Operating Manual for

UMD 701

Short version 2.0

Contents

1

General Description 1

2

Operating the Meter 2

2.1 Safety requirements when using UMD 701

2.2 Installation of the instrument

2.2.1 Supply voltage

2.2.2 Measured voltage

2.2.3 Measured currents

2.2.4 Communication peripherals

2.2.5 Outputs and inputs

2.3 Downloading data to PC

2.4 Energy meter readings

..................................................................................................................................

.........................................................................................................................................

..................................................................................................................

..............................................................................................................................

...................................................................................................................................

..............................................................................................................

.....................................................................................................................

........................................................................................................................

...................................................................................................

2

3

3

3

4

4

5

6

6

3

Technical Specifications 7

3.1 Basic Parameters

3.2 Measured Quantities

4

Maintenance, Service, Warranty 11

..................................................................................................................................................

....................................................................................................................................

7

8

1

1 General Description

The UMD 701 is specially designed for monitoring of energy and power quality in advanced power systems and

smart grids. It is intended to be used mostly for DIN rail mounting. This display-less design with multiple

communication options is suitable for a wide spectrum of automation tasks in modern buildings, distributed

power generation, remote supervision of the infrastructure and also remote load management. Absence of local

panel controls (display and keyboard) limits possibilities for hostile user interaction. To protect the actual

setup and collected data each instrument can be locked by a custom pin. Inputs and outputs can be custum

programmed for basic local control applications. It uses standard RS-485 serial line for communication with

remote control systems. Optionally it can be equipped with other communication peripherals such as secondary

RS-485 or M-Bus communication line, or USB, WiFi and Ethernet interface.

It is equipped with one voltage input and two, four or eight current inputs. The instrument can be also

supplied with for current transformers with X/100 mA ratio, for special Hall probes (to measure DC or AC+DC

currents) with ➧4 V output, or Sxxx and Pxxx option for external through-hole or clamp-on current sensors for

direct measuring up to 2400 A nominal current according to the type of the current transformer.

Warning !

The X/100mA, Sxxx and Pxxx, X/➧4 V options are specially designed to be used only in

combination with provided external current sensors which are supported with the respective option.

The UMD 701 is available in several configurations according to the customer requirements1. See the ordering

scheme on figure 1.

1

Complete and most up to date list of optional and other accessories are available on request from the device vendor.

2

Instrument model

UMD = Universal Meassering Device

Measuring inputs

1 voltage + 8 current inputs

Auxiliary power supply

U = 75 V ÷ 275 VAC, 75 V ÷ 35O VDC

Current inputs

X/1OOmA = 1OOmA AC (indirect measurement

Optional digital output

pulse output

Optional peripheral

two digital inputs

Optional expanding module

E = Ethernet interface

UMD 701

Figure 1: Schematics of the UMD 701 ordering options and variants. It includes special codes for proper current

and voltage rating options.

2 Operating the Meter

2.1 Safety requirements when using UMD 701

Warning !:

protection of persons and property against injury and electric shock.

❼

The device must be operated by a person with all required qualifications for such work and this person

must know in detail the operation principles of the equipment listed in this description!

❼

When the device is being connected to the parts which are under dangerous voltage it is necessary to comply

When working with the instrument it is necessary to perform all necessary measures for the

with all the necessary measures to protect users and equipment against injury with electrical shock.

❼

Person, performing the installation or maintenance of the instrument must be equipped with and must use

personal protective clothing and tools.

❼

If the analyzer is used in a manner not specified by the manufacturer, the protection provided by the

analyzer may be impaired.

3

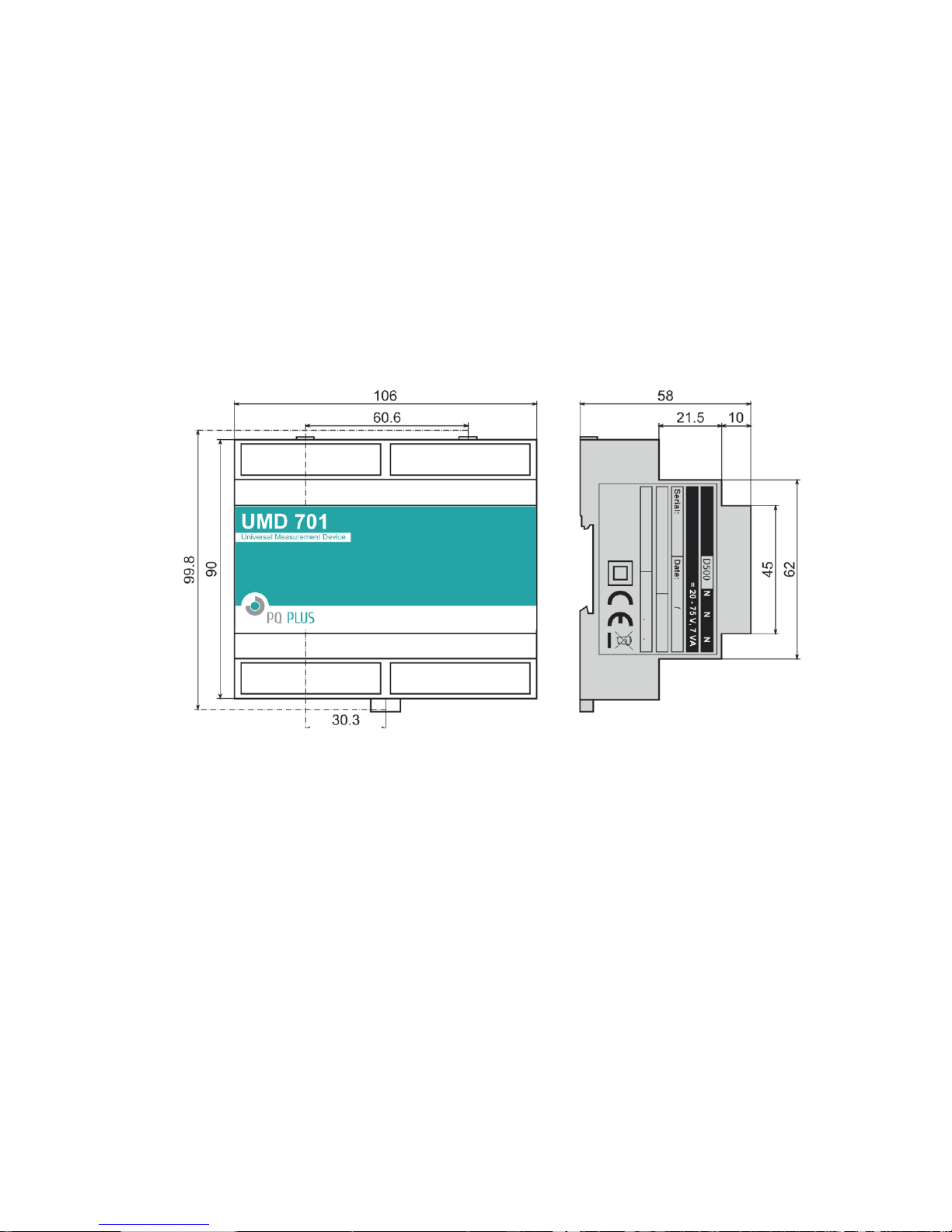

58

21.5 10

60.6

30.3

106

UMD

UMD 701

X/4V

001

03

2014

99.8

90

45

62

❼

If the analyzer or its accessories appear to be impaired or not functioning properly, do not use it and send

it in for repair.

2.2 Installation of the instrument

Natural air circulation should be provided inside the distribution board cabinet, and in the instrument’s neighborhood. Especially underneath the instrument, no other instrumentation that is source of heat should be installed

or the temperature value measured may be influenced. A connection

2

mm

in case of all screw terminals.

wire’s

maximum cross section area is 2.5

The UMD 701 is primarily intended for DIN-rail mounting. Dimensions of the instrument are on figure 2.

There are also positions marked with dash dot lines of holes for wall-mounting with three screws.

Figure 2: Dimensions of the UMD 701 analyzer.

2.2.1 Supply voltage

Power supply voltage (options in ch. 3) must be connected to the terminals X1 and X2 via a circuit breaking

device (power switch – see installation diagram on figure 3). It has to be located left to the instrument and

reachable by the operator. The circuit breaking device must be identified as the equipment power disconnection

switch. A circuit breaker of the nominal value 1 A is a convenient circuit breaking device. Its function and

position has to be clearly identified (symbols

galvanically isolated from internal circuits.

2.2.2 Measured voltage

The measured voltage is connected to the terminal L1. Connect the neutral wire to the terminal N. Voltage

measurement inputs are connected with internal circuits over high impedance.

It is suitable to protect the measured voltage lines for example with 1A fuses of the required rating. Measured

voltages can also be connected via instrument voltage transformers. A connection cable maximum cross section

area is 2.5

2

mm

for voltage terminals.

‘0’

and

‘I’

acc. to IEC EN 61010-1). Internal power supply is

4

L

N

X/4V

X/4V

X1 S X2

O- DO O+

R A1 A2 G B- A+ G2 B- A+

X1 L X2

O- DO O+

R A1 A2 G B- A+ G2 B- A+

X1 L X2 O- DO O+

R A1 A2 G B- A+ G2 B- A+

C I1 I2 I3 I4 I5 I6 I7 I8

+15 -15

C I1 I2

C I1 I2 I3 I4

N

L

JSxJSxxxHS

-xxxxxx

JSxJSxxxHS

-xxxxxx

JSxJSxxxHS

-xxxxxx

USB

Figure 3: An example of typical installation of UMD 701 instrument in a low voltage network — left to right:

with low voltage supply voltage (possible DC, AC including battery backed UPS setups); with supply from

measured network. Option E for Ethernet port remote communication, option U for local USB communication

port (all instruments provide RS485 serial line).

2.2.3 Measured currents

For proper current measuring the current sensors must be installed with correct orientation and polarity. Figure 3

illustrates such a connection of various current transformers in LV network. Intended direction of power flow

is from left (source) to right (load). It is highly recommended to verify correctness of wiring and polarity of

currents with phasor diagram in Actual Data window ot the EnVis.Daq application.

The current inputs are directly connected with internal circuits. Inputs I1,I2,..,I8 and C are connected through

shunt resistors (or divider in case of X/4V option). A connection cable maximum cross section area is 2.5

Warning !: Current inputs can not be used for dirrect current measurement. Connection of

unsupported type of current transformer such as the common type with 5A or 1A secondary to

an instrument is strictly forbidden! The instrument can be seriously damaged!

Warning !: Do not connect the current input signals with neither ground nor other potential!

Otherwise, measurement accuracy can be affected or the instrument can be damaged!

Always use only correctly rated measurement current transformers (such as ➧X mA or ➧4V) which were

originally supplied with the actual instrument.

2.2.4 Communication peripherals

All peripherals stated below are galvanically isolated from the rest of the instrument and from each other.

USB (optional)

intended for easy local configuration and fast download of archived data to the local PC. Use the supplied USB

communication port for USB slave is located on the front panel. This communication port is

2

mm

.

5

Figure 4: Typical wiring of the RS-485 communication line terminals in UMD 701 or optional M-Bus (right).

cable only (USB-A/mini). UMD 701 is a USB 2.0 slave device. For correct operation it needs a driver installed

in your operating system (see the EnVis user guide for more info).

Ethernet interface (optional)

on a top panel of the device. Ethernet interface can be used as substitution for the primary RS-485 for connection

of the device to LAN and for easy connection of remote control PC.

10Base-T Ethernet interface with RJ-45 connector described

RS-485 serial line

device configuration. Serial RS-485 line uses terminals A+,

4). The end point of the communication line must be properly terminated with ˜120n resistor.

serves usually as a remote communication for reading of actual data, archive downloading and

B-

Secondary RS-485 (optional)

display unit. Secondary RS-485 line uses terminals A+,

The final points of the communication line have to be fitted with terminating resistor approx. 120n.

communication line serves for connection of external I/O modules or remote

B-

with shielding at terminal

M-Bus interface (optional)

M-Bus implementation is described in a standalone

uses terminals

M1

and

M2

of

provides predefined measured values to the remote M-Bus control system. the

Communication Protocol Mbus

COM2

block on fig. 4 (right). Polarity of the connection is free to choose.

with shielding at terminal G of

G2

of

COM2

manual. Its physical interface

ETH

COM1

is situated

block (fig.

block (fig. 4).

2.2.5 Outputs and inputs

Digital Inputs

terminal,

input

right there is a sample schema for connection of two external switches in series with voltage source of 24 V

Digital Output

(24 V

comply with terminal poles (see fig. 5).

D1

D1

or

is recommended). In case of solid state based DO outputs an external voltage supply polarity must

DC

DI1 and DI2, sensitive to voltage, are using three terminals in

is first and

D2

is evaluated as inactive state, voltage greater than 10 V is evaluated as active state. On fig. 5

D2

connected through terminals

DI

block —

is second digital input. Voltage lower than 3 V applied between

O+

and O-. There must be an external voltage source in series

DI

is common

DI

and digital

DC

.

6

Relay Output

Digital Output

Digital Inputs

Figure 5: An example of wiring connection for inputs and outputs in UMD 701 .

2.3 Downloading data to PC

Connect the instrument to the PC and run EnVis.Daq application. Select the appropriate communication

option and connect to the instrument. In the next screen press

status of each supported archive.

Device Information

Time Frame for Other Archives

main archive. In the

the file. The check boxes in

The actual download will start by pressing the

finished the archive can be viewed in the EnVis application. User can open the downloaded file directly from

EnVis.Daq.

section contains editable description and name under which the actual record is stored.

Destination

tab allows you to limit the date ranges of all archives by the time interval of the

section the actual storage can be selected - either to the SQL database or to

Archives to Download

Download All

determines which specific archive(s) you want to download.

2.4 Energy meter readings

UMD 701 has an embedded four-quadrant energy meter with automatic meter reading functions and multiple

programmable tariffs (Time-of-Use, TOU). The instrument registers active energy (EP, EP+, EP-) and reactive

energy (EQL, EQC or EQC+, EQC-, EQL+, EQL-). According to the configuration of meter readings are

shuffled to the respective tariffs. It automatically provides summaries per phase. For star connections and single

phase measurements it can also register energy for each phase separately.

Meter data readings can be downloaded and analyzed in EnVis or via the standard ModBus protool in any

other system.

Refresh All

button. progress is displayed on screen. When

. This will load and display the actual

7

Other Specifications

operational temperature

- 20 to 60°C

storage temperature

- 40 to 80°C

operational and storage humidity

< 95 % - non-condensable environment

EMC – immunity

EN 61000 – 4 - 2 (4 kV / 8 kV)

EN 61000 – 4 - 3 (10 V/m up to 1 GHz)

EN 61000 – 4 - 4 (2 kV)

EN 61000 – 4 - 5 (2 kV)

EN 61000 – 4 - 6 (3 V)

EN 61000 – 4 - 11 (5 periods)

EMC – emissions

EN 55011, class A

EN 55022, class A (not for home use)

communication ports

RS-485 (1200 ÷ 921600 Bd), optional USB, Ethernet 10Base-T, M-bus

communication protocols

PQ PLUS, Modbus RTU and TCP, web server, DHCP

accuracy of RTC

± 2 seconds per day

capacity of RTC backup battery

> 5 years (without supply voltage applied)

protection class

front panel whole

instrument

IP 40

IP 20

dimensions

front panel

whole instrument

106 x 45 mm

106 x 90 x 58 mm

weight

max. 0.25 kg

Auxiliary Voltage

10.01.6004

10.01.8004

AC aux. voltage range, f: 40÷450 Hz

85 ÷ 275 VAC

20 ÷ 50 VAC

DC aux. voltage range

80 ÷ 350 VDC

20 ÷ 75 VDC

power supply

14 VA / 6 W

overvoltage category

III

pollution degree

2

connection

isolated, polarity free

3 Technical Specifications

3.1 Basic Parameters

AUX

Ostatni

8

Measured Quantities – Voltage

Frequency

f

NOM

– nominal frequency

50 / 60 Hz

measuring range

40 ÷ 70 Hz

uncertainty

± 10 mHz

Voltage

voltage input option

standard variant („230“)

U

NOM (UDIN

)– rated voltage

180 ÷ 250 VAC

measuring range line-to-neutral

8 ÷ 360 VAC

measuring range line-to-line

–

intrinsic uncertainty (tA=23 ± 2ºC)

± 0.05 % of rdg ± 0.02 % of rng

temperature drift

± 0.03 % of rdg ± 0.01 % of rng / 10 ºC

measurement category

300V CAT III

permanent overload

1500 VAC (UL–N)

peak overload, 1 second

2300 VAC (UL–N)

burden power ( impedance)

< 0.03 VA (Ri = 3.24 MΩ)

Voltrage Unbalance

measuring range

–

measuring uncertainty

–

THDU

measuring range

0 ÷ 20 %

measuring uncertainty

± 0.5

Harmonics (up to 50

th

order )

reference conditions

other harmonics up to 200 % of class 3 acc. to IEC 61000–2-4 ed.2

measuring range

10 ÷ 100 % of class 3 acc. to IEC 61000–2-4 ed.2

measuring uncertainty

twice the levels of class II acc. to IEC 61000–4-7 ed.2

3.2 Measured Quantities

Veliciny - U

9

Measured Quantities – Current, Temperature

Current

current input option

„X/100mA“

INOM (IB) – rated (basic) current

0.1 AAC

measuring range

0.00025 ÷ 0.12 AAC

intrinsic uncertainty (tA=23 ±2 ºC)

± 0.05 % of rdg ± 0.02 % of rng

temperature drift

± 0.03 % of rdg ± 0.01 % of rng / 10 ºC

measurement category

600V CAT III

permanent overload

0.2 AAC

peak overload

1 second, maximum repetition

frequency > 5 minutes

1 AAC

burden power (impedance)

< 0.005 VA (Ri < 0.5 Ω)

Current Unbalance

measuring range

0 ÷ 100 %

measuring uncertainty

± 1 % of rdg or ± 0.5

Harmonics & Interharmonics (up to 50

th

order )

reference conditions

other harmonics up to 1000 % of class 3 acc. to IEC 61000–2-4 ed.2

measuring range

500 % of class 3 acc. to IEC 61000–2-4 ed.2

measuring uncertainty

Ih <= 10 % INOM: ± 1 % INOM

Ih > 10 % INOM: ± 1 % of rdg

THDI

measuring range

0 ÷ 200 %

measuring uncertainty

THDI <= 100 %: ± 0.6

THDI > 100 %: ± 0.6 % of rdg

Temperature (internal sensor, measured value affected by the instrument power dissipation)

measuring range

- 40 ÷ 80°C

measuring uncertainty

± 2 ºC

Veliciny - I, T

10

Measured Quantities – Power, Power Factor, Energy

Active / Reactive Power, Power Factor (PF), cos φ (PNOM = UNOM x INOM)

reference conditions “A”:

ambient temperature (tA)

U, I

for active power, PF, cos φ

for reactive power

23 ± 2 ºC

U = 80 ÷ 120 % UNOM, I = 1 ÷ 120 % INOM

PF = 1.00

PF = 0.00

act. / react. power uncertainty

± 0.5 % of rdg ± 0.005 % PNOM

PF & cos φ uncertainty

± 0.005

“reference conditions ”B”:

ambient temperature (tA)

U, I

for active power, PF, cos φ

for reactive power

23 ± 2 ºC

U = 80 ÷ 120 % UNOM, I = 2 ÷ 120 % INOM

PF >= 0.5

PF <= 0.87

act. / react. power uncertainty

± 1 % of rdg ± 0.01 % PNOM

PF & cos φ uncertainty

± 0.005

temperature drift of powers

± 0.05 % od rdg ± 0.02 % PNOM / 10 ºC

Energy

measuring range

6 „quadrants“, corresponds to U & I measuring ranges

active energy uncertainty

class 1 acc. to EN 62053 – 21

reactive energy uncertainty

class 2 acc. to EN 62053 – 23

Veliciny - P,Q,PF,E

11

4 Maintenance, Service, Warranty

Maintenance:

reliable operation it is only necessary to meet the operating conditions specified and not expose the instrument

to violent handling and contact with water or chemicals which could cause mechanical damage.

The lithium cell built in the instrument can backup a real time circuit for more than 5 years without power

supply, at average temperature 20

is necessary to ship the instrument to the manufacturer for battery replacement.

the UMD 701 power analyzer does not require any maintenance during its operation. For

➦

C

and load current in the instrument less than 10 µA. If the cell is empty, it

Service:

PQ Plus GmbH

Kersbacherstraße 5

91094 Langensendelbach

Tel.: ( +4 9 ) 9 1 3 3 - 6 0 444 -25

E-mail: info@pq-plus.de

Web: www.PQ-Plus.de

The product must be in proper packaging to prevent damage during transit. A description of the problem

or its symptoms must be delivered together with the product.

If a warranty repair is claimed, the warranty certificate must be sent in. In case of an out-of-warranty repair

you have to enclose an order for the repair.

in the case of failure or a breakdown of the product, you should contact the supplier at their address:

Warranty certificate:

however, no longer than 30 months from the day of dispatch from the manufacturer. Problems in the warranty

period, provably because of faulty workmanship, design or inconvenient material, will be repaired free of charge

by the manufacturer or an authorized servicing organization.

The warranty ceases even within the warranty period if the user makes unauthorized modifications or changes

to the instrument, connects it to out-of-range quantities, if the instrument is damaged due to ineligible or

improper handling by the user, or when it is operated in contradiction with the technical specifications presented.

warranty period of 24 months from the date of purchase is provided for the instrument,

Type of product: UMD 701 . . . . . . . . . . . . . . . . . Serial number: . . . . . . . . . . . . . . . . . . . . . . . . . . .

Date of dispatch: . . . . . . . . . . . . . . . . . . . . . . . . . . . Final quality

Date of purchase: . . . . . . . . . . . . . . . . . . . . . . . . . . .

inspection:

Manufacturer’s seal:

Supplier’s seal:

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading...

Loading...