PPA POTENZA PREDIAL SP, POTENZA PREDIAL JET FLEX, POTENZA PREDIAL Technical Manual

WARNING:

Do not operate the equipment without rst reading

the instruction manual.

Technical Manual

POTENZA

PREDIAL

BV

2

INDEX

IMPORTANT SECURITY INSTRUCTIONS ................................................................................... 3

TECHNICAL CHARACTERISTICS .................................................................................................. 4

TOOLS REQUIRED FOR INSTALLATION ..................................................................................... 5

ELECTRICAL INSTALLATION ....................................................................................................... 5

PRECAUTIONS WITH THE GATE BEFORE INSTALLATION ................................................7

FIXATION AND INSTALLATION OF THE OPERATOR .............................................................. 7

ANALOGIC LIMIT SWITCH INSTALLATION .............................................................................11

MAINTENANCE ...............................................................................................................................13

3

IMPORTANT SECURITY INSTRUCTIONS

Recommendation:

For the installation of the equipment, it is

important that a PPA specialist installer

follow all instructions given in this technical

manual and in the user manual.

With the user’s manual, the installer must

present all the information, uses and safety

items of the equipment to the user.

Before using the automation, read and

follow all instructions contained in this manual carefully.

-Before installing the operator, make sure

that the local power supply is compatible

with that required on the equipment identication label;

- Do not connect the electrical grid until installation / maintenance is complete. Always

make electrical connections to the control

unit with the electrical grid switched o;

-After installation, make sure that the parts

of the gate do not extend through the roads and public walk;

-It is mandatory to use full shutdown devices in the automation system

4

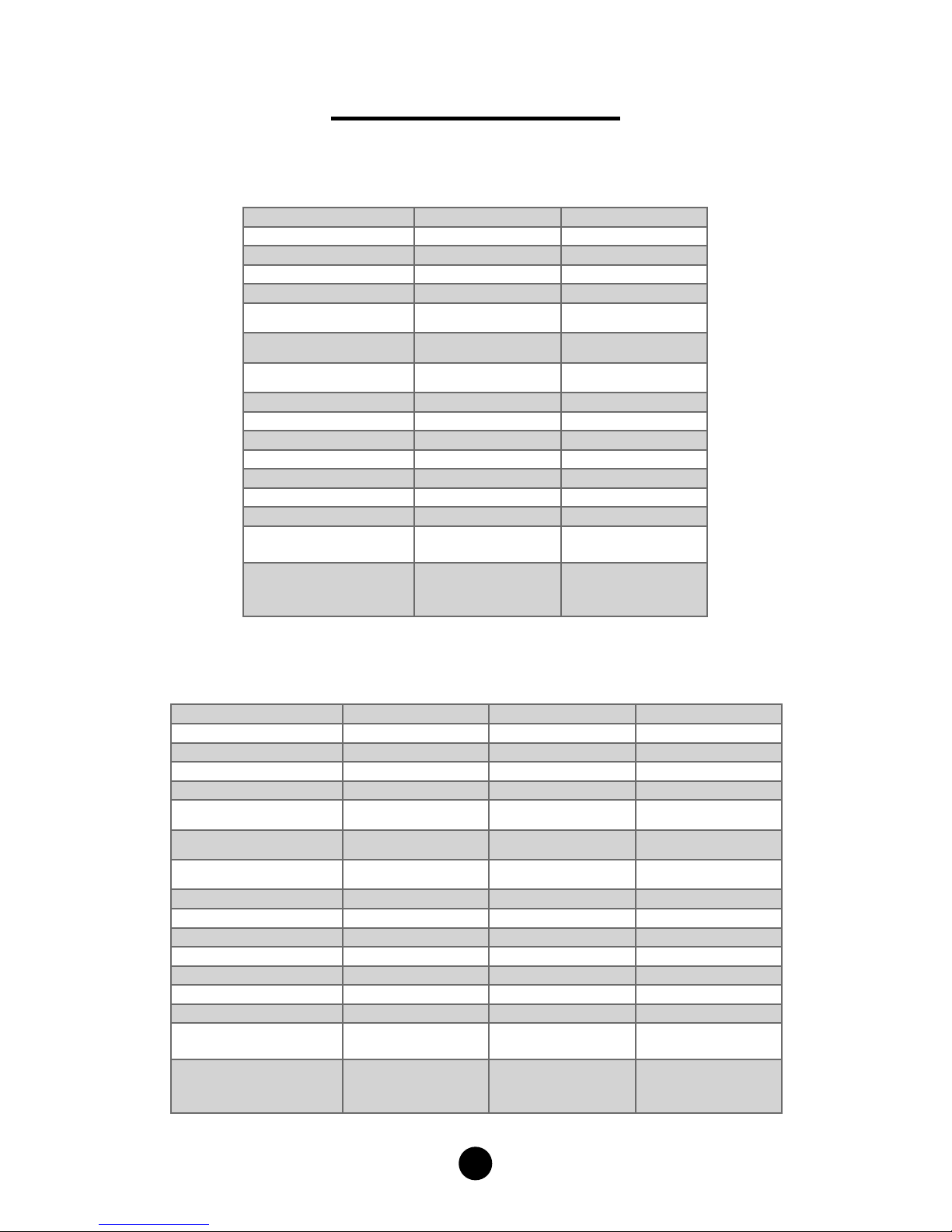

TECHNICAL CHARACTERISTICS

* Maximum height is calculated by the value obtained in the product description (value in meters) applied in the equation.

POTENZA PREDIAL

POTENZA PREDIAL SP / POTENZA PREDIAL JET FLEX

OPERATOR TYPE OVERHEAD OVERHEAD

MODEL Single Phase Single Phase

RATED VOLTAGE 220 V 127 V

NOMINAL FREQUENCY 60 Hz 60 Hz

NOMINAL POWER 540 W 390 W

RPM 1740 RPM 1740 RPM

NOMINAL CURRENT 2,5 A 3,7 A

REDUCTION 2:30 2:30

LINEAR SPEED 7 m/min 7 m/min

MANEUVER 50 cycles/h 50 cycles/h

PROTECTION LEVEL IPX4 IPX4

RAIL Aluminum Aluminum

TEMPERATURE RANGE -5° C / +50° C -5° C / +50° C

ISOLATION TYPE Class B, 130° C Class B, 130° C

LIMIT SWITCH Analogic / Digital Analogic / Digital

MAX. WEIGHT OF

GATE LEAF

400 Kg 400 Kg

MAX. DIMENSION OF

THE GATE

*HEIGHT = (Value

in meters -0,15) x 2

LENGTH = 4,0 m

*HEIGHT = (Value in

meters -0,15) x 2

LENGTH = 4,0 m

OPERATOR TYPE OVERHEAD OVERHEAD OVERHEAD

MODEL Single Phase Single Phase Jet Flex

RATED VOLTAGE 220 V 127 V 220 V / 127 V

NOMINAL FREQUENCY 60 Hz 60 Hz 60 Hz

NOMINAL POWER 540 W 390 W 300 W

RPM 1740 RPM 1740 RPM 4365 RPM

NOMINAL CURRENT 2,5 A 3,7 A 2,2 A / 3,1 A

REDUCTION 2:30 2:30 2:30

LINEAR SPEED 7 m/min 7 m/min 17,4 m/min

MANEUVER 50 cycles/h 50 cycles/h 60 cycles/h

PROTECTION LEVEL IPX4 IPX4 IPX4

RAIL Aluminum Aluminum Aluminum

TEMPERATURE RANGE -5° C / +50° C -5° C / +50° C -5° C / +50° C

ISOLATION TYPE Class B, 130° C Class B, 130° C Class B, 130° C

LIMIT SWITCH Hybrid Hybrid Hybrid

MAX. WEIGHT OF

GATE LEAF

320 Kg 320 Kg 400 Kg

MAX. DIMENSION OF

THE GATE

*HEIGHT = (Value

in meters - 0,15) x 2

LENGTH = 4,0 m

*HEIGHT = Value in

meters - 0,15) x 2

LENGTH = 4,0 m

*HEIGHT = (Value

in meters - 0,15) x 2

LENGTH = 4,0 m

5

TOOLS REQUIRED FOR INSTALLATION

Here are some tools required to install the automation:

ELECTRICAL GRID

For electrical installation, the network shall contain the following characteristics:

- Electric network 127 V or 220 V;

- Have 5 A circuit breakers in the electrical distribution box;

- 3/4 “diameter conduit between the electrical distribution box and the total

disconnect device;

- 3/4 “diameter conduit between the total shut-o device and the automator’s

connection point;

- 1/2 “diameter conduits for external and optional push button;

- Theres of 1/2 “diameter for safety photocells (optional).

PLIERS HACKSAW NUT DRIVER SCREWDRIVER WRENCH

LADDER

WELDING MACHINE HAMMER LEVEL MEASURING TAPE

SQUARE DRILLER PENCIL SANDER

Loading...

Loading...