Page 1

LD SERIES PRESSURE WASHERS

USERS MANUAL

Model Numbers

Power Systems

LD20

PW200

PW240

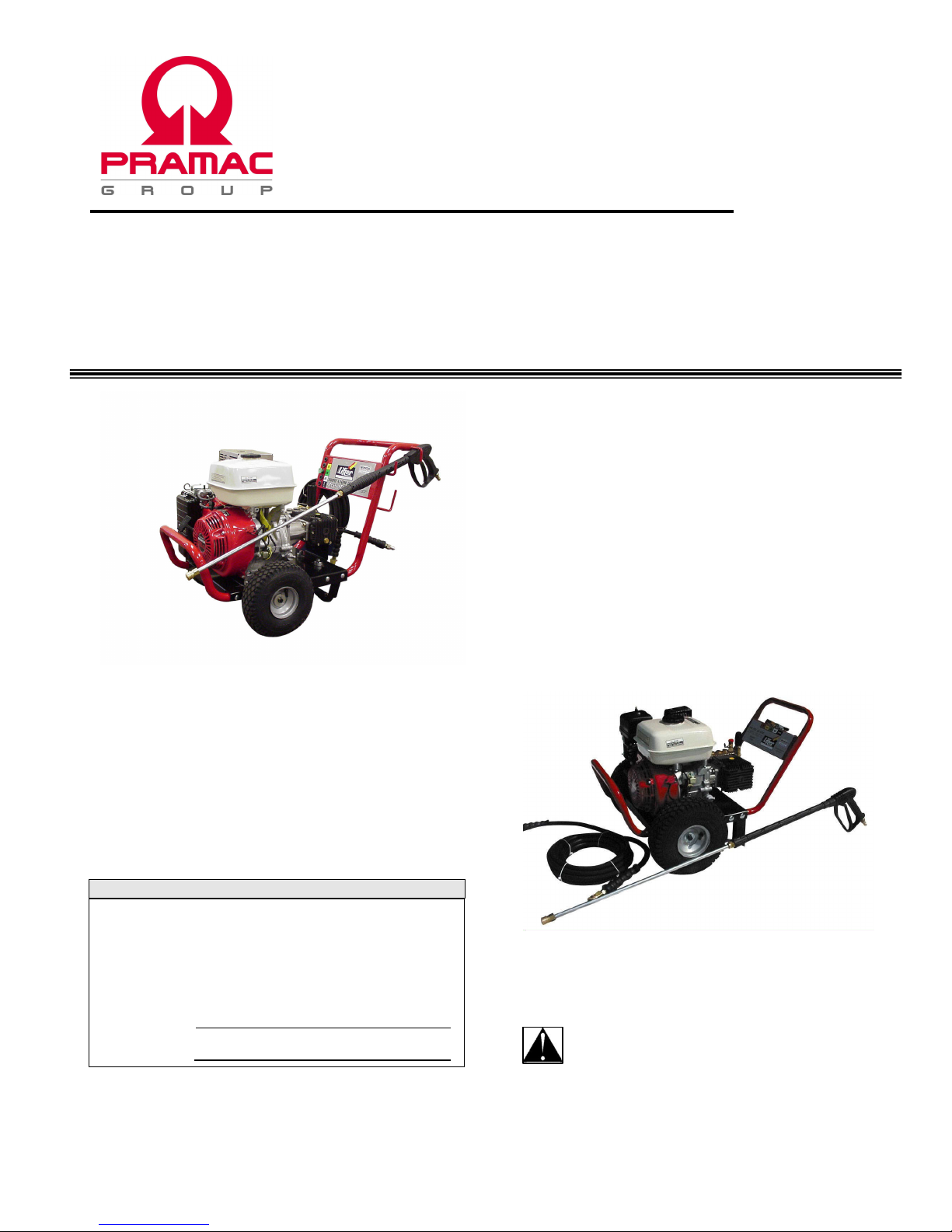

PW240 Model Shown

MODEL & SERIAL NUMBER

Enter the Model and Serial numbers of your pressure

washer in the spaces provided below. Retain these

numbers for future reference. The Model and Serial

numbers are located on the data plate on the base plate

or handle name plate, along with other important

information.

Model Number

Serial Number

DOCPRA0018 1

8/17/06 Rev. 1

LD20 Model Shown

Attention: Before operating your

Pressure Washer please read and

understand this manual. Please provide

this manual to any user or subsequent owner of

this machine.

Page 2

LIMITED 1 YEAR WARRANTY STATEMENT

A. PRAMAC Lifter pressure washers originally sold by PRAMAC Industries, Inc. or an authorized Distributor/ Dealer

thereof, are covered by a limited warranty for a period of 12 months. The Warranty period begins on the date of purchase by

the end user, 2 days after shipment to the end user by the PRAMAC Lifter™ Distributor/ Dealer, or 12 months from the date

of original invoice by PRAMAC Industries, Inc.- whichever occurs first. PRAMAC Industries, Inc. warrants their PRAMAC

Lifter products to be free of defects in materials and workmanship for the time period shown above and within the

limitations presented in the following. This PRAMAC Lifter Limited Warranty does not cover components or assemblies

manufactured by other organizations, including, but not limited to – engine, pump, lances, etc. Warranties for items and

assemblies not manufactured by PRAMAC Industries, Inc. are covered under the warranties of the respective

manufacturers of those products. Documentation concerning the warranty policies of items not manufactured by PRAMAC

Industries, Inc., but included as part of the PRAMAC Lifter pressure washer is included within the pressure washer

documentation.

These warranties are in lieu of and exclude all other warranties of merchantability, fitness, or otherwise, express or implied.

There are no warranties which extend beyond the description on the face thereof. The sole obligation of PRAMAC Industries,

Inc. (Seller) shall be to repair or replace any components thereof which are proved to be other than warranted. PRAMAC

Industries, Inc. shall have the sole right to determine whether such goods shall be repaired or replaced. This remedy of

repair or replacement is in lieu of all other remedies, and it is agreed that no other claim may be made by the Buyer. Buyer

and Seller agree that the sole purpose of this remedy is to provide the Buyer a satisfactory product under the contract. It is

further agreed that in no event shall the Seller be liable for incidental or consequential damages arising from any breach of

warranty. If goods are claimed to be other than as warranted the Seller or Sellers Authorized Agent, upon notice promptly

given, will issue shipping instructions for return to the Seller or Sellers authorized Agent (transportation costs to be

responsibility of Buyer) the goods or components, and if goods are proven to be other than as warranted, replacement or

repaired components will be shipped (cheapest way) to the Buyer with transportation costs paid by the Seller. PRAMAC

Industries, Inc. reserves absolute and final decision power regarding the warrantability of any and all failed components or

parts. Some states do not allow limitations on how long an implied warranty lasts, and some states do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights and you may also have other rights which vary from state to state.

B. All warranties of merchantability, fitness or otherwise, whether express or implied, shall not extend to any goods or parts

thereof which have been: subject to misuse or neglect, damaged by accident, rendered defective by reason of improper

handling or application, damaged or rendered defective due to tampering of factory set adjustments, damaged due to

shipment, damaged due to lack of maintenance, damaged due to collision, impact or shock loads, or damaged due to

corrosion. Further, any modifications to the intended and original designed use of the PRAMAC Lifter pressure washer will

negate all warranties. Seller does not accept any liability for normal wear and tear, typical maintenance, nor for charges for

repairs or replacements made without authority, nor contingent liability of any kind.

C. YOUR WARRANTY RESPONSIBILITIES: You are responsible for the performance of all maintenance including the use

of approved fluids. Upon first indication of a problem, you are to cease operation of your PRAMAC Lifterpressure washer

and report the problem to your Authorized PRAMAC Lifter Distributor/ Dealer. Upon request, you will be required to

produce proof of purchase and other pertinent information. Your Authorized PRAMAC Lifter Distributor/ Dealer will instruct

you regarding transportation (prepaid by buyer) of your PRAMAC Lifter product to the Authorized Distributor/ Dealer

location or arrange for shipment (prepaid by buyer) of the failed components to the Authorized Distributor/ Dealer for

warranty inspection. The name, address and telephone number of your local PRAMAC Lifter Distributor/ Dealer or

authorized service facility may be obtained by contacting PRAMAC Industries, Inc. at (770) 218-2810.

January 01, 2000

2

Page 3

GENERAL WARRANTY STATEMENT

Items on this pressure washer not manufactured by PRAMAC Industries, Inc. are not covered by the previously

defined 12 month warranty. Most of these parts carry a warranty from the respective manufacturer. The general

warranty information for these parts is described below. See the documentation provided by each manufacturer

which is included with this pressure washer for a complete definition of warranty and claims information. Please

note that in the event of discrepancies between this information and that of the manufacturer, the manufacturers

data takes precedence.

Engine

Honda GX160

Honda GX270

Honda GX390

2 year limited warranty

Pump

Annovi Reverberi (AR)

5 year limited warranty - North America

Accessories

Meccanica Veneta (Gun/Lance)

6 month limited warranty

3

Page 4

Contents

LIMITED 1 YEAR WARRANTY STATEMENT ......................................................................................................... 2

GENERAL WARRANTY STATEMENT...................................................................................................................... 3

SECTION 1..................................................................................................................................................................... 5

GENERAL INFORMATION........................................................................................................................................ 5

SAFETY RULES.......................................................................................................................................................... 5

GENERAL SAFETY OPERATIONAL GUIDELINES ................................................................................................. 6

GENERAL MAINTENANCE....................................................................................................................................... 6

CLEANING YOUR MACHINE.................................................................................................................................... 6

PRESSURE WASHER MAINTENANCE..................................................................................................................... 6

GENERAL STORAGE GUIDELINES.......................................................................................................................... 6

USING YOUR PRESSURE WASHER ......................................................................................................................... 7

PRESSURE WASHER SPECIFICATIONS .................................................................................................................. 8

GENERAL PRODUCT INFORMATION ..................................................................................................................... 8

TROUBLESHOOTING PROCEDURE......................................................................................................................... 9

SECTION 2....................................................................................................................................................................10

LD20 PARTS AND PART LISTS................................................................................................................................10

SECTION 3....................................................................................................................................................................12

LD30 PARTS AND PART LISTS................................................................................................................................12

SECTION 4....................................................................................................................................................................14

LD35 PARTS AND PART LISTS................................................................................................................................14

All information provided in this manual is believed to be correct at the time of printing. The manufacturer reserves the right to correct any

errors and omissions.

4

Page 5

SECTION 1

GENERAL INFORMATION

This manual is provided for you so that your

pressure washer may be properly, safely and

effectively applied and operated. Please read and

understand all aspects of this manual before

operating your pressure washer. Please also read

and understand the documentation supplied with

this pressure washer regarding the engine and

pump. Keep this documentation in a safe and

accessible place so that reference can be made as

needed. All operators, users and subsequent

owners of this pressure washer must read and

understand all aspects of this documentation before

operation. Please make note that your pressure

washer is equipped with a thermal relief valve. If

water begins to spray from your pump during

operation it is likely because water temperature

has exceeded 140°F. This usually occurs if the

machine is left running during periods(usually 5

minutes or more) of non-use. This is a safeguard

against damage which can occur with high water

temperatures. It is recommended that the engine be

shut down if the pressure washer will not be used

for extended periods.

SPARK ARRESTING MUFFLER

Certain States and Jurisdictions require that engine

driven equipment be fitted with spark arresting mufflers.

Depending on the model, spark arresting mufflers may

or may not be fitted. If spark arresting mufflers are

required for your specific location and the pressure

washer muffler is not spark arresting, contact your local

dealer for instructions for a retrofit.

EXHAUST EMISSION CONTROL SYSTEM

The exhaust emission control system for this pressure

washer complies to the standards set forth by the

California Air Resources Board (CARB) and the

Environmental Protection Agency (EPA). Warranties for

the exhaust emission system are administered by the

respective engine manufacturers. Refer to the engine

documentation for warranty information.

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

THIS SYMBOL IS USED THROUGHOUT YOUR

OWNER’S MANUAL TO BRING ATTENTION TO

IMPORTANT SAFETY INSTRUCTIONS. FAILURE TO

READ, UNDERSTAND AND FOLLOW SAFETY

INSTRUCTIONS COULD ENDANGER YOU OR OTHERS AND

RESULT IN PERSONAL INJURY OR DEATH.

DO NOT OPERATE THIS PRESSURE WASHER

WITHIN AN ENCLOSED AREA. THE EXHAUST

GASES OF THIS PRESSURE WASHER EMIT “DEADLY”

CARBON MONOXIDE. EXPOSURE TO CARBON MONOXIDE

CAN CAUSE CARBON MONOXIDE POISONING,

HEADACHES, NAUSEA, SEVERE SICKNESS OR DEATH.

DANGER: PARTS OF THIS PRESSURE WASHER

SUCH AS THE ENGINE, MUFFLER, AND PUMP CAN

BECOME VERY HOT DURING OPERATION.

CONTACT WITH THESE PARTS CAN CAUSE SERIOUS

INJURY. ALWAYS ALLOW ADEQUATE COOL DOWN TIME

BEFORE SERVICING.

DANGER: NEVER ADD FUEL TO A HOT MACHINE

OR RUNNING MACHINE. HOT ENGINE PARTS

SPARKS, OR LIT CIGARETTES COULD IGNITE

GASOLINE. NEVER STORE FUEL OR OTHER

COMBUSTIBLE MATERIAL NEAR THIS MACHINE.

SAFETY RULES

DANGER: This equipment produces a very high

pressure stream of water which can penetrate

the skin and cause serious injury. Under no

circumstance should the spray gun be aimed at people,

animals or any delicate items which might be damaged.

DANGER: Users of this machine should always

dress properly before using. Safety glasses,

shoes, long pants, shirt, and ear protection are

recommended. Specific situations, such as during

chemical application, could require a much greater level

of protective clothing.

DANGER: When using chemicals in conjunction

with this machine you should always wear gloves,

eye protection and clothing which leaves no

exposed skin.

DANGER: Never point the output water stream

at electrical wiring or devices. This can lead to

damaged components, personal injury or even

fatal electrical shock.

CAUTION: Do not modify the factory engine

settings on your pressure washer. The factory

settings are made to produce the designed

pressure and flow rate for your equipment. Any

misapplication can lead to damaged components or even

bodily injury.

CAUTION: Only qualified personnel should be

allowed to use this machine. Under no

circumstances should children be allowed to

operate this machine.

CAUTION: The water supply should always be

clean. Never use water if it contains dirt, sand,

chemicals or any other foreign matter. For information

regarding chemical use refer to the section titled Chemical

Application included later in this manual.

5

Page 6

GENERAL SAFETY OPERATIONAL

GUIDELINES

Read and understand all of the general safety

operational guidelines and rules before operating

this pressure washer.

Always follow National and Local codes and

restrictions.

When moving or transporting this machine, take

proper precautions to avoid fuel spillage. Further,

always use common sense when lifting this pressure

washer. An adequate number of people and proper

lifting procedures must be used.

Whenever changing or adjusting the spraying tip you

should always use the trigger lock-off feature on the

spray gun. This feature should also be engaged

when making any other adjustments to this machine;

the machine should never be left unattended.

Do not operate this pressure washer unless the lock-

off feature on the gun is in good mechanical

condition.

Do not operate this machine above the maximum

factory preset pressure.

Always inspect this machine for damaged, loose or

missing parts before use.

The area of operation should be relatively

obstruction free and very well ventilated.

Always locate this machine on a relatively flat (20%

grade or less) and stable surface before operation.

Use proper parts, which are equivalent to those

provided when new, if performing maintenance or

repairs. Improper parts could cause damage or

reduced performance of your machine.

Always remember that the muffler, engine, and

pump can become very hot during operation and

remain that way for a considerable time.

Gasoline is highly FLAMMABLE and its vapors

are EXPLOSIVE. Handle gasoline with extreme

care. Failure to properly handle gasoline can result

in explosion or fire. Do not permit smoking within

50ft of this machine.

NEVER REFILL A HOT OR RUNNING PRESSURE

WASHER WITH FUEL. Spillage onto the engine or

other hot parts could result in an explosion or fire.

Always allow the unit to cool before refilling.

Do not store this machine in any location where

gasoline fumes could potentially come into contact

with sparks, a pilot light or an open flame. Improper

storage could result in an explosion or fire.

Inspect the high pressure hose often. In the event a

hose becomes damaged, discontinue use

immediately and replace with a properly rated hose.

Service or fluid level inspection should be performed

on a level surface only.

GENERAL MAINTENANCE

ENGINE FUEL: Use Unleaded Fuel - ONLY!

ENGINE OIL AND MAINTENANCE: Refer to the

Engine related documentation for specifications and

recommended maintenance schedule.

HOSES: Inspect the high pressure hose, garden hose

and chemical hose often. Defects can cause

decreased performance or damage to the machine.

WATER AND CHEMICAL FILTERS: Inspect any filters

supplied with your unit for damage or debris before

each use.

SPRAY GUN AND NOZZLES: Inspect the gun, lance,

and nozzles for leakage each use. Also, ensure the

lock-off mechanism on the gun is operational before

each use.

CHEMICAL HOSE: The hose should be flushed after

each application of chemicals. Do this by inserting

the hose into a bucket of clean water and running the

unit in low pressure (chemical application) mode for a

few minutes.

CLEANING YOUR MACHINE

CAUTION!: ALWAYS SHUT OFF THE PRESSURE

WASHER AND ALLOW TO COMPLETELY COOL

BEFORE PERFORMING CLEANING OPERATIONS.

Compressed air (max. 25 psi) may be used to blow

loose dirt and dust from your machine. DO NOT

DIRECT COMPRESSED AIR DIRECTLY INTO ANY

OPENING IN THE ENGINE OR AT PEOPLE OR

ANIMALS.

Use a dampened cloth to wipe clean exterior

surfaces.

Use a soft bristle brush to clean/ loosen heavy dirt, oil

or grease deposits.

NEVER insert rags, tools or any device into the

engine openings.

PRESSURE WASHER MAINTENANCE

During the course of standard use you will find that some

items wear out. The most common of these will probably

be the spray tips and the o-rings at some of the joints.

This is natural and when you consider the high pressure

applied it should be expected. These are very simple to

replace and when replacement parts are needed simply

contact the Dealer/Distributor where the pressure washer

was purchased.

The spray tips may also become clogged from time to

time. You will notice the pump pulsing and also pressure

buildup. This can be easily corrected by removing the tip

from the wand following proper safety procedures and

using a small wire, push the wire through the tip in the

reverse direction of water flow.

GENERAL STORAGE GUIDELINES

WARNING: GASOLINE FUMES ARE FLAMMABLE.

DO NOT STORE YOUR PRESSURE WASHER IN

ANY AREA THAT IS INDOORS OR IN POORLY

6

Page 7

VENTILATED AREAS. GASOLINE FUMES CAN IGNITE IN

THE PRESENCE OF ANY OPEN FLAME, PILOT LIGHT,

CLOTHES DRYER, WATER HEATER, ETC.

Your machine should be started and operated for

several minutes at least every 30 days.

If the machine cannot be operated every 30 days,

follow the storage recommendations within the engine

documentation. Disconnect all hoses and drain

completely. Also, be certain that the pump is drained

completely. Turn over the engine with the recoil

starter several times to do this.

NOTE: A fuel shut-off valve is positioned on the

engine. The valve should be closed during storage

periods.

USING YOUR PRESSURE WASHER

Refer to the General Product Information Section for

visual reference to this section.

Assembly

The first step after removing your generator from the box

is assembling the handle and the hoses. The handle is

mounted to the base plate along with the rear support

piece using the carriage bolts supplied. Please note that

the battery kit for electric start models should be intalled at

the same time as the handle. The gun and hose can now

be attached using the quick connect fittings. Refer to the

pictures in the parts list section of this manual for

clarification.

Preparation for Starting the Pressure Washer

After assembly you are almost ready. Next, remove the

shipping cap from the oil inlet on the pump and replace it

with the supplied dipstick. Now add oil to the engine as

specified in the engine documentation. Finally, put

gasoline into the fuel tank on the engine.

Starting the Pressure Washer

Verify that the lubrication levels are correct. Connect the

pump to a water supply capable of providing at least

4.5gpm and turn the water on. Most outdoor faucets

provide an adequate supply of water. If you are not sure

you have a proper water supply then simply measure the

amount of time it takes to fill a container of a known

quantity, such as a one gallon milk jug, and determine the

flow rate. You should never run the machine without being

connected to an adequate water supply. Squeeze the gun

trigger until a steady flow of water comes from the tip.

Turn the fuel valve to the ON position and choke the

engine as needed. Be sure to set the lock-off device on

the gun. Turn the engine ON/OFF switch to the ON

position and now give a firm pull on the recoil starter (or

turn the key for electric start models). Return the choke to

the standard position as the engine warms up.

Stopping the Pressure Washer

Discontinue use of the spray gun. Turn the engine switch

to the off position. When the engine is at rest, squeeze the

trigger to release the pressure in the pump. Turn the fuel

valve to the off position. Turn the water supply off.

Squeeze the trigger to release any remaining water from

the pump. Note: This does not replace the procedures for

storing the pressure washer because it will not completely

empty the pump and hoses.

Using your Pressure Washer

Your pressure washer is designed to clean surfaces

through the use of high water pressure. The extreme

pressure produced can damage surfaces if care is not

used. Always test in an obscure area to determine the

proper spray angle and distance between tip and surface

starting about 2 feet away and gradually moving closer.

The spray angle is determined by the color coded tips or

by turning the knob on the adjustable style tip.

Interchanging tips or adjusting spray angle on

adjustable tips should only been done with the gun

lock-off feature engaged. The following is a description

of the tips. Note that all tips are not included with your

pressure washer.

Adjustable Tip. This tip is typically barrel shaped and

rotates around the lance axis to adjust spray angle. To

apply chemicals with this tip, grasp the tip firmly and pull

away from the gun making certain the trigger is locked off.

This should “click” into the low pressure mode. After

applying chemicals simply pull the tip back to the original

position for high pressure spraying. Experiment with the

angle adjustments for the optimum cleaning position for

each surface.

The following 5 tips are typically included as a set when

the adjustable tip is not used. These utilize a quickcoupler to switch between tips.

Low Pressure – Black. This tip is used to apply

chemicals at low pressure. This nozzle has a 25° spray

angle.

0° - Red. Provides the most cleaning force but over a

smaller area.

15° - Yellow. Provides strong cleaning force over a

slightly larger area.

25° - Green. Provides good cleaning force over a larger

area. Popular for surfaces which do not have too much

tough dirt because of the wider area and good force.

40° - White. Provides the most gentle force but over the

largest area.

Chemical Application. Always dress properly when using

chemicals. Chemical application can only be done in the

low pressure mode through the supplied chemical

injection system. The chemical tube should be inserted

into the chemical tank and the Black tip installed or the

adjustable tip set in low pressure position. The chemicals

are automatically drawn into the water flow and applied to

the surface to be cleaned. After application, return to the

desired high pressure settings to clean. Chemicals should

never be introduced through the water supply because

they will damage the internals of the pump. They should

only be supplied through the downstream chemical

injector included with the machine. Care should always be

taken when using chemicals because they can be harmful

to people, animals, and plants. Care should also be taken

to prevent overspray on the pressure washer itself

because they can corrode the external components.

7

Page 8

PRESSURE WASHER SPECIFICATIONS

Table 1 outlines the specifications for each model.

Table 1 SPECIFICATIONS

Model Pressure(psi) Flow(gpm) Engine

LD20HHP 2000 3 Honda GX160 (5.5HP)

PW200 3000 3 Honda GX270 (9HP)

PW240 3500 4 Honda GX390 (13HP)

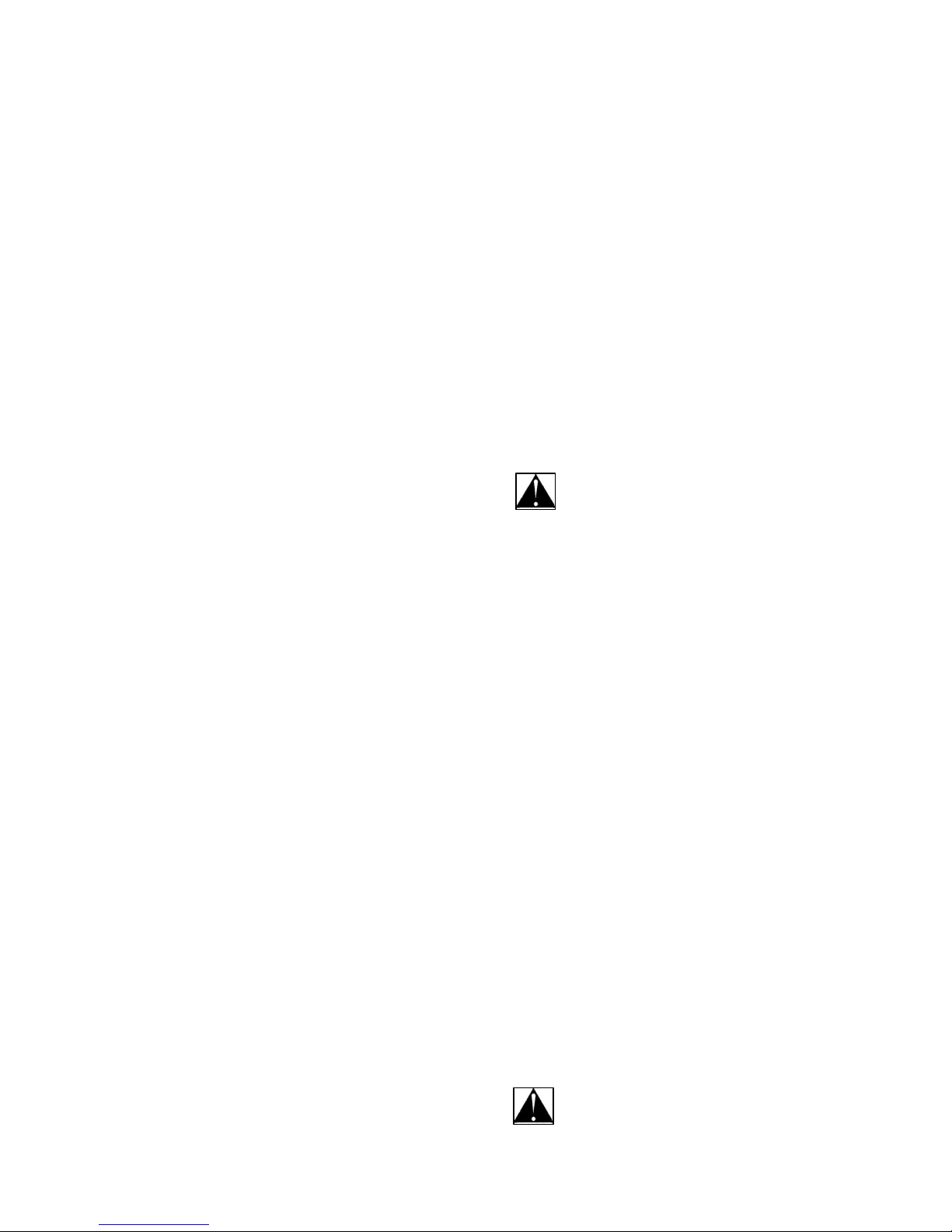

GENERAL PRODUCT INFORMATION

LD35 Shown, other models may vary slightly in appearance.

8

Page 9

TROUBLESHOOTING PROCEDURE

Problem Possible Cause Solution

Low Pressure 1. Blockage or kink in supply line.

2. Leak in system.

3. Clogged spray nozzle.

4. Faulty pump or unloader valve.

5. Water temperature too high.

Engine Will Not Start 1. No oil.

2. No gas.

3. Bad gas.

4. Spark plug problem.

5. Air cleaner problem.

6. Other.

Engine Loads Up

When Not Actively

Spraying

Chemicals Do Not

Mix In Outlet Spray

Pump Oil Emulsified

(Grey in Color)

Engine Shuts Down 1. Out of fuel.

1. Unloader valve setting too high.

2. Faulty unloader valve.

1. Nozzle in high pressure mode.

2. Clog or kink in chemical hose.

3. Chemical hose not fully

immersed.

1. Worn oil seals. 1. Contact pump service point.

2. Oil level is low.

1. Check water supply, supply line, and filter for

kinks or blockage.

2. Check all connections for leaks and replace

any worn parts causing problems.

3. Clean nozzle.

4. Contact pump service point.

5. Use different water source.

1. Add oil as specified by engine manufacturer.

2. Add fuel.

3. Drain fuel tank and use fresh fuel.

4. Connect spark plug wire or replace spark

plug.

5. Clean or replace.

6. Contact engine service point.

1. Adjust unloader valve to lower pressure.

2. Contact pump service point.

1. Use black low pressure tip or set adjustable

tip to low pressure mode.

2. Unclog and/or straighten hose.

3. Make sure chemical hose is fully immersed in

the chemical solution.

1. Add fuel.

2. Add oil.

9

Page 10

SECTION 2

LD20 PARTS AND PART LISTS

10

Page 11

11

Page 12

SECTION 3

PW200 PARTS AND PART LISTS

ITEM

NO. QTY. PART NO. DESCRIPTION

1 2 WHE0001 Wheel, 10" Pneumatic

2 1 FRA0064_Bumper Frame, Bumper

3 1 BRA0061_FrameSupport Frame Support

4 2 VIB0015_50X16 Isolator, 50 X 16 X 10mm

5 6 M10 lockwasher Lockwasher, M10

6 6 m10 nut Nut, M10

11 10 M8-1.25 x 30

16 1 XMV4G30D 3gpm, 3000psi, 3400rpm Pump

17 1 GUN0003 High Pressure Spray Gun

GUN0002

18 1

19 8 SCRM080005_CarriageBolt Carriage Bolt, M8 X 60

20 8 M8 NUT Nut, M8 - Nylon Insert

21 7 M8 flatwasher Flatwasher, M8

22 1 VAL0004_ThermalValve Thermal Relief Valve

23 4 M10 x 40 Bolt Bolt, M10 x 40 Z

24 2 1-8 cotter pin 1/8" Cotter Pin

25 2 WASHER- FLAT- 5-8 Washer, 5/8" Flat

26 1 HOS0009_ChemHose 3' Chemical Injection Hose

27 1 CPL0001 Quick Couple (Fem x Fem)

28 1 CPL0002 Quick Couple (Male x Male)

29 1 CPL0003 Quick Couple (Garden x Male)

30 1 TIP0006_0Deg_3000psi 0 Degree Nozzle, #3.5

31 1 TIP0007_15Deg_3000psi 15 Degree Nozzle, #3.5

32 1 TIP0008_25Deg_3000psi 25 Degree Nozzle, #3.5

33 1 TIP0009_40Deg_3000psi 40 Degree Nozzle, #3.5

34 1 TIP0005_25Deg_Chemical 25 Degree, Chemical Nozzle

(Connected to Gun0003)

Lance, Gun Extension

12

Page 13

35 1 PLA0025-2_BasePlate Base Plate

36 1 AXL0013_Axle Axle

37 2 BRA0064_1_AXLE MONTE

38 1 FRA0065_Handle Frame, Handle

39 1 BRA0063_HOSEHOLDER

42 1 BRA0022-0_WandHolder Bracket, Wand

43 5 GRM0004 .438 ID X .563OD Grommet

44 2 SCRM100001_M10x40_Z Bolt, M10 x 40 Z

45 5 WASM100001_Lock Lockwasher, M10

46 4 NUTM100001_Nut Nut, M10

47 1 BRA0065_Front GunHolder Bracket, Wand

48 1 HOS0007_50FT Hose, 50 FT x 3/8" ID

PW200 EXPLODED VIEW

13

Page 14

SECTION 4

PW240 PARTS AND PART LISTS

ITEM

NO. QTY. PART NO. DESCRIPTION

1 2 WHE0001 Wheel, 10" Pneumatic

2 1 FRA0064_Bumper Frame, Bumper

3 1 BRA0061_FrameSupport Frame Support

4 2 VIB0015_50X16 Isolator, 50 X 16 X 10mm

5 6 M10 lockwasher Lockwasher, M10

6 6 m10 nut Nut, M10

11 10 M8-1.25 x 30

16 1 RKV_4G35 4gpm, 3500psi, 3400rpm Pump

17 1 GUN0001 High Pressure Spray Gun

GUN0002

18 1

19 8 SCRM080005_CarriageBolt Carriage Bolt, M8 X 60

20 8 M8 NUT Nut, M8 - Nylon Insert

21 7 M8 flatwasher Flatwasher, M8

22 1 VAL0004_ThermalValve Thermal Relief Valve

23 4 M10 x 40 Bolt Bolt, M10 x 40 Z

24 2 1-8 cotter pin 1/8" Cotter Pin

25 2 WASHER- FLAT- 5-8 Washer, 5/8" Flat

26 1 HOS0009_ChemHose 3' Chemical Injection Hose

27 1 CPL0001 Quick Couple (Fem x Fem)

28 1 CPL0002 Quick Couple (Male x Male)

29 1 CPL0003 Quick Couple (Garden x Male)

30 1 TIP0001_0Deg_3500psi 0 Degree Nozzle, #4.0

31 1 TIP0002_15Deg_3500psi 15 Degree Nozzle, #4.0

32 1 TIP0003_25Deg_3500psi 25 Degree Nozzle, #4.0

33 1 TIP0004_40Deg_3500psi 40 Degree Nozzle, #4.0

34 1 TIP0005_25Deg_Chemical 25 Degree, Chemical Nozzle

(Connected to Gun0001)

Lance, Gun Extension

14

Page 15

35 1 PLA0025-2_BasePlate Base Plate

36 1 AXL0013_Axle Axle

37 2 BRA0064_1_AXLE MONTE

38 1 FRA0065_Handle Frame, Handle

39 1 BRA0063_HOSEHOLDER

42 1 BRA0022-0_WandHolder Bracket, Wand

43 5 GRM0004 .438 ID X .563OD Grommet

44 2 SCRM100001_M10x40_Z Bolt, M10 x 40 Z

45 5 WASM100001_Lock Lockwasher, M10

46 4 NUTM100001_Nut Nut, M10

47 1 BRA0065_Front GunHolder Bracket, Wand

48 1 HOS0007_50FT Hose, 50 FT x 3/8" ID

PW200 EXPLODED VIEW

15

Page 16

Section 5

Assembly

16

Page 17

Notes

17

Page 18

18

Loading...

Loading...