HumiTherm Ultra User Manual

HumiTherm Ultra

Temperature + Humidity (%RH)

Control & Recording System

with 8 / 16 Mapping Inputs

Touch Operation Panel

PPI

HumiTherm Ultra

User Manual

HumiTherm Ultra User Manual

CONTENTS

1. MOUNTING & ELECTRICAL CONNECTIONS : HMI (TOUCH PANEL) 1

2. MOUNTING & ELECTRICAL CONNECTIONS : microPLC 4

3. MOUNTING, ELECTRICAL CONNECTIONS & JUMPER SETTINGS : MAPPING 7

4. BASIC OPERATION & PARAMETERS ORGANIZATION 11

5. OPERATOR LEVEL PARAMETERS 20

6. SUPERVISORY LEVEL PARAMETERS 22

7. FACTORY LEVEL PARAMETERS 26

APPENDIX-A : DC LINEAR SIGNAL INTERFACE 47

APPENDIX-B : COMPRESSOR SETTING PARAMETERS 50

APPENDIX-C : STANDBY SENSORS 53

APPENDIX-D : STANDBY CONTROL GADGET 55

APPENDIX-E : DOOR LOCK 58

APPENDIX-F : DIGITAL INPUT & OUTPUT 59

HumiTherm Ultra User Manual

Section 1

MOUNTING & ELECTRICAL CONNECTIONS : HMI (TOUCH PANEL)

4.3” Mounting

Table 1.1

Dimensions

Overall

Panel Cutout

128(W) X 102(H) X 55(D), mm

121(W) X 95(H), mm

Figure 1.1

102 mm

95 mm

(Panel Cut)

4.3” Electrical Connections

128 mm

5 mm

55 mm

Figure 1.2

121 mm

(Panel Cut)

3

12

1

HumiTherm Ultra User Manual

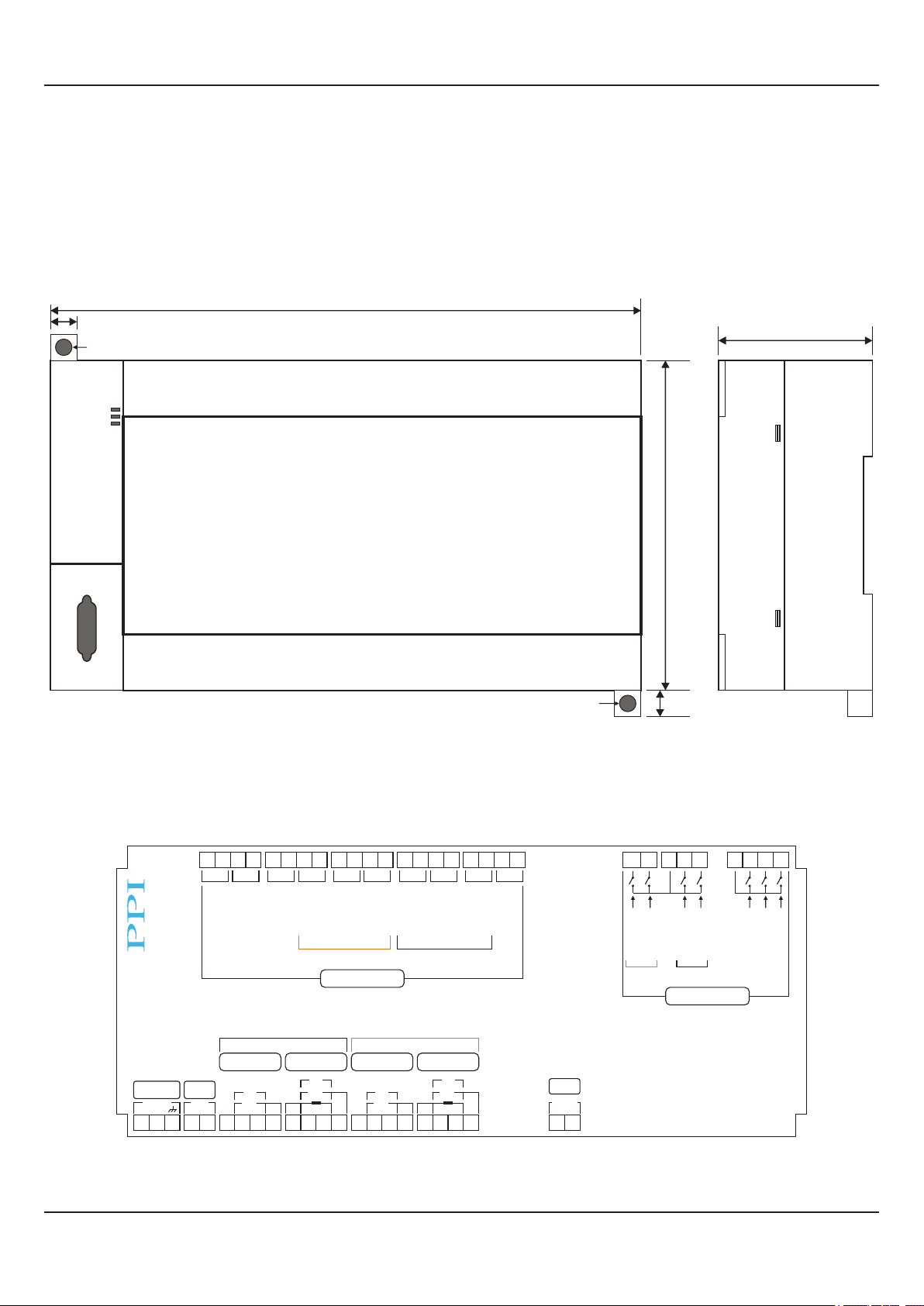

7” Mounting

Table 1.2

Dimensions

Overall

Panel Cutout

206(W) X 136(H) X 44(D), mm

199(W) X 129(H), mm

Figure 1.3

136 mm

129 mm

(Panel Cut)

206 mm

199 mm

(Panel Cut)

6.5 mm

44 mm

2

HumiTherm Ultra User Manual

7” Electrical Connections

24VDC FG

-

+

Figure 1.4

PULL

COM2 ETHERNET

RESET

SD-CARD

USB

HOST

COM1

Battery Cover

3

1

2

3

15 Pin

1 2

Table 1.3

3-Pin Male / Female Connector (5.08 mm pitch)

Supply Voltage : 20 to 28 VDC (24 V Nominal)

9 (4.3” HMI) / 15 (7” HMI) Pin D Type Connector

RS485 Serial Communication with microPLC &

Mapping Unit

9 Pin

6 Pin PS/2 Connector

RS232 Serial Communication with PC

3

HumiTherm Ultra User Manual

Section 2

MOUNTING & ELECTRICAL CONNECTIONS : microPLC

Mounting (Base / Wall Mounting)

179mm

8mm

ø5mm Mounting Hole

Figure 2.1

77mm

100mm

microPLC Electrical Connections

27262524

+-+

Main Set Select

Main

Temperature

+

+

-

-

-

mA

Pt100

+-+

-

Door Lock

Stby Set Select

Humidity

Supply

-

5VDC

Exc

+

-

V

mA

-

-

18~32VDC

+

1 2 3 4 5 6 7 8 9 10 11 12 13 22 2314 15 16 17 18 19 20 21

-

Humidifier

Compressor

Standby

Digital Outputs

V

+

+

+

Humidity

-

Heater

-

V

mA

-

+

Standby

+

+

-

Compressor

Figure 2.2

-

+

-

+

Humidifier

Main

Temperature

V

+

-

+

-

mA

Pt100

ø5mm Mounting Hole

43424140393837363534333231302928

+

-

+

Alarm

Heater

HMI

RS485

-

+

Thermostat

Water Level

Stby

8mm

Thermostat

Water Level

Main

Digital Inputs

microPLC

Stability Control

Alarm ACK

525150494847464544

Power Fail

Door Open

4

HumiTherm Ultra User Manual

DESCRIPTIONS

The connections are described as under:

Main Humidity (%RH) Transmitter Input (Terminals : 7,8, 9)

The Controller accepts DC Current (mA) / DC Voltage (V) as Humidity input. The connections are

described below.

Humidity Transmitter with DC Voltage (V) Output

Figure 2.3 (a)

0/1~5V, 0~10V

7 8 9

V

The Figures 2.3(a) depicts wiring connections for voltage output transmitter. The Excitation Voltage

can be obtained from an external source or from the controller (5 VDC).

Humidity Transmitter with DC Current (mA) Output

The Figures 2.3(b) depict wiring connections for current output transmitter. Note that terminals 8 & 9

Figure 2.3 (b)

0/4~20mA

7

8 9

should be shorted. The Excitation Voltage can be obtained from an external source or from the

controller (5 VDC).

mA

Main Temperature (°C) Sensor / Transmitter Input (Terminals : 10, 11, 12, 13 )

The Controller accepts RTD Pt100 (3-wire / 2-wire) or DC Current (mA) / DC Voltage (V) as Temperature input. The

connections are described.

Figure 2.4 (a) Figure 2.4 (b) Figure 2.4 (c)

RTD Pt100

0/1~5V, 0~10V

0/4~20mA

10 11 12 13

10 11 12 13

V

10 11 12 13

mA

RTD Pt100, 3-wire

Connect single leaded end of RTD bulb to terminal 10 and the double leaded ends to terminals 11 & 12 as shown in Figure

2.4(a). Use copper conductor leads of very low resistance ensuring that all 3 leads are of the same gauge and length. Avoid

joints in the cable.

Temperature Transmitter with DC Voltage (V) Output

The Figures 2.4(b) depicts wiring connections for voltage output transmitter. The Excitation Voltage can be obtained from an

external source or from the controller (5 VDC).

Temperature Transmitter with DC Current (mA) Output

The Figures 2.4(c) depict wiring connections for current output transmitter. Note that terminals 12 & 13 should be shorted. The

Excitation Voltage can be obtained from an external source or from the controller (5 VDC).

5 VDC Excitation Voltage (Terminals : 4, 5)

The Controller is supplied with inbuilt 5VDC Excitation Voltage as standard. The Excitation Voltage can be used to power

external Temperature and/or RH Transmitters.

The ‘+’ and ‘-’ terminals are for voltage ‘Source’ and ‘Return’ paths, respectively.

5

HumiTherm Ultra User Manual

[Optional] Standby Humidity (%RH) Transmitter Input (Terminals : 14, 15, 16, 17)

[Optional] Standby Temperature (°C) Sensor / Transmitter Input (Terminals : 18, 19, 20, 21)

The Control Unit optionally supports Inputs for Standby (redundant) Humidity & Temperature sensor / transmitter. The

Connection detail are the same as for main sensor / transmitter described above.

[Optional] Door Output (terminals : 24, 25)

[Optional] Standby Set Select Output (terminals : 26, 27)

[Optional] Main Set Select Output (terminals : 28, 29)

[Optional] Standby Compressor Output (terminals : 30, 31)

[Optional] Standby Humidifier Output (terminals : 32, 33)

[Optional] Standby Heater Output (terminals : 34, 35)

Main Compressor Output (terminals : 36, 37)

Main Humidifier Output (terminals : 38, 39)

Main Heater Output (terminals : 40, 41)

Alarm Output (terminals : 42, 43)

All the above control & alarm outputs are Voltage pulses (12VDC @ 40mA) for driving external SSR or Relay. The ‘+’ and ‘-’

terminals are for voltage ‘Source’ and ‘Return’ paths, respectively.

The Optional Outputs are fitted only if Controller is ordered with Standby Control Outputs.

[Optional] Standby Thermostat Digital Input (Terminals 44, )46

[Optional] Standby Water Level Digital Input (Terminals 45, )46

Main Thermostat Digital Input (Terminals 47, )46

Main Water Level Digital Input (Terminals 48, )46

Alarm Acknowledge Digital Input (Terminals 50, )49

Power Fail Digital Input (Terminals 51, )49

Door Open Digital Input (Terminals 52, )49

(Terminals 46 & 49 are Common)

Potential-free contact closure input terminals are provided as digital inputs. An ‘Open’ or ‘Close’ switch position is detected as

input.

HMI (Terminals 22, 23) COMMUNICATION PORT

For reliable noise free communication, use a pair of twisted wires inside screened cable. The wire should have less than 100

ohms / km nominal DC resistance (Typically 24 AWG or thicker). Connect the terminating resistor (Typically 100 to 150 ohm)

at one end to improve noise immunity.

POWER SUPPLY 1(Terminals , 2, 3)

As standard, the is supplied with power connections suited Module

for to V C . The accuracy / p formance of the 18 32 D power source er

Module is not affected by the variations in the supply within sp cified e

limits of to 3 VDC. Use well-insulated copper conductor wire of 18 2

the size not smaller than 0.5mm² for power supply connections

ensuring proper polarity as shown in Figure . The is not 2.5 Module

provided with fuse and power switch. If necessary, mount them

DC Power

Source

+

-

Figure 2.5

Fuse

2 Pole

Isolating Switch

Mains

Earth

1

+

2

-

3

separately. Use a blow fuse rated for 0.5A current. slow

For safety and enhanced electrical noise immunity, it is highly recommended to connect Main Power Supply ‘Earth’

to terminal 3.

6

HumiTherm Ultra User Manual

Section 3

MOUNTING, ELECTRICAL CONNECTIONS & JUMPER SETTINGS : MAPPING

Mounting (Base / Wall Mounting)

Figure 3.1

210mm

205mm

ø5mm

Mounting Hole

5mm

8mm

ø5mm Mounting Hole

Mapping Electrical Connections

52 53

54

55

COMM PORT

B BB B

A1A2

28293031323334353637383940

B1B2

A3

°C

MAP 5

%RH

B3

A1A2

88mm

110mm

Figure 3.2

°C

A3

mA

mV / V

B1B2

MAP 8

B3

%RH

A1A2

B3

44

464748495051

45

%RH

4142

°C

RTD

A3

B1B2

43

MAP 7

mA

mV / V

%RH

B3

A1A2

B1B2

A3

°C

MAP 6

°C

PPI

MAP 1

°C

1 2

A1 A2 A3 B1 B2 B3

%RH

5

3

6 7 8 9 10

4

B1 B2 B3 A1 A2 A3 B1 B2 B3 A1 A2 A3 B1 B2 B3 A1 A2 A3

MAP 2

°C

A1 A2 A3

%RH

11 121314

MAP 3

°C

15 161718 19 20

%RH

%RH

B1 B2 B3

MAP 4

°C

21 222324

7

%RH

25

84 ~ 264

VAC

L

N

26 27

UniMap

SUPPLY

4 / 8 Points

Mapping Module

Sr. No.:

HumiTherm Ultra User Manual

Map Inputs

Each of the °C and %RH inputs are identical from wiring connection viewpoint. The descriptions below apply to all the inputs

with no deviations.

Make sure that proper jumper settings are made for each input for the selected input type as described later in this ection.s

Figure 3.3(b)Figure 3.3(a)

°C

RTD

A1 A2 A3

RTD Pt100, 3-wire

Connect single leaded end of bulb to and the double leaded ends to terminals and (interchangeable) as shown RTD A1 A2 A3

in Use copper conductor leads of very low resistance ensuring that all 3 leads are of the same gauge and length. Figure 3.3(a).

Avoid joints in the cable.

DC Linear Voltage (mV / V) & Current (mA)

Use a shielded twisted pair with the shield grounded at the signal source for connecting mA / mV / V source. Connect common

(-) to and the signal (+) to , as shown in A2 / B2 A1 / B1 Figure 3.3(a) & (b).

mV / V / mA

A1 A2

A3

%RH

mV / V / mA

B1 B2

B3

POWER SUPPLY

Figure 3.4

Fuse

2 Pole

Isolating Switch

Power Supply

Terminal

Line

26 (L)

Neutral

As standard, the controller is supplied with power connections suited for 8 to 264 VAC line supply. Use well-insulated copper 5

conductor wire of the size not smaller than 0.5mm² for power supply connections. Connect Line (Phase) supply line to terminal

26 and the Neutral (Return) supply line to terminal 27 as shown in Figure . . The controller is not provided with fuse and 3 4

power switch. If necessary, mount them separately. Use a time lag fuse rated 1A @ 240 VAC.

27 (N)

8

HumiTherm Ultra User Manual

SERIAL COMMUNICATION PORT

Figure 3.5

HMI

Port

RS485

Mapping

RS485 Port

IN

OUT

To microPLC

The wiring connections for interfacing the HMI with mapping unit is shown in the figure 3.5.

INPUT TYPE : JUMPER SETTINGS

The Mapping Unit (UniMap) is supplied with 8 ( ) or 16 ( T + 8RH) s. Each can be user configured for a 4T + 4RH 8 Map Input Input

variety of input types which requires appropriate parameters settings and jumper settings on . The figure shows UniMap 3.6

the locations of jumper setting arrangements for each . input

Figure 3.6

°C

MAP 1

1

2

4

3

°C

MAP 5

%RH

MAP 4

%RH

MAP 8

4

1

2

3

9

HumiTherm Ultra User Manual

The jumper setting arrangement comprises of as shown in the figure below. The figure also depicts Pins & Shorting-Link 3.7

how to mount the Shorting-Link for a particular jumper setting.

Figure 3.7

Pins

The figures below show the jumper settings for different input types.

Shorting

Link

Shorting Link

Placed

RTD Pt100 (3-wire)

3

2

1

Place Shorting

Link on Pins 1 & 2

4

0-50mV, 0-200mV, 0-1.25V,

0-5V, 1-5V, 0-10V

Shorting Link

Parked

0-20mA, 4-20mA

Place Shorting

Link on Pins 2 & 3

3

2

1

4

Park Shorting Link

10

3

2

1

4

HumiTherm Ultra User Manual

Section 4

BASIC OPERATION & PARAMETER ORGANIZATION

Upon Power up to the HMI, after a few initialization screens, the Main (Home) screen is displayed. This is the screen that shall

be used most often and is described below in details.

Battery Indicator

Comm Error Indicator

Calendar Date

Alarm Indicator

Clock Time

Temperature Value

Status View Button

Map View Button

Temperature Setpoint

(Optional Touch Button)

Tuning

Tune Status Indicator

%RH Value

%RH Setpoint

(Optional Touch Button)

Set-up Mode Button

Door Open Button

ALARM INDICATOR

This icon appears if one or more process alarms are active. The Alarm Relay gets activated whenever any alarm becomes

active. The user can acknowledge the alarm (de-activate the relay) by touching this icon.

BATTERY INDICATOR

This icon appears if the Mains power has failed and the controller is currently powered through an auxiliary power source like

Battery or Inverter.

COMM ERROR INDICATOR

This icon appears if the HMI communication link with the Control Unit, Mapping Unit or GSM Module is broken. Upon touching

this icon a message window pops up showing which communication link(s) is broken.

CALENDER DATE & CLOCK TIME

These two fields show the current date (DD/MM/YY) & time (HH:MM:SS, 24 Hours format), respectively.

TEMPERATURE VALUE & %RH VALUE

These two fields show the Temperature & %RH Process Values in 0.1 °C / %RH resolution. In case of errors the field shows

OPEN (Sensor Open), OVER (Process Value above Max Range), UNDR (Process Value below Min Range). The Process

Values are shown in Black color under normal condition. The Error Messages are shown in Red color.

TEMPERATURE SETPOINT & %RH SETPOINT

These two fields show the Temperature & %RH Set Values (SP) in 0.1 °C / %RH resolution. If enabled, these values can be

edited by touching the respective field. Upon touching a Numeric Keypad pops up for setting.

TUNE STATUS INDICATOR

This text appears if the controller is self tuning the temperature and / or %RH control loop.

STATUS VIEW BUTTON

This a touch button that enables navigation through various process status screens. The Screens are shown below.

11

HumiTherm Ultra User Manual

Process Status Screen

This screen shows various rocess Alarm status and the information regarding working / fa ure of p il various Main and Standby

Sensors (Temperature & %RH) & Control Gadgets (Air Heater, Boiler Heater & Compressor). The contents on this screen are

dependent on whether Standby Sensors and / or Standby Control Gadgets are installed or not. Accordingly the following four

variants of this screen exist:

1. Alarm Only

2. Alarm + Standby Sensor

3. Alarm + Standby Control

4. Alarm + Standby Sensor + Standby Control

Alarm Only

Touch Button to go to

Home (Main) Screen

Touch Button to go to

Next Screen

Touch Button to

Acknowledge Alarm

Alarm + Standby Control

Touch Button to go to

Previous Screen

Alarm + Standby Sensor

Alarm + Standby Sensor + Standby Control

12

HumiTherm Ultra User Manual

Output Status

This screen shows :

w Heating & Humidification % output power

w On-Off Status for Main & Standby (if installed) Air Heater, Boiler Heater (Humidifier) & Compressor

w Alarm Relay Status

Record Status

Th rage capacity, numbers of current stored records and available free space.is screen shows the total record sto

SMS Status

This screen shows the status related to GSM Module (if installed).

5000

1

4999

13

HumiTherm Ultra User Manual

MAP VIEW BUTTON

This is a touch button that opens up screen(s) to view process values for mapping s. The installed mapping s could input input

be 8 (4 Map Points : 4T + 4RH) or 16 (8 8T + 8RH) and accordingly 1 or 2 screens displayed. Note that this Map Points : are

touch button is not available if no mapping inputs are installed. The Screens are shown below.

Appears for both 8 & 16 Map Inputs

22.0

57.5

25.1

60.8

DOOR OPEN BUTTON

If the Humidity cabinet is equipped with Door Lock, this touch button opens a screen that allows password entry for unlocking

the cabinet door by authorised person. Also the authorised person’s identity is logged for audit purpose.

24.8

61.2

27.2

62.3

Appears for 16 Map Inputs only

25.0

59.6

25.2

60.8

24.7

60.2

25.3

60.1

SET-UP MODE BUTTON

This touch button opens a screen that allows access to Operator, Supervisory or Factory Level parameter settings through

appropriate password entry. 4 character

The Factory default passwords are as below :

Access Level

Operator

Supervisory

Factory

Default Password

0000

0001

0002

14

HumiTherm Ultra User Manual

Upon touching one of the levels, a keyboard for password entry pops-up as shown below.

The user must touch the text screen to make it

editable. Upon touch the text screen shows a blue

band as shown below.

Text Screen

****

Non Editable

Editable after touch

****

Password entry on

editable text Screen

While the screen is editable, type 4 character password & then press ENTER Key. If the password is correct, the parameter

setting screen opens up. Use ESC key (in case password is not known) to pop down the key pad.

Once an access level is entered, the user can change the password for that level as shown below as an example for operator

level.

25.0

2.0

2.0

60.0

2.0

2.0

0005

15

HumiTherm Ultra User Manual

Each access level may have sub levels for convenient parameter grouping. The Table . lists various parameters with levels 4 1

and sub levels.

Table 4.1

Level

Operator

Supervisory

Recording

Clock & Calendar

SMS

SMS Alert

Door Lock Access

Standby Switching

Sub-Level

Parameters

Temperature

Set Value

Low Deviation Alarm

High Deviation Alarm

%RH

Set Value

Low Deviation Alarm

High Deviation Alarm

SP Edit on Home Screen

Recording Interval

‘Delete Record’ Command

Calendar Date (DD/MM/YY)

Clock Time (HH:MM:SS)

GSM Machine ID

Reset GSM Module

Lock Position (On / Off)

Password Entry

‘Switch Main / Standby Outputs’

‘Switch to Standby Sensors’

Factory

Maintenance

Temperature

%RH

Input Settings

Alarm Settings

Control Settings

Input Settings

Alarm Settings

Control Settings

Repair Acknowledge ‘Control Gadget’

Repair Acknowledge ‘Input Sensor’

Input Type,

Signal Range Low, Signal Range High,

Display Range Low, Display Range High,

Zero Offset

Inhibit (Yes / No),

Low Alarm Deviation, High Alarm Deviation,

Hysteresis

Heat Zone PID Constants,

Cool Zone PID Constants,

Output Cycle Time (Sec.),

Control SP

Setpoint Low Limit, Setpoint High Limit

Self Tune

Input Type,

Signal Range Low, Signal Range High,

Display Range Low, Display Range High,

Zero Offset

Inhibit (Yes / No),

Low Alarm Deviation, High Alarm Deviation,

Hysteresis

Heat Zone PID Constants,

Cool Zone PID Constants,

Output Cycle Time (Sec.),

Control SP

Setpoint Low Limit, Setpoint High Limit

Self Tune

16

HumiTherm Ultra User Manual

Level

Factory

Compressor

Water Level

Door Open

Power Fail

Standby

Sub-Level

Sensor Inputs

Control Gadgets

Parameters

Mode (ON, OFF, PV Based, SP Based),

Boundary SP or Compressor SP,

Time Delay, Hysteresis

Zone Select (Single, Dual)

Float

Detection Enable (Yes / No),

Low Level Logic (Open / Close)

Thermostat

Detection Enable (Yes / No),

Low Level Logic (Open / Close)

Common Boiler (Yes / No)

Detection Enable (Yes / No),

Door Open Logic (Open / Close),

Alarm Delay (Sec.)

Detection Enable (Yes / No),

Power Fail Logic (Open / Close)

Sensor Fail Detection Limits

Fail Detect Time (Min)

Cyclic Time (Hrs.)

Inhibit Time (Hrs.)

Mapping

Configuration

Temperature

%RH

Alarm Settings

Input Settings

Alarm Settings

Input Settings

Select Mapping Inputs (4T + 4RH, 8T + 8RH)

Low Alarm (Common for all Inputs)

Set Value, Hysteresis, Inhibit

High Alarm (Common for all Inputs)

Set Value, Hysteresis, Inhibit

Input Type,

Range Low, Range High,

Zero Offset

Low Alarm (Common for all Inputs)

Set Value, Hysteresis, Inhibit

High Alarm (Common for all Inputs)

Set Value, Hysteresis, Inhibit

Input Type,

Range Low, Range High,

Zero Offset

17

HumiTherm Ultra User Manual

PARAMETER SETTINGS

There are 3 types of parameters; Numeric, String Option and Commands. The setting methods for different types are

described below.

Numeric Parameters

This type of parameter has 2 fields; & as shown in the figure. The value for this type of parameter is set Name Field Value Field

using a Numeric keypad that pops up upon touching the for the parameter. The value can be edited using numeric Value Field

keys & other functional keys as shown in the figure. Use ENT key for storing the new value or use ESC key to revert without

changes. Touching ENT or ESC key, the keypad automatically collapses.

Note that if the modified value falls outside the Minimum or Maximum limits specified for the

parameter value then the parameter retains the old value.

Name Field Value Field

String Option Parameters

This type of parameter has 2 or more fixed options to choose from. All the options are shown in rectangular boxes with

appropriate texts as shown in the figure. Only one of the several options can be selected. The selected option box is shown in

bright ( ) color, while all other unselected options are shown in dark ( ) color. For selecting the desired option. just touch

the box and wait for a while until the color changes from unselected to selected.

Selected Option

Unselected Options

18

HumiTherm Ultra User Manual

Command Parameters

This type of parameter is used to perform specific actions like Start / Abort tuning, Delete Records, etc. A touch Push Button

image is provided for issuance of command as shown in the figure. Usually an acknowledgment window with OK button pops

up to indicate the action performed. The window collapses upon touching the OK button.

ALARM MESSAGE WINDOWS

For the Alarms related to gadget or sensor failure, door open detection, low water level detection, etc.; message windows are

popped up on the Main (Home) Screen showing the cause of alarm and action taken by the controller. The figure below shows,

for example, the message screen that pops up when the controller detects Main Sensor Set Failure & changes over to the

Standby Set.

19

HumiTherm Ultra User Manual

Section 5

OPERATOR LEVEL PARAMETERS

Operator

25.0

2.0

2.0

Temperature Set Value

Range : Temperature Setpoint ow imit to Temperature Setpoint High LimitL L

Default : 25.0 °C

This is the Setpoint Value for temperature control loop. This value can also be set on home screen if enabled through the

parameter SP Edit on Home Screen.

Temperature Low Deviation Alarm

Range : 0.2 to 99.9 °C

Default : 2.0 °C

This Parameter sets a Negative Deviation (offset) limit with respect to the ‘ ’. The Alarm is activated if the Temperature Set Value

measured temperature value falls below this limit.

60.0

2.0

2.0

Temperature High Deviation Alarm

Range : 0.2 to 99.9 °C

Default : 2.0 °C

This Parameter sets a Positive Deviation (offset) limit with respect to the ‘ ’. The Alarm is activated if the Temperature Set Value

measured temperature value exceeds this limit.

%RH Set Value

Range : %RH Setpoint Low Limit to %RH Setpoint High Limit

Default : 60.0 %

This is the Setpoint Value for %RH control loop. This value can also be set on home screen if enabled through the parameter

SP Edit on Home Page.

%RH Low Deviation Alarm

Range : 0.2 to 99.9 %

Default : 2.0 %

This Parameter sets a Negative Deviation (offset) limit with respect to the ‘ ’. The Alarm is activated if the %RH Set Value

measured %RH value falls below this limit.

20

HumiTherm Ultra User Manual

%RH High Deviation Alarm

Range : 0.2 to 99.9 %

Default : 2.0 %

This Parameter sets a Positive Deviation (offset) limit with respect to the ‘ ’. The Alarm is activated if the %RH Set Value

measured %RH value exceeds this limit.

SP Edit on Home Screen

This parameter allows to Enable or Disable the set editing for both temperature & %RH on Home (Main) Screen. If value

Enabled, the temperature & %RH set values can be edited by touching the receptive indicated values on the ome creen.H S

21

HumiTherm Ultra User Manual

Section 6

SUPERVISORY LEVEL PARAMETERS

Supervisory Recording

Recording Interval

Range : 1 to 250 Minutes

Default : 5 Minutes

The Controller generates and stores periodic records at the interval set by this parameter.

‘Delete Record’ Command

This command is issued using the touch push button. All the stored records are deleted from the memory.

Supervisory

Clock & Calendar

16

12

2016

212112

Operate this touch button

to register new Date / Time

Calendar Date

Clock Time

The Calendar Date is set using 3 separate fields; Date (DD), Month (MM) & Year (YY).

The Clock Time is set in 24 Hours format using 3 separate fields; Hours (HH), Minutes (MM) & Seconds (SS).

It is a must to operate the ‘Apply’ touch button in order to register the modified values.

22

HumiTherm Ultra User Manual

Supervisory

SMS

SMS Alert

(Available only if the controller is supplied with GSM Module Version)

GSM Machine ID

Range : 1 to 128

Default : 1

This parameter can be used to assigned a unique ID to the machine (chamber) to identify the source of SMS alert.

‘Reset GSM Module’

Use this touch button if for any reason the GSM module fails to send SMS alerts.

Supervisory

Door Lock Access

USER1234

USER1234

ABCDEFGH

12345678

Valid Password entries

Unused IDs

Key for registering

New Password entry

Key for Deleting an

existing Password entry

23

HumiTherm Ultra User Manual

Lock Position

Options : Solenoid O , Solenoid ON FF

Default : Solenoid OFF

Set this parameter to ‘Solenoid ON’, if the chamber door is locked when the solenoid is turned ON (energized). Set this

parameter to ‘Solenoid OFF’, if the chamber door is locked when the solenoid is turned OFF (de-energized).

Password Entry

The Supervisor can Authorize up to 7 Persons by assigning them their respective . A 8 Character Alpha-Numeric Password

table with 2 columns (ID & PASSWORD) is provided for password entries. The ID numbers are fixed from 1 to 7 and

correspond to the made in the PC Software (HumiLog). The Password against each ID can be entered / edited / Name Entries

deleted by touching the table cell provided for the ID. Upon touching the cell, an alpha numeric keypad pops up. Use alpha

numeric keys to assign a new password (or edit the existing password) and then press ENTER key. To delete an exiting

password use CLR key and then press ENTER key. The passwords can be entered / deleted in any order of ID. The password

fields for unused Ids must be cleared (empty).

Supervisory

Standby Switchings

Switch Main / Standby Outputs

If the controller is installed with standby control gadget set, the user can manually switch between the Main and the Standby

set by using the touch push button. The switching is permitted / performed only if both sets are working.

Switch to Standby Sensors

If the controller is installed with Standby Sensor set, the user can manual switch to the Standby set if he detects failure of either

temperature or RH sensor from Main set. The switching is permitted / performed only if the Standby Sensor set is working.

24

HumiTherm Ultra User Manual

Supervisory

Maintenance

Repair Acknowledge

In case the control system is installed with standby set of sensors and / or control gadgets, the controller automatically

switches to the Standby set should any of the sensors / control gadgets of the Main set fail. After fixing the fault / failure, the

user must acknowledge the same to the controller for resuming the operation with the main set. The following touch buttons

are provided for the purpose depending on the standby installation.

25

HumiTherm Ultra User Manual

Section 7

FACTORY LEVEL PARAMETERS

Temperature

Input Type

Options RTD Pt100, 0 to 20 mA, 4 to 20 mA, 0 to 5 V, 0 to 10 V, 1 to 5 V :

Default : RTD Pt100

Select Input type in accordance with the type of Temperature sensor / transmitter connected for measurement.

Signal Range Low

(Available for DC Linear Volts & mA Inputs only)

Input SettingsFactory

Input Type

0 to 20 mA

4 to 20 mA

0 to 5 V

0 to 10 V

1 to 5 V

This parameter is the transmitter output signal value that corresponds to the Range Low process value. Refer Appendix-A :

DC Linear Signal Interface for details.

Signal Range High

(Available for DC Linear Volts & mA Inputs only)

Input Type

0 to 20 mA

4 to 20 mA

0 to 5 V

0 to 10 V

1 to 5 V

Settings

0.00 to Signal High

4.00 to Signal High

0.000 to Signal High

0.00 to Signal High

1.000 to Signal High

Settings

Signal Low to 20.00

Signal Low to 20.00

Signal Low to 5.000

Signal Low to 10.00

Signal Low to 5.000

Default

0.00

4.00

0.000

0.00

1.000

Default

20.00

20.00

5.000

10.00

5.000

This parameter is the transmitter output signal value that corresponds to the Range High process value. Refer Appendix-A :

DC Linear Signal Interface for details.

26

HumiTherm Ultra User Manual

Display Range Low

(Available for DC Linear Volts & mA Inputs only)

Range : -199.9 to Range High

Default : 0.0

This parameter is the rocess alue that correspond to the Signal Low value fromP V s the transmitter. Refer Appendix-A : DC

Linear Signal Interface for details.

Display Range High

(Available for DC Linear Volts & mA Inputs only)

Range : Range Low to 999.9

Default : 100.0

Th Process alue that correspond to the Signal High value from the transmitter. is parameter is the V s Refer Appendix-A : DC

Linear Signal Interface for details.

Zero offset

Range : -50.0 to 50.0 °C

Default : 0.0 °C

This value is algebraically added to the measured Temperature Value to derive the final Value that is displayed and compared

for alarm / control. Use this value to nullify any known constant error.

Final Value = Measured Value + Offset

Factory

Temperature

Alarm Settings

5.0

5.0

2.0

Inhibit

Options Enable, Disable :

Default : Enable

If this parameter is set to ‘ ’, the Alarm activation is suppressed until the Temperature value is within Alarm limits from the Enable

time the controller is switched ON. This allows suppressing the Alarm during the start-up Alarm conditions.

If this parameter is set to ‘Disable’, the Alarm is not suppressed during the start-up Alarm conditions.

27

HumiTherm Ultra User Manual

Low Alarm Deviation

Range : 0.2 to 99.9 °C

Default : 2.0 °C

This parameter sets the maximum permissible process value deviation the temperature setpoint. If the temperature below

exceeds this deviation, the alarm is activated.

High Alarm Deviation

Range : 0.2 to 99.9 °C

Default : 2.0 °C

This parameter sets the maximum permissible process value deviation the temperature setpoint. If the temperature above

exceeds this deviation, the alarm is activated.

Hysteresis

Range : 0.1 to 99.9

Default : 0.2

This parameter sets a differential (dead) band between the ON and OFF emperature Deviation Alarm status change. Keep it T

large enough to avoid frequent switching of the Alarm Status/Relay.

Factory

Temperature

50.0

Control Settings

50.0

25.0

100

100

0.0

16

16

100.0

10.0

The control settings for temperature comprises of two screens shown above. Also the first screen parameters change

depending on the selection for the parameter ‘Zone elect’ (Single or Dual) provided on the screen “Compressor SS ettings”.

The Cool Zone and Heat Appendix-B : Compressor Switching StrategiesZone are described in details in . The screen for

parameters for Dual Zone is shown above and that for Single Zone is shown below.

28

50.0

100

16

10.0

HumiTherm Ultra User Manual

The PID Constants are described below.Dual Zone

Heat Zone Proportional Band

Range : 0.1 to 999.9 °C

Default : 50.0 °C

Sets proportional gain for Heat Pre-dominant zone.

Heat Zone Integral Time

Range : 0 to 3600 Sec.

Default : 100 Sec.

Sets integral time constant in Seconds for Heat Pre-dominant zone. Setting the value to 0, cuts-off integral action.

Heat Zone Derivative Time

Range : 0 to 600 Sec.

Default : 16 Sec.

Sets derivative time constant in Seconds for Heat Pre-dominant zone. Setting the value to 0, cuts-off derivative action.

Cool Zone Proportional Band

Range : 0.1 to 999.9 °C

Default : 50.0 °C

Sets proportional gain for Cool Pre-dominant zone.

Cool Zone Integral Time

Range : 0 to 3600 Sec.

Default : 100 Sec.

Sets integral time constant in Seconds for Cool Pre-dominant zone. Setting the value to 0, cuts-off integral action.

Cool Zone Derivative Time

Range : 0 to 600 Sec.

Default : 16 Sec.

Sets derivative time constant in Seconds for Cool Pre-dominant zone. Setting the value to 0, cuts-off derivative action.

The PID Constants are described below.Single Zone

Proportional Band

Range : 0.1 to 999.9 °C

Default : 50.0 °C

Sets proportional gain.

Integral Time

Range : 0 to 3600 Sec.

Default : 100 Sec.

Sets integral time constant in Seconds. Setting the value to 0, cuts-off integral action.

29

HumiTherm Ultra User Manual

Derivative Time

Range : 0 to 600 Sec.

Default : 16 Sec.

Sets derivative time constant in Seconds. Setting the value to 0, cuts-off derivative action.

The parameters below are applicable to both & .Single Zone Dual Zone

Output Cycle Time (Sec.)

Range : 0.5 to 100.0 Sec.

Default : 10.0 Sec.

Sets the total ‘On + Off’ time in seconds for time proportional power output for Air Heater through Relay / SSR.

Set Value (Temperature Control Loop)

Range : Temperature Setpoint Low Limit to Temperature Setpoint High Limit

Default : 25.0

Sets Value for Temperature Control.

Low Limit (for Temperature Control Set Value)

Range : -199.9 to Temperature Setpoint High Limit

Default : 10.0

Minimum permissible setpoint value for Temperature control.

High Limit (for Temperature Control Set Value)

Range : For RTD : Temperature Setpoint Low Limit to 600.0

For mA/V : Temperature Setpoint Low Limit to 999.9

Default : 60.0

Maximum permissible setpoint value for Temperature control.

Self Tune

This parameter is a command to Start or Abort Self Tuning for automatic computation of PID constants. The command starts or

aborts self tuning for both temperature & %RH simultaneously. For Dual Zone setting, the controller needs to be tuned

separately for Heat prominent & Cool Prominent zones.

Pressing the touch push button initiates tuning if the controller is already not tuning. However, if the controller is tuning,

pressing the touch button causes the controller to abort tuning.

30

HumiTherm Ultra User Manual

%RH

Input Type

Options 0 to 20 mA, 4 to 20 mA, 0 to 5 V, 0 to 10 V, 1 to 5 V :

Default : 0 to 5 V

Select Input type in accordance with the type of sensor / transmitter connected for measurement.%RH

Signal Range Low

Input SettingsFactory

Input Type

0 to 20 mA

4 to 20 mA

0 to 5 V

0 to 10 V

1 to 5 V

This parameter is the transmitter output signal value that corresponds to the Range Low process value. Refer Appendix-A :

DC Linear Signal Interface for details.

Signal Range High

Input Type

0 to 20 mA

4 to 20 mA

0 to 5 V

0 to 10 V

1 to 5 V

This parameter is the transmitter output signal value that corresponds to the Range High process value. Refer Appendix-A :

DC Linear Signal Interface for details.

Settings

0.00 to Signal High

4.00 to Signal High

0.000 to Signal High

0.00 to Signal High

1.000 to Signal High

Settings

Signal Low to 20.00

Signal Low to 20.00

Signal Low to 5.000

Signal Low to 10.00

Signal Low to 5.000

Default

0.00

4.00

0.000

0.00

1.000

Default

20.00

20.00

5.000

10.00

5.000

31

HumiTherm Ultra User Manual

Display Range Low

Range : -199.9 to Range High

Default : 0.0

This parameter is the rocess alue that correspond to the Signal Low value fromP V s the transmitter. Refer Appendix-A : DC

Linear Signal Interface for details.

Display Range High

Range : Range Low to 999.9

Default : 100.0

Th Process alue that correspond to the Signal High value from the transmitter. is parameter is the V s Refer Appendix-A : DC

Linear Signal Interface for details.

Zero offset

Range : -50.0 to 50.0 %

Default : 0.0 %

This value is algebraically added to the measured Value to derive the final Value that is displayed and compared for %RH

alarm / control. Use this value to nullify any known constant error.

Final Value = Measured Value + Offset

Factory Alarm Settings

%RH

5.0

5.0

2.0

Inhibit

Options Enable, Disable :

Default : Enable

If this parameter is set to ‘ ’, the Alarm activation is suppressed until the value is within Alarm limits from the time Enable %RH

the controller is switched ON. This allows suppressing the Alarm during the start-up Alarm conditions.

If this parameter is set to ‘Disable’, the Alarm is not suppressed during the start-up Alarm conditions.

Low Alarm Deviation

Range : 0.2 to 99.9 %

Default : 2.0 %

This parameter sets the maximum permissible process value deviation the setpoint. If the exceeds this below %RH %RH

deviation, the alarm is activated.

32

HumiTherm Ultra User Manual

High Alarm Deviation

Range : 0.2 to 99.9 %

Default : 2.0 %

This parameter sets the maximum permissible process value deviation the setpoint. If the exceeds this above %RH %RH

deviation, the alarm is activated.

Hysteresis

Range : 0.1 to 99.9

Default : 0.2

This parameter sets a differential (dead) band between the ON and OFF Deviation Alarm status change. Keep it large %RH

enough to avoid frequent switching of the Alarm Status/Relay.

Factory Control Settings

%RH

50.0

50.0

25.0

100

100

0.0

16

16

100.0

10.0

The control settings for comprises of two screens shown above. Also the first screen parameters change depending on %RH

the selection for the parameter ‘Zone elect’ (Single or Dual) provided on the screen “Compressor SS ettings”. The Cool Zone

and Heat Appendix-B : Compressor Switching StrategiesZone are described in details in . The screen for parameters for

Dual Zone is shown above and that for Single Zone is shown below.

33

50.0

100

16

10.0

HumiTherm Ultra User Manual

The PID Constants are described below.Dual Zone

Heat Zone Proportional Band

Range : 0.1 to 999.9 %RH

Default : 50.0 %RH

Sets proportional gain for Heat Pre-dominant zone.

Heat Zone Integral Time

Range : 0 to 3600 Sec.

Default : 100 Sec.

Sets integral time constant in Seconds for Heat Pre-dominant zone. Setting the value to 0, cuts-off integral action.

Heat Zone Derivative Time

Range : 0 to 600 Sec.

Default : 16 Sec.

Sets derivative time constant in Seconds for Heat Pre-dominant zone. Setting the value to 0, cuts-off derivative action.

Cool Zone Proportional Band

Range : 0.1 to 999.9 %RH

Default : 50.0 %RH

Sets proportional gain for Cool Pre-dominant zone.

Cool Zone Integral Time

Range : 0 to 3600 Sec.

Default : 100 Sec.

Sets integral time constant in Seconds for Cool Pre-dominant zone. Setting the value to 0, cuts-off integral action.

Cool Zone Derivative Time

Range : 0 to 600 Sec.

Default : 16 Sec.

Sets derivative time constant in Seconds for Cool Pre-dominant zone. Setting the value to 0, cuts-off derivative action.

The PID Constants are described below.Single Zone

Proportional Band

Range : 0.1 to 999.9 %RH

Default : 50.0 %RH

Sets proportional gain.

Integral Time

Range : 0 to 3600 Sec.

Default : 100 Sec.

Sets integral time constant in Seconds. Setting the value to 0, cuts-off integral action.

34

HumiTherm Ultra User Manual

Derivative Time

Range : 0 to 600 Sec.

Default : 16 Sec.

Sets derivative time constant in Seconds. Setting the value to 0, cuts-off derivative action.

The parameters below are applicable to both & .Single Zone Dual Zone

Output Cycle Time (Sec.)

Range : 0.5 to 100.0 Sec.

Default : 10.0 Sec.

Sets the total ‘On + Off’ time in seconds for time proportional power output for Air Heater through Relay / SSR.

Set Value ( Control Loop)%RH

Range : Setpoint Low Limit to Setpoint High Limit%RH %RH

Default : 25.0

Sets Value for Control.%RH

Low Limit (for %RH Control Set Value)

Range : . to Setpoint High Limit0 0 %RH

Default : 0.0

Minimum permissible setpoint value for control.%RH

High Limit (for %RH Control Set Value)

Range : %RH Setpoint Low Limit to 100.0

Default : 0.010

Maximum permissible setpoint value for control.%RH

Self Tune

This parameter is a command to Start or Abort Self Tuning for automatic computation of PID constants. The command starts or

aborts self tuning for both %RH & temperature simultaneously. For Dual Zone setting, the controller needs to be tuned

separately for Heat prominent & Cool Prominent zones.

Pressing the touch push button initiates tuning if the controller is already not tuning. However, if the controller is tuning,

pressing the touch button causes the controller to abort tuning.

35

HumiTherm Ultra User Manual

Factory

Compressor

For detailed description and functioning of the parameters related to compressor operation, refer

Appendix-B : Compressor Switching Strategies.

Mode

Options FF N : Continuous O , Continuous O , SP Based ON-OFF, PV Based ON-OFF

Default : Continuous OFF

Compressor SP

Range : 0.0 to 100.0

Default : .045

Boundary SP

Range : 0.0 to 100.0

Default : .0 45

Time Delay

Range : 0 to 1000 Sec.

Default : 200 Sec.

Hysteresis

Range : 0.1 to 99.9 °C

Default : 2.0 °C

Zone Select

Options : Single, Dual

Default : Single

36

HumiTherm Ultra User Manual

Factory

Water Level

Float Detection Enable

Options No, Yes :

Default : No

Set to ‘Yes’ if Float Switch is mounted for detecting Low water level.

Float Low Level Logic

Options : Switch Open, Switch Close

Default : Switch Close

If set to ‘Switch Close’, the water level is considered Low if the switch is CLOSE. If set to ‘Switch Open’, the water level is

considered Low if the switch is OPEN.

Thermostat Detection Enable

Options No, Yes :

Default : No

Set to ‘Yes’ if Thermostat is mounted for detecting Low water level.

Thermostat Low Level Logic

Options : Switch Open, Switch Close

Default : Switch Close

If set to ‘Switch Close’, the water level is considered Low if the thermostat contacts are CLOSE. If set to ‘Switch Open’, the

water level is considered Low if the thermostat contacts are OPEN.

Common Boiler

Options : No, Yes

Default : No

This parameter is shown on the screen only if Standby Control Gadget option is enabled / installed. Set this parameter to ‘Yes’

if both, Main and Standby, heaters are mounted in a single steam generating boiler. In this case, only a single pair of Float

Switch & Thermostat is used and connected to Main Digital Inputs.

37

HumiTherm Ultra User Manual

Factory

Door Open

Detection Enable

Options No, Yes :

Default : No

Set to ‘Yes’ if Door Open detection switch is mounted.

Door Open Logic

Options : Switch Open, Switch Close

Default : Switch Close

If this parameter is set to ‘Switch Close’, the door is detected as if the switch is CLOSE. If this parameter is set to ‘Switch Open

Open’, the door is detected as if the switch is OPEN.Open

Alarm Delay (Sec.)

Range : 0 to 1000 Sec.

Default : 60 Sec.

This parameter sets a timer. From the time the door is opened, the timer begins counting down. If the door is not closed before

the timer reaches 0, the alarm is activated.Door Open

Factory

Power Fail

38

HumiTherm Ultra User Manual

Detection Enable

Options No, Yes :

Default : No

Set to ‘Yes’ if provision is made for running the controller on an auxiliary power sources like battery or inverter and a Switch is

mounted for detecting main power source failure.

Power Fail Logic

Options : Switch Open, Switch Close

Default : Switch Close

If set to ‘Switch Close’, the CLOSE witch position indicates that the Mains Power has failed and the Controller is operating on s

auxiliary power source. If set to ‘Switch Open’, the OPEN switch position indicates that the Mains Power has failed and the

Controller is operating on auxiliary power source.

Factory Standby

Sensor Inputs

These parameters are particularly useful when sensors with DC Volts / Current Outputs are used for measuring temperature

and / or %RH.

Temperature Low Limit for Sensor Fail Detection

Range : 0 to 25.0 °C

Default : 0 °C

This parameter should be set to a value below which the temperature is not likely to fail under normal conditions. In case of

sensor open / fail, the output signal will generally fall to minimum level corresponding to Low Process Value. This condition is

detected as sensor fail & the controller switches to alternate set of sensors.

%RH Low Limit for Sensor Fail Detection

Range : 0 to 60.0 %

Default : 0 %

Description is same as for “Temperature Low Limit for Sensor Fail Detection”.

39

HumiTherm Ultra User Manual

Factory

Standby Control Gadgets

Fail Detect Time (Min)

Range : 0 to 250 Min.

Default : 10 Min

This parameter sets a timer. If either temperature or %RH process value exceeds “High Alarm Deviation” limit, the timer starts

counting down. If the process value does not return below the “High Alarm Deviation” limit before the timer reaches 0, the

working control gadget set is detected as failed. The controller then switches to the alternate control gadget set.

Cyclic Time (Hrs.)

Range : 0 to 500 Hrs.

Default : 48 Hrs.

If both, Main & Standby, control gadget sets are in working condition, the controller keeps switching between these two sets

periodically with a time interval set by this parameter value.

Inhibit Time (Hrs.)

Range : 0 to 250 Hrs.

Default : 1 Hrs.

This parameter sets a time interval for which the controller stops monitoring the control gadget fail detection condition

(described under parameter “Fail Detect Time”). This time interval is usually applied under following conditions.

1. System is powered (Start Up)

2. Change-over from Auxiliary Power source (Battery / Inverter) to Mains Power

3. After recovery from Door Open Alarm

4. Change-over from Main to Standby Control gadget Set or vice-a-versa

This feature suppresses false detection of control gadget failure.

40

HumiTherm Ultra User Manual

Factory

Mapping Configuration

Select Mapping Inputs

Options : 4T + 4RH, 8T + 8RH

Default : 4T + 4RH

Select this parameter depending upon whether 8 input (4 Temperature + 4 %RH) or 16 input (8 Temperature + 8 %RH) unit is

installed for mapping.

Factory Mapping

Temperature

Alarm Settings

Low Alarm Set Value

Range : -199.9 to 600.0 °C

Default : 0 °C

This parameter sets a Temperature value limit which an alarm is generated. common below

Low Alarm Hysteresis

Range : 0.1 to 50.0 °C

Default : 2.0 °C

This parameter sets a differential (dead) band between the ON and OFF Low Temperature Alarm status change. Keep it large

enough to avoid frequent switching of the Alarm Status/Relay.

Low Alarm Inhibit

Options : Enable, Disable

Default : Disable

If this parameter is set to ‘Enable’, the Alarm activation is suppressed until the Temperature value is above the Low Alarm Set

Value from the time the controller is switched ON. This allows suppressing the Alarm during the start-up Alarm conditions.

41

HumiTherm Ultra User Manual

If this parameter is set to ‘Disable’, the Alarm is not suppressed during the start-up Alarm conditions.

High Alarm Set Value

Range : -199.9 to 600.0 °C

Default : 0 °C

This parameter sets a Temperature value limit which an alarm is generated. common above

High Alarm Hysteresis

Range : 0.1 to 50.0 °C

Default : 2.0 °C

This parameter sets a differential (dead) band between the ON and OFF High Temperature Alarm status change. Keep it large

enough to avoid frequent switching of the Alarm Status/Relay.

High Alarm Inhibit

Options : Enable, Disable

Default : Disable

If this parameter is set to ‘Enable’, the Alarm activation is suppressed until the Temperature value is below the High Alarm Set

Value from the time the controller is switched ON. This allows suppressing the Alarm during the start-up Alarm conditions.

If this parameter is set to ‘Disable’, the Alarm is not suppressed during the start-up Alarm conditions.

Factory Mapping

Temperature

0.0

100.0

Input Settings

All the arameter settings, except Zero Offset, on this screen are Common for all p

Temperature Inputs.

Input Type

Options RTD Pt100, 0 to 20 mA, 4 to 20 mA, 0 to 50 mV, 0 to 200 mV, 0 to 1.25 V, 0 to 5 V, : 1 to 5 V, 0 to 10 V

Default : RTD Pt100

Select Input type in accordance with the type of Temperature sensor / transmitter connected for measurement.

Signal Range Low

(Available for DC Linear Volts & mA Inputs only)

42

HumiTherm Ultra User Manual

Input Type

0 to 20 mA

4 to 20 mA

0 to 50 mV

0 to 200 mV

0 to 1.25 V

0 to 5 V

1 to 5 V

0 to 10 V

This parameter is the transmitter output signal value that corresponds to the Range Low process value. Refer Appendix-A :

DC Linear Signal Interface for details.

Signal Range High

(Available for DC Linear Volts & mA Inputs only)

Input Type

0 to 20 mA

4 to 20 mA

0 to 50 mV

0 to 200 mV

0 to 1.25 V

0 to 5 V

1 to 5 V

0 to 10 V

Settings

0.00 to Signal High

4.00 to Signal High

0.00 to Signal High

0.0 to Signal High

0.000 to Signal High

0.000 to Signal High

1.000 to Signal High

0.00 to Signal High

Settings

Signal Low to 20.00

Signal Low to 20.00

Signal Low to 50.00

Signal Low to 200.0

Signal Low to 1.250

Signal Low to 5.000

Signal Low to 5.000

Signal Low to 10.00

Default

0.00

4.00

0.00

0.0

0.000

0.000

1.000

0.00

Default

20.00

20.00

50.00

200.0

1.250

5.000

5.000

10.00

This parameter is the transmitter output signal value that corresponds to the Range High process value. Refer Appendix-A :

DC Linear Signal Interface for details.

Display Range Low

(Available for DC Linear Volts & mA Inputs only)

Range : -199.9 to Range High

Default : 0.0

This parameter is the Process Value that corresponds to the Signal Low value from the transmitter (0 mA or 0 mV or 0/1 V).

Display Range High

(Available for DC Linear Volts & mA Inputs only)

Range : Range Low to 999.9

Default : 100.0

This parameter is the Process Value that corresponds to the Signal High value from the transmitter (20 mA or 50/200 mV or

5/10V).

Zero Offset

Range : -50.0 to 50.0 °C

Default : 0.0 °C

This parameter value is individually set for each Temperature Input (4 8). This value is algebraically added to the measured or

Temperature Value to derive the final Value that is displayed and compared for alarm / control. Use this value to nullify any

known constant error.

Final Value = Measured Value + Offset

43

HumiTherm Ultra User Manual

Factory Mapping Alarm Settings

%RH

Low Alarm Set Value

Range : 0 to 100.0 %RH

Default : 0 %RH

This parameter sets a value limit which an alarm is generated. common %RH below

Low Alarm Hysteresis

Range : 0.1 to 50.0 %RH

Default : 2.0 %RH

This parameter sets a differential (dead) band between the ON and OFF Low Alarm status change. Keep it large enough %RH

to avoid frequent switching of the Alarm Status/Relay.

Low Alarm Inhibit

Options : Enable, Disable

Default : Disable

If this parameter is set to ‘Enable’, the Alarm activation is suppressed until the value is above the Low Alarm Set Value %RH

from the time the controller is switched ON. This allows suppressing the Alarm during the start-up Alarm conditions. If this

parameter is set to ‘Disable’, the Alarm is not suppressed during the start-up Alarm conditions.

High Alarm Set Value

Range : 0 to 100.0 %RH

Default : 0 %RH

This parameter sets a value limit which an alarm is generated. common %RH above

High Alarm Hysteresis

Range : 0.1 to 50.0 %RH

Default : 2.0 %RH

This parameter sets a differential (dead) band between the ON and OFF High Alarm status change. Keep it large enough %RH

to avoid frequent switching of the Alarm Status/Relay.

High Alarm Inhibit

Options : Enable, Disable

Default : Disable

If this parameter is set to ‘Enable’, the Alarm activation is suppressed until the value is below the High Alarm Set Value %RH

from the time the controller is switched ON. This allows suppressing the Alarm during the start-up Alarm conditions. If this

parameter is set to ‘Disable’, the Alarm is not suppressed during the start-up Alarm conditions.

44

HumiTherm Ultra User Manual

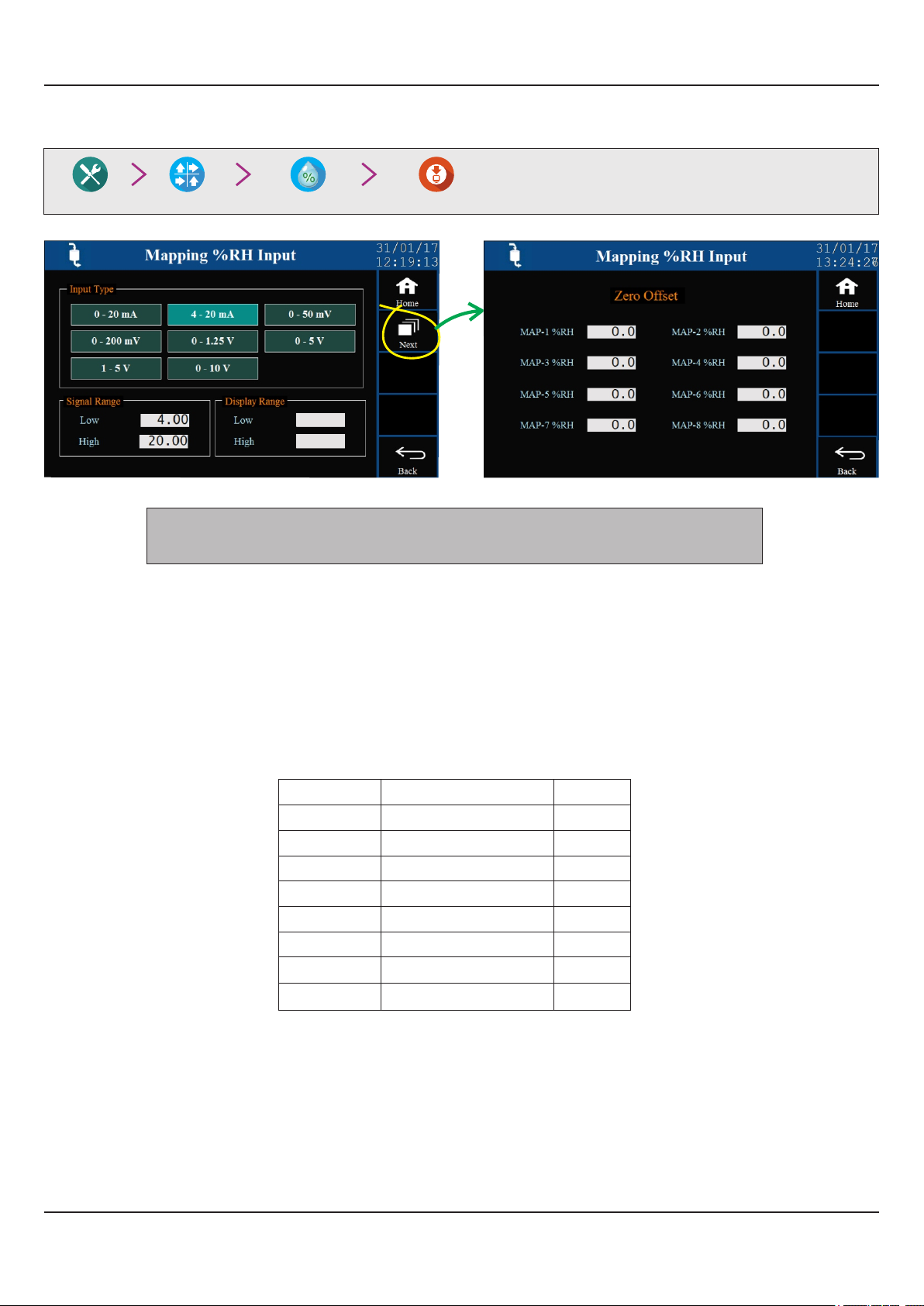

Factory Mapping Input Settings

%RH

0.0

100.0

All the arameter settings, except Zero Offset, on this screen are Common for all p

%RH Inputs.

Input Type

Options : 0 to 20 mA, 4 to 20 mA, 0 to 50 mV, 0 to 200 mV, 0 to 1.25 V, 0 to 5 V, 1 to 5 V, 0 to 10 V

Default : 0 to 5 V

Select Input type in accordance with the type of sensors / transmitters connected for measurement on all %RH Inputs.

Signal Range Low

(Available for DC Linear Volts & mA Inputs only)

Input Type

0 to 20 mA

4 to 20 mA

0 to 50 mV

0 to 200 mV

0 to 1.25 V

0 to 5 V

1 to 5 V

0 to 10 V

Settings

0.00 to Signal High

4.00 to Signal High

0.00 to Signal High

0.0 to Signal High

0.000 to Signal High

0.000 to Signal High

1.000 to Signal High

0.00 to Signal High

Default

0.00

4.00

0.00

0.0

0.000

0.000

1.000

0.00

This parameter is the transmitter output signal value that corresponds to the Range Low process value. Refer Appendix-A :

DC Linear Signal Interface for details.

Signal Range High

(Available for DC Linear Volts & mA Inputs only)

45

HumiTherm Ultra User Manual

Input Type

0 to 20 mA

4 to 20 mA

0 to 50 mV

0 to 200 mV

0 to 1.25 V

0 to 5 V

1 to 5 V

0 to 10 V

This parameter is the transmitter output signal value that corresponds to the Range High process value. Refer Appendix-A :

DC Linear Signal Interface for details.

Display Range Low

Range : .0 % to Range High0

Default : 0.0 %

This parameter is the Process Value that corresponds to the Signal Low value from the transmitter ( ).0 mA or 0 mV or 0/1 V

Display Range High

Range : Range Low to .100 0 %

Default : 100.0 %

This parameter is the Process Value that corresponds to the Signal High value from the transmitter (20 mA or 50/200 mV or

5/10V).

Settings

Signal Low to 20.00

Signal Low to 20.00

Signal Low to 50.00

Signal Low to 200.0

Signal Low to 1.250

Signal Low to 5.000

Signal Low to 5.000

Signal Low to 10.00

Default

20.00

20.00

50.00

200.0

1.250

5.000

5.000

10.00

Zero Offset

Range : -50.0 to 50.0 %

Default : 0.0 %

This parameter value is individually set for each Input (4 8). This value is algebraically added to the measured %RH or %RH

Value to derive the final Value that is displayed and compared for alarm / control. Use this value to nullify any known constant

error.

Final Value = Measured Value + Offset

46

HumiTherm Ultra User Manual

APPENDIX - A

DC LINEAR SIGNAL INTERFACE

This appendix describes the parameters required to interface process transmitters that produce Linear DC Voltage (mV/V) or

Current (mA) signals in proportion to the measured process values. A few examples of such transmitters are;

1. Pressure Transmitter producing for 4 to 20 mA 0 to 5 psi

2. Relative Humidity Transmitter producing for 1 to 4.5 V 5 to 95 %RH

3. Temperature Transmitter producing for 0 to 20 mA -50 to 250 °C

The instrument (indicator/controller/recorder) that accepts the linear signal from the transmitter computes the measured

process value by solving the mathematical equation for Straight-Line in the form:

Y

Y = mX + C

Where;

X : Signal Value from Transmitter

Y : Process Value Corresponding to Signal Value X

C : Process Value Corresponding to X = 0 (Y-intercept)

m : Change in Process Value per unit Change in Signal Value (Slope)

C

Process Value

Y = mX + C

m = / ΔY ΔX

Transmitter Signal

ΔY

ΔX

X

As is evident from the aforementioned transmitter examples, different transmitters produce signals varying both in Type

(m /V/mA) and . Most PPI instruments, thus, provide programmable Signal Type and Range to facilitate interface with V Range

a variety of transmitters. A few industry standard signal types and ranges offered by the PPI instruments are: 0-50mV, 0200mV, 0-5 V, 1-5 V, 0-10V, 0-20 mA, 4-20 mA, etc.

Also, the output signal range (e.g. 1 to 4.5 V) from different transmitters corresponds to different process value range (e.g. 5 to

95 %RH); the instruments thus also provide facility for programming the measured process value range with programmable

Resolution.

The linear transmitters usually specify two signal values (Signal Low and Signal High) and the corresponding Process Values

(Range Low and Range High). In the example Pressure Transmitter above; the Signal Low, Signal High, Range Low & Range

High values specified are: 4 mA, 20 mA, 0 psi & 5 psi, respectively.

In summary, the following 6 parameters are required for interfacing Linear Transmitters:

1. Input Type : Standard DC Signal Type in which the transmitter signal range fits (e.g. 4-20 mA)

2. Signal Low : Signal value corresponding to Range Low process value (e.g. 4 mA)

3. Signal High : Signal value corresponding to Range High process value (e.g. 20 mA)

4. PV Resolution : Resolution (least count) with which to compute process value (e.g. 0.01)

5. Range Low : Process value corresponding to Signal Low value (e.g. 0.00 psi)

6. Range High : Process value corresponding to Signal High value (e.g. 5.00 psi)

47

HumiTherm Ultra User Manual

The following examples illustrate appropriate parameter value selections.

Example 1: Pressure Transmitter producing for 4 to 20 mA 0 to 5 psi

Y (psi)

Presume the pressure is to be measured

Range High

5.00

with 0.01 Resolution, that is 0.00 to 5.00 psi.

Input Type : 4-20 mA

Signal Low : 4.00 mA

Signal High : 20.00 mA

PV Resolution : 0.01

Range Low

0.00

4.00 20.00

Signal Low Signal High

X (mA)

Range Low : 0.00

Range High : 5.00

Example 2: Relative Humidity Transmitter producing for 1 to 4.5 V 5 to 95 %RH

Y (% RH)

Presume the humidity is to be measured

with 0.1 Resolution, that is 0.0 to 100.0 %.

Range High

95.0

Input Type : 0-5 V

Signal Low : 1.000 V

Signal High : 4.500 V

Range Low

5.0

0

0 5

1.000 4.500

Signal Low Signal High

X (V)

PV Resolution : 0.1

Range Low : 5.0

Range High : 95.0

Example 3: Temperature Transmitter producing for 0 to 20 mA -50 to 250 °C

Y (°C)

Range High

250.0

Presume the Temperature is to be measured

with 0.1 Resolution, that is -50.0 to 250.0°C.

Input Type : 0-20 mA

Signal Low : 0.00 mA

Signal High : 20.00 mA

PV Resolution : 0.1

Range Low

-50.0

0

0.00

Signal Low

20.00

Signal High

X (mA)

Range Low : -50.0

Range High : 250.0

48

HumiTherm Ultra User Manual

The following table list various parameters related to DC linear signal input interface & their respective locations.

Parameter Name

Main & Standby

Temperature Control Sensors

Temperature Input Type

Temperature Signal Low

Temperature Signal High

Temperature Range Low

Temperature Range High

Main & Standby

%RH Control Sensors

%RH Input Type

%RH Signal Low

%RH Signal High

%RH Range Low

%RH Range High

Temperature Mapping Sensors

Temperature Input Type

Temperature Signal Low

Temperature Signal High

Temperature Range Low

Temperature Range High

Factory

Navigation

(Where to Locate)

Temperature

%RH

Mapping Input Settings

Input SettingsFactory

Input SettingsFactory

Temperature

%RH Mapping Sensors

%RH Input Type

%RH Signal Low

%RH Signal High

%RH Range Low

%RH Range High

Mapping Input SettingsFactory

%RH

49

HumiTherm Ultra User Manual

APPENDIX - B

COMPRESSOR SETTING PARAMETERS

Compressor Switching Strategies

The PPI “Temperature + Humidity” composite controllers offer different programmable strategies for compressor switching to

meet different design approaches by the manufacturers of Humidity Chambers. The various strategies and the

implementations are described here.

1. Compressor Off

The compressor is kept Off. This trategy is usually selected for emperature values significantly above the ambient s t

temperature.

2. Comp Onressor

The compressor is kept On regardless of the measured or set temperature value. This trategy is usually selected for s

t belowemperature values significantly the ambient temperature.

3. SP Based Strategy

In this strategy, the chamber temperature range is split in two zones by setting the parameter 'Boundary Set-point' (BSP).

Refer Figure below.

70°C

Temp. Control SP in

Compressor Status

45°C

30°C

0°C

ON

OFF

Heat Pre-dominant Zone

Temp. Control SP in

Cool Pre-dominant Zone

50°C

Boundary Set-point

The zone at and above the boundary SP ( ) is referred as Heat Pre-dominant zone and that below the boundary SP ) (

is referred as Cool Pre-dominant zone. The controller automatically switches between the two zones depending upon the

Temperature SP. If the Temperature SP is below boundary SP, Cool Pre-dominant zone is active and the compressor is kept

ON. If the Temperature SP is at or above boundary SP, Heat Pre-dominant zone is active and the compressor is kept OFF. This

strategy eliminates the need for the user to manually switch the compressor ON or OFF.

I Control Zones “Dual”; separate tuning can be performed in the Cool and Heat Pre-dominant zones for f the parameter is set to

accurate control in each zone. The controller maintains separate sets of Proportional Band, Integral Time & Derivative Time

constants for each zone that are automatically selected and used by the controller depending upon the active zone.

However, if the parameter Control Zones is set to “Single”; the controller uses a single set of Proportional Band, Integral Time

& Derivative Time constants for both zones.

50

HumiTherm Ultra User Manual

4. PV Based Strategy

In this strategy, the compressor is switched to cool down the chamber air temperature. The controller switches the

compressor ON or OFF based on the comparison between the chamber temperature value and the SP. Temperature

Refer Figure below.

Measured Temperature

Temperature SP

Compressor Switch-ON Level

Compressor Switch-OFF Level

Temperature SP = 20.0°C

Compressor Set-point = 1.0°C

Compressor Hysteresis = 1.2°C

Compressor Switch-ON Level = 20.0 + 1.0 = 21.0°C

Compressor Switch-OFF Level = 21.0 - 1.2 = 19.8°C

Compressor

Status

21.0

20.0

19.8

ON

OFF

°C

The compressor is turned ON if the chamber air temperature value is above the SP by an amount set by the Temperature

parameter 'Compressor Set-point'. That is;

Compressor Switch - ON Level = (Temperature SP) + (Compressor Set-point)

Once the air temperature falls below Compressor Switch-ON Level by an amount set by the parameter 'Compressor

Hysteresis', the compressor is turned OFF. That is;

Compressor Switch - OFF Level = (Compressor Switch-ON Level) – (Compressor Hysteresis)

The hysteresis inserts a dead band between the Compressor Switch-ON Level and Compressor Switch-OFF Level to avoid

frequent switching of the compressor.

Compressor Time Delay

Once the compressor is switched off, a time delay is desired before it is turned ON again. The time delay prevents the possible

damage due to short cycling. When the compressor switches off, it spins backward as pressure equalizes. If compressor is

energized while it is still spinning backward, it continues to run backward until it trips on internal overloads. This may cause

damage to the compressor.

The time delay cycle is executed every time the compressor is turned off. The compressor turning off may be a result of power

failure or the on-off control algorithm executed by the controller. The controller in “Auto Mode” monitors the Process Value (PV)

against the Set-Point (SP) and attempts to switch the compressor or depending upon whether the PV is or ON OFF above

below the SP.

The time delay starts counting down from the instance the compressor is switched off. The compressor is inhibited from

switching-on until the delay elapses regardless of the difference between the PV and SP. Once the time delay is elapsed, the

control algorithm switches the compressor ON as and when the PV is above SP.

51

HumiTherm Ultra User Manual

°C

PV (Temperature)

SP

Compressor Switch-ON Level

Compressor Switch-OFF Level

Temperature SP = 20.0°C

Compressor Set-point = 1.0°C

Compressor Hysteresis = 1.2°C

Compressor Switch-ON Level = 20.0 + 1.0 = 21.0°C

Compressor Switch-OFF Level = 21.0 - 1.2 = 19.8°C

Compressor

Status

21.0

20.0

19.8

ON

OFF

Case 2 Case 3Case 1

The figure above illustrates 3 cases. Case (1) illustrates power-up delay. In case (2); the time elapses before PV rises above

the SP. The compressor is thus switched ON as soon as the PV rises above the SP. In case (3); the PV rises above the SP while

the time delay is still in progress. The compressor is switched ON as soon as the delay time elapses.

The following table list various parameters related to Compressor Switching Mode / Operation & their respective locations.

Parameter Name

Navigation

(Where to Locate)

Mode

Boundary SP

Time Delay

Hysteresis

Factory

Compressor

Zone Select

52

HumiTherm Ultra User Manual

APPENDIX - C

STANDBY SENSORS

If the Controller is supplied with option, two additional analog inputs are provided for interfacing an additional Standby Sensors

set of temperature & %RH sensors as standby. That is, there are two sets of Sensors; Main & Standby.

Sensor / Transmitter Fail Detection

In case of RTD Pt100 sensor the controller can directly detect Sensor failure through Sensor Open, Over-range or Underrange condition.

For DC linear inputs (mA or Volts), the controller can not detect the transmitter open or short condition. Therefore, the

controller provides two programmable Setpoint Limits, one each for Temperature & %RH. If the measured process value falls

below the respective setpoint limit, the condition is treated as transmitter failure or mal-functioning.

Note the Setpoint Limit for temperature is applicable even if input sensor used for temperature is RTD Pt100.

Main Set Failure

The controller, by default, uses the Main set for measurement, control & alarm purpose. Should any one or both Main Sensors

/ Transmitters fail, the controller automatically switches to the Standby set and stores in its non-volatile memory the Main Set

Failure Main Set Failure condition. The controller continues to work with Standby Set until the condition is cleared from its

memory through Repair Acknowledge button (explained later).

Standby Set Failure

The controller uses the Standby Set only if Main Set Failure condition is stored in its memory. The Main Set Failure condition is

set upon Main Sensor failure detection by controller or manual change over by user from Main Set to Standby Set (explained

later). Should any one or both Standby Sensors / Transmitters fail, the controller switches off all the control outputs and stores

in its non-volatile memory the condition. That is, now both Main & Standby Failure conditions are stored in Standby Set Failure

memory. As long as this condition prevails, the controller behaves like an indicator by keeping all its outputs off. Replace /

repair sensors / transmitters and then use Repair Acknowledge button to bring controller to its normal operation mode.

Manual Switch-over to Standby Set

If the controller is working with the Main Set sensors, the user can switch to Standby Set by using touch push button provided

for this purpose. This feature facilitates the user to use Standby Set should he observe misbehavior in measurement readings

(like continuous fluctuations or intermittent spikes) through Main Set sensors. The manual change-over is treated same as

Main Set Failure condition and is thus stored in memory.

Repair Acknowledge

Once the Main Set and / or Standby Set Failure condition is stored in memory, the only way to clear the same is through Repair

Acknowledge touch button. This feature avoids continuous toggling between Main & Standby Sets should both fail.

Note that Repair Acknowledge button clears both Main & Standby Set Failure conditions from memory.

53

HumiTherm Ultra User Manual

The following table list various parameters related to Standby Sensors & their respective locations.

Parameter Name

Sensor Fail Detection Limit

Temperature Low

%RH Low

Switch to Standby Sensor

Input Sensor Repair

Acknowledge

Navigation

(Where to Locate)

Factory Standby

Supervisory Standby Switchings

Supervisory

Maintenance

Sensor Inputs

54

HumiTherm Ultra User Manual

APPENDIX - D

STANDBY CONTROL GADGETS

If the Controller is supplied with Standby Control Gadgets option, 5 additional digital outputs are provided for interfacing an

additional set of Control Gadgets as standby. That is, there are two sets of Control Gadgets; Main & Standby.

The additional 5 outputs (besides 3 standard outputs, viz., Main Compressor, Main Heater & Main Humidifier) are; Standby

Compressor, Standby Heater, Standby Humidifier, Main Set Select & Standby Set Select. The Main Set Select & the Standby

Set Select outputs are used to drive two external gadgets (usually electromechanical relays) that switch power to SSRs that

drive Main & Standby gadgets respectively. Refer generic electrical connection diagram below.

Line Neutral

+12 V Coil

NO

C

NC

Door Lock

Stby Set Select

Main Set Select

Compressor

Standby

Digital Outputs

Humidifier

Compressor

Main

Humidifier