Page 1

-,~ ~OREAMBLE

-

VIINSTRUMENTS

1820/1822

DIFFERENTIAL AMPLIFIER

OPERA TOR’S

MANUAL

Revision D

August 1999

Page 2

Table of Contents

Section 1

Specifications

Introduction .............................................................................

1 - 1

1820/1822 Specifications ........................................................

1-2

Nominal Characteristics ..........................................................

1-3

Warranted and Typical Characteristics .................................... 1-4

Environmental and Physical Characteristics ............................

1-5

Section 2

Operating Instructions, Controls and Indicators

Front Panel ..............................................................................

2-1

Rear Panel ...............................................................................

2-4

Oscilloscope Settings ...............................................................

2-5

Model 1820 Operation .............................................................

2-6

Section 3

General Operating Information

Getting Started .........................................................................

3-1

1822 Front Panel Operation .....................................................

3-1

Comparison Voltage Operation ...............................................

3-2

Differential Offset Operation ..................................................

3-3

User Traps to Avoid ................................................................

3-4

Section 4

Performance Verification

Introduction ............................................................................. 4-1

Test Equipment Required ........................................................

4-2

Preliminary Procedure .............................................................

4-3

Procedure .................................................................................

4-3

1820/1822 Test Record ..........................................................

4-11

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Page 3

Section 1

Specifications

Introduction

182011822 Operator’s Manual

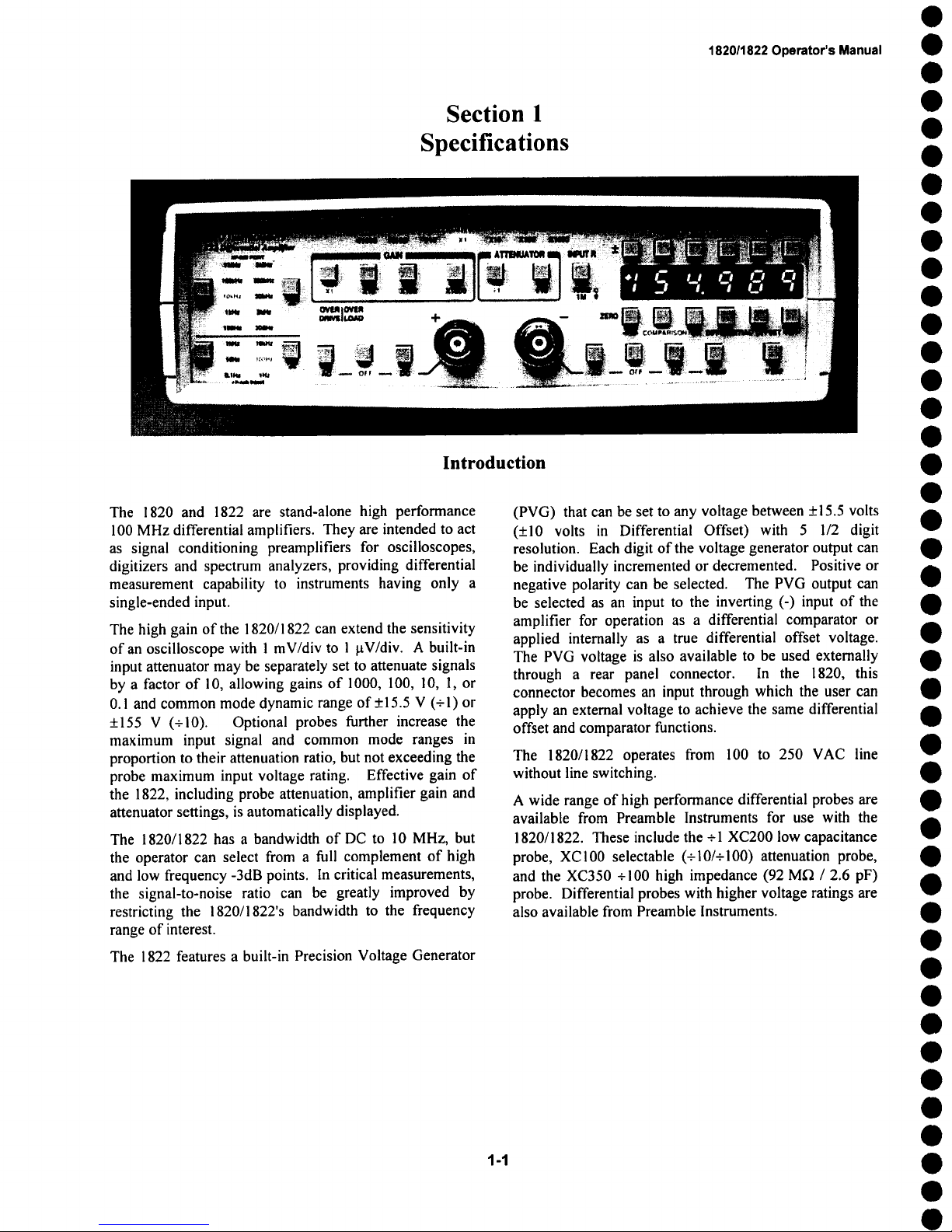

The 1820 and 1822 are stand-alone high performance

100 MHz differential amplifiers. They are intended to act

as signal conditioning preamplifiers for oscilloscopes,

digitizers and spectrum analyzers, providing differential

measurement capability to instruments having only a

single-ended input.

The high gain of the 1820/1822 can extend the sensitivity

of an oscilloscope with 1 mV/div to 1 laV/div. A built-in

input attenuator may be separately set to attenuate signals

by a factor of 10, allowing gains of 1000, 100, 10, 1, or

0.1 and common mode dynamic range of +15.5 V (+1)

+155 V (+10). Optional probes further increase the

maximum input signal and common mode ranges in

proportion to their attenuation ratio, but not exceeding the

probe maximum input voltage rating. Effective gain of

the 1822, including probe attenuation, amplifier gain and

attenuator settings, is automatically displayed.

The 1820/1822 has a bandwidth of DC to 10 MHz, but

the operator can select from a full complement of high

and low frequency -3dB points. In critical measurements,

the signal-to-noise ratio can be greatly improved by

restricting the 1820/1822’s bandwidth to the frequency

range of interest.

The 1822 features a built-in Precision Voltage Generator

(PVG) that can be set to any voltage between +15.5 volts

(+10 volts in Differential Offset) with 5 1/2 digit

resolution. Each digit of the voltage generator output can

be individually incremented or decremented. Positive or

negative polarity can be selected. The PVG output can

be selected as an input to the inverting (-) input of the

amplifier for operation as a differential comparator or

applied internally as a true differential offset voltage.

The PVG voltage is also available to be used externally

through a rear panel connector. In the 1820, this

connector becomes an input through which the user can

apply an external voltage to achieve the same differential

offset and comparator functions.

The 1820/1822 operates from 100 to 250 VAC line

without line switching.

A wide range of high performance differential probes are

available from Preamble Instruments for use with the

1820/1822. These include the +1 XC200 low capacitance

probe, XCI00 selectable (+10/+100) attenuation probe,

and the XC350 +100 high impedance (92 M~ / 2.6 pF)

probe. Differential probes with higher voltage ratings are

also available from Preamble Instruments.

1-1

Page 4

1820/1822 Operator’s Manual

1820/1822 Specifications

Except where otherwise noted, the following specifications apply to model 1820, 1822,

1820-PR2 and 1822-PR2

Differential Amplifiers.

The specifications are valid for instruments when the following conditions have been met:

The instrument is being operated from a power source which meets the line voltage and frequency specifications.

The instrument has been operating for at least 30 minutes in an environment which is within the operating

environmental specifications.

¯

The instrument has been calibrated within the last 12 months. Calibration was performed in a controlled environment

of 25 +5°C.

Nominal Characteristics

Nominal characteristics describe parameters and attributes which have are guaranteed by design, but do not have

associated tolerances.

General

Input Configuration:

True Differential, + and - Inputs.

Precision Voltage Generator (1822 and 1822-PR2

models), or external offset reference source (1820

and 1820-PR2 models) can be selected as - input

source in VCOMP mode.

Offset Capability

The Precision Voltage Generator (1822 and 1822PR2 models), or external offset reference source

(1820 and 1820-PR2 models) can be used

provide true differential offset.

+ Input Coupling Selections

- Input Coupling Selections

Input Connectors

AC, Off (Precharge),

AC, Off (Precharge), DC, VcouP

BNC. + Input incorporates Probe Attenuation

Coding sensing connector (1822 Only).

Maximum Non-Destruct Input Voltage

Withstands up to +250 V.

Automatic input disconnect with manual reset

Output Configuration

Output Impedance

Intended Output Load

Output Connector

Amplifier Gain

Input Attenuation

Bandwidth Limit Filters (Upper Limit)

Single Ended, Ground referenced.

50

50f)

BNC

X1, X10, XI00, or X1000

+1 or +10

100 Hz, 300 Hz, 1 KHz, 3 KHz, 10 KHz,

30 KHz, 100 KHz, 300 KHz, 1 MHz, 3 MHz

Bandwidth Limit Filters (Lower Limit)

Bandwidth Limit Filter Characteristics

Autobalance

0.1 Hz, 1 Hz, 10 Hz, 100 Hz, 1 KHz, 10 KHz

Single pole, 6 dB/octave

Amplifier initiates an automatic balance cycle

when either gain button is depressed.

Effective Gain Indicator

(1822 and 1822-PR2 models only)

LEDs indicate the effective gain by factoring

Probe Attenuation, Attenuator and Gain settings.

(Probes must have coding connectors.

+ 1, + 10, + 100, and + 1000 probes are

recognized.)

1-2

Page 5

182011822 Operator’s Manual

Nominal Characteristics (continued)

Dynamic Ranges

Maximum Differential Linear Input:

X 1000 Gain, + 1 Attenuator

X100 Gain, +1 Attenuator

X 10 Gain, - 1 Attenuator

XI Gain, +l Attenuator

XI000 Gain, +10 Attenuator

X 100 Gain, + I 0 Attenuator

X 10 Gain, + ! 0 Attenuator

XI Gain, +10 Attenuator

~

+5 mV

j

+50 mV

1

+0.5 V

I

+5 V

I

_+50 mV

l

¯ +0.5 V

~

+5 V

t

+50 V

Maximum Common Mode Input

+ 1 Attenuator

+ 10 Attenuator

1

+15.5 V

l

¯ +155 V

Differential Offset Range (VD~FV Mode)

(referred to input)

X 10, X 100, X 1000 Gain, + 1 Attenuator

X 1 Gain, + ! Attenuator

Xi0, X100, XI000 Gain, +10 Attenuator

X ! Gain, +l 0 Attenuator

I

¯ +! V

1

¯ +!0 V

l

±10 V

I

±100 V

Comparison Offset Range (VcoMP Mode)

(referred to input)

+ 1 Attenuator

+ 10 Attenuator

Output Range

I

_+15.5 V

I

¯ +i55 V

Limitedto _+5 V into 50 ~ load

t Voltages are referred amplifier input connector. Multiply by probe attenuation factor to obtain value refer to probe

input. (e.g. _+50 mV1 becomes +0.5V at the probe tip when using a +10 probe.)

Precision Voltage Generator (1822 and 1822-PR2 models

Output Range

Resolution

Control

Reference Type

Output Routing

Autozero

Power Requirements

Line Voltage Range

Line Frequency Range

only)

±15.5 V

1 O0 p.V

Individual increment and decrement buttons for

each digit. Digit carries over to next decade.

Oven stabilized buried Zener

Can be applied to - input and available at rear

panel BNC connector.

Removes output offset when 0.0000 volts is

selected and periodically thereafter.

100 - 250 VAC

48 - 66 Hz

1-3

Page 6

1820/1822 Operator’s Manual

Warranted Characteristics

Warranted characteristics describe parameters which have guaranteed performance.

provided in the Performance Verification Procedure for all warranted specifications.

Unless otherwise noted, tests are

Gain Accuracy

+1% + Uncertainty of termination resistance

Bandwidth (- 3dB)

X1 or XI0 Gain

X 100 Gain

X 1000 Gain

Rise Time (XI or X10 Gain)

>10 MHz

>2.5 MHz

>1 MHz

<35 ns (Calculated from Bandwidth)

Common Mode Rejection Ratio

(X 1 or X 10 Gain)

70 Hz

100 KHz

1 MHz

Precision Voltage Generator Accuracy

>100,000:1 (100 dB)

>100,000:1 (100 dB)

>1,000:1 (60 dB)

0.05% of reading + 500 ~tV (15° to 45° C.)

Typical Characteristics

Typical characteristics describe parameters which do not have guaranteed performance. Tests for typical characteristics

are not provided in the Performance Verification Procedure.

Input Resistance

+1 Attenuator

1 MF2 or 100 Mr2

1 Mr2 only with attenuating probe

+ 10 Attenuator

Input Capacitance

AC Input Coupling Capacitance

+ 10 Attenuator Accuracy

DC Drift (X10 Gain, referred to input)

Input Leakage Current

1 Mr2

20 pF

0.1 ~tF

0.05%

50 ~tVPC

<10 pA (0° - 45° C.)

(X 1 or X 10 Gain, + 1 Attenuator)

Differential Offset Accuracy

X i 0, X 100, X 1000 Gain, + 1 Attenuator

XI Gain, +1 Attenuator

X 10, X 100, X 1000 Gain, + 10 Attenuator

XI Gain, +10 Attenuator

Precision Voltage Generator Temperature

O. 1% + 50 laV

2

0.1% + 500 ~tV

2

O. 15% + 500 ~tV

2

O. 15% + 5 mV

<5 mVPC of full scale

2

Coefficient (1822 and 1822-PR2 models)

Power Consumption

26 W, ~ 36 VA (1820 and 1822)

52 W, ~ 72 VA (1820-PR2 and 1822-PR2)

2 Voltages are referred amplifier input connector. Multiply by probe attenuation factor to obtain value refer to probe

input. (e.g. 0.1% + 50 ~tV2 becomes 0.1% + 500 laV at the probe tip when using a +10 probe.)

Page 7

1820/1822 Operator’s Manual

Environmental Characteristics

The Environmental Characteristics are tested to specification MIL-T28800D Class 5.

performance verification of environmental characteristics is required.

Refer to this specification if

Temperature Range, operating

Temperature Range, non-operating

0° - 50° C.

-40° - 75° C.

Physical Characteristics

Height

Width

Depth

Weight

Shipping Weight

7.29 cm (2.87") (1820 and 1822 models)

8.75 cm (3.4") (1820-PR2 and 1822-PR2 models)

21.2 cm (8.36") (1820 and 1822 models)

43.9 cm (17.3") (1820-PR2 and 1822-PR2 models

without rack mounting ears installed)

23.2 cm (9.12") (1820 and 1822 models)

42.5 cm (16.7")(1820-PR2 and 1822-PR2 models)

2.15 kg (4 Ibs. 12 oz.) (1820 and 1822 models)

9.5 kg (21 lbs.) (1820-PR2 and 1822-PR2 models)

3.12 kg (6 lbs. 14 oz.) (1820 and 1822 models)

11.3 kg (25 lbs.) (I 820-PR2 and 1822-PR2 models)

Compliances

EC Declaration of Conformity

Designed to comply with EN61010-1 : 1993

Installation Category l, 42.2V, pollution degree 1.

Conforms to Low Voltage Directive 73.72 EEC for

product safety.

1-5

Page 8

1820/1822 Operator’s Manual

Section 2

Operating Instructions, Controls, and Indicators

Front Panel

Attenuator

Signals connected to the +INPUT and the -INPUT are

connected either directly to the 1820/1822’s amplifier

inputs or to the input attenuators. The input attenuators

are passive networks which divide each signal by ten.

In ÷1 mode the front panel input connectors are directly

connected to the 1820/1822 amplifier’s differential inputs.

In ÷10 mode each front panel input connector is

connected to a passive 1 Mr2 attenuator. The attenuator

output is connected to the 1820/1822 amplifier’s

corresponding differential input. The signal at each input

is attenuated by a factor of ten.

Gain

The 1820/1822 amplifier gain (amplification) is selectable

XI, XI0, XI00 and XI000. The amplified signal appears

at the rear panel AMPLIFIER OUTPUT connector.

A signal connected to the +INPUT will maintain its

polarity at the output connector. A signal connected to

the -INPUT will be inverted in polarity.

Proper gain is obtained when the 1820/1822 drives a 50

load such as an oscilloscope with input impedance set to

50 fL An oscilloscope with only 1 Mr2 input impedance

available should have a 50 f2 coaxial termination placed

on its input connector. The ! 820/1822 is then connected

to the oscilloscope through the coaxial termination.

The amplifier gain and the input attenuator are

individually selectable to provide versatility. For

example, the comparison voltage range is changed from

+15.5000 to ±155.000 volts by changing the

ATTENUATOR from +1 to ÷10. The overall gain can

still be set to 100, 10, 1 or 0.1 by selecting the GAIN

mode, XI000, X100, XI0 or XI, as desired.

Autobalance is a feature invoked when any gain button is

pushed, even if a different gain is not selected.

Autobalance momentarily sets the INPUT COUPLING

to OFF and determines the offset necessary to set the

output at 0 volts within about 25~tV. During this process

the front panel input coupling controls are unresponsive.

When finished, the INPUT COUPLING returns to its

previous mode. Autobalance usually takes less than one

second. This handy feature allows the operator to DC

balance the 1820/1822 simply by pushing the GAIN

button which is already illuminated. When changing

gains, the Autobalance feature is automatically invoked,

freshly adjusting the amplifier’s DC balance.

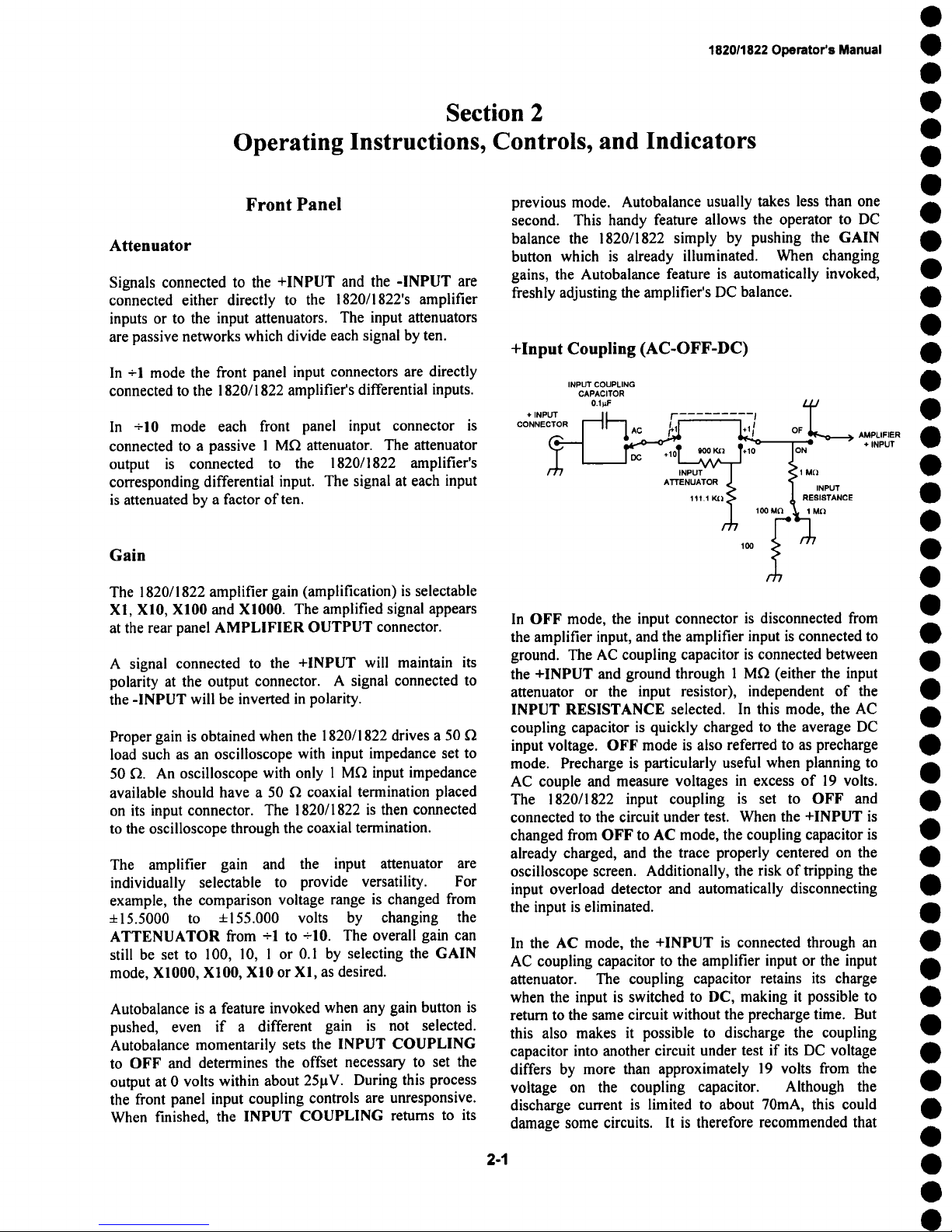

+Input Coupling (AC-OFF-DC)

INPUT COUPLING

CAPACITOR

+ INPUT

CONNECTOR [----11--7 AC ~11 I+1[

0.I~ .......

l [ r--- , ¯

10 900 K~ +10

ATTENUATOR

11111

i

In OFF mode, the input connector is disconnected from

the amplifier input, and the amplifier input is connected to

ground. The AC coupling capacitor is connected between

the +INPUT and ground through 1 M~ (either the input

attenuator or the input resistor), independent of the

INPUT RESISTANCE selected. In this mode, the AC

coupling capacitor is quickly charged to the average DC

input voltage. OFF mode is also referred to as precharge

mode. Precharge is particularly useful when planning to

AC couple and measure voltages in excess of 19 volts.

The 1820/1822 input coupling is set to OFF and

connected to the circuit under test. When the +INPUT is

changed from OFF to AC mode, the coupling capacitor is

already charged, and the trace properly centered on the

oscilloscope screen. Additionally, the risk of tripping the

input overload detector and automatically disconnecting

the input is eliminated.

In the AC mode, the +INPUT is connected through an

AC coupling capacitor to the amplifier input or the input

attenuator. The coupling capacitor retains its charge

when the input is switched to DC, making it possible to

return to the same circuit without the precharge time. But

this also makes it possible to discharge the coupling

capacitor into another circuit under test if its DC voltage

differs by more than approximately 19 volts from the

voltage on the coupling capacitor. Although the

discharge current is limited to about 70mA, this could

damage some circuits. It is therefore recommended that

2-1

Page 9

182011822 Operator’s Manual

the +INPUT COUPLING first be changed to OFF

(precharge) when measuring a new circuit point. This

will safely recharge the AC coupling capacitor in less

than 0.3 seconds. The value of the AC coupling capacitor

is 0.1 laF.

DC and low frequencies are attenuated by the AC

coupling capacitor and the input resistance. With the

ATTENUATOR set to +10, or set to +1 with the INPUT

RESISTANCE set to 1 Mr2, the low frequency cut off

(-3dB point) is approximately 1.6Hz, lower than most

oscilloscopes by a factor of 5. When the input attenuator

is set to +1, the INPUT RESISTANCE may be set to

100 M~, and the -3dB point is 0.016Hz. This extremely

low frequency cut off is often handy in observing low

frequency noise riding on large (up to 400 volts)

voltages.

In the DC mode, the +INPUT connector is connected to

the amplifier either directly or through the input

attenuator, and the AC and DC attenuation are the same.

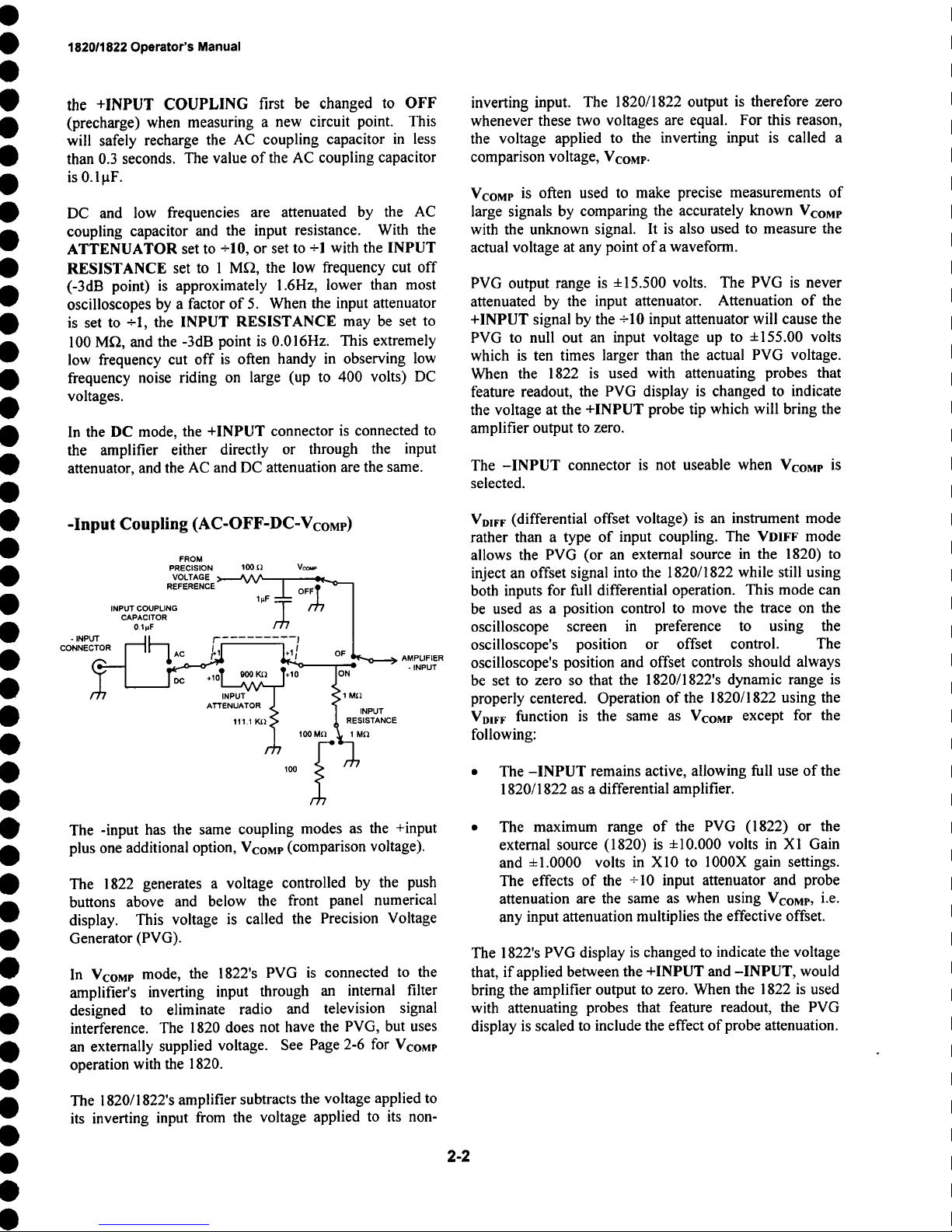

-Input Coupling (AC-OFF-DC-VcoMP)

PRECISION

VOLTAGE )-

REFERENCE

INPUT COUPLING

CAPACITOR

- INPUT

CONNECTOR

~ I.~ /-" .........

l r Ac

("~ I1~

I

~ -+lOT 900 KI] ~*10-

/7/ INPUT

FROM

100 II Vcoup

~

I I

H

ATTENUATOR

111.1 KI2

v A_

/ (’O--I

1 I / / I

I

]

M OF L

~______.~..~’~O ). AMPLIFIER

I

ION-

~1 Mr1

RESISTANCE

100 Mfl fl

INPUT

-INPUT

inverting input. The 1820/1822 output is therefore zero

whenever these two voltages are equal. For this reason,

the voltage applied to the inverting input is called a

comparison voltage, VcoMP.

VcoMP is often used to make precise measurements of

large signals by comparing the accurately known Vcome

with the unknown signal. It is also used to measure the

actual voltage at any point ofa waveform.

PVG output range is +15.500 volts. The PVG is never

attenuated by the input attenuator. Attenuation of the

+INPUT signal by the -10 input attenuator will cause the

PVG to null out an input voltage up to ±155.00 volts

which is ten times larger than the actual PVG voltage.

When the 1822 is used with attenuating probes that

feature readout, the PVG display is changed to indicate

the voltage at the +INPUT probe tip which will bring the

amplifier output to zero.

The -INPUT connector is not useable when Vcome is

selected.

VDIFF (differential offset voltage) is an instrument mode

rather than a type of input coupling. The VBIFF mode

allows the PVG (or an external source in the 1820)

inject an offset signal into the 1820/1822 while still using

both inputs for full differential operation. This mode can

be used as a position control to move the trace on the

oscilloscope screen in preference to using the

oscilloscope’s position or offset control. The

oscilloscope’s position and offset controls should always

be set to zero so that the 1820/1822’s dynamic range is

properly centered. Operation of the 1820/1822 using the

VD|FF function is the same as VCOMP except for the

following:

The -input has the same coupling modes as the +input

plus one additional option, VcoMv (comparison voltage).

The 1822 generates a voltage controlled by the push

buttons above and below the front panel numerical

display. This voltage is called the Precision Voltage

Generator (PVG).

In VCOMP mode, the 1822’s PVG is connected to the

amplifier’s inverting input through an internal filter

designed to eliminate radio and television signal

interference. The 1820 does not have the PVG, but uses

an externally supplied voltage. See Page 2-6 for VcoMv

operation with the 1820.

The 1820/i 822’s amplifier subtracts the voltage applied to

its inverting input from the voltage applied to its non-

¯

The -INPUT remains active, allowing full use of the

1820/1822 as a differential amplifier.

The maximum range of the PVG (1822) or the

external source (1820) is ±10.000 volts in XI Gain

and ±1.0000 volts in X10 to 1000X gain settings.

The effects of the +10 input attenuator and probe

attenuation are the same as when using VCOMP, i.e.

any input attenuation multiplies the effective offset.

The 1822’s PVG display is changed to indicate the voltage

that, if applied between the +INPUT and -INPUT, would

bring the amplifier output to zero. When the 1822 is used

with attenuating probes that feature readout, the PVG

display is scaled to include the effect of probe attenuation.

2-2

Page 10

1820/1822 Operator’s Manual

Input Resistance

When the input ATTENUATOR is set to -1 and no

attenuating probe is connected, the input resistance can be

increased from 1 Mr2 to 100 Mr2 by pressing the

100M/IM button. This is advantageous when measuring

high impedance circuits or when AC coupling is needed

with a very low frequency cut off. When the input

ATTENUATOR is set to -10 or an attenuating probe

with readout capability is attached, 1 Mr2 (IM) input

resistance is automatically selected.

Unbalanced source impedances can have an adverse

effect on common mode rejection. For example, a

differential source with impedances of 1000 and 2000 [2,

each loaded with 1 M£2 will have a common mode

rejection ratio (CMRR) of 1000 to 1. The common mode

rejection ration can be improved to 100,000 to 1 by using

100 M~ input resistance.

This limitation is also apparent when trying to make

accurate measurements using VCOMP. A 10.000 volt

reference with a 1000 f2 output impedance will be

reduced to 9.9900 volts by the 1820/1822 1 M~ input

resistance, introducing a 10 mV error in the measurement.

Increasing the input resistance to 100 M~ decreases this

error to 100~tV.

frequency -3 dB points are 3MHz, I MHz, 300kHz,

100kHz, 30kHz, 10kHz, 3kHz, IkHz, 300Hz and 100Hz.

Selections for the lower -3 dB points are 0.1Hz, IHz,

10Hz, 100Hz, lkHz and 10kHz. These filters make it

possible to improve the signal-to-noise ratio when making

measurements on microvolt magnitude signals.

Precision Voltage Generator (1822 Only)

The PVG generates the voltage which is used in the

VCOMP and VDWF modes and appears at the rear panel

PRECISION VOLTAGE GENERATOR OUTPUT

connector.

Above each digit is a push button which increments the

corresponding digit by one when pushed. When held, the

digit continues to increment, eventually incrementing the

next higher digit.

Similarly, below each digit is a push button which

decrements the corresponding digit.

The 4- button above the left-most digit changes the PVG

output polarity. The ZERO button below the left-most

digit sets the output to zero and invokes the Autozero

function.

Oscilloscope inputs have a small input current which can

cause an offset when measuring high impedance circuits.

The offset can be observed by opening and shorting the

input to ground. The 1820/1822 has a temperaturecompensated input current pull away (cancellation) which

works in both the 1 M~ and 100 Mr2 INPUT

RESISTANCE modes. Its input offset current is

considerably less than that of most oscilloscopes.

Effective Gain (1822 Only)

Seven lights (LEDs) across the top of the 1822 front panel

indicate the total gain from the instrument input to output.

When the X1 light is lighted, the overall amplifier voltage

gain (amplification) is unity. Similarly, XI0 indicates

overall amplification of ten times. +10 indicates the

voltage amplification is 0.1, and so forth.

When Preamble Instruments or other encoded probes are

properly used, the effective gain includes the probe’s

attenuation factor.

Upper and Lower -3 dB Points

The 1820/22 allows the user to select both the upper and

lower frequency -3 dB points. Selections for the high

Autozero resets the PVG output to zero to eliminate any

drift which may have occurred in the PVG due to low

frequency noise, or long term drift. Autozero is invoked

each time the ZERO button is pressed and re-invoked

approximately every minute thereafter. This is useful

when the instrument has been unplugged and a cold start

is required.

Overdrive (yellow)

When a signal is applied to either input of the 1820/1822

that exceeds its ±15.5 volt input range the yellow

OVERDRIVE indicator is lighted. The light remains on

as long as the input remains larger than the linear range.

The linear range is multiplied by the ATTENUATOR

factor and by the use of an attenuating probe.

The yellow OVERDRIVE light is intended to warn the

user of potentially distorted waveforms.

Overload (red)

When a signal which could damage to the 1820/1822 has

been applied to either input connector, the 1820/1822

protects itself by disconnecting the signal. The input

2-3

Page 11

182011822 Operator’s Manual

coupling mode changes to OFF, and the red

OVERLOAD light is turned on.

The 1820/1822 is reset and the OVERLOAD light goes

out when any of the input coupling modes is selected.

When the ATTENUATOR is set to -1, a signal of

approximately ±19 volts will cause the input to draw

current and the OVERLOAD light to come on.

Transients too rapid to he disconnected by the input

coupling relay will draw up to about 70mA of input

current. Inputs in excess of 250 volts may cause

permanent damage to the i 820/1822.

The input is not disconnected when the ATTENUATOR

is set to +10.

Rear Panel

Power

Normal instrument operation is obtained in the ON

position. The instrument reaches its specified

performance in 30 minutes.

PRECISION VOLTAGE GENERATOR

OUTPUT (1822 Only)

The rear panel PRECISION VOLTAGE

GENERATOR OUTPUT BNC connector is a monitor

of the Precision Voltage Generator (PVG). It is the same

voltage that is applied to the -INPUT when the -INPUT

coupling is VCOMe or internally to the 1822 when VDIFF

is selected. The PRECISION VOLTAGE

GENERATOR OUTPUT can be used either to monitor

the PVG with a DVM (digital voltmeter) or as an input

one or more Preamble 1820s or 1822s. There is a

1.59kHz single-pole low pass filter between the PVG

output and the -INPUT which removes radio frequency

interference (RFI). This filter does not attenuate the PVG

signal.

The PVG output is not attenuated by the input attenuator

or probes, whereas the input signal is. Therefore the

effective range of V¢OMP is increased by a factor of 10

when the +10 attenuator is selected or a +10 attenuating

probe is used to attenuate the input signal. The PVG

numerical display reflects the attenuator setting and probe

attenuation when the probe is readout encoded. As an

example, if there are no probes attached, the +10

attenuator is selected and the display is set to read

+155.000, the PVG output will actually be _+15.5 volts.

The decimal in the display will be in the correct location

to indicate the voltage at the PVG output when no probes

are attached and ÷1 attenuator and X1 gain are selected.

The PRECISION VOLTAGE GENERATOR OUT

BNC also presents the same voltage used internally for

differential offset when VDIFF is selected. Because the

PVG is applied to the amplifier to create a true differential

offset, the relationship between VDIFr and the voltage at

the PVG output BNC changes with the amplifier gain

selection according to the following table:

Front Panel Settings

Gain

X1

Atten

+1 +IOV

Xl +10 +I00V

XI0,X100,

+1

VDIFF

+IV +10v

Maximum

PVG Output

+IOV

+10v

XI000

Xl0,Xi00,

+10 +lOV ±lOV

Xl000

The maximum VDIFF is multiplied by any probe

attenuation factor. When using readout encoded probes

which the 1822 senses, the PVG readout calculates the

effective differential offset at the probe tip. Of course,

both probes must have the same attenuation factor.

Amplifier Output

The amplifier’s output BNC is intended to be used with an

oscilloscope, spectrum analyzer or digitizer having a 50 if2

input resistance. The 1820/1822 output impedance is

50 f2. Without the 50 ~ load, the amplifier gain is twice

the amount indicated on the front panel. Additionally, the

signal presented to an oscilloscope (spectrum analyzer or

digitizer) is as large as ± 10 volts.

Probe Coding Input (1822 Only)

This jack is to be used with Preamble Instruments probes

and other probes that have multiple selectable attenuation

factors. Other manufacturer’s probes with standard probe

coding capability will be properly decoded through the

1822’s front panel +INPUT BNC connector.

2-4

Page 12

182011822 Operator’s Manual

Oscilloscope Settings

The Preamble Instruments 1820/1822 output is intended

to connect directly to the input of an oscilloscope,

spectrum analyzer or digitizer, but it is important to

observe some rules so that the 1820/1822 delivers its

specified performance.

Oscilloscope Input Impedance

The 1820/1822 output impedance is 50 f~ and the

intended load impedance is also 50 ~. Nominal gain

(amplification) is obtained only when the oscilloscope (or

digitizer) input impedance is set to 50fL The

EFFECTIVE GAIN display is correct only when the

1822 is properly terminated into 50 f~.

A factor of two additional gain is achieved by setting the

oscilloscope input impedance to 1 M fL However, the

operator needs to be aware that all the 1820/1822 gain

indicators will be off by a factor of two.

Sensitivity, Position, and Offset

Oscilloscopes are designed to maintain their accuracy for

that portion of a signal that is displayed on-screen. When

the signal is large enough to drive the display off-screen,

the oscilloscope’s amplifier must limit the signal in a non-

linear mode. Oscilloscopes are designed so that no matter

how the sensitivity, position and offset controls are set,

the operator cannot view this distorted portion of the

signal.

The maximum 1820/! 822 output is carefully controlled so

it will not exceed +5V when the output is properly

terminated into a 50 ~ load.

Set the oscilloscope vertical sensitivity to no less than

500mV/div. The most useful range for the oscilloscope

deflection factors will be between ! mV/div and

500mV/div. Using a deflection factor of 2V/Div will

bring the nonlinear portion of the 1820/1822’s output on

screen. Digitizers should not expect accurate

measurements for high frequency signals from the

1820/1822 exceeding +2.5V into a 50 ~ load. This is

equivalent to +5 divisions of deflection at 500mV/div in

an oscilloscope.

More sensitive settings (e.g. 100~tV/div) available on

some oscilloscopes are perfectly acceptable, but their

usefulness may be limited by noise, particularly with the

full bandwidth limit selection and without averaging.

With the oscilloscope set to lmV/div and the 1820/1822

in the XI000 gain mode, the over all deflection factor will

be 1 laV/div.

In its Xl0 gain mode, the 1820/1822 is somewhat quieter

than most oscilloscopes, so it is preferable to use the

1820/1822 X10 gain mode and a lower oscilloscope

deflection factor rather than the other way around. For

example, to obtain the best noise performance at

lmV/div, set the 1820/1822 to XI0 mode and the

oscilloscope to 10mV/div rather than the use XI mode

and lmV/div. Other oscilloscopes give up bits of

resolution to obtain ImV or 2 mV/div sensitivity. The

1820/1822 is very quiet in its XI0 or greater gain mode,

but no better than most oscilloscopes in the X1 mode.

Any oscilloscope bandwidth limit setting may be used so

long as the unlimited signal does not exceed full screen

before invoking bandwidth limit. This is a good rule to

follow in using oscilloscopes with or without the

1820/1822.

The oscilloscope’s gain and position controls should be

properly set to avoid displaying the non-linear portion of

the 1820/1822’s output signal when it is in overdrive.

This can be accomplished by observing the two following

rules:

Turn the oscilloscope input coupling to "OFF" or

"GND", set the oscilloscope position control to center

screen, and do not change it! If the oscilloscope has an

offset control, it too should be set to zero. Return the

oscilloscope’s input coupling to "DC". Subsequently

adjust the trace position on the oscilloscope screen using

the 1822 PVG (an external source for the 1820) and

VDIFF mode or VCOMP input. This assures that the

oscilloscope is looking at the center of the 1820/1822’s

dynamic range.

2-5

Page 13

0

1820/1822 Operator’s Manual

Model 1820 Operation

The performance and operation of the 1820 Differential

Amplifier is identical to that of the 1822 except as

follows:

The 1822 EFFECTIVE GAIN indicator is not

included in the 1820. The 1820 operator will need to

keep track of the various attenuator and gain settings

to accurately account for the proper deflection factor

on the oscilloscope.

Front Panel Settings Effective Full Scale Range

GAIN ATTEN

VCOMP VDIFF

XI +10 +155V +lOOV

XI0, xl00,

+1o +155v +lOV

xl000

XI

+1 +15.5V +lOV

Xi0, xl00, +! +15.5V

+lV

xl000

Front Panel Effective Full Scale Range

Settings

with +100 Probe

GAIN ATTEN

VCOMP VDIFF

X1 +10 +15.5kV

+lOkV

XI0 +!0 ±15.5kV

41000V

X!

+!

+ 1550V + ! 000V

Xl0 +1 +1550V +iOOV

.

The VcoMe and WHIFF functions operate the same as

in the 1822. The 1820 does not contain the Precision

Voltage Generator, but the voltages required for the

operation of VCOMP and VDIFF can be provided

from an external source. This voltage source is

applied to the 1820 through the OFFSET

VOLTAGE connector on the rear panel. By using a

stable voltage source and monitoring the level with a

DVM, operation and accuracy similar to that of the

1822 can be achieved. The maximum input voltage

that can be applied depends on whether the 1820 is

operated in VCOMP or VDIFF.

The following charts will help the operator stay within the

maximum input voltage limits and understand the

relationship between the actual voltage applied and the

effective voltage. Effective voltage is always referred to

the input of the 1820 or the probe tip if a probe is used.

When using probes, the maximum effective voltage range

may be limited by the maximum voltage rating of the

probe.

When operating the 1820 with an external voltage source,

the applied voltage should not exceed 15.5 volts in

Comparison mode and 10.0 volts in Differential Offset

mode.

When these maximum external voltages are applied, the

effective voltage as seen by the amplifier is as follows:

2-6

Note that the effective voltage is always increased by the

attenuator. It therefore follows that any probe will

increase the effective voltage of both VCOMP and VDIFF

by its attenuation factor. In other words, a probe with a

+100 attenuation factor will increase the effective full

scale range by 100.

Although the full scale range may be 10kV or 15.5kV,

most probes have a much lower maximum input voltage

rating which must not be exceeded.

Page 14

Section 3

General Operating Information

1820/1822 Operator’s Manual

Getting Started

This section will help the first time user become familiar

with the operation of the 1822 and how it interfaces with

an oscilloscope. Operation of the 1820 is very similar

except an external voltage source is needed for operation

of the comparison and differential offset modes.

To carry out the following exercises, the operator will

need an oscilloscope and a general purpose function

generator.

Power Connection

Check to make sure the POWER switch located on the

rear panel is in the OFF position. Connect the power

cord to an appropriate power source. The 1822 will

operate on a 50 or 60 Hz AC power source with a

nominal voltage range from 100 volts to 250 volts.

Connection to and Setting up the Oscilloscope

Connect a 50 f2 coaxial cable between the AMPLIFIER

OUTPUT BNC on the 1822 rear panel and the

oscilloscope’s input connector. If the oscilloscope has

1 M tq and 50 if2 input capability, select 50 f2. If the

oscilloscope has only a I M f2 input, terminate the

coaxial cable at the oscilloscope’s input with a 50

feed-through terminator. It is important that the 1822 be

terminated into 50 fL

Set the oscilloscope scale factor to 50mV/div. Set the

oscilloscope’s input coupling to GND or OFF and

position the trace to center screen. Do not move the

oscilloscope position setting after this initial set-up.

Change the oscilloscope input coupling to DC.

1822 Front Panel Operation

Change the POWER switch located on the 1822’s rear

panel to ON and observe the 1822’s front panel

indicators. Initially, there will be about a 2 second delay

and then each function, other than the upper and lower 3dB points, will have one indicator light lighted. The red

OVERLOAD and yellow OVERDRIVE lights will be

lighted as well as all segments in the Precision Voltage

Generator display. After approximately 3 seconds, the 1822

will be set to its power-up reset state. This state is as follows:

+ INPUT

- INPUT

HF-3dB POINT

LF-3dB POINT

GAIN

ATTENUATOR +10

INPUT RESISTANCE

PRECISION VOLTAGE GENERATOR

COMPARISON or DIFFERENTIAL COMPARISON

EFFECTIVE GAIN -10

Attenuator and Gain Operation

Connect the function generator output to the +INPUT BNC

connector and apply a sinewave of 50 kHz and 0.5V peak

amplitude. Push the DC button on the 1822’s +INPUT. The

signal on the oscilloscope should be 2 divisions peak to peak

amplitude. Adjust the oscilloscope’s time/division and trigger

to display at least two complete cycles of the waveform.

Press the +1 ATTENUATOR button. The waveform’s

magnitude on the oscilloscope’s display will increase by a

factor of 10 and extend off the top and bottom of the screen.

The XI light will be lighted in the EFFECTIVE GAIN

display. Reduce the function generator’s output until the

oscilloscope’s display is again 2 divisions peak to peak. The

overall sensitivity of the 1822 and the oscilloscope is now

50mV/div.

Now press the Xl0 GAIN button. Observe the following

changes: The +INPUT DC light will momentarily go out and

its OFF light will be lighted before returning to their previous

states. This momentary change is the result of the 1822

automatically adjusting its DC Balance. The XI0 light will be

lighted in the EFFECTIVE GAIN display and the display on

the oscilloscope will again extend off screen. The overall

sensitivity of the 1822 and the oscilloscope is now 5mV/div.

No lights on (full BW)

No lights on (DC)

OFF

OFF

Xl

1M

+ 00.000

3-1

Page 15

182011822 Operator’s Manual

Comparison Voltage Operation (VcoMP)

Leave the 1822 set up as in the previous exercise or set

as follows:

+ INPUT DC

- INPUT OFF

HF-3dB POINT No lights on (full BVV)

LF-3dB POINT No lights on (DC)

GAIN Xl0

ATTENUATOR

+1

INPUT RESISTANCE t M

PRECISION VOLTAGE GENERATOR + 0.0000

COMPARISON or DIFFERENTIAL COMPARISON

EFFECTIVE GAIN Xl0

¯ Function Generator output: 50 kHz 50 mVpk sine

wave. connected to the 1822’s +INPUT.

¯ Oscilloscope: Set at 50mV/div (equivalent to 5 mV/div

with 1822 at X10 GAIN) and time/division adjusted for

2 to 3 cycles.

Under these conditions, the display on the oscilloscope

will extend off the top and bottom of the screen.

Press the -INPUT VCOMP button. This internally

applies the Precision Voltage Generator’s output to the

1822’s -INPUT and the OFF light goes out (the

-INPUT connector is disabled).

The positive and negative peaks of the waveform

displayed on the oscilloscope are (respectively)

divisions above and below the display center line. Push

the button above the digit that is two places right of the

decimal (10 mV) in the Precision Voltage Generator

(PVG) until the positive peak of the waveform appears

the oscilloscope’s display. Continue incrementing and

decrementing Precision Voltage Generator’s digits until

the peak of the waveform is at the centerline of the

oscilloscope’s display. The number in the Precision

Voltage Generator display is the waveform’s positive

peak voltage.

Press the + button in the Precision Voltage Generator.

Observe that the negative peak of the signal is now at or

near the oscilloscope’s display centerline. By

incrementing and decrementing the digits, the negative

peak can be positioned to the oscilloscope’s display

center line. Now the number in the Precision Voltage

Generator’s display is the waveform’s negative peak

voltage.

Change the oscilloscope’s sensitivity from 50 mV/div to

10mV/div. Overall sensitivity, including the 1822, is now

lmV/div. Temporarily change the oscilloscope’s input

coupling from DC to GND (or OFF) and re-center the trace

center screen using the oscilloscope’s position control. Return

its input coupling to DC. Now press the XI0 button on the

1822 to invoke its Autobalance function. (Note that pressing

the gain button that is already selected causes the 1822 to

adjust its DC balance, but does not change its gain.)

Change the Precision Voltage Generator’s reading to again

place the negative peak of the waveform at the oscilloscope’s

center screen. Note that the Precision Voltage Generator’s

display represents the negative peak voltage of the waveform

with greater resolution.

Return the oscilloscope’s sensitivity to 50mV/div and press the

1822’s -INPUT OFF (or AC or DC) button. The Precision

Voltage Generator will retain its setting and the display on the

oscilloscope will be centered about the center line. Press the

-INPUT VCOMP button again and observe that the Precision

Voltage Generator’s output is again connected to the minus

input of the 1822’s -INPUT.

Following are a few observations on using the 1822

comparison voltage mode (VCOMP):

The negative input and its AC, OFF and DC coupling are

disabled. Instead of being a differential amplifier, the

1822 becomes a differential comparator. It compares the

voltage present at the +INPUT with the output of the

Precision Voltage Generator and when they are equal, the

output of the 1822 is zero volts.

The value displayed by the Precision Voltage Generator

indicates a waveform’s voltage, with respect to ground, as

it passes through the oscilloscope display’s centerline. It

is very important that the oscilloscope’s trace be

positioned to center screen if an accurate measurement is

to be made using this method.

By using the 1822 in the comparison voltage mode and

the oscilloscope in a high sensitivity setting, highly

accurate voltage measurements can be made.

The Precision Voltage Generator can be used as a position

control which allows the 1820/1822 to operate in its linear

region.

3-2

Page 16

Differential Offset Operation

Leave the 1822 set up as in the previous exercise or set

it up as follows:

+ INPUT

DC

- INPUT

VCOMP

HF-3dB POINT

No lights on (full BW)

LF-3dB POINT

No lights on (DC)

GAIN

Xl0

ATTENUATOR

)1

INPUT RESISTANCE 1M

PRECISION VOLTAGE GENERATOR - 0.0500*

COMPARISON or DIFFERENTIAL COMPARISON

EFFECTIVE GAIN XI0

*approximate

¯ Function Generator output: 50kHz 50mVpk sine

wave. connected to the +INPUT of the 1822.

¯ Oscilloscope: set at 50mV/div (equivalent to 5mV/div

with 1822 at X10 GAIN) and sweep adjusted for 2 to

cycles.

¯ Externally trigger the oscilloscope on the function

generator’s output (same signal as is applied to the 1822’s

+INPUT)

Under these conditions, the negative peak of the display

on the oscilloscope should be very near center screen.

Adjust the value in the Precision Voltage Generator until

the negative peak is at center screen.

Press the VawF button. This internally applies the output

of the Precision Voltage Generator to a point within the

1822’s amplifier that facilitates a true differential offset.

Also note that the Precision Voltage Generator display

was reset to zero (+ .00000) and the -INPUT coupling

changed. The VcoMP light went out and the OFF light

was lighted. In the line under the Precision Voltage

Generator display (COMPARISON or

DIFFERENTIAL OFFSET), the COMPARISON light

went out and the DIFFERENTIAL light was lighted.

This indicates that the Precision Voltage Generator will

now be applied as a differential offset rather than as a

comparison voltage as in the previous exercise. Both the

+INPUT and the -INPUT inputs are now enabled.

The positive and negative peaks of the waveform

displayed on the oscilloscope are 10 divisions above and

below (respectively) the center line of the display. Push

the button above the digit that is two places right of the

decimal (10mV) in the Precision Voltage Generator until

the positive peak of the waveform appears in the

182011822 Operator’s Manual

oscilloscope’s display. Continue incrementing and

decrementing the digits in the Precision Voltage Generator

until the peak of the waveform is at the center line of the

oscilloscope’s display. The number in the Precision Voltage

Generator display is the value of the waveform’s positive peak

voltage.

Press the + button in the Precision Voltage Generator.

Observe that the negative peak of the signal is now at or near

the oscilloscope display’s center line. By incrementing and

decrementing the digits, the negative peak can be positioned to

the oscilloscope display’s center line. Now the number in the

Precision Voltage Generator’s display is the value of the

waveform’s negative peak voltage.

Change the oscilloscope’s sensitivity from 50mV/div to

10mV/div. Overall sensitivity, including the 1822, is now

ImV/div. Temporarily change the oscilloscope’s input

coupling from DC to GND (or OFF) and re-center the trace

center screen using the oscilloscope’s position control. Return

its input coupling to DC. Now press the XI0 button on the

1822 to invoke its Autobalance function. (Note that pressing

the gain button that is already selected causes the 1822 to

adjust its DC Balance, but does not change its gain.)

Change the Precision Voltage Generator’s reading to again

place the negative peak of the waveform at the oscilloscope’s

center line. Note that the Precision Voltage Generator’s

display more accurately represents the negative peak voltage

of the waveform.

Return the oscilloscope’s sensitivity to 50 mV/div and again

press the 1822’s VDwv button. The VmFF light will go out and

the display on the oscilloscope will be centered about the

center line. Notice that the PVG retains its setting, but the

output of the PVG is not applied to the amplifier. Press the

VD=FF button again and observe that the Precision Voltage

Generator’s output is reapplied internally to the 1822

amplifier.

Following are a few observations on using the differential

offset mode (VDw~) of the 1820/1822:

Both the positive and negative inputs (AC, OFF and DC)

are enabled and the 1820/1822 remains a true differential

amplifier.

The value displayed by the Precision Voltage Generator

indicates a waveform’s differential voltage, with respect

to the -INPUT, as it passes through the oscilloscope

display’s center line. It is very important that the

oscilloscope’s trace be positioned to center screen if an

accurate measurement is to be made using this method.

The voltage applied to the 1820’s EXTERNAL

3-3

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

Q

e

e

e

e

e

i

Page 17

182011822 Operator’s Manual

VOLTAGE INPUT also indicates the waveform’s

differential voltage with respect to its -INPUT.

By using the 1822 in the differential offset mode and

the oscilloscope in a high sensitivity setting, high

resolution voltage measurements can be made. The

-INPUT is the reference for these measurements.

The Precision Voltage Generator can be used as a

position control which allows the 1822 to operate in

its most linear region.

Which Offset Mode Should be Used?

The operation of the Comparison (VcoMv) and

Differential Offset modes (VwvF) are quite similar. The

Comparison mode is easier to understand and has a wider

range, 15.5 volts versus 10.0 volts. The Differential

Offset mode provides offset operation while allowing the

1822 to function as a true differential amplifier.

For most applications, the Differential Offset (VDIFF)

mode has advantages over the Comparison (VcoMv)

mode. When using the Comparison mode, the Precision

Voltage Generator’s output is subtracted from the

+INPUT. Except for the PVG’s offset, operation is the

same as a standard single-ended oscilloscope - only one

1820/1822 input is available. In the Differential Offset

mode, the 1820/1822 functions as a differential amplifier

- both +INPUT and -INPUT function. This allows the

operator to choose a measurement reference point other

than ground. Even in ground referenced measurements,

signal degradation can be reduced by using the -INPUT

probe to select a ground reference point with the least

noise. This method is especially useful in eliminating

hum and noise from ground loops.

User Traps to Avoid

There are a few situations the user of either the 1820 or 1822

should be aware of to avoid some potential measurement traps.

Exceeding the Common Mode Range

The 1820 and 1822 Differential Amplifiers have the largest

common mode range available for this type of amplifier and

are very good at measuring small differences between two

large signals. However, care still must be taken not to allow a

large common mode signal to exceed the available common

mode range.

The maximum common mode range is +15.5 volts when a

signal is applied directly (+1 ATTENUATOR and no probes)

to the 1820/1822’s + and - inputs. The yellow OVERDRIVE

light illuminates to warn the user of possible waveform

distortion caused by exceeding +15.5 volts.

Attenuating the input signal extends the common mode range

by the same factor as the attenuation. Pressing the +10

ATTENUATOR button increases the common mode range to

+155 volts, and using a probe with a +10 attenuation factor

will too. The effect of the internal +10 ATTENUATOR and

the attenuation factor of probes is multiplied just as the signal

is attenuated. As an example, using the amplifier’s +10

ATTENUATOR with a probe having a +100 attenuation

factor (total attenuation of+1000) results in a common mode

range of 15,500 volts. In this case, the probe’s maximum

voltage rating probably limits the maximum common mode

input voltage.

The gain setting of the amplifier has no effect on common

mode range; it is the same in XI000, XI00, XI0 or XI gains.

There is one instance in which the Differential Offset

(VmFv) mode might result in more noise. Magnetic pickup is proportional to the area between the probes. If

twisting the probe leads together is not sufficient to

reduce magnetic pick-up, the Comparison Offset (Vco~)

mode may be preferable.

Because the Comparison Offset mode uses the CMRR of

the 1822 while the Differential Offset mode uses an

internal amplifier, the Comparison Offset mode is

slightly more accurate.

The Differential Offset (VDIFF) mode is usually the mode

of choice if the wider range or higher accuracy of the

Comparison (VcoMP) mode is not needed.

When making measurements on circuits that are line

referenced, be sure to use enough total attenuation to keep the

peak voltage at the amplifier input below 15.5 volts. The US

line can exceed 170 peak volts and therefore at least a total

attenuation of +100 should be used. Line voltages in some

other countries are larger but their peak voltages do not exceed

the 1550 volt common mode range that a +100 attenuation

factor provides.

Moving the oscilloscope position setting away from

center screen

When operating the 1820/1822 with an oscilloscope, it is very

important to set the oscilloscope position and/or offset control

to center screen. There are a couple of reasons for this:

3-4

Page 18

182011822 Operator’s Manual

First, the linear portion of the 1820/1822’s +5V output

range is around zero volts. As the 1820/1822

approaches its limits, the output signal will be distorted.

Moving the oscilloscope position control way from

center screen can allow these distortions to appear on the

oscilloscope’s screen where they may be mistaken for

part of the displayed signal.

Second, proper operation of the 1822’s Precision Voltage

Generator (PVG) depends on the operator knowing the

location of zero volts on the display. The readout in the

PVG is designed to display the voltage of the signal as it

crosses the center line of the oscilloscope screen. If the

oscilloscope position or offset control has been moved,

incorrect readings could result.

Using Oscilloscope V/Div Settings Greater than

500 mV/Div

"I know the input to the 1820/1822 is a sinewave, but I

am seeing a square wave on the oscilloscope." This

comment is the result of the operator setting the

oscilloscope sensitivity to something less than 1V/div. If

the oscilloscope sensitivity is set to 2V/div, the

1820/1822 will limit at 2-1/2 divisions above and below

center screen (zero volt point if the oscilloscope’s

position control is properly set). Thus, a sinewave large

enough to overdrive the 1820/1822 will appear as a

square wave on the oscilloscope.

Failure to Terminate the Amplifier into 50 f2

"All the signals displayed on my oscilloscope seem to be twice

as large as they should be." This comment results from not

having the output of the 1820/1822 properly terminated into 50

if2. The 1820/1822 output impedance is 50 f). The cable

connecting the 1820/1822 to the oscilloscope or spectrum

analyzer should be 50 f2 and be terminated with a 50 ~ load.

If the termination at the end of the connecting coaxial cable

is missing, the amplifier will not be properly terminated.

The gain of the amplifier will be twice that indicated by the

front panel settings and the 1822’s EFFECTIVE GAIN

indicator will be offby a factor of two.

In some measurements, the operator can take advantage of this

increased gain if the problems caused by not terminating the

output are fully understood and taken into account.

The 1820/1822 is designed to cleanly limit the output

signal to +5V. Keeping the oscilloscope’s position at

center screen and using oscilloscope sensitivities between

500mV/div and I mV/div (or the oscilloscope’s most

sensitive setting) will insure good signal integrity. When

the displayed signal contains mostly low frequency

components, the operator can use the oscilloscope’s

1V/div setting to allow large signals to be completely

shown on screen.

3-5

Page 19

Section 4

Performance Verification

1820/1822 Operator’s Manual

Introduction

This procedure can be used to verify the warranted

characteristics of the

Differential Amplifiers.

Unless otherwise noted the 1820 refers to the 1820, and

1820-PR2. 1822 refers to the 1822, and 1822-PR2.

The-PR2 models contain two complete single channel

amplifiers within a single housing. To verify the

performance of the -PR2 models, complete the entire

procedure on one channel, then repeat the procedure

with the remaining channel.

The recommended calibration interval for the model

1820 and 1822 Differential Amplifiers is one year. The

complete performance verification procedure should be

performed as the first step of annual calibration. Test

results can be recorded on a photocopy of the Test

Record provided at the end of this section.

Performance verification can be completed without

removing the instrument covers or exposing the user to

hazardous voltages. Adjustment should only be

attempted if a parameter measured in the Performance

Verification Procedure is outside of the specification

limits.

1820 and 1822 series of

NOTE

Adjustment should only be performed by qualified

personnel. Removing the covers from the instrument

may alter critical compensation adjustments, requiring

the instrument to be re-calibrated. Re-establishing these

adjustments requires the use of special calibration

fixtures. Therefore, the covers should never be removed

by the user. The Adjustment Procedure is part of this

service manual.

Test Equipment Required

Table 4-1 on the following page lists the test

equipment and accessories, or their equivalents,

which are required for performance verification of

the 1820/1822.

This procedure has been developed to minimize

the number calibrated test instruments required.

Only the parameters listed in boldface in the

Minimum Requirements column must be

calibrated to the accuracy indicated.

Because the input and output connector types may

vary on different brands and models of test

instruments, additional adapters or cables may be

required.

4-1

Page 20

182011822 Operator’s Manual

TABLE 4-1

List of required Equipment

Description

Minimum Requirements Test Equipment Examples

Wide Band Oscilloscope

Oscilloscope Preamplifier

Digital Multimeter

Oscillator/Function Generator

Leveled Sine Wave Generator

100 MHz bandwidth

2 mV-200 mV scale factors

1 ns-10 [as time/division

2% vertical accuracy

50 ~ termination

200laV- 10mY scale factors

10 MHz bandwidth

DC: 0.2% accuracy

AC: 0.2% accuracy to measure

200 mV and 2 Vrms @ 1 kHz

6% digit resolution

Sinewave output

5 Vp-p

50 Hz - 1 MHz frequency range

Relative output level accurate to

3% flatness from 1 - 100 MHz

and 50 kHz.

Output adjustable to 2 Vp-p

LeCroy LT342 or

LeCroy LC584AM

Wide band oscilloscope plus Preamble

1822.

HP 34401A, or

Fluke 8842A-09, or

Keithley 2001

Stanford Research Model DS340, or

Hewlett Packard 33120A, or

Leader LAG- 120B

Tegam SG503 with TM series mainframe

with 012-0482-00 precision BNC cable.

A semiautomatic software leveled signal

source calibrated with a power meter may

be substituted.

Terminator, in-line, BNC 50 f2 + 1% coaxial termination

ITT Pomona 4119-50, or

AIM 27-9008

Terminator, precision, BNC 50 ~ + 0.05%

Tektronix 011-0129-00

Attenuator, BNC, (2 ca) 50 f~ + 2%, +10 (20 dB),

ITT Pomona 4108-20dB, or

BNC coaxial cable, (2 ca) Male-male BNC (approx. 1 meter)

ITT Pomona 5697-36

BNC coaxial cable, (2 ca) Male-male BNC 4"-6" length

Pasternack Enterprises PE3067-5

BNC ’Y’ connector Male to dual female, BNC

AIM 27-9294

BNC Tee connector Male to dual female, BNC

ITT Pomona 3285, or

AIM 27-8140

BNC adapter Female to female AIM 25-7430, or

ITT Pomona 3283

Banana Plug adapter BNC female to banana plug.

ITT Pomona 1269

Note: Boldface indicates parameters required to be calibrated. Other parameters are compensated for in the procedure

and can be approximate.

4-2

Page 21

Preliminary Procedure

1. Connect the Differential Amplifier to an AC power

source within the range listed in the Nominal

Characteristics in the Specification section.

1. Allow at least 20 minutes warm-up time for the

1820/1822 and test equipment before performing the

Verification Procedure.

2. Turn on the other test equipment and allow it to warm

up for the time recommended by the manufacturer.

The warranted characteristics of the 1820/1822 series

Differential Amplifiers are valid at any temperature

within the Environmental Characteristics listed in

Section 1. However, some of the other test equipment

used to verify the performance may have environmental

limitations required to meet the accuracy requirements

needed for the procedure. Be sure that the ambient

conditions meet the requirements of all the test

instruments used in the procedure.

NOTE

When the oscilloscope input is connected to the

1820/1822 AMPLIFIER OUTPUT, the oscilloscope

input impedance should be set to 50 .(-2 unless otherwise

stated Use a 50 .(2 inline termination when using an

oscilloscope without an internal 50 .(2 termination.

Position the oscilloscope display to center screen.

Unless otherwise noted, the oscilloscope position and

offset must remain at zero for the duration of the

adjustment procedure.

Set the 1820/! 822 front panel controls as follows:

HF -3 dB POINT All LEDs Off

(Maximum bandwidth)

LF-3dB POINT

All LED’s Off

(DC)

GAIN

Xl

ATTENUATOR .-1

INPUT RESISTANCE

1 MQ

+INPUT OFF

-INPUT OFF

VCOMP

OFF

VDIFF

OFF

PRECISION VOLTAGE 00.000 V

GENERATOR

4-3

1820/1822 Operator’s Manual

Procedure

1. CheckXl Gain Accuracy

a. Set the 1820/1822 +INPUT to DC.

b. Connect the High Amplitude Sine Wave

generator via a 50 f2 BNC coaxial cable, a

standard 50 f2 termination to a female BNC

to banana plug adapter.

c. Set the DMM to measure AC volts.

d. Connect the banana plug adapter to the

DMM.

e. Set the sine wave generator to 70 Hz and the

output amplitude to read 2 Vrms + 50 mV on

the DMM.

f. Record the DMM reading to 100 laV

resolution as ’Sine Wave Generator Output

Voltage’ in the Test Report.

g. Disconnect the sine wave generator output

cable with the 50 f2 termination from the

BNC to banana plug adapter on the DMM.

Leave the banana plug adapter installed on

the DMM for the remainder of the

procedure.

h. Connect the sine wave generator via the

coaxial cable with the standard 50 f2

termination to the +INPUT of the

1820/1822.

i. Connect the 1820/1822 AMPLIFIER

OUTPUT connector via another coaxial

cable and the precision 50 ~ termination to

the banana plug adapter on the DMM.

j. Press the XI GAIN button to remove any

residual DC offset from the input. (A DC

component may interfere with the RMS

computation in some DMMs.)

k. After the DMM has stabilized, record the

reading to 1 mV resolution as ’Amplifier

Output Voltage’ in the Test Record.

1. Divide the measured output voltage from

step 1-k by the sine wave generator output

voltage (amplifier input voltage) in step i-f.

Subtract 1.0 from the ratio and multiply the

result by 100% to get the error in percent.

I

Measured Output Voltage _ 11 x

Error = Amplifier Input Voltage 100%

I

Page 22

1820/1822 Operator’s Manual

m. Record the result to two decimal places

(±0.xx%) as ’Xl Gain Error’ in the Test

Record.

n.

CHECK -- That the XI GAIN error is less

than ± 1%.

2. Check +10 Attenuator Accuracy.

NOTE

The accuracy of the internal +10 attenuator is not a

warranted specification. However, the attenuator will

be used in the XIO00 gain test where it’s absolute

accuracy will be included in the calculations.

a.

Verify that the measured output voltage is still

the same value as recorded in step l-k.

b. Set the 1820/1822 ATTENUATOR to +10.

c. After the DMM has stabilized, record the

reading as ’Amplifier Output Voltage’ in the

Test Record to 10 laV resolution.

d. Divide the output voltage recorded in step 1-k

by the attenuated output voltage recorded in

step 2-c. Record the result to four digit

resolution in the Test Record. This is the

’Actual Attenuation’.

e.

Divide the attenuation calculated in step 2-d

by 10.0. Subtract the 1.0 from the result and

multiply this number by 100% to get the

attenuation error in percentage.

Error=(Actual Attenuation(StePlo 2-d)-13

xl00%

f. Record this value as ’+10 Attenuator Error’ in

the Test Record.

g. Add the attenuation error recorded in step 2-f

to the X 1 gain error recorded in step l-k. Be

sure to include the signs of the two terms

when performing this addition. Record the

result to two decimal places (±0.xx%) as ’XI

Gain + +10 Attenuation Error’ in the Test

Record.

h. CHECK -- That the combined X1 Gain +10

Attenuation error is less than ± 1%.

4-4

3, Check the Xl0, Xl00 and Xl000 Gain

Accuracy.

NOTE

Because most DMMs do not provide the required

accuracy on lower AC voltage ranges, the check for

XIO, XIO0 and XIO00 Gain Accuracy uses a ratio

technique with an external +10 attenuator. The actual

attenuation of the attenuator is determined using higher

amplitude signals.

i. Disconnect the amplifier output cable and the

precision 50 f2 termination from the BNC to

banana plug adapter on the DMM.

j. Disconnect the sine wave generator output

cable from the +INPUT and remove the 50 f2

termination from the coaxial cable.

k.

Connect one female end of the BNC Tee to

the sine wave generator cable.

1. Connect a 50 f2 + 10 attenuator to the male

end of the BNC Tee followed by a standard

50 f~ termination.

m. Connect another coaxial cable from the

banana plug on the DMM to the other female

end of the BNC Tee.

n. Set the sine wave generator output amplitude

to read 2.00 Vrms ± 50 mV on the DMM.

o. Record the reading to 1 mV resolution as

’Sine Wave Generator Output Voltage’ in the

Test Record.

p.

Remove the DMM cable from the BNC Tee.

q. Connect the 50 if2 termination end of the

termination/attenuator/BNC Tee combination

of the sine wave generator cable to the DMM

banana plug adapter.

r. Record the DMM reading to 100 laV

resolution in the Test Record as ’ Actual

Amplifier Input Voltage’.

(Note: This reading should be approximately

200 mV. If it is not, verify that the in-line

attenuator and termination are installed in the

correct order. The 50 if2 termination should

be closest to the DMM).

s. Divide the DMM reading in step 3-j into the

output amplitude measured in step 3-g. This

is the exact attenuation of the attenuator-

termination combination.

t. Record the result to four digit resolution as ’

Exact Attenuation’ in the Test Record.

Page 23

182011822 Operator’s Manual

Disconnect the termination/attenuator/BNC

u.

Tee combination from the DMM.

v. Connect the terminated end of the

termination/attenuator/BNC Tee combination

to the 1820/1822 +INPUT.

Connect the DMM to the free female end of

w.

the BNC Tee connector.

Adjust the sine wave generator output

x.

amplitude to read 200 mVrms + 50 mV on the

DMM.

y. Record the DMM reading to 100 p.V in the

Test Record as ’Sine Wave Generator Output

Voltage’.

z. Disconnect the DMM cable from the BNC

Tee.

aa. Connect the DMM cable to the 1820/1822

AMPLIFIER OUTPUT connector.

bb. Insert the precision 50 f) termination between

this cable end the banana plug adapter on the

DMM.

cc. Set the 1820/1822 GAIN to XI0.

jj. Record the calculated error to two decimal

places (+0.xx%) in the Test Record as ’X

Gain Error’.

kk. CHECK -- That the calculated error is less

than + 1%.

11. Press the XI00 GAIN button on the

1820/I 822.

mm. Multiply the actual input voltage of the

1820/1822 which was recorded in step 3-w by

100.0.

nn. Record the result to four digit resolution in the

Test Record as ’Expected Amplifier Output

Voltage’.

oo. After the DMM has stabilized, record the

measured output voltage to 1 mV resolution

as ’Measured Amplifier Output Voltage’ in

the Test Record.

pp. Calculate the error by dividing the measured

output voltage recorded in step 3-gg by the

expected output voltage recorded in step 3-ff.

Subtract !.0 from this ratio and multiply by

100% to get the error in percent.

dd. Divide the sine wave generator amplitude

recorded in step 3-q by the actual attenuation

calculated in step 3-1. This represents the

actual voltage on the input of the amplifier.

ee. Record the result as ’Actual Amplifier Input

Voltage’ in the Test Record.

ff. Multiply the actual input voltage as recorded

in step 3-w by 10.0 to obtain the expected

output voltage.

gg. Record the result to four digit resolution as

’Expected Amplifier Output Voltage’ in the

Test Record.

hh. After the DMM reading has stabilized, record

the measured voltage to 100 !aV resolution as

’Measured Amplifier Output Voltage’ in the

Test Record.

ii. Calculate the error by dividing the measured

output voltage recorded in step 3-z by the

expected output voltage recorded in step 3-y.

Subtract 1.0 from this ratio and multiply by

100% to get the error in percent.

Measured Output Voltage

I

qq. Record the calculated error to two decimal

places (+0.xx%) in the Test Record as X i00

Gain Error.

rr. CHECK -- That the calculated error is less

than + 1%.

ss. Press the +10 ATTENUATOR and then the

X1000 GAIN button on the 1820/1822.

Divide the actual input voltage recorded in

tt.

step 3-w by the internal +10 attenuation

factor, recorded in step 2-d. This represents

the effective amplifier input voltage.

Multiply this number by 1000 to get the

expected output voltage.

uu. Record this reading as ’Expected Amplifier

Output Voltage’ in the Test Record.

1") x 100%Error = Expected Output Voltage

)

Error= ~, Expected Output Voltage

(.Measured Output Voltage _ 11 x 100%

vv. After the DMM has stabilized, record the

measured output voltage to I mV resolution

)

4-5

in the Test Record as ’Measured Amplifier

Output Voltage’.

Page 24

182011822 Operator’s Manual

ww. Calculate the error by dividing the measured

output voltage recorded in step 3-00 by the

expected output voltage recorded in step 3.

Subtract 1.0 from this ratio and multiply by

100% to get the error in percent.

Error =

Measured Output Voltage

Expected Output Voltage

1) x 100%

°

xx. Record the calculated error to two decimal

places (±0.xx%) as ’X1000 Gain Error’ in the

Test Record.

yy. CHECK -- That the calculated error is less

than ± 1%.

Check X1 and XI0 Bandwidth and Calculate

Rise Time.

a. Connect the AMPLIFIER OUTPUT to

channel 1 of the oscilloscope.

b. Set the channel input coupling to 50 fL

NOTE

If the oscilloscope does not have an internal 50 [2 input

termination, inset the standard inline 50 [2 termination

between the cable and the oscilloscope input.

Use the standard wide bandwidth 50 [2 termination.

The precision termination is not accurate at frequencies

higher than 100 kHz.

c. Set the 1820/1822 GAIN to XI and the

ATTENUATOR to +10.

d.

Connect a BNC cable to the output of the

leveled sine wave generator.

NOTE

Many leveled sine wave generators, including the

SG503, are calibrated only when a special BNC cable is

used on its output. Be sure to use a cable which is

specified for the generator.

Insert a standard 50 ~ termination on the free

cable end and connect the termination to the

+INPUT of the 1820/1822.

4-6

f. Set the sine wave generator output frequency

to 50 kHz, and the amplitude to

approximately 3 Vp-p.

g. Set the oscilloscope V/div to 50 mV/div and

the time/div to 20 p.sec/div. Adjust the trigger

level for a stable display.

h. Adjust the sine wave generator output for an

amplitude of exactly 6 divisions (300 mV)

the oscilloscope.

i. Set the sine wave generator output frequency

to 500 kHz. Be careful not to alter the output

amplitude.

NOTE