ............14, 15

Concealed Vertical Rod Devices ..............................16, 17

NARROW STILE EXIT DEVICES & TRIMS

Rim Devices ..............................................................10, 11

Concealed Vertical Rod Devices ..............................12, 13

MULLIONS

Removable Mullion ..........................................................18

Fire Labeled Removable Mullion ....................................18

Key Removable Mullion ..................................................18

EXIT DEVICE OPTIONS

ALK Exit Alarm (Battery Operated) ................................27

ALW Exit Alarm (Remote Power) ....................................27

BRL Braille Touchbar ......................................................35

CD Cylinder Dogging ......................................................19

DE Delayed Egress ..................................................24, 25

DS Door Position Switch..................................................29

E Electric Rim & Mortise Devices ....................................28

ELR Electric Latch Retraction ............................21, 22, 23

HC Windstorm and Hurricane Code Devices ..................20

LD Less Dogging ............................................................19

LS Latchbolt Monitoring ..................................................29

LDS Latchbolt Monitoring Double Switch ........................29

Q Wireless Access Management System ..................30-32

TS Touchbar Monitoring ..................................................29

TDS Touchbar Monitoring Double Switch ........................29

WALW Weatherized Exit Alarm (Remote Power) ............27

WTS Weatherized Touchbar Monitoring ..........................29

WTDS Weatherized Touchbar Mon. Double Switch ........29

Double Cylinder ................................................................9

Electric Mortise Lock........................................................28

ACCESSORIES Page

ALK Exit Alarm Kit ..........................................................27

CDK Cylinder Dogging Kit ..............................................19

E Electric Lock/Unlock Kit................................................28

ELR Conversion Kit ........................................................21

ELR150 Power Supply and Modules..........................21,22

LSK Latchbolt Monitoring Conversion Kit........................29

PS160-6 Power Supply....................................................25

TSK Touchbar Monitoring Conversion Kit........................29

Cylinders ..........................................................................19

Double Cylinders Conversion Kit ....................................19

Sex Nuts & Bolts................................................................3

Strikes ..............................................................................34

MISCELLANEOUS COMPONENTS

Braille Touchbar ..............................................................35

Dummy Touchbar ............................................................35

End Cap & Mounting Bracket ..........................................35

Dogging Key & Rod Guide ..............................................35

Fire Bolt Assembly ..........................................................35

Power Transfers ..............................................................35

Security Screws ..............................................................35

Shim Kit............................................................................35

Top Rod & Bottom Rod lengths ......................................35

ADDITION INFORMATION

Introduction ........................................................................2

Base Material and Finishes ..............................................3

DE Application Charts......................................................26

Device Dimensions ..........................................................37

Device Minimum Stile Width......................................36, 37

ELR application Charts ....................................................23

Fasteners ..........................................................................3

Fire Label Rating Chart....................................................33

Quiet Operation..................................................................2

Touchbar Clearance ..........................................................2

Trim Dimensions ..............................................................38

Introduction

The Apex 2000 Series Touchbar Style Exit Device is highly

regarded by architects and end-users alike. Many of the nation’s

largest healthcare and educational facilities prefer the Apex for

it’s aesthetic design and efficient engineering. All Apex 2000

Series Exit Devices are UL listed for panic and fire hardware

and are certified to ANSI A156.3 Grade 1. Several models are

also certified for hurricane resistant applications.

A complete offering of mechanical and electrical options provide

a wide range of exit device security solutions. However, the

traditional core strenghts of the product can’t be overstated.

Simple operation with few moving parts, manufactured with true

Touchbar Clearance

The Apex Wide Stile Series Exit Devices accommodate doors

with vision lites or glass windows where the vision lite frames

or moldings project up to 1/4 beyond the face of the door. The

Active Case and End Cap Mounting Bracket are mounted on the

face of the door without shims or without cutting the glass molding. These devices have a 1/4" gap between the face of the door

and the Touchbar Assembly. This gap allows proper functioning

of the devices even on doors which are not perfectly flat. Since

the Active Case is mounted directly on the face of the door, it

accommodates standard lengths of through bolting screws,

thumbpieces, knob & lever Trim fingers, and cylinder tail pieces.

ANSI/BHMA architectural finishes. The chassis is constructed

from investment cast steel and the universal mounting holes

provide an easier retrofit installation.

Quiet Operation

Sound Dampeners reduce the noise associated with Exit Device

1/4" Gap

operation on the depression and return stroke of the Touchpad.

2

APEX 2000 SE

Exit Device

Door (Top View)

Page 3

GENERAL INFORMATION

C - Touch Bar End Caps

D - Touch Bar

B - Lock Side Filler

A - Active Case Cover

Base Materials

Finishes ANSI/BHMA US Aluminum Brass Bronze Stainless Steel

Polished Brass, Clear Coated 605 US3

Satin Brass, Clear Coated 606 US4

Satin Bronze, Clear Coated 612 US10

Dark Oxidized Satin Bronze 613 US10B

Satin Aluminum, Clear Anodized 628 US28

Satin Stainless Steel 630 US32D

Finishes

ANSI/BHMA US Description

605 US3 Polished Brass, Clear Coated

606 US4 Satin Brass, Clear Coated

612 US10 Satin Bronze, Clear Coated

613 US10B Dark Oxidized Satin Bronze

625 US26 Polished Chromium Plated

628 US28 Satin Aluminum, Clear Anodized

630 US32D Satin Stainless Steel

Antimicrobial finishes

626AM Satin Chrome Plated with

UltraShield™ Antimicrobial

coating

630AM Satin Stainless Steel with

UltraShield™ Antimicrobial

coating

Mullion finishes

600 USP Primed for Paint

689 Aluminum Paint

695 Dark Bronze Paint

Fasteners

Furnished standard with machine screws and full

thread wood/sheet metal screws. Specify Sex Nuts

and Bolts (SNB) where recommended or required by

the door manufacturer.

–– A,B,C,D,E,F,G,H –– ––

–– A,B,C,D,E,F,G,H –– ––

–– –– A,B,C,D,E,F,G,H ––

–– –– A,B,C,D,E,F,G,H ––

A,E,F –– –– B,C,D,G,H

–– –– –– A,B,C,D,E,F,G,H

Security Screws

All exposed screws will be a Torx pin in tamper resistant

type, machine screws only. Specify (SEC) Security

Screws. Cover Screws use

a T20 driver, End Cap

Screws use a T25 driver.

Door Sizes

Stock sizes for door widths and heights are listed below. If

required, cut to size in the field.

Door Widths Stock Sizes

2'-0"to 2'-6

2'-7"to 3'-0

3'-1"to 4'-0

* Not available for Narrow Stile Devices.

Vertical Rod Devices

Device Door Heights Stock Sizes

Surface Vertical up to 7'-0

Rod Device* 7'-1"to 8'-0

Concealed Vertical 6'-8"to 8'-0

Rod Device 8'-1"to 10'-0

* Surface Vertical Rods are furnished of the same material as

the device. Stainless steel rods are furnished for 625, 628

and 630 devices.

Hand of Doors

E - Device Channel

F - Hinge Slide Filler

"

"

"

2'-6"*

3'-0

"

4'-0

"

8'-1"to 10'-0

G - Device Endcap

H - Rods and Latch Covers

(for Surface Vertical Rod

Devices)

"

"

"

"

"

7'-0

8'-0

10'-0

8'-0

10'-0

"

"

"

"

"

GENERAL INFORMATION

Sex Nuts & Bolts

Sex Nuts & Bolts are

furnished with No. 10-24

x 1"OHMS (1-1/2"long

screws required for

guides).

RIES DEVICES

(not furnished std.)

1-5/8

"

Inside

LHRB Shown RHRB Shown

Outside

3

Page 4

RIM EXIT DEVICES

S300

Standard

RIM EXIT DEVICES

Apex 2100 Series Apex FL2100 Fire Exit Series -

DOORS - For all types of single and double doors with a mullion.

For mullions, see page 18. Available for 1-3/4"to 2-1/4"thick,

up to 4'-0"wide opening. For thicker doors, consult factory.

Furnished standard for 1-3/4"thick, 3'-0"wide opening.

DEVICE - Covers ANSI A115.2 (Type 161), A115.18 cylinder

lock and A115.1 (Type 86) Mortise Lock preparation.

FUNCTIONS - Functions are field selectable except for the

Double Cylinder option. The device is furnished for a desired

function if specified. If not specified the “03” function is

furnished standard.

DOUBLE CYLINDER - Handed, “10” Function available.

Requires two rim type cylinders, not furnished standard.

See page 5 and 19.

BASE MATERIAL - The Cover, Touchbar, Device Channel,

Lock/Hinge Side Filler and End Cap are furnished of heavy

wrought Brass, Bronze or Stainless Steel. 628 Devices are

furnished with Aluminum, Brass, Bronze and Stainless Steel

components. See “Finish & Base Material” chart page 3.

CHASSIS - Investment Cast Steel, Zinc Dichromated.

LATCHBOLT - Stainless Steel, Deadlocking, 3/4"throw.

STRIKES - No. S300, Investment Cast Stainless Steel, Black

Powder Coated furnished standard. No. S988, optional strike

for use on Aluminum Door applications, please specify when

ordering. No. S458, optional strike for use on Mullion applications, please specify when ordering.

For optional strike information see page 34.

DOGGING - 1/4

on Fire Exit Hardware.

TOUCHBAR HEIGHT - 39-15/16

varied as situation dictates.

REVERSIBLE - Reversible for all functions and Trims.

Standard packaging RHRB.

UL LISTED - Panic and Fire Exit Hardware. For FIRE EXIT

HARDWARE Ratings see page 33. Conforms to UL10C and

UBC 7-2.

ANSI/BHMA - Devices are BHMA certified for ANSI 156.3,

Grade 1.

FINISHES - 605, 606, 612, 613, 625, 628, 630.

For Finish description see page 3.

Reversible

"

turn hex key dogging standard. NOT available

"

from floor standard. May be

S301

Optional

S458

Optional

S988

Optional

Reversible

CYLINDERS - Rim Type, not furnished standard. Specify when

required. For cylinder details see page 19.

STILE WIDTH - See Stile Information on page 36.

RETROFIT APPLICATIONS - The 2100 and FL2100 Series

Devices are designed to retrofit into other manufacturers’

mounting hole locations. 1700 Series Pull Trim and 4900

Series Lever Trim may also be factory set for these

applications by specifying prefix “R” (e.g. 2108 R4908A).

Consult factory for details.

Apex 21 Series –

Nonhanded

The 21 Series Device is designed to be compatible with many

manufacturers’ Access Control exterior trim. The device incorporates a center driven cam to receive the tailpiece of the

access control product. The tailpiece rotation required to

retract the latch is a minimum of 50 degrees.

Consult factory for details.

DEVICE OPTIONS

Prefix Description Page

DE Delayed Egress ..................................................24

E Electric Device ....................................................28

ELR Electric Latch Retraction ....................................21

FL Fire Exit Hardware ................................................4

HC Windstorm and Hurricane Code Device .............20

LDS Latchbolt Monitoring Double Switch ...................29

LS Latchbolt Monitoring Switch ................................29

Q Wireless Access Management System..........30-32

TDS Touchbar Monitoring Double Switch....................29

TS Touchbar Monitoring Switch ................................29

WTDS Weatherized Touchbar Mon. Dbl. Switch ............29

WTS Weatherized Touchbar Monitoring Switch ..........29

To specify add Prefix to Device No. (e.g. TS2103)

Suffix Description Page

ALK Exit Alarm: battery operated................................27

ALW Exit Alarm: remote power....................................27

BRL Braille Touchbar ..................................................35

CD Cylinder Dogging ................................................19

DS Door Position Monitoring Switch ........................29

LD Less Dogging ......................................................19

SEC Security Screws ....................................................3

SNB Sex Nut and Bolt ..................................................3

WALW Weatherized Exit Alarm: remote power ..............27

To specify add Suffix to Device No. (e.g. 2103CD)

4

APEX 2000 SE

Page 5

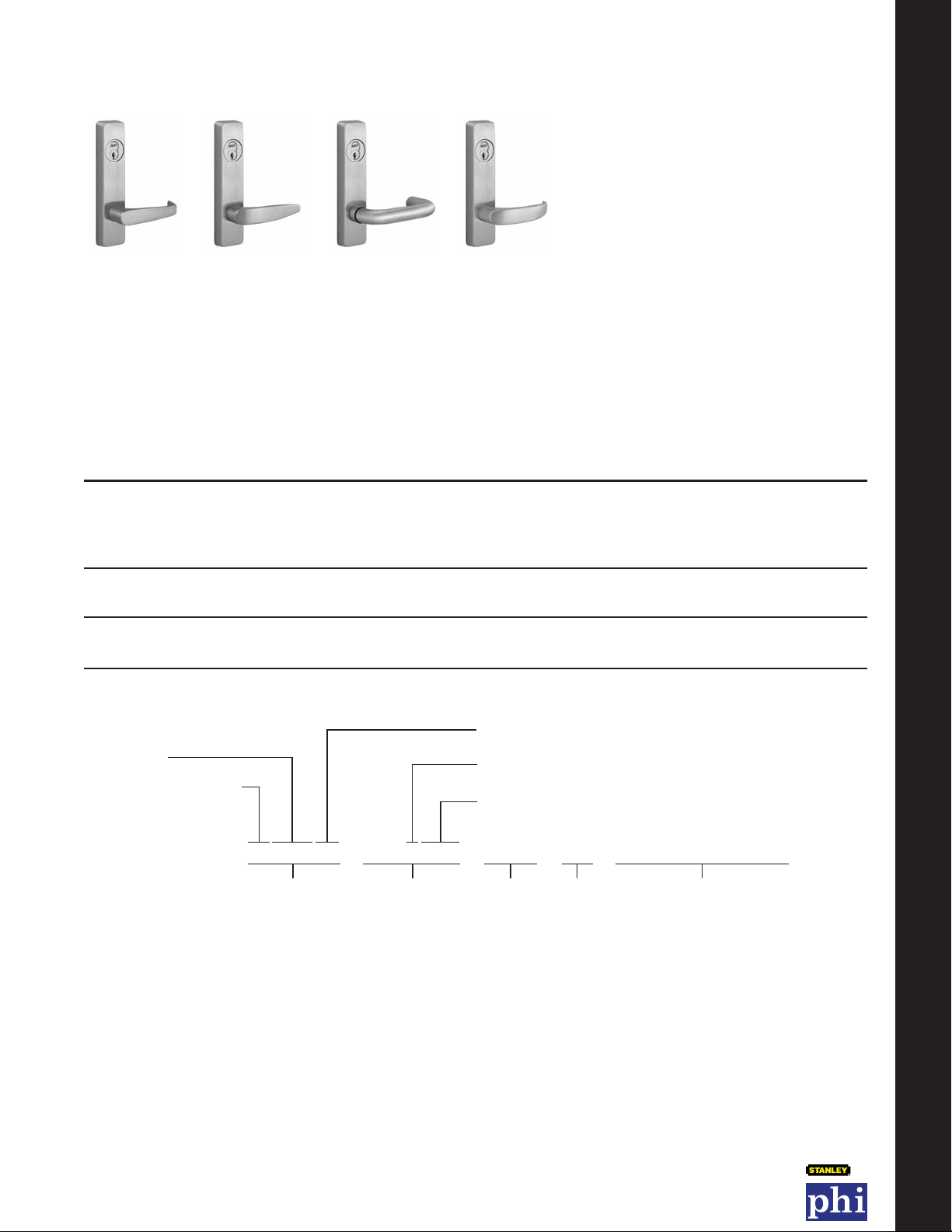

1700A

“A” Grip

1700B

“B” Grip

1700C

“C” Grip

2000C

“C” Grip

TRIMS

1. All Trims are furnished with wrought plates

and extruded or cast solid grips.

2. Specify Grip Design (A,B,C) (“A” Grip

furnished standard for 1700 Series Trim, “C”

Grip furnished standard for 2000 Series Trim)

3. 630 Trim is furnished for 628 Devices.

Retrofit Applications

The R1700 Series Trim is designed to retrofit

into other manufacturers’ installations when

used with the wide stile Apex Series Devices.

Consult factory for details.

TRIMS

4900A

“A” Lever

1. All the escutcheons and levers are castings or forgings.

2. Specify Lever or Knob Design (A,B,C,D,K) and Handing

(“A” Lever x RHRB furnished standard)

3. 626 Trim furnished for 628 and 630 Devices.

• For Trim dimensions see page 38.

• Trims are BHMA certified for ANSI 156.3, Grade 1.

• Trims are through bolted and will cover 161 and 86 cutouts (except for 2000C Trim).

• Cylinder, Rim Type, not furnished standard. For cylinder details see page 19.

ANSI 01 02 03 05 08 10* 14 15

Function Double Cylinder No Cylinder No Cylinder

Device 2101 2102 2103** 2105 2108 2110 2114 2115

Nos. FL2101 FL2103** FL2105 FL2108 FL2110 FL2114 FL2115

Trim 1701 1702A 1703A 1705A 4908A 4908A 4914A 1715A

Nos. R1701 R1702A R1703A R1705A V4908A V4908A R4914A R1715A

4900B

“B” Lever

Exit Only Dummy Key Key Key Inside Key Lever/Knob Thumbpiece

(cover plate) Trim Retracts Locks/Unlocks Locks/Unlocks Locks/Unlocks Always Always

2101 2102C 2103C 2105C R4908A R4908A 2015C

4901 4902A 4903A RV4908A RV4908A

R4901 R4902A R4903A

4900C

“C” Lever

Latchbolt Thumbpiece Lever/Knob Lever/Knob Active Active

4900D

“D” Lever

4900K

“K” Knob

V4908A

Vandal Resistant Trim

A heavy duty lever trim designed to with

stand abuse and vandalism. Composed of

extra strength shock-absorbing “overload”

springs and heavy duty investment cast

stainless steel internal components. Lever

returns to the “home” position eliminating the

need to reset the lever.

Retrofit Applications

The R4900 Series Trim is designed to retrofit

into other manufacturers’ installations when

used with the wide stile Apex Series

Devices.Consult factory for details.

Device with Trim:

Device No.

Add Prefix for options,

see page 4.

Add Suffix: for options, see page 4.

Add Prefix: “V” Vandal Resistant Lever Trim

“R” Retrofit Trim

Add Suffix: Lever or Knob Design (A,B,C,D, K)

Grip Design (A,B,C)

Add Suffix: “KNR” Knurled Lever or Grip

TS2108CD x V4908AKNR x RHRB x 630 x S300 x 3'-0" x 7'-0" x 1-3/4"

Device w/options Trim No. Hand Finish Strike Door Size

Device Only:

Trim Only: Trim no., hand, finish, strike, and door size including thickness: (e.g. V4908A x RHRB x 626 x 1-3/4" )

* “10” Function is handed

** 2103 & FL2103 x Cylinder Only Application includes Cylinder Attachment Kit “CA-03”

Device no., hand, finish, strike, and door size including thickness:

(e.g. TS2108CD x RHRB x 630 x S300 x 3'-0" x7'-0" x 1-3/4" )

5

Page 6

SURFACE VERTICAL ROD EXIT DEVICES

SURFACE VERTICAL ROD EXIT DEVICES

S300

Apex 2200 Series Apex FL2200 Fire Exit Series -

DOORS - For all types of single and double door

applications. Available for 1-3/4" to 2-1/4" thick, up to

4'-0" wide by 10'-0" high openings. For thicker doors,

consult factory. Furnished standard for 1-3/4" thick, 3'-0"

wide by 7'-0" high openings.

DEVICE - Covers ANSI A115.2 (Type 161), A115.18

cylinder lock and A115.1 (Type 86) Mortise Lock

preparation.

FUNCTIONS - Functions are field selectable. The device

is furnished for a desired function if specified. If not

specified the “03” function is furnished standard.

BASE MATERIAL - The Covers, Touchbar, Device

Channel, Lock/Hinge Side Filler, Vertical Rods and End

Cap are furnished of heavy wrought Brass, Bronze or

Stainless Steel. US28 Devices are furnished with

Aluminum, Brass, Br

components. See “Finish & Base Material” chart on

page 3.

CHASSIS - Investment Cast Steel, Zinc Dichromated.

TOP LATCHBOLT - Stainless Steel, Deadlocking,

3/4" throw.

onze and Stainless Steel

Reversible

REVERSIBLE - Reversible for all functions and trims.

Standard packing RHRB.

UL LISTED - Panic and Fire Exit Hardware. For FIRE

EXIT HARDWARE Ratings see page 33. Conforms to

UL10C and UBC 7-2.

ANSI/BHMA - Devices are BHMA certified ANSI 156.3,

Grade 1.

FINISHES - 605, 606, 612, 613, 625, 628, 630. For finish

description see page 3.

CYLINDERS - Rim type, not furnished standard. Specify

when required. For cylinder details see page 19.

STILE WIDTH - See Stile Information on page 36.

LESS BOTTOM ROD (LBR) OPTION - Specify suffix

“LBR” (e.g. 2208LBR). See UL FIRE LABEL RATING

chart on page 39. Fire Rated Devices include FB277

Fire Bolt Assembly. For Fire Bolt Assembly image

see page 35.

RETROFIT APPLICATIONS - The 2200 and FL2200

Series Devices are designed to retrofit into other manu

facturers’ mounting hole locations. 1700 Series Pull Trim

and 4900 Series Lever Trim may also be factory set for

these applications by specifying prefix “R” (e.g. 2208

R4908A).

Reversible

S460

BOTTOM BOLT - Steel plated, independent action 5/8"

throw, with adjustment range to suit 3/4" door undercut.

TOP STRIKE - No. S300 Surface applied, Investment

Cast Stainless Steel, Black Powder Coated furnished

standard. For optional strikes see page 34.

BOTTOM STRIKE - No. S460, Flush mounted, Steel,

Black Powder Coated.

DOGGING - 1/4" turn hex key dogging standard. NOT

available on Fire Exit Hardware.

TOUCHBAR HEIGHT - 39-15/16" from floor standard.

Specify required hei

DEVICE OPTIONS

Prefix Description ....................................................Page

E Electric Device......................................................28

ELR Electric Latch Retraction ......................................21

FL Fire Exit Hardware..................................................6

HC Windstorm and Hurricane Code Device ............20

LS Latchbolt Monitoring Switch ................................29

Q Wireless Access Management System ..30-32

TDS Touchbar Monitoring Double Switch ..................29

TS Touchbar Monitoring Switch ................................29

WTDS Weatherized Touchbar Mon. Dbl Switch ............29

WTS Weatherized Touchbar Mon. Switch ..................29

To specify add Prefix to Device No. (e.g. TS2203)

ght if other than standard.

Apex 22 Series -

The 22 Series Device is designed to be compatible with

many manufacturers’ Access Control exterior trim. The

device incorporates a center driven cam to receive the

tailpiece of the access control product. The tailpiece

rotation required to retract the latch is a minimum of 50

degrees.

Consult factory for details.

Suffix Description Page

ALK Exit Alarm: battery operated ............................27

ALW Exit Alarm: remote power ................................27

BRL Braille Touchbar ................................................35

CD Cylinder Dogging..............................................19

DS Door Position Monitoring Switch ....................29

LBR Less Bottom Rod................................................6

LD Less Dogging ............................................19

SEC Security Screws..................................................3

SNB Sex Nut and Bolt ................................................3

TMB Transom Bracket ..............................................35

WALW Weatherized Exit Alarm: remote power ..........27

To specify add Prefix to Device No. (e.g. TS2203)

Reversible

6

APEX 2000 SE

Page 7

1700A

“A” Grip

1700B

“B” Grip

1700C

“C” Grip

2000C

“C” Grip

TRIMS

1. All Trims are furnished with wrought plates

and extruded or cast solid grips.

2. Specify Grip Design (A,B,C) (“A” Grip

furnished standard for 1700 Series Trim, “C”

Grip furnished standard for 2000 Series Trim)

3. 630 Trim is furnished for 628 Devices.

Retrofit Applications

The R1700 Series Trim is designed to retrofit

into other manufacturers’ installations when

used with the wide stile Apex Series Devices.

Consult factory for details.

TRIMS

4900A

“A” Lever

1. All the escutcheons and levers are castings or forgings.

2. Specify Lever or Knob Design (A,B,C,D,K) and Handing

(“A” Lever x RHRB furnished standard)

3. 626 Trim furnished for 628 and 630 Devices.

• For Trim dimensions see page 38.

• Trims are BHMA certified for ANSI 156.3, Grade 1.

• Trims are through bolted and will cover 161 and 86 cutouts (except for 2000C Trim).

• Cylinder, Rim Type, not furnished standard. For cylinder details see page 19.

ANSI 01 02 03 05 08 14 15

Function Exit Only Dummy Key Key Key No Cylinder No Cylinder

Device 2201 2202 2203** 2205 2208 2214 2215

Nos. FL2201 FL2203** FL2205 FL2208 FL2214 FL2215

Trim 1701 1702A 1703A 1705A 4908A 4914A 1715A

Nos. R1701 R1702A R1703A R1705A V4908A R4914A R1715A

4900B

“B” Lever

(cover plate) Trim Retracts Locks/Unlocks Locks/Unlocks Lever/Knob Thumbpiece

2101 2102C 2103C 2105C R4908A 2015C

4901 4902A 4903A RV4908A

R4901 R4902A R4903A

4900C

“C” Lever

Latchbolt Thumbpiece Lever/Knob Always Active Always Active

4900D

“D” Lever

4900K

“K” Knob

V4908A

Vandal Resistant Trim

A heavy duty lever trim designed to with

stand abuse and vandalism. Composed of

extra strength shock-absorbing “overload”

springs and heavy duty investment cast

stainless steel internal components. Lever

returns to the “home” position eliminating the

need to reset the lever.

Retrofit Applications

The R4900 Series Trim is designed to retrofit

into other manufacturers’ installations when

used with the wide stile Apex Series

Devices.Consult factory for details.

Device with Trim:

Device No.

Add Prefix for options,

see page 6.

Add Suffix: for options, see page 6.

Add Prefix: “V” Vandal Resistant Lever Trim

“R” Retrofit Trim

Add Suffix: Lever or Knob Design (A,B,C,D,K)

Grip Design (A,B,C)

Add Suffix: “KNR” Knurled Lever or Grip

TS2208CD x V4908AKNR x RHRB x 630 x 3'-0" x 7'-0" x 1-3/4"

Device w/options Trim No. Hand Finish Door Size

Device Only:

Trim Only: Trim no., hand, finish, strike, and door size including thickness: (e.g. V4908A x RHRB x 626 x 1-3/4" )

* 2203 & FL2203 x Cylinder Only Application includes Cylinder Attachment Kit “CA-03”

Device no., hand, finish, strike, and door size including thickness:

(e.g. TS2208CD x RHRB x 630 x 3'-0" x7'-0" x 1-3/4" )

7

Page 8

MORTISE EXIT DEVICES

S982

MORTISE EXIT DEVICES

Apex 2300 Series Apex FL2300 Fire Exit Series -

DOORS - For all types of single and double door applications.

Available for 1-3/4" to 2-1/4" thick, up to 4-0" wide opening.

For thicker door, consult factory. Furnished standard for

1-3/4" thick, 3'-0" wide opening.

DEVICE - Covers ANSI A115.1 (Type 86) Mortise Lock

preparation.

DOUBLE CYLINDER - Handed, “10” Function available.

Requires one rim type cylinder and one 1-1/4" long mortise

type cylinder, not furnished standard. See page 9 and 19.

BASE MATERIAL - The Cover, Touchbar, Device Channel,

Lock/Hinge Side Filler and End Cap are furnished of heavy

wrought Brass, Bronze or Stainless Steel. US28 Devices are

furnished with Aluminum, Brass, Bronze and Stainless Steel

components. See “Finish & Base Material” chart on page 3.

CHASSIS - Investment Cast Steel, Zinc Dichromated.

DOGGING - 1/4" turn hex key dogging standard. NOT available

on Fire Exit Hardware.

TOUCHBAR HEIGHT - 39-15/16" from floor standard.

HANDED - Specify hand when ordering as RHRB or LHRB.

Touchbar Assembly, Mortise Lock and Trim may be reversed

in the field. For reversibility of complete device, mortise strike

is required for the other hand.

UL LISTED - Panic and Fire Exit Hardware. For FIRE EXIT

HARDWARE Ratings see page 33. Conforms to UL10C and

UBC 7-2.

ANSI/BHMA - Devices are BHMA certified for ANSI 156.3,

Grade 1.

FINISHES - 605, 606, 612, 613, 625, 628, 630. For finish

description see page 3.

STILE WIDTH - See Stile Information on page 36.

Handed

Handed

CYLINDERS - Mortise type, not furnished standard. For

cylinder details see page 19.

RETROFIT APPLICATIONS - The 2300 and FL2300 Series

Devices are designed to retrofit into other manufacturers’

mounting hole locations. 1700 Series Pull Trim and 4900

Series Lever Trim may also be factory set for these applications by specifying prefix “R” (e.g. 2308 R4908A).

Consult factory for details.

Exit Series -

Fits doors machined per ANSI A115.1 (Type 86) Mortise

Lock preparation.

BACKSET - 2-3/4".

CASE - Wrought Steel, Zinc Dichromate finish.

LOCK FRONT PLATE - 8" x 1-1/4" Bronze, Brass or

Stainless Steel, pivots for beveled or square edged doors.

LATCHBOLT - Stainless Steel, Deadlocking, 3/4" throw,

anti-friction.

GUARDBOLT - Stainless Steel, sliding type.

FINISHES - LOCK FRONT PLATE and STRIKE

605, 606, 612, 613, 625, 630. 630 furnished for 626 and

628 locks. For finish description see page 3.

STRIKES - No. S982, handed curved lip strike furnished

standard. For optional strikes see page 34.

LOCK NO.

• M303: 01, 02 & 03 functions.

• M308: 05, 08, 14 & 15 functions.

• M310: 10 function.

NOTE - For Mortise Lock dimensions see page 28.

For Mortise Lock with Electrical options see page 28.

Handed

DEVICE OPTIONS

Prefix Description Page

DE Delayed Egress ..................................................24

E Electric Lock/Unlock............................................28

ELR Electric Latch Retraction ....................................21

FL Fire Exit

HC Windstorm and Hurricane Code Device ............20

LS Latchbolt Monitoring, “03” Function ..............28, 29

LS Latchbolt and Trim locked or unlocked

monitoring, “08” Function ..............................28, 29

TDS Touchbar Monitoring Double Switch ..................29

TS Touchbar Monitoring Switch................................29

To specify add Prefix to Device No. (e.g. TS2303)

8

Hardware ....

............................................8

Prefix Description Page

WTDS Weatherized Touchbar Mon. Dbl. Switch ............29

WTS Weatherized Touchbar Monitoring Switch ..........29

Suffix Description Page

ALK Exit Alarm: battery operated................................27

ALW Exit Alarm: remote power ....................................27

BRL Braille Touchbar ..................................................35

CD Cylinder Dogging ................................................19

DS Door Position Monitoring Switch ........................29

LD Less Dogging ......................................................19

SEC Security Screws ....................................................3

SNB Sex Nut and Bolt ..................................................3

WALW Weatherized Exit Alarm: remote power ..............27

To specify add Suffix to Device No. (e.g. 2303CD)

APEX 2000 SE

Page 9

1700A

“A” Grip

1700B

“B” Grip

1700C

“C” Grip

2000C

“C” Grip

TRIMS

1. All Trims are furnished with wrought plates

and extruded or cast solid grips.

2. Specify Grip Design (A,B,C) (“A” Grip

furnished standard for 1700 Series Trim, “C”

Grip furnished standard for 2000 Series Trim)

3. 630 Trim is furnished for 628 Devices.

NOTE: B & C grip pull handles are not available in the

05 and 15 functions.

Retrofit Applications

The R1700 Series Trim is designed to retrofit

into other manufacturers’ installations when

used with the wide stile Apex Series Devices.

Consult factory for details.

TRIMS

4900A

“A” Lever

1. All the escutcheons and levers are castings or forgings.

2. Specify Lever or Knob Design (A,B,C,D,K) and Handing

(“A” Lever x RHRB furnished standard)

3. 626 Trim furnished for 628 and 630 Devices.

4. All Lever Trims, M4908K and M4914K are Handed, Specify Hand.

• For Trim dimensions see page 38.

• Trims are BHMA certified for ANSI 156.3, Grade 1.

• Trims are through bolted and will cover 161 and 86 cutouts (except for 2000C Trim).

• Cylinder 1-1/4" long Mortise Type, not furnished standard. For cylinder details see page 19.

ANSI 01 02 03 05 08 10* 14 15

Function Exit Only Dummy Key Key Key Double Cylinder No Cylinder No Cylinder

Device 2301 2302 2303** 2305 2308 2310 2314 2315

Nos. FL2301 FL2303** FL2305 FL2308 FL2310 FL2314 FL2315

Trim 1701 1702A 1703A M1705A M4908A M4908A M4914A M1715A

Nos. R1701 R1702A R1703A RM1705A VM4908A VM4908A RM4914A RM1715A

4900B

“B” Lever

(cover plate) Trim Retracts Locks/Unlocks Locks/Unlocks Inside Key Lever/Knob Thumbpiece

2001 2002C 2003C RM4908A RM4908A

4901 4902A 4903A VRM4908A VRM4908A

R4901 R4902A R4903A

4900C

“C” Lever

Latchbolt Thumbpiece Lever/Knob Locks/Unlocks Always Active Always

4900D

“D” Lever

4900K

“K” Knob

V4908A

Vandal Resistant Trim

A heavy duty lever trim designed to with

stand abuse and vandalism. Composed of

extra strength shock-absorbing “overload”

springs and heavy duty investment cast

stainless steel internal components. Lever

returns to the “home” position eliminating the

need to reset the lever.

Retrofit Applications

The R4900 Series Trim is designed to retrofit

into other manufacturers’ installations when

used with the wide stile Apex Series

Devices.Consult factory for details.

Lever/Knob Active

Device with Trim:

Device No.

Add Prefix for options,

see page 8.

Add Suffix: for options, see page 8.

Add Prefix: “V” Vandal Resistant Lever Trim

“M” Mortise Trim (per specific function, see above)

“R” Retrofit Trim

Add Suffix: Lever or Knob Design (A,B,C,D,K)

Grip Design (A,B,C)

Add Suffix: “KNR” Knurled Lever or Grip

TS2308CD x V4908AKNR x RHRB x 630 x S982 x 3'-0" x 7'-0" x 1-3/4"

Device w/options Trim No. Hand Finish Strike Door Size

Device Only:

Trim Only: Trim no., hand, finish, strike, and door size including thickness: (e.g. VM4908A x RHRB x 626 x 1-3/4" )

Device no., hand, finish, strike, and door size including thickness:

(e.g. TS2108CD x RHRB x 630 x S982 x 3'-0" x7'-0" x 1-3/4" )

9

Page 10

RIM EXIT DEVICES

S988

For (single)

aluminum

door

applications.

S458

For (paired) mullion

applicaions.

NARROW RIM EXIT DEVICES

Apex 2400 Series Apex FL2400 Fire Exit Series -

Non Handed

DOORS - For all types of single and double doors with a

mullion. For mullions, see page 18. Available for 1-3/4"to

2-1/4"thick, up to 4'-0"wide opening. For thicker door,

consult factory. Furnished standard for 1-3/4"thick, 3'-0

"

wide opening.

FUNCTIONS - A universal exit device. Add trim for desired

function.

BASE MATERIAL - The Cover, Touchbar, Device Channel,

Lock/Hinge Side Filler and End Cap are furnished of heavy

wrought brass, bronze or stainless steel. US28 devices

are furnished with aluminum, brass, bronze and stainless

steel components. See “Finish & Base Material” chart on

page 3.

CHASSIS - Investment cast steel, zinc dichromated.

LATCHBOLT - Stainless steel, deadlocking, 3/4"throw.

STRIKES -

No. S988, for (single) aluminum door applications, Black

Powder Coated Stainless Steel Roller Strike.

No. S458, for (paired) mullion applications, please specify

when ordering.

For optional strike information see page 34.

DOGGING - 1/4"turn hex key dogging standard.

NOT available on Fire Exit Hardware.

TOUCHBAR HEIGHT - 39-15/16"from floor standard. May

be varied as situation dictates.

UL LISTED - Panic and Fire Exit Hardware. For FIRE EXIT

HARDWARE Ratings see page 33. Conforms to UL10C

and UBC 7-2.

ANSI/BHMA - Devices are BHMA certified for ANSI 156.3,

Grade 1.

Non Handed

FINISHES - 605, 606, 612, 613, 625, 628, 630. For finish

description see page 3.

CYLINDERS - Rim type for “03” function, Mortise type for

“08” function. Use 1-1/4"long standard mortise cylinder.

Cylinders are not furnished standard. Specify when

required. For cylinder details see page 19.

STILE WIDTH - See Stile Information on page 37.

DEVICE OPTIONS

Prefix Description Page

DE Delayed Egress ..................................................24

ELR Electric Latch Retraction ....................................21

FL Fire Exit Hardware ..............................................10

TDS Touchbar Monitoring Double Switch....................29

TS Touchbar Monitoring Switch ................................29

WTDS Weatherized Touchbar Mon. Dbl. Switch ............29

WTS Weatherized Touchbar Monitoring Switch ..........29

To specify add Prefix to Device No. (e.g. TS2403)

Suffix Description Page

ALK Exit Alarm: battery operated................................27

ALW Exit Alarm: remote power ....................................27

BRL Braille Touchbar ..................................................35

CD Cylinder Dogging ................................................19

DS Door Position Monitoring Switch ........................29

LD Less Dogging ......................................................19

SEC Security Screws ....................................................3

SNB Sex Nut and Bolt ..................................................3

WALW Weatherized Exit Alarm: remote power ..............27

To specify add Suffix to Device No. (e.g. 2403CD)

10

APEX 2000 SE

Page 11

2900A

“A” Lever

• For Trim dimensions see page 38.

• Trims are BHMA certified for ANSI 156.3, Grade 1.

• Trims are through bolted.

• Cylinder, not furnished standard – Rim type for “03” function, 1-1/4"long mortise type for “08” function.

For cylinder details see page 19.

2900B

“B” Lever

2900C

“C” Lever

2900D

“D” Lever

2000C

“C” Grip

1. All the escutcheons and levers are castings

or forgings.

2. For Lever Trim specify Lever Design

(A, B, C, D) and Handing (“A” Lever RHRB

furnished standard).

3. For 2900 Series Trim, 626 finish is furnished

for 628 and 630 Devices.

4. 2000 Series Trim is furnished with a wrought

plate and extruded solid “C” Grip.

TRIMS

TRIMS

ANSI 01 02 03 08 14

Function Exit Only Dummy Key Key No Cylinder

Device 2401 2402 2403* 2408 2414

Nos. FL2401 FL2403* FL2408 FL2414

Trim 2901 2902A 2903A 2908A 2914A

Nos. 2001 2002C 2003C

Device with Trim:

Device No.

Add Prefix for options,

see page 10.

(cover plate) Trim Retracts Locks/Unlocks Lever

Latchbolt Lever Always Active

Add Suffix: for options, see page 10.

Add Suffix: Lever Design (A,B,C,D)

Grip Design (C)

Add Suffix: “KNR” Knurled Lever

TS2408CD x 2908AKNR x RHRB x 630 x S988 x 3'-0" x 7'-0" x 1-3/4"

Device w/options Trim No. Hand Finish Strike Door Size

Device Only:

Trim Only: Trim no., hand, finish, strike, and door size including thickness: (e.g. 2908A x RHRB x 626 x 1-3/4" )

Device no., hand, finish, strike, and door size including thickness:

(e.g. TS2408CD x RHRB x 630 x S988 x 3'-0" x7'-0" x 1-3/4" )

* 2403 & FL2403 x Cylinder Only Application includes Cylinder Attachment Kit “NCA-03”

11

Page 12

NARROW CONCEALED VERTICAL ROD EXIT DEVICES

S519

Apex 2600 Series Apex FL2600 Fire Exit Series -

Reversible

Reversible

DOORS - For all types of metal single and double door

applications. Available for 1-3/4" to 2-1/4" thick, up to

4'-0" wide by 10'-0" high openings. For thicker doors,

consult factory. Furnished standard for 1-3/4" thick, 3'-0"

wide by 6'-8" to 8'-0" high openings.

FUNCTIONS - A Universal Exit Device. Add Trim for

desired function.

BASE MATERIAL - Side Filler and End Cap are

furnished of heavy wrought Brass, Bronze or Stainless

Steel. 628 Devices are furnished with Aluminum, Brass,

Bronze and Stainless Steel components. See “Finish &

Base Material” chart on page 3.

CHASSIS - Lock Stile Assembly - Investment Cast Steel,

Zinc Dich-romated.

TOP LATCHBOLT - Stainless Steel, Deadlocking,

3/4" throw.

TOP STRIKE - No. S519 Surface applied, Investment Cast

Stainless Steel, Black Powder Coated.

BOTTOM STRIKE - No. S460, Flush mounted, Steel, Black

Powder Coated.

DOGGING - 1/4" turn hex key dogging standard.

NOT available on Fire Exit Hardware.

TOUCHBAR HEIGHT - 39-15/16" from floor standard.

Specify required height if other than standard.

UL LISTED - Panic and Fire Exit Hardware. For FIRE

EXIT HARDWARE Ratings see page 33. Conforms to

UL10C and UBC 7-2.

ANSI/BHMA - Devices are BHMA certified for ANSI 156.3,

Grade 1.

FINISHES - 605, 626, 612, 613, 625, 628, 630. For finish

description see page 3.

CYLINDERS - Rim Type for “03” function, 1-1/4" Long

Mortise Type for “08” function. Cylinders are not furnished

standard. Specify when required. For cylinder details see

page 19.

NARROW CONCEALED VERTICAL ROD EXIT DEVICES

12

S460

BOTTOM BOLT - Steel plated, independent action 5/8"

throw, with adjustment range to suit 3/4" door undercut.

CENTER CHASSIS - Steel plated, heavy wrought Steel

Assembly with lock in place Top and Bottom Latch

Adjustors. Adjustment is accessible through the door

after installation.

DEVICE OPTIONS

Prefix Description Page

DE Delayed Egress ................................................24

ELR Electric Latch Retraction ..................................21

FL Fire Exit Hardware............................................12

TDS Touchbar Monitoring Double Switch ..............29

TS Touchbar Monitoring Switch ............................29

WTDS Weatherized Touchbar Mon. Dbl. Switch ......29

WTS Weatherized Touchbar Mon. Switch ..............29

To specify add Prefix to Device No. (e.g. TS2603)

APEX 2000 SE

STILE WIDTH - See Stile Information on page 37.

LESS BOTTOM ROD (LBR) OPTION - Specify suffix

“LBR” (e.g. 2603LBR). See UL FIRE LABEL RATING

Chart on page 33. Fire Rated Devices include FB277

Fire Bolt Assembly. For Fire Bolt Assembly image

see page 35.

Suffix Description Page

ALK Exit Alarm: battery operated ............................27

ALW Exit Alarm: remote power ................................27

BRL Braille Touchbar ................................................35

CD Cylinder Dogging..............................................19

DS Door Position Monitoring Switch ....................29

LBR Less Bottom Rod..............................................12

LD Less Dogging ............................................19

SEC Security Screws..................................................3

SNB Sex Nut and Bolt ................................................3

WALW Weatherized Exit Alarm: remote power..........27

To specify add Prefix to Device No. (e.g. TS2603)

Page 13

2900A

“A” Lever

2900B

“B” Lever

2900C

“C” Lever

2900D

“D” Lever

1. All the escutcheons and levers are castings

or forgings.

2. Specify Lever Design (A, B, C, D) and

Handing (“A” Lever RHRB furnished

standard).

3. 626 finish is furnished for 628 and 630

Devices.

• For Trim dimensions see page 38.

• Trims are BHMA certified for ANSI 156.3, Grade 1.

• Trims are through bolted.

• Cylinder, not furnished standard – Rim type for “03” function, 1-1/4"long mortise type for “08” function.

For cylinder details see page 19.

ANSI 01 02 03 08 14

Function Exit Only Dummy Key Key No Cylinder

(cover plate) Trim Retracts Locks/Unlocks Lever

Latchbolt Lever Always Active

TRIMS

TRIMS

Device 2601 2602 2603* 2608 2614

Nos. FL2601 FL2603* FL2608 FL2614

Trim 2901 2902A 2903A 2908A 2914A

Nos.

Device with Trim:

Device No.

Add Suffix: for options, see page 12.

Add Suffix: Lever Design (A,B,C,D)

Add Prefix for options,

see page 12.

Add Suffix: “KNR” Knurled Lever

TS2608CD x 2908AKNR x RHRB x 630 x 3'-0" x 7'-0" x 1-3/4"

Device w/options Trim No. Hand Finish Door Size

Device Only:

Trim Only: Trim no., hand, finish, strike, and door size including thickness: (e.g. 2908A x RHRB x 626 x 1-3/4" )

* 2603 & FL2603 x Cylinder Only Application includes Cylinder Attachment Kit “NCA-03”

Device no., hand, finish, strike, and door size including thickness:

(e.g. TS2608CD x RHRB x 630 x 3'-0" x7'-0" x 1-3/4" )

13

Page 14

WOOD DOOR CONCEALED VERTICAL ROD EXIT DEVICES

S519

Apex 2700 Series Apex FL2700 Fire Exit Series -

Reversible

Reversible

DOORS - For all types of single and double door

applications. Available for 1-3/4" to 2-1/4" thick, up to

4'-0" wide by 10'-0" high openings. For thicker doors,

consult factory. Furnished standard for 1-3/4" thick, 3'-0"

wide by 6'-8" to 8'-0" high openings.

FUNCTIONS - A Universal Exit Device. Add Trim for

desired function.

BASE MATERIAL - Side Filler and End Cap are

furnished of heavy wrought Brass, Bronze or Stainless

Steel. 628 Devices are furnished with Aluminum, Brass,

Bronze and Stainless Steel components. See “Finish &

Base Material” chart on page 3.

CHASSIS - Lock Stile Assembly - Investment Cast Steel,

Zinc Dich-romated.

VERTICAL RODS - Steel, plated. Top Rod is adjustable

from 6'-8" to 8'-0" or from 8'-1" to 10'-0". Additional

adjustments are available through the lock front filler.

BOTTOM STRIKE - No. S460 Flush mounted, Steel, Black

Powder Coated.

DOGGING - 1/4 turn hex key dogging standard. NOT

available on Fire Exit Hardware.

TOUCHBAR HEIGHT - 39-15/16 from floor standard.

Specify required height if other than standard.

REVERSIBLE - Reversible for all functions and trims.

Standard packaging RHRB.

UL LISTED - Panic and Fire Exit Hardware. For FIRE EXIT

HARDWARE Ratings see page 33. Conforms to UL10C

and UBC 7-2.

ANSI/BHMA - Devices are BHMA certified for ANSI 156.3,

Grade 1.

FINISHES - 605, 606, 612, 613, 625, 628, 630. For finish

description see page 3.

CYLINDERS - Rim Type, not furnished standard. Specify

when required. For cylinder details see page 19.

WOOD DOOR CONCEALED VERTICAL ROD EXIT DEVICES

14

S460

TOP LATCHBOLT - Stainless Steel, Deadlocking, 3/4"

throw.

BOTTOM BOLT - Steel plated, independent action 5/8"

throw, with adjustment range to suit 3/4 door undercut.

TOP STRIKE - No. S519 Surface applied, Investment

Cast Stainless Steel, Black Powder Coated.

DEVICE OPTIONS

Prefix Description Page

DE Delayed Egress....................................................24

E Electric Device......................................................28

ELR Electric Latch Retraction......................................21

FL Fire Exit Hardware ..............................................14

LS Latchbolt Monitoring Switch ................................29

Q Wireless Access Management System ..30-32

TDS Touchbar Monitoring Double Switch ..................29

TS Touchbar Monitoring Switch................................29

WTDS Weatherized Touchbar Mon. Dbl. Switch ..........29

WTS Weatherized Touchbar Mon. Switch ..................29

To specify add Prefix to Device No. (e.g. TS2703)

APEX 2000 SE

STILE WIDTH - See Stile Information on page 36.

LESS BOTTOM ROD (LBR) OPTION - Specify suffix

“LBR” (e.g. 2703LBR). See UL FIRE LABEL RATING

Chart on page 33. Fire Rated Devices include FB277

Fire Bolt Assembly. For Fire Bolt Assembly image

see page 35.

Suffix Description Page

ALK Exit Alarm: battery operated ............................27

ALW Exit Alarm: remote power ................................27

BRL Braille Touchbar ................................................35

CD Cylinder Dogging..............................................19

DS Door Position Monitoring Switch ....................29

LBR Less Bottom Rod..............................................14

LD Less Dogging ............................................19

SEC Security Screws..................................................3

SNB Sex Nut and Bolt ................................................3

WALW Weatherized Exit Alarm: remote power..........27

To specify add Prefix to Device No. (e.g. TS2703)

Page 15

1700A

“A” Grip

1700B

“B” Grip

1700C

“C” Grip

2000C

“C” Grip

TRIMS

1. All Trims are furnished with wrought plates

and extruded or cast solid grips.

2. Specify Grip Design (A,B,C) (“A” Grip

furnished standard for 1700 Series Trim, “C”

Grip furnished standard for 2000 Series Trim)

3. 630 Trim is furnished for 628 Devices.

TRIMS

4900A

“A” Lever

1. All the escutcheons and levers are castings or forgings.

2. Specify Lever or Knob Design (A,B,C,D,K) and Handing

(“A” Lever x RHRB furnished standard)

3. 626 Trim furnished for 628 and 630 Devices.

• For Trim dimensions see page 38.

• Trims are BHMA certified for ANSI 156.3, Grade 1.

• Trims are through bolted and will cover 161 and 86 cutouts (except for 2000C Trim).

• Cylinder, Rim Type, not furnished standard. For cylinder details see page 19.

ANSI 01 02 03 05 08 14 15

Function Exit Only Dummy Key Key Key No Cylinder No Cylinder

Device 2701 2702 2703** 2705 2708 2714 2715

Nos. FL2701 FL2703** FL2705 FL2708 FL2714 FL2715

4900B

“B” Lever

(cover plate) Trim Retracts Locks/Unlocks Locks/Unlocks Lever/Knob Thumbpiece

4900C

“C” Lever

Latchbolt Thumbpiece Lever/Knob Always Active Always Active

4900D

“D” Lever

4900K

“K” Knob

V4908A

Vandal Resistant Trim

A heavy duty lever trim designed to with

stand abuse and vandalism. Composed of

extra strength shock-absorbing “overload”

springs and heavy duty investment cast

stainless steel internal components. Lever

returns to the “home” position eliminating the

need to reset the lever.

Trim 1701 1702A 1703A 1705A 4908A 4914A 1715A

Nos. 2001 2002C 203C 2005C V4908A 2015C

Device with Trim:

Device No.

Add Prefix for options,

see page 14.

4901 4902A 4903A

Add Suffix: for options, see page 14.

Add Prefix: “V” Vandal Resistant Lever Trim

Add Suffix: Lever or Knob Design (A,B,C,D,K)

Grip Design (A,B,C)

Add Suffix: “KNR” Knurled Lever or Grip

TS2708CD x V4908AKNR x RHRB x 630 x 3'-0" x 7'-0" x 1-3/4"

Device w/options Trim No. Hand Finish Door Size

Device Only:

Trim Only: Trim no., hand, finish, strike, and door size including thickness: (e.g. V4908A x RHRB x 626 x 1-3/4" )

* 2703 & FL2703 X Cylinder Only Application includes Cylinder Attachment Kit “CA-03”.

Device no., hand, finish, strike, and door size including thickness:

(e.g. TS2708CD x RHRB x 630 x 3'-0" x7'-0" x 1-3/4" )

15

Page 16

CONCEALED VERTICAL ROD EXIT DEVICES

S519

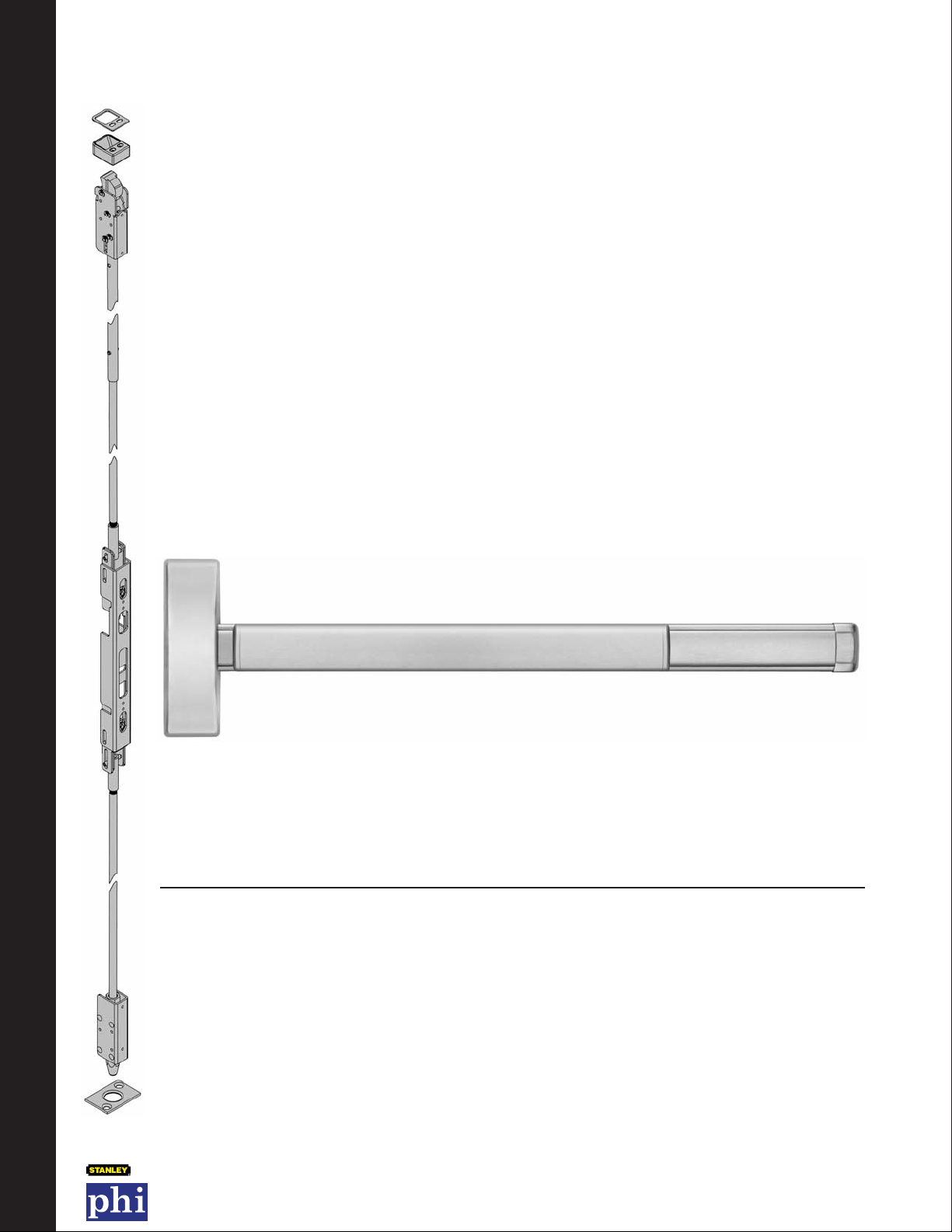

Apex 2800 Series Apex FL2800 Fire Exit Series -

DOORS - For all types of metal single and double door

applications. Available for 1-3/4" to 2-1/4" thick, up to

4'-0" wide by 10-0 high openings. For thicker doors,

consult factory. Furnished standard for 1-3/4" thick, 3'-0"

wide by 6'-8" to 8'-0" high openings.

FUNCTIONS - Functions are field selectable. The device

is furnished for a desired function if specified. If not

specified the “03” function is furnished standard.

BASE MATERIAL - The Cover, Touchbar, Device

Channel, Lock/Hinge Side Filler and End Cap are

furnished of heavy wrought Brass, Bronze or Stainless

Steel. US28 Devices are furnished with Aluminum,

Brass, Bronze and Stainless Steel components. See

“Base Material and Finish Chart” on page 3.

CHASSIS - Lock Stile Assembly - Investment Cast Steel,

Zinc Dichromated.

VERTICAL RODS - Steel, plated. Top Rod is adjustable

from 6'-8" to 8'-0" or from 8'-1" to 10'-0".

TOP LATCHBOLT - Stainless Steel, Deadlocking, 3/4"

throw.

Reversible

TOP STRIKE - No. S519 Surface applied, Investment Cast

Stainless Steel, Black Powder Coated.

BOTTOM STRIKE - No. S460 Flush mounted, Steel, Black

Powder Coated.

DOGGING - 1/4" turn hex key dogging standard.

NOT available on Fire Exit Hardware.

TOUCHBAR HEIGHT - 39-15/16" from floor standard.

Specify required height if other than standard.

REVERSIBLE - Reversible for all functions and trims.

Standard packaging RHRB.

UL LISTED - Panic and Fire Exit Hardware. For FIRE EXIT

HARDWARE Ratings see page 33. Conforms to UL10C

and UBC 7-2.

ANSI/BHMA - Devices are BHMA certified for ANSI 156.3,

Grade 1.

FINISHES - 605, 606, 612, 613, 625, 628, 630. For

Finish description see page 3.

CYLINDERS - Rim Type, not furnished standard. Specify

when required. For cylinder details see page 19.

Reversible

CONCEALED VERTICAL ROD EXIT DEVICES

S460

BOTTOM BOLT - Steel plated, independent action 5/8"

throw, with adjustment range to suit 3/4" door undercut.

CENTER CHASSIS - Steel plated, heavy wrought Steel

Assembly with lock in place Top and Bottom Latch

Adjustors. Adjustment accessible through the door after

installation.

DEVICE OPTIONS

Prefix Description Page

DE Delayed Egress ..................................................24

E Electric Device......................................................28

ELR Electric Latch Retraction......................................21

FL Fire Exit Hardware ..............................................16

HC Windstorm and Hurricane Code Device............20

LS Latchbolt Monitoring Switch ................................29

Q Wireless Access Management System ..30-32

TDS Touchbar Monitoring Double Switch ..................29

TS Touchbar Monitoring Switch................................29

WTDS Weatherized Touchbar Mon. Dbl. Switch ..........29

WTS Weatherized Touchbar Mon. Switch ..................29

To specify add Prefix to Device No. (e.g. TS2803)

STILE WIDTH - See Stile Information on page 36.

LESS BOTTOM ROD (LBR) OPTION - Specify suffix

“LBR” (e.g. 2808LBR). See UL FIRE LABEL RATING

chart on page 33. Fire Rated Devices include FB277

Fire Bolt Assembly. For Fire Bolt Assembly image

see page 35.

Suffix Description Page

ALK Exit Alarm: battery operated ............................27

ALW Exit Alarm: remote power ................................27

BRL Braille Touchbar ................................................35

CD Cylinder Dogging ..............................................9

DS Door Position Monitoring Switch ....................29

LBR Less Bottom Rod..............................................16

LD Less Dogging ............................................19

SEC Security Screws..................................................3

SNB Sex Nut and Bolt ..............................................3

WALW Weatherized Exit Alarm: remote power..........27

To specify add Prefix to Device No. (e.g. TS2803)

16

APEX 2000 SE

Page 17

1700A

“A” Grip

1700B

“B” Grip

1700C

“C” Grip

C03

Cast Plate

“Pull by others”

The CVR2803 with “Pull by

Other” must be specified

with No. C03 Cylinder

Attachment Trim to secure

the Rim Cylinder. Specify

finish.

TRIMS

1. All Trims are furnished with wrought plates

and extruded or cast solid grips.

2. Specify Grip Design (A,B,C) (“A” Grip

furnished standard for C1700 Series Trim)

3. 630 Trim is furnished for 628 Devices.

TRIMS

4900A

“A” Lever

4900B

“B” Lever

4900C

“C” Lever

4900D

“D” Lever

4900K

“K” Knob

V4908A

Vandal Resistant Trim

A heavy duty lever trim designed to with

stand abuse and vandalism. Composed of

extra strength shock-absorbing “overload”

springs and heavy duty investment cast

stainless steel internal components. Lever

returns to the “home” position eliminating the

need to reset the lever.

1. All the escutcheons and levers are castings or forgings.

2. Specify Lever or Knob Design (A,B,C,D,K) and Handing

(“A” Lever x RHRB furnished standard)

3. 626 Trim furnished for 628 and 630 Devices.

• For Trim dimensions see page 38.

• Trims are BHMA certified for ANSI 156.3, Grade 1.

• Trims are through bolted and will cover 161 and 86 cutouts (except for 2000C Trim).

• Cylinder, Rim Type, not furnished standard. For cylinder details see page 19.

ANSI 01 02 03 05 08 14 15

Function Exit Only Dummy Key Key Key No Cylinder No Cylinder

(cover plate) Trim Retracts Locks/Unlocks Locks/Unlocks Lever/Knob Thumbpiece

Latchbolt Thumbpiece Lever/Knob Always Active Always Active

Device 2801 2802 2803** 2805 2808 2814 2815

Nos. FL2801 FL2803** FL2805 FL2808 FL2814 FL2815

Trim C1701 C1702A C03 1705A 4908A 4914A C1715A

Nos. 4901 4902A C1703A V4908A

4903A

Device with Trim:

Device No.

Add Prefix for options,

see page 16.

Add Suffix: for options, see page 16.

Add Prefix: “V” Vandal Resistant Lever Trim

“C” Concealed Vertical Rod – Pull Trim

“R” Retrofit Trim

Add Suffix: Lever or Knob Design (A,B,C,D,K)

Grip Design (A,B,C)

Add Suffix: “KNR” Knurled Lever or Grip

TS2808CD x V4908AKNR x RHRB x 630 x 3'-0" x 7'-0" x 1-3/4"

Device w/options Trim No. Hand Finish Door Size

Device Only:

Trim Only: Trim no., hand, finish, strike, and door size including thickness: (e.g. V4908A x RHRB x 626 x 1-3/4" )

Device no., hand, finish, strike, and door size including thickness:

(e.g. TS2808CD x RHRB x 630 x 3'-0" x7'-0" x 1-3/4" )

17

Page 18

MULLIONS

Mullion

Cap

MC822

MULLIONS

Mullion

Base

MB822

Mullion

Cap

MC811

Key Removable

Mullion Cap

KMC822

(Rim Cylinder required)

Interlock

S1447

Removable Mullions

Mullion Cap Spacer

MCS822

Stabilizer

ST989

The Mullion is used to adapt a double door opening to two single door openings with Rim Exit Devices.

When the full width of an opening is required, the mullion may be removed.

KEY REMOVABLE MULLION (KR) - Provides a secure yet quick & easy means of removing the 822 or

FL822 Mullion. The mullion can be reinstalled and locked without the need of the key.

STOCK SIZE - For openings 8'-0" high. For openings less than 8'-0" high the mullion can be cut down.

For openings greater than 8'-0" high using the 822, KR822 or 811 mullions, consult factory.

FINISHES - 600, 689, 695. For finish description see page 3.

822, FL822, KR822, FLKR822 Mullion

U.L. LISTED - FL822 and FLKR822 listed for Fire Exit Hardware. For FIRE LABEL RATING Chart see

page 33.

MULLION - 2" x 3" Steel.

MULLION BASE - Investment Cast Steel, 2" wide 3-1/2" deep. Furnished with steel anchors for

concrete floors.

INTERLOCK - Black Powder Coated Investment Cast Stainless Steel. Furnished standard for FL822

and FLKR822 Mullions. It interlocks the mullion to the Rim Active Case and S300 or S301 strike.

STABILIZERS - Black Powder Coated Steel. Stabilizers are furnished standard for FL822 and

FLKR822 Mullions.

MULLION CAP SPACER - Minimum width 3-1/2". For 2-1/4" frame spacer specify part No. MCS822.

For use with 822 series mullion only (e.g. 822, FL822, HC822, HCKR822, KR822, FLKR822).

MCS822 Kit or 822 mullion sufix option. See “To Order” example below.

822, FL822 MULLION CAP - MC822 Investment Cast Steel, 4" wide 3-5/8" deep.

KR822, FLKR822 KEY REMOVABLE MULLION CAP ASSEMBLY - Investment Cast Steel - can be

ordered to convert existing 822 or FL822 mullions to Keyed Removable Mullions. Retrofits to the hole

pattern of an MC822 Mullion Cap. To order specify: KMC822 or KMC822F. For wire run

information, please consult factory.

CYLINDER - not furnished standard - Rim Type required. See page 19 for cylinder details.

18

Mullion

Base

MB811

HC822, HCKR822 Mullion

MULLION - 2" x 3" Steel Mullion is reinforced with a 1-1/2" x 2-1/2" 11 gage Steel Tube. MC822 or

KMC822 Mullion Cap and MB822 Mullion Base Assemblies are used to secure the HC Mullion in the

door opening. The S1447 Interlock must be used to Interlock the Active Case with the strike and is

furnished standard with the HC822 Mullion.

To Order: Specify Mullion No. Height Finish (e.g. MCS822 x 8'-0" x 600)

811 Mullion

MULLION - 2" x 2" Steel Mullion.

MULLION CAP - Cast 4-1/2" wide x 2-5/16", furnished with machine screws for metal frames.

MULLION BASE - Cast 2" wide x 2-3/4", furnished with sheet metal screws and plastic anchors.

To Order: Specify Mullion No. Height Finish (e.g. 822 x 8'-0" x 600)

APEX 2000 SE

Page 19

Cylinder Dogging

Available for all Apex Series Devices except Fire Exit

Hardware and Delayed Egress Devices.

Cylinder Dogging provides the ability to lock down the touch

bar with a key cylinder so the door can be used in the

push/pull mode. To order, specify suffix “CD” (e.g. 2103CD).

Requires the use of a 1-1/4 mortise cylinder, not furnished

standard. Specify when required.

Less Dogging

Available for all Apex Series Devices except Fire Exit

CYLINDER FUNCTIONS

Cylinder Dogging Kit

To convert from hex key

dogging to cylinder dogging

in the field, a cylinder dogging

kit is available. The kit consists

of a channel filler, blocking ring,

cylinder locator and lock nut.

Requires the use of a 1-1/4" mortise cylinder, not

furnished standard. Specify when required.

Note: The channel fillers are different lengths for narrow

and wide stile devices. “NCDK” - Narrow Cylinder

Dogging Kit.

To Order: specify CDK-3, NCDK-3 for up to 3-0 and

CDK4, NCDK-4 for devices up to 4-0.

CYLINDER FUNCTIONS

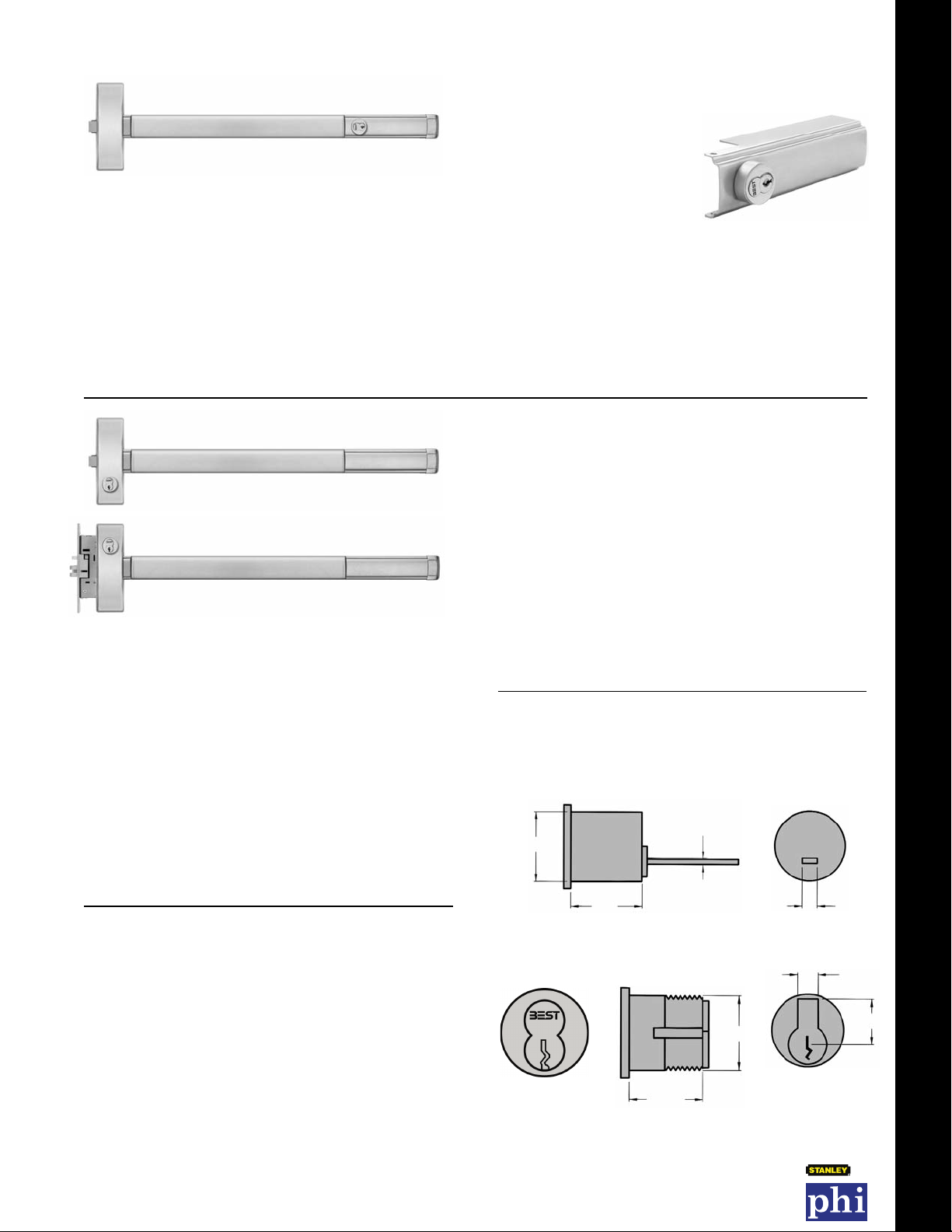

2110 Rim Device -

2310 Mortise Device -

Double Cylinder

(“10” Function)

Handed

Handed

-

Handed

The Double Cylinder option is available on the Wide Stile

Rim and Mortise Exit Devices. The inside key cylinder locks

or unlocks the outside Trim and the outside key cylinder

retracts the latchbolt. Specify Outside Trim with “08” function.

When only the inside key cylinder is required to lock or

unlock the outside trim and no outside cylinder operation is

necessary, specify outside trim with “14” function.

Cylinders - Not furnished standard.

Rim Devices - Two rim type required.

Mortise Devices - One rim type and one 1-1/4"long mortise

type required.

Type Device No. Trim No.

Rim 2110, FL2110 x 4908A, V4908A, 4914A

Mortise 2310, FL2310 x M4908A, VM4908A, M4914A

To Order: Specify Hand and Finish

(e.g. 2110 4908A RHRB 630)

Double Cylinder Kits

-

Handed

The kit is available to convert 2103, FL2103, 2303 and

FL2303 devices to 2110, FL2110, 2310 and FL2310 in the

field.

Rim Kit No. RDC10 - Includes locking assembly, cylinder

assembly, cylinder collar and active case cover. Two rim type

cylinders are required, not furnished standard.

Mortise Kit No. MDC10 - Includes M310 Mortise Lock,

extension assembly, cylinder bracket, cylinder collar and

active case cover. One rim type and one 1-1/4

"

long mortise

type cylinder required, not furnished standard.

To Order: Specify Hand and Finish

(e.g. RDC10 RHRB 630)

Cylinders

Cylinders are not furnished standard with the device or trim.

®

7-pin core standard. Available in 612 finish. Specify

BEST

type and finish when ordering. (e.g. 1E74 x 630)

1/16

"

1-1/8

"

.075

1-1/4

"

"

1/4

"

Rim Cylinder - 1E72 x Finish

.300

"

RIES DEVICES

1-5/32

"

1-1/4

"

Mortise Cylinder - 1E74-C4 x Finish

.703

"

19

Page 20

WINDSTORM AND HURRICANE CODE DEVICES

WINDSTORM AND HURRICANE CODE DEVICES

Compliance - HC2100, HC2200, HC2300, HC2800 Series

Devices and HC822, KRHC822 Mullions comply with the Florida

Building Code including the High Velocity Hurricane Zone. The

HC2100 , HC2200,

HC2300, HC2800 Series

Devices HC822,

KRHC822 Mullions

The Hurricane Devices have passed the structural tests as per

South Florida Building Code Protocol. These tests are designed

to provide sufficient resistance to high wind forces and windborne debris. The devices provide a high level of security for

door openings even if hurricane rated door components are not

required. A brief description of the test is provided below.

Static Air Pressure Test - Simulates wind loading by evenly

distributing air pressure to the face of the door assembly in

positive and negative directions. The door assembly must not

have excessive deflection or deformation and must remain

secure in the chamber.

Missile Impact Test - Simulates impacts created by wind driven

debris by impacting the exterior face of the doors with a 2 x 4

board at 50 feet per second. The board must not pass

through the doors and the doors must remain secure in the

chamber.

Cyclic Wind Pressure Test - Simulates wind gusts by repeating

cycles of positive and negative air pressure to determine that

the integrity of the door assembly is not compromised with

the Missile Impact Test. The door assembly must not have

excessive deflection or deformation and must remain secure

in the chamber.

Component Approval - These devices are approved as compo-

nents to be used with any 16 gage Single or a Pair of Hollow

Metal Doors and Frames holding a current Notice of

Acceptance (NOA). The lowest Design Pressure Rating of

the doors or components shall apply.

Door Device Design

SINGLE DOOR Opening Series Pressure

Rim Device HC2100 80 PSF

Surface Vertical

Rod Device

Mortise Device HC2300 60 PSF

Concealed Vertical

Rod Device

PAIR OF DOORS

Two Rim Devices

with Mullion

Two Surface

Vertical Rod Device

Mortise Device x

Concealed Vertical

Rod Device

Two Concealed

Vertical Rod Device

4'-0" W

8'-0" H

4'-0" W

8'-0" H

4'-0" W

8'-0" H

4'-0" W

8'-0" H

8'-0" W

8'-0" H

8'-0" W

8'-0" H

8'-0" W

8'-0" H

8'-0" W

8'-0" H

HC2200 80 PSF

HC2800 80 PSF

HC2100 x

HC822,

KRHC822

HC2200 x

HC2200

HC2300 x

HC2800

HC2800 x

HC2800

80 PSF

80 PSF

60 PSF

80 PSF

Miami-Dade County Product Control Division has approved these

devices to be used in Miami-Dade County and other areas where

allowed by the Authority Having Jurisdiction (AHJ). Product

Control NOA No. 09-0218.09 is issued for these devices which

expires on September 30, 2014.

To see the NOA documentation online: http://www.miamidade.

gov/buildingcode/pc-search_app.asp and type in the NOA

number: 05-1102.12 under the Product Search Application link.

ANSI Function Device No. Trim No.

HC2101, FLHC2101

Exit Only

01

(cover plate

Dummy Trim

02

Key Retracts

03

Latchbolt

Key Locks /

Unlocks

05

Thumbpiece

Key Locks /

Unlocks

08

Lever / Knob

Double Cylinder

Inside Key

10

Locks / Unlocks

Lever / Knob

No Cylinder

Lever / Knob

14

Always Active

No Cylinder

Thumbpiece

15

Always Active

• Trims with the Prefix “M” are for 2300 Series Devices only.

• 2000 Series Trim not available with 2800 Series Device.

• “10” Function is handed.

Device Specifications and Options page

Rim Exit Devices and Trims ....................................................4,5

Surface Vertical Rod Devices and Trims ................................6,7

Mortise Devices and Trims ......................................................8,9

Concealed Vertical Rod Devices and Trims ......................16,17

HC822 & HCKR822 Mullions ..................................................18

HC2201, FLHC2201

HC2301, FLHC2301

HC2801, FLHC2801

HC2102

HC2202

HC2302

HC2802

HC2103, FLHC2103

HC2203, FLHC2203

HC2303, FLHC2303

HC2803, FLHC2803

HC2105, FLHC2105

HC2205, FLHC2205

HC2305, FLHC2305

HC2805, FLHC2805

HC2108, FLHC2108

HC2208, FLHC2208

HC2308, FLHC2308

HC2808, FLHC2808

HC2110, FLHC2110

HC2310, FLHC2310

HC2114, FLHC2114

HC2214, FLHC2214

HC2314, FLHC2314

HC2814, FLHC2814

HC2115, FLHC2115

HC2215, FLHC2215

HC2315, FLHC2315

HC2815, FLHC2815

1701

2001

4901

1702A

2002C

4902A

C03

1703

2003

4903

M4903A

1705A

2005A

M1705A

M2005A

4908A

V4908A

M4908A

VM4908A

4910A

V4910A

M4910A

VM4910A

4914A

M4914A

1715A

2015C

M1715A

M2015C

20

APEX 2000 SE

Page 21

ELECTRIC LATCH RETRACTION

Available for all Series

Devices

ELR150 Power supply door opened

The ELR option provides remote Latch Retraction of exit

devices. Continuous duty solenoids retract the Latchbolt(s)

for momentary unlatching or continuously for dogging. The

ELR feature can be interfaced with automatic door operators,

card readers, push buttons, toggle/key switches, and fire

alarm systems.

• ELR option REQUIRES ELR150 Series Power Supply.

• UL Listed for Panic and Fire for Class II Circuitry

• ELR can be used in combination with all Apex options

including Hex Key or Cylinder Dogging. ELR option is not

available for (DE) Delayed Egress Devices.

Door Widths – 3 Device - 2-7 to 3-0 Door

4 Device - 3-1 to 4-0 Door

The Power Supply model number is determined based on

the number of devices requiring electrical power.

See To Order ELR150 Power Supply below.

To order: specify prefix “ELR” (e.g. ELR2108)

ELR Conversion Kit

A standard device can be retrofit to the Electric Latch

Retraction option by ordering the kits listed below. A ELR

Conversion Kit REQUIRES a ELR150 Series Power Supply.

To Order:

Wide Stile Devices

3-0 ELRK-3, ELRKF-3

4-0 ELRK-4, ELRKF-4

Narrow Stile Devices

3-0 NELRK-3, NELRKF-3

4-0 NELRK-4, NELRKF-4

Note: Power may be supplied through a 4-wire continuous

circuit hinge (furnished by others).

Solenoid Specifications

Current Pulse (2 seconds max.) ....................... 4.75 Amp.

Continuous ......................................... 3.6 VDC / 0.8 Amp.

ELR150 Series Power Supply

The ELR150 Series is a power supply REQUIRED to control

ELR Devices. The power supply contains a Motherboard that

will accept up to four plug-in Control Modules. Each Control

Module (part #CM150-08, see page 22) controls one ELR

Device and includes a Time Delay Feature. The Time Delay

provides a variable (0 - 4 minutes) Latch Retraction period in

response to a momentary input.

Specifications

• UL Listed for Class II Output.

• UL 294 - Conforms to U.L. 294 Standards incorporating

enhanced Access Control communication capabilities.

• Circuit breakers provide protection for Motherboard

• 115 or 230 Volt user selectable switch.

• A.C. Input = 115 Volts at 1 Amp.

• Battery Back-up / Power Tap available (see page 22).

• LED Indicator - Provides clear indication that power is

available to the supply.

• Keyed Cabinet - To maintain safety and security, each

Power Supply is equipped with a preinstalled key-cylinder.

• Includes lockable box with key lock.

• Dimensions: 16" W x 14" H x 6" D.

ELR150 Power supply door closed

• Weight: 15 lbs.

To Order: ELR150 Power Supply – The model number is determined based on the number of devices requiring electrical power.

ELR150 - Power Supply, no control modules

ELR151 - Power Supply including (1) control module to control (1) exit device

ELR152 - Power Supply including (2) control modules to control (2) exit devices

ELR153 - Power Supply including (3) control modules to control (3) exit devices

ELR154 - Power Supply including (4) control modules to control (4) exit devices

To order power supply with Battery Backup specify suffix BT (e.g. ELR151BT)

ELECTRIC LATCH RETRACTION

21

Page 22

ELR POWER SUPPLY ACCESSORIES

Control Module

The CM150-08 Control Module is a card that is installed in

the ELR150 Series Power Supply and controls one ELR

device and includes a Time Delay Feature. The Time Delay

provides a variable Latch Retraction period in response to a

momentary input.

Specifications

Input

Switch Input

Voltage Input

Output

• Current Pulse: 4.75 Amp. (2 seconds max.)

• Continuous: 3.6 VDC / 0.8 Amp.

Time Delay

• User selectable: 0-4 minutes delay after input is removed

Fire Alarm Terminal

• Red LED (D3) blinks when Fire Alarm interrupts circuit

• Provides immediate termination of output

Switch Input:

ELR POWER SUPPLY ACCESSORIES

Voltage Input:

Auxiliary Contacts

• Relay isolated contacts provided for remote signaling

• Normally open or normally closed contacts are rated at

• Contact operation follows successful operation of the

To Order: specify CM150-08

• Normally open

• Input Voltage: 5-24VDC or VAC

• Input Current: approx. 0.005 Amp.

• Minimum pulse width: 0.25 seconds

• Accepts normally closed contacts or 5-24 Volts

from a listed fire detecting device.

• Input Current: 0.005 Amp.

• Minimum pulse width: 0.25 seconds

(e.g. door operator)

0.5 Amp., 24VDC or VAC

ELR device.

POWER INDICATOR

GREEN: when power is present

FIRE INDICATOR

BLINKS RED: fire detected,

will not accept input

ON RED: no fire detected,

will accept input

STATUS LIGHT 2

BLINKS GREEN:

Independent Mode

DOUBLE BLINKS GREEN:

Sequential Mode

ON GREEN:

Latches retracted

STATUS LIGHT 1

ON GREEN: input

received

(CN1)

MODE SELECTION JUMPER

For Sequence Mode or

Independent Mode

(CN2-V)

TIME DELAY JUMPER

Used to activate Time Del

when voltage input received

(CN2-SW)

TIME DELAY JUMPER

Used to activate Time Delay

when a switch (dry contact)

closure is detected

TIME DELAY

ADJUSTMENT

Allows for outputs

to continue for

0 - 4 minutes after

input is removed.

Note: Time Delay is

over ridden when a

fire is detected.

ay

22

Battery Backup

Power Tap

The BT150-07 Battery Backup is an optional card that can

be installed in the ELR150 Series Power Supply to provide

temporary power to ELR Devices in case of power

shortage or outages. Uses (2) 12VDC Lead Acid batteries

(furnished by others). One Amp hour set of batteries

provides approximately 15 minutes of backup to four exit