PP Systems WMA-5 Operation Manual

WMA-5

CO

Gas Analy zer

2

Operation Manual

Version 1.01

2015 PP Systems. All Rights Reserved

rd

3

November 2016

PP Systems

110 Haverhill Road, Suite 301

Tel: +1 978-834-0505 Fax: +1 978-834-0545

Email: support@ppsystems.com URL: www.ppsystems.com

Amesbury, MA 01913 U.S.A.

Contents

Welcome ....................................................................................................................................................... 6

User Registration .......................................................................................................................................... 6

Service & Warranty ....................................................................................................................................... 7

Contact Information ....................................................................................................................................... 7

Unpacking and Storage of Your Equipment.................................................................................................. 7

Unpacking .............................................................................................................................................. 7

Technical Specification ................................................................................................................................. 8

Summary of System Design .......................................................................................................................... 9

Overview and Theory ................................................................................................................................ 9

Optional Sensors for use with WMA-5 ........................................................................................................ 11

O2 Sensor ................................................................................................................................................ 11

H2O Sensor .............................................................................................................................................. 11

Mechanical Specifications & Mounting Instructions .................................................................................... 11

System Power ............................................................................................................................................. 11

Getting Familiar with the WMA-5 ................................................................................................................ 12

Touch Display .......................................................................................................................................... 12

Status Box ............................................................................................................................................ 12

Gas Ports ................................................................................................................................................. 13

Water Trap ............................................................................................................................................... 13

Terminal Block ......................................................................................................................................... 13

Recommended Cable Interface ........................................................................................................... 14

USB Memory Stick Port ........................................................................................................................... 15

Flow Adjustment ...................................................................................................................................... 15

Absorber Column and CO2 Scrubber ...................................................................................................... 15

Data Port.................................................................................................................................................. 15

Routine System Checks .............................................................................................................................. 16

Touch Display Overview ............................................................................................................................. 16

Splash Screen ............................................................................................................................................. 18

General Screen Info .................................................................................................................................... 18

Data Entry Screen ................................................................................................................................... 18

Measurement Mode .................................................................................................................................... 19

Measure Screen Info ............................................................................................................................... 19

Measure Screen ...................................................................................................................................... 20

Variables 1 Screen .................................................................................................................................. 21

WMA-5 Operation Manual V. 1.01 2 support@ppsystems.com

Variables 2 Screen .................................................................................................................................. 22

Graph Screen .......................................................................................................................................... 22

Main Menu................................................................................................................................................... 23

Settings ....................................................................................................................................................... 24

Settings 1 Menu ....................................................................................................................................... 24

Zero Settings ........................................................................................................................................ 24

Alarm Settings ...................................................................................................................................... 26

Reset Zero Absorber............................................................................................................................ 27

Flow Settings ....................................................................................................................................... 27

Alarm Sound Settings .......................................................................................................................... 28

CO2 Units Settings ............................................................................................................................... 28

Settings 2 Menu ....................................................................................................................................... 29

Analog Settings .................................................................................................................................... 29

Averaging Settings ............................................................................................................................... 30

WMA ID Settings .................................................................................................................................. 30

Graph Setting ....................................................................................................................................... 31

Settings 3 Menu ....................................................................................................................................... 31

Host Settings ........................................................................................................................................ 32

WiFi Settings ........................................................................................................................................ 33

Memory Settings .................................................................................................................................. 33

Host Port Settings ................................................................................................................................ 34

Reset WiFi Settings ............................................................................................................................. 34

Settings 4 Menu ....................................................................................................................................... 35

Set Clock Settings ................................................................................................................................ 35

Default Settings .................................................................................................................................... 36

Calibration ................................................................................................................................................... 36

CO2 Calibration ........................................................................................................................................ 37

O2 Calibration .......................................................................................................................................... 39

Connecting Reference Gas the WMA-5 .............................................................................................. 40

Touch Calibration .................................................................................................................................... 41

Diagnostics .................................................................................................................................................. 42

ADC Diagnostics ..................................................................................................................................... 42

Zeros Diagnostics .................................................................................................................................... 43

Hours Diagnostics ................................................................................................................................... 44

Voltage Diagnostics ................................................................................................................................. 44

WMA-5 Operation Manual V. 1.01 3 support@ppsystems.com

Information Menu ........................................................................................................................................ 45

About ....................................................................................................................................................... 45

Contact .................................................................................................................................................... 46

Connecting WMA-5 to External Devices ..................................................................................................... 47

Analog Voltage Output ............................................................................................................................ 47

4-20 mA Analog Current Output .............................................................................................................. 47

Alarm Relay Outputs ............................................................................................................................... 47

USB Memory Stick .................................................................................................................................. 47

Digital Connection Methods..................................................................................................................... 48

USB ...................................................................................................................................................... 48

RS232 .................................................................................................................................................. 48

Wireless ............................................................................................................................................... 48

Digital Communication Protocols and Software ...................................................................................... 49

WMA-5 Command Set ......................................................................................................................... 49

GAS (Gas Analysis Software) ................................................................................................................. 55

Communication Summ ary ....................................................................................................................... 58

Wireless Network Settings....................................................................................................................... 58

Connecting To WMA-5 Via Direct Wireless Connection ...................................................................... 59

Connecting to WMA-5 via a Local Area Network ................................................................................ 60

Measure Format Settings Table .................................................................................................................. 63

Error Messages for the WMA-5 Table ........................................................................................................ 66

Maintenance ................................................................................................................................................ 68

Absorber Column and CO2 Scrubber ...................................................................................................... 68

Soda Lime ............................................................................................................................................ 68

Gray Foam Filters ................................................................................................................................ 69

Absorber Filters .................................................................................................................................... 69

End Cap “O” Rings ............................................................................................................................... 69

Water Trap ............................................................................................................................................... 70

Hydrophobic Filter ................................................................................................................................... 70

Sampling Pump ....................................................................................................................................... 71

Infrared Source ........................................................................................................................................ 71

Appendix 1. WiFi Compliance .................................................................................................................... 72

Table C-1 Country Certifications .......................................................................................................... 72

Table C-2 Country Transmitter Ids ...................................................................................................... 73

Table C-3 Safety .................................................................................................................................. 73

WMA-5 Operation Manual V. 1.01 4 support@ppsystems.com

Federal Communication Commission Interference Statement ............................................................ 73

Radiation Exposure Statement ............................................................................................................ 74

WMA-5 Operation Manual V. 1.01 5 support@ppsystems.com

Welcome

Thank you very much for purchasing our WMA-5 CO2 Gas Analyzer. We greatly appreciate your

business and we look forward to working with you and your team for many years to come.

This manual and the information contained within are copyrighted to PP Systems. No part of the

manual may be copied, stored, transmitted or reproduced in any way or by any means including,

but not limited to, photocopying, photography, magnetic or other mechanical or electronic means,

without the prior written consent of PP Systems, Inc.

For applications where failure of this equipment to function correctly would lead to consequenti al damage,

the equipment must be checked for correct operation and calibration at intervals appropriate to the

circumstances. The PP Systems' equipment warranty is limited to replacement of defective components,

and does not cover injury to persons or property or other consequential damage.

This manual is provided to help you install and operate the equipment. Every effort has been made to

ensure that the information it contains is accurate and complete. PP Systems does not accept any

liability for losses or damages resulting from the use of this information.

It is the operator’s responsibility to review this information prior to installation and operation of the

equipment. Otherwise, damage may be caused which is not covered under our normal warranty policy.

User Registration

It is very important that ALL new customers register themselves with us to ensure that our user’s list is

kept up-to-date. If you are a PP Systems’ user, please go to www.ppsystems.com

Registration in the upper left hand corner.

Only REGISTERED users will be allowed access to the protected “Users” section of our web site. This

section will contain important product information including hardware/software updates, app lication notes,

newsletters, etc.

Thank you in advance for your cooperation.

and click on Customer

WMA-5 Operation Manual V. 1.01 6 support@ppsystems.com

Service & Warranty

PP Systems' equipment warranty is limited to replacement of defective components, and does not cover

injury to persons or property or other consequential damage.

The equipment is covered under warranty for one complete year, parts and labor included. This, of

course, is provided that the equipment is properly installed, operated and maintained in accordance with

written instructions (i.e. Operator's Guide).

The warranty excludes all defects in equipment caused by incorrect installa tion, o p eration or

maintenance, misuse, alteration, and/or accident.

If for some reason, a fault is covered under warranty, it is the responsibility of the customer to return the

goods to PP Systems or an authorized agent for repair or replacement of the defective part(s).

Prior to returning equipment to PP Systems for service, you must first get in contact with our Service

Manager (service@ppsystems.com

) to request a case number for reference and tracking purposes.

Contact Information

PP Systems, Inc.

110 Haverhill Rd, Suite 301

Amesbury, MA 01913 USA

Tel: 978-834-0505 Fax: 978-834-0545

Sales: sales@ppsystems.com

Support: support@ppsystems.com

Service: service@ppsystems.com

URL: www.ppsystems.com

Unpacking and Storage of Your Equipment

Unpacking

It is extremely important that you check the contents of your equipment immediately upon receipt to

ensure that your order is complete and that it has arrived safely. Please refer to packing list to show all

items that are included with your order. DO NOT DISCARD ANY OF THE PACKAGING MATERIAL

UNTIL ALL OF THE ITEMS LISTED ARE ACCOUNTED FOR. WE RECOMMEND THAT YOU RETAIN

THE ORIGINAL PACKING FOR FUTURE USE. If you suspect that any of the items listed on the packing

list are not included or damaged, you must contact PP Systems or your authorized distributor

immediately.

WMA-5 Operation Manual V. 1.01 7 support@ppsystems.com

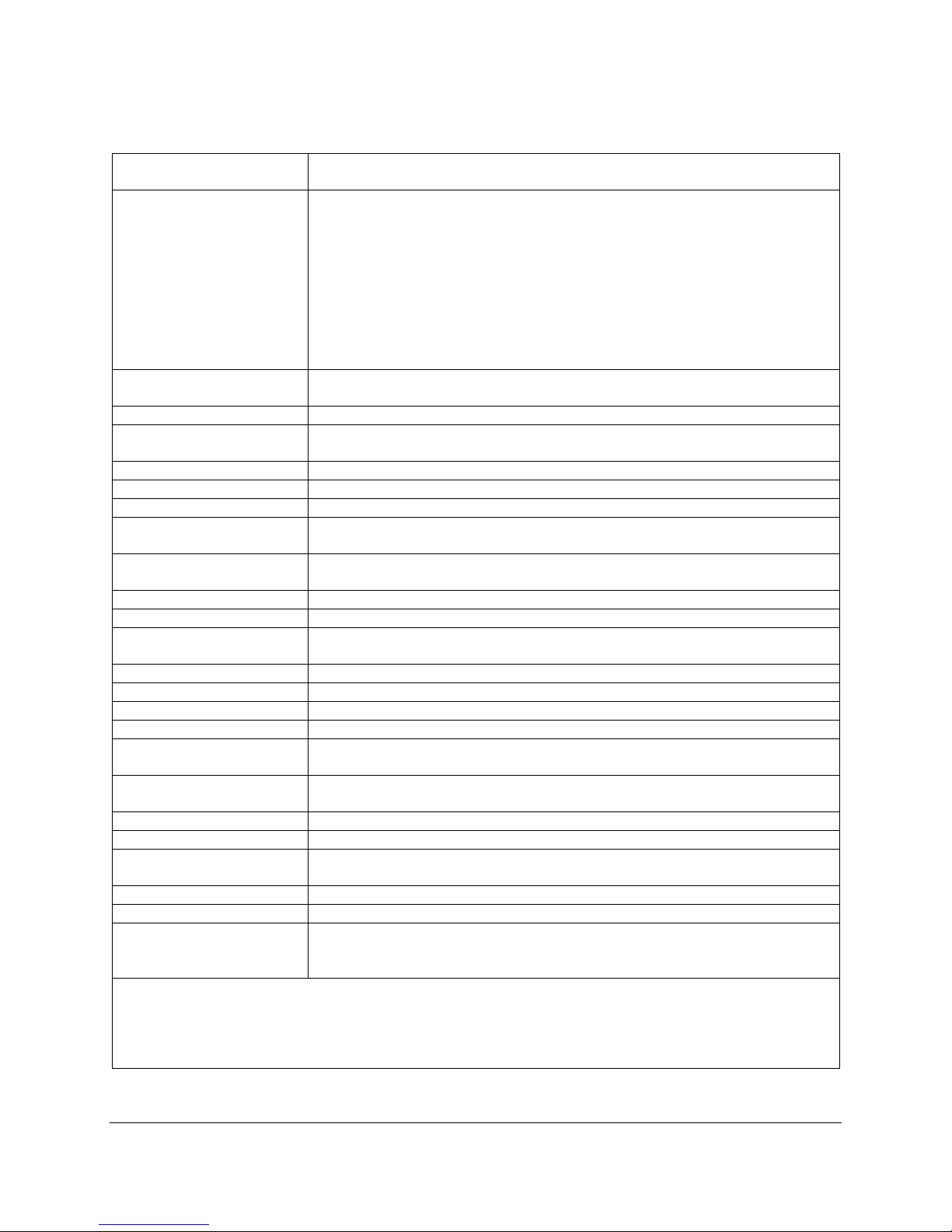

Technical Specifica tion

Analysis Method

Non-dispersive infrared, configured as an absolute absorptiometer with

microprocessor control of linearization

CO2 Measurement

0-1000 ppm (µmol mol-1)

Readings are automatically corrected for temperature and pressure.

Accuracy

< 1% of span concentration over the calibrated range but limited by the

accuracy of the calibration mixture.

Linearity

< 1% throughout the range

Stability

Auto-zero at regular intervals corrects for sample cell contamination,

source and detector ageing and changes in electronics.

Warm-up Time

Approximately 15 minutes

Sampling Rate

10 Hz. Sample data is averaged and output ever y 1.0 seconds.

Sampling Pump

Integral, long life 12V air sampling pump

Gas Flow Rate

200-500 cc/min (280-340 cc/min is optimal). An internal, electronic flow

sensor monitors flow rate.

Terminal Block

System power, analog, digital and current (4-20mA) outputs and sensor

inputs are available from the 22 pin terminal block

Analog Output

0-2.5V (CO2 range selectable) and 4-20mA

Digital Output

RS232 and USB

Air Filter & Water Trap

An external water trap and internal hydrophobic filter are used to protect

analyzer from water.

Alarm

Visual and audible alarm/war nings. 2 relay contacts (Alarm1 and Alarm2)

CO2 Control

High and low user set points

Data Storage (USB)

USB Flash Drive for data storage in multiple formats.

Display

2.7” electronic paper touch display with 264 x 176 pixel resolution

Power Requirements

12 VDC, 1.5A or

100-240 VAC, 50-60 Hz, 0.6A (AC Adapter included)

Power Consumption

Warm up: 12W (12V @ 1.0A)

Normal operation: 6W (12V @ 0.5A)

Enclosure

High impact, IP65 enclosure

Gas Connections

Two barbed fittings (inlet and exhaust) for use with 1/8” (.125”) ID tubing

Operating Temperature

0-50 oC, non-condensing. External filtration may be required in dirty

environments.

Dimensions

213 cm L x 185 cm H 114 cm W (Enclosure only)

Weight

1.5 kg

Optional Accessories

- H2O Sensor - Range: 0-Dewpoint (mb)

- WIFi

PP Systems is a registered trademark of PP Systems, Inc.

respective owners.

Ranges

0-2000 ppm (µmol mol-1)

0-5000 ppm (µmol mol

-1

0-10000 ppm (µmol mol

0-20000 ppm (µmol mol

0-30000 ppm (µmol mol

0-50000 ppm (µmol mol

0-100000 ppm (µmol mol

)

-1

)

-1

)

-1

)

-1

)

-1

)

- O2 Sensor – Range: 0-100%

PP Systems is continuously updating its products and reserves the right to amend product

specifications without notice. All brand names are trademarks or registered trademarks of their

WMA-5 Operation Manual V. 1.01 8 support@ppsystems.com

Summary of System Design

Overview and Theory

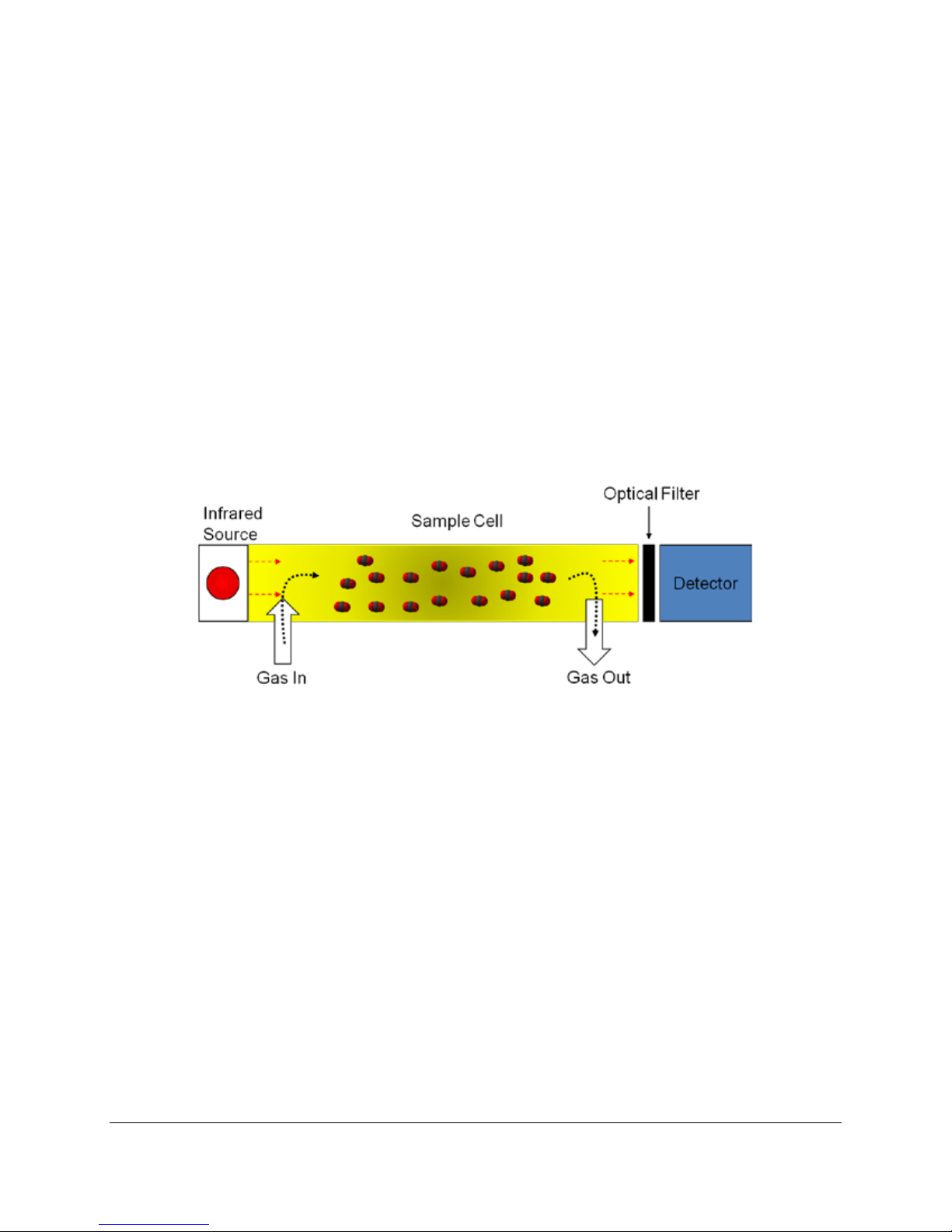

The WMA-5 is designed to function as a self-contained instrument for continuous measurement of CO2 in

air. Its open-path design allows for continuous, unattended air sampling, as the pump introduces fresh

sample gas to the essential component, the IRGA (infrared gas analyzer).

The IRGA forms the core of gas analysis systems that measure CO

refers to the transmission of a broad-band inf ra-red wavelength from the IRGA source lamps. A single

IRGA consists of four basic components:

. Non-dispersive infra-red (NDIR)

2

• Infra-red source

• Sample cell of known path length and volume

• Optical interference filter

• Infra-red detector

The theory itself is quite simple – light from mid-infra-red wavelengths is produced by the source and

pulsed through a gold plated cell. The interference filter narrows the bandwidth of the IR source received

by the detector to the signature wavelength absorbed by the target gas molecule, e.g. CO

employs a unique optical filter. As the sample gas fills the cell, the target gas molecule absorbs IR

energy at the particular wavelength, and the reduction in IR energy reaching the detector is measured.

The higher the target gas concentration, the lower the infra-red signal received at the detector, as defined

by the Lambert-Beer Law of Attenuation.

. The CO2 cell

2

CO

molecules have a discrete absorption band at 4.26 µm that has very little overlap with any other

2

molecule’s absorption band, so that wavelength provides good sensitivity and selectivity. The WMA-5

electronics could be considered another major component, which processes raw analog-to-digital (A/D)

information from the IRGA detector, accurately translating this information into gas concentrations.

WMA-5 Operation Manual V. 1.01 9 support@ppsystems.com

The WMA-5 detector is optimized

for this CO2 waveband (4.26 µm)

The gas sample is of course a mixture of gas molecules, and this can present problems in terms of

accurate detection of concentrations of a specific gas, such carbon dioxide. This effect, foreign gas

broadening (FGB), must be corrected to ensure accurate measurement of gas concentrations. With FGB,

the CO

This effect is about 0.1 µmol mol

in infra-red absorption, which is detected as an apparent increase in [CO

gas in the IRGA cell is somewhat diluted by the increased air volume induced by water vapor.

2

-1

CO2 mb-1 H2O. The presence of water vapor also causes an increase

]. This is of a similar magnitude,

2

but opposite to the dilution effect, and the WMA-5 automatically corrects these FGB effects.

The WMA-5 IRGAs are quite stable owing to their construction, calibration and thermal environment, but

various circumstances can cause apparent changes over time. Some changes may require recalibration,

although one of the strengths of the WMA-5 is that recalibration is not a routine (annual) maintenance

task as a result of our innovative “Auto-Zero” function. Our Auto-Zero function corrects for nearly all

changes that result in calibration drifts. It minimizes effects on span (gas sensitivity), of sample cell

contamination, lamp ageing, changes in detector sensitivity, amplifier gains and reference voltages.

Measurements are ratioed to the Zero reading before IR absorbance is determined. From the

relationship between absorbance and concentration determined in the factory for each instrument, and

the current calibration factor, the sample concentration is determined.

WMA-5 Operation Manual V. 1.01 10 support@ppsystems.com

Optional Sensors for use with WMA-5

O2 Sensor

An optional electrochemical O2 sensor can be used with the WMA-5 for measurement of oxygen in

addition to CO

.

2

• Range: 0-100%

• Response Time: ≤ 15 seconds at 23 ± 2

• Linearity: ± 1.0% of full scale

The O

to sample the incoming gas stream. Recalibration should not be necessary and based on our experience

with this sensor it should have a working life of approximately 4-5 years.

sensor is mounted into a manifold located inside the terminal block enclosure and is fitted in-line

2

o

C

H2O Sensor

An optional solid state H2O sensor can be used with the WMA-5 for measurement of H2O in addition to

CO

.

2

• Range: 0-Dewpoint (mb)

• Accuracy: < 2% RH

The humidity sensor is mounted into a manifold located inside the terminal block enclosure and is fitted

in-line to sample the incoming gas stream. Readings are displayed and recorded in absolute vapor

pressure (mb). Recalibration of this sensor is not necessary.

Mechanical Specifications & Mounting

Instructions

The WMA-5 is very easy to mount. The rear of the enclosure has convenient markings showing where to

place mounting screws. All dimensions are in centimeters (cm).

System Power

The WMA-5 is supplied with its own power supply to allow operation from local mains power. The

specification of the power supply is as follows:

Input: 12 VDC, 1.5A or 100-240 VAC, 50-60 Hz, 0.6A (AC adapter included)

The WMA-5 can be powered by 12V if required via direct connection to the terminal block. It requires a

12V DC input at 1.5A. Connect the positive to +12V and the negative to GND. The terminal block is

clearly marked for ease of connection.

WMA-5 Operation Manual V. 1.01 11 support@ppsystems.com

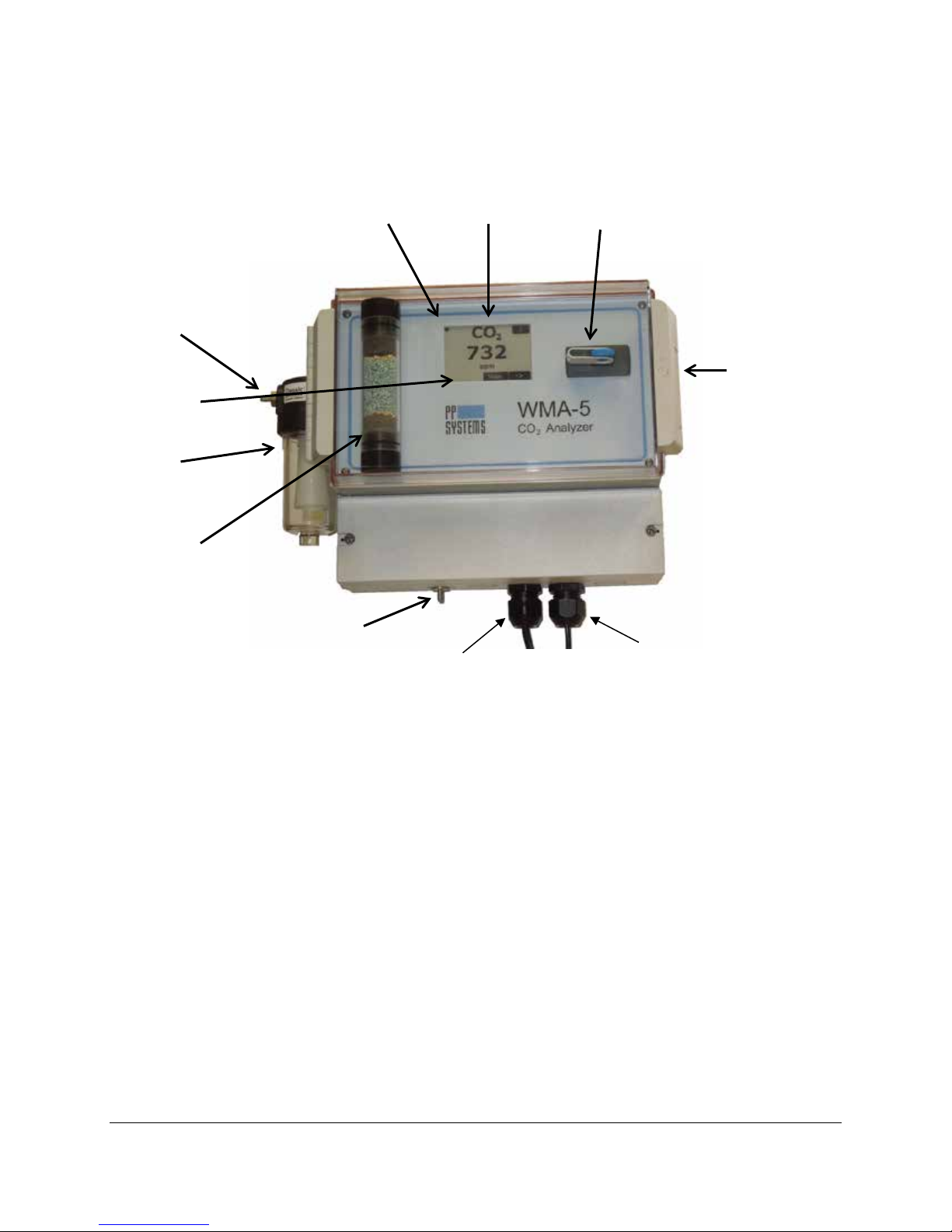

Getting Familiar with the WMA-5

Gas Inlet

Latch to open

Terminal Block Enclosure

Power

Data Port

Gas Outlet

Status Box

Water Trap

Absorber

Column (CO

Scrubber)

Power Status (♥) Touch Display USB Flash Memory Port

clear cover to

access display,

absorber and

USB port.

2

Touch Display

The WMA-5 features a 2.7” a-Si, active matrix TFT, Electronic Paper Display (EPD) touch panel. The

panel has such high resolution (117 dpi) that it is able to easily display fine patterns. Due to its bi-stable

nature, the EPD panel requires very little po wer to update and nee ds no power to m aintain an im age.

Features

• a-Si TFT active matrix Electronic Paper Display(EPD)

• Resolution: 264 x 176 pixel

• Ultra low power consum ption

• Super Wide Viewing Angle - near 180°

• Extra thin & light

• SPI interfac e

• RoHS compliant

Status Box

All messages and warnings are displayed in the Status Box which is located in the bottom left hand

corner of the display. A flashing ♥ (Heart) symbol in the upper left hand corner of the display indicates that

the system is powered on.

WMA-5 Operation Manual V. 1.01 12 support@ppsystems.com

Gas Ports

There are two gas ports (barb fittings) on the WMA-5. The gas inlet is located on the water trap and the

gas outlet is located on the bottom of the WMA-5 enclosure. Each port is designed for use with 1/8”

(.125) ID tubing. The sampling line should be fitted to the gas inlet port using 1/8” tubing. The gas outlet

should be left open to atmosphere to allow the sample air to exhaust without restriction.

Water Trap

The water trap (also referred to as a “Float Valve Housing”) is an essential filtration tool when gas is being

drawn to the CO

How the Water Trap Works

As liquid is collected in the bowl the level starts to rise, gas becomes trapped in the open-end of the float

and it too starts to rise. The entire float assembly then begins to move upwards and eventually closes the

valve and shuts of the flow to the analyzer. This loss of flow is then detected by the WMA-5 mass flow

controller ensuring flow is cut-off to the analyzer. An error message is also displayed in the Status Box.

analyzer preventing the carry-over of water from getting into the system.

2

Terminal Block

A terminal block is located inside the small rectangular enclosure below the main enclosure for simple

and convenient connection to external devices (i.e. power, RS232, power, microprocessors, etc.). To

access the terminal block, remove the two screws on either side of the enclosure to remove the cover.

We recommend that the terminal block cover is always fitted and secured in place during operation.

WMA-5 Operation Manual V. 1.01 13 support@ppsystems.com

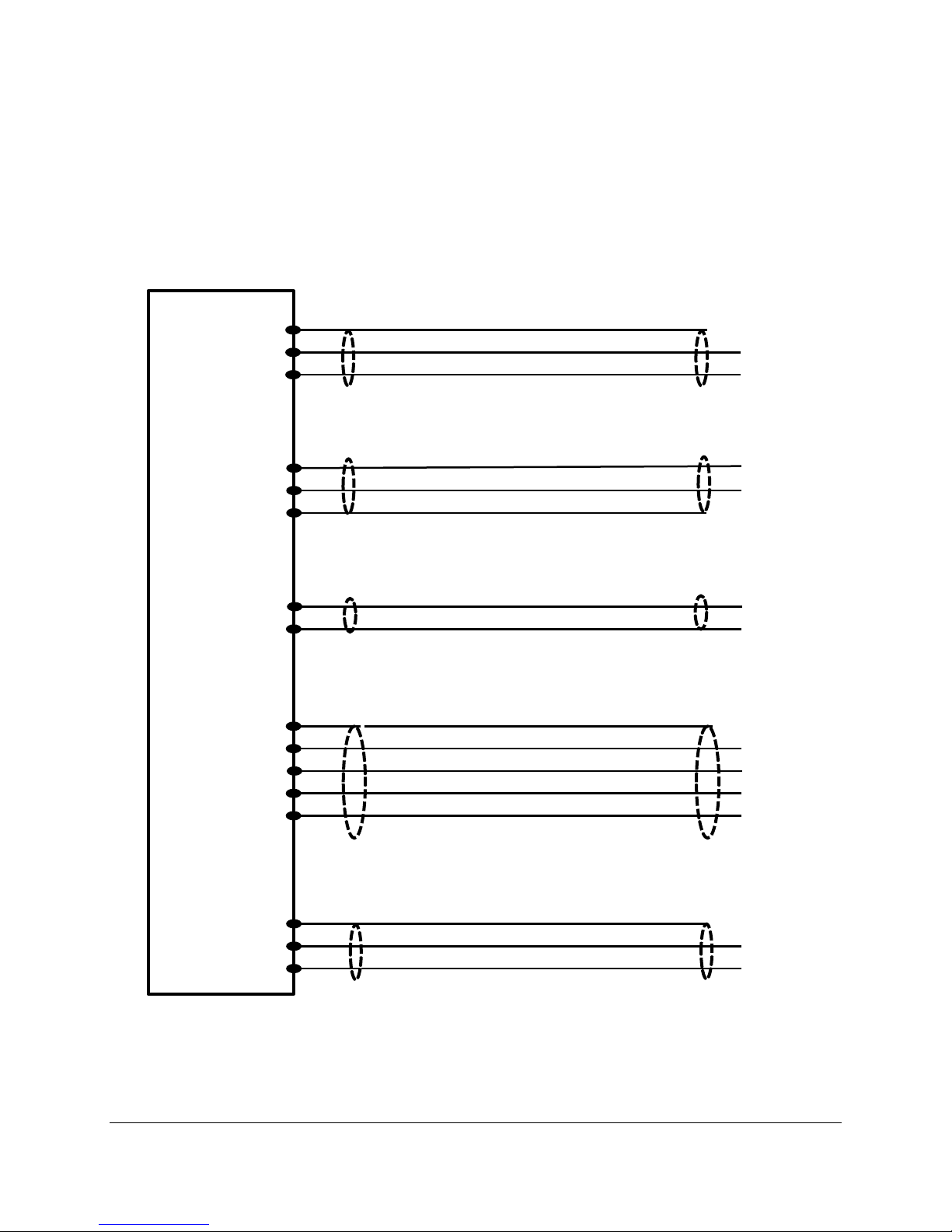

Recommended Cable Interface

WMA-5 Terminal Block

Vout

GND

Shielded cable to external relays or Programmable Logic Controller

Typical cable Belden 9609 4C 24 Shielded. Length 10 Ft Maximum.

Shielded cable to Data Logger or Programmable Logic Controller

Typical cable Belden 8413 2C 24 Shielded. Length 5 Ft Maximum.

GND

Alarm 1

Alarm 1

Alarm 2

Alarm 2

GND

TX RS232

RX RS232

Supply 4-20

Iout 4-20

GND

GND

5V out

AUX1 in

Shielded cable to PC or Data Logger

Typical cable Belden 9609 4C 24 Shielded. Length 10 Ft Maximum

Shielded cable to Data Logger

Typical cable Belden 8413 2C 24 Shielded. Length 10 Ft Maximum.

Shielded cable to sensor of manual zero switch

Typical cable Belden 9609 4C 24 Shielded. Length 5 Ft Maximum.

When connecting up to external devices via the WMA-5 terminal block we recommend the following cable

type and lengths.

WMA-5 Operation Manual V. 1.01 14 support@ppsystems.com

USB Memory Stick Port

A USB Memory Stick Port is available on the front panel to allow users to save data directly to a USB

flash drive (also commonly referred to as a “thumb drive” or “memory stick”). When a USB flash drive is

inserted into the USB Memory Stick port, the LED indicator will first turn red in recognition of the flash

drive and then it will flash green indicating that it is available to save data to it.

Flow Adjustment

The WMA-5 features an internal electronic flow sensor for measuring the flow. It is factory calibrated by

the manufacturer and should remain within the accuracy tolerance for life. Flow rate is adjustable by

changing the Pump Power percent in the Flow settings in the touch display.

Flow Range: 200-500 cc/min

We recommend a flow rate of 280-340 cc/min for optimal performance.

Important Note

If the WMA-5 is reading low CO2, chances are that there is no flow through the analyzer. Check the water

trap to make sure that it is not filled with water.

Absorber Column and CO2 Scrubber

The absorber column contains a CO2 scrubbing desiccant commonly referred to as Soda Lime. When air

passes through this column, it removes all of the CO

into the WMA-5 periodically switches the flow of gas from the analyzer through this column to check the

analyzer zero. This routine ensures long term stability and accuracy of the CO

corrects for such things as sample cell contamination, source aging, detector sensitivity and changes in

electronics.

from the air stream. The “Auto-Zero” facility built

2

analyzer. It automatically

2

Soda Lime (CO

Soda lime (Sodium Hydroxide) is used to remove CO

(white to violet) and non-indic at ing So da Lime can be can be used with the WMA-5. Refer to Soda Lime

on page 68 for maintenance and replacement information.

Scrubber)

2

from air entering the WMA-5. Both self-indicting

2

Data Port

The Data Port line can be connected to the COM port of a PC that is running a terminal emulation

program (i.e. Hyperterminal). Measure data is continuously sent through this port.

WMA-5 Operation Manual V. 1.01 15 support@ppsystems.com

Routine System Checks

The WMA-5 is designed to monitor CO2 24/7 and should require minimal maintenance. The routine

system checks are as follows:

Flashing Heart (♥) – Make sure that the heart symbol is flashing in the upper left hand corner.

Water Trap – Periodically inspect for water build-up and empty as required.

Status Box – Inspect periodically for error messages/warnings.

Absorber Column

• Make sure absorber column is seated properly in its manifold.

• Soda lime is fresh to ensure that the unit receives a good Zero to maintain calibration and

stability. If you have any doubt about the freshness of the soda lime you should replace it.

• All “O” rings are lubricated with silicone grease to ensure good seal and to avoid problems

associated with breaking or cracking.

• Inspect gray foam filters and replace if worn or reduced in size.

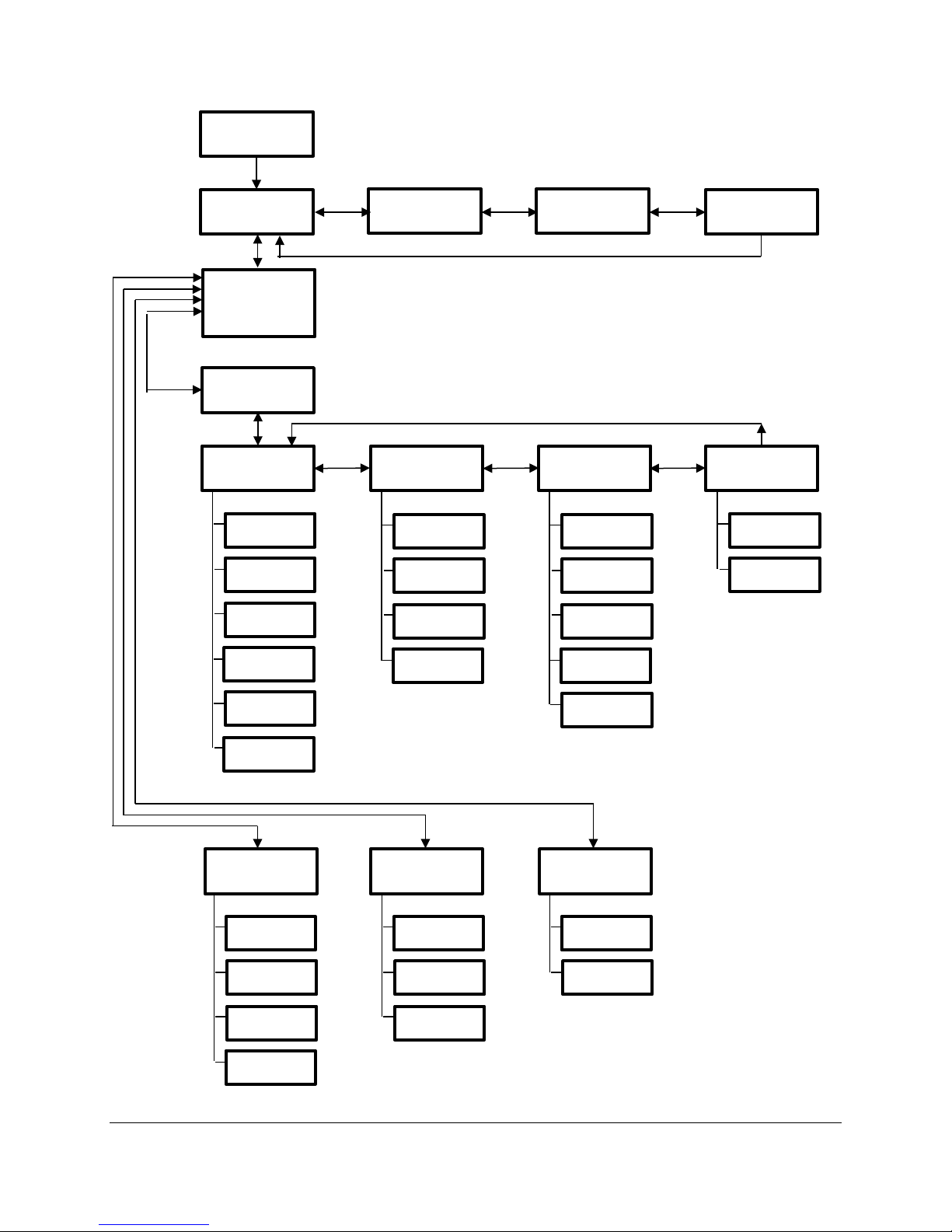

Touch Display Overview

The flowchart below describes an overview of the touch display for the WMA-5. When the instrument is

first powered up, there is a brief period where the Splash screen is shown. After this time, the instrument

goes into the warm-up period which is appr oximately 10-15 minutes and the Measure screen is displayed.

During and after the warm-up period, the user has the ability to navigate through the menus as shown in

the flowchart below. The following sections describe each screen and its functionality.

WMA-5 Operation Manual V. 1.01 16 support@ppsystems.com

Main Menu

Settings 1

Menu

Settings 2

Menu

Settings 3

Menu

Settings 4

Menu

Settings

Menu

Zero

Alarms

Reset Abs

Flow

Alarm Sound

CO2 Unit

Analog

Averaging

WMA ID

Graph

Host

WiFi

Memory

Host Port

Reset WiFi

Set Clock

Defaults

Info

Menu

Diagnostics

Menu

Calibration

Menu

ADC

Zeros

Hours

Voltages

About

Contact

CO2

O2

Touch Cal

Splash Screen

CO2

Screen

Variables 1

Screen

Variables 2

Screen

Graphic

Display Screen

WMA-5 Operation Manual V. 1.01 17 support@ppsystems.com

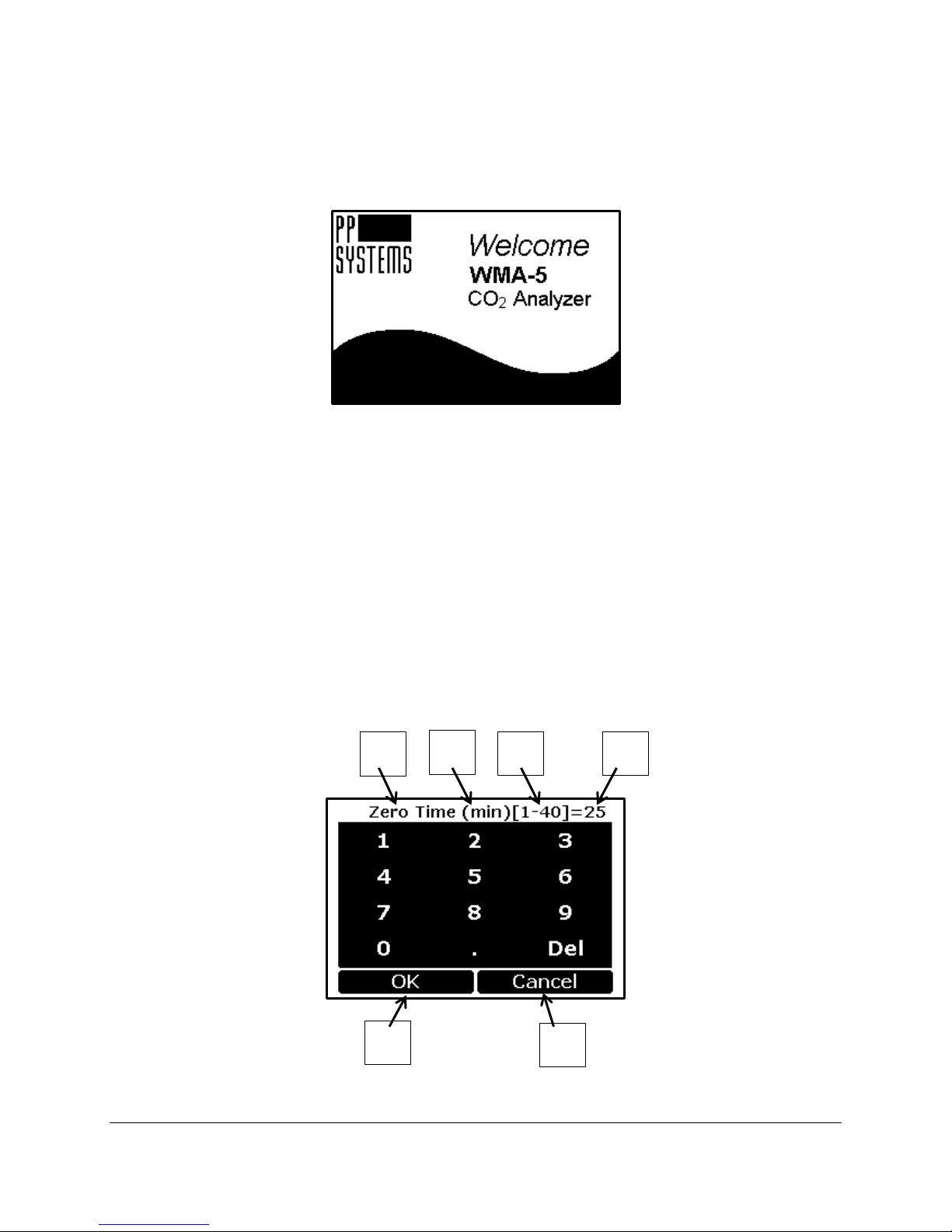

Splash Screen

6

1

3 4 5

2

When the instrument is first powered up, the Splash screen is displayed momentarily, and then the

Measure screen is displayed.

General Screen Info

New screens are displayed by the user selecting either the lower left or the lower right buttons. Generally

speaking, the left button brings you back to the previous screen and the right button to the next available

screen.

Data Entry Screen

The Data Entry Screen is used to enter new num eric al values. The sc reen is displ a yed whene ver a ne w

value is required.

1. The name of the parameter.

WMA-5 Operation Manual V. 1.01 18 support@ppsystems.com

2. The units associated with the parameter.

1 3 4

5

2

3. The acceptable range of values.

4. The value being entered.

5. The OK button selects the entered value. If the entered value is out of range, it is set to the

minimum or maximum value. It then returns to the previous screen.

6. The Cancel button returns to previous screen without changing the initial value.

Measurement Mode

The Measurement Mode is comprised of four screens; Measure screen, Variables 1 screen, Variables 2

screen, and the Graphic Display screen. Each screen allows the user to view the WMA-5 data in various

ways. The screens can be rotated through by the user using the left and right arrow buttons. The initial

screen is the Measure screen which displays the value of CO

Second screen is the Variables 1 screen which displays the values of six variables in real time; CO

O

, Temperature, Flow Rate, and Pressure. The Third screen is the Variables 2 screen which displays

2

the values of four variables in real time; CO

screen which displays CO

, H2O or O2 concentration graphic all y over tim e.

2

, H2O, O2, and Aux. The forth screen is the Graphic Display

2

Measure Screen Info

concentration in a large bold font. The

2

, H2O,

2

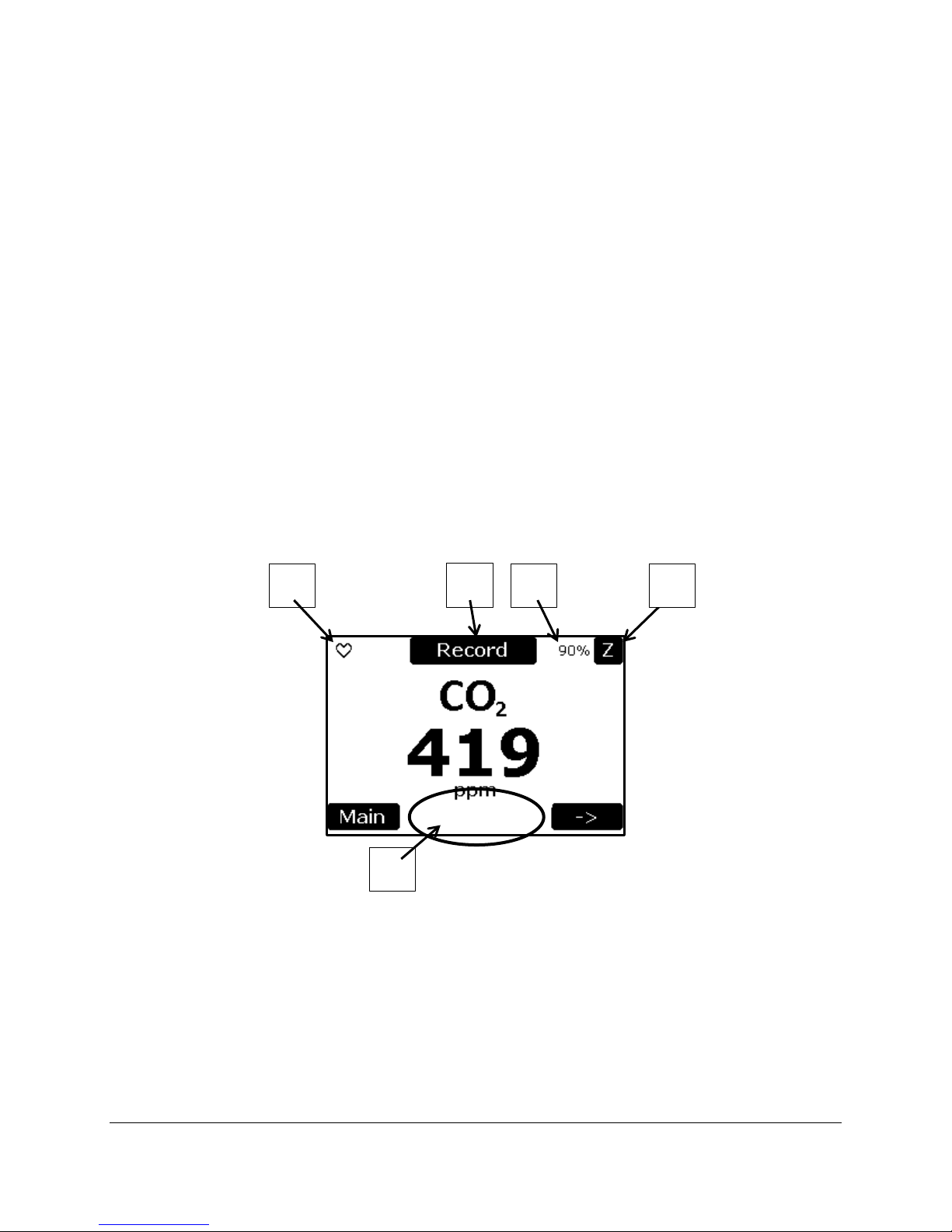

Each measurement screen contains these common features.

1. There is a pulsing

2. The Record button saves data as a marked record in the USB memory stick, and also sends the

record to the host and WiFi ports.

3. The percentage value in the top right corner is the estimated percentage of Auto-zero abs or ber

column capacity remaining based on the number of zeros performed since the last time the

counter was reset by the user (See Reset Zero Absorber on page xx).

♥ icon to confirm that the WMA-5 display is actively on.

4. The ‘Z’ button is used to initiate a manual zero.

5. A status or error message can be displayed in the Status Area.

WMA-5 Operation Manual V. 1.01 19 support@ppsystems.com

Measure Screen

The Measure screen is displayed after the Splash screen and when the WMA-5 is powered up. For the

first 10-15 minutes, the WMA-5 goes into a warm-up period until it achieves its stable temperature of

55°C and an Auto-Zero is performed. During this time, messages are displayed in the Status Box area

that indicates that the instrument is in the warm-up stage. At the completion of the warm-up period, the

proper CO

The Main and right arrow buttons are operational during and after the warm-up period.

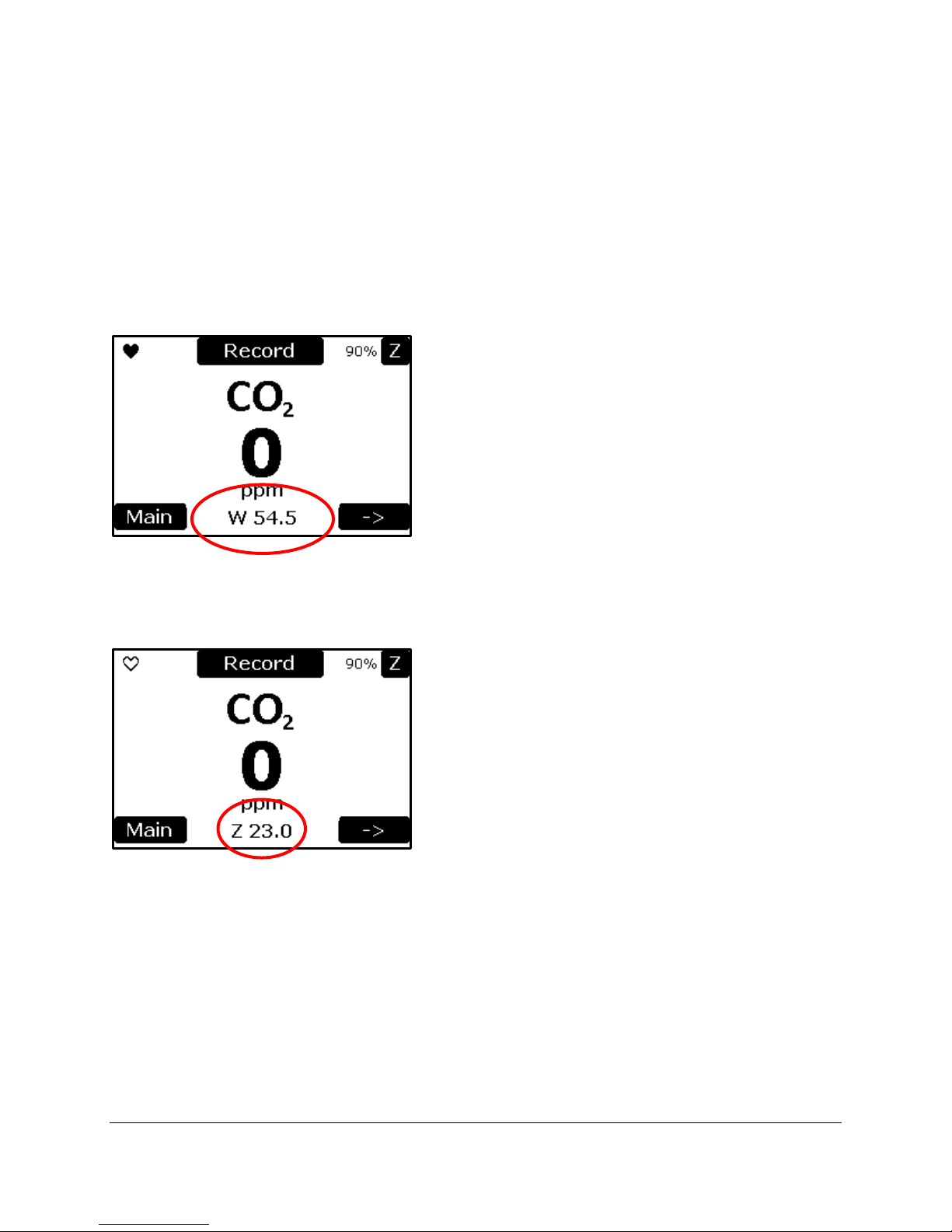

Warming Up

value is displayed and the Status Box is blank.

2

The status of ‘W 54.1’ means the WMA-5 is warming and the CO

warm-up, the CO

value is displayed as 0.

2

IRGA temperature is 54.1°C. During

2

Performing a Zero

The status of ‘Z 23’ means the WMA-5 is performing a zero. The number is how many seconds it will take

to complete the sequence. A normal zero starts at 25 seconds. During a Zero, the CO

value is displayed

2

as 0 as the readings are not valid during the Zero sequence.

At the completion of the warm-up and the first Zero, valid readings are displayed.

WMA-5 Operation Manual V. 1.01 20 support@ppsystems.com

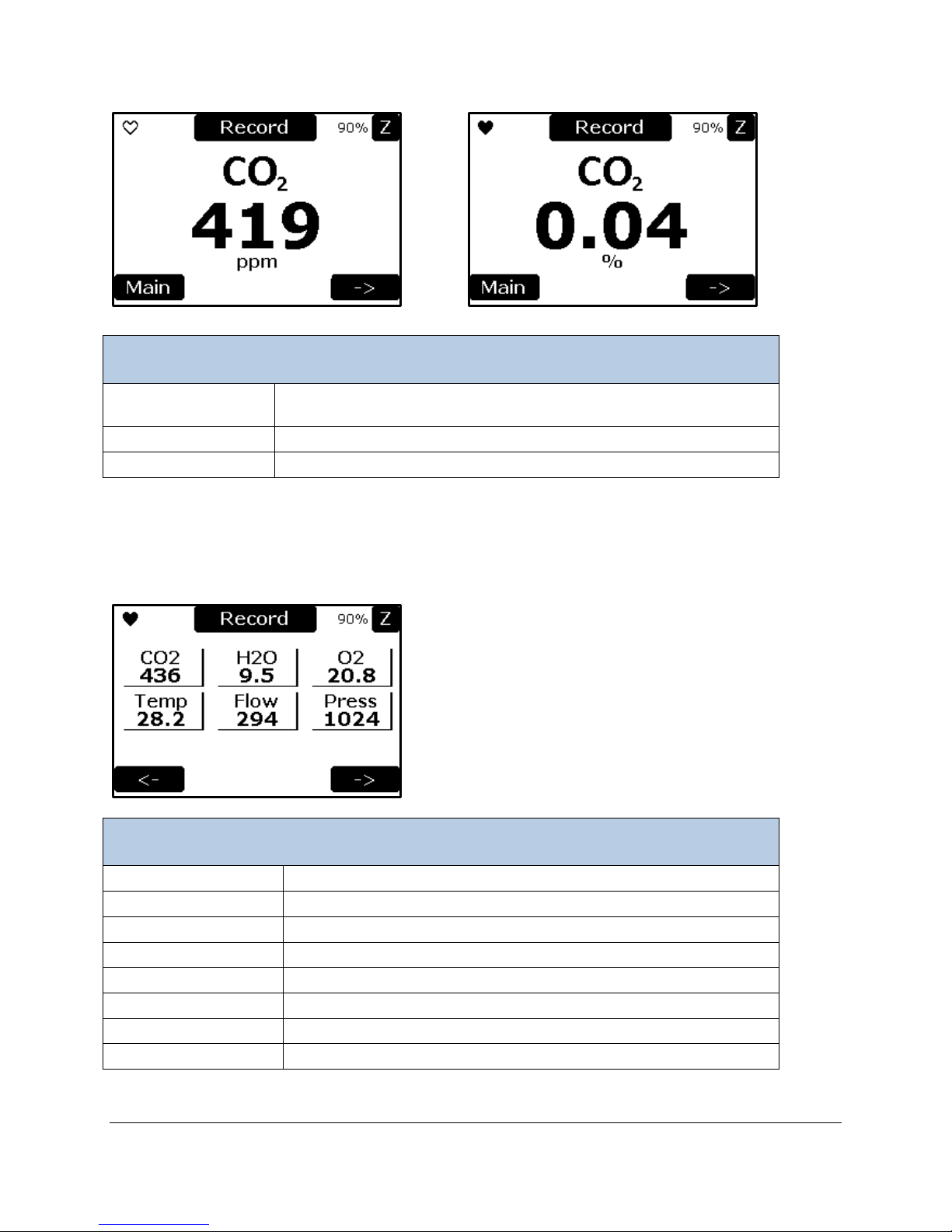

or

Measure Screen

CO2

CO2 Concentration (ppm or %). You can display CO2 in ppm or as a

percentage. See CO2 Units Settings on page 28.

Main Button

The Main Menu screen is displayed when this button is selected.

Right Arrow Button

Selects the next measurement screen (Variables 1 Screen).

Variables 1 Screen

CO2

CO2 concentration reading (ppm).

H2O

H2O reading (mb), only if optional humidity sensor is installed.

O2

O2 reading (%), only if optional O2 sensor is installed.

Temp

Inlet air temperature (C), only if optional humidity sensor is installed.

Flow

Flow rate reading (cc/min).

Press

Absolute pressure in sample cell (mb).

Left Arrow Button

Displays the previous measurement screen, the Measure Screen.

Right Arrow Button

Displays the next measurement screen, the Variables 2 Screen.

Variables 1 Screen

The Variable 1 screen displays the values of six variables in real time; CO2, H2O, O2, Temperature, Flow

Rate, and Pressure.

WMA-5 Operation Manual V. 1.01 21 support@ppsystems.com

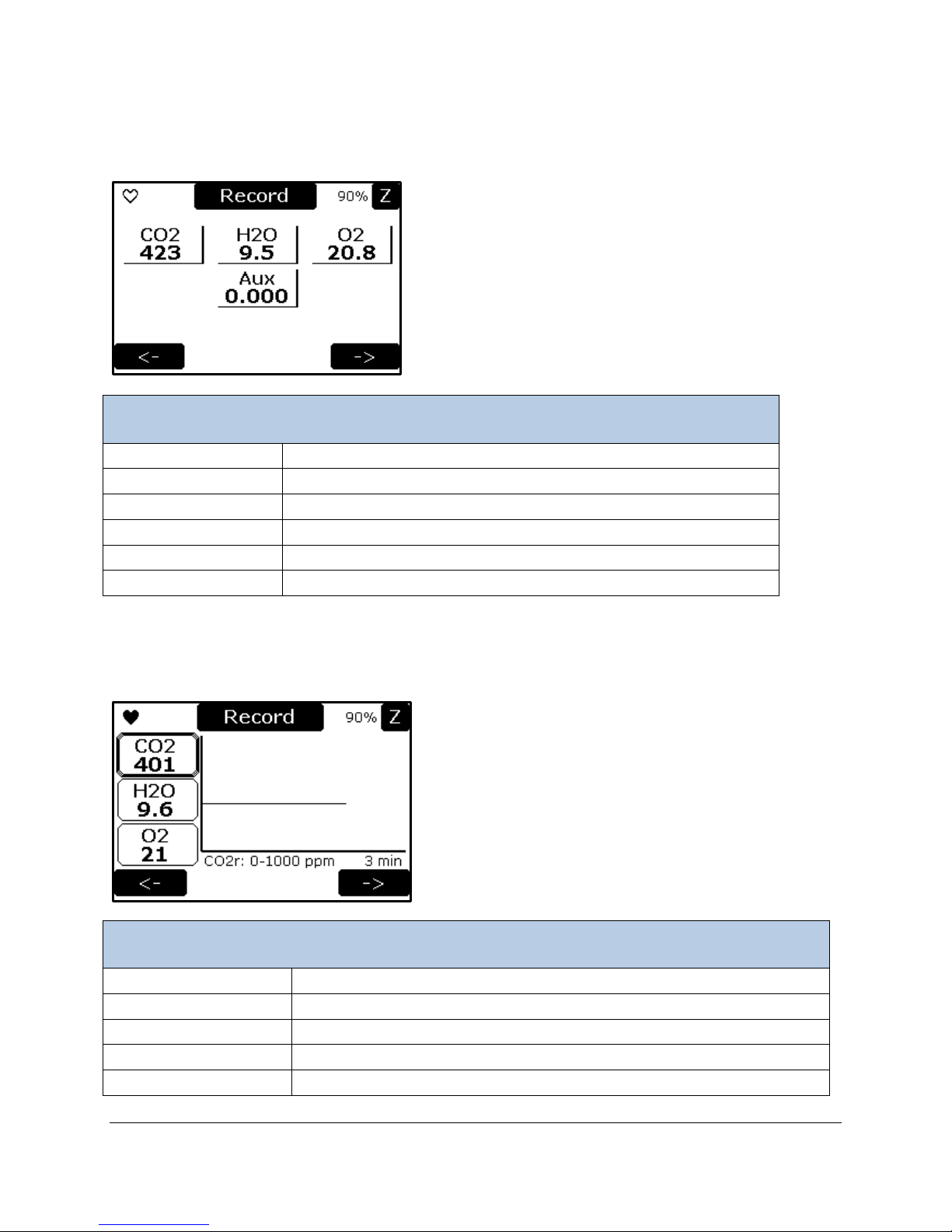

Variables 2 Screen

Variables 2 Screen

CO2

CO2 concentration reading (ppm).

H2O

H2O reading (mb), only if optional humidity sensor is installed.

O2

O2 reading (%), only if optional O2 sensor is installed.

AUX

AUX1 input voltage (volts)

Left Arrow Button

Displays the previous measurement screen, the Variables 1 Screen.

Right Arrow Button

Displays the next measurement screen, the Graph Screen.

Graph Screen

CO2 Button

Selectable parameter to graph (0 – 100000 ppm)

H2O Button

Selectable parameter to graph (0 - 30 mb)

O2 Button

Selectable parameter to graph (0 – 100 %)

Y-axis

Range and units are located under the graph on left side

X-axis

X-axis time; fixed value of 3 minutes.

The Variable 2 screen displays the values of four variables in real time; CO2, H2O, O2, and Aux.

Graph Screen

The Graph screen shows a real-time display of the data.

WMA-5 Operation Manual V. 1.01 22 support@ppsystems.com

Left Arrow Button

Goes back the previous screen (Variables 2 Screen).

Right Arrow Button

Selects the next measurement screen (Meas ure Sc r ee n).

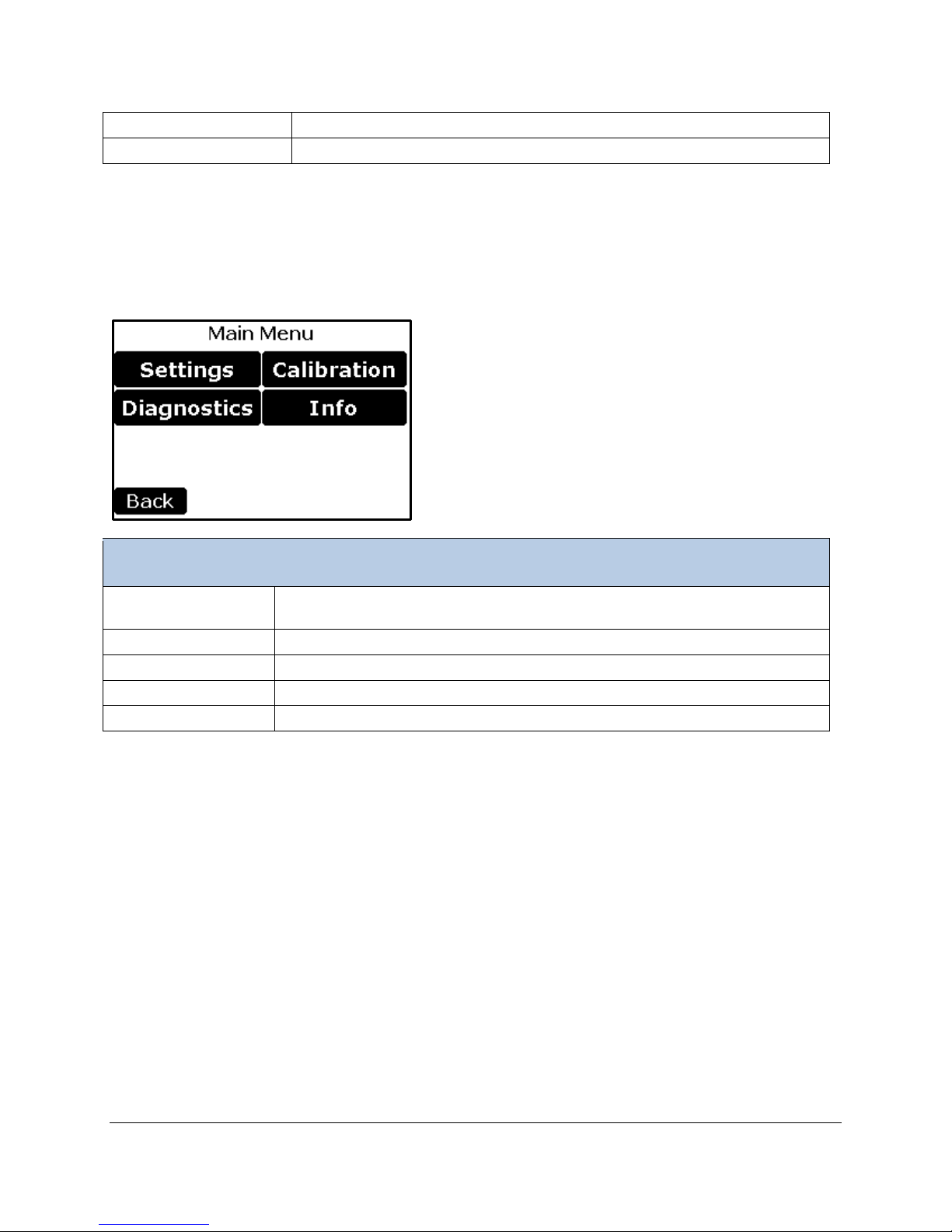

Main Menu

Settings Button

Controls major settings of the WMA-5. There are four sub menus under

Settings.

Diagnostics Button

Performs system diagnostics for troubleshooting purposes.

Calibration Button

Used to calibrate the CO2 gas analyzer, O2 Sensor, and the Touch Screen.

Info Button

To obtain version information and contact info

Back Button

Goes back to Measure screen

Main Menu

The Main Menu screen is displayed when the Main button is selected in the Measure screen. This menu

is the top level menu for all settings and user functionality of the system.

WMA-5 Operation Manual V. 1.01 23 support@ppsystems.com

Loading...

Loading...